Preparation of Transparent and Thick CNF/Epoxy Composites by Controlling the Properties of Cellulose Nanofibrils

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

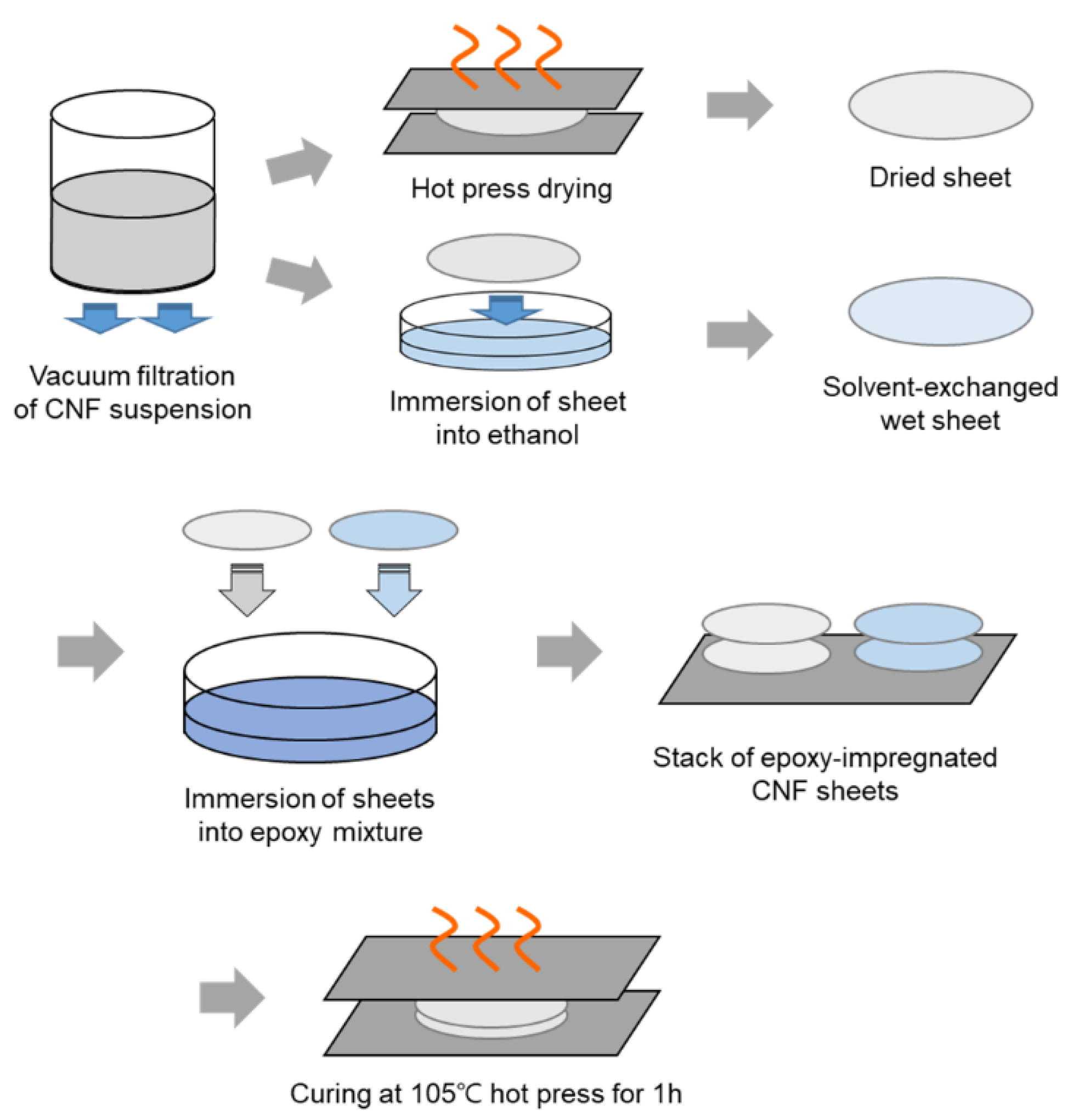

2.2. Preparation of Untreated CNF and Carboxymethylated CNF Sheets

2.2.1. Carboxymethylation of Pulp

2.2.2. Preparation of Untreated CNF and Carboxymethylated CNF

2.2.3. Preparation of Dried- and Solvent-Exchanged-CNF Sheets

2.3. Preparation of CNF/Epoxy Composite

2.4. Characterization of the CNF/Epoxy Composite

3. Results and Discussion

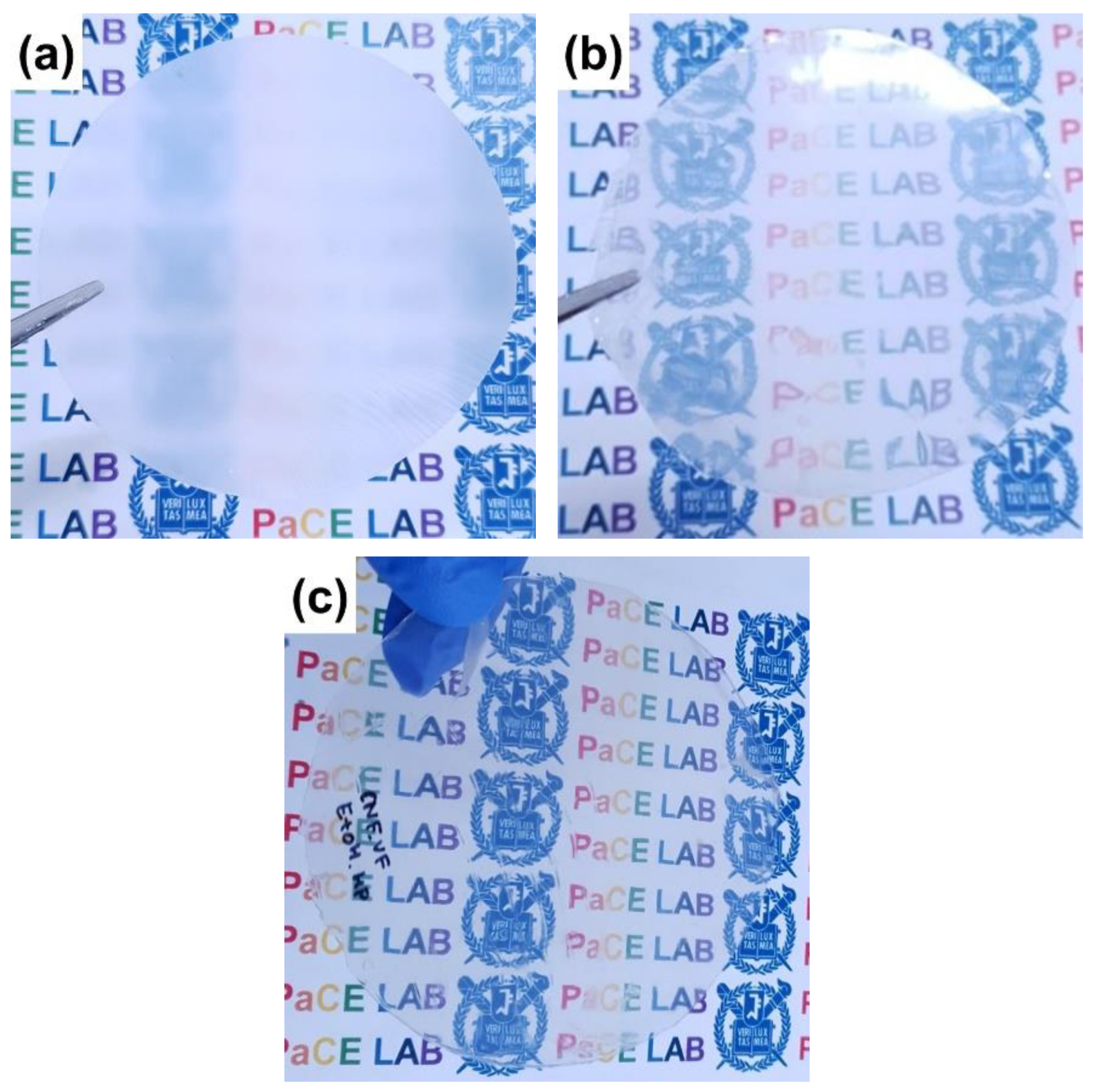

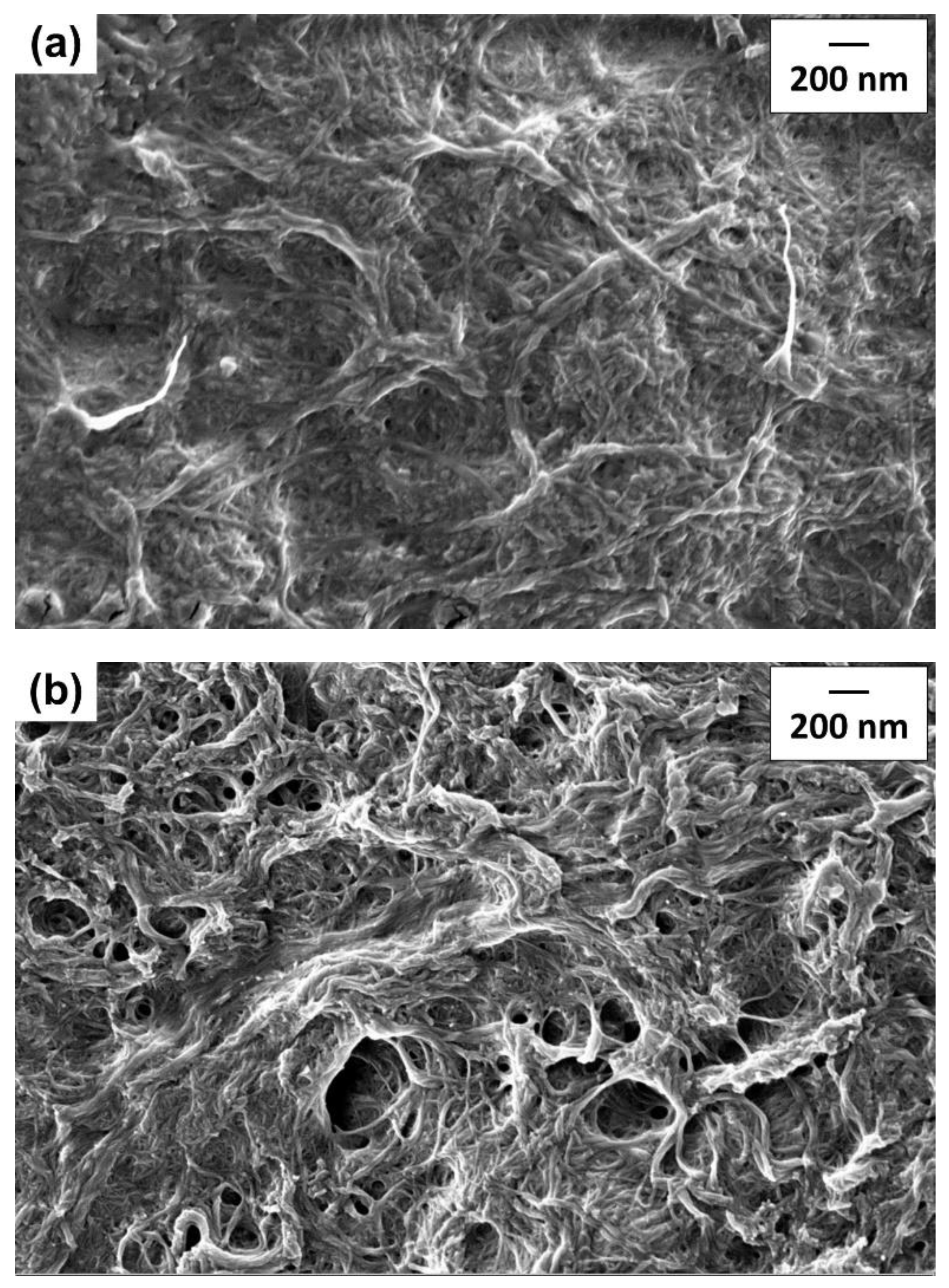

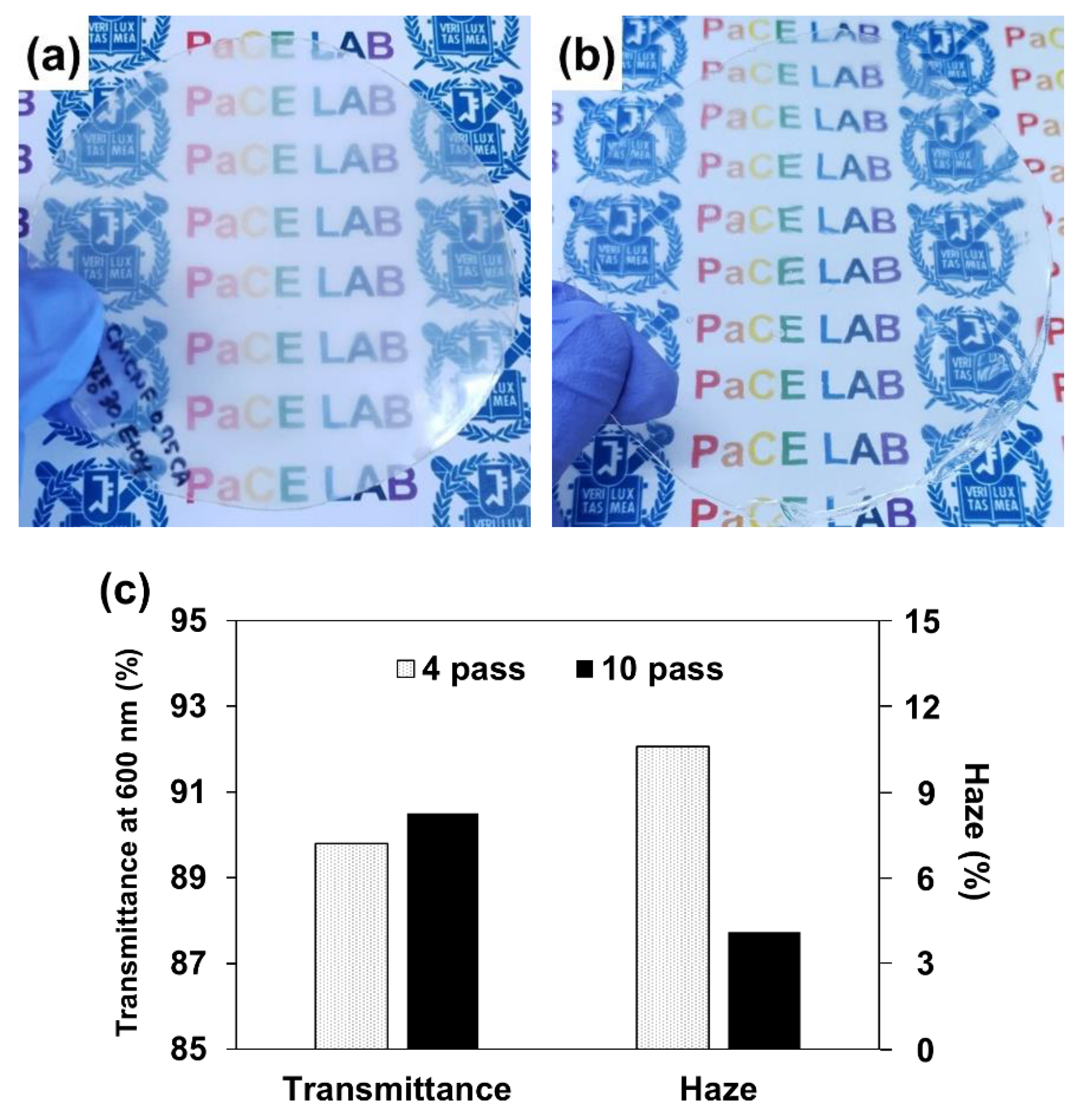

3.1. Effect of Solvent-Exchange Process of the Sheet on the Composites Properties

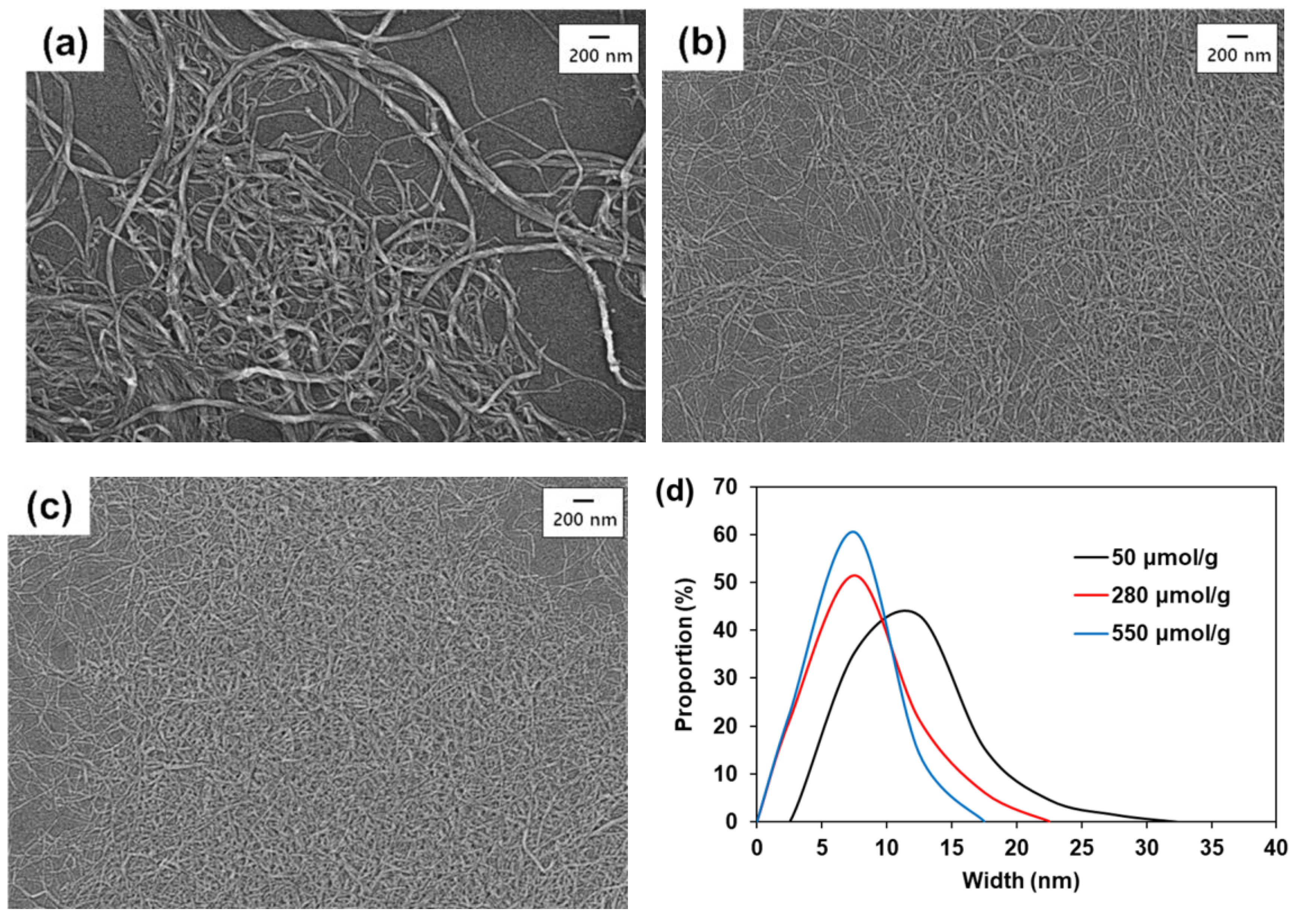

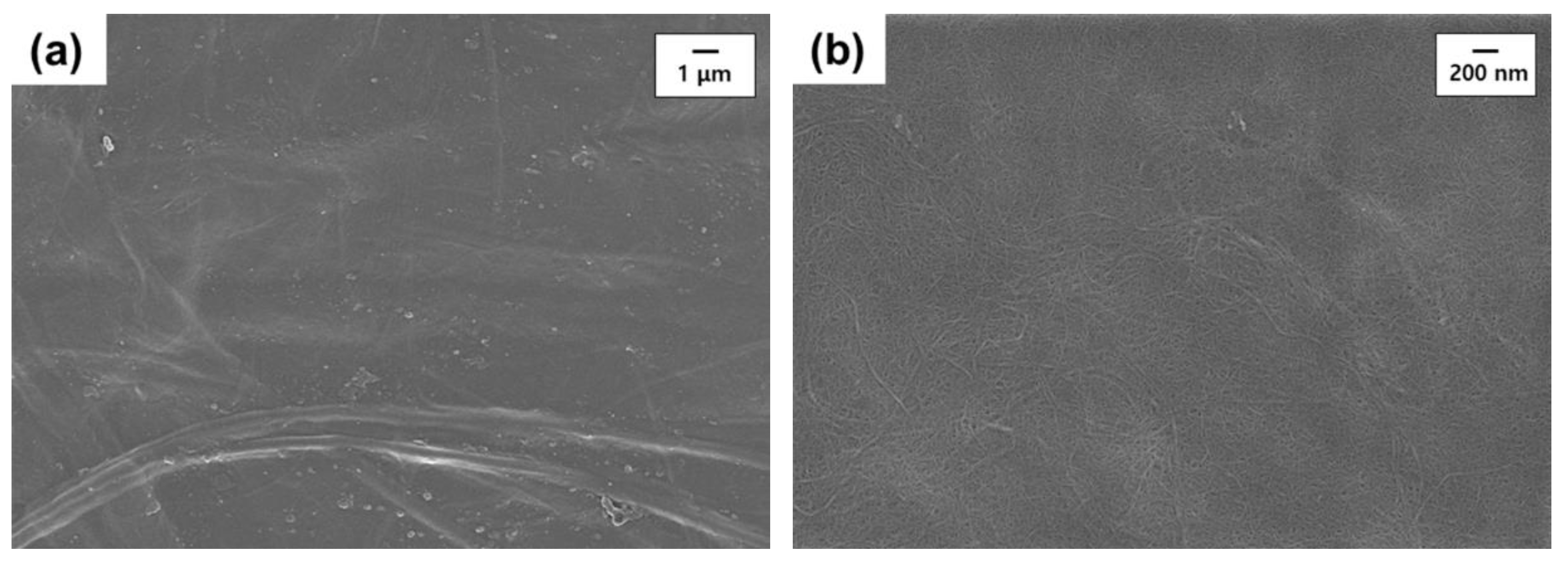

3.2. Effect of CNF Morphology on the Composite Properties

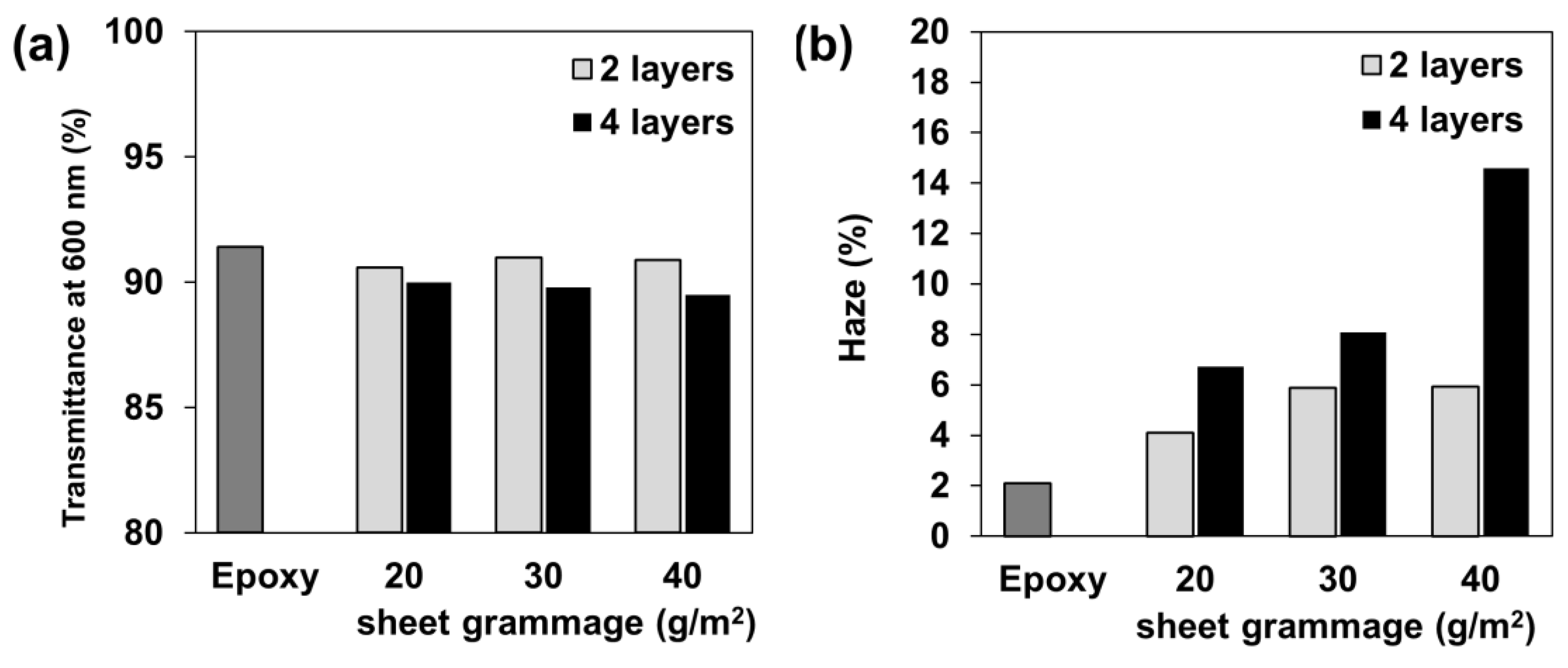

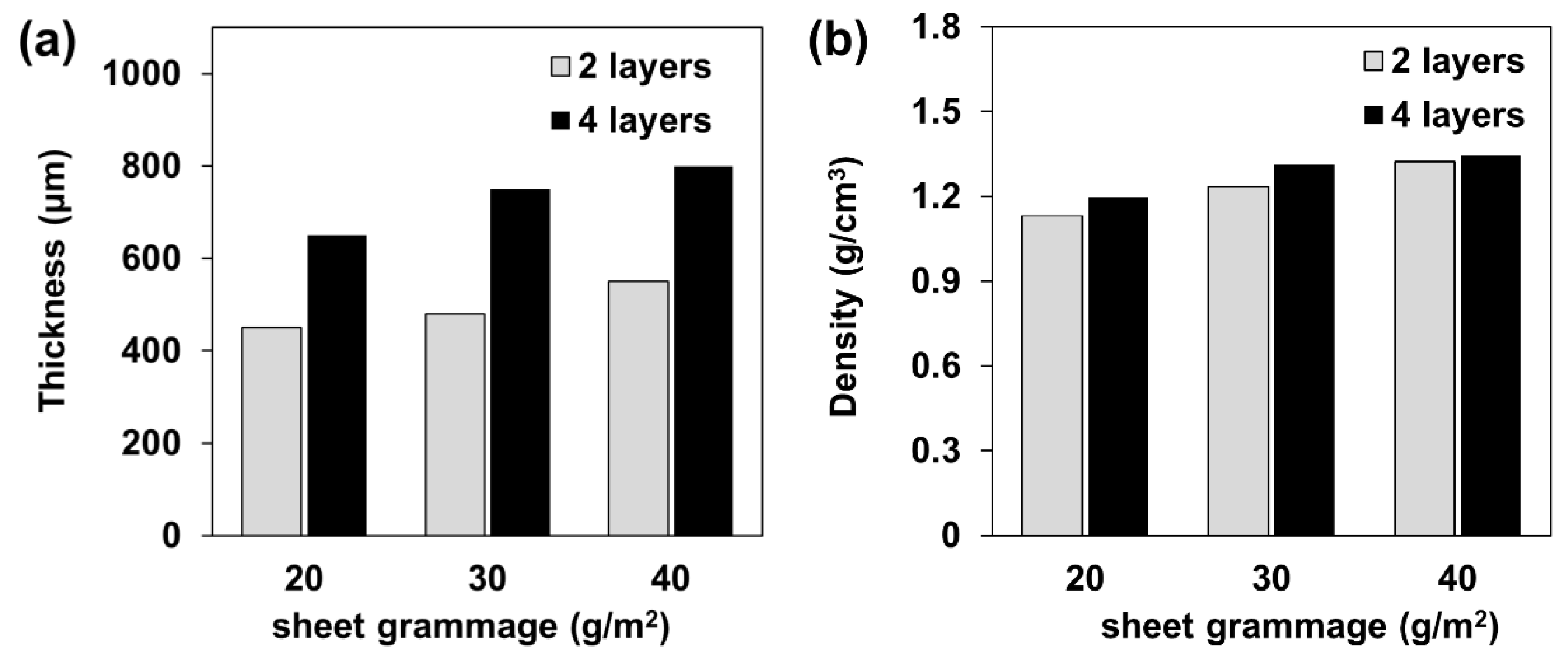

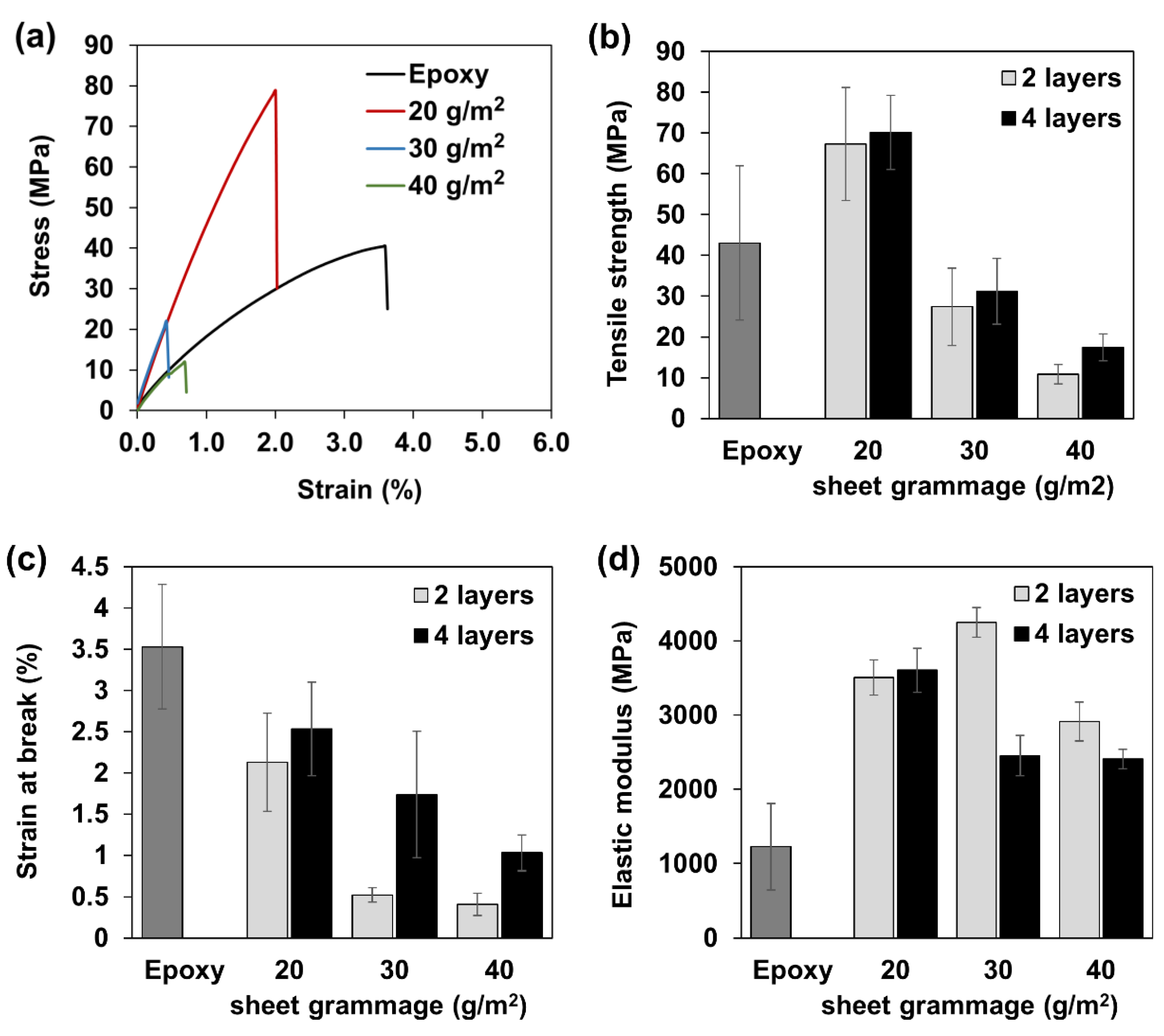

3.3. Effects of Sheet Grammage and the Number of Sheet Layers on the Composite Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, J.-H.; Shim, B.S.; Kim, H.S.; Lee, Y.-J.; Min, S.-K.; Jang, D.; Abas, Z.; Kim, J. Review of nanocellulose for sustainable future materials. Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 197–213. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Dufresne, A. Nanocellulose: From Nature to High Performance Tailored Materials; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2017. [Google Scholar]

- Farahbakhsh, N.; Roodposhti, P.S.; Ayoub, A.; Venditti, R.A.; Jur, J.S. Melt extrusion of polyethylene nanocomposites reinforced with nanofibrillated cellulose from cotton and wood sources. J. Appl. Polym. Sci. 2015, 132, 41857. [Google Scholar] [CrossRef]

- Kiziltas, A.; Nazari, B.; Kiziltas, E.E.; Gardner, D.J.; Han, Y.; Rushing, T.S. Cellulose nanofiber-polyethylene nanocomposites modified by polyvinyl alcohol. J. Appl. Polym. Sci. 2016, 133, 42933. [Google Scholar] [CrossRef]

- Maia, T.H.S.; Larocca, N.M.; Beatrice, C.A.G.; de Menezes, A.J.; de Freitas Siqueira, G.; Pessan, L.A.; Dufresne, A.; Franca, M.P.; de Almeida Lucas, A. Polyethylene cellulose nanofibrils nanocomposites. Carbohydr. Polym. 2017, 173, 50–56. [Google Scholar] [CrossRef]

- Yang, H.-S.; Gardner, D.J.; Nader, J.W. Characteristic impact resistance model analysis of cellulose nanofibril-filled polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2028–2035. [Google Scholar] [CrossRef]

- Peng, Y.; Gallegos, S.A.; Gardner, D.J.; Han, Y.; Cai, Z. Maleic anhydride polypropylene modified cellulose nanofibril polypropylene nanocomposites with enhanced impact strength. Polym. Compos. 2016, 37, 782–793. [Google Scholar] [CrossRef]

- Qu, P.; Gao, Y.; Wu, G.; Zhang, L. Nanocomposites of poly (lactic acid) reinforced with cellulose nanofibrils. BioResources 2010, 5, 1811–1823. [Google Scholar]

- Wang, T.; Drzal, L.T. Cellulose-nanofiber-reinforced poly (lactic acid) composites prepared by a water-based approach. ACS Appl. Mater. Interfaces 2012, 4, 5079–5085. [Google Scholar] [CrossRef]

- Silva, M.; Sanches, A.; Medeiros, E.; Mattoso, L.; McMahan, C.; Malmonge, J. Nanocomposites of natural rubber and polyaniline-modified cellulose nanofibrils. J. Therm. Anal. Calorim. 2014, 117, 387–392. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, T.; Sabo, R.; Clemons, C.; Dan, Y.; Turng, L.-S. Reinforcing natural rubber with cellulose nanofibrils extracted from bleached eucalyptus kraft pulp. J. Biobased Mater. Bioenergy 2014, 8, 317–324. [Google Scholar] [CrossRef]

- Yano, H.; Sugiyama, J.; Nakagaito, A.N.; Nogi, M.; Matsuura, T.; Hikita, M.; Handa, K. Optically transparent composites reinforced with networks of bacterial nanofibers. Adv. Mater. 2005, 17, 153–155. [Google Scholar] [CrossRef]

- Novak, B.M. Hybrid nanocomposite materials—between inorganic glasses and organic polymers. Adv. Mater. 1993, 5, 422–433. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Qing, Y.; Sabo, R.; Wu, Y.; Zhu, J.; Cai, Z. Self-assembled optically transparent cellulose nanofibril films: Effect of nanofibril morphology and drying procedure. Cellulose 2015, 22, 1091–1102. [Google Scholar] [CrossRef]

- Li, S.; Lee, P.S. Development and applications of transparent conductive nanocellulose paper. Sci. Technol. Adv. Mater. 2017, 18, 620–633. [Google Scholar] [CrossRef]

- Iwamoto, S.; Nakagaito, A.N.; Yano, H.; Nogi, M. Optically transparent composites reinforced with plant fiber-based nanofibers. Appl. Phys. A 2005, 81, 1109–1112. [Google Scholar] [CrossRef]

- Nogi, M.; Iwamoto, S.; Nakagaito, A.N.; Yano, H. Optically transparent nanofiber paper. Adv. Mater. 2009, 21, 1595–1598. [Google Scholar] [CrossRef]

- Zhu, H.; Fang, Z.; Preston, C.; Li, Y.; Hu, L. Transparent paper: Fabrications, properties, and device applications. Energy Environ. Sci. 2014, 7, 269–287. [Google Scholar] [CrossRef]

- Biswas, S.K.; Sano, H.; Shams, M.I.; Yano, H. Three-dimensional-moldable nanofiber-reinforced transparent composites with a hierarchically self-assembled “reverse” nacre-like architecture. ACS Appl. Mater. Interfaces 2017, 9, 30177–30184. [Google Scholar] [CrossRef]

- Zhao, M.; Ansari, F.; Takeuchi, M.; Shimizu, M.; Saito, T.; Berglund, L.; Isogai, A. Nematic structuring of transparent and multifunctional nanocellulose papers. Nanoscale Horiz. 2018, 3, 28–34. [Google Scholar] [CrossRef]

- Shimizu, M.; Saito, T.; Fukuzumi, H.; Isogai, A. Hydrophobic, ductile, and transparent nanocellulose films with quaternary alkylammonium carboxylates on nanofibril surfaces. Biomacromolecules 2014, 15, 4320–4325. [Google Scholar] [CrossRef] [PubMed]

- Shimazaki, Y.; Miyazaki, Y.; Takezawa, Y.; Nogi, M.; Abe, K.; Ifuku, S.; Yano, H. Excellent thermal conductivity of transparent cellulose nanofiber/epoxy resin nanocomposites. Biomacromolecules 2007, 8, 2976–2978. [Google Scholar] [CrossRef] [PubMed]

- Ansari, F.; Galland, S.; Johansson, M.; Plummer, C.J.; Berglund, L.A. Cellulose nanofiber network for moisture stable, strong and ductile biocomposites and increased epoxy curing rate. Compos. Part A Appl. Sci. Manuf. 2014, 63, 35–44. [Google Scholar] [CrossRef]

- Qing, Y.; Cai, Z.; Wu, Y.; Yao, C.; Wu, Q.; Li, X. Facile preparation of optically transparent and hydrophobic cellulose nanofibril composite films. Ind. Crops Prod. 2015, 77, 13–20. [Google Scholar] [CrossRef]

- Mi, H.; Liu, C.-H.; Chang, T.-H.; Seo, J.-H.; Zhang, H.; Cho, S.J.; Behdad, N.; Ma, Z.; Yao, C.; Cai, Z. Characterizations of biodegradable epoxy-coated cellulose nanofibrils (CNF) thin film for flexible microwave applications. Cellulose 2016, 23, 1989–1995. [Google Scholar] [CrossRef]

- Im, W.; Lee, S.; Park, H.; Lee, H.L.; Youn, H.J. Characteristics of cellulose nanofibrils by carboxymethylation pretreatment: Effect of the carboxyl contents. J Korea TAPPI 2016, 48, 195–202. [Google Scholar] [CrossRef]

- Sood, Y.V.; Tyagi, R.; Tyagi, S.; Pande, P.C.; Tondon, R. Surface charge of different paper making raw materials and its influence on paper properties. J. Sci. Ind. Res. 2010, 69, 300–304. [Google Scholar]

- Zhu, H.; Parvinian, S.; Preston, C.; Vaaland, O.; Ruan, Z.; Hu, L. Transparent nanopaper with tailored optical properties. Nanoscale 2013, 5, 3787–3792. [Google Scholar] [CrossRef]

- Bohren, C.F.; Huffman, D.R. Absorption and Scattering of Light by Small Particles; Wiley-VCH: Weinheim, Germany, 2004. [Google Scholar]

- Saba, N.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.Y.; Sain, M. Mechanical, morphological and structural properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 97, 190–200. [Google Scholar] [CrossRef]

| Sample | Transmittance at 600 nm (%) | Haze (%) |

|---|---|---|

| Dried U-CNF sheet (single layer) | 89.6 | 76.0 |

| Two-layered dried U-CNF/epoxy composite | 83.9 | 30.4 |

| Two-layered solvent-exchanged U-CNF/epoxy composite | 83.9 | 26.2 |

| CNF Type | Carboxyl contents of CNF (μmol/g) | Transmittance at 600 nm (%) | Haze (%) |

|---|---|---|---|

| U-CNF | 50 | 83.9 | 26.2 |

| CM-CNF | 280 | 84.6 | 21.1 |

| 355 | 86.3 | 17.2 | |

| 470 | 88.3 | 15.0 | |

| 550 | 89.8 | 10.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.Y.; Yook, S.; Goo, S.; Im, W.; Youn, H.J. Preparation of Transparent and Thick CNF/Epoxy Composites by Controlling the Properties of Cellulose Nanofibrils. Nanomaterials 2020, 10, 625. https://doi.org/10.3390/nano10040625

Park SY, Yook S, Goo S, Im W, Youn HJ. Preparation of Transparent and Thick CNF/Epoxy Composites by Controlling the Properties of Cellulose Nanofibrils. Nanomaterials. 2020; 10(4):625. https://doi.org/10.3390/nano10040625

Chicago/Turabian StylePark, Shin Young, Simyub Yook, Sooim Goo, Wanhee Im, and Hye Jung Youn. 2020. "Preparation of Transparent and Thick CNF/Epoxy Composites by Controlling the Properties of Cellulose Nanofibrils" Nanomaterials 10, no. 4: 625. https://doi.org/10.3390/nano10040625

APA StylePark, S. Y., Yook, S., Goo, S., Im, W., & Youn, H. J. (2020). Preparation of Transparent and Thick CNF/Epoxy Composites by Controlling the Properties of Cellulose Nanofibrils. Nanomaterials, 10(4), 625. https://doi.org/10.3390/nano10040625