Preparation and Properties of Cassava Residue Cellulose Nanofibril/Cassava Starch Composite Films

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of CNF

2.3. Modification of CNF

2.4. Preparation of Cassava Residue CNF/Cassava Starch Composite Film

2.5. Testing and Characterization

2.5.1. Apparent Morphological Representation

2.5.2. Characterization of the Chemical Structure

2.5.3. Characterization of the Crystallinity

2.5.4. Thermal Stability Analysis

2.5.5. Characterization of Hydrophobic Properties

2.5.6. Characterization of Mechanical Properties

2.5.7. Barrier Characterization

3. Results and Discussion

3.1. Testing and Characterization of Modified CNF

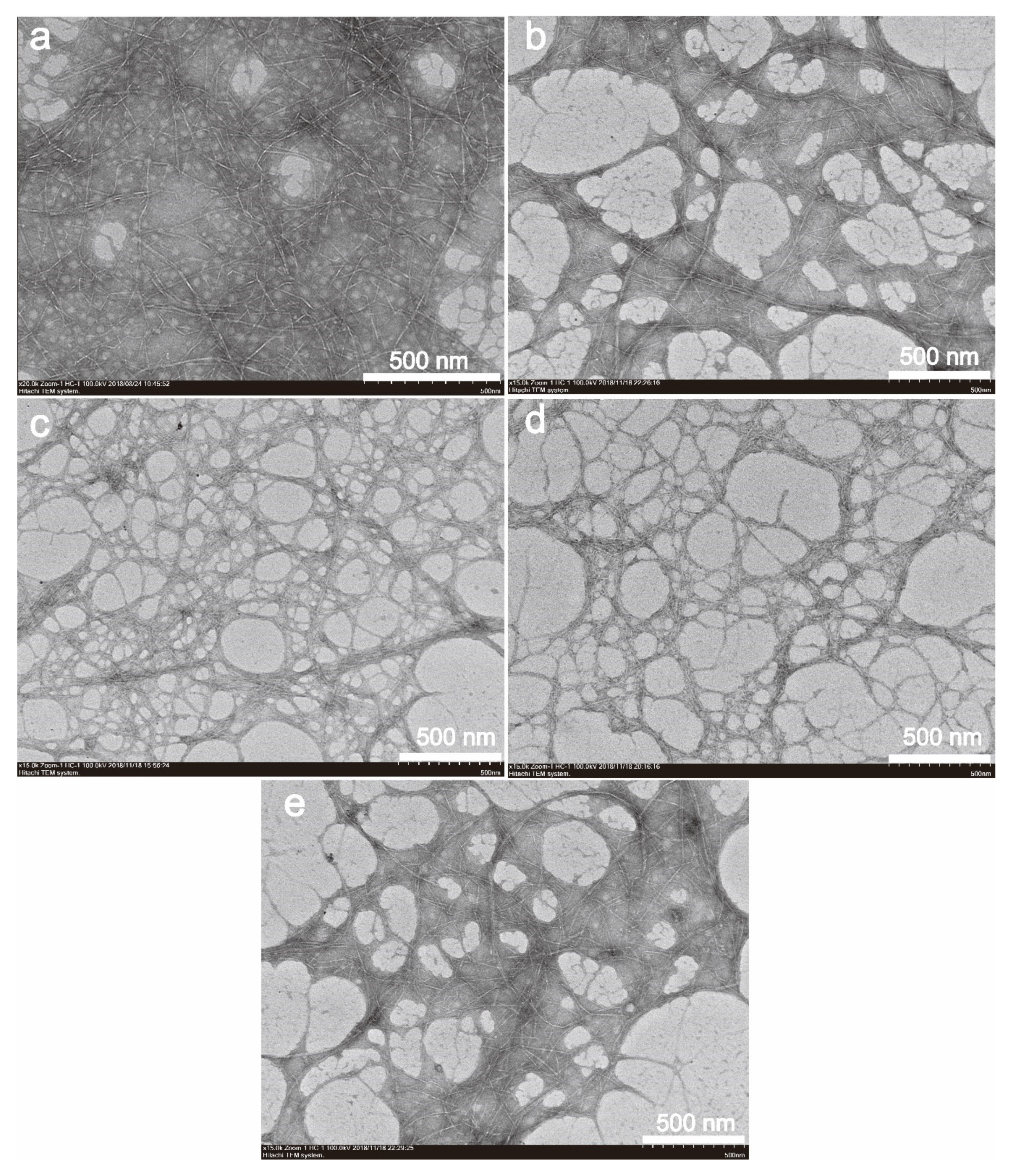

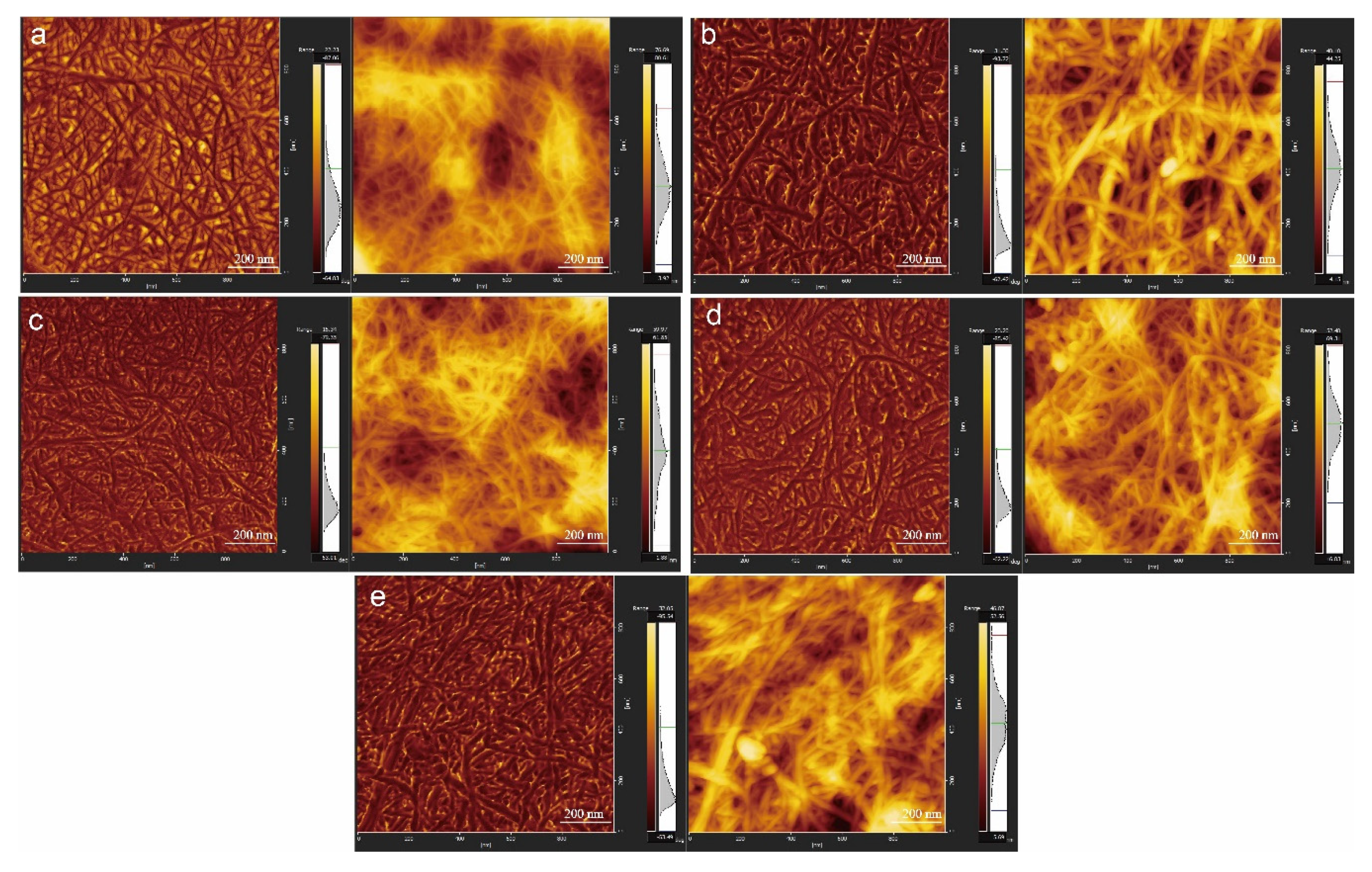

3.1.1. Apparent Morphological Representation

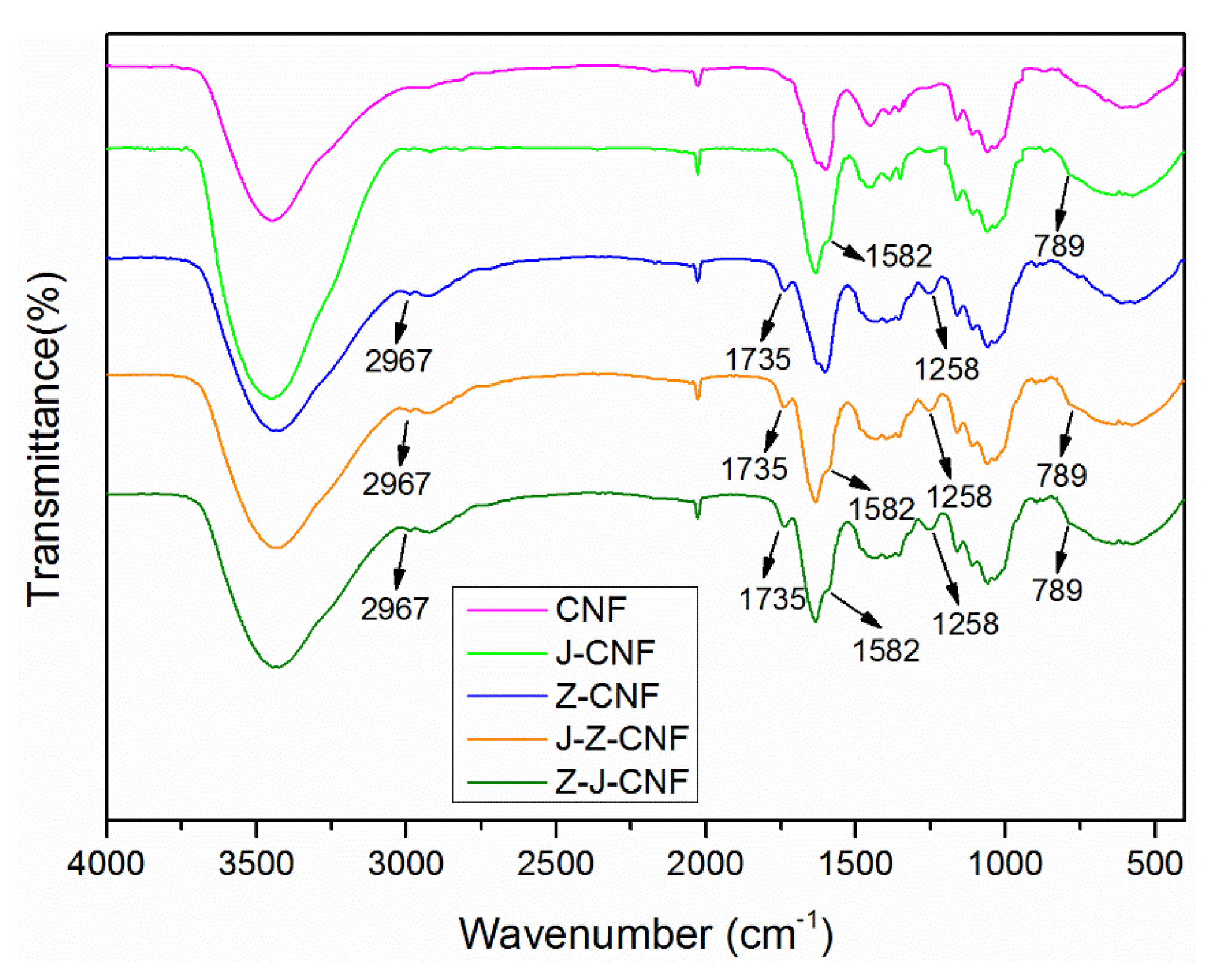

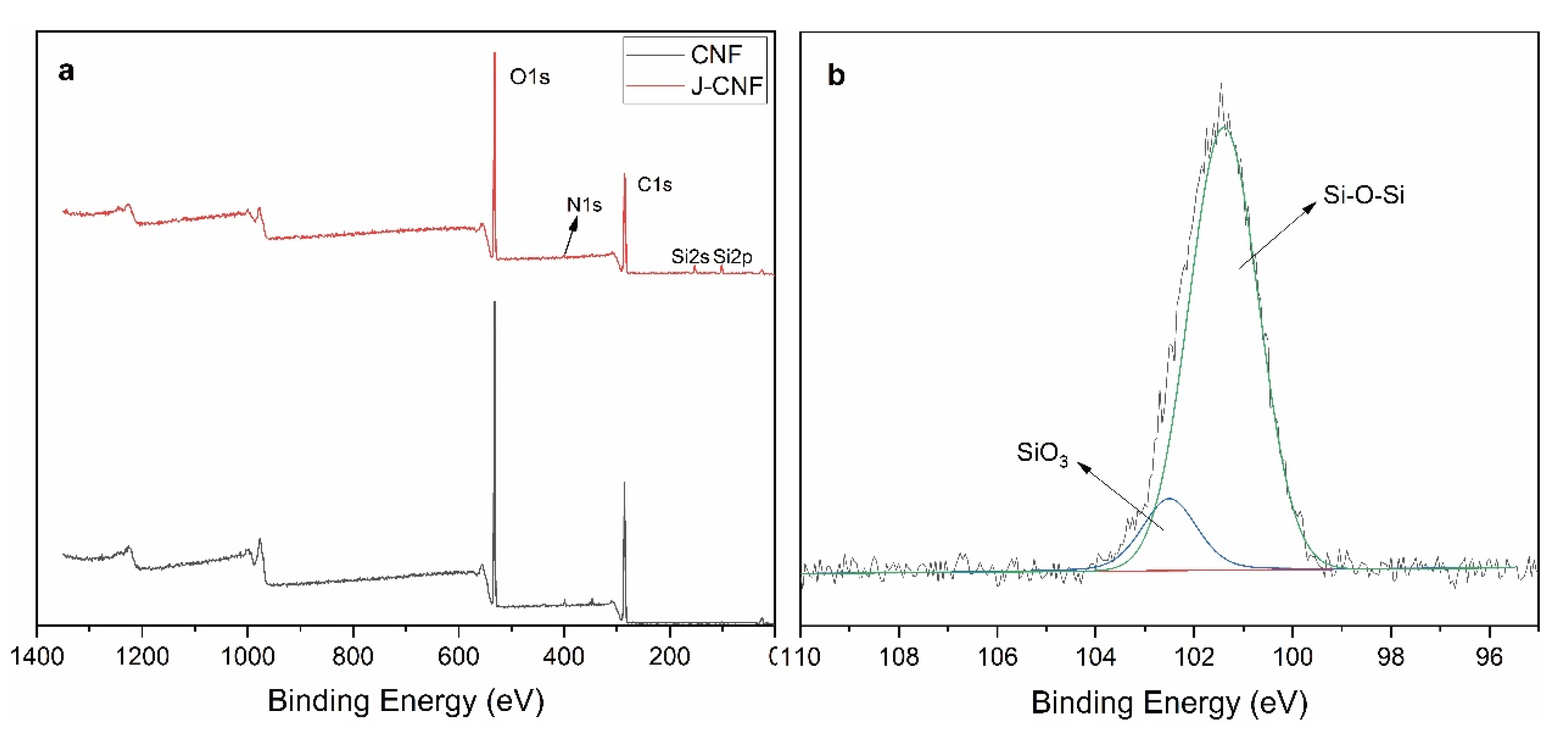

3.1.2. Chemical Structure

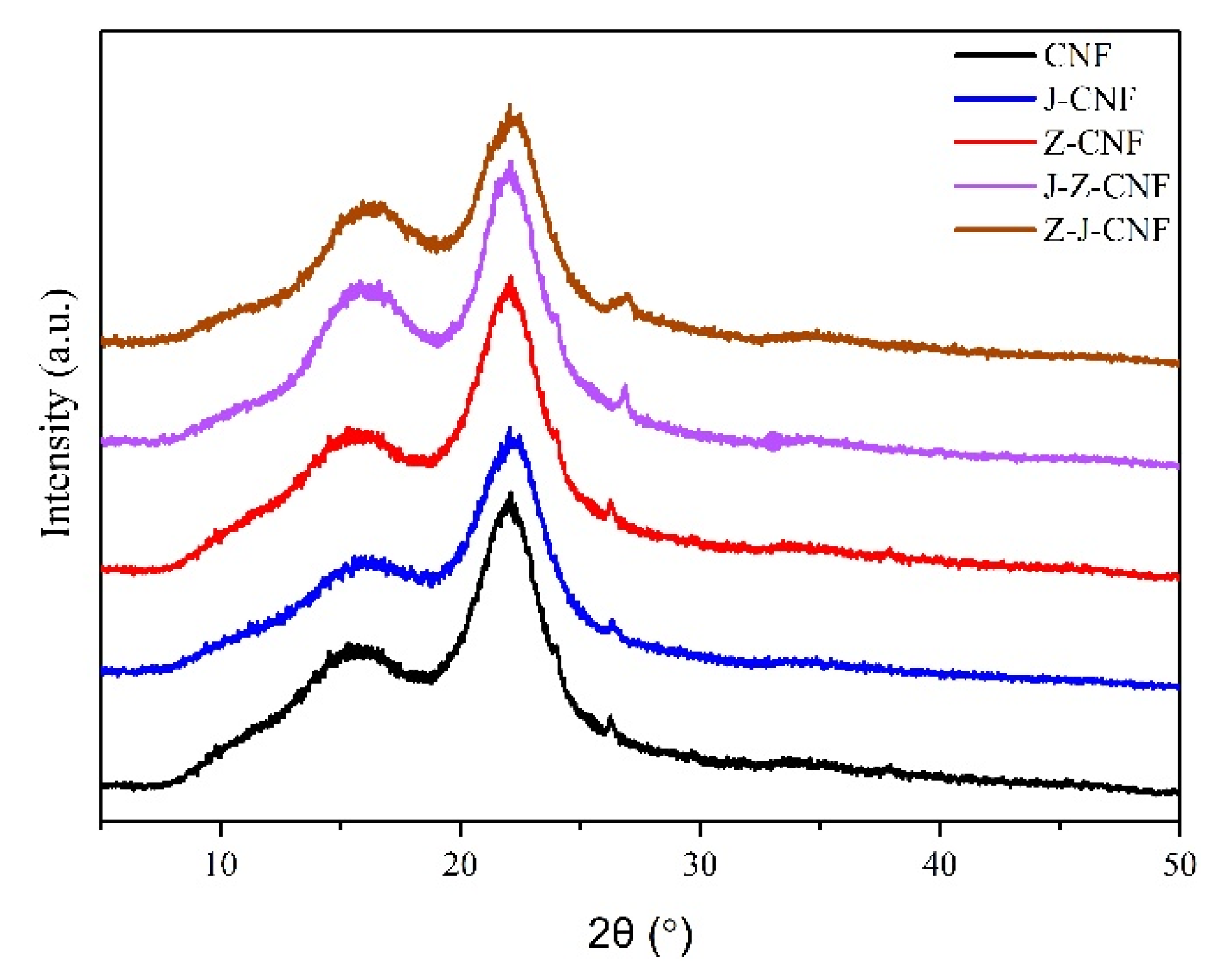

3.1.3. Crystallinity

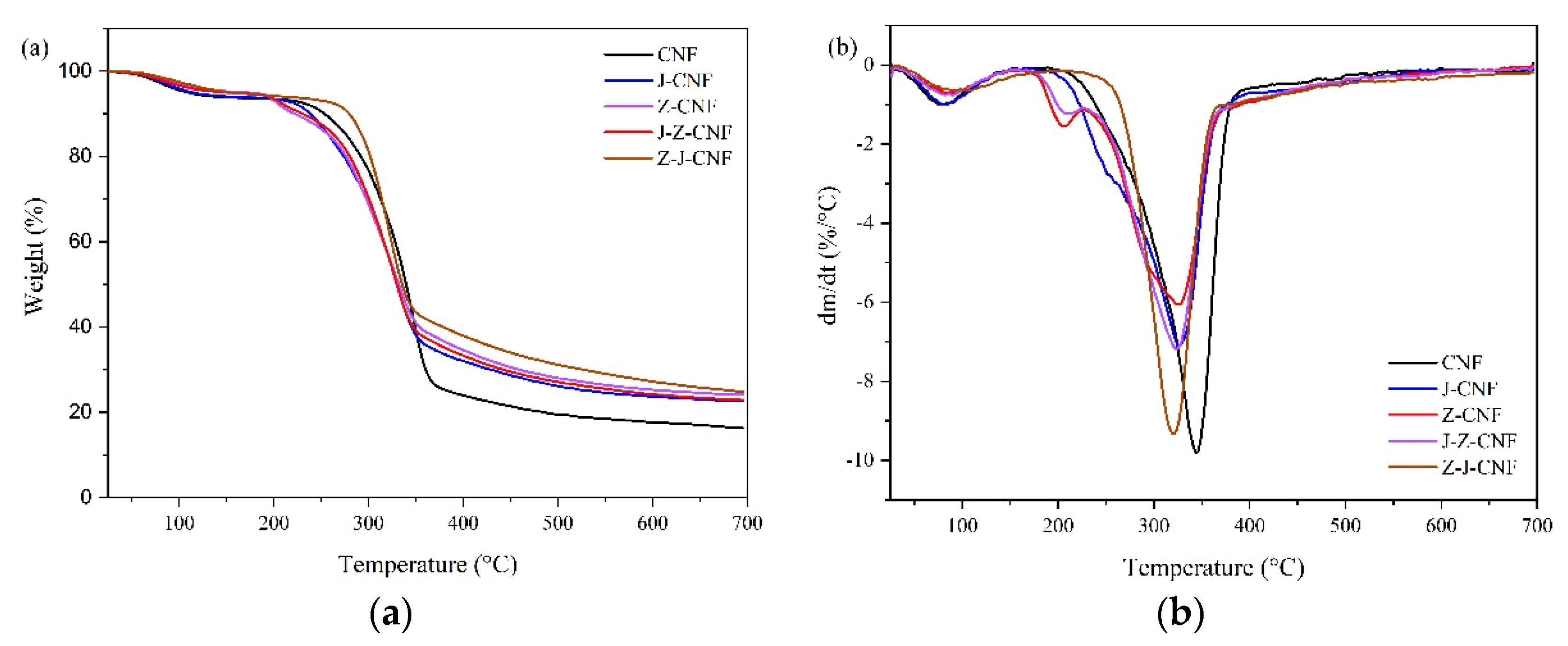

3.1.4. Thermal Stability

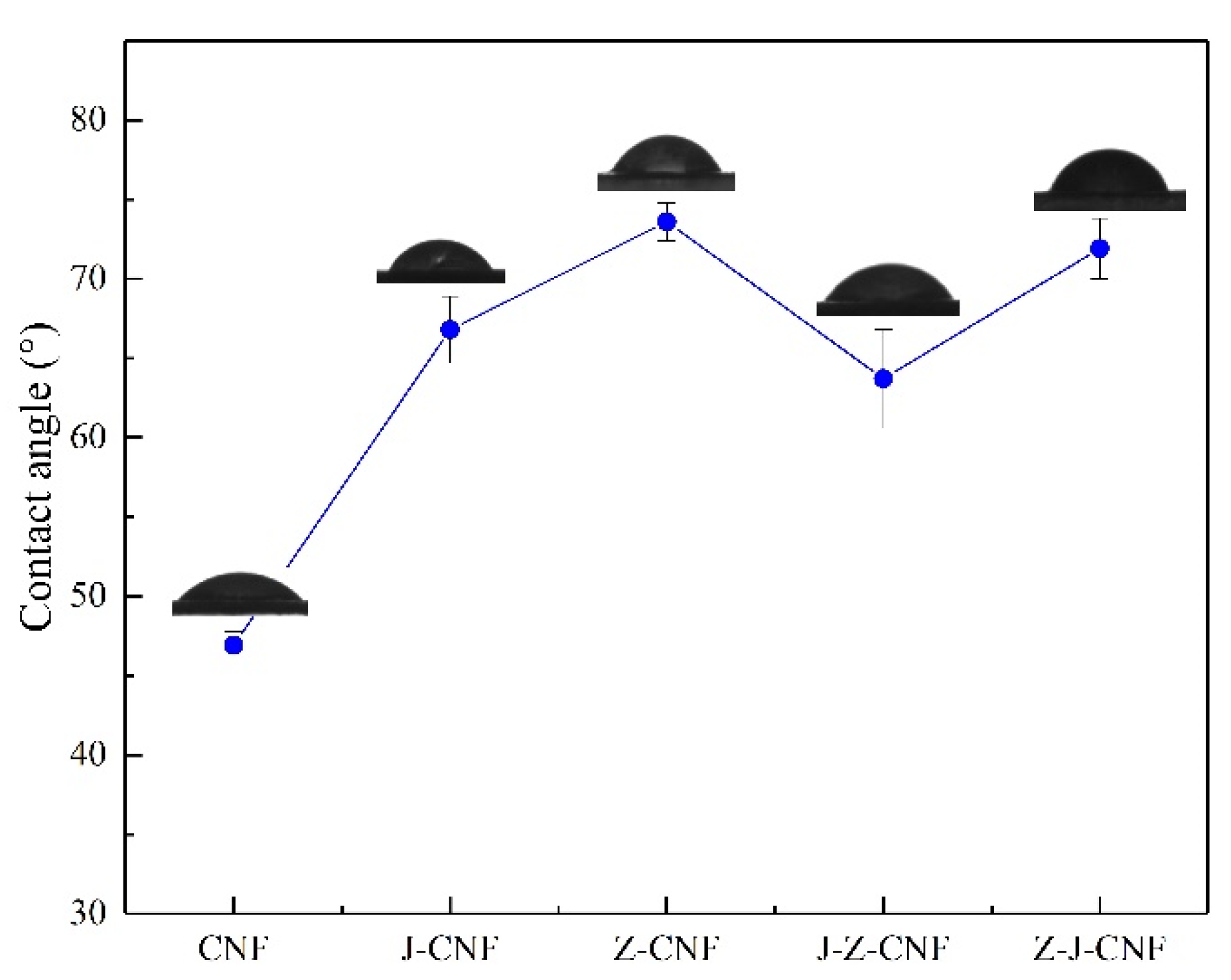

3.1.5. Contact Angle Analysis

3.2. Characterization of Cassava Residue CNF/Cassava Starch Composite Films

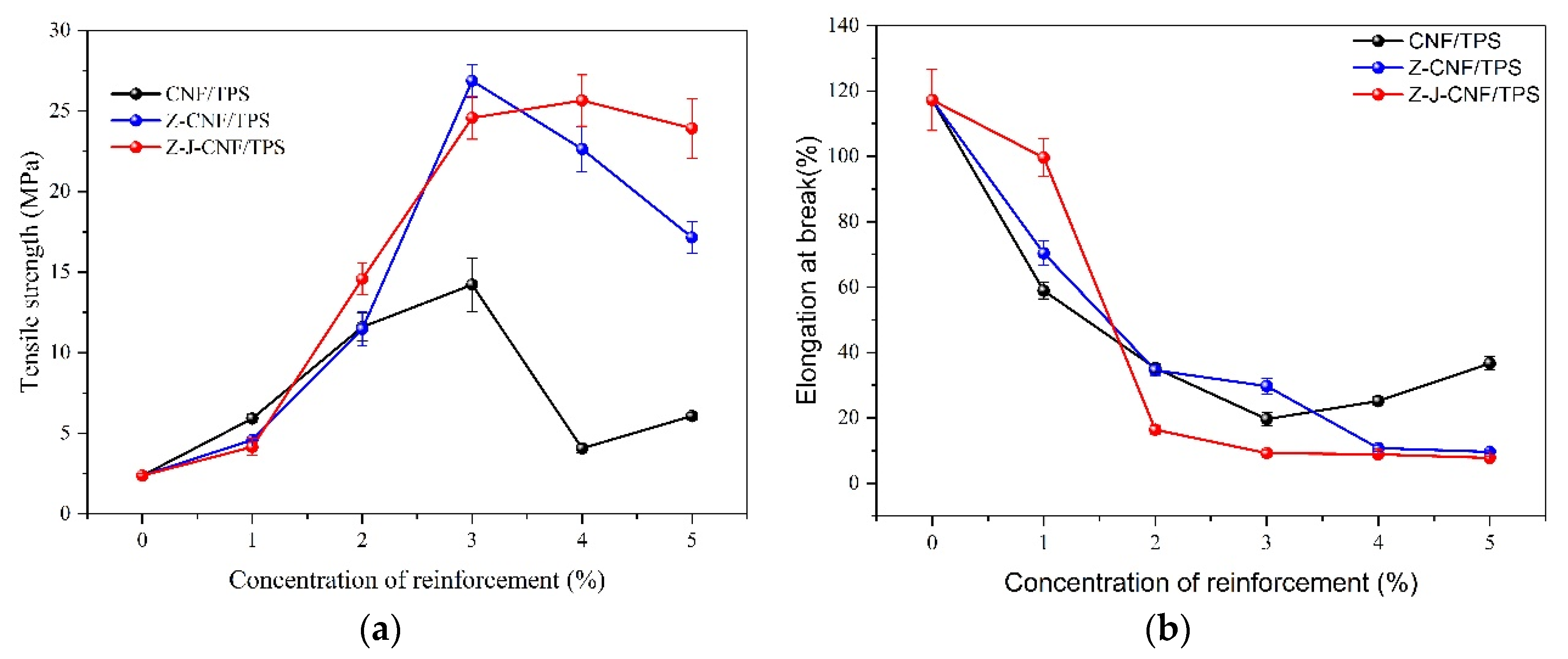

3.2.1. Mechanical Performance of Composite Films

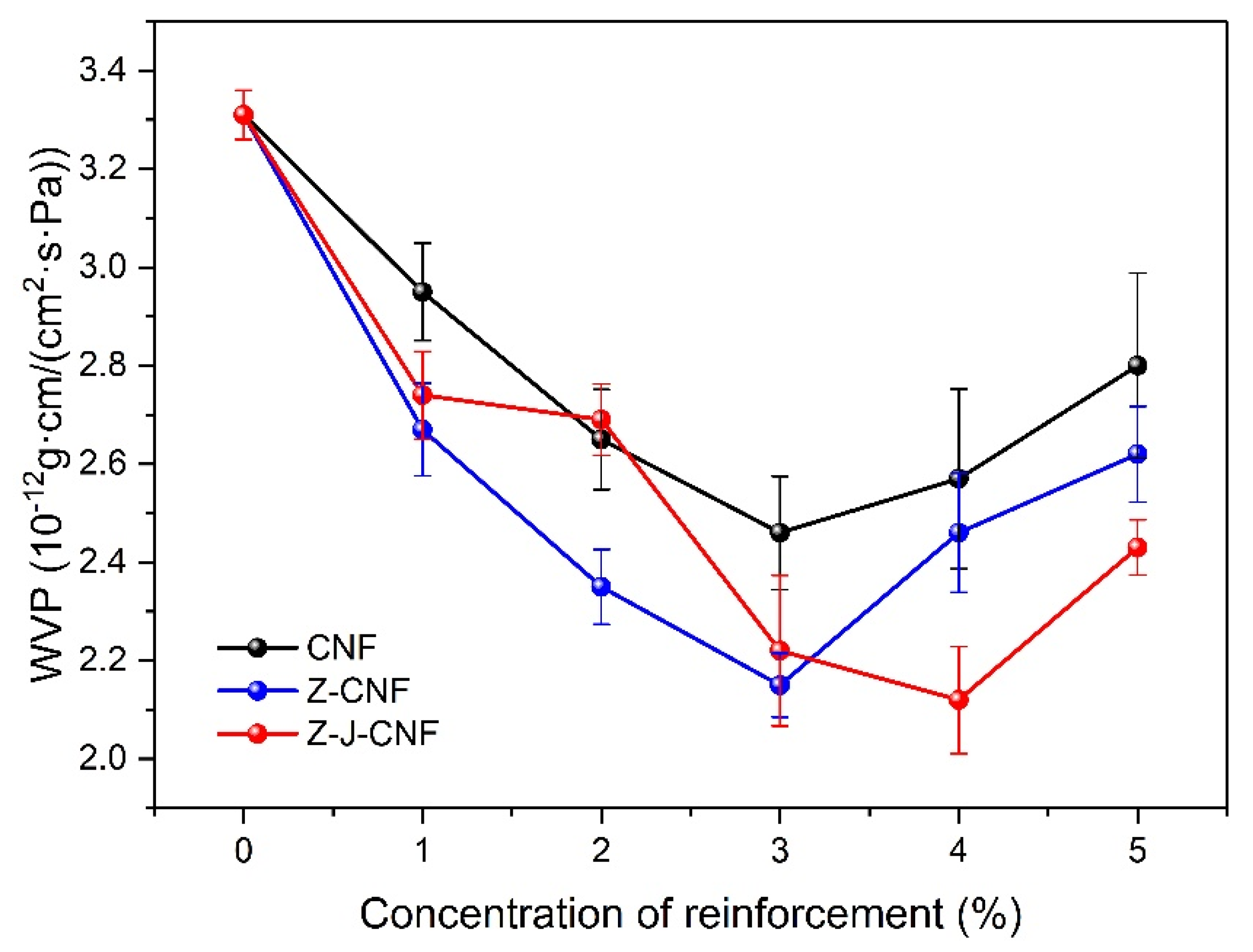

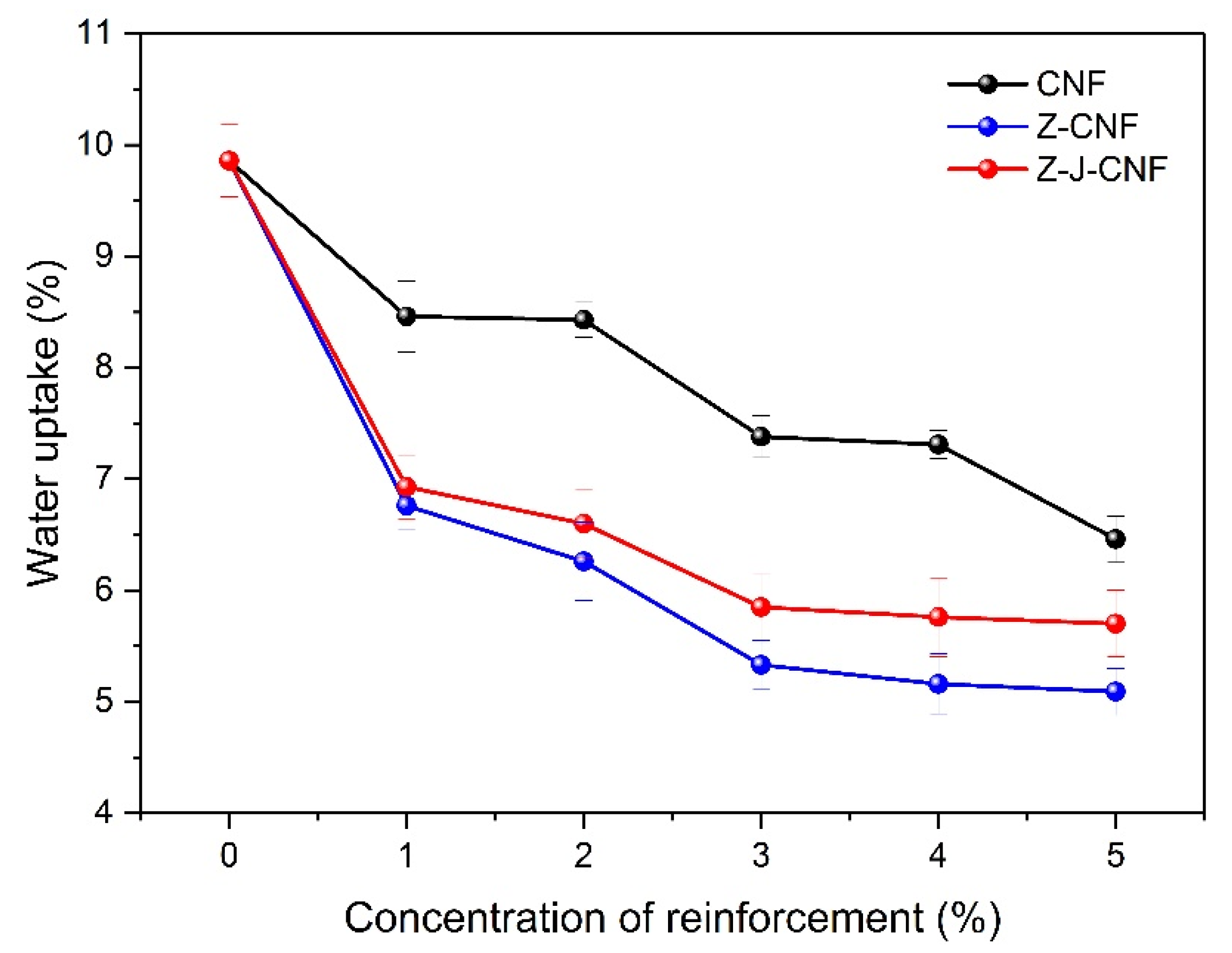

3.2.2. Barrier Analysis

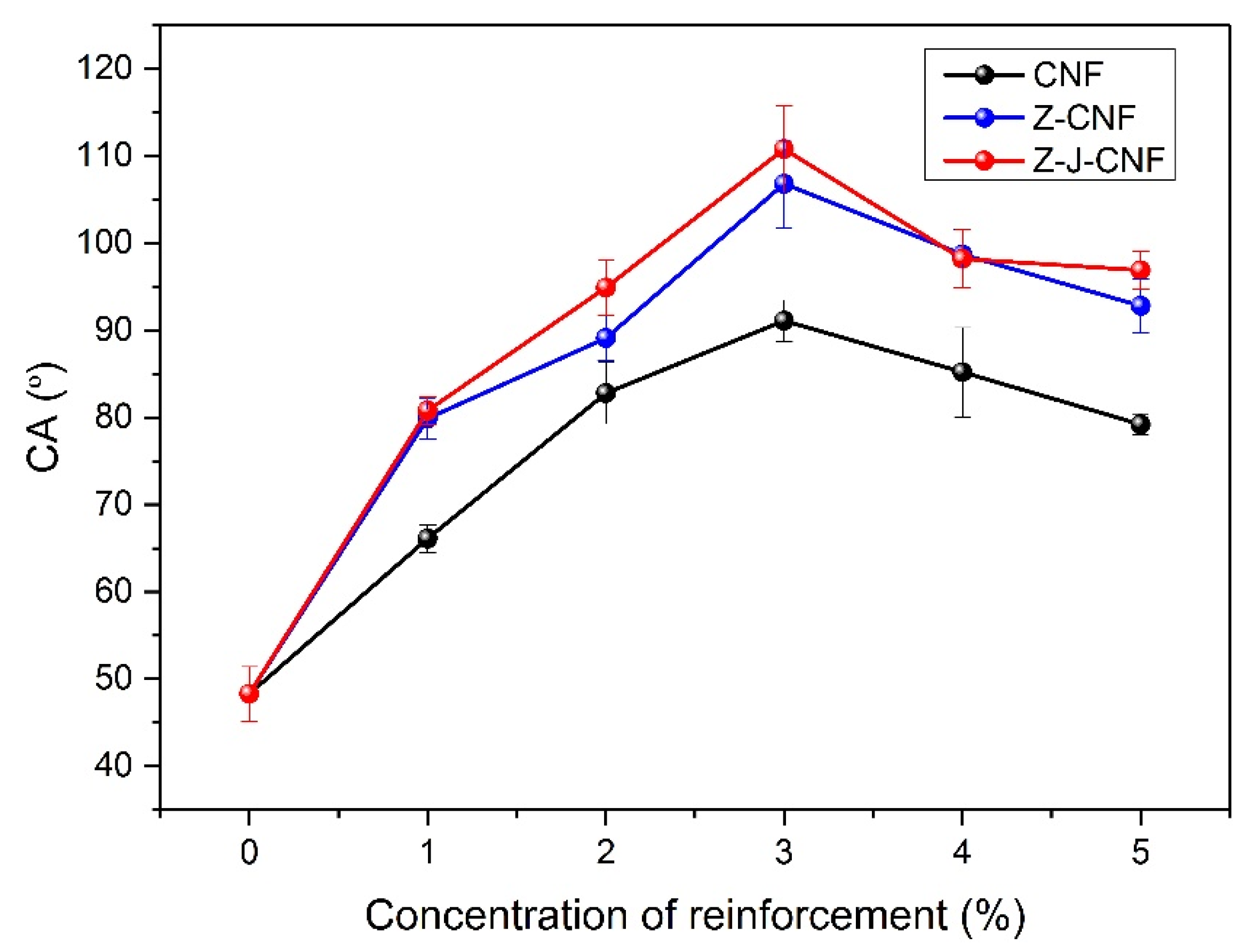

3.2.3. Hydrophobicity of Composite Films

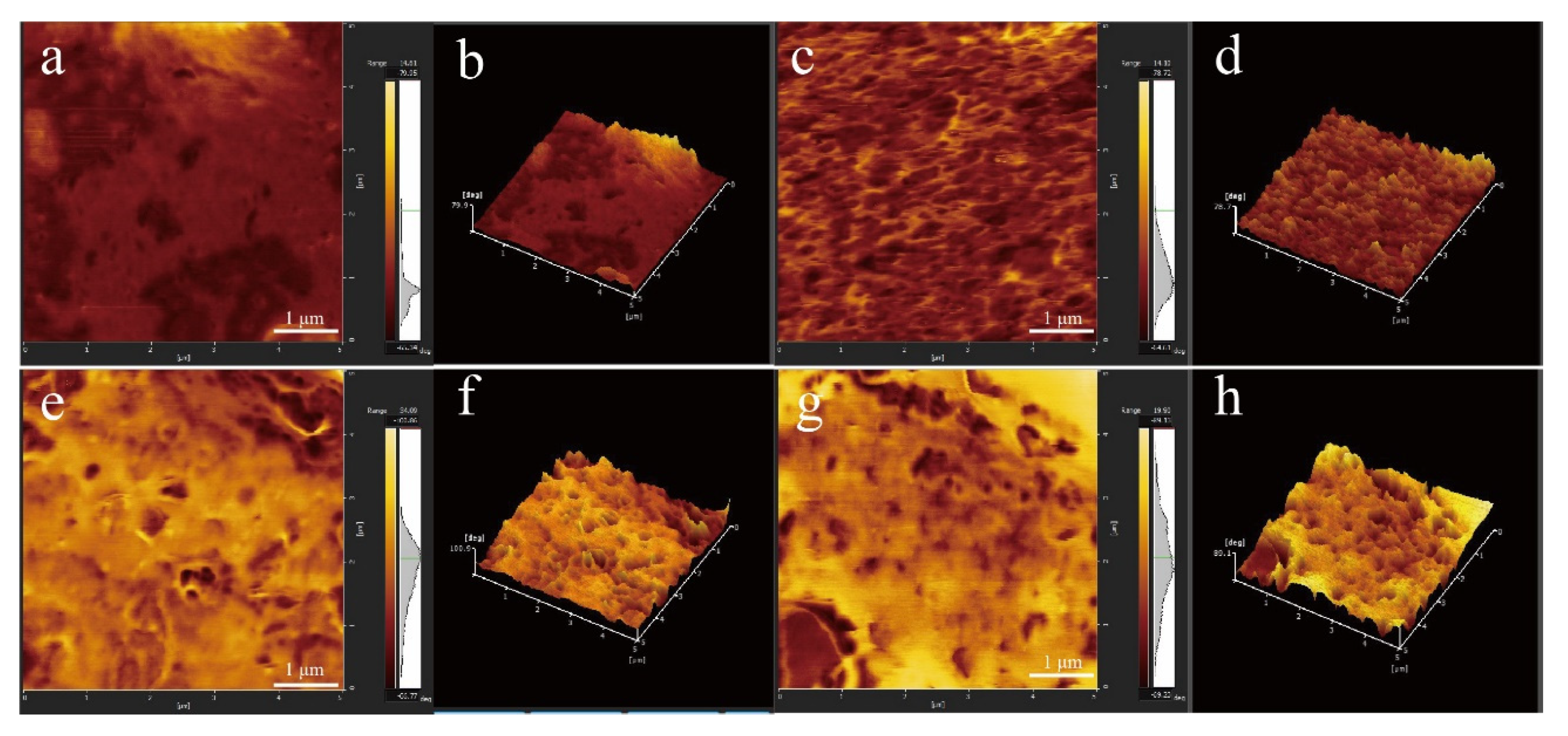

3.2.4. Atomic Force Microscopy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Heidbreder, L.M.; Bablok, I.; Drews, S.; Menzel, C. Tackling the plastic problem: A review on perceptions, ehaviors, and interventions. Sci. Total Environ. 2019, 668, 1077–1093. [Google Scholar] [CrossRef] [PubMed]

- Statista. Global Plastic Production. 2018. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 20 October 2018).

- Liu, E.K.; He, W.Q.; Yan, C.R. ‘White revolution’ to ‘white pollution’—Agricultural plastic film mulch in China. Environ. Res. Lett. 2014, 9, 091001. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef] [PubMed]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of Sugar Palm-derived Cellulose Reinforcement on the Mechanical and Water Barrier Properties of Sugar Palm Starch Biocomposite Films. Bioresources. 2016, 11, 4134–4145. [Google Scholar] [CrossRef]

- Du, H.S.; Liu, W.M.; Zhang, M.L.; Si, C.L.; Zhang, X.Y.; Li, B. Cellulose nanocrystals and cellulose nanofibrils based hydrogels for biomedical applications. Carbohydr. Polym. 2019, 209, 130–144. [Google Scholar] [CrossRef]

- Wang, K.; Wang, W.H.; Ye, R.; Liu, A.J.; Xiao, J.D.; Liu, Y.W.; Zhao, Y.N. Mechanical properties and solubility in water of corn starch-collagen composite films: Effect of starch type and concentrations. Food Chem. 2017, 216, 209–216. [Google Scholar] [CrossRef]

- Hu, X.; Jia, X.; Zhi, C.; Jin, Z.; Miao, M. Improving properties of normal maize starch films using dual-modification: Combination treatment of debranching and hydroxypropylation. Int. J. Biol. Macromol. 2019, 130, 179–202. [Google Scholar] [CrossRef]

- Kanmani, P.; Rhim, J.W. Properties and characterization of bionanocomposite films prepared with various biopolymers and ZnO nanoparticles. Carbohydr. Polym. 2014, 106, 190–199. [Google Scholar] [CrossRef]

- Ni, S.Z.; Jiao, L.; Zhang, H.; Zhang, Y.C.; Fang, G.G.; Xiao, H.N.; Dai, H.Q. Enhancing hydrophobicity, strength and UV shielding capacity of starch film via novel co-cross-linking in neutral conditions. R. Soc. Open Sci. 2018, 5, 181206. [Google Scholar] [CrossRef]

- Dos Santos, B.H.; Do Prado, K.D.; Jacinto, A.A.; Spinace, M.A.D. Influence of Sugarcane Bagasse Fiber Size on Biodegradable Composites of Thermoplastic Starch. J. Renew. Mater. 2018, 6, 176–182. [Google Scholar] [CrossRef]

- Hassan, M.M.; Tucker, N.; Le Guen, M.J. Thermal, mechanical and viscoelastic properties of citric acid-crosslinked starch/cellulose composite foams. Carbohydr. Polym. 2020, 230, 115675. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.F.; Shi, Y.H.; Chen, G.X.; Cai, M. Enhanced mechanical and hydrophobic properties of composite cassava starch films with stearic acid modified MCC (microcrystalline cellulose)/NCC (nanocellulose) as strength agent. Int. J. Biol. Macromol. 2020, 142, 846–854. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Gibril, M.E.; Lekha, P.; Andrew, J.; Sithole, B.; Tesfaye, T.; Ramjugernath, D. Beneficiation of pulp and paper mill sludge: Production and characterisation of functionalised crystalline nanocellulose. Clean Technol. Environ. Policy. 2018, 20, 1835–1845. [Google Scholar] [CrossRef]

- Khan, A.; Khan, R.A.; Salmieri, S.; Le Tien, C.; Riedl, B.; Bouchard, J.; Chauve, G.; Tan, V.; Kamal, M.R.; Lacroix, M. Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydr. Polym. 2012, 90, 1601–1608. [Google Scholar] [CrossRef]

- Nevo, Y.; Peer, N.; Yochelis, S.; Igbaria, M.; Meirovitch, S.; Shoseyov, O.; Paltiel, Y. Nano bio optically tunable composite nanocrystalline cellulose films. RSC Adv. 2015, 5, 7713–7719. [Google Scholar] [CrossRef]

- Nguyen, L.H.; Naficy, S.; Chandrawati, R.; Dehghani, F. Nanocellulose for Sensing Applications. Adv. Mater. Interfaces 2019, 6, 1900424. [Google Scholar] [CrossRef]

- Frank, B.P.; Durkin, D.P.; Caudill, E.R.; Zhu, L.C.; White, D.H.; Curry, M.L.; Pedersen, J.A.; Fairbrother, D.H. Impact of Silanization on the Structure, Dispersion Properties, and Biodegradability of Nanocellulose as a Nanocomposite Filler. ACS Appl. Nano Mater. 2018, 1, 7025–7038. [Google Scholar] [CrossRef]

- Rol, F.; Sillard, C.; Bardet, M.; Yarava, J.R.; Emsley, L.; Gablin, C.; Leonard, D.; Belgacem, N.; Bras, J. Cellulose phosphorylation comparison and analysis of phosphorate position on cellulose fibers. Carbohydr. Polym. 2020, 229, 115294. [Google Scholar] [CrossRef]

- Wagberg, L.; Decher, G.; Norgren, M.; Lindstrom, T.; Ankerfors, M.; Axnas, K. The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 2008, 24, 784–795. [Google Scholar] [CrossRef]

- Isogai, A.; Hanninen, T.; Fujisawa, S.; Saito, T. Review: Catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions. Prog. Polym. Sci. 2018, 86, 122–148. [Google Scholar] [CrossRef]

- Thiangtham, S.; Runt, J.; Manuspiya, H. Sulfonation of dialdehyde cellulose extracted from sugarcane bagasse for synergistically enhanced water solubility. Carbohydr. Polym. 2019, 208, 314–322. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.F. Research progress in cellulose modification. Chem. Ind. Eng. Prog. 2010, 29, 1493–1501. [Google Scholar]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Benkaddour, A.; Journoux-Lapp, C.; Jradi, K.; Robert, S.; Daneault, C. Study of the hydrophobization of TEMPO-oxidized cellulose gel through two routes: Amidation and esterification process. J. Mater. Sci. 2014, 49, 2832–2843. [Google Scholar] [CrossRef]

- Owi, W.T.; Ong, H.L.; Sam, S.T.; Villagracia, A.; Tsai, C.K.; Akil, H.M. Unveiling the physicochemical properties of natural Citrus aurantifolia crosslinked tapioca starch/nanocellulose bionanocomposites. Ind. Crops Prod. 2019, 139, 111548. [Google Scholar] [CrossRef]

- Fitch-Vargas, P.R.; Camacho-Hernandez, I.L.; Martinez-Bustos, F.; Islas-Rubio, A.R.; Carrillo-Canedo, K.I.; Calderon-Castro, A.; Jacobo-Valenzuela, N.; Carrillo-Lopez, A.; Delgado-Nieblas, C.I.; Aguilar-Palazuelos, E. Mechanical, physical and microstructural properties of acetylated starch-based biocomposites reinforced with acetylated sugarcane fiber. Carbohydr Polym. 2019, 219, 378–386. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Potential of using multiscale corn husk fiber as reinforcing filler in cornstarch-based biocomposites. Int. J. Biol. Macromol. 2019, 139, 596–604. [Google Scholar] [CrossRef]

- Tian, Y.; Zhu, P.X.; Zhou, M.; Guo, R.; Yang, R. Microfibrillated cellulose modified with urea and its reinforcement for starch-based bionanocomposites. Cellulose 2019, 26, 5981–5993. [Google Scholar] [CrossRef]

- Guimaraes, M.; Teixeira, F.G.; Tonoli, G.H.D. Effect of the nano-fibrillation of bamboo pulp on the thermal, structural, mechanical and physical properties of nanocomposites based on starch/poly(vinyl alcohol) blend. Cellulose 2018, 25, 1823–1849. [Google Scholar] [CrossRef]

- Gilfillan, W.N.; Moghaddam, L.; Doherty, W.O.S. Preparation and characterization of composites from starch with sugarcane bagasse nanofibres. Cellulose 2014, 21, 2695–2712. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, Y.; Chen, G. A comparative study on the starch-based biocomposite films reinforced by nanocellulose prepared from different non-wood fibers. Cellulose 2019, 26, 2425–2435. [Google Scholar] [CrossRef]

- Fu, J.J. Preparation and Application of Nano-Cellulose/Nano-Gold Composites. Master’s Thesis, South China University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Tan, Y. Study on Silane Coupling Agent kh550 Modified Nano-Cellulose and Its Enhanced Water-Borne Acrylic Composite Coating. Master’s Thesis, Northeast Forestry University, Harbin, China, 2016. [Google Scholar]

- Kwak, H.W.; You, J.; Lee, M.E. Prevention of cellulose nanofibril agglomeration during dehydration and enhancement of redispersibility by hydrophilic gelatin. Cellulose 2019, 26, 4357–4369. [Google Scholar] [CrossRef]

- Diniz, J.M.B.F.; Gil, M.H.; Castro, J.A.A.M. Hornification—Its origin and interpretation in wood pulps. Wood Sci. Technol. 2004, 37, 489–494. [Google Scholar] [CrossRef]

- Lin, W.; Hu, X.; You, X. Hydrophobic Modification of Nanocellulose via a Two-Step Silanation Method. Polymers 2018, 10, 1035. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Liang, T.; Zhang, B. Green functionalization of cellulose nanocrystals for application in reinforced poly (methyl methacrylate) nanocomposites. Carbohydr. Polym. 2018, 202, 591–599. [Google Scholar] [CrossRef]

- Wang, X. Study on Nanocellulose Modified Polylactic Acid Composite and Its Compatibilizing Mechanism. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2016. [Google Scholar]

- He, W.; Li, J.P.; Jin, H. Alkylation of Moso Bamboo Nanocellulose. J. Nanjing For. Univ. (Nat. Sci. Ed.) 2016, 40, 144–148. [Google Scholar]

- Liang, T. Esterification and Application of Nanocellulose. Master’s Thesis, Jiangnan University, Wuxi, China, 2018. [Google Scholar]

- Mangayil, R.; Rajalla, S.; Pammo, A.; Sarlin, E.; Luo, J.; Santala, V.; Karp, M.; Tuukkanen, S. Engineering and characterization of bacterial nanocellulose films as low cost and flexible sensor material. ACS Appl. Mater. Interfaces 2017, 9, 19048–19056. [Google Scholar] [CrossRef]

- Hanninen, A.; Sarlin, E.; Lyyra, I.; Salpavaara, T.; Kellomaki, M.; Tuukkanen, S. Nanocellulose and chitosan based films as low cost, green piezoelectric materials. Carbohydr. Polym. 2018, 202, 418–424. [Google Scholar] [CrossRef]

- Tongdeesoontorn, W.; Mauer, L.J.; Wongruong, S. Effect of carboxymethyl cellulose concentration on physical properties of biodegradable cassava starch-based films. Chem. Cent. J. 2011, 5, 6. [Google Scholar] [CrossRef]

- Pelissari, F.M.; Andrade-Mahecha, M.M.; Sobral, P.J.D.A. Nanocomposites based on Banana Starch Reinforced with Cellulose Nanofibers Isolated from Banana Peels. J. Colloid Interface Sci. 2017, 505, 154–167. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.W.; Nair, S.S.; Chen, H.; Yan, N.; Farnood, R.; Li, F.Y. Thermally stable, enhanced water barrier, high strength starch bio-composite reinforced with lignin containing cellulose nanofibrils. Carbohydr. Polym. 2020, 230, 115626. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Cheng, Y.; Qin, X. Hydrophilic modification of cellulose nanocrystals improves the physicochemical properties of cassava starch-based nanocomposite films. Food Sci. Technol.-Braz. 2017, 86, 318–326. [Google Scholar] [CrossRef]

- Wang, P.; Chen, F.; He, Z. Large-scale preparation of jute fiber reinforced starch-based composites with high mechanical strength and optimized biodegradability. Starch-Starke 2017, 69, 11–12. [Google Scholar] [CrossRef]

- Teixeira, E.D.M.; Pasquini, D.; Curvelo, A.A.S. Cassava bagasse cellulose nanofibers reinforced thermoplastic cassava starch. Carbohydr. Polym. 2009, 78, 422–431. [Google Scholar] [CrossRef]

- González, A.; Gastelú, G.; Barrera, G.N. Preparation and characterization of soy protein films reinforced with cellulose nanofibers obtained from soybean by-products. Food Hydrocoll. 2019, 89, 758–764. [Google Scholar] [CrossRef]

- Balakrishnan, P.; Gopi, S.; Sreekala, M.S. UV resistant transparent bionanocomposite films based on potato starch/cellulose for sustainable packaging. Starch-Starke 2017, 70, 1700139. [Google Scholar] [CrossRef]

- Chaichi, M.; Hashemi, M.; Badii, F. Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydr. Polym. 2017, 157, 167–175. [Google Scholar] [CrossRef]

| Sample | C1 (C–C) | C2 (C–OH) | C3(O–C–O) |

|---|---|---|---|

| CNF | 25% ± 2% | 47% ± 4% | 28% ± 3% |

| J-CNF | 33% ± 2% | 38% ± 3% | 28% ± 2% |

| Sample | Crystallinity/% |

|---|---|

| CNF | 57.5 ± 2.0 |

| J-CNF | 53.2 ± 4.2 |

| Z-CNF | 55.4 ± 4.3 |

| J-Z-CNF | 53.1 ± 2.8 |

| Z-J-CNF | 50.3 ± 3.1 |

| Sample | T1/°C | Weight Loss/% | Tmax/°C | Weight Loss/% | At 700 °C Residual Amount/% |

|---|---|---|---|---|---|

| CNF | 251 | 9.6 ± 0.9 | 343 | 54.0 ± 3.5 | 16.3 ± 1.2 |

| J-CNF | 231 | 8.7 ± 0.6 | 326 | 47.8 ± 4.3 | 22.6 ± 2.0 |

| Z-CNF | 201 | 8.0 ± 0.8 | 326 | 46.4 ± 5.6 | 24.2 ± 2.9 |

| J-Z-CNF | 208 | 7.6 ± 0.5 | 324 | 45.4 ± 4.4 | 22.9 ± 1.8 |

| Z-J-CNF | 273 | 8.7 ± 0.4 | 321 | 36.9 ± 2.7 | 24.8 ± 2.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Zhao, H.; Yi, T.; Qi, M.; Xu, H.; Mo, Q.; Huang, C.; Wang, S.; Liu, Y. Preparation and Properties of Cassava Residue Cellulose Nanofibril/Cassava Starch Composite Films. Nanomaterials 2020, 10, 755. https://doi.org/10.3390/nano10040755

Huang L, Zhao H, Yi T, Qi M, Xu H, Mo Q, Huang C, Wang S, Liu Y. Preparation and Properties of Cassava Residue Cellulose Nanofibril/Cassava Starch Composite Films. Nanomaterials. 2020; 10(4):755. https://doi.org/10.3390/nano10040755

Chicago/Turabian StyleHuang, Lijie, Hanyu Zhao, Tan Yi, Minghui Qi, Hao Xu, Qi Mo, Chongxing Huang, Shuangfei Wang, and Yang Liu. 2020. "Preparation and Properties of Cassava Residue Cellulose Nanofibril/Cassava Starch Composite Films" Nanomaterials 10, no. 4: 755. https://doi.org/10.3390/nano10040755

APA StyleHuang, L., Zhao, H., Yi, T., Qi, M., Xu, H., Mo, Q., Huang, C., Wang, S., & Liu, Y. (2020). Preparation and Properties of Cassava Residue Cellulose Nanofibril/Cassava Starch Composite Films. Nanomaterials, 10(4), 755. https://doi.org/10.3390/nano10040755