High Figure of Merit Optical Buffering in Coupled-Slot Slab Photonic Crystal Waveguide with Ionic Liquid

Abstract

1. Introduction

2. Theoretical Characteristics

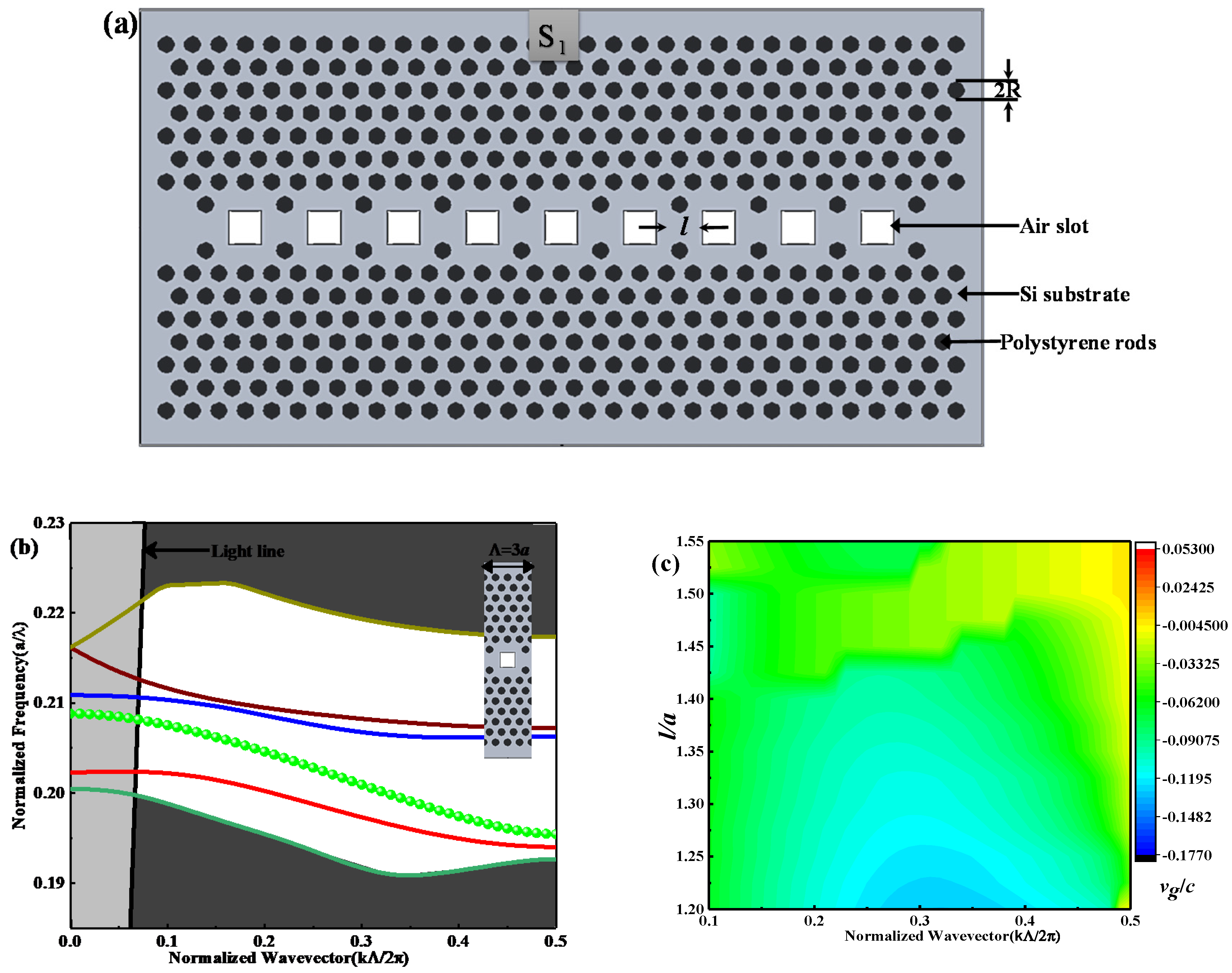

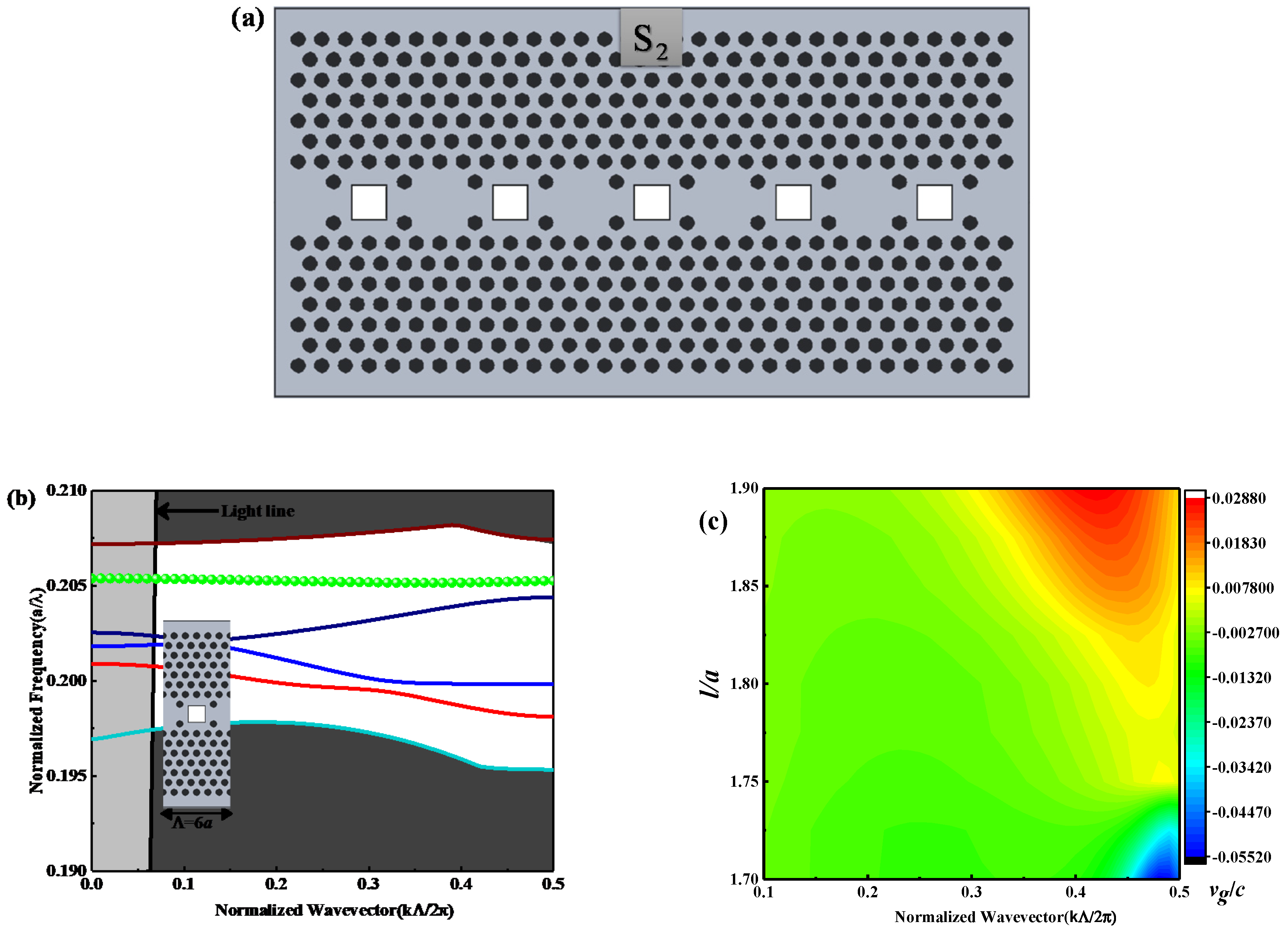

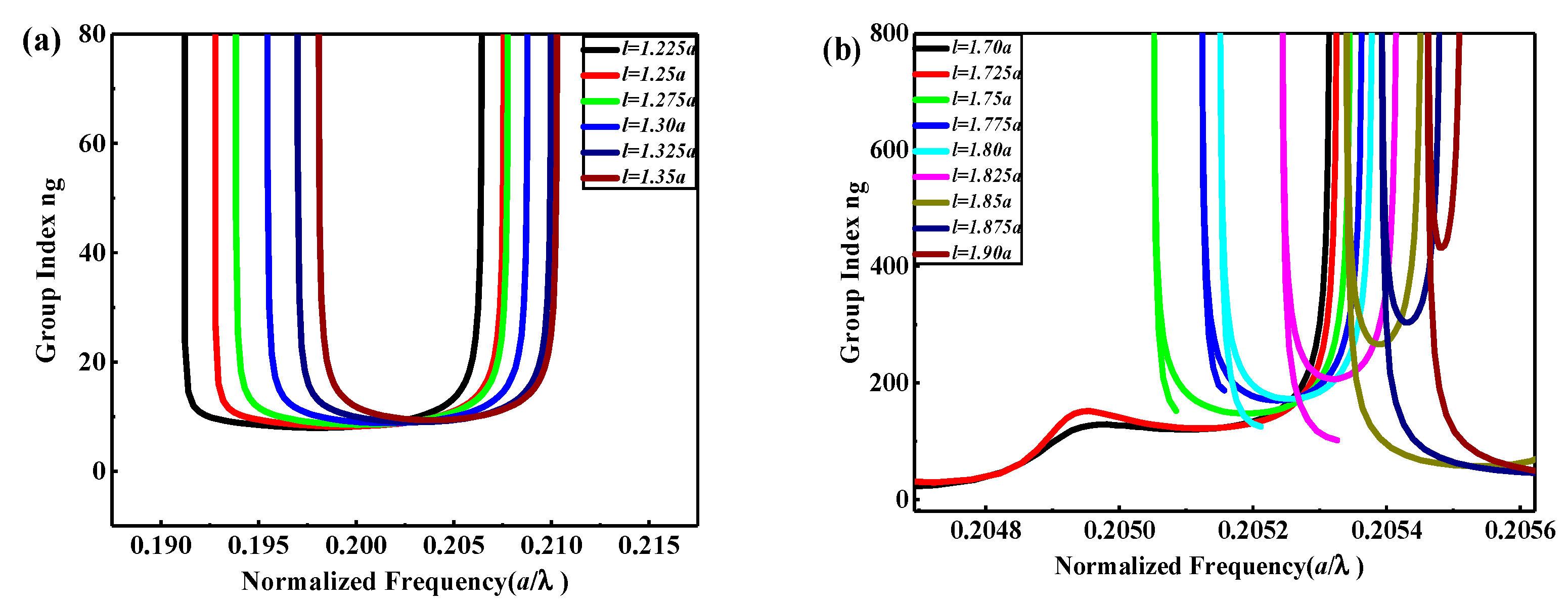

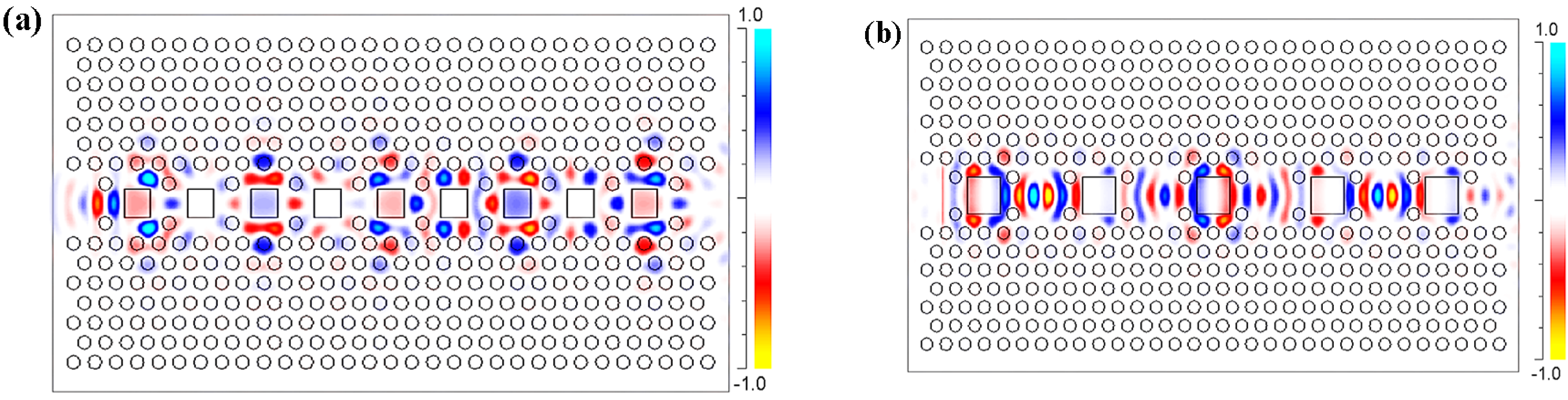

3. Structure Geometry and Simulation Results

4. Implementation Considerations

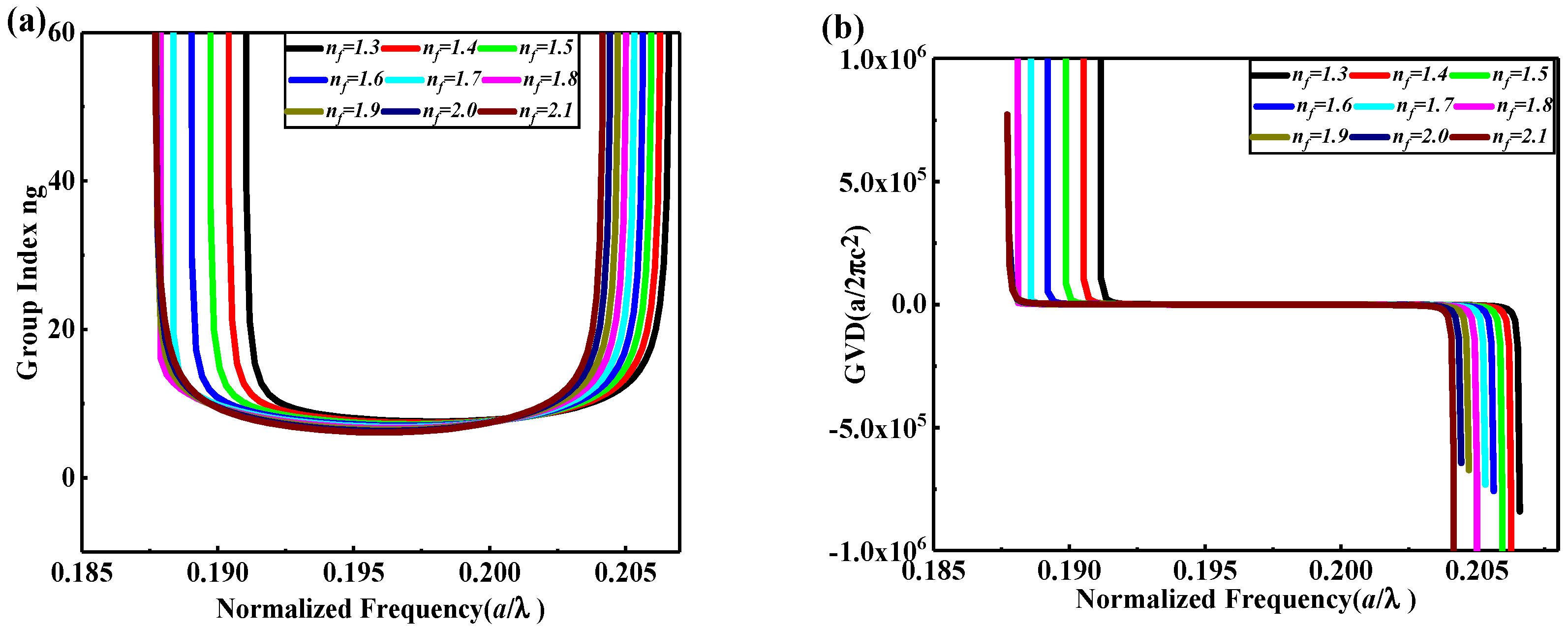

4.1. Dispersion

4.2. Losses

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Uddin, M.A.; Chan, H.P. The challenges in the fabrication of reliable polymer photonic devices. J. Mater. Sci. Mater. Electron. 2008, 20, 277–281. [Google Scholar] [CrossRef]

- Kruse, K.; Middlebrook, C. Laser-direct writing of single mode and multi-mode polymer step index waveguide structures for optical backplanes and interconnection assemblies. Photon Nanostruct. Fundam. Appl. 2015, 13, 66–73. [Google Scholar] [CrossRef]

- Oh, M.-C.; Chu, W.-S.; Shin, J.-S.; Kim, J.-W.; Kim, K.-J.; Seo, J.-K.; Lee, H.-K.; Noh, Y.-O.; Lee, H.-J. Polymeric optical waveguide devices exploiting special properties of polymer materials. Opt. Commun. 2016, 362, 3–12. [Google Scholar] [CrossRef]

- Krauss, T.F. Why Do We Need Slow Light? Nat. Photonics 2008, 2, 448–449. [Google Scholar] [CrossRef]

- Wu, X.; Muntzeck, M.; Arcos, T.D.L.; Grundmeier, G.; Wilhelm, R.; Wagner, T. Determination of the refractive indices of ionic liquids by ellipsometry, and their application as immersion liquids. Appl. Opt. 2018, 57, 9215–9222. [Google Scholar] [CrossRef]

- Higashino, Y.; Isobe, T.; Matsushita, S.; Nakajima, A. Preparation and properties of transparent solid–liquid hybrid materials using porous silica with silicone oil or ionic liquid. Mater. Res. Bull. 2020, 130, 110902. [Google Scholar] [CrossRef]

- Park, J.H.; Ko, I.J.; Kim, G.W.; Lee, H.; Jeong, S.H.; Lee, J.Y.; Lampande, R.; Kwon, J.H. High transmittance and deep RGB primary electrochromic color filter for high light out-coupling electro-optical devices. Opt. Express 2019, 27, 25531–25543. [Google Scholar] [CrossRef]

- Watanabe, M.; Thomas, M.L.; Zhang, S.; Ueno, K.; Yasuda, T.; Dokko, K. Application of Ionic Liquids to Energy Storage and Conversion Materials and Devices. Chem. Rev. 2017, 117, 7190–7239. [Google Scholar] [CrossRef]

- Qiu, M.; Zhang, B.; Wu, H.; Cao, L.; He, X.; Li, Y.; Li, J.; Xu, M.; Jiang, Z. Preparation of anion exchange membrane with enhanced conductivity and alkaline stability by incorporating ionic liquid modified carbon nanotubes. J. Membr. Sci. 2019, 573, 1–10. [Google Scholar] [CrossRef]

- Nasirpour, N.; Mohammadpourfard, M.; Heris, S.Z. Ionic liquids: Promising compounds for sustainable chemical processes and applications. Chem. Eng. Res. Des. 2020, 160, 264–300. [Google Scholar] [CrossRef]

- Rola, K.P.; Zajac, A.; Czajkowski, M.; Cybinska, J.; Martynkien, T.; Smiglak, M.; Komorowska, K. Ionic liquids—A novel material for planar photonics. Nanotechnology 2018, 29, 475202. [Google Scholar] [CrossRef] [PubMed]

- Rola, K.P.; Zajac, A.; Czajkowski, M.; Fiedot-Tobola, M.; Szpecht, A.; Cybinska, J.; Smiglak, M.; Komorowska, K. Electron Beam Patterning of Polymerizable Ionic Liquid Films for Application in Photonics. Langmuir 2019, 35, 11968–11978. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Paloczi, G.T.; Yariv, A.; Zhang, C.; Dalton, L. Fabrication and Replication of Polymer Integrated Optical Devices Using Electron-Beam Lithography and Soft Lithography. J. Phys. Chem. B 2004, 108, 8606–8613. [Google Scholar] [CrossRef]

- Sun, H.; Chen, A.; Olbricht, B.C.; Davies, J.A.; Sullivan, P.A.; Liao, Y.; Dalton, L. Direct electron beam writing of electro-optic polymer microring resonators. Opt. Express 2008, 16, 6592–6599. [Google Scholar] [CrossRef] [PubMed]

- Minamimoto, H.; Irie, H.; Uematsu, T.; Tsuda, T.; Imanishi, A.; Seki, S.; Kuwabata, S. Polymerization of Room-Temperature Ionic Liquid Monomers by Electron Beam Irradiation with the Aim of Fabricating Three-Dimensional Micropolymer/Nanopolymer Structures. Langmuir 2014, 31, 4281–4289. [Google Scholar] [CrossRef]

- Frandsen, L.H.; Lavrinenko, A.V.; Fage-Pedersen, J.; Borel, P.I. Photonic crystal waveguides with semi-slow light and tailored dispersion properties. Opt. Express 2006, 14, 9444–9450. [Google Scholar] [CrossRef]

- Elshahat, S.; Abood, I.; Khan, K.; Yadav, A.; Bibbo, L.; Ouyang, Z. Five-Line Photonic Crystal Waveguide for Optical Buffering and Data Interconnection of Picosecond Pulse. J. Light. Technol. 2018, 37, 788–798. [Google Scholar] [CrossRef]

- Ma, J.; Jiang, C. Demonstration of Ultraslow Modes in Asymmetric Line-Defect Photonic Crystal Waveguides. IEEE Photon Technol. Lett. 2008, 20, 1237–1239. [Google Scholar] [CrossRef]

- Baba, T. Slow light in photonic crystals. Nat. Photonics 2008, 2, 465. [Google Scholar] [CrossRef]

- Zhai, Y.; Tian, H.; Ji, Y. Slow Light Property Improvement and Optical Buffer Capability in Ring-Shape-Hole Photonic Crystal Waveguide. J. Light. Technol. 2011, 29, 3083–3090. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Wang, Q.; Hu, H. Review on the Optimization Methods of Slow Light in Photonic Crystal Waveguide. IEEE Trans. Nanotechnol. 2015, 14, 407–426. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Hu, H. Dispersion Engineering of Slow Light in Ellipse-Shaped-Hole Slotted Photonic Crystal Waveguide. J. Light. Technol. 2014, 32, 2144–2151. [Google Scholar] [CrossRef]

- Elshahat, S.; Abood, I.; Khan, K.; Yadav, A.; Ouyang, Z. High-capability micro-optical buffer based on coupled hexagonal cavity in photonic crystal waveguide. Appl. Nanosci. 2019, 9, 1963–1970. [Google Scholar] [CrossRef]

- Tucker, R.; Ku, P.-C.; Chang-Hasnain, C. Slow-light optical buffers: Capabilities and fundamental limitations. J. Light. Technol. 2005, 23, 4046–4066. [Google Scholar] [CrossRef]

- Elshahat, S.; Abood, I.; Khan, K.; Yadav, A.; Wang, Q.; Liu, Q.; Lin, M.; Tao, K.; Ouyang, Z. Ultra-wideband slow light transmission with high normalized delay bandwidth product in W3 photonic crystal waveguide. Superlattices Microstruct. 2018, 121, 45–54. [Google Scholar] [CrossRef]

- Elshahat, S.; Khan, K.; Yadav, A.; Bibbò, L.; Ouyang, Z. Slow-light transmission with high group index and large normalized delay bandwidth product through successive defect rods on intrinsic photonic crystal waveguide. Opt. Commun. 2018, 418, 73–79. [Google Scholar] [CrossRef]

- Deetlefs, M.; Seddon, K.R.; Shara, M. Neoteric optical media for refractive index determination of gems and minerals. New J. Chem. 2006, 30, 317. [Google Scholar] [CrossRef]

- Kayama, Y.; Ichikawa, T.; Ohno, H. Transparent and colourless room temperature ionic liquids having high refractive index over 1. Chem. Commun. 2014, 50, 14790–14792. [Google Scholar] [CrossRef]

- Alsharif, M.H.; Kelechi, A.H.; Albreem, M.A.M.; Chaudhry, S.A.; Zia, M.S.; Kim, S. Sixth Generation (6G) Wireless Networks: Vision, Research Activities, Challenges and Potential Solutions. Symmetry 2020, 12, 676. [Google Scholar] [CrossRef]

- You, X.H.; Wang, C.-X.; Huang, J.; Gao, X.Q.; Zhang, Z.; Wang, M.; Huang, Y.; Zhang, C.; Jiang, Y.X.; Jiaheng, W.; et al. Towards 6G wireless communication networks: Vision, enabling technologies, and new paradigm shifts. Sci. China Inf. Sci. 2020, 1–83. [Google Scholar] [CrossRef]

- Yang, Y.; Yamagami, Y.; Yu, X.; Pitchappa, P.; Webber, J.; Zhang, B.; Fujita, M.; Nagatsuma, T.; Singh, R. Terahertz topological photonics for on-chip communication. Nat. Photonics 2020, 14, 446–451. [Google Scholar] [CrossRef]

- Tsuruda, K.; Fujita, M.; Nagatsuma, T. Extremely low-loss terahertz waveguide based on silicon photonic-crystal slab. Opt. Express 2015, 23, 31977–31990. [Google Scholar] [CrossRef] [PubMed]

- O’Faolain, L.; Schulz, S.A.; Beggs, D.M.; White, T.E.; Spasenović, M.; Kuipers, L.; Morichetti, F.; Melloni, A.; Mazoyer, S.; Hugonin, J.-P.; et al. Loss engineered slow light waveguides. Opt. Express 2010, 18, 27627–27638. [Google Scholar] [CrossRef] [PubMed]

- Schulz, S.A.; O’Faolain, L.; Beggs, D.M.; White, T.E.; Melloni, A.; Krauss, T.F. Dispersion engineered slow light in photonic crystals: A comparison. J. Opt. 2010, 12, 104004. [Google Scholar] [CrossRef]

- Dutta, H.S.; Goyal, A.K.; Srivastava, V.; Pal, S. Coupling light in photonic crystal waveguides: A review. Photon Nanostruct. Fundam. Appl. 2016, 20, 41–58. [Google Scholar] [CrossRef]

- Krauss, T.F. Slow light in photonic crystal waveguides. J. Phys. D Appl. Phys. 2007, 40, 2666–2670. [Google Scholar] [CrossRef]

- Elshahat, S.; Abood, I.; Liang, Z.; Pei, J.; Ouyang, Z. Futuristic elongated-hexagonal photonic crystal waveguide for slow light. Opt. Commun. 2020, 474, 126082. [Google Scholar] [CrossRef]

- Palik, E. (Ed.) This page is intentionally left blank. In Handbook of Optical Constants of Solids; Elsevier BV: Amsterdam, The Netherlands, 1997; 1000p. [Google Scholar]

- Yan, S.; Cheng, Z.; Frandsen, L.H.; Ding, Y.; Zhou, F.; Dong, J.; Zhang, X. Bandwidth-adaptable silicon photonic differentiator employing a slow light effect. Opt. Lett. 2017, 42, 1596–1599. [Google Scholar] [CrossRef]

- Vlasov, Y.A.; O’Boyle, M.; Hamann, H.F.; McNab, S.J. Active control of slow light on a chip with photonic crystal waveguides. Nature 2005, 438, 65–69. [Google Scholar] [CrossRef]

- Serna, S.; Colman, P.; Zhang, W.; Le Roux, X.; Caer, C.; Vivien, L.; Cassan, É. Experimental GVD engineering in slow light slot photonic crystal waveguides. Sci. Rep. 2016, 6, 26956. [Google Scholar] [CrossRef]

- Elshahat, S.; Abood, I.; Liang, Z.; Pei, J.; Ouyang, Z. Sporadic-Slot Photonic-Crystal Waveguide for All-Optical Buffers With Low-Dispersion, Distortion, and Insertion Loss. IEEE Access 2020, 8, 77689–77700. [Google Scholar] [CrossRef]

- Aghababaeian, H.; Vadjed-Samiei, M.-H.; Granpayeh, N. Temperature Stabilization of Group Index in Silicon Slotted Photonic Crystal Waveguides. J. Opt. Soc. Korea 2011, 15, 398–402. [Google Scholar] [CrossRef]

| Structure | NDBP | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| S1 | 1.225 | 9.5 | 0.01343 | 104.81 | 0.64237 | 31.667 | 207.215 | 4.8259 | 3.2718 |

| 1.25 | 10 | 0.01327 | 102.78 | 0.66313 | 33.333 | 213.912 | 4.6748 | 3.2087 | |

| 1.275 | 10.4 | 0.01239 | 95.689 | 0.64205 | 34.667 | 207.112 | 4.8283 | 2.9872 | |

| 1.3 | 10.72 | 0.01167 | 89.499 | 0.61899 | 35.733 | 199.673 | 5.0082 | 2.7939 | |

| 1.325 | 11 | 0.01139 | 86.761 | 0.61573 | 36.667 | 198.621 | 5.0347 | 2.7085 | |

| 1.35 | 11.68 | 0.0108 | 81.927 | 0.61736 | 38.933 | 199.149 | 5.0214 | 2.5576 | |

| S2 | 1.7 | 137 | 0.00037 | 2.8196 | 0.24922 | 456.67 | 80.393 | 12.4389 | 8.8 × 10−5 |

| 1.725 | 144 | 0.00039 | 2.9488 | 0.27395 | 480 | 88.372 | 11.3158 | 9.2 × 10−5 | |

| 1.75 | 173 | 0.00024 | 1.7842 | 0.19914 | 576.67 | 64.238 | 15.5671 | 5.6 × 10−5 | |

| 1.775 | 198 | 0.00019 | 1.4281 | 0.18243 | 660 | 58.847 | 16.9931 | 4.5 × 10−5 | |

| 1.8 | 204 | 0.00018 | 1.3955 | 0.18367 | 680 | 59.247 | 16.8785 | 4.4 × 10−5 | |

| 1.825 | 242 | 0.00013 | 1.0153 | 0.15852 | 806.67 | 51.136 | 19.5559 | 3.2 × 10−5 | |

| 1.85 | 313 | 8.4 × 10−5 | 0.6354 | 0.12831 | 1043.3 | 41.391 | 24.16 | 2 × 10−5 | |

| 1.875 | 348 | 6.4 × 10−5 | 0.4836 | 0.10858 | 1160 | 35.026 | 28.55 | 1.5 × 10−5 | |

| 1.9 | 481 | 3.5 × 10−5 | 0.267 | 0.08286 | 1603.3 | 26.73 | 37.4107 | 8.3 × 10−6 |

| Structure | NDBP | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| S1 | 1.3 | 9.33 | 0.01387 | 108.13 | 0.65086 | 30.5 | 209.956 | 4.7629 | 3.37549 |

| 1.4 | 9.15 | 0.01417 | 110.74 | 0.65375 | 29.9 | 210.888 | 4.7419 | 3.45718 | |

| 1.5 | 8.97 | 0.01447 | 113.36 | 0.65602 | 29.067 | 211.619 | 4.7255 | 3.53878 | |

| 1.6 | 8.72 | 0.01481 | 116.47 | 0.65523 | 29.433 | 211.366 | 4.7311 | 3.63588 | |

| 1.7 | 8.83 | 0.01556 | 122.66 | 0.69878 | 29.667 | 225.414 | 4.4363 | 3.82923 | |

| 1.8 | 8.9 | 0.01595 | 126.09 | 0.72402 | 28.8 | 233.553 | 4.2817 | 3.93629 | |

| 1.9 | 8.64 | 0.01521 | 120.15 | 0.66974 | 28.233 | 216.046 | 4.6287 | 3.75079 | |

| 2.0 | 8.47 | 0.01471 | 116.27 | 0.63537 | 27.533 | 204.959 | 4.879 | 3.62974 | |

| 2.1 | 8.26 | 0.01425 | 112.64 | 0.60028 | 30.5 | 193.637 | 5.1643 | 3.51642 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abood, I.; Elshahat, S.; Ouyang, Z. High Figure of Merit Optical Buffering in Coupled-Slot Slab Photonic Crystal Waveguide with Ionic Liquid. Nanomaterials 2020, 10, 1742. https://doi.org/10.3390/nano10091742

Abood I, Elshahat S, Ouyang Z. High Figure of Merit Optical Buffering in Coupled-Slot Slab Photonic Crystal Waveguide with Ionic Liquid. Nanomaterials. 2020; 10(9):1742. https://doi.org/10.3390/nano10091742

Chicago/Turabian StyleAbood, Israa, Sayed Elshahat, and Zhengbiao Ouyang. 2020. "High Figure of Merit Optical Buffering in Coupled-Slot Slab Photonic Crystal Waveguide with Ionic Liquid" Nanomaterials 10, no. 9: 1742. https://doi.org/10.3390/nano10091742

APA StyleAbood, I., Elshahat, S., & Ouyang, Z. (2020). High Figure of Merit Optical Buffering in Coupled-Slot Slab Photonic Crystal Waveguide with Ionic Liquid. Nanomaterials, 10(9), 1742. https://doi.org/10.3390/nano10091742