Enhanced Microwave Absorption Bandwidth in Graphene-Encapsulated Iron Nanoparticles with Core–Shell Structure

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

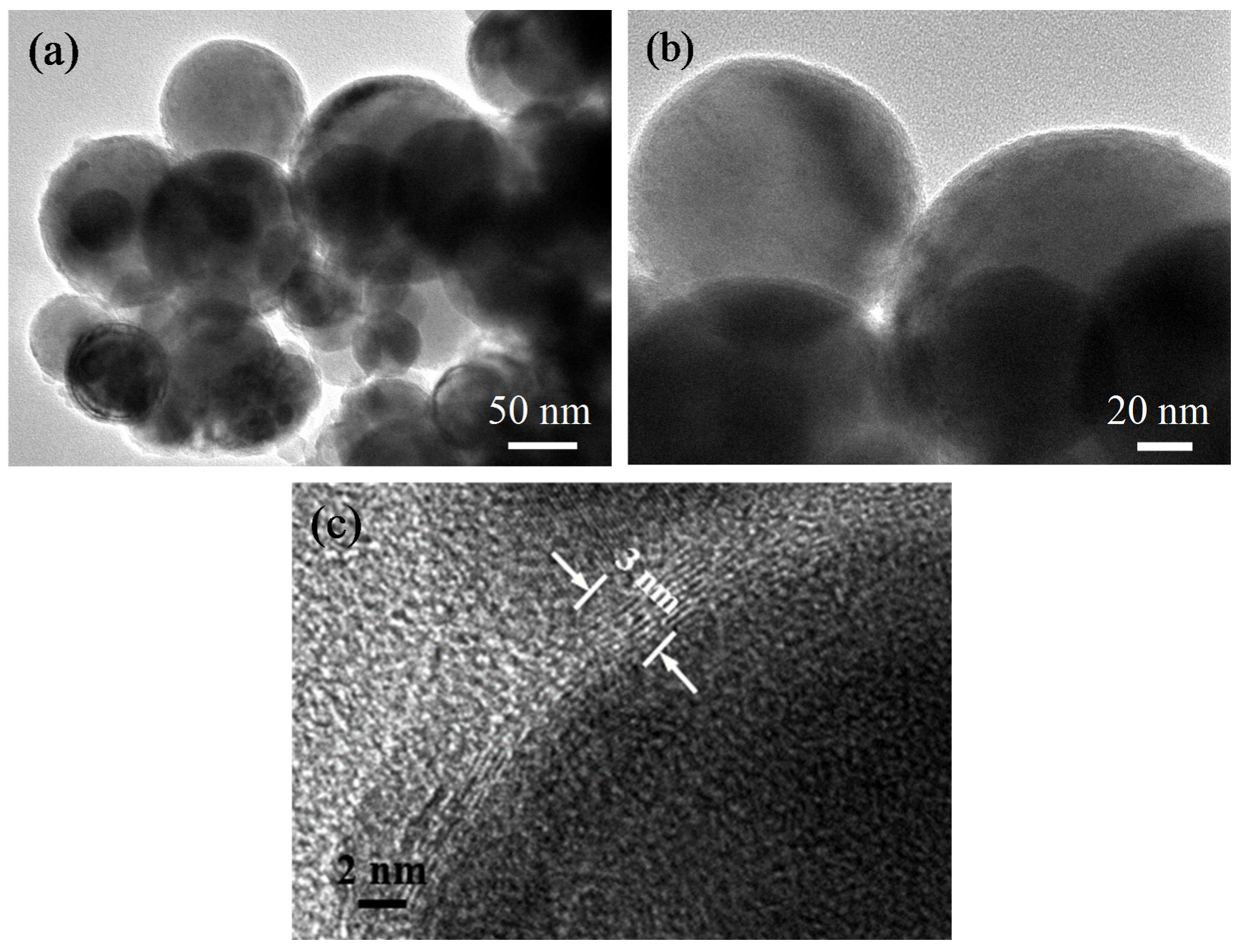

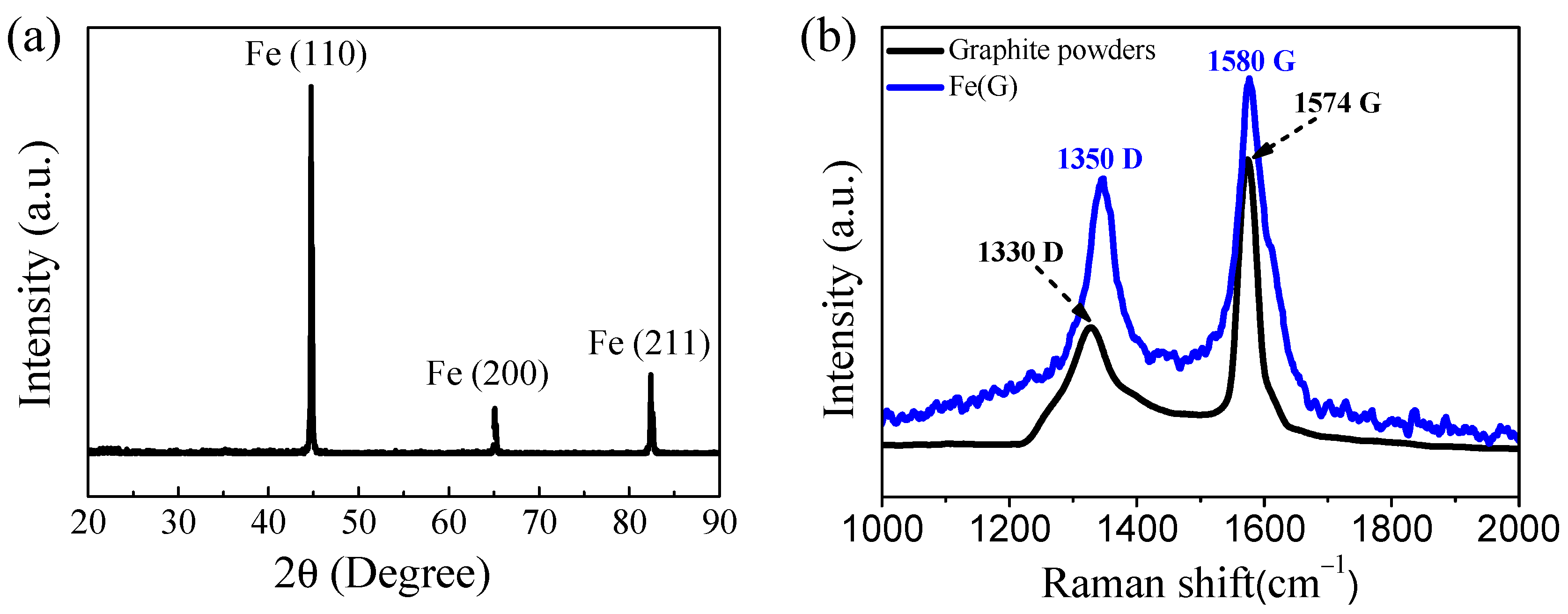

3.1. Characterization of Fe(G)

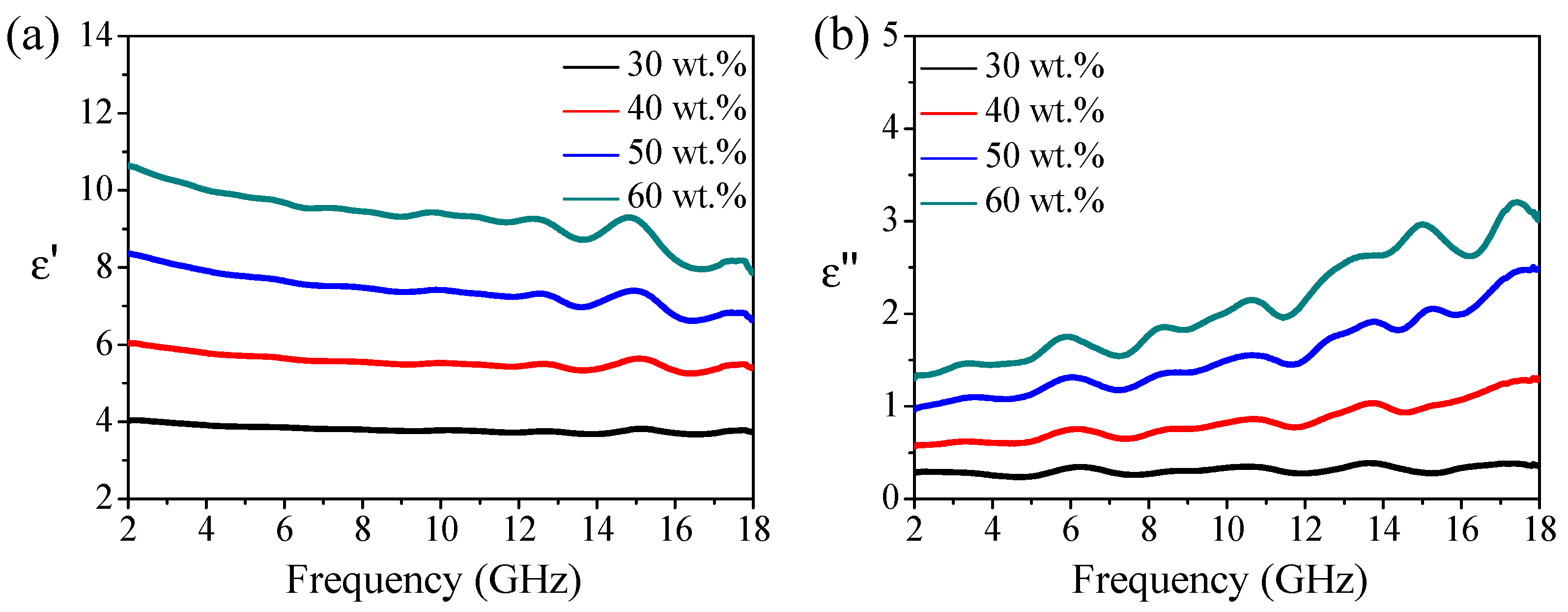

3.2. Complex Permittivity of the Fe(G)/Paraffin Composites

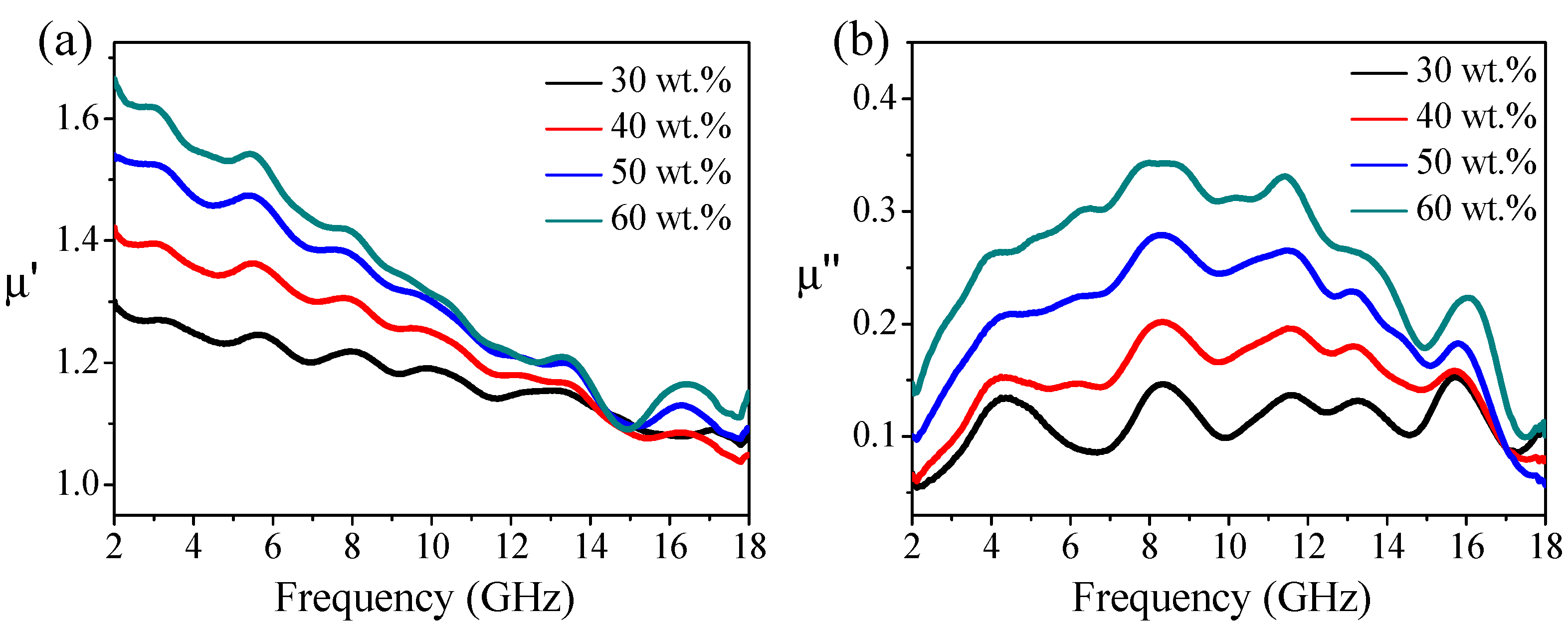

3.3. Complex Permeability of Fe(G)/Paraffin Composites

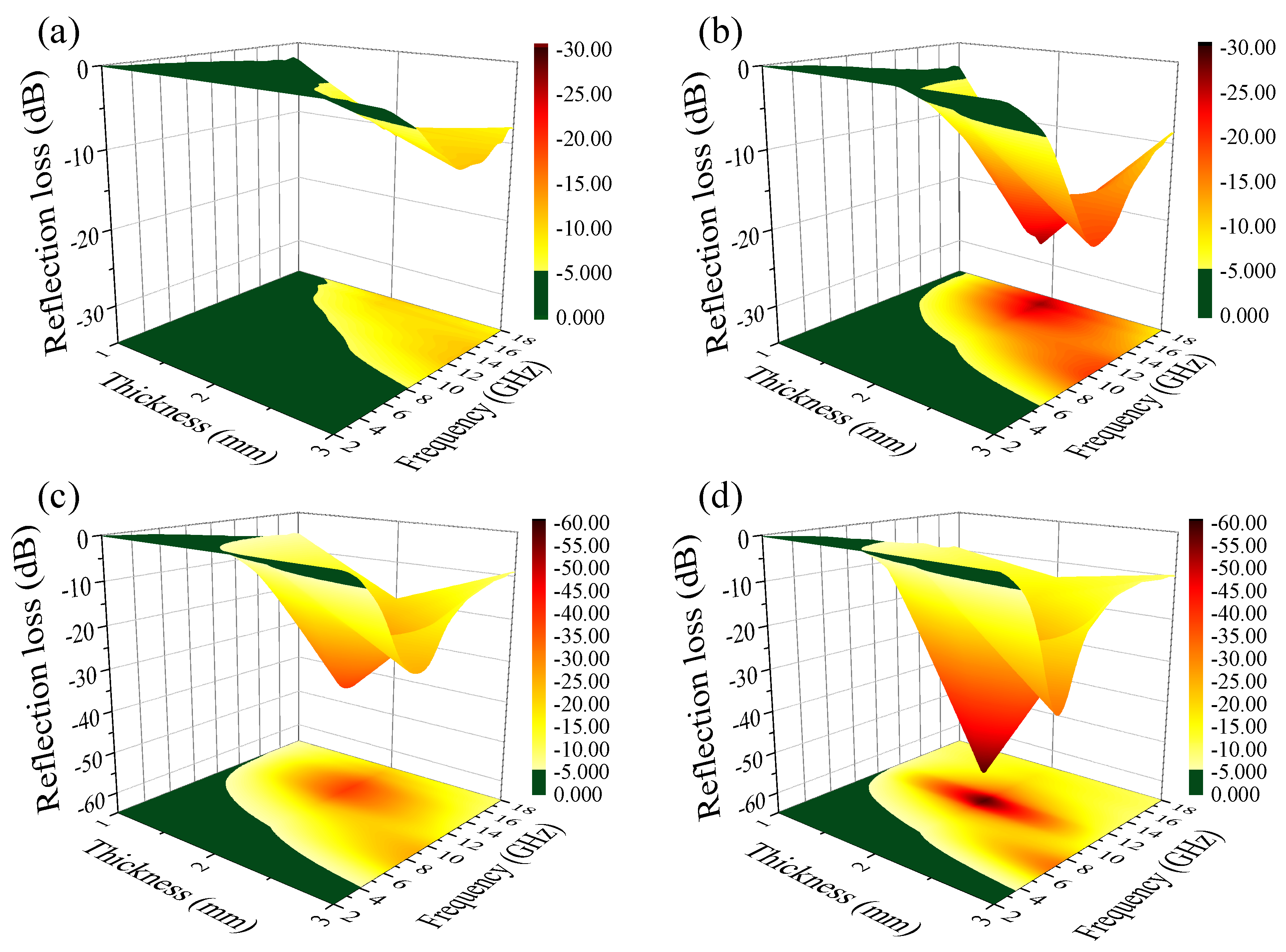

3.4. Calculated R Values for Fe(G)/Paraffin Composites

3.5. Measured R of the Fe(G)/Epoxy Coatings

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Zhu, Q.; Chen, X.; Wu, Z.; He, Y.; Lv, Y.; Zhang, L.; Zou, Y. Ni@C composites derived from Ni-based metal organic frameworks with a lightweight, ultrathin, broadband and highly efficient microwave absorbing properties. Appl. Phys. Express 2018, 12, 011001. [Google Scholar] [CrossRef]

- Chen, W.; Liu, Q.; Zhu, X.; Fu, M. One-step in situ growth of magnesium ferrite nanorods on graphene and their microwave-absorbing properties. Appl. Organomet. Chem. 2017, 32, e4017. [Google Scholar] [CrossRef]

- Hosseini, H.; Mahdavi, H. Nanocomposite based on epoxy and MWCNTs modified with NiFe2O4 nanoparticles as efficient microwave absorbing material. Appl. Organomet. Chem. 2018, 32, e4294. [Google Scholar] [CrossRef]

- Lv, H.; Yang, Z.; Wang, L.P.; Ji, G.; Song, J.; Zheng, L.; Zeng, H.; Xu, Z.J. A Voltage-Boosting Strategy Enabling a Low-Frequency, Flexible Electromagnetic Wave Absorption Device. Adv. Mater. 2018, 30, 1706343. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Gao, X.; Zhang, Q.; Li, T.; Chen, H.; Chen, X. Preparation and microwave absorption properties of asphalt carbon coated reduced graphene oxide/magnetic CoFe2O4 hollow particles modified multi-wall carbon nanotube composites. J. Alloys Compd. 2017, 723, 912–921. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, G.; Liu, W.; Quan, B.; Liang, X.; Shang, C.; Cheng, Y.; Du, Y. Thermal conversion of an Fe3O4 @metal–organic framework: A new method for an efficient Fe–Co/nanoporous carbon microwave absorbing material. Nanoscale 2015, 7, 12932–12942. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Z.; Song, Y.; Xiong, J.; Pan, Z.; Wang, X.; Liu, L.; Liu, R.; Yang, H.; Lu, W. Enhanced electromagnetic wave absorption of nanoporous Fe3O4 @ carbon composites derived from metal-organic frameworks. Carbon 2019, 142, 20–31. [Google Scholar] [CrossRef]

- Liu, L.; He, N.; Wu, T.; Hu, P.; Tong, G. Co/C/Fe/C hierarchical flowers with strawberry-like surface as surface plasmon for enhanced permittivity, permeability, and microwave absorption properties. Chem. Eng. J. 2019, 355, 103–108. [Google Scholar] [CrossRef]

- Wu, N.; Liu, C.; Xu, N.; Liu, J.; Liu, W.; Shao, Q.; Guo, Z. Enhanced Electromagnetic Wave Absorption of Three-Dimensional Porous Fe3O4/C Composite Flowers. ACS Sustain. Chem. Eng. 2018, 6, 12471–12480. [Google Scholar] [CrossRef]

- Lü, Y.; Wang, Y.; Li, H.; Lin, Y.; Jiang, Z.; Xie, Z.; Kuang, Q.; Zheng, L. MOF-Derived Porous Co/C Nanocomposites with Excellent Electromagnetic Wave Absorption Properties. ACS Appl. Mater. Interfaces 2015, 7, 13604–13611. [Google Scholar] [CrossRef]

- Fukutsuka, T.; Yamaguchi, T.; Miyano, S.-I.; Matsuo, Y.; Sugie, Y.; Ogumi, Z. Carbon-coated stainless steel as PEFC bipolar plate material. J. Power Sources 2007, 174, 199–205. [Google Scholar] [CrossRef]

- Guo, L.; Song, W.; Xie, C.; Zhang, X.; Hu, M. Characterization and thermal properties of carbon-coated aluminum nanopowders prepared by laser-induction complex heating in methane. Mater. Lett. 2007, 61, 3211–3214. [Google Scholar] [CrossRef]

- Kang, Y.; Jiang, Z.; Ma, T.; Chu, Z.; Li, G. Hybrids of Reduced Graphene Oxide and Hexagonal Boron Nitride: Lightweight Absorbers with Tunable and Highly Efficient Microwave Attenuation Properties. ACS Appl. Mater. Interfaces 2016, 8, 32468–32476. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhang, H.; Zeng, G.; Li, Z.; Zhang, D.; Zhu, H.; Xie, R.; Zheng, L.; Zhu, J. The microwave absorption properties of carbon-encapsulated nickel nanoparticles/silicone resin flexible absorbing material. J. Alloys Compd. 2016, 682, 138–143. [Google Scholar] [CrossRef]

- Kang, D.; Kwon, J.Y.; Cho, H.; Sim, J.-H.; Hwang, H.S.; Kim, C.S.; Kim, Y.J.; Ruoff, R.S.; Shin, H.S. Oxidation Resistance of Iron and Copper Foils Coated with Reduced Graphene Oxide Multilayers. ACS Nano 2012, 6, 7763–7769. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.F.; Guan, P.F.; Dong, X.L. Multidielectric polarizations in the core/shell Co/graphite nanoparticles. Appl. Phys. Lett. 2010, 96, 223111. [Google Scholar] [CrossRef]

- Liu, X.G.; Li, B.; Geng, D.Y.; Cui, W.B.; Yang, F.; Xie, Z.G.; Kang, D.J.; Zhang, Z.D. (Fe, Ni)/C nanocapsules for electromagnetic-wave-absorber in the whole Ku-band. Carbon 2009, 47, 470–474. [Google Scholar] [CrossRef]

- Han, Z.; Li, D.; Wang, H.; Liu, X.G.; Li, J.; Geng, D.; Zhang, Z.D. Broadband electromagnetic-wave absorption by FeCo/C nanocapsules. Appl. Phys. Lett. 2009, 95, 23114. [Google Scholar] [CrossRef]

- Han, D.; Or, S.W.; Dong, X.; Liu, B. FeSn2/defective onion-like carbon core-shell structured nanocapsules for high-frequency microwave absorption. J. Alloys Compd. 2017, 695, 2605–2611. [Google Scholar] [CrossRef]

- Cheng, C. Solid-state optoelectronic device based on TiO2/SnSe2 core-shell nanocable structure. Opt. Mater. Express 2017, 7, 3691. [Google Scholar] [CrossRef]

- Jian, X.; Chen, G.; Liu, H.; Mahmood, N.; Zhu, S.; Yin, L.; Tang, H.; Lv, W.; He, W.; Zhang, K.H.L.; et al. Vapor–Dissociation–Solid Growth of Three-Dimensional Graphite-like Capsules with Delicate Morphology and Atomic-level Thickness Control. Cryst. Growth Des. 2016, 16, 5040–5048. [Google Scholar] [CrossRef]

- Jiang, Z.; Xiao, X.; Kuang, F.; Jian, X.; Rao, G.; Yin, L.; Liu, S.; Tian, W.; Mahmood, N.; Tan, Z. Mechanistic study of graphitic carbon layer and nanosphere formation on the surface of T-ZnO. Inorg. Chem. Front. 2017, 4, 978–985. [Google Scholar] [CrossRef]

- Liu, L.; Das, A.; Megaridis, C.M. Terahertz shielding of carbon nanomaterials and their composites–A review and applications. Carbon 2014, 69, 1–16. [Google Scholar] [CrossRef]

- Wang, H.; Guo, H.; Dai, Y.; Geng, D.; Han, Z.; Li, D.; Yang, T.; Ma, S.; Liu, W.; Zhang, Z. Optimal electromagnetic-wave absorption by enhanced dipole polarization in Ni/C nanocapsules. Appl. Phys. Lett. 2012, 101, 083116. [Google Scholar] [CrossRef]

- Lu, B.; Dong, X.; Huang, H.; Zhang, X.F.; Zhu, X.; Lei, J.; Sun, J. Microwave absorption properties of the core/shell-type iron and nickel nanoparticles. J. Magn. Magn. Mater. 2008, 320, 1106–1111. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, X.; Feng, C.; Fan, J.; Lv, Y.; Wang, Y.; Li, C. A facile synthesis of FeNi3@C nanowires for electromagnetic wave absorber. J. Alloy. Compd. 2014, 586, 688–692. [Google Scholar] [CrossRef]

- Liu, X.G.; Ou, Z.Q.; Geng, D.Y.; Han, Z.; Xie, Z.G.; Zhang, Z.D. Enhanced natural resonance and attenuation properties in superparamagnetic graphite-coated FeNi3 nanocapsules. J. Phys. D Appl. Phys. 2009, 42, 155004. [Google Scholar] [CrossRef]

- Qin, F.; Brosseau, C. A review and analysis of microwave absorption in polymer composites filled with carbonaceous particles. J. Appl. Phys. 2012, 111, 061301. [Google Scholar] [CrossRef]

- Liu, X.; Ou, Z.; Geng, D.; Han, Z.; Wang, H.; Li, B.; Brück, E.; Zhang, Z. Enhanced absorption bandwidth in carbon-coated supermalloy FeNiMo nanocapsules for a thin absorb thickness. J. Alloys Compd. 2010, 506, 826–830. [Google Scholar] [CrossRef]

- Liu, X.; Ou, Z.; Geng, D.; Han, Z.; Jiang, J.; Liu, W.; Zhang, Z. Influence of a graphite shell on the thermal and electromagnetic characteristics of FeNi nanoparticles. Carbon 2010, 48, 891–897. [Google Scholar] [CrossRef]

- Jian, X.; Wu, B.; Wei, Y.; Dou, S.; Wang, X.; He, W.; Mahmood, N. Facile Synthesis of Fe3O4/GCs Composites and Their Enhanced Microwave Absorption Properties. ACS Appl. Mater. Interfaces 2016, 8, 6101–6109. [Google Scholar] [CrossRef] [PubMed]

- Guan, H.; Liu, S.; Duan, Y. Expanded Polystyrene as an Admixture in Cement-Based Composites for Electromagnetic Absorbing. J. Mater. Eng. Perform. 2007, 16, 68–72. [Google Scholar] [CrossRef]

- Yan, S.; Xu, C.-Y.; Jiang, J.; Liu, D.; Wang, Z.; Tang, J.; Zhen, L. Strong dual-frequency electromagnetic absorption in Ku-band of C@FeNi3 core/shell structured microchains with negative permeability. J. Magn. Magn. Mater. 2014, 349, 159–164. [Google Scholar] [CrossRef]

- Micheli, D.; Apollo, C.; Pastore, R.; Morles, R.B.; Laurenzi, S.; Marchetti, M. Nanostructured composite materials for electromagnetic interference shielding applications. Acta Astronaut. 2011, 69, 747–757. [Google Scholar] [CrossRef]

- Ismach, A.; Druzgalski, C.; Penwell, S.; Schwartzberg, A.M.; Zheng, M.; Javey, A.; Bokor, J.; Zhang, Y. Direct Chemical Vapor Deposition of Graphene on Dielectric Surfaces. Nano Lett. 2010, 10, 1542–1548. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.F.; Dong, X.L.; Huang, H.; Liu, Y.Y.; Wang, W.N.; Zhu, X.G.; Lv, B.; Lei, J.; Lee, C.G. Microwave absorption properties of the carbon-coated nickel nanocapsules. Appl. Phys. Lett. 2006, 89, 053115. [Google Scholar] [CrossRef]

- Xie, Z.; Geng, D.; Liu, X.; Ma, S.; Zhang, Z. Magnetic and Microwave-absorption Properties of Graphite-coated (Fe, Ni) Nanocapsules. J. Mater. Sci. Technol. 2011, 27, 607–614. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Liu, X.G.; Geng, D.; Meng, H.; Shang, P.J.; Zhang, Z.D. Microwave-absorption properties of ZnO-coated iron nanocapsules. Appl. Phys. Lett. 2008, 92, 173117. [Google Scholar] [CrossRef]

- Feng, J.; Zong, Y.; Sun, Y.; Zhang, Y.; Yang, X.; Long, G.; Wang, Y.; Li, X.; Zheng, X. Optimization of porous FeNi3/N-GN composites with superior microwave absorption performance. Chem. Eng. J. 2018, 345, 441–451. [Google Scholar] [CrossRef]

- Liu, X.G.; Geng, D.; Meng, H.; Li, B.; Zhang, Q.; Kang, D.J.; Zhang, Z.D. Corrigendum: Fluorescence and microwave-absorption properties of multi-functional ZnO-coated α-Fe solid-solution nanocapsules. J. Phys. D Appl. Phys. 2012, 45, 239502. [Google Scholar] [CrossRef]

- Zhang, X.F.; Dong, X.L.; Huang, H.; Lv, B.; Lei, J.P.; Choi, C.J. Microstructure and microwave absorption properties of carbon-coated iron nanocapsules. J. Phys. D Appl. Phys. 2007, 40, 5383–5387. [Google Scholar] [CrossRef]

- Naito, Y.; Suetake, K. Application of Ferrite to Electromagnetic Wave Absorber and its Characteristics. In Proceedings of the G-MTT 1970 International Microwave Symposium, Newport Beach, CA, USA, 11–14 May 1970. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Deng, Y.; Han, C.; Zhu, H.; Yan, C.; Zhang, H. Enhanced Microwave Absorption Bandwidth in Graphene-Encapsulated Iron Nanoparticles with Core–Shell Structure. Nanomaterials 2020, 10, 931. https://doi.org/10.3390/nano10050931

Zhang D, Deng Y, Han C, Zhu H, Yan C, Zhang H. Enhanced Microwave Absorption Bandwidth in Graphene-Encapsulated Iron Nanoparticles with Core–Shell Structure. Nanomaterials. 2020; 10(5):931. https://doi.org/10.3390/nano10050931

Chicago/Turabian StyleZhang, Danfeng, Yunfei Deng, Congai Han, Haiping Zhu, Chengjie Yan, and Haiyan Zhang. 2020. "Enhanced Microwave Absorption Bandwidth in Graphene-Encapsulated Iron Nanoparticles with Core–Shell Structure" Nanomaterials 10, no. 5: 931. https://doi.org/10.3390/nano10050931

APA StyleZhang, D., Deng, Y., Han, C., Zhu, H., Yan, C., & Zhang, H. (2020). Enhanced Microwave Absorption Bandwidth in Graphene-Encapsulated Iron Nanoparticles with Core–Shell Structure. Nanomaterials, 10(5), 931. https://doi.org/10.3390/nano10050931