CuFeAl Nanocomposite Catalysts for Coal Combustion in Fluidized Bed

Abstract

1. Introduction

- High catalytic activity;

- High mechanical strength and attrition resistance;

- Spherical shape and narrow distribution of the granule size;

- Catalytic stability throughout the catalyst lifetime.

2. Materials and Methods

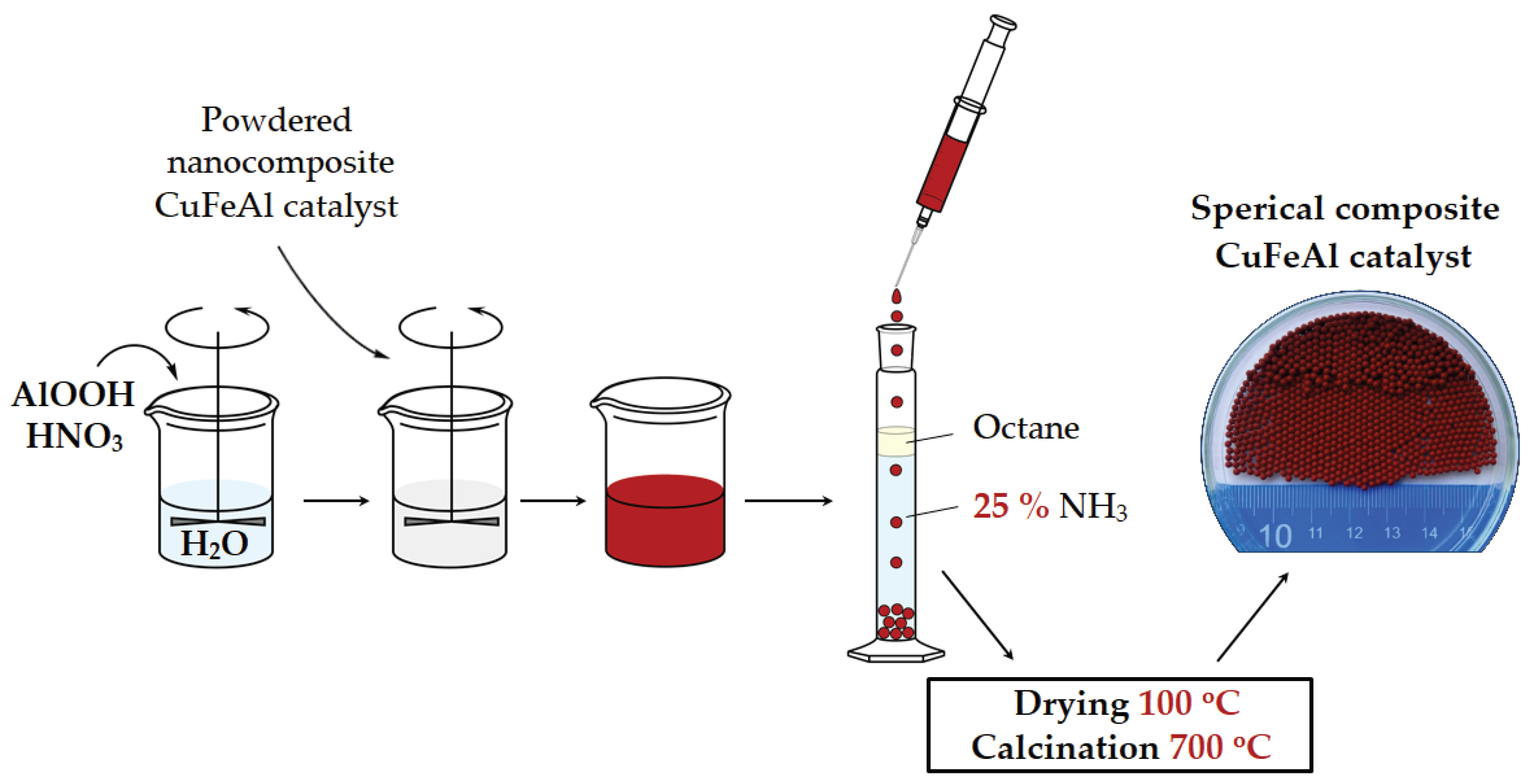

2.1. Catalyst Preparation

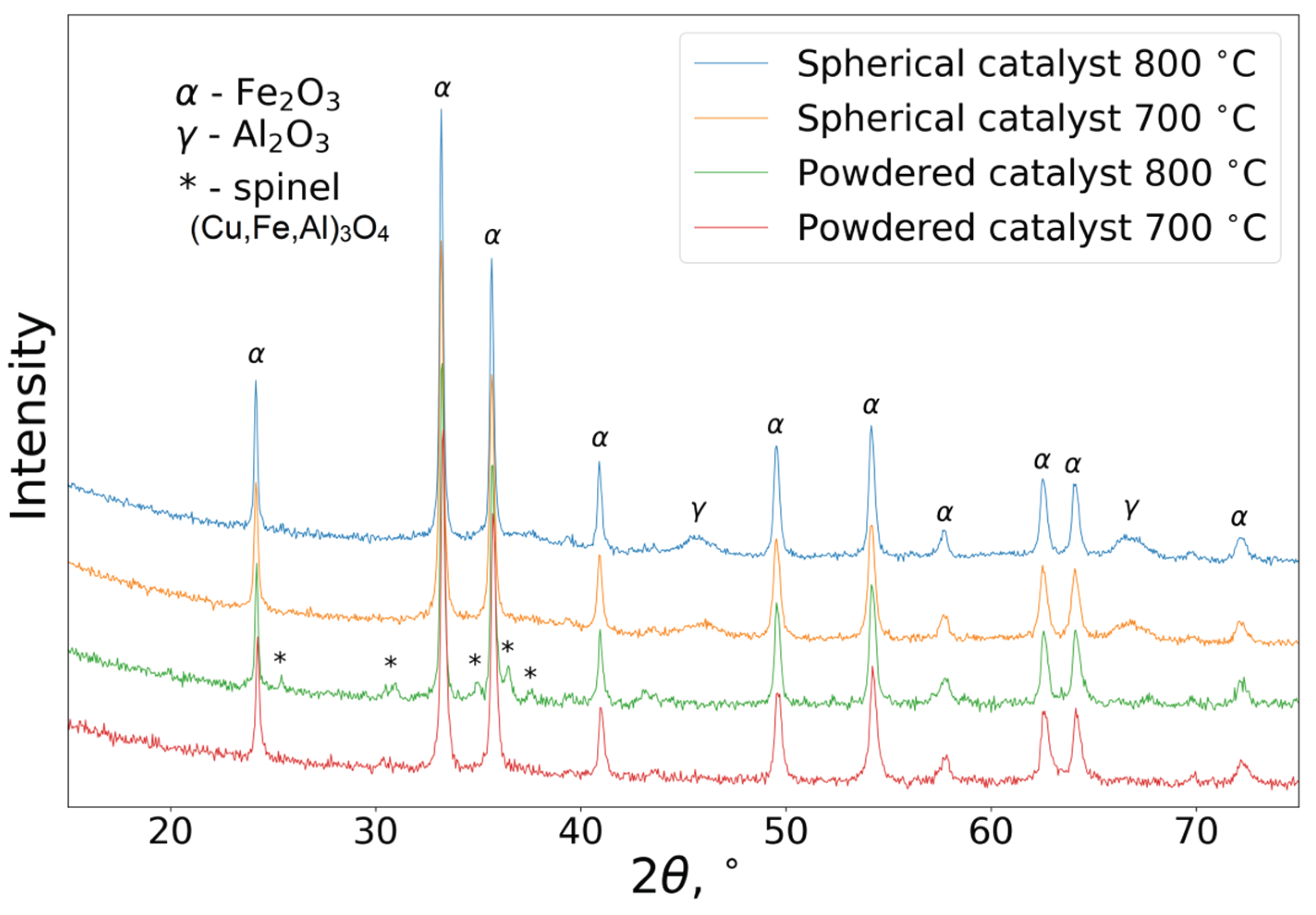

2.2. X-ray Diffraction

2.3. Specific Surface Area Analysis

2.4. Crushing Strength

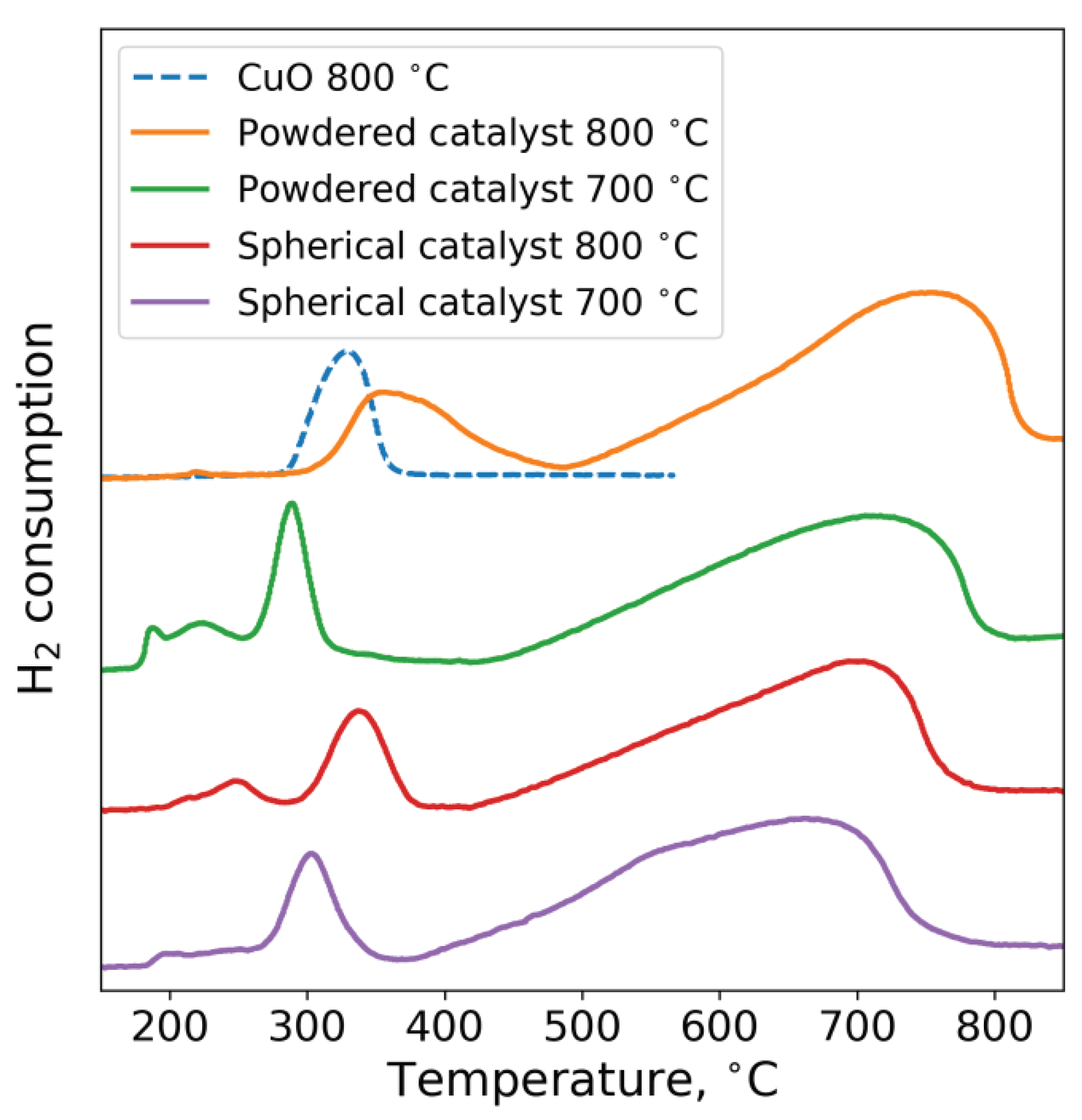

2.5. Temperature-Programmed Reduction

2.6. Catalytic Activity Tests

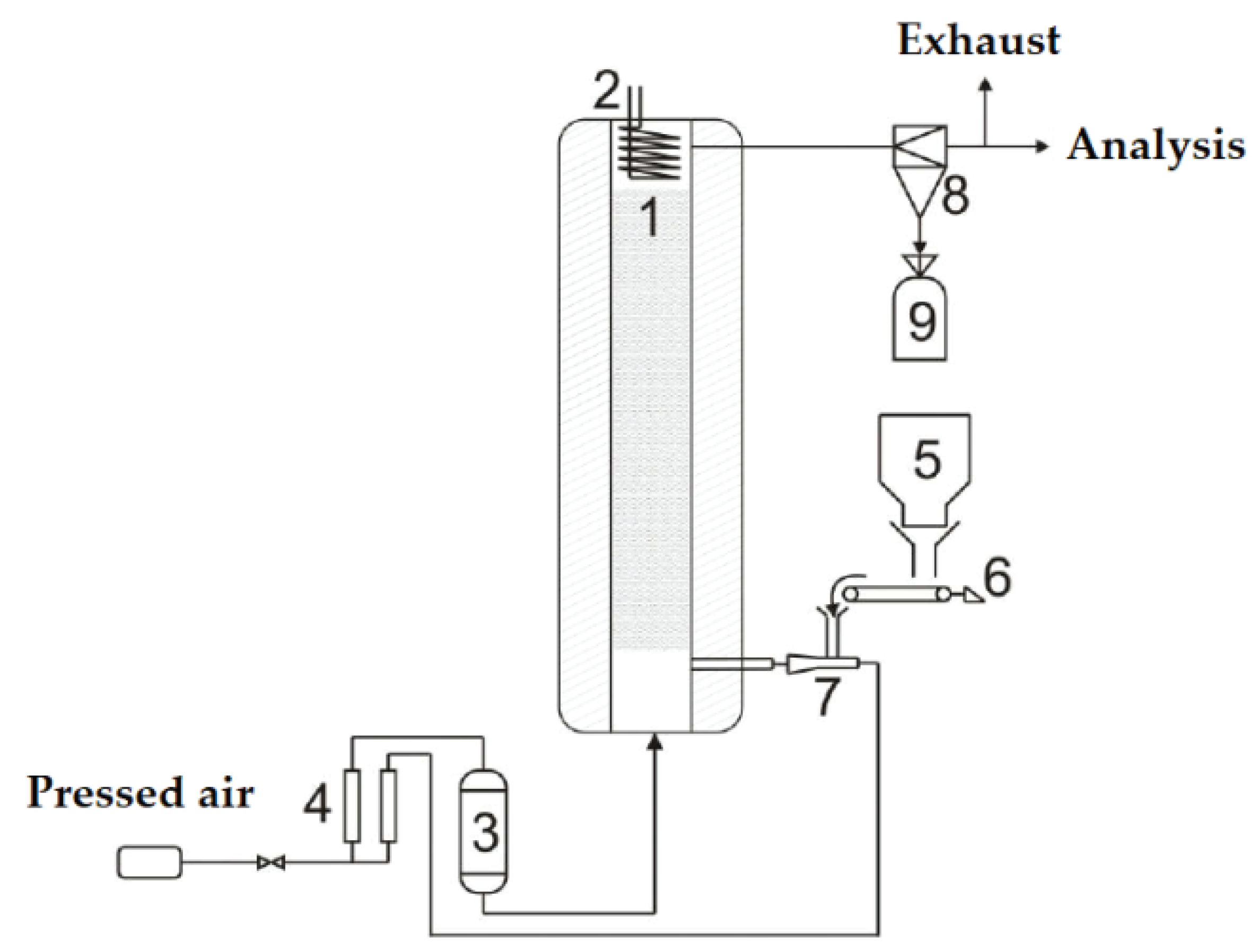

2.7. Coal Combustion in a Fluidized Bed of a Catalyst

3. Results and Discussion

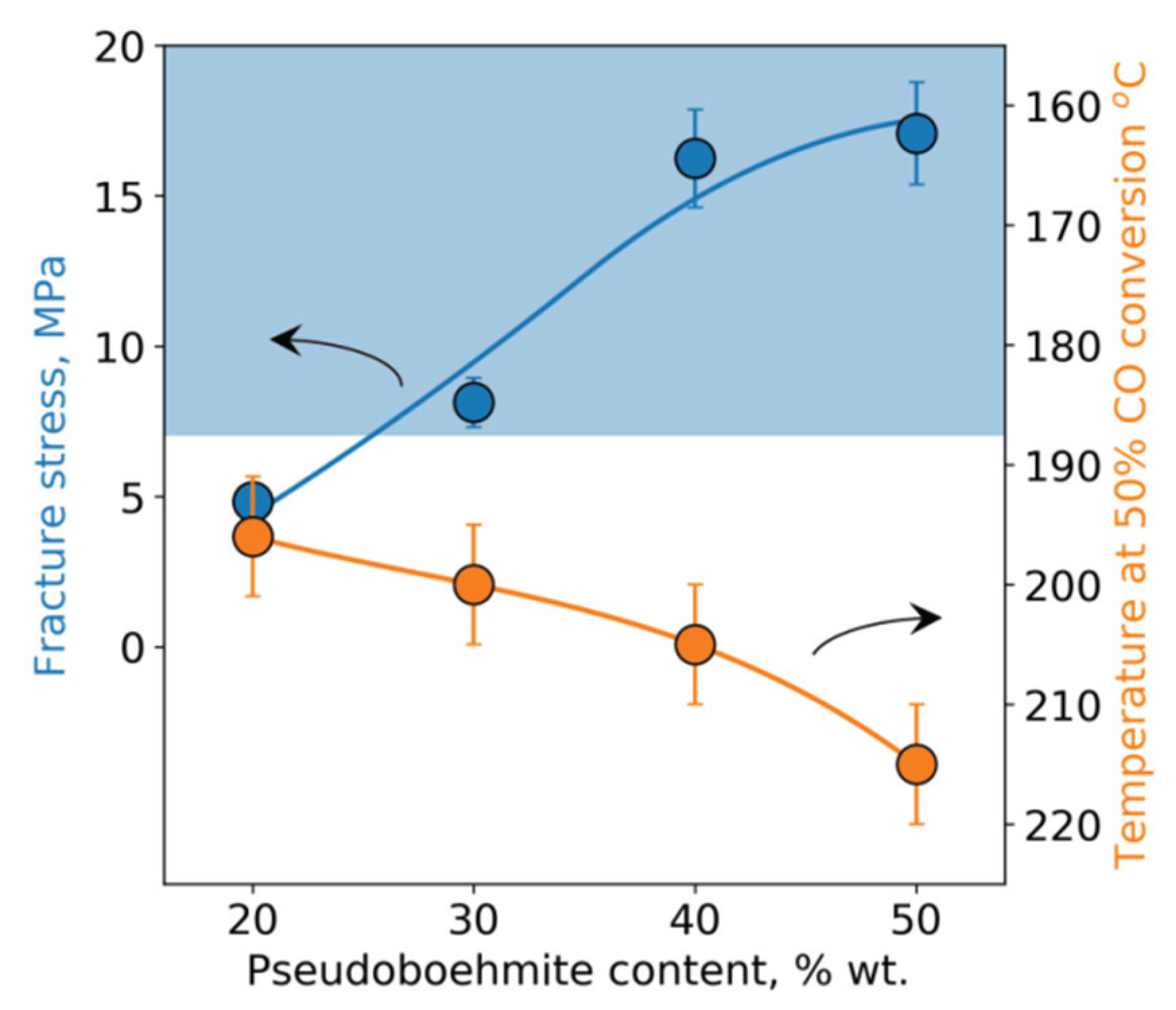

3.1. Strength and Activity of Spherical CuFeAl-Composite Catalysts

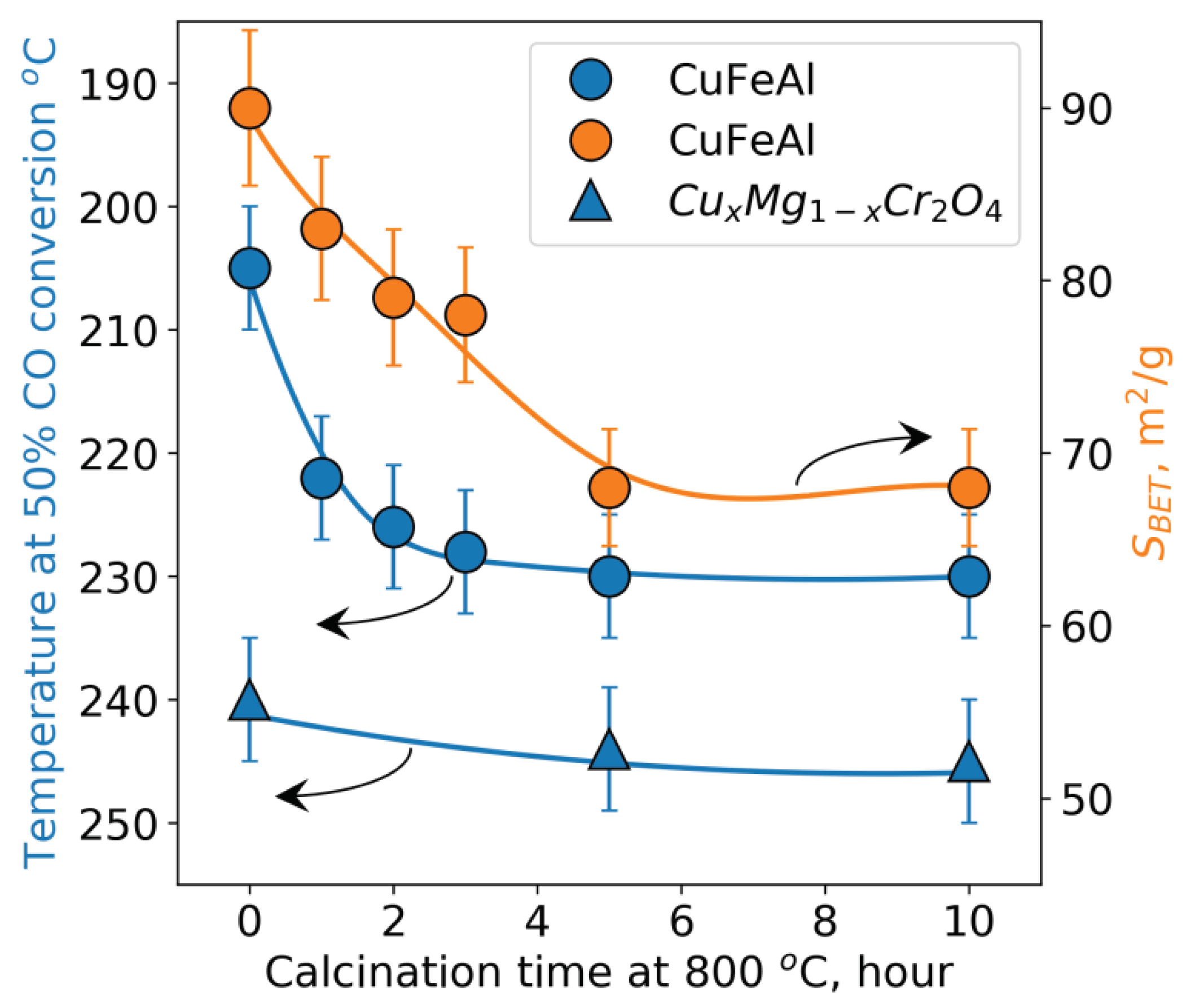

3.2. Thermal Stability of Spherical CuFeAl Nanocomposite Catalysts

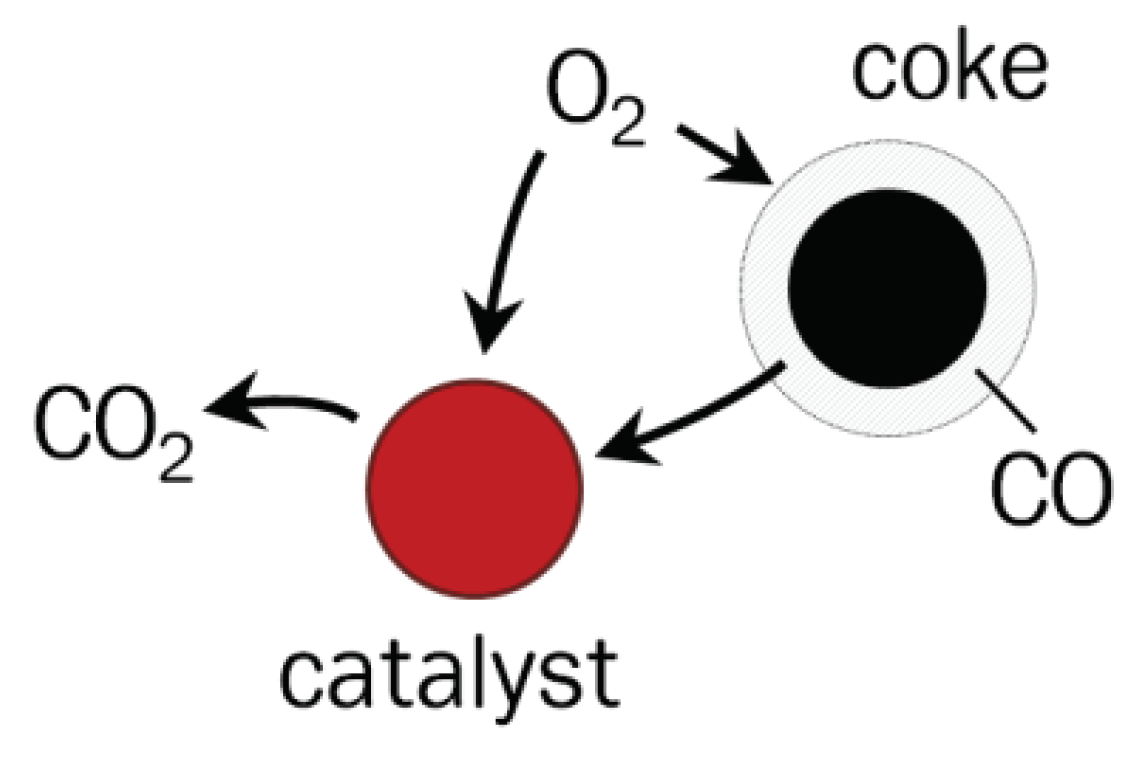

3.3. Coal Combustion in a Fluidized Bed of a Catalyst

- C + O2 → CO2;

- 2C + O2 → 2CO;

- C + CO2 → 2CO;

- C + H2O → CO + H2.

- 5.

- NO2 + CO → NO + CO2;

- 6.

- NO + 2CO → N2 + 2CO2.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ismagilov, Z.R.; Kerzhentsev, M.A. Fluidized bed catalytic combustion. Catal. Today 1999, 47, 339–346. [Google Scholar] [CrossRef]

- Parmon, V.N.; Simonov, A.D.; Sadykov, V.A.; Tikhov, S.F. Catalytic combustion: Achievements and problems. Combust. Explos. Shock Waves 2015, 51, 143–150. [Google Scholar] [CrossRef]

- Yazykov, N.A.; Dubinin, Y.V.; Simonov, A.D.; Reshetnikov, S.I.; Yakovlev, V.A. Features of sulfur oils catalytic combustion in fluidized bed. Chem. Eng. J. 2016, 283, 649–655. [Google Scholar] [CrossRef]

- Iamarino, M.; Chirone, R.; Lisi, L.; Pirone, R.; Salatino, P.; Russo, G. Cu/γ-Al2O3 catalyst for the combustion of methane in a fluidized bed reactor. Catal. Today 2002, 75, 317–324. [Google Scholar] [CrossRef]

- Foka, M.; Chaouki, J.; Guy, C.; Klvana, D. Natural gas combustion in a catalytic turbulent fluidized bed. Chem. Eng. Sci. 1994, 49, 4269–4276. [Google Scholar] [CrossRef]

- Simonov, A.; Yazykov, N.; Vedyakin, P.; Lavrov, G.; Parmon, V. Industrial experience of heat supply by catalytic installations. Catal. Today 2000, 60, 139–145. [Google Scholar] [CrossRef]

- Simonov, A.D.; Fedorov, N.A.; Dubinin, Y.V.; Yazykov, N.A.; Yakovlev, V.A.; Parmon, V.N. Catalytic heat-generating units for industrial heating. Catal. Ind. 2013, 5, 42–49. [Google Scholar] [CrossRef]

- Ismagilov, Z.R.; Shkrabina, R.A.; Koryabkina, N.A. New technology for production of spherical alumina supports for fluidized bed combustion. Catal. Today 1999, 47, 51–71. [Google Scholar] [CrossRef]

- Klvana, D.; Delval, J.; Kirchnerova, J.; Chaouki, J. Deactivation of fiber-supported La0.65Sr0.35Ni0.29Co0.69Fe0.02O3 catalyst by mercaptan during combustion of methane or natural gas. Appl. Catal. A Gen. 1997, 165, 171–182. [Google Scholar] [CrossRef]

- Mahato, N.; Banerjee, A.; Gupta, A.; Omar, S.; Balani, K. Progress in material selection for solid oxide fuel cell technology: A review. Prog. Mater. Sci. 2015, 72, 141–337. [Google Scholar] [CrossRef]

- Rosso, I.; Garrone, E.; Geobaldo, F.; Onida, B.; Saracco, G.; Specchia, V. Sulphur poisoning of LaMn1−xMgxO3 catalysts for natural gas combustion. Appl. Catal. B Environ. 2001, 30, 61–73. [Google Scholar] [CrossRef]

- Buelna, G.; Lin, Y.S. Sol–gel-derived mesoporous γ-alumina granules. Microporous Mesoporous Mater. 1999, 30, 359–369. [Google Scholar] [CrossRef]

- Islam, A.; Taufiq-Yap, Y.H.; Chu, C.-M.; Chan, E.-S.; Ravindra, P. Synthesis and characterization of millimetric gamma alumina spherical particles by oil drop granulation method. J. Porous Mater. 2012, 19, 807–817. [Google Scholar] [CrossRef]

- Shepeleva, M.N.; Shkrabina, R.A.; Ismagilov, Z.R.; Fenelonov, V.B. Preparation of Strong Alumina Supports for Fluidized Bed Catalysts. Stud. Surf. Sci. Catal. 1991, 63, 583–590. [Google Scholar]

- Arendarskii, D.A.; Ismagilov, Z.R.; Barannik, G.B. Study of the deactivation and regeneration of copper chromite on γ-alumina and magnesium chromite on γ-alumina catalysts for fuel combustion. Catal. Lett. 1992, 15, 347–351. [Google Scholar] [CrossRef]

- Shanker, A.K.; Cervantes, C.; Loza-Tavera, H.; Avudainayagam, S. Chromium toxicity in plants. Environ. Int. 2005, 31, 739–753. [Google Scholar] [CrossRef]

- Miki, T.; Tai, Y. Catalytic Oxidation of Toluene over Fe2O3/Al2O3 Catalyst. Mater. Sci. Forum 2011, 695, 101–104. [Google Scholar] [CrossRef]

- Abdel Halim, K.S.; Khedr, M.H.; Nasr, M.I.; El-Mansy, A.M. Factors affecting CO oxidation over nanosized Fe2O3. Mater. Res. Bull. 2007, 42, 731–741. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Chang, Z.; Sun, X.; Li, Y. Crystal plane effect of Fe2O3 with various morphologies on CO catalytic oxidation. Catal. Commun. 2011, 12, 530–534. [Google Scholar] [CrossRef]

- Fedorov, A.V.; Tsapina, A.M.; Bulavchenko, O.A.; Saraev, A.A.; Odegova, G.V.; Ermakov, D.Y.; Zubavichus, Y.V.; Yakovlev, V.A.; Kaichev, V.V. Structure and Chemistry of Cu–Fe–Al Nanocomposite Catalysts for CO Oxidation. Catal. Lett. 2018, 148, 3715–3722. [Google Scholar] [CrossRef]

- Cheng, T.; Fang, Z.; Hu, Q.; Han, K.; Yang, X.; Zhang, Y. Low-temperature CO oxidation over CuO/Fe2O3 catalysts. Catal. Commun. 2007, 8, 1167–1171. [Google Scholar] [CrossRef]

- Cao, J.-L.; Wang, Y.; Yu, X.-L.; Wang, S.-R.; Wu, S.-H.; Yuan, Z.-Y. Mesoporous CuO–Fe2O3 composite catalysts for low-temperature carbon monoxide oxidation. Appl. Catal. B 2008, 79, 26–34. [Google Scholar] [CrossRef]

- Litt, G.; Almquist, C. An investigation of CuO/Fe2O3 catalysts for the gas-phase oxidation of ethanol. Appl. Catal. B 2009, 90, 10–17. [Google Scholar] [CrossRef]

- Bulavchenko, O.A.; Vinokurov, Z.S.; Saraev, A.A.; Tsapina, A.M.; Trigub, A.L.; Gerasimov, E.Y.; Gladky, A.Y.; Fedorov, A.V.; Yakovlev, V.A.; Kaichev, V.V. The Influence of Cu and Al Additives on Reduction of Iron(III) Oxide: In Situ XRD and XANES Study. Inorg. Chem. 2019, 58, 4842–4850. [Google Scholar] [CrossRef] [PubMed]

- Saraev, A.A.; Tsapina, A.M.; Fedorov, A.V.; Trigub, A.L.; Bulavchenko, O.A.; Vinokurov, Z.S.; Zubavichus, Y.V.; Kaichev, V.V. CuFeAl-composite catalysts of oxidation of gasification products of solid fuels: In situ XAS and XRD study. Radiat. Phys. Chem. 2020, in press. [Google Scholar] [CrossRef]

- Hiramatsu, Y.; Oka, Y. Determination of the tensile strength of rock by a compression test of an irregular test piece. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1966, 3, 89–90. [Google Scholar] [CrossRef]

- ASTM D4179-11. Standard Test Method for Single Pellet Crush Strength of Formed Catalysts and Catalyst Carriers; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Wu, D.; Zhou, J.; Li, Y. Mechanical strength of solid catalysts: Recent developments and future prospects. AIChE J. 2007, 53, 2618–2629. [Google Scholar] [CrossRef]

- Zakeri, M.; Samimi, A.; Afarani, M.S.; Salehirad, A. Interaction between Weibull parameters and mechanical strength reliability of industrial-scale water gas shift catalysts. Particuology 2017, 32, 160–166. [Google Scholar] [CrossRef]

- Wu, D.; Li, Y.; Shi, Y.; Fang, Z.; Wu, D.; Chang, L. Effects of the calcination conditions on the mechanical properties of a PCoMo/Al2O3 hydrotreating catalyst. Chem. Eng. Sci. 2002, 57, 3495–3504. [Google Scholar] [CrossRef]

- Fedorov, A.V.; Gulyaeva, Y.K. Strength statistics for porous alumina. Powder Technol. 2019, 343, 783–791. [Google Scholar] [CrossRef]

- Antonyuk, S.; Tomas, J.; Heinrich, S.; Mörl, L. Breakage behaviour of spherical granulates by compression. Chem. Eng. Sci. 2005, 60, 4031–4044. [Google Scholar] [CrossRef]

- Cimino, S.; Pirone, R.; Russo, G. Thermal Stability of Perovskite-Based Monolithic Reactors in the Catalytic Combustion of Methane. Ind. Eng. Chem. Res. 2001, 40, 80–85. [Google Scholar] [CrossRef]

- Arai, H.; Machida, M. Thermal stabilization of catalyst supports and their application to high-temperature catalytic combustion. Appl. Catal. A 1996, 138, 161–176. [Google Scholar] [CrossRef]

- Arai, H.; Fukuzawa, H. Research and development on high temperature catalytic combustion. Catal. Today 1995, 26, 217–221. [Google Scholar] [CrossRef]

- Bulavchenko, O.A.; Pochtar’, A.A.; Gerasimov, E.Y.; Fedorov, A.V.; Chesalov, Y.A.; Saraev, A.A.; Yakovlev, V.A.; Kaichev, V.V. Chemical and texture promoters in Cu-Fe-Al oxide nanocomposite catalysts for combustion of solid fuel gasification products. Appl. Catal. A 2020, 590, 117364. [Google Scholar] [CrossRef]

- Luo, M.-F.; Fang, P.; He, M.; Xie, Y.-L. In situ XRD, Raman, and TPR studies of CuO/Al2O3 catalysts for CO oxidation. J. Mol. Catal. A 2005, 239, 243–248. [Google Scholar] [CrossRef]

- He, M.; Luo, M.; Fang, P. Characterization of CuO Species and Thermal Solid-Solid Interaction in CuO/CeO2-Al2O3 Catalyst by In-Situ XRD, Raman Spectroscopy and TPR. J. Rare Earths 2006, 24, 188–192. [Google Scholar] [CrossRef]

- Zieliński, J.; Zglinicka, I.; Znak, L.; Kaszkur, Z. Reduction of Fe2O3 with hydrogen. Appl. Catal. A Gen. 2010, 381, 191–196. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Q.; Zhang, T.; Wang, J.; Wei, G.; Liu, M.; Ning, P. Structural tuning and NH3-SCO performance optimization of CuO-Fe2O3 catalysts by impact of thermal treatment. Appl. Surf. Sci. 2019, 485, 81–91. [Google Scholar] [CrossRef]

- Basu, P. Combustion of coal in circulating fluidized-bed boilers: A review. Chem. Eng. Sci. 1999, 54, 5547–5557. [Google Scholar] [CrossRef]

- Ismagilov, Z.R.; Kerzhentsev, M.A.; Besidin, V.I.; Susharina, T.L. Formation of nitrogen oxides in the oxidation of pyridine on some oxide catalysts. React. Kinet. Catal. Lett. 1983, 23, 49–54. [Google Scholar] [CrossRef]

- Ismagilov, Z.R.; Kerzhentsev, M.A. Catalytic Fuel Combustion—A Way of Reducing Emission of Nitrogen Oxides. Catal. Rev. 1990, 32, 51–103. [Google Scholar] [CrossRef]

- Ni, W.; Li, H.; Zhang, Y.; Zou, Z. Effects of Fuel Type and Operation Parameters on Combustion and NOx Emission of the Iron Ore Sintering Process. Energies 2019, 12, 213. [Google Scholar] [CrossRef]

| AlOOH Content, wt% | HNO3:Al2O3 Molar Ratio | H2O Content, wt% | Powdered Catalyst, Weight, g | AlOOH Weight, g | 2 M HNO3, Vol. mL | H2O Weight, g |

|---|---|---|---|---|---|---|

| 20 | 0.100 | 85 | 8.40 | 2.10 | 1.47 | 56.6 |

| 30 | 0.084 | 82 | 7.59 | 3.24 | 1.90 | 45.6 |

| 40 | 0.067 | 78 | 6.71 | 4.47 | 2.10 | 35.5 |

| 50 | 0.050 | 75 | 5.69 | 5.69 | 1.99 | 30.0 |

| Moisture, % | Ash Content, % | Volatiles, % | C, % | H, % | N, % | O, % | S, % |

|---|---|---|---|---|---|---|---|

| 9.8 | 11.1 | 48.0 | 54.6 | 4.4 | 1.5 | 26.9 | 1.5 |

| Catalyst | Pseudoboehmite Content, wt% | T50, °C | Fracture Stress, MPa | Fraction of Fragile Granules (<7 MPa), % | α Parameter | m, Weibull Modulus |

|---|---|---|---|---|---|---|

| CuFeAl nanocomposite catalysts | 20 | 196 | 4.3 | 94 | 13.4 | 4.4 |

| 30 | 200 | 8.1 | 35 | 12.8 | 4.1 | |

| 40 | 205 | 16.2 | 0.7 | 12.2 | 3.9 | |

| 50 | 215 | 17.1 | 0.6 | 11.2 | 3.5 | |

| CuxMg1−xCr2O4/Al2O3 | - | 240 | 14.4 | 2.7 | 10.0 | 3.5 |

| Catalyst | Powdered CuFeAl Catalyst | Spherical CuFeAl Catalyst | |||

|---|---|---|---|---|---|

| Calcination conditions | 700 °C 1 h | 800°C 5 h | 700 °C 1 h | 800°C 5 h | |

| T50, °C | 190 | 240 | 195 | 230 | |

| SSA, m2/g | 60 | 12 | 90 | 68 | |

| Composition, wt% | CuO | 5.0 | 3.3 | ||

| Fe2O3 | 77.9 | 51.1 | |||

| Al2O3 | 17.1 | 45.6 | |||

| Catalyst | CO, ppm | NO, ppm | Coal Burnout, % |

|---|---|---|---|

| SiO2 (quartz sand) | >8000 | 100 | 70 |

| Spherical CuFeAl nanocomposite catalyst * | 600 | 220 | 95 |

| CuxMg1−xCr2O4/Al2O3 | 700 | 230 | 95 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedorov, A.V.; Yazykov, N.A.; Bulavchenko, O.A.; Saraev, A.A.; Kaichev, V.V.; Yakovlev, V.A. CuFeAl Nanocomposite Catalysts for Coal Combustion in Fluidized Bed. Nanomaterials 2020, 10, 1002. https://doi.org/10.3390/nano10051002

Fedorov AV, Yazykov NA, Bulavchenko OA, Saraev AA, Kaichev VV, Yakovlev VA. CuFeAl Nanocomposite Catalysts for Coal Combustion in Fluidized Bed. Nanomaterials. 2020; 10(5):1002. https://doi.org/10.3390/nano10051002

Chicago/Turabian StyleFedorov, Aleksandr V., Nikolay A. Yazykov, Olga A. Bulavchenko, Andrey A. Saraev, Vasily V. Kaichev, and Vadim A. Yakovlev. 2020. "CuFeAl Nanocomposite Catalysts for Coal Combustion in Fluidized Bed" Nanomaterials 10, no. 5: 1002. https://doi.org/10.3390/nano10051002

APA StyleFedorov, A. V., Yazykov, N. A., Bulavchenko, O. A., Saraev, A. A., Kaichev, V. V., & Yakovlev, V. A. (2020). CuFeAl Nanocomposite Catalysts for Coal Combustion in Fluidized Bed. Nanomaterials, 10(5), 1002. https://doi.org/10.3390/nano10051002