Multi-Scale Analysis and Testing of Tensile Behavior in Polymers with Randomly Oriented and Agglomerated Cellulose Nanofibers

Abstract

1. Introduction

2. Numerical Procedure

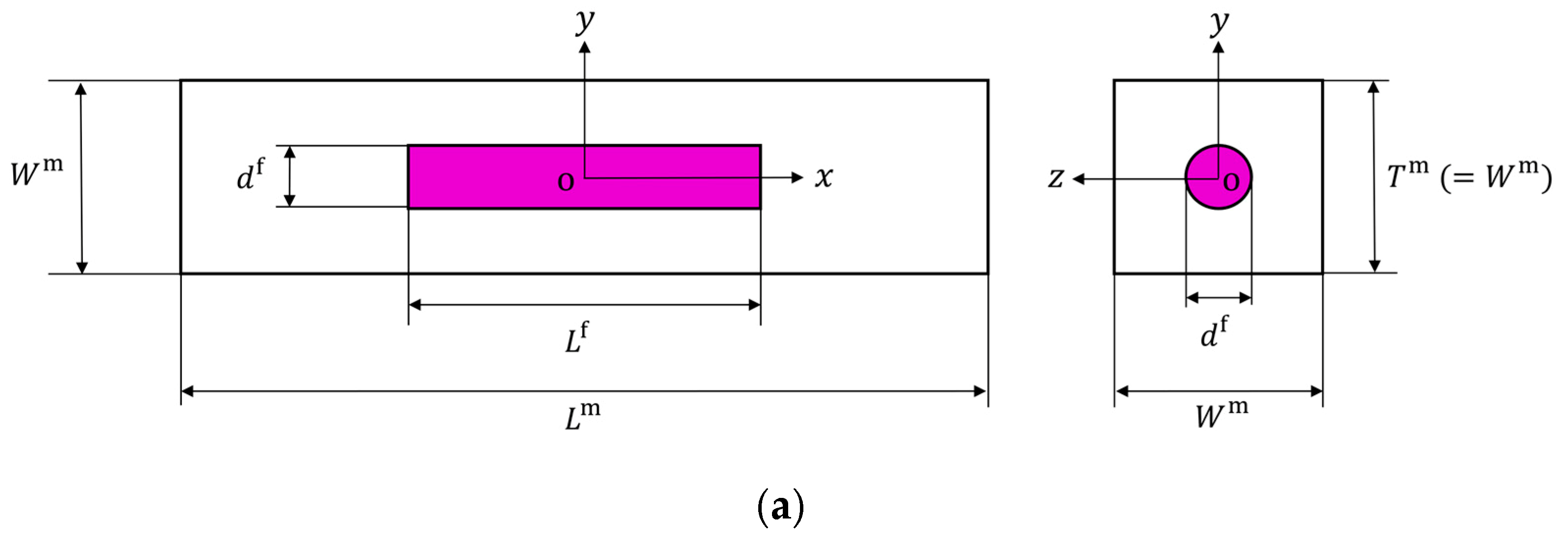

2.1. Definition of Representative Volume Element

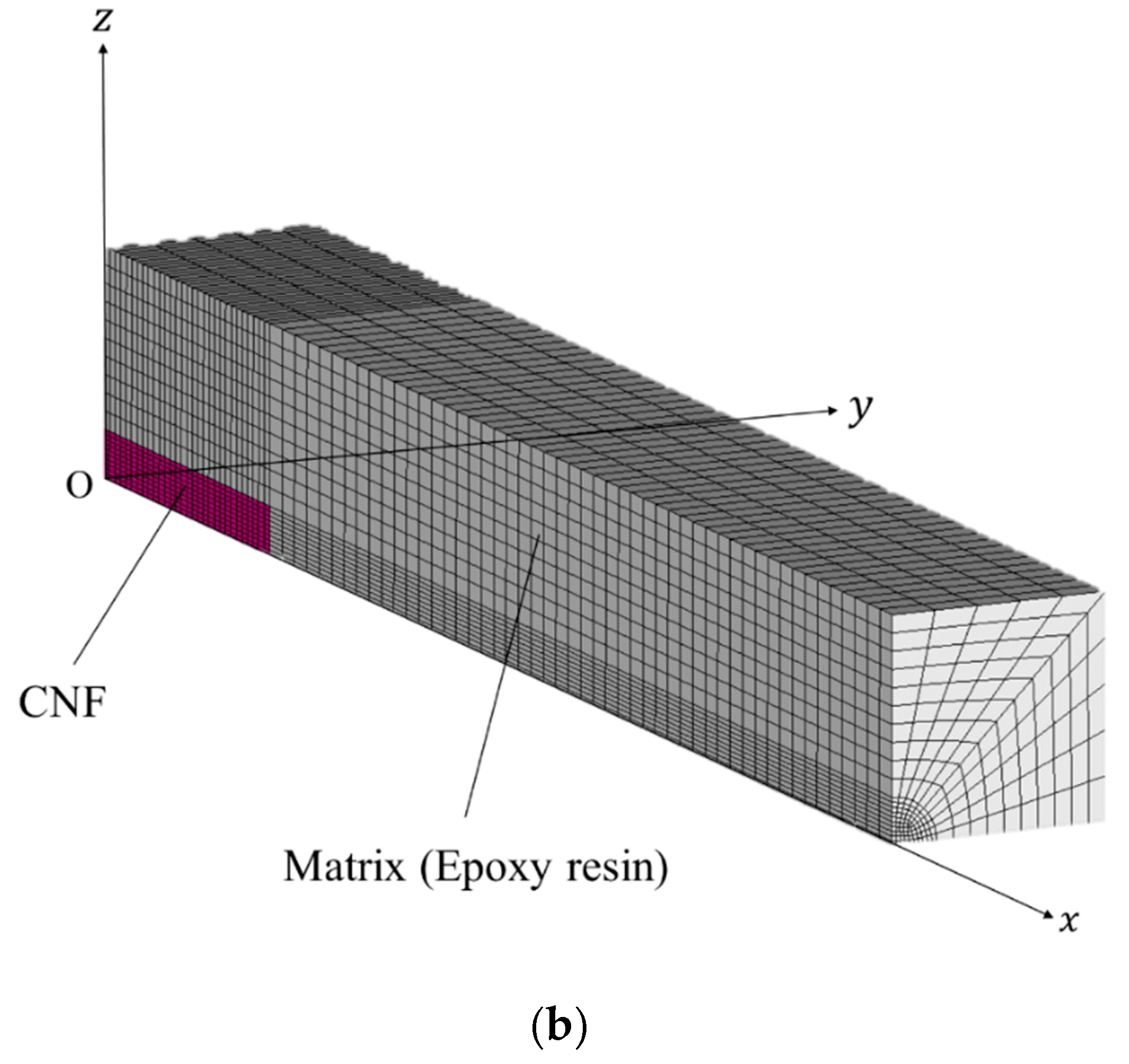

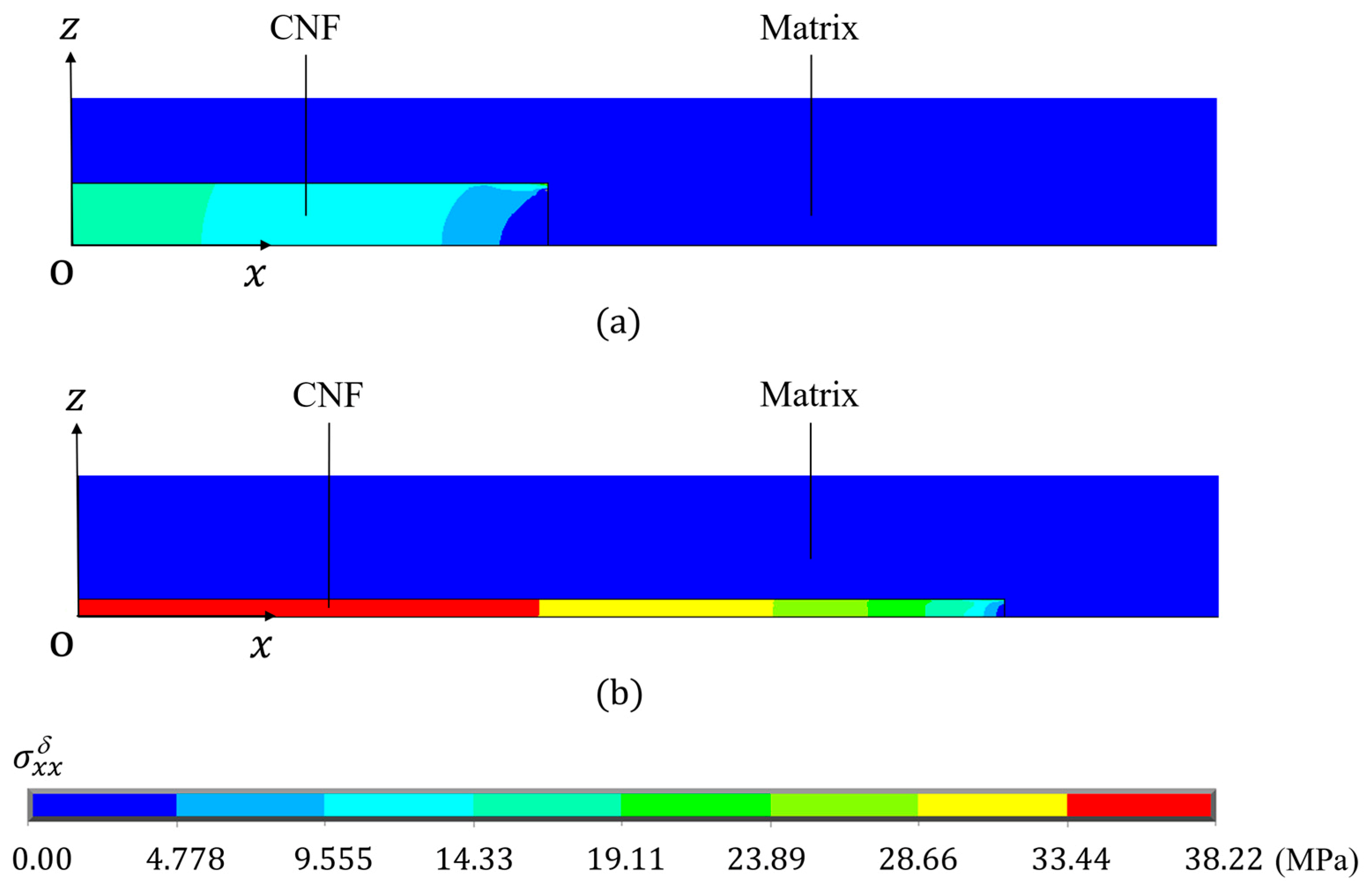

2.2. Finite Element Analysis of Representative Volume Element

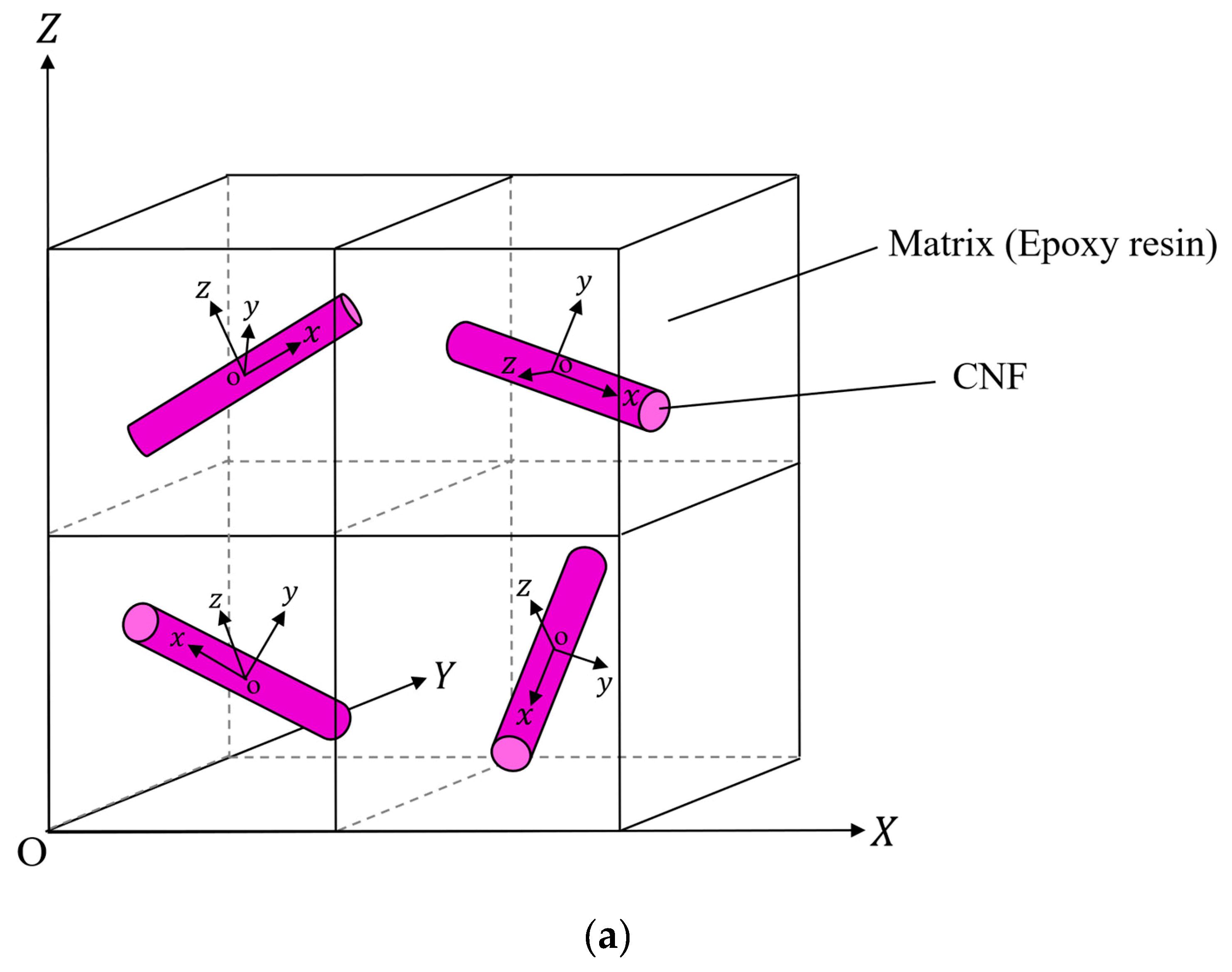

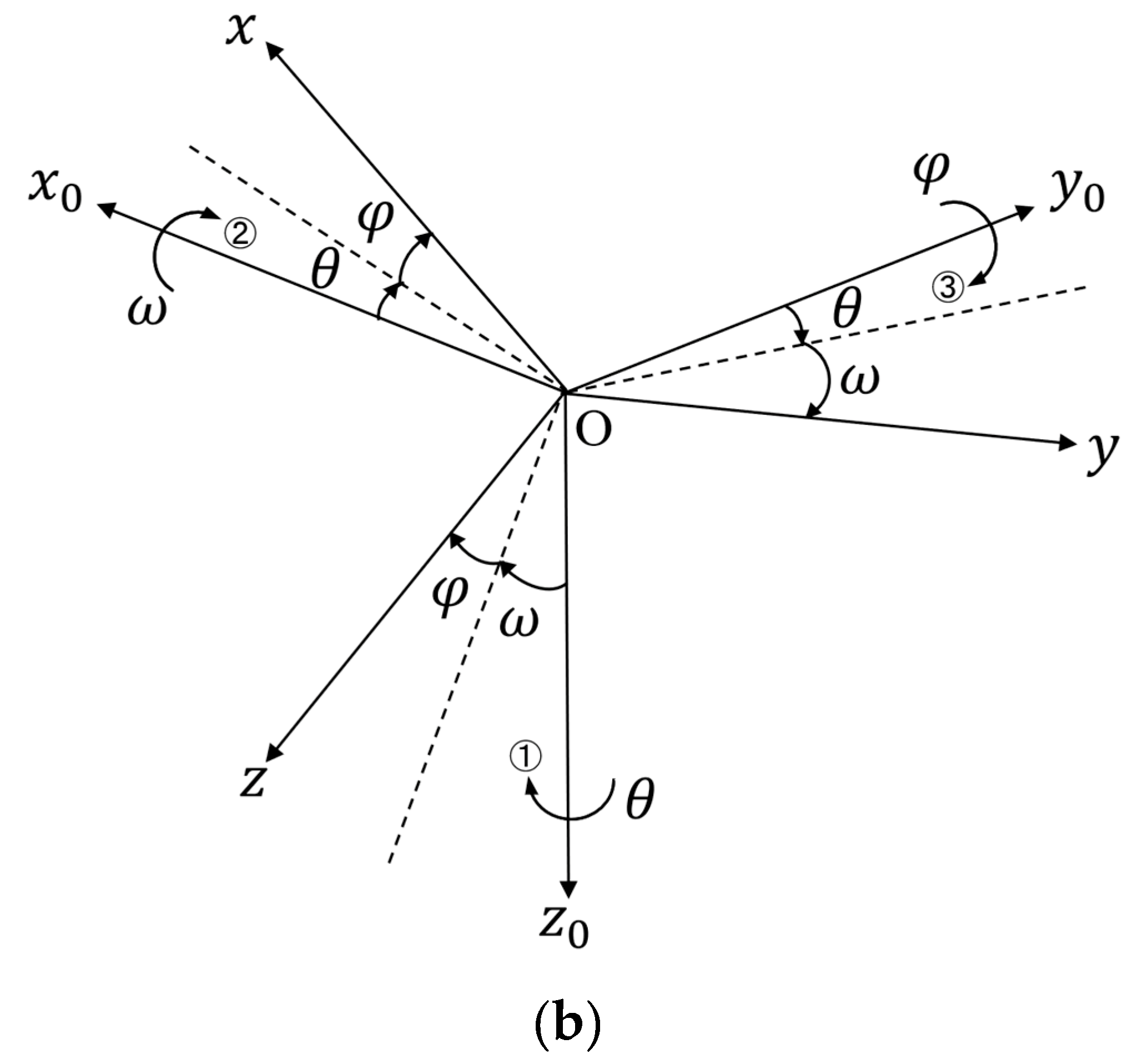

2.3. Definition of Randomly Oriented CNF-reinforced Composite

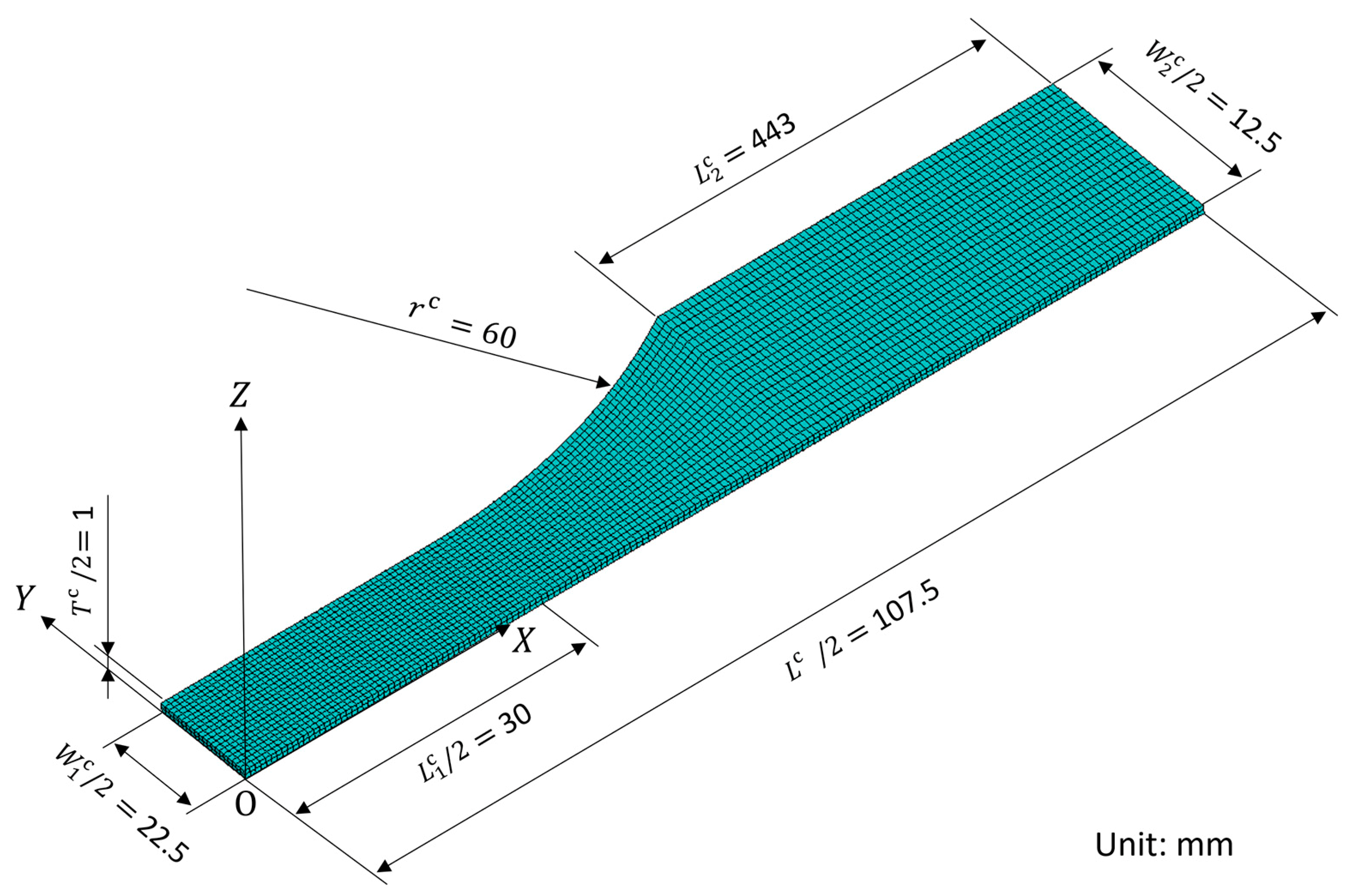

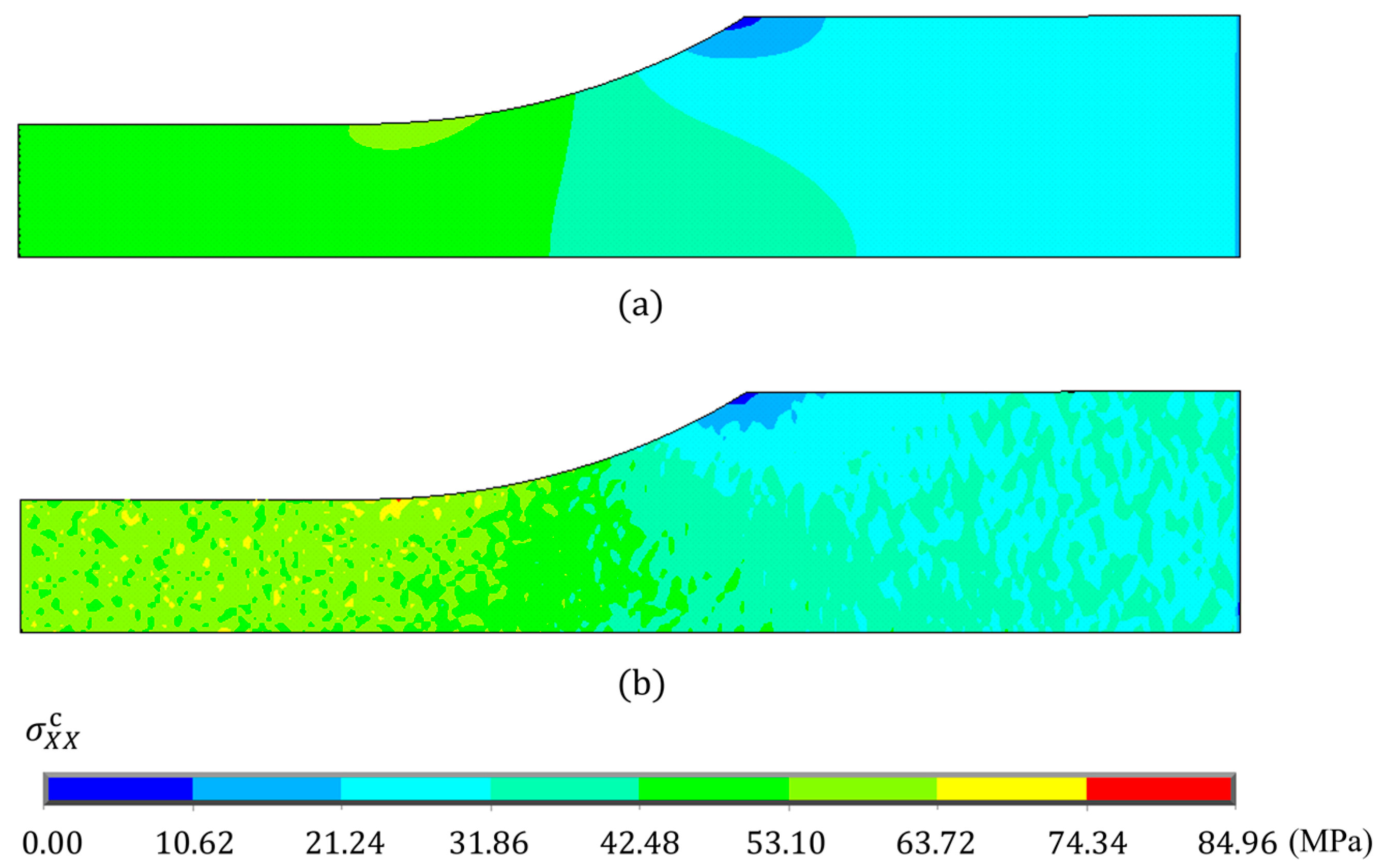

2.4. Finite Element Analysis of Randomly Oriented CNF-reinforced Composite Specimen

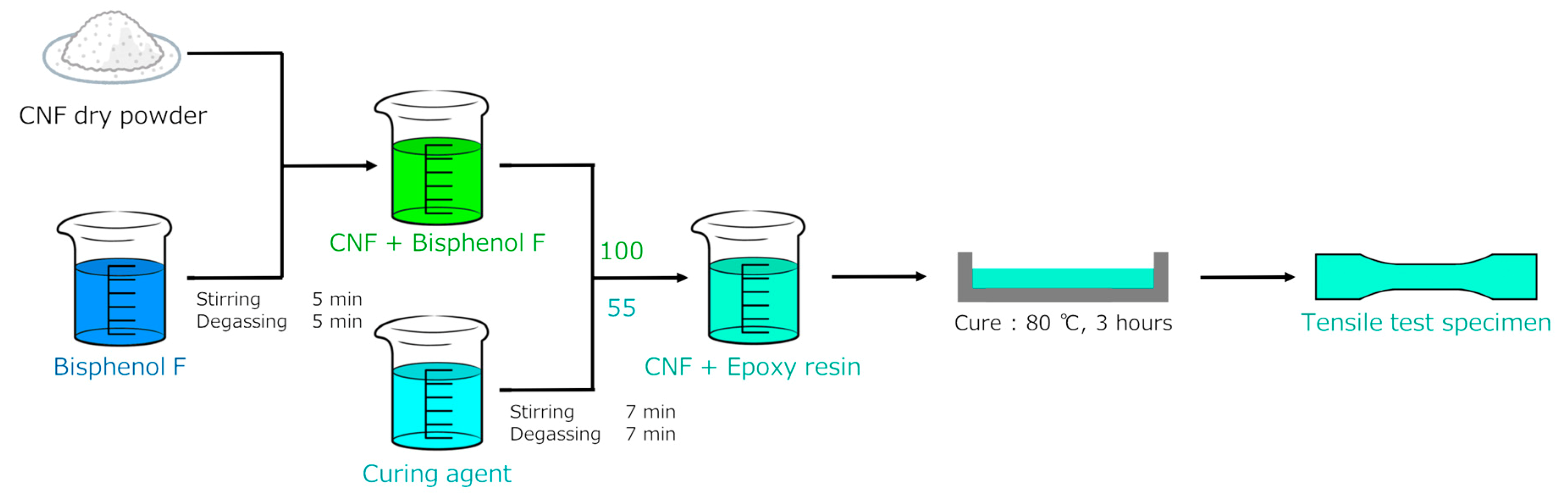

3. Experimental Procedure

4. Results and Discussion

4.1. Parameters of Representative Volume Element

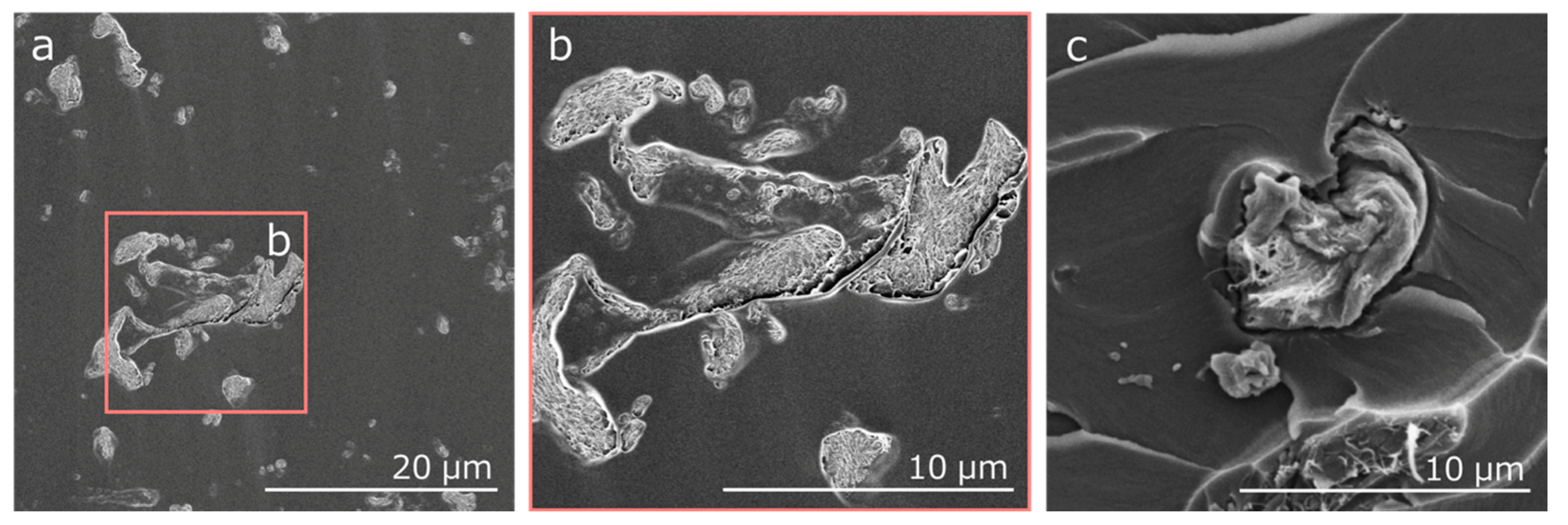

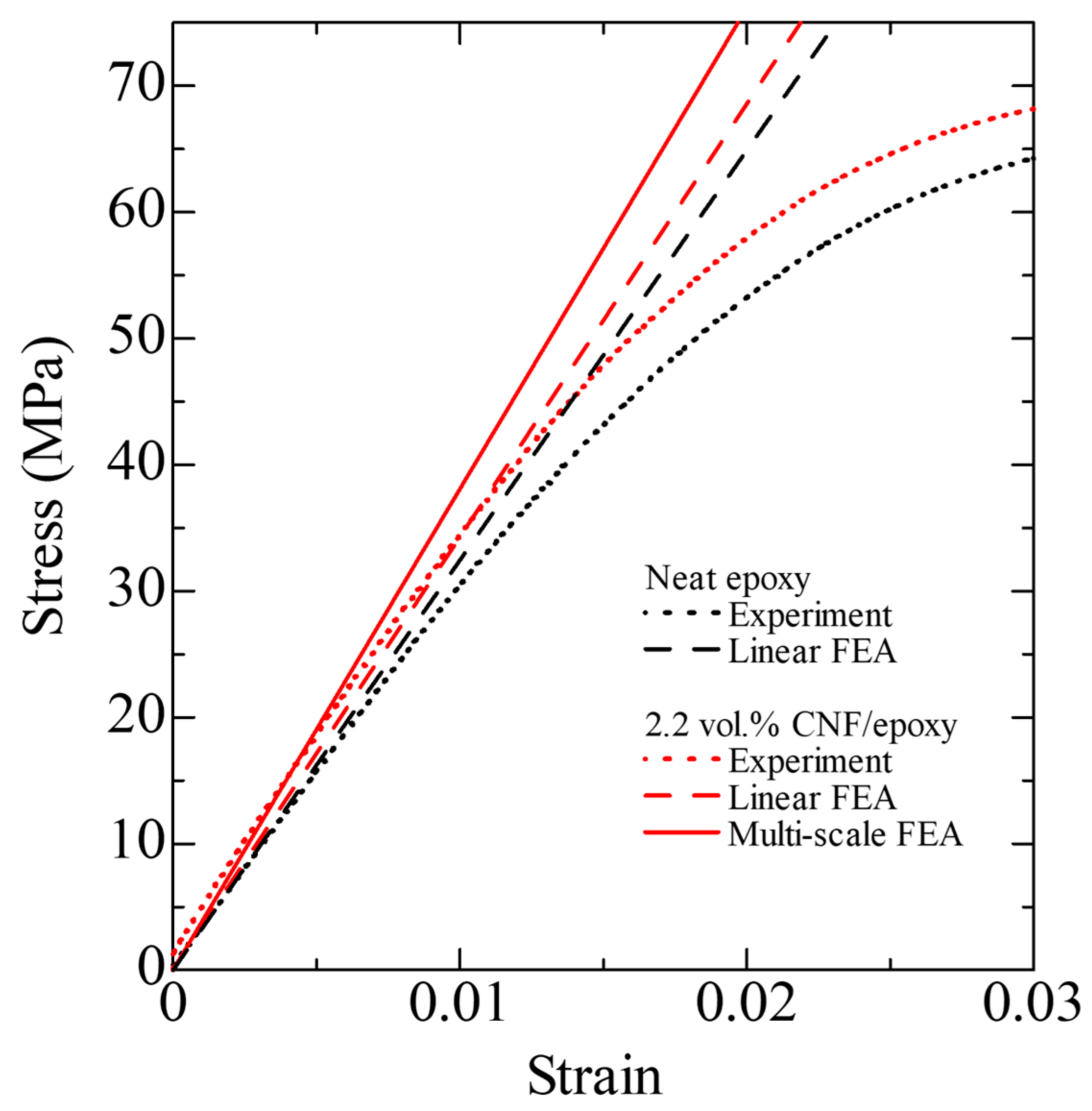

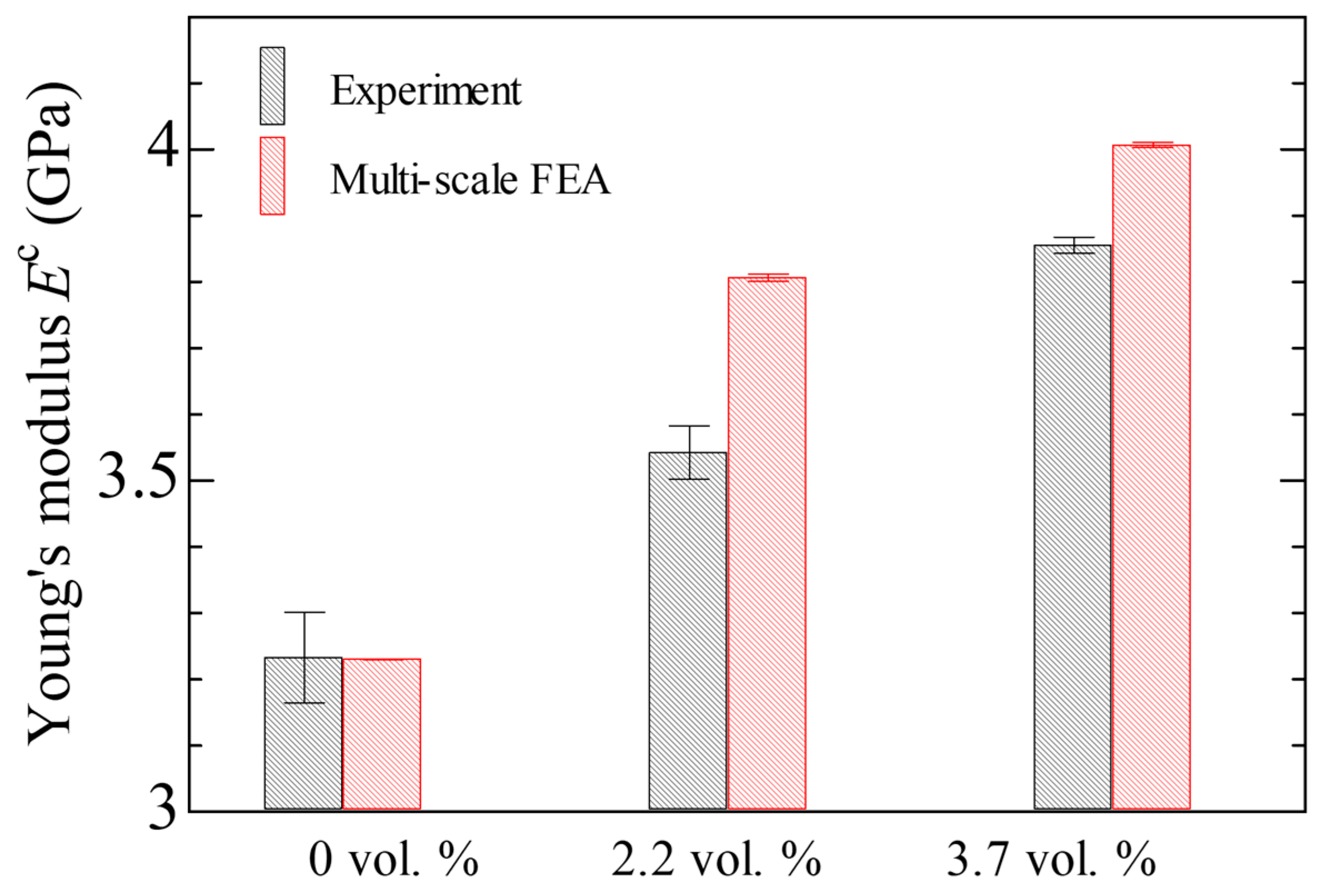

4.2. CNF/epoxy Composite Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cao, W.-T.; Chen, F.-F.; Zhu, Y.-J.; Zhang, Y.-G.; Jiang, Y.-Y.; Ma, M.-G.; Chen, F. Binary strengthening and toughening of MXene/cellulose nanofiber composite paper with nacre-inspired structure and superior electromagnetic interference shielding properties. ACS Nano 2018, 12, 4583–4593. [Google Scholar] [CrossRef] [PubMed]

- Fazeli, M.; Keley, M.; Biazar, E. Preparation and characterization of starch-based composite films reinforced by cellulose nanofibers. Int. J. Biol. Macromol. 2018, 116, 272–280. [Google Scholar] [CrossRef] [PubMed]

- Nissilä, T.; Hietala, M.; Oksman, K. A method for preparing epoxy–cellulose nanofiber composites with an oriented structure. Compos. Part A 2019, 125, 105515. [Google Scholar] [CrossRef]

- Noguchi, T.; Endo, M.; Niihara, K.; Jinnai, H.; Isogai, A. Cellulose nanofiber/elastomer composites with high tensile strength, modulus, toughness, and thermal stability prepared by high-shear kneading. Compos. Sci. Technol. 2020, 188, 108005. [Google Scholar] [CrossRef]

- Nishino, T.; Takano, K.; Nakamae, K. Elastic modulus of the crystalline regions cellulose polymorphs. J. Polym. Sci. Part B 1995, 33, 1647. [Google Scholar] [CrossRef]

- Bledzki, A.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Sain, M.; Oksman, K. Cellulose nanocomposites. J. Am. Chem. Soc. 2006, 938, 2–8. [Google Scholar]

- Chirayil, C.J.; Mathew, L.; Hassan, P.A.; Mozetic, M.; Thomas, S. Rheological behavior of nanocellulose reinforced unsaturated polyester nanocomposites. Int. J. Biol. Macromol. 2014, 69, 274–281. [Google Scholar] [CrossRef]

- Ansari, F.; Skrifvars, M.; Berglund, L. Nanostructured biocomposites based on unsaturated polyester resin and a cellulose nanofiber network. Compos. Sci. Technol. 2015, 117, 298–306. [Google Scholar] [CrossRef]

- Kurita, H.; Yingmei, X.; Katabira, K.; Narita, F. The insert effect of cellulose nanofiber layer on glass fiber-reinforced plastic laminates and their flexural properties. Mater. Des. Process. Commun. 2019, 1, e58. [Google Scholar] [CrossRef]

- Xie, Y.; Kurita, H.; Ishigami, R.; Narita, F. Assessing the flexural properties of epoxy composites with extremely low addition of cellulose nanofiber content. Appl. Sci. 2020, 10, 1159. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Narita, F. Three-dimensional thermoelastic analysis of cracked plain weave glass/epoxy composites at cryogenic temperatures. Compos. Sci. Technol. 2004, 64, 2353–2362. [Google Scholar] [CrossRef]

- Miura, M.; Shindo, Y.; Takeda, T.; Narita, F. Effect of damage on the interlaminar shear properties of hybrid composite laminates at cryogenic temperatures. Compos. Struct. 2010, 93, 124–131. [Google Scholar] [CrossRef]

- Shindo, Y.; Kuronuma, Y.; Takeda, T.; Narita, F.; Fu, S.-Y. Electrical resistance change and crack behavior in carbon nanotube/polymer composites under tensile loading. Compos. Part B 2012, 43, 39–43. [Google Scholar] [CrossRef]

- Levy, A.; Papazian, J.M. Tensile properties of short fiber-reinforced SiC/Al composites: Part II. Finite-element analysis. Metall. Trans. A 1990, 21, 411–420. [Google Scholar] [CrossRef]

- Sun, C.T.; Vaidya, R.S. Prediction of composite properties from a representative volume element. Compos. Sci. Technol. 1996, 56, 171–179. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Narita, F.; Mito, Y. Tensile characterization of carbon nanotube-reinforced polymer composites at cryogenic temperatures: Experiments and multiscale simulations. Mater. Trans. 2009, 50, 436–445. [Google Scholar] [CrossRef]

- Hutchinson, J.W.; Neale, K.W. Neck propagation. J. Mech. Phys. Solids 1983, 31, 405–426. [Google Scholar] [CrossRef]

- Narita, F.; Shindo, Y.; Takeda, T.; Kuronuma, Y.; Sanada, K. Loading rate-dependent fracture properties and electrical resistance-based crack growth monitoring of polycarbonate reinforced with carbon nanotubes under tension. ASTM J. Test. Eval. 2015, 43, 115–122. [Google Scholar] [CrossRef]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Taylor, A.C.; Kinloch, I. The effect of carbon nanotubes on the fracture toughness and fatigue performance of a thermosetting epoxy polymer. J. Mater. Sci. 2011, 46, 7525–7535. [Google Scholar] [CrossRef]

- Zaman, I.; Phan, T.T.; Kuan, H.-C.; Meng, Q.L.L.; Bao, T.; Luong, L.; Youssf, O.; Ma, J. Epoxy/graphene platelets nanocomposites with two levels of interface strength. Polymer 2011, 52, 1603–1611. [Google Scholar] [CrossRef]

- Guevara-Morales, A.; Taylor, A.C. Mechanical and dielectric properties of epoxy–clay nanocomposites. J. Mater. Sci. 2014, 49, 1574–1584. [Google Scholar] [CrossRef]

- Ogasawara, T.; Moon, S.-Y.; Inoue, Y.; Shimamura, Y. Mechanical properties of aligned multi-walled carbon nanotube/epoxy composites processed using a hot-melt prepreg method. Compos. Sci. Technol. 2011, 71, 1826–1833. [Google Scholar] [CrossRef]

| Nanomaterial | Content | Modulus (GPa) | Increase Rate (%) | |

|---|---|---|---|---|

| Dry CNF | 0 | 3.23 | This study | |

| 0.73 vol % | 3.30 | 2.1 | ||

| 2.2 vol % | 3.54 | 10 | ||

| 3.7 vol % | 3.85 | 19 | ||

| Silica | 0 | 2.96 | [20] | |

| 2.5 vol % | 3.20 | 8.1 | ||

| 4.9 vol % | 3.42 | 16 | ||

| 7.1 vol % | 3.57 | 21 | ||

| 9.6 vol % | 3.60 | 22 | ||

| 13.4 vol % | 3.85 | 30 | ||

| CNT | 0 | 2.90 | [21] | |

| 0.1 wt.% | 3.01 | 3.8 | ||

| 0.2 wt.% | 3.11 | 7.2 | ||

| 0.3 wt.% | 3.26 | 12 | ||

| Aligned CNT | 0 | 2.5 | [24] | |

| 4.5 vol % | 19 | 660 | ||

| 8.4 vol % | 32 | 1180 | ||

| 21.4 vol % | 50 | 1900 | ||

| 0 | 2.69 | [22] | ||

| Graphene (GP) | 4.0 wt.% | 2.89 | 7.4 | |

| Surface-modified GP | 4.0 wt.% | 3.27 | 22 | |

| Clay | 0 | 3.53 | [23] | |

| 2.0 wt.% | 3.58 | 1.4 | ||

| 5.0 wt.% | 3.66 | 3.7 | ||

| CNF slurry | 0 | 2.20 * | [11] | |

| 0 | 2.20 * | 26 | ||

| 0.25 vol % | 3.67 * | 67 | ||

| 0.74 vol % | 2.84 * | 29 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narita, F.; Wang, Y.; Kurita, H.; Suzuki, M. Multi-Scale Analysis and Testing of Tensile Behavior in Polymers with Randomly Oriented and Agglomerated Cellulose Nanofibers. Nanomaterials 2020, 10, 700. https://doi.org/10.3390/nano10040700

Narita F, Wang Y, Kurita H, Suzuki M. Multi-Scale Analysis and Testing of Tensile Behavior in Polymers with Randomly Oriented and Agglomerated Cellulose Nanofibers. Nanomaterials. 2020; 10(4):700. https://doi.org/10.3390/nano10040700

Chicago/Turabian StyleNarita, Fumio, Yinli Wang, Hiroki Kurita, and Masashi Suzuki. 2020. "Multi-Scale Analysis and Testing of Tensile Behavior in Polymers with Randomly Oriented and Agglomerated Cellulose Nanofibers" Nanomaterials 10, no. 4: 700. https://doi.org/10.3390/nano10040700

APA StyleNarita, F., Wang, Y., Kurita, H., & Suzuki, M. (2020). Multi-Scale Analysis and Testing of Tensile Behavior in Polymers with Randomly Oriented and Agglomerated Cellulose Nanofibers. Nanomaterials, 10(4), 700. https://doi.org/10.3390/nano10040700