Reversible and Non-Reversible Transformation of Magnetic Structure in Amorphous Microwires

Abstract

1. Introduction

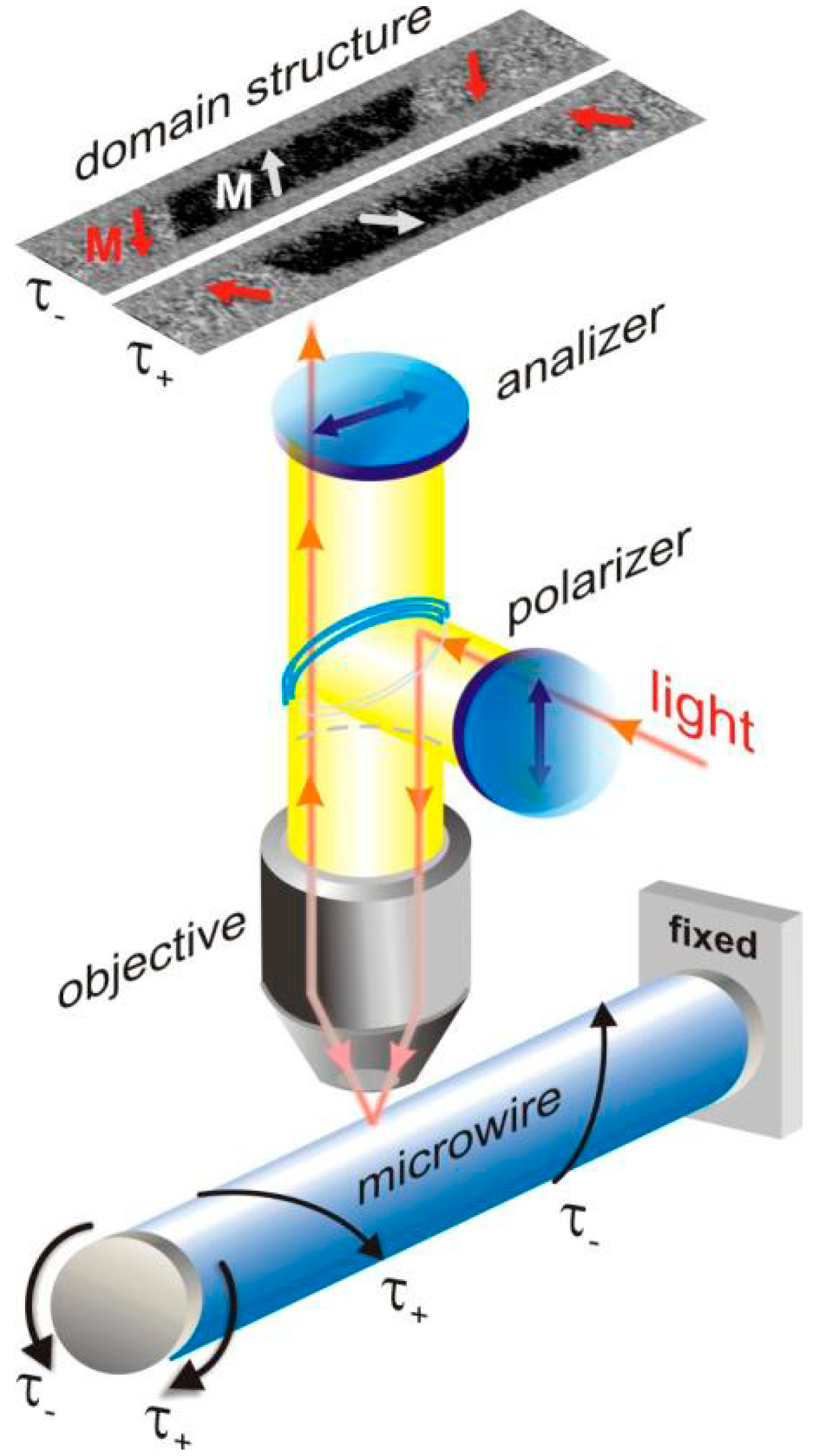

2. Materials and Methods

- №1 Fe71.7B13.4Si11Nb3Ni0.9, a metallic nucleus diameter of d = 103 μm and a total diameter including the glass coating of D = 158 μm,

- №2 Co41.7Fe36.4Si10.1B11.8, diameter of metallic nucleus d = 13.6 μm and total diameter D = 24.6 μm,

- №3 Fe3.6Co69.2Ni1B12.5Si11Mo1.5C1.2, d = 22.8 μm, D = 23.2 μm, annealed at Tann = 300 °C for tann = 1 h,

- №4 Co67.05Fe3.84Ni1.44B11.33Mo1.69Si14.47, d = 21.4 μm, D = 26.2 μm,

- №5 Co66.87Fe3.66Ni2.14Si11.47B13.36Mo1.52C0.98 with different diameters of metallic nucleus and total diameters,

- №6 (Co1-xMnx)75Si10B15 (x = 0.08, 0.09, and 0.10).

3. Results and Discussions

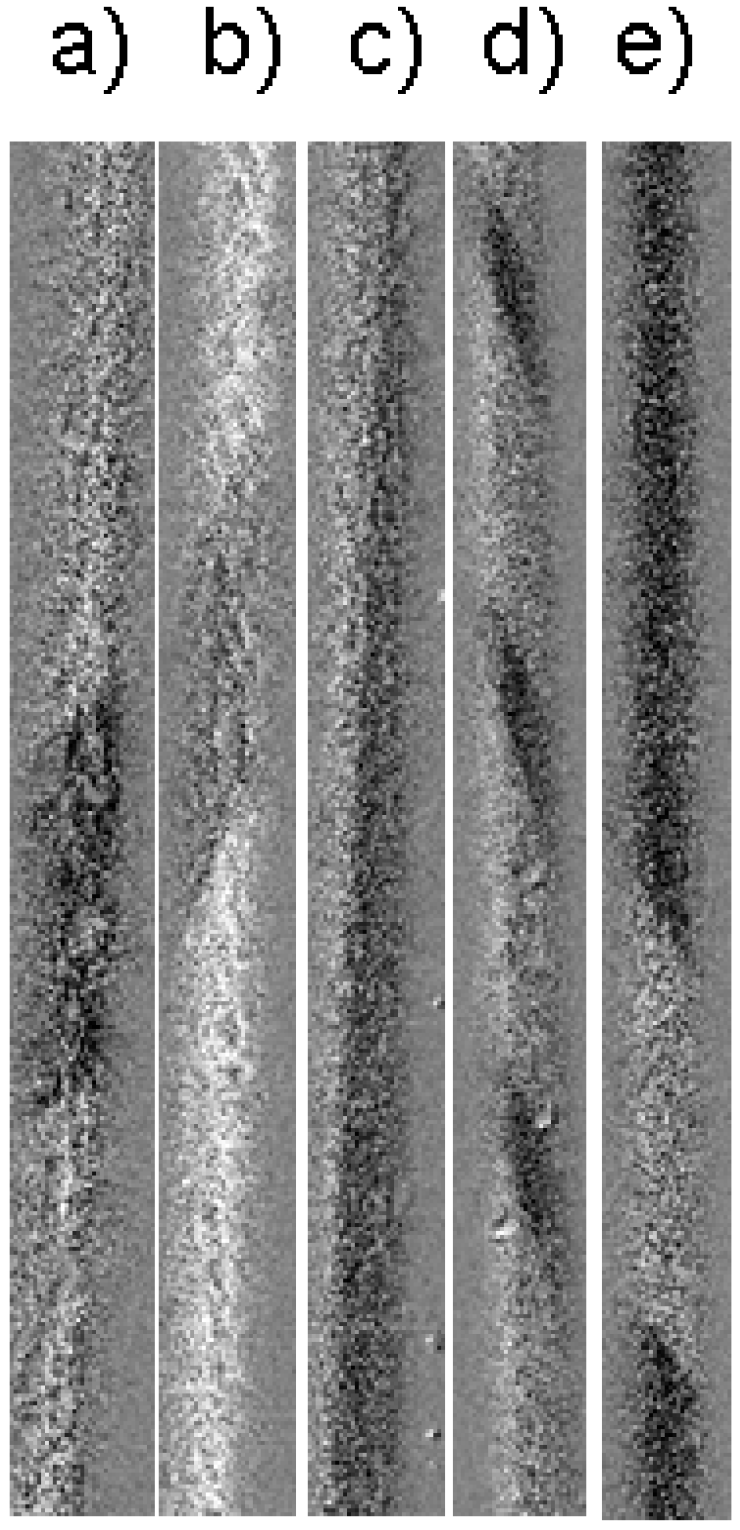

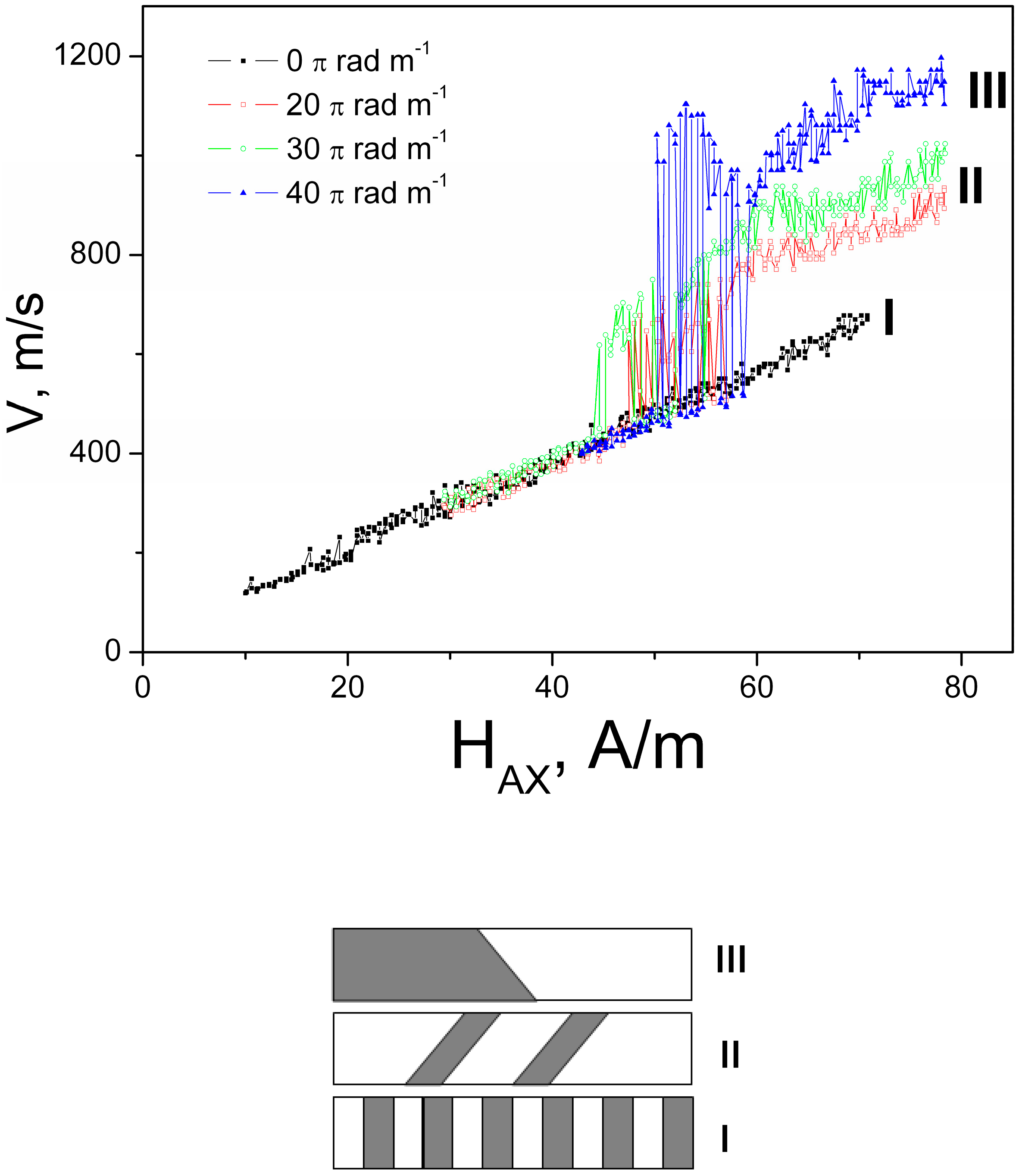

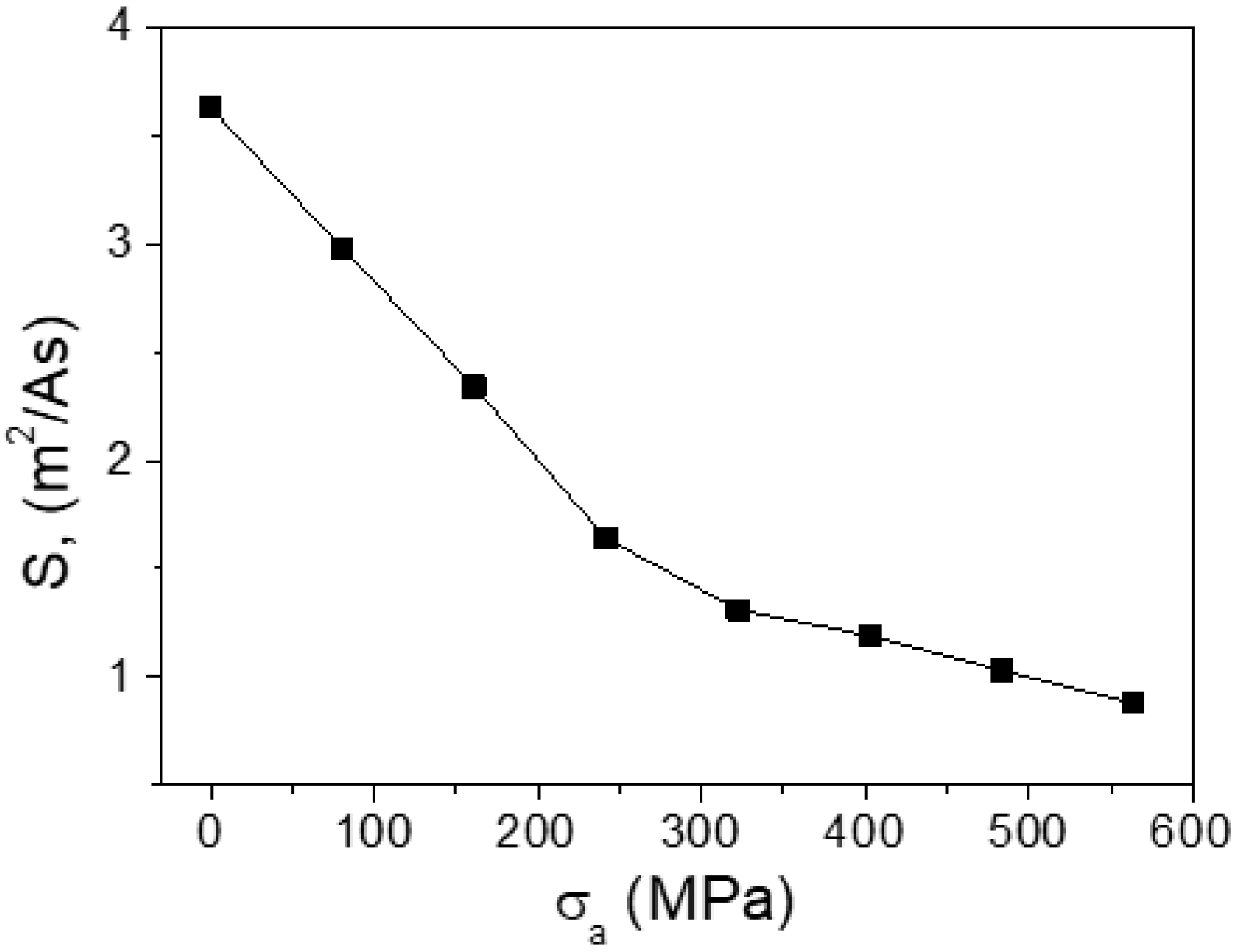

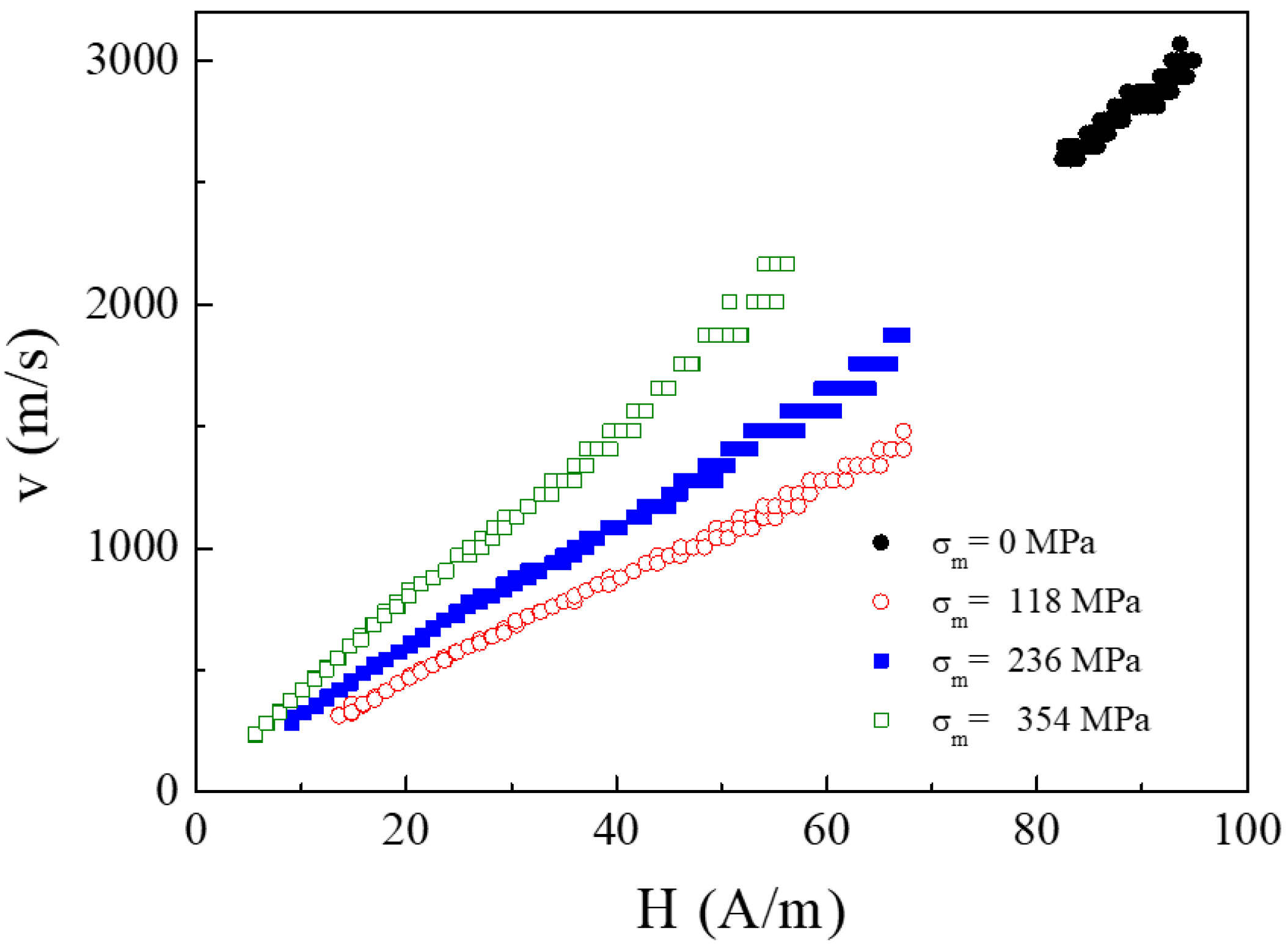

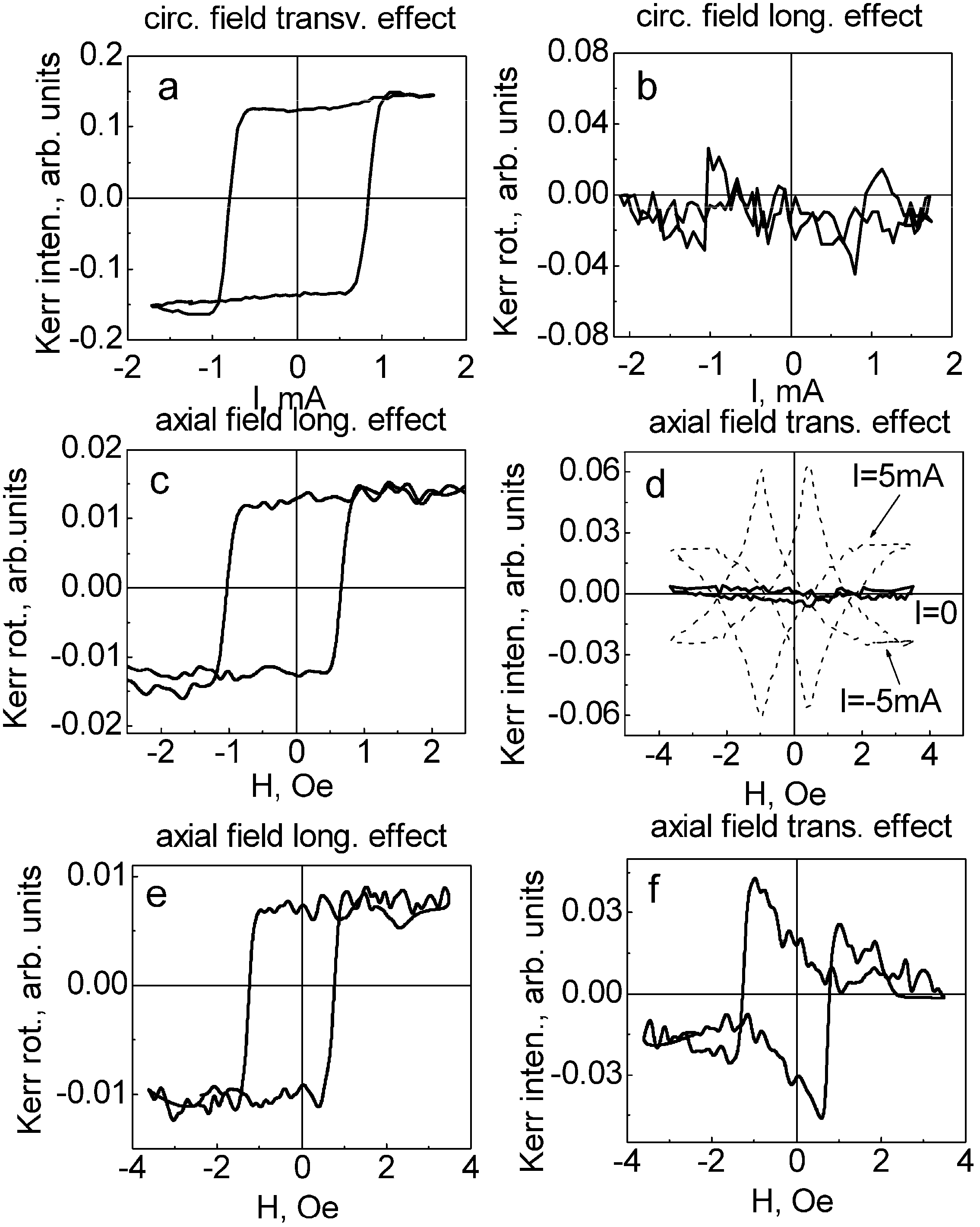

3.1. Reversible Transformation

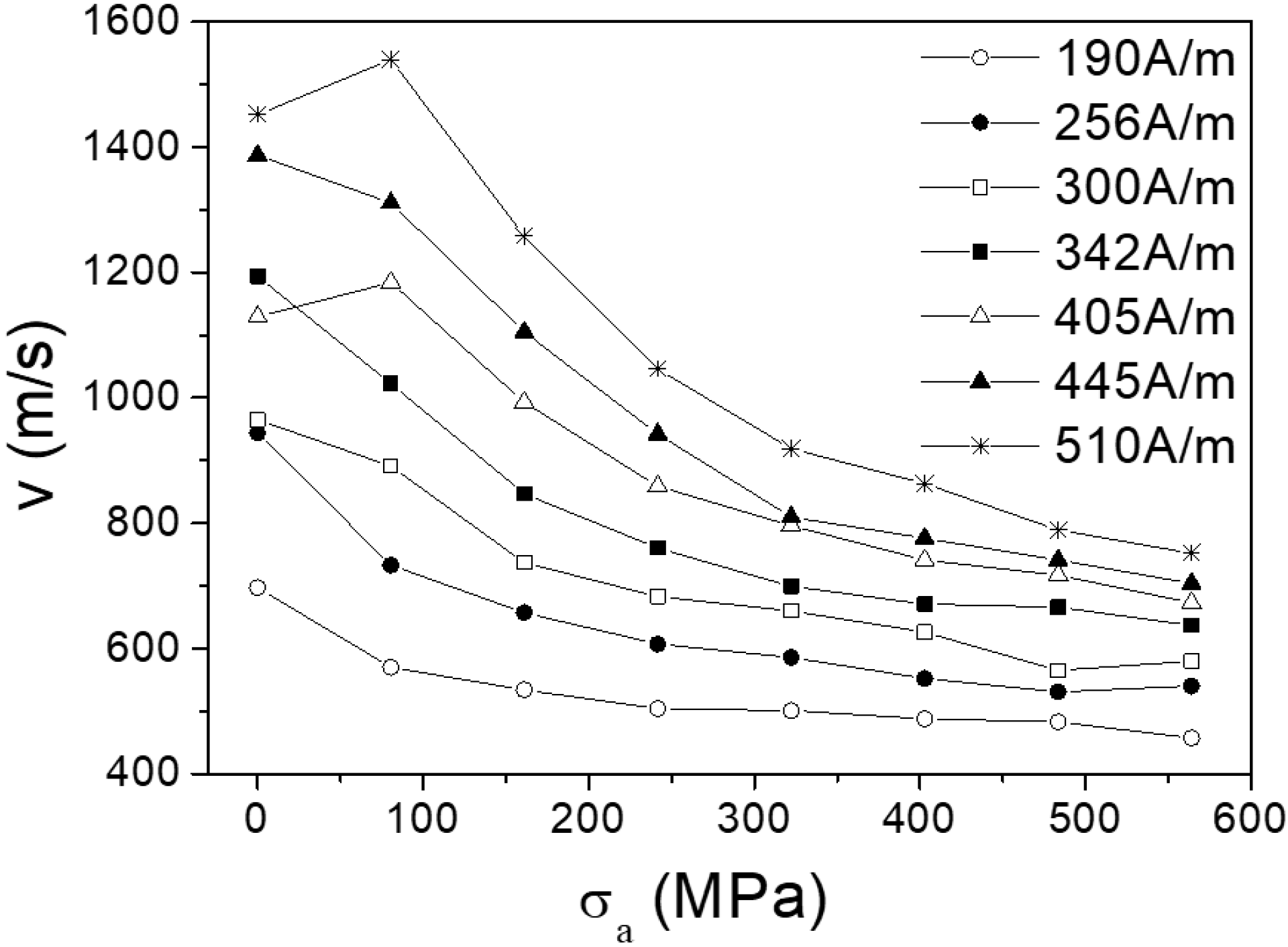

3.2. Ir-Reversible Transformation

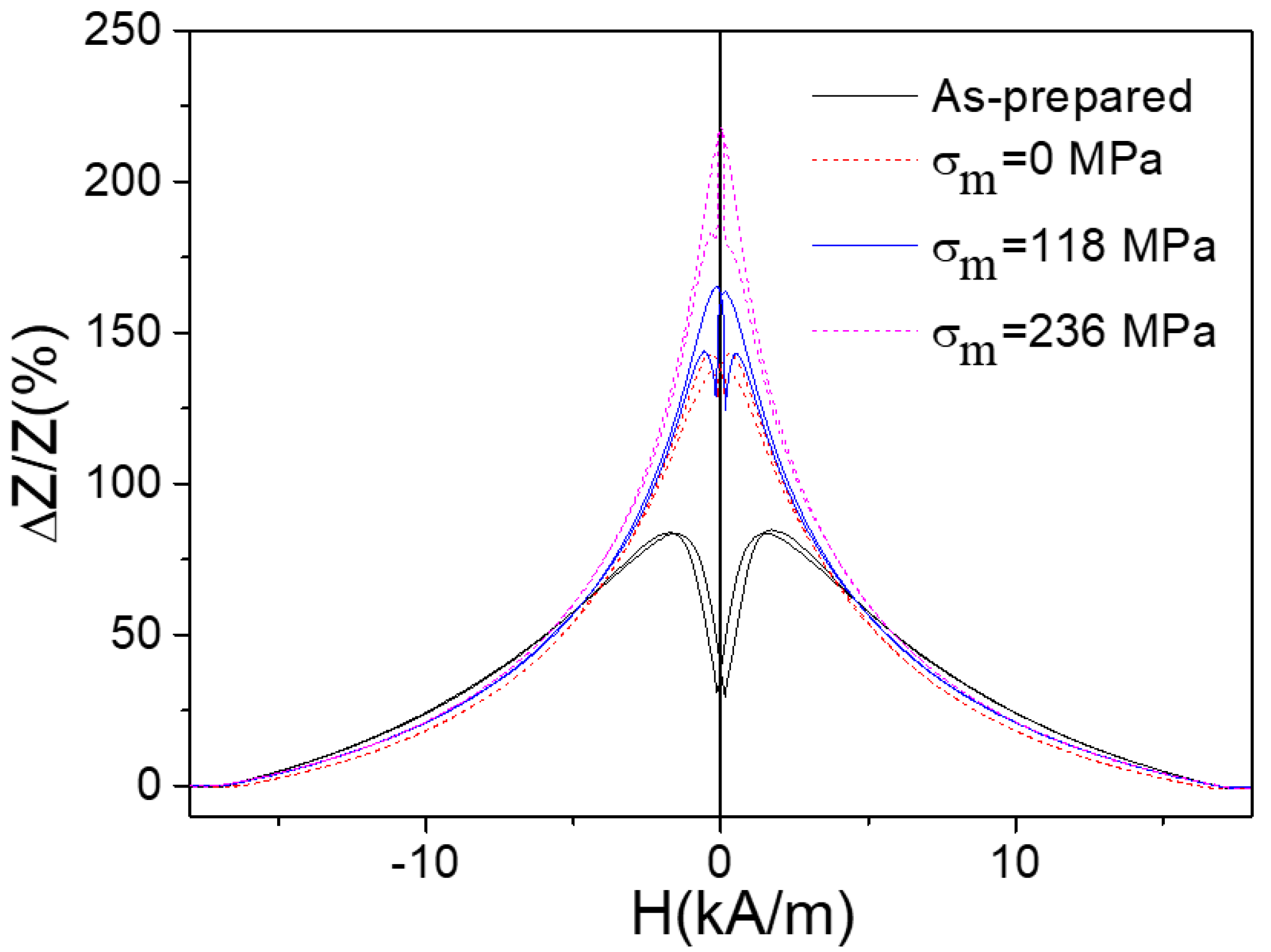

3.2.1. Annealing

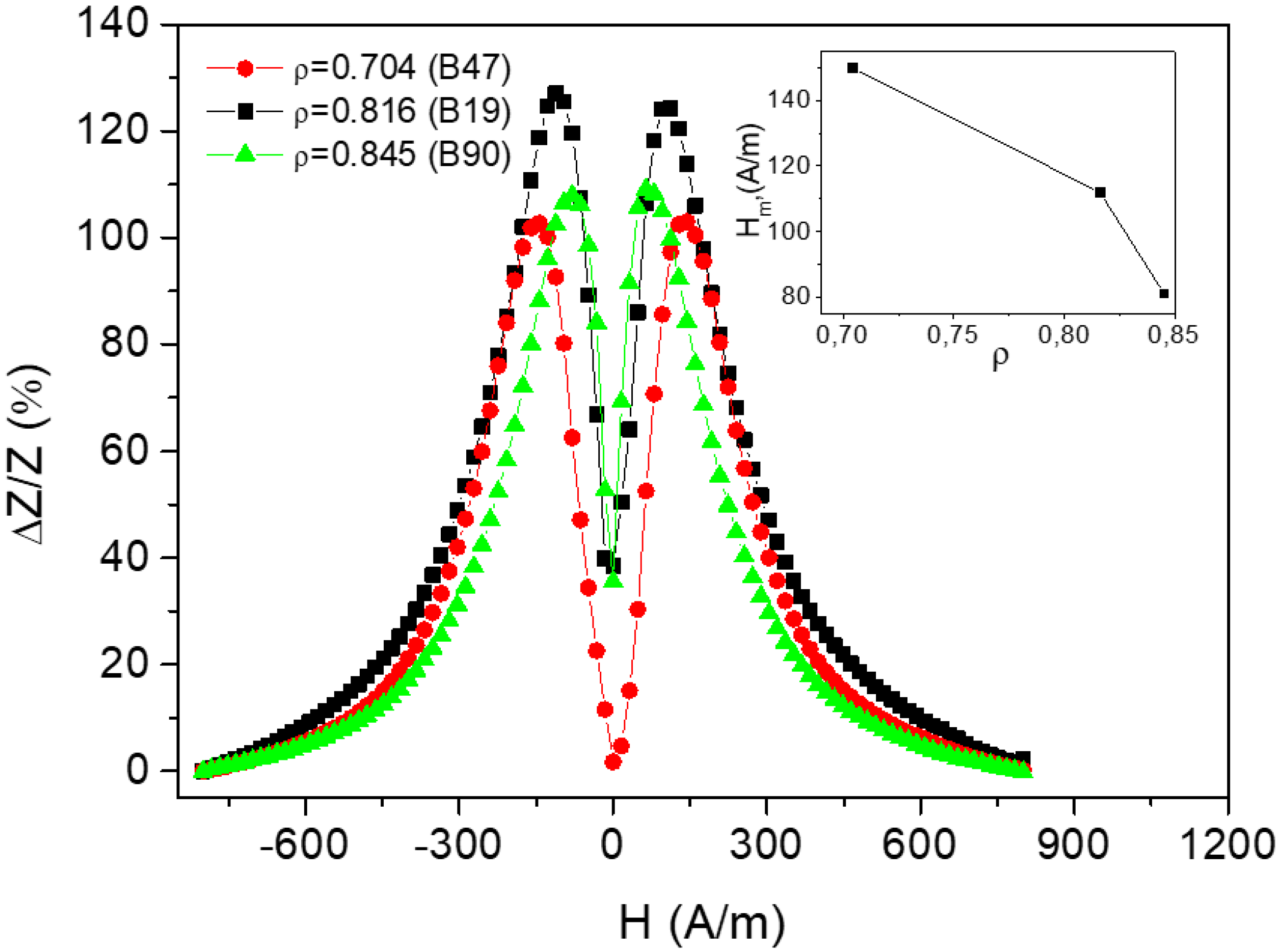

3.2.2. Geometric Ratio

3.2.3. Chemical Composition

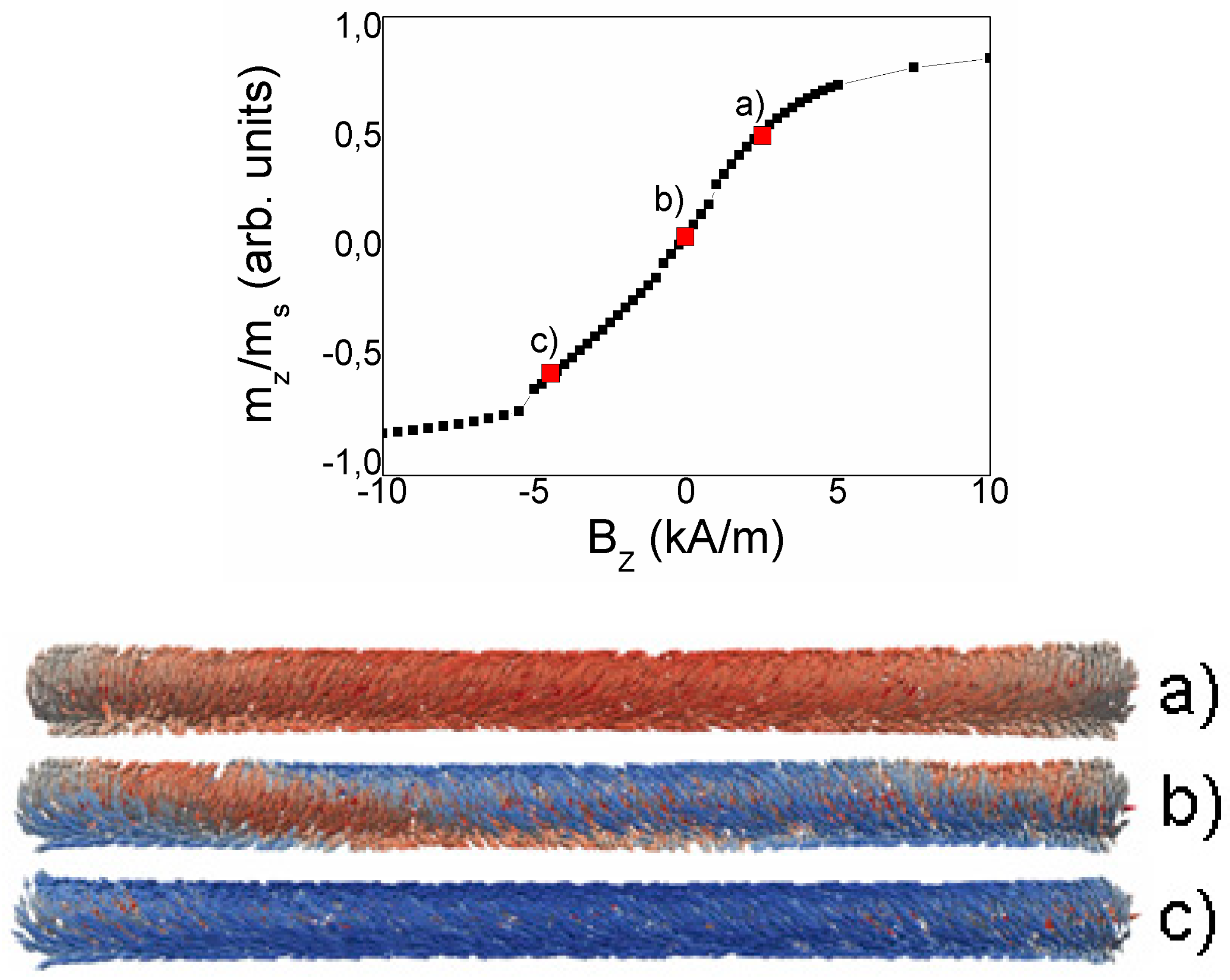

4. Simulation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jiles, D. Recent advances and future directions in magnetic materials. Acta Mater. 2003, 51, 5907–5939. [Google Scholar] [CrossRef]

- Vázquez, M.; Chiriac, H.; Zhukov, A.; Panina, L.; Uchiyama, T. On the state-of-the-art in magnetic microwires and expected trends for scientific and technological studies. Phys. Status Solid A 2011, 208, 493–501. [Google Scholar] [CrossRef]

- Mohri, K.; Humphrey, F.; Kawashima, K.; Kimura, K.; Mizutani, M. Large barkhausen and matteucci effects in FeCoSiB, FeCrSiB, and FeNiSiB amorphous wires. IEEE Trans. Magn. 1990, 26, 1789–1791. [Google Scholar] [CrossRef]

- Panina, L.V.; Mohri, K. Magneto-impedance effect in amorphous wires. Appl. Phys. Lett. 1994, 65, 1189–1191. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Corte-León, P.; Gonzalez-Legarreta, L.; Blanco, J.; Zhukova, V. Soft magnetic microwires for sensor applications. J. Magn. Magn. Mater. 2020, 498, 166180. [Google Scholar] [CrossRef]

- Zhukov, A.; Blanco, J.M.; Ipatov, M.; Zhukova, V. Magnetoelastic contribution in domain wall propagation of micrometric wires. J. Nanosci. Nanotechnol. 2012, 12, 7582–7586. [Google Scholar] [CrossRef] [PubMed]

- Zhukova, V.; Chizhik, A.; Zhukov, A.; Torcunov, A.; Larin, V.; Gonzalez, J. Optimization of gaint magnetoimpedance in Co-rich amorphous microwires. IEEE Trans. Mag. 2002, 38, 3090–3092. [Google Scholar] [CrossRef]

- Karnaushenko, D.; Karnaushenko, D.D.; Makarov, D.; Baunack, S.; Schafer, R.; Schmidt, O.G. Self-assembled on-chip-integrated giant magneto-impedance sensorics. Adv. Mater. 2015, 27, 6582–6589. [Google Scholar] [CrossRef]

- Beach, R.S.; Berkowitz, A.E. Giant magnetic field dependent impedance of amorphous FeCoSiB wire. Appl. Phys. Lett. 1994, 64, 3652. [Google Scholar] [CrossRef]

- Knobel, M.; Vazquez, M.; Kraus, L. Giant magnetoimpedance. In Handbook of Magnetic Materials; Bruck, E., Ed.; Elsevier: Amsterdam, The Netherlands, 2003; Volume 15, pp. 497–563. [Google Scholar]

- Knobel, M.; Pirota, K.R. Giant magnetoimpedance: Concepts and recent progress. J. Magn. Magn. Mater. 2002, 242–245, 33. [Google Scholar] [CrossRef]

- Phan, M.H.; Peng, H.X. Giant magnetoimedance materials: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 323. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Hayashi, M.; Thomas, L. Magnetic domain-wall racetrack memory. Science 2008, 320, 190–194. [Google Scholar] [CrossRef] [PubMed]

- Allwood, D.A.; Xiong, G.; Faulkner, C.C.; Atkinson, D.; Petit, D.; Cowburn, R.P. Magnetic domain-wall logic. Science 2005, 309, 1688–1692. [Google Scholar] [CrossRef] [PubMed]

- Ekstrom, P.A.; Zhukov, A. Spatial structure of the head-to-head propagating domain wall in glass-covered FeSiB microwire. J. Phys. D: Appl. Phys. 2010, 43, 205001. [Google Scholar] [CrossRef]

- Chizhik, A.; Gonzalez, J.; Zhukov, A.; Gawroński, P.; Stupakiewicz, A. Fine tuning of domain helical structure in magnetic microwires. J. Magn. Magn. Mater. 2020, 497, 166019. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukov, A.; Corte-Leon, P.; Blanco, J.M.; Gonzalez, J.; Gawroński, P. Torsion induced acceleration of domain wall motion in magnetic microwires. J. Magn. Magn. Mater. 2019, 489, 165420. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Zhukova, V. Advances in giant magnetoimpedance of materials. In Handbook of Magnetic Materials; Elsevier BV: Amsterdam, The Netherlands, 2015; Volume 24, pp. 139–236. [Google Scholar]

- Zhukov, A.; Ipatov, M.; Churyukanova, M.; Kaloshkin, S.; Zhukova, V. Giant magnetoimpedance in thin amorphous wires: From manipulation of magnetic field dependence to industrial applications. J. Alloys Compd. 2014, 586, S279–S286. [Google Scholar] [CrossRef]

- Taylor, G.F. A method of drawing metallic filaments and a discussion of their properties and uses. Phys. Rev. 1924, 23, 655–660. [Google Scholar] [CrossRef]

- Inoue, A.; Masumoto, T. Properties and applications of amorphous alloy wire. Engng. Mater. 1982, 5, 47. [Google Scholar]

- Chiriac, H.; Óvári, T. Amorphous glass-covered magnetic wires: Preparation, properties, applications. Prog. Mater. Sci. 1996, 40, 333–407. [Google Scholar] [CrossRef]

- Larin, V.; Torcunov, A.; Zhukov, A.; González, J.; Vazquez, M.; Panina, L. Preparation and properties of glass-coated microwires. J. Magn. Magn. Mater. 2002, 249, 39–45. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeño, A.; Zhukov, A.; Blanco, J.; Larin, V.; González, J. Coercivity of glass-coated Fe73.4-xCu1Nb3.1Si13.4+xB9.1 (0≤ x ≤1.6) microwires. Nanostruct. Mater. 1999, 11, 1319–1327. [Google Scholar] [CrossRef]

- Arcas, J.; Gómez-Polo, C.; Zhukov, A.; Vazquez, M.; Larin, V.; Hernando, A. Magnetic properties of amorphous and devitrified FeSiBCuNb glass-coated microwires. Nanostruct. Mater. 1996, 7, 823–834. [Google Scholar] [CrossRef]

- Evstigneeva, S.; Morchenko, A.T.; Trukhanov, A.; Panina, L.; Larin, V.; Volodina, N.; Yudanov, N.; Nematov, M.; Hashim, H.; Ahmad, H. Structural and magnetic anisotropy of directionally-crystallized ferromagnetic microwires. EPJ Web Conf. 2018, 185, 04022. [Google Scholar] [CrossRef]

- Del Val, J.; González, J.; Zukhov, A. Structural and magnetic anisotropy of directionally-crystallized ferromagnetic microwires. Mater. Sci. Eng. A 2004, 679–682. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Zhukov, A. Magnetic properties and domain wall propagation in FeNiSiB glass-coated microwires. J. Appl. Phys. 2014, 115, 17A309. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Rodionova, V.V.; Ipatov, M.; Zhukov, A. Domain wall propagation in micrometric wires: Limits of single domain wall regime. J. Appl. Phys. 2012, 111, 07E311. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Zhukov, A. Effect of transverse magnetic field on domain wall propagation in magnetically bistable glass-coated amorphous microwires. J. Appl. Phys. 2009, 106, 113914. [Google Scholar] [CrossRef]

- Sixtus, K.J.; Tonks, L. Propagation of large barkhausen discontinuities. Phys. Rev. 1932, 42, 419–435. [Google Scholar] [CrossRef]

- Varga, R.; Zhukov, A.; Blanco, J.M.; Ipatov, M.; Zhukova, V.; Gonzalez, J.; Vojtaník, P. Fast magnetic domain wall in magnetic microwires. Phys. Rev. B 2006, 74, 212405. [Google Scholar] [CrossRef]

- Hudak, J.; Blazek, J.; Cverha, A.; Gonda, P.; Varga, R. Improved Sixtus–Tonks method for sensing the domain wall propagation direction. Sens. Actuators A Phys. 2009, 156, 292–295. [Google Scholar] [CrossRef]

- Calle, E.; Jiménez, A.; Vázquez, M.; Del Real, R. Time-resolved velocity of a domain wall in a magnetic microwire. J. Alloys Compd. 2018, 767, 106–111. [Google Scholar] [CrossRef]

- Neagu, M.; Chiriac, H.; Hristoforou, E.; Darie, I.; Vinai, F. Domain wall propagation in Fe-rich glass covered amorphous wires. J. Magn. Magn. Mater. 2001, 226, 1516–1518. [Google Scholar] [CrossRef]

- Chizhik, A.; Zhukova, V.; Zhukov, A.; Gonzalez, J.; Gawroński, P.; Kułakowski, K.; Stupakiewicz, A. Surface magnetic structures induced by mechanical stresses in Co-rich microwires. J. Alloys Compd. 2018, 735, 1449–1453. [Google Scholar] [CrossRef]

- González, J.; Chizhik, A.; Zhukov, A.; Blanco, J. Surface magnetic behavior of nearly zero magnetostrictive Co-rich amorphous microwires. J. Magn. Magn. Mater. 2003, 258, 177–182. [Google Scholar] [CrossRef]

- Zhukova, V.; Usov, N.; Zhukov, A.; González, J. Length effect in a Co-rich amorphous wire. Phys. Rev. B 2002, 65, 134407. [Google Scholar] [CrossRef]

- Squire, P.T.; Atalay, S.; Chiriac, H. Δ effect in amorphous glass covered wires. IEEE Transactions on Magnetics 2000, 36, 3433. [Google Scholar] [CrossRef]

- Antonov, A.S.; Borisov, V.T.; Borisov, O.V.; Prokoshin, A.F.; Usov, N.A. Residual quenching stresses in glass-coated amorphous ferromagnetic microwires. J. Phys. D Appl. Phys. 2000, 33, 1161–1168. [Google Scholar] [CrossRef]

- Chiriac, H.; Óvári, T.-A.; Zhukov, A. Magnetoelastic anisotropy of amorphous microwires. J. Magn. Magn. Mater. 2003, 254, 469–471. [Google Scholar] [CrossRef]

- Zhukova, V.; Ipatov, M.; Zhukov, A. Thin magnetically soft wires for magnetic microsensors. Sensors 2009, 9, 9216–9240. [Google Scholar] [CrossRef]

- Konno, Y.; Mohri, K. Magnetostriction measurements for amorphous wires. IEEE Trans. Magn. 1989, 25, 3623–3625. [Google Scholar] [CrossRef]

- Zhukov, A.; Zhukova, V. Magnetic Properties and Applications of Ferromagnetic Microwires with Amorphous and Nanocrystalline Structure; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2009; ISBN 978-1-60741-770-5. [Google Scholar]

- Zhukov, A.; Zhukova, V.; Blanco, J.; González, J. Recent research on magnetic properties of glass-coated microwires. J. Magn. Magn. Mater. 2005, 294, 182–192. [Google Scholar] [CrossRef]

- Humphrey, F.B.; Mohri, K.; Yamasaki, J.; Kawamura, H.; Malmhall, R.; Ogasawara, I. Magnetic Properties of Amorphous Metals; Hernando, A., Madurga, V., Sanchez-Trujillo, M.C., Vazquez, M., Eds.; Elsevier Science: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Chizhik, A.; Zhukov, A.; Gonzalez, J.; Gawroński, P.; Kułakowski, K.; Stupakiewicz, A. Spiral magnetic domain structure in cylindrically-shaped microwires. Sci. Rep. 2018, 8, 15090. [Google Scholar] [CrossRef] [PubMed]

- Chizhik, A.; Gonzalez, J.; Zhukov, A.; Gawronski, P. Study of length of domain walls in cylindrical magnetic microwires. J. Magn. Magn. Mater. 2020, 512, 167060. [Google Scholar] [CrossRef]

- Vansteenkiste, A.; Leliaert, J.; Dvornik, M.; Helsen, M.; Garcia-Sanchez, F.; Van Waeyenberge, B. The design and verification of MuMax3. AIP Adv. 2014, 4, 107133. [Google Scholar] [CrossRef]

- Chiriac, H.; Óvári, T.-A.; Pop, G. Internal stress distribution in glass-covered amorphous magnetic wires. Phys. Rev. B 1995, 52, 10104–10113. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chizhik, A.; Gonzalez, J.; Zhukov, A.; Gawronski, P.; Ipatov, M.; Corte-León, P.; Blanco, J.M.; Zhukova, V. Reversible and Non-Reversible Transformation of Magnetic Structure in Amorphous Microwires. Nanomaterials 2020, 10, 1450. https://doi.org/10.3390/nano10081450

Chizhik A, Gonzalez J, Zhukov A, Gawronski P, Ipatov M, Corte-León P, Blanco JM, Zhukova V. Reversible and Non-Reversible Transformation of Magnetic Structure in Amorphous Microwires. Nanomaterials. 2020; 10(8):1450. https://doi.org/10.3390/nano10081450

Chicago/Turabian StyleChizhik, Alexander, Julian Gonzalez, Arcady Zhukov, Przemyslaw Gawronski, Mihail Ipatov, Paula Corte-León, Juan Mari Blanco, and Valentina Zhukova. 2020. "Reversible and Non-Reversible Transformation of Magnetic Structure in Amorphous Microwires" Nanomaterials 10, no. 8: 1450. https://doi.org/10.3390/nano10081450

APA StyleChizhik, A., Gonzalez, J., Zhukov, A., Gawronski, P., Ipatov, M., Corte-León, P., Blanco, J. M., & Zhukova, V. (2020). Reversible and Non-Reversible Transformation of Magnetic Structure in Amorphous Microwires. Nanomaterials, 10(8), 1450. https://doi.org/10.3390/nano10081450