Electrospun Fibre Webs Templated Synthesis of Mineral Scaffolds Based on Calcium Phosphates and Barium Titanate

Abstract

1. Introduction

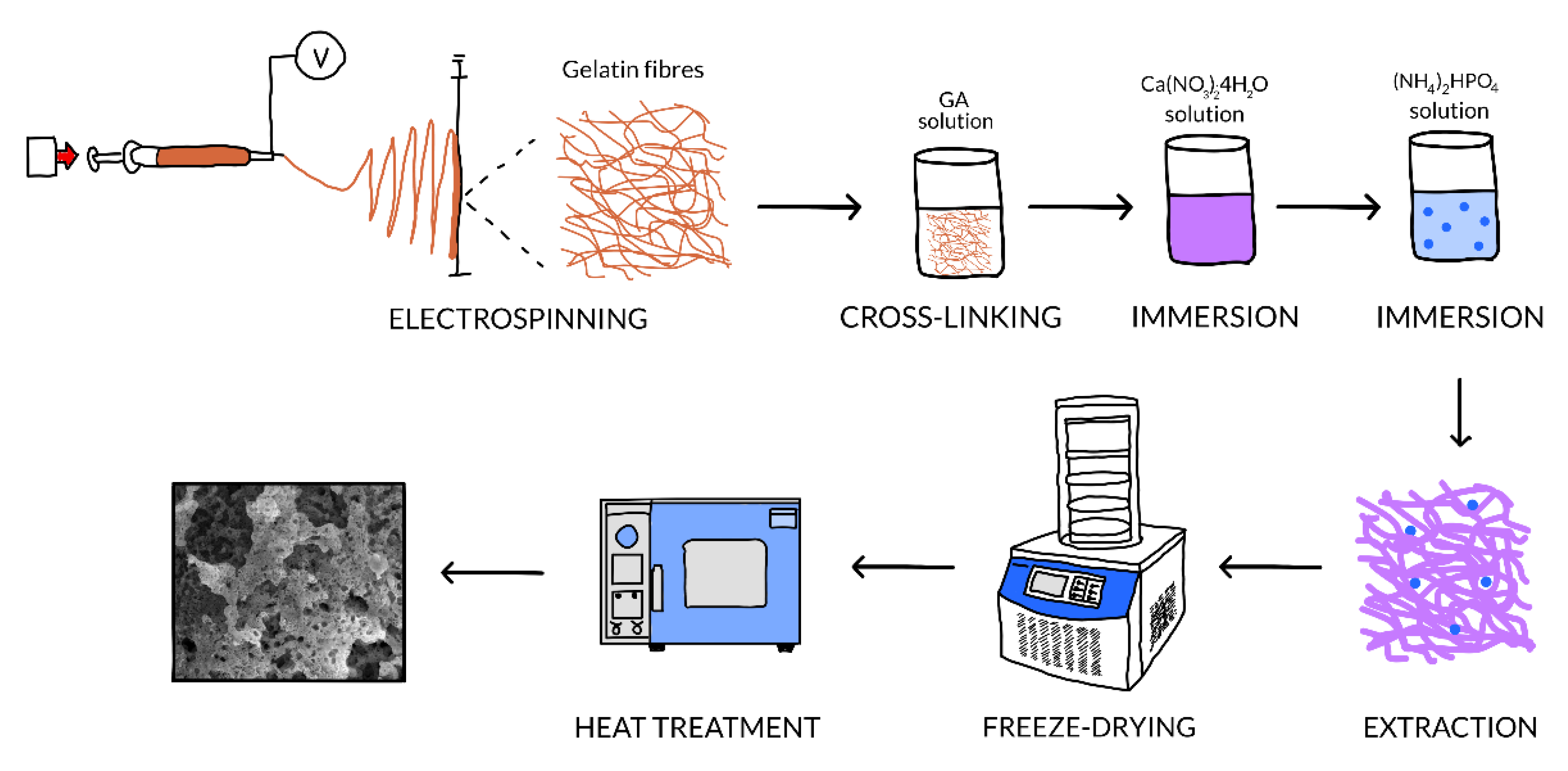

2. Materials and Methods

2.1. Fibrous Template Production

2.2. Hybrid Composites Synthesis

2.3. Mineral Scaffolds Fabrication

2.4. Materials Characterisation

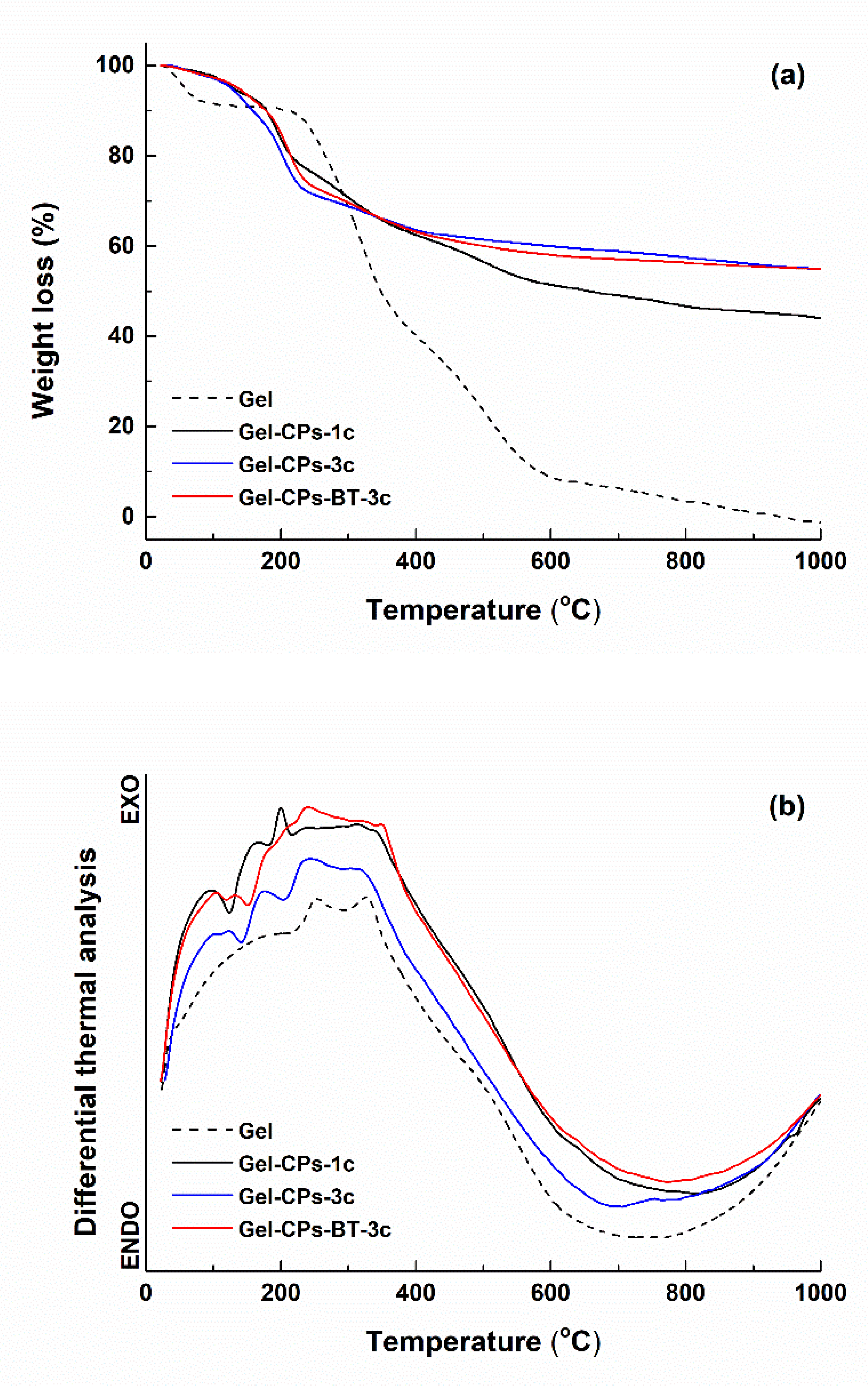

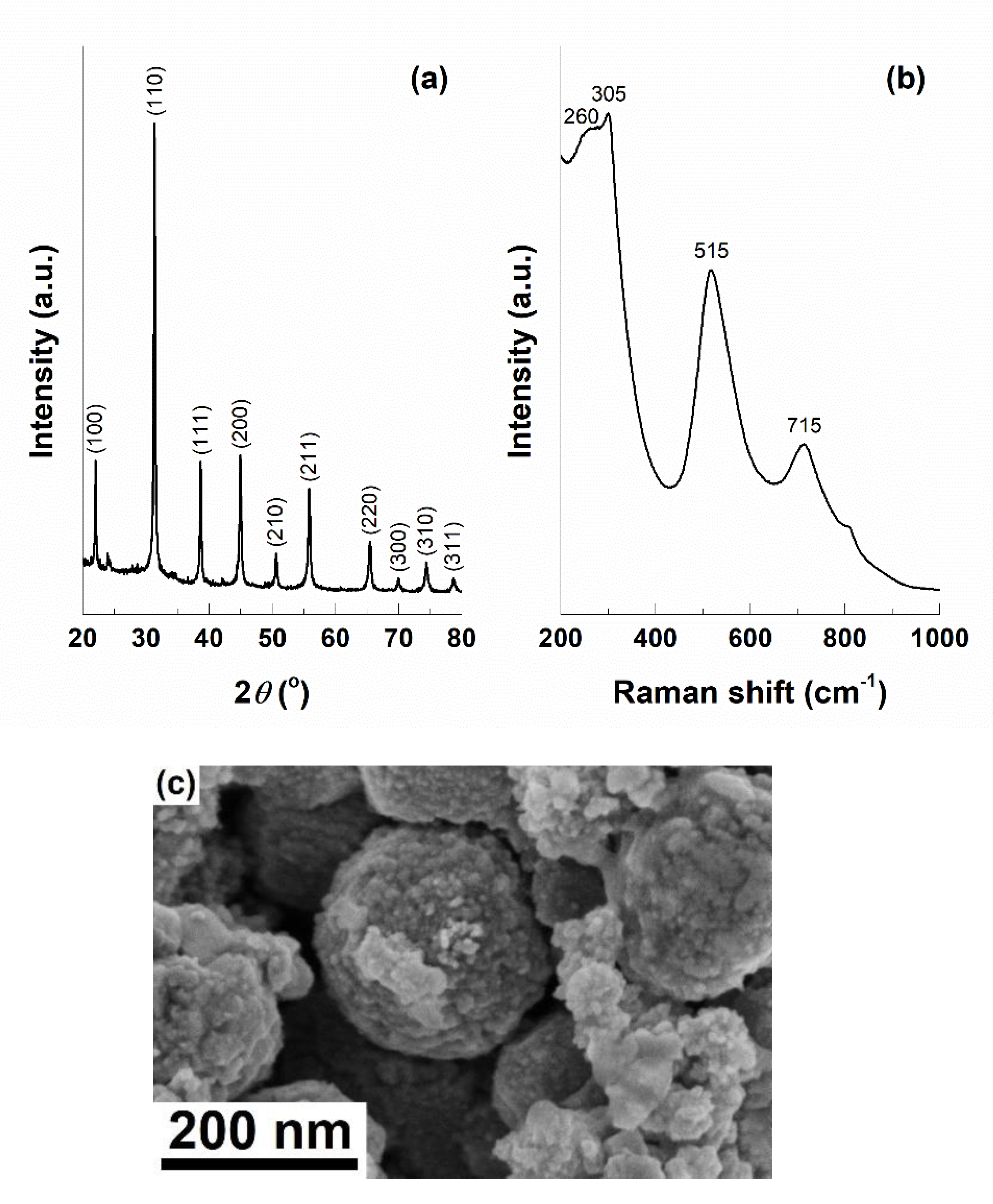

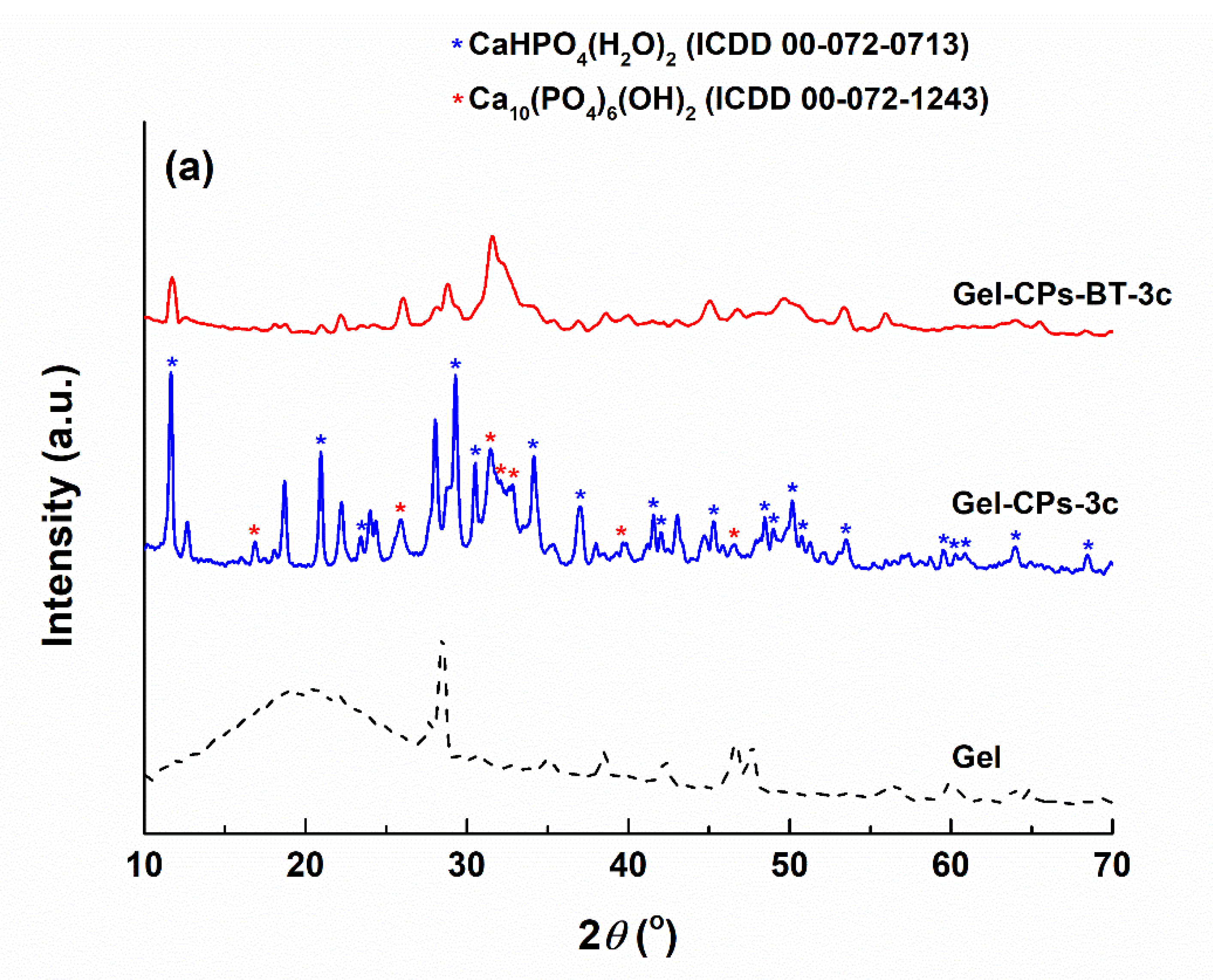

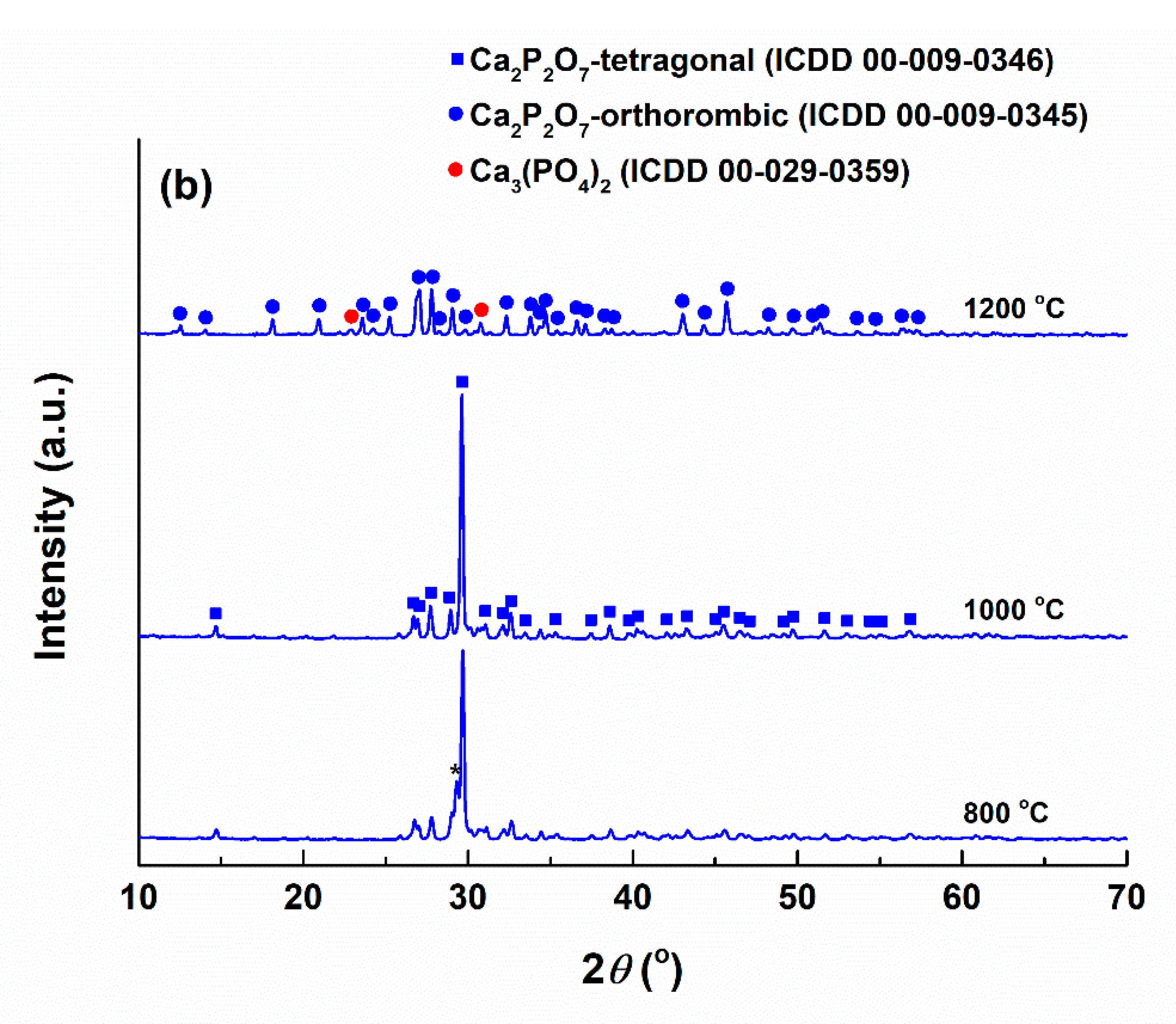

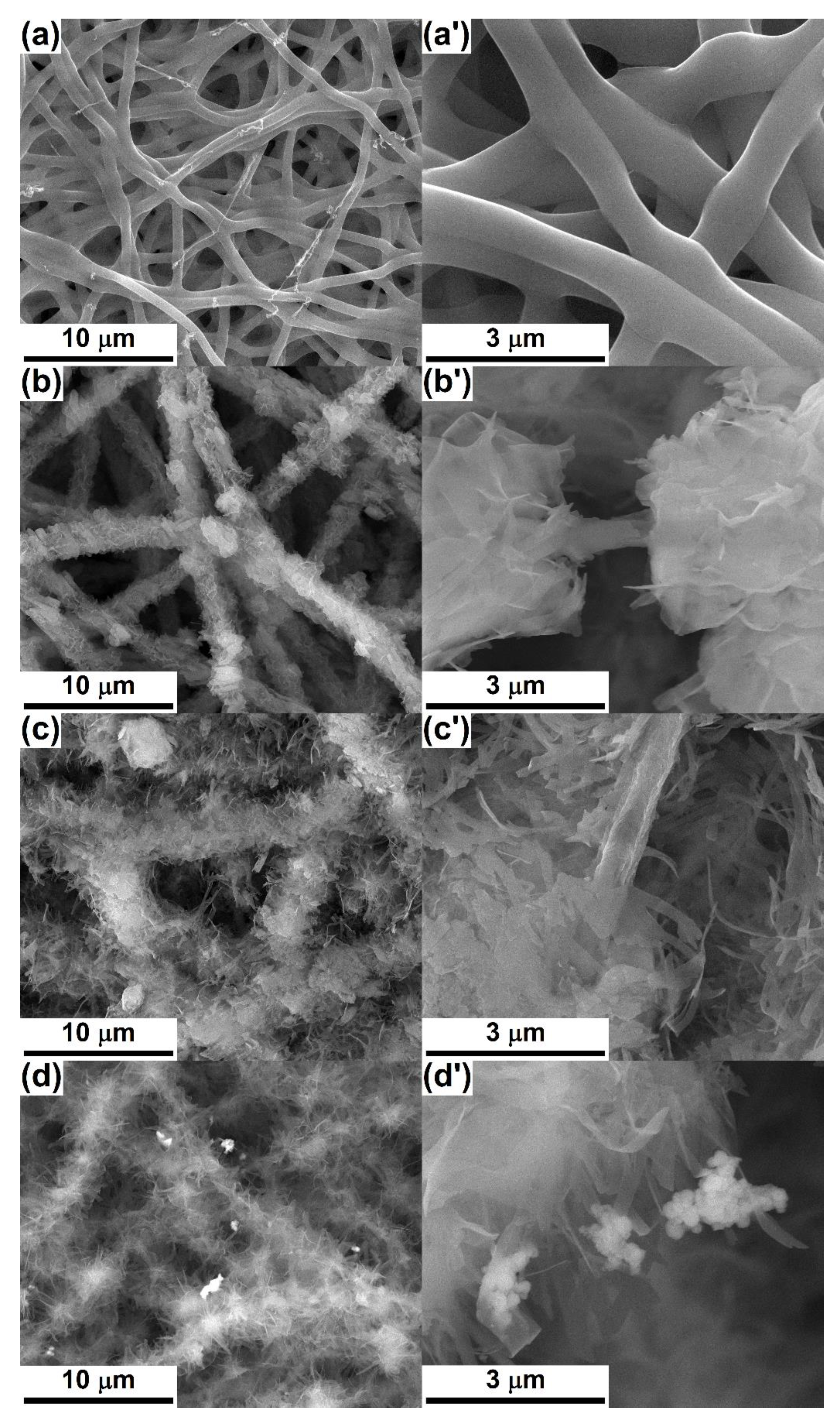

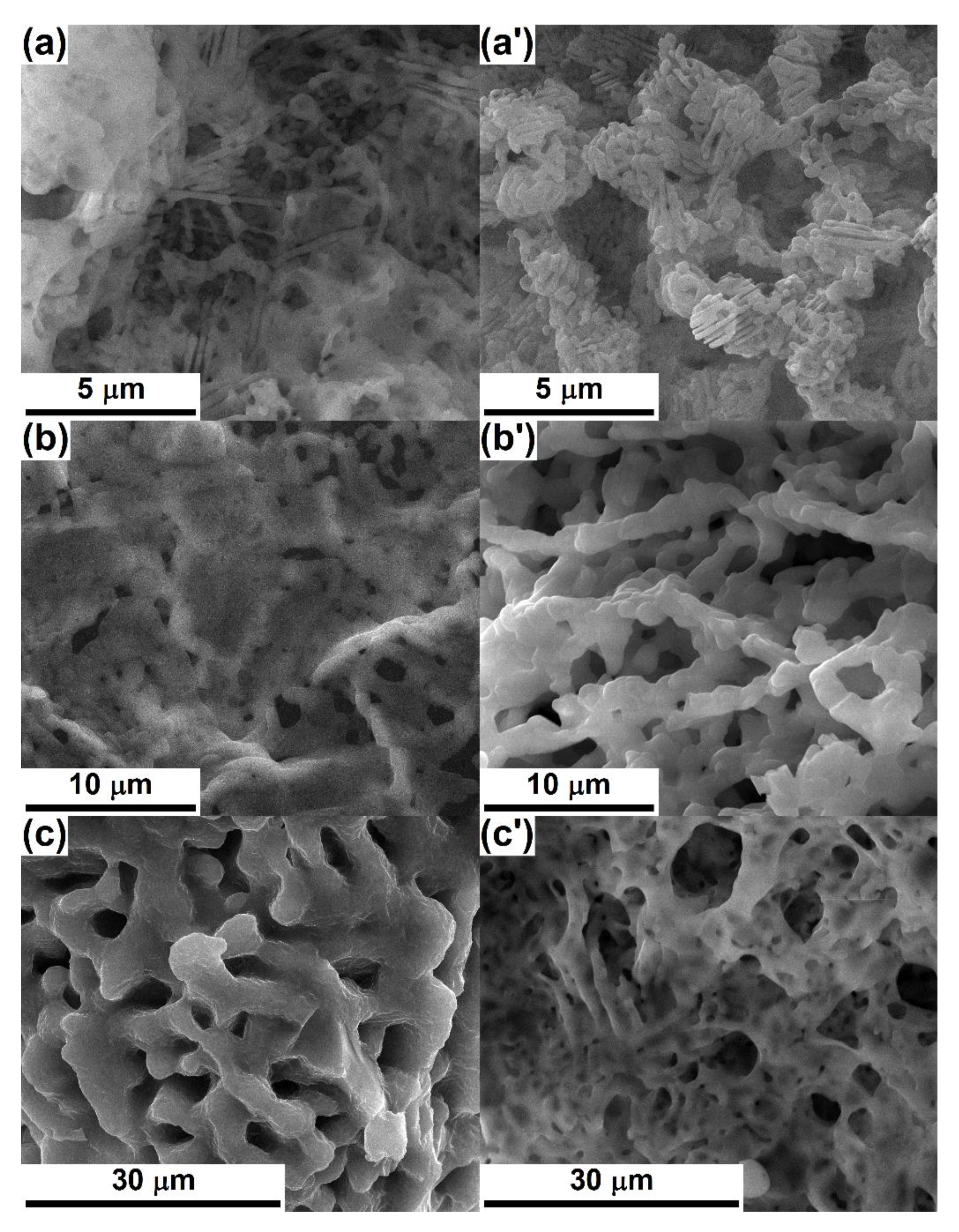

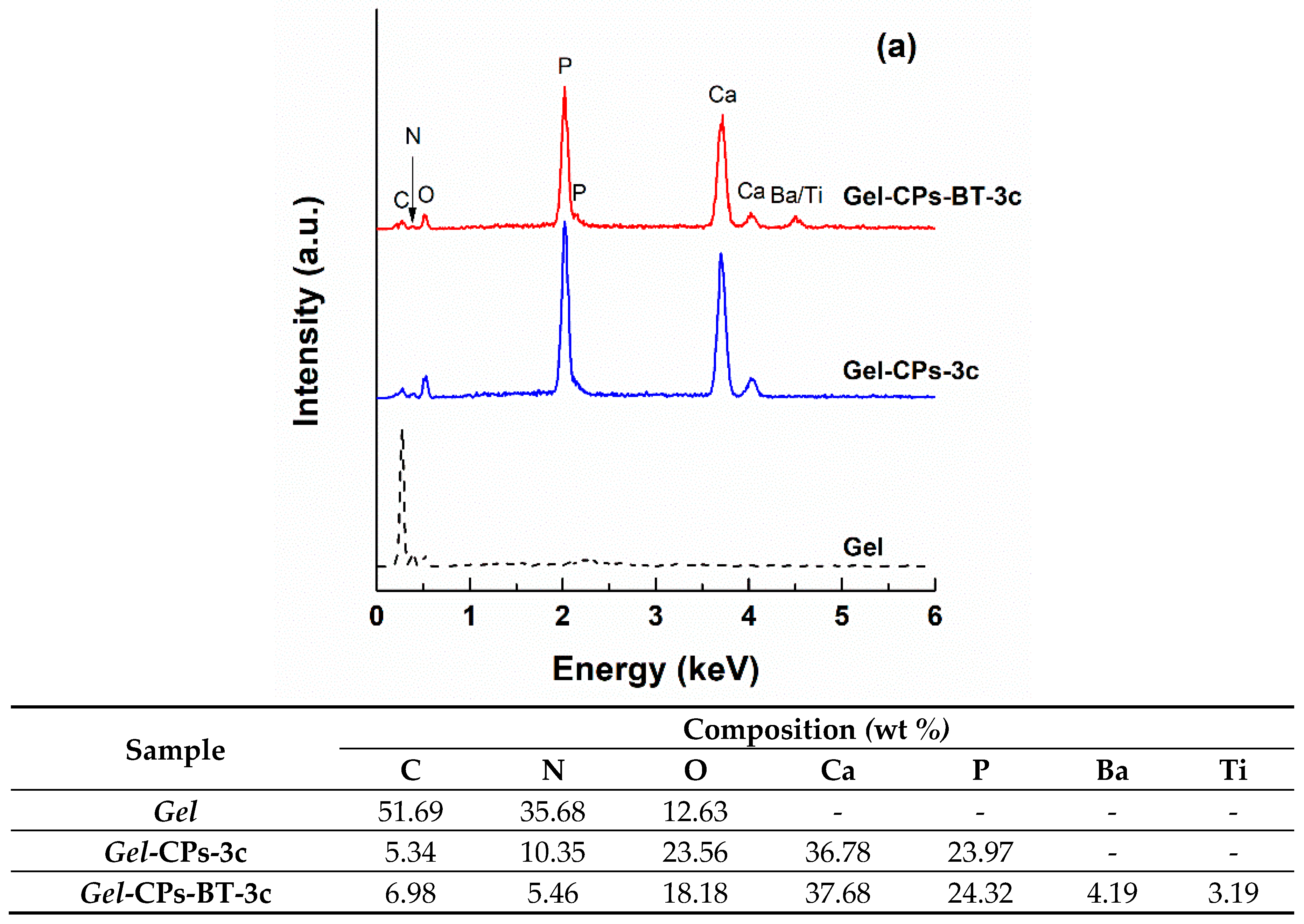

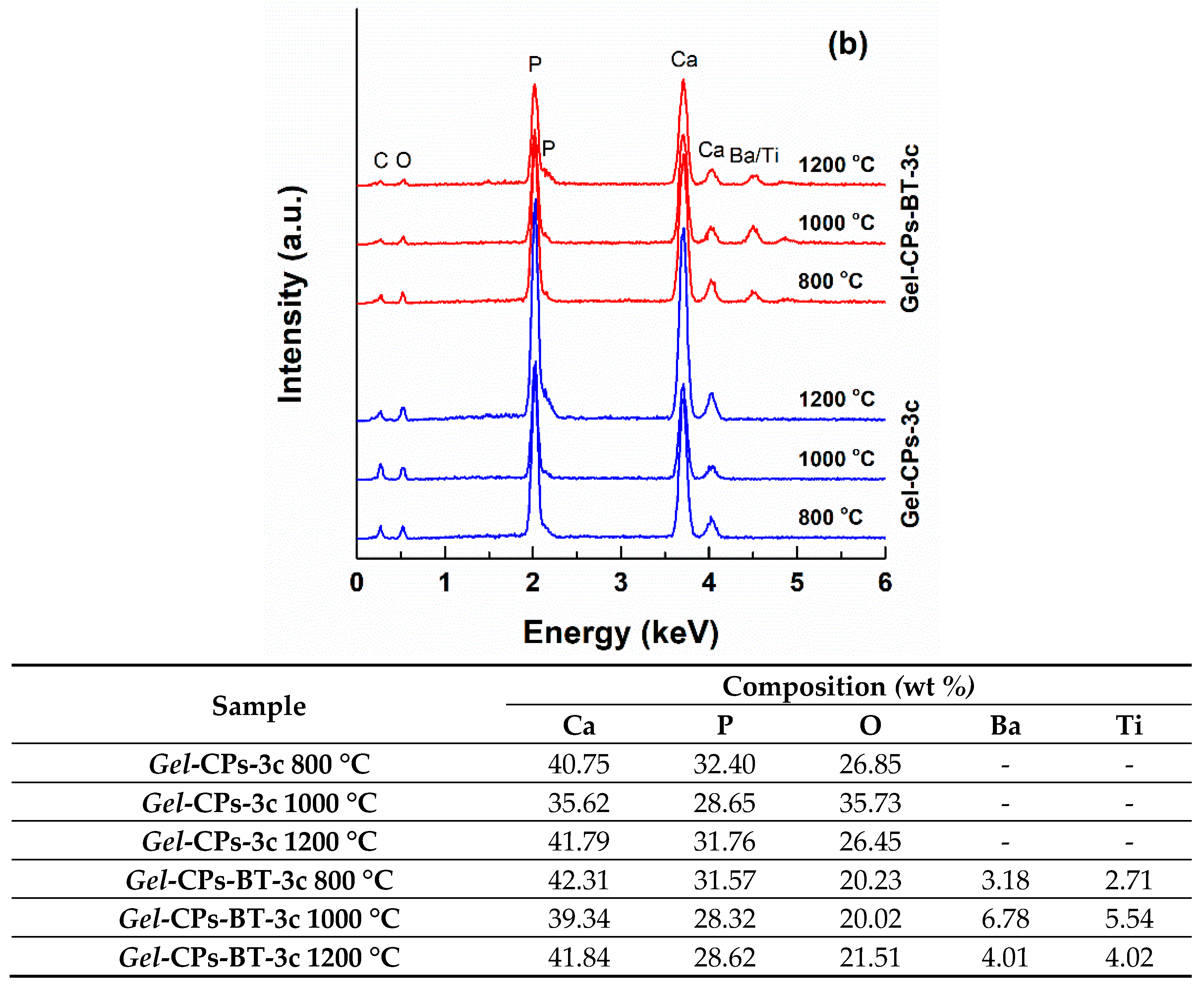

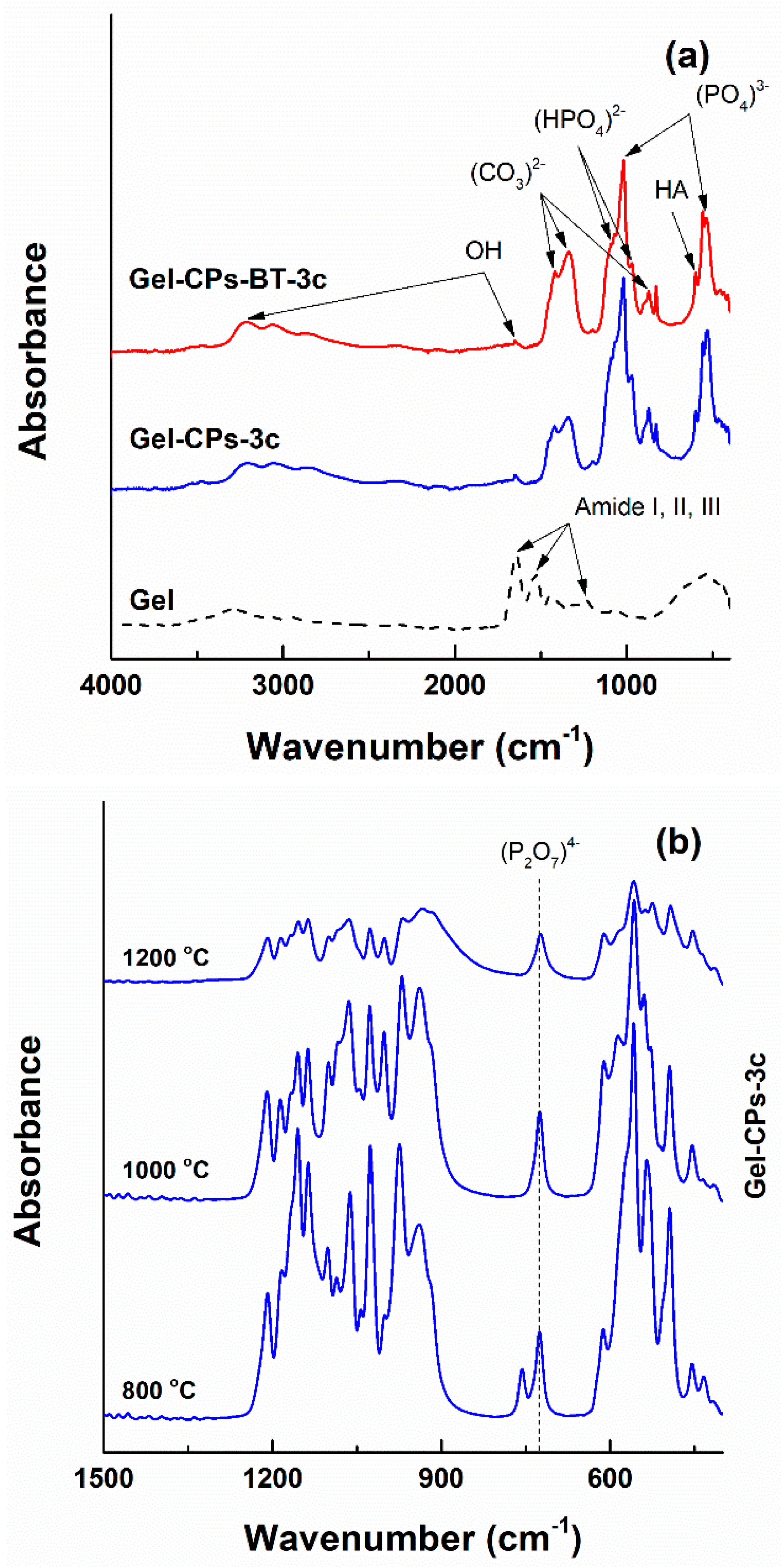

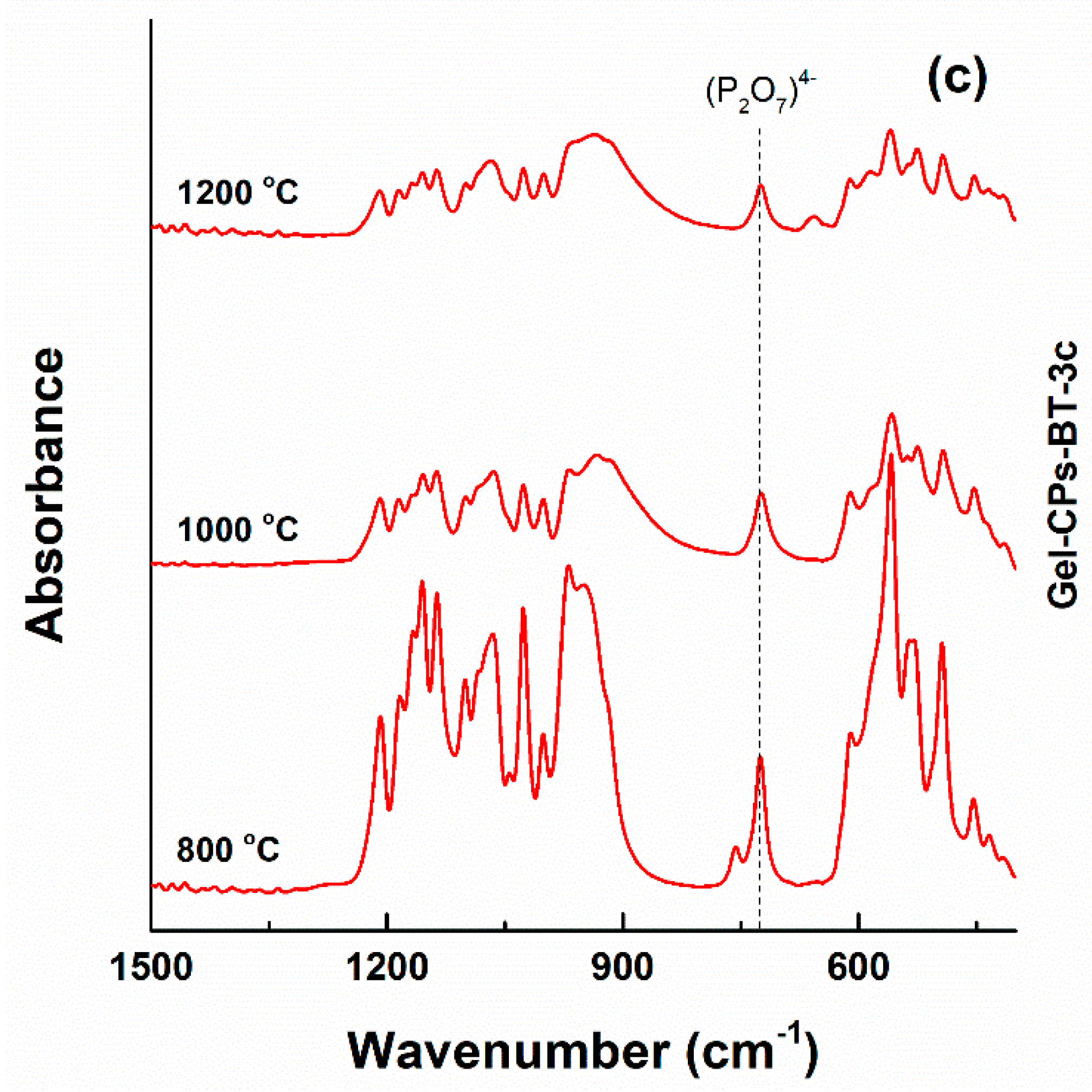

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lanza, R.; Langer, R.; Vacanti, J. Principles of Tissue Engineering; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Mohamed, K.R. Biocomposite materials. In Composites and Their Applications; Hu, N., Ed.; IntechOpen: London, UK, 2012. [Google Scholar]

- Voicu, G.; Jinga, S.I.; Drosu, B.G.; Busuioc, C. Improvement of silicate cement properties with bacterial cellulose powder addition for applications in dentistry. Carbohydr. Polym. 2017, 174, 160–170. [Google Scholar] [CrossRef] [PubMed]

- Cunha, C.; Sprio, S.; Panseri, S.; Dapporto, M.; Marcacci, M.; Tampieri, A. High biocompatibility and improved osteogenic potential of novel Ca–P/titania composite scaffolds designed for regeneration of load-bearing segmental bone defects. J. Biomed. Mater. Res. A 2013, 101, 1612–1619. [Google Scholar] [CrossRef] [PubMed]

- Jianmin, X.; Xiaocheng, W.; Endian, W.; Tian, L.; Jiang, C.; Chengtie, W. Bioinspired multifunctional biomaterials with hierarchical microstructure for wound dressing. Acta Biomater. 2019, 100, 270–279. [Google Scholar]

- Fernandes, J.S.; Gentile, P.; Pires, R.A.; Reis, R.L.; Hatton, P.V. Multifunctional bioactive glass and glass-ceramic biomaterials with antibacterial properties for repair and regeneration of bone tissue. Acta Biomater. 2017, 59, 2–11. [Google Scholar] [CrossRef]

- Antoniac, I.V. Handbook of Bioceramics and Biocomposites; Springer: New York, NY, USA, 2016. [Google Scholar]

- Florencio-Silva, R.; da Silva Sasso, G.R.; Sasso-Cerri, E.; Simoes, M.J.; Cerri, P.S. Biology of bone tissue: Structure, function, and factors that influence bone cells. BioMed Res. Int. 2015, 2015, 421746. [Google Scholar] [CrossRef]

- El-Fiqi, A.; Kim, J.H.; Kim, H.W. Novel bone-mimetic nanohydroxyapatite/collagen porous scaffolds biomimetically mineralized from surface silanized mesoporous nanobioglass/collagen hybrid scaffold: Physicochemical, mechanical and in vivo evaluations. Mater. Sci. Eng. C 2020, 110, 110660. [Google Scholar] [CrossRef]

- Jinga, S.I.; Zamfirescu, A.I.; Voicu, G.; Enculescu, M.; Evanghelidis, A.; Busuioc, C. PCL-ZnO/TiO2/HAp electrospun composite fibres with applications in tissue engineering. Polymers 2019, 11, 1793. [Google Scholar] [CrossRef]

- Cojocaru, F.D.; Balan, V.; Popa, M.I.; Lobiuc, A.; Antoniac, A.; Antoniac, I.V.; Verestiuc, L. Biopolymers—Calcium phosphates composites with inclusions of magnetic nanoparticles for bone tissue engineering. Int. J. Biol. Macromol. 2019, 125, 612–620. [Google Scholar] [CrossRef]

- Jinga, S.I.; Constantinoiu, I.; Surdu, V.A.; Iordache, F.; Busuioc, C. Sol-gel-derived mineral scaffolds within SiO2–P2O5–CaO–MgO–ZnO–CaF2 system. J. Sol-Gel Sci. Technol. 2019, 90, 411–421. [Google Scholar] [CrossRef]

- Erasmus, E.P.; Sule, R.; Johnson, O.T.; Massera, J.; Sigalas, I. In vitro evaluation of porous borosilicate, borophosphate and phosphate bioactive glasses scaffolds fabricated using foaming agent for bone regeneration. Sci. Rep. 2018, 8, 3699. [Google Scholar] [CrossRef]

- Cernencu, A.I.; Lungu, A.; Stancu, I.C.; Serafim, A.; Heggset, E.; Syverud, K.; Iovu, H. Bioinspired 3D printable pectin-nanocellulose ink formulations. Carbohydr. Polym. 2019, 220, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Terranova, L.; Dragusin, D.M.; Mallet, R.; Vasile, E.; Stancu, I.C.; Behets, C.; Chappard, D. Repair of calvarial bone defects in mice using electrospun polystyrene scaffolds combined with β-TCP or gold nanoparticles. Micron 2017, 93, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Draghici, A.D.; Busuioc, C.; Mocanu, A.; Nicoara, A.I.; Iordache, F.; Jinga, S.I. Composite scaffolds based on calcium phosphates and barium titanate obtained through bacterial cellulose templated synthesis. Mater. Sci. Eng. C 2020, 110, 110704. [Google Scholar] [CrossRef] [PubMed]

- Busuioc, C.; Ghitulica, C.D.; Stoica, A.; Stroescu, M.; Voicu, G.; Ionita, V.; Averous, L.; Jinga, S.I. Calcium phosphates grown on bacterial cellulose template. Ceram. Int. 2018, 44, 9433–9441. [Google Scholar] [CrossRef]

- Busuioc, C.; Stroescu, M.; Stoica-Guzun, A.; Voicu, G.; Jinga, S.I. Fabrication of 3D calcium phosphates based scaffolds using bacterial cellulose as template. Ceram. Int. 2016, 42, 15449–15458. [Google Scholar] [CrossRef]

- Loh, Q.L.; Choong, C. Three-dimensional scaffolds for tissue engineering applications: Role of porosity and pore size. Tissue Eng. B 2013, 19, 485–502. [Google Scholar] [CrossRef]

- Shuai, C.; Liu, G.; Yang, Y.; Yang, W.; He, C.; Wang, G.; Liu, Z.; Qi, F.; Peng, S. Functionalized BaTiO3 enhances piezoelectric effect towards cell response of bone scaffold. Colloids Surf. B 2020, 185, 110587. [Google Scholar] [CrossRef]

- Hendi, A.A.; Yakuphanoglu, F. Dielectric and ferroelectric properties of the graphene doped hydroxyapatite ceramics. J. Mol. Struct. 2020, 1207, 127734. [Google Scholar] [CrossRef]

- Mitxelena-Iribarren, O.; Campisi, J.; Martinez de Apellaniz, I.; Lizarbe-Sancha, S.; Arana, S.; Zhukova, V.; Mujika, M.; Zhukov, A. Glass-coated ferromagnetic microwire-induced magnetic hyperthermia for in vitro cancer cell treatment. Mater. Sci. Eng. C 2020, 106, 110261. [Google Scholar] [CrossRef]

- Aoki, K.; Haniu, H.; Kim, Y.A.; Saito, N. The use of electrospun organic and carbon nanofibers in bone regeneration. Nanomaterials 2020, 10, 562. [Google Scholar] [CrossRef]

- Jin, Y.; Gao, Q.; Xie, C.; Li, G.; Du, J.; Fu, J.; He, Y. Fabrication of heterogeneous scaffolds using melt electrospinning writing: Design and optimization. Mater. Des. 2020, 185, 108274. [Google Scholar] [CrossRef]

- Wsoo, M.A.; Shahir, S.; Bohari, S.P.M.; Nayan, N.H.M.; Razak, S.I.A. A review on the properties of electrospun cellulose acetate and its application in drug delivery systems: A new perspective. Carbohydr. Res. 2020. [Google Scholar] [CrossRef] [PubMed]

- Fahimirad, S.; Ajalloueian, F. Naturally-derived electrospun wound dressings for target delivery of bioactive agents. Int. J. Pharm. 2019, 566, 307–328. [Google Scholar] [CrossRef] [PubMed]

- Esfahani, H.; Jose, R.; Ramakrishna, S. Electrospun ceramic nanofiber mats today: Synthesis, properties, and applications. Materials 2017, 10, 1238. [Google Scholar] [CrossRef]

- George, A.; Sanjay, M.R.; Srisuk, R.; Parameswaranpillai, J.; Siengchin, S. A comprehensive review on chemical properties and applications of biopolymers and their composites. Int. J. Biol. Macromol. 2020, 154, 329–338. [Google Scholar] [CrossRef]

- Niaounakis, M. Medical, dental, and pharmaceutical applications. In Biopolymers: Applications and Trends; Niaounakis, M., Ed.; William Andrew: Norwich, NY, USA, 2015. [Google Scholar]

- Selaru, A.; Dragusin, D.M.; Olaret, E.; Serafim, A.; Steinmuller-Nethl, D.; Vasile, E.; Iovu, H.; Stancu, I.C.; Costache, M.; Dinescu, S. Fabrication and biocompatibility evaluation of nanodiamonds-gelatin electrospun materials designed for prospective tissue regeneration applications. Materials 2019, 12, 2933. [Google Scholar] [CrossRef]

- Serafim, A.; Cecoltan, S.; Lungu, A.; Vasile, E.; Iovu, H.; Stancu, I.C. Electrospun fish gelatin fibrous scaffolds with improved bio-interactions due to carboxylated nanodiamond loading. RSC Adv. 2015, 5, 95467–95477. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, W.; Guo, Y.; Zhu, Y.; Song, Y. Electrospun gelatin fibers surface loaded ZnO particles as a potential biodegradable antibacterial wound dressing. Nanomaterials 2019, 9, 525. [Google Scholar] [CrossRef]

- Ridi, F.; Meazzini, I.; Castroflorio, B.; Bonini, M.; Berti, D.; Baglioni, P. Functional calcium phosphate composites in nanomedicine. Adv. Colloid Interface Sci. 2017, 244, 281–295. [Google Scholar] [CrossRef]

- Ben-Nissan, B. Advances in Calcium Phosphate Biomaterials; Springer: New York, NY, USA, 2014. [Google Scholar]

- Sun, R.; Ahlen, M.; Tai, C.W.; Bajnoczi, E.G.; de Kleijne, F.; Ferraz, N.; Persson, I.; Stromme, M.; Cheung, O. Highly porous amorphous calcium phosphate for drug delivery and bio-medical applications. Nanomaterials 2020, 10, 20. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Ma, P.X. Tissue Engineering Using Ceramics and Polymers; Woodhead Publishing: Sawston, UK, 2014. [Google Scholar]

- Baptista, A.C.; Ferreira, I.; Borges, J.P. Electrospun fibers in composite materials for medical applications. J. Compos. Biodegrad. Polym. 2013, 1, 56–65. [Google Scholar] [CrossRef][Green Version]

- Chan, K.; Tsoi, J.K.H.; Wu, O.K.; Yon, M.J.Y.; Wong, R.W.K. Mechanical and biological evaluations of novel electrospun PLLA composite scaffolds doped with oxide ceramics. J. Mech. Behav. Biomed. Mater. 2019, 97, 229–237. [Google Scholar] [CrossRef] [PubMed]

- Santos, D.; Correia, C.O.; Silva, D.M.; Gomes, P.S.; Fernandes, M.H.; Santos, J.D.; Sencadas, V. Incorporation of glass-reinforced hydroxyapatite microparticles into poly(lactic acid) electrospun fibre mats for biomedical applications. Mater. Sci. Eng. C 2017, 75, 1184–1190. [Google Scholar] [CrossRef]

- Ahmed, M.K.; Ramadan, R.; El-dek, S.I.; Uskokovic, V. Complex relationship between alumina and selenium-doped carbonated hydroxyapatite as the ceramic additives to electrospun polycaprolactone scaffolds for tissue engineering applications. J. Alloys Compd. 2019, 801, 70–81. [Google Scholar] [CrossRef]

- Liu, F.; Wang, X.; Chen, T.; Zhang, N.; Wei, Q.; Tian, J.; Wang, Y.; Ma, C.; Lu, Y. Hydroxyapatite/silver electrospun fibers for anti-infection and osteoinduction. J. Adv. Res. 2020, 21, 91–102. [Google Scholar] [CrossRef] [PubMed]

- Kudryavtseva, V.; Stankevich, K.; Kibler, E.; Golovkin, A.; Mishanin, A.; Bolbasov, E.; Choynzonov, E.; Tverdokhlebov, S. The deposition of thin titanium-nitrogen coatings on the surface of PCL-based scaffolds for vascular tissue engineering. Appl. Phys. Lett. 2018, 112, 153705. [Google Scholar] [CrossRef]

- Nandakumar, A.; Yang, L.; Habibovic, P.; van Blitterswijk, C. Calcium phosphate coated electrospun fiber matrices as scaffolds for bone tissue engineering. Langmuir 2010, 26, 7380–7387. [Google Scholar] [CrossRef]

- Kraft, G.M.; Hire, C.C.; Santiago, A.; Adamson, D.H. Electrospun biomimetic catalytic polymer template for the sol-gel formation of multidimensional ceramic structures. Mater. Lett. 2019, 240, 242–245. [Google Scholar] [CrossRef]

- Buscaglia, V.; Randall, C.A. Size and scaling effects in barium titanate. An overview. J. Eur. Ceram. Soc. 2020. [Google Scholar] [CrossRef]

- Busuioc, C.; Voicu, G.; Jinga, S.I.; Mitran, V.; Cimpean, A. The influence of barium titanate on the biological properties of collagen-hydroxiapatite composite scaffolds. Mater. Lett. 2019, 253, 317–322. [Google Scholar] [CrossRef]

- Zanfir, A.V.; Voicu, G.; Busuioc, C.; Jinga, S.I.; Albu, M.G.; Iordache, F. New Coll-HA/BT composite materials for hard tissue engineering. Mater. Sci. Eng. C 2016, 62, 795–805. [Google Scholar] [CrossRef] [PubMed]

- Zanfir, A.V.; Voicu, G.; Jinga, S.I.; Vasile, E.; Ionita, V. Low-temperature synthesis of BaTiO3 nanopowders. Ceram. Int. 2016, 42, 1672–1678. [Google Scholar] [CrossRef]

- Fomekong, R.L.; You, S.; Enrichi, F.; Vomiero, A.; Saruhan, B. Impact of oxalate ligand in co-precipitation route on morphological properties and phase constitution of undoped and Rh-doped BaTiO3 nanoparticles. Nanomaterials 2019, 9, 1697. [Google Scholar] [CrossRef] [PubMed]

- Manea, L.R.; Popa, A.; Bertea, A.P. Medical applications of functional electrospun nanofibers—A review. Key Eng. Mater. 2017, 752, 132–138. [Google Scholar] [CrossRef]

- Kim, Y.J.; Lee, S.Y.; Roh, Y.; Lee, J.; Kim, J.; Lee, Y.; Bang, J.; Lee, Y.J. Optimizing calcium phosphates by the control of pH and temperature via wet precipitation. J. Nanosci. Nanotechnol. 2015, 15, 10008–10016. [Google Scholar] [CrossRef]

- Chuaynukul, K.; Prodpran, T.; Benjakul, S. Preparation, thermal properties and characteristics of gelatin molding compound resin. Res. J. Chem. Environ. Sci. 2014, 2, 1–9. [Google Scholar]

- Singh, M.; Yadav, B.C.; Ranjan, A.; Kaur, M.; Gupta, S.K. Synthesis and characterization of perovskite barium titanate thin film and its application in LPG sensor. Sens. Actuators B 2017, 241, 1170–1178. [Google Scholar] [CrossRef]

- Hayashi, H.; Nakamura, T.; Ebina, T. In-situ Raman spectroscopy of BaTiO3 particles for tetragonal-cubic transformation. J. Phys. Chem. Solids 2013, 74, 957–962. [Google Scholar] [CrossRef]

- Verma, K.C.; Sharma, A.; Goyal, N.; Kotnala, R.K. Ferromagnetism in multiferroic BaTiO3, spinel MFe2O4 (M = Mn, Co, Ni, Zn) ferrite and DMS ZnO nanostructures. In Electromagnetic Materials and Devices; Han, M.G., Ed.; IntechOpen: London, UK, 2020. [Google Scholar]

- Bahoosh, S.G.; Trimper, S.; Wesselinowa, J.M. Origin of ferromagnetism in BaTiO3 nanoparticles. Phys. Status Solidi 2011, 5, 382–384. [Google Scholar] [CrossRef]

- Kim, D.W.; An, J.S.; Cho, I.S. Effects of Mg and Sr co-addition on the densification and biocompatible properties of calcium pyrophosphate. Ceram. Int. 2018, 44, 9689–9695. [Google Scholar] [CrossRef]

- El-Kady, A.M.; Mohamed, K.R.; El-Bassyouni, G.T. Fabrication, characterization and bioactivity evaluation of calcium pyrophosphate/polymeric biocomposites. Ceram. Int. 2009, 35, 2933–2942. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Y.; Meng, Z.; Jiang, Y.; Zhou, R. Microstructure evolution, mechanical properties and enhanced bioactivity of Ti-Nb-Zr based biocomposite by bioactive calcium pyrophosphate. J. Alloys Compd. 2017, 720, 567–581. [Google Scholar] [CrossRef]

- Filippov, Y.Y.; Orlov, E.D.; Klimashina, E.S.; Evdokimov, P.V.; Safronova, T.V.; Putlayev, V.I.; Rau, J.V. Colloidal forming of macroporous calcium pyrophosphate bioceramics in 3D-printed molds. Bioact. Mater. 2020, 5, 309–317. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.; Ramos, T.; Wieringa, P.; van Blitterswijk, C.; de Boer, J.; Moroni, L. Geometric constraints of endothelial cell migration on electrospun fibres. Sci. Rep. 2018, 8, 6386. [Google Scholar] [CrossRef] [PubMed]

- Hasmad, H.; Yusof, M.R.; Razi, Z.R.M.; Idrus, R.B.H.; Chowdhury, S.R. Human amniotic membrane with aligned electrospun fiber as scaffold for aligned tissue regeneration. Tissue Eng. C 2018, 24, 368–378. [Google Scholar] [CrossRef]

- Lyu, S.; Huang, C.; Yang, H.; Zhang, X. Electrospun fibers as a scaffolding platform for bone tissue repair. J. Orthop. Res. 2013, 31, 1382–1389. [Google Scholar] [CrossRef]

- Das, M.P.; Suguna, P.R.; Prasad, K.; Vijaylakshmi, J.V.; Renuka, M. Extraction and characterization of gelatin: A functional biopolymer. Int. J. Pharm. Pharm. Sci. 2017, 9, 239–242. [Google Scholar] [CrossRef]

- Idowu, B.; Cama, G.; Deb, S.; Di Silvio, L. In vitro osteoinductive potential of porous monetite for bone tissue engineering. J. Tissue Eng. 2014, 5, 1–14. [Google Scholar] [CrossRef]

- Lee, H.B.; Hsu, H.C.; Wu, S.C.; Hsu, S.K.; Wang, P.H.; Ho, W.F. Microstructure and characteristics of calcium phosphate layers on bioactive oxide surfaces of air-sintered titanium foams after immersion in simulated body fluid. Materials 2016, 9, 956. [Google Scholar] [CrossRef]

- Koroleva, L.F.; Larionov, L.P.; Gorbunova, N.P. Biomaterial based on doped calcium carbonate-phosphate for active osteogenesis. J. Biomater. Nanobiotechnol. 2012, 3, 226–237. [Google Scholar] [CrossRef]

- Jastrzebski, W.; Sitarz, M.; Rokita, M.; Bulat, K. Infrared spectroscopy of different phosphates structures. Spectrochim. Acta A 2011, 79, 722–727. [Google Scholar] [CrossRef] [PubMed]

- Prekajski, M.; Mirkovic, M.; Todorovic, B.; Matkovic, A.; Marinovic-Cincovic, M.; Lukovic, J.; Matovic, B. Ouzo effect—New simple nanoemulsion method for synthesis of strontium hydroxyapatite nanospheres. J. Eur. Ceram. Soc. 2016, 36, 1293–1298. [Google Scholar] [CrossRef]

- Brzezinska-Miecznik, J.; Jelen, P.; Haberko, K.; Mozgawa, W.; Sitarz, M. The effect of NaOH and KOH treatment on the behavior of CO32− and OH− groups in natural origin hydroxyapatite. Ceram. Int. 2017, 43, 12540–12545. [Google Scholar] [CrossRef]

- Brundavanam, S.; Poinern, G.E.J.; Fawcett, D. Growth of flower-like brushite structures on magnesium substrates and their subsequent low temperature transformation to hydroxyapatite. Am. J. Biomed. Eng. 2014, 4, 79–87. [Google Scholar]

- Ashiri, R. Detailed FT-IR spectroscopy characterization and thermal analysis of synthesis of barium titanate nanoscale particles through a newly developed process. Vib. Spectrosc. 2013, 66, 24–29. [Google Scholar] [CrossRef]

- Chinchamalatpure, V.R.; Ghosh, S.A.; Chaudhari, G.N. Synthesis and electrical characterization of BaTiO3 thin films on Si(100). Mater. Sci. Appl. 2010, 1, 187–190. [Google Scholar] [CrossRef]

- Berzina-Cimdina, L.; Borodajenko, N. Research of calcium phosphates using Fourier Transform Infrared Spectroscopy. In Infrared Spectroscopy—Materials Science, Engineering and Technology; Theophanides, T., Ed.; IntechOpen: London, UK, 2012. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Busuioc, C.; Olaret, E.; Stancu, I.-C.; Nicoara, A.-I.; Jinga, S.-I. Electrospun Fibre Webs Templated Synthesis of Mineral Scaffolds Based on Calcium Phosphates and Barium Titanate. Nanomaterials 2020, 10, 772. https://doi.org/10.3390/nano10040772

Busuioc C, Olaret E, Stancu I-C, Nicoara A-I, Jinga S-I. Electrospun Fibre Webs Templated Synthesis of Mineral Scaffolds Based on Calcium Phosphates and Barium Titanate. Nanomaterials. 2020; 10(4):772. https://doi.org/10.3390/nano10040772

Chicago/Turabian StyleBusuioc, Cristina, Elena Olaret, Izabela-Cristina Stancu, Adrian-Ionut Nicoara, and Sorin-Ion Jinga. 2020. "Electrospun Fibre Webs Templated Synthesis of Mineral Scaffolds Based on Calcium Phosphates and Barium Titanate" Nanomaterials 10, no. 4: 772. https://doi.org/10.3390/nano10040772

APA StyleBusuioc, C., Olaret, E., Stancu, I.-C., Nicoara, A.-I., & Jinga, S.-I. (2020). Electrospun Fibre Webs Templated Synthesis of Mineral Scaffolds Based on Calcium Phosphates and Barium Titanate. Nanomaterials, 10(4), 772. https://doi.org/10.3390/nano10040772