Thin-Film Engineering of Mechanical Fragmentation Properties of Atomic-Layer-Deposited Metal Oxides

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental

2.2. Theory

3. Results

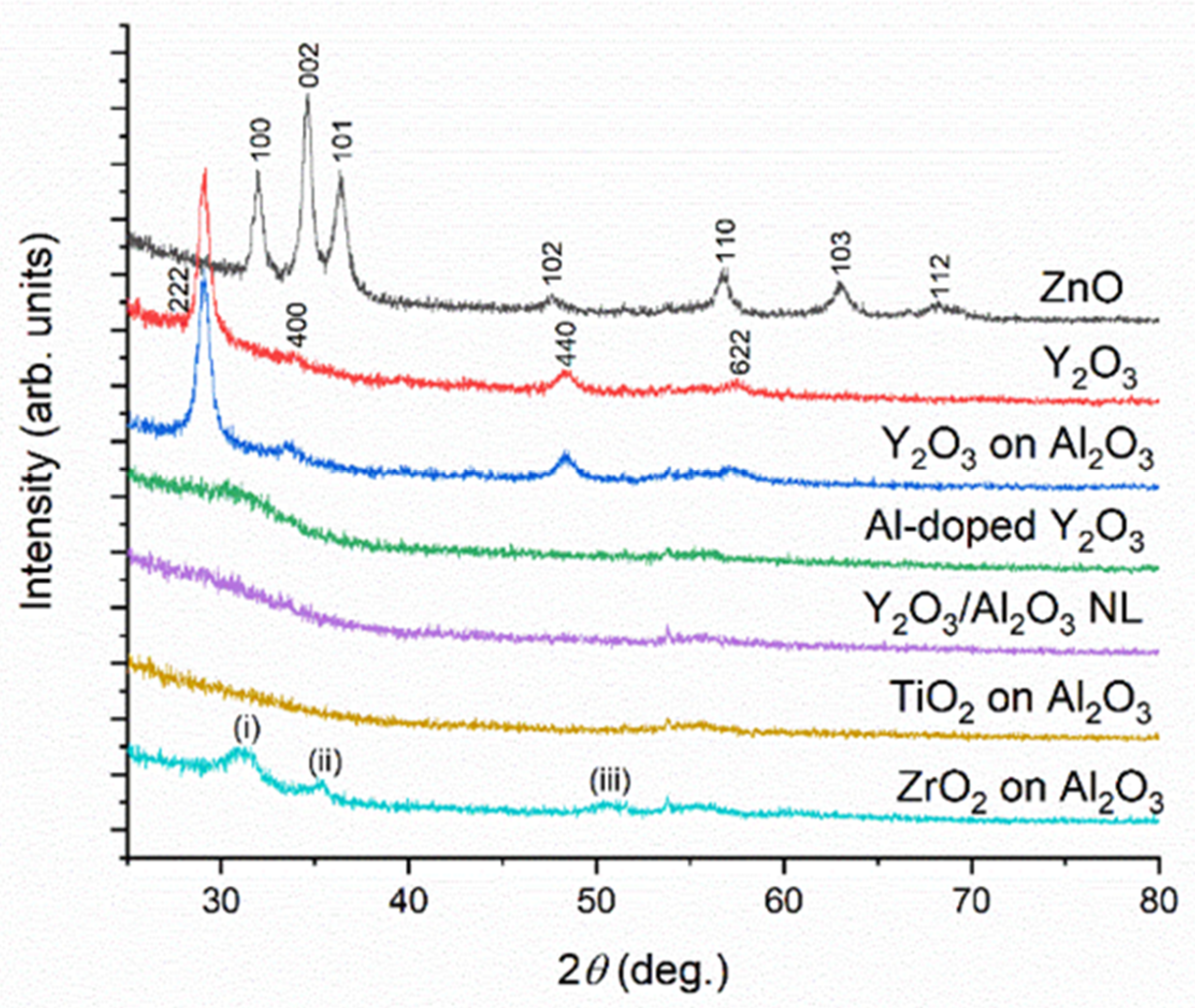

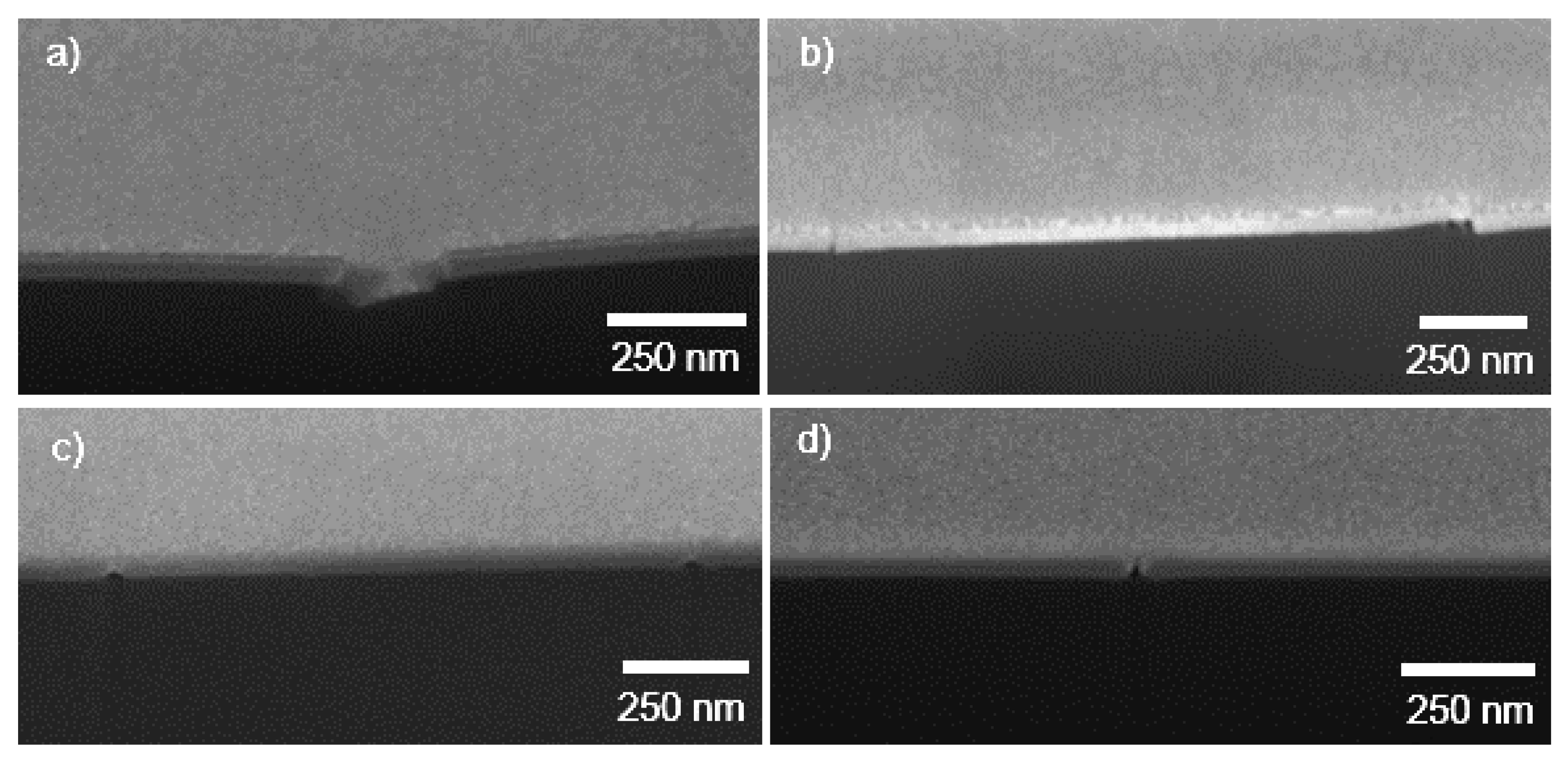

3.1. Crystallinity and Composition of the Films

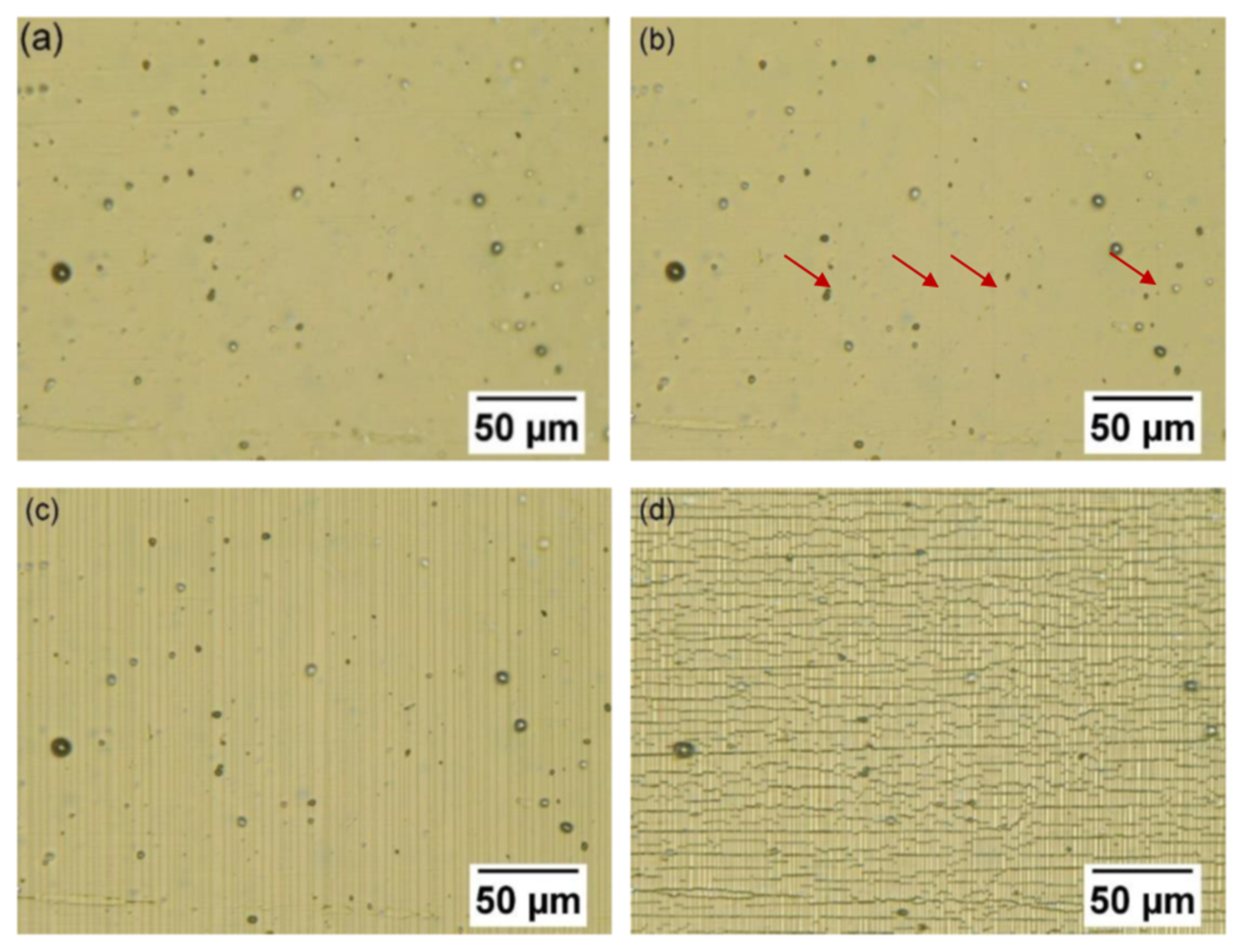

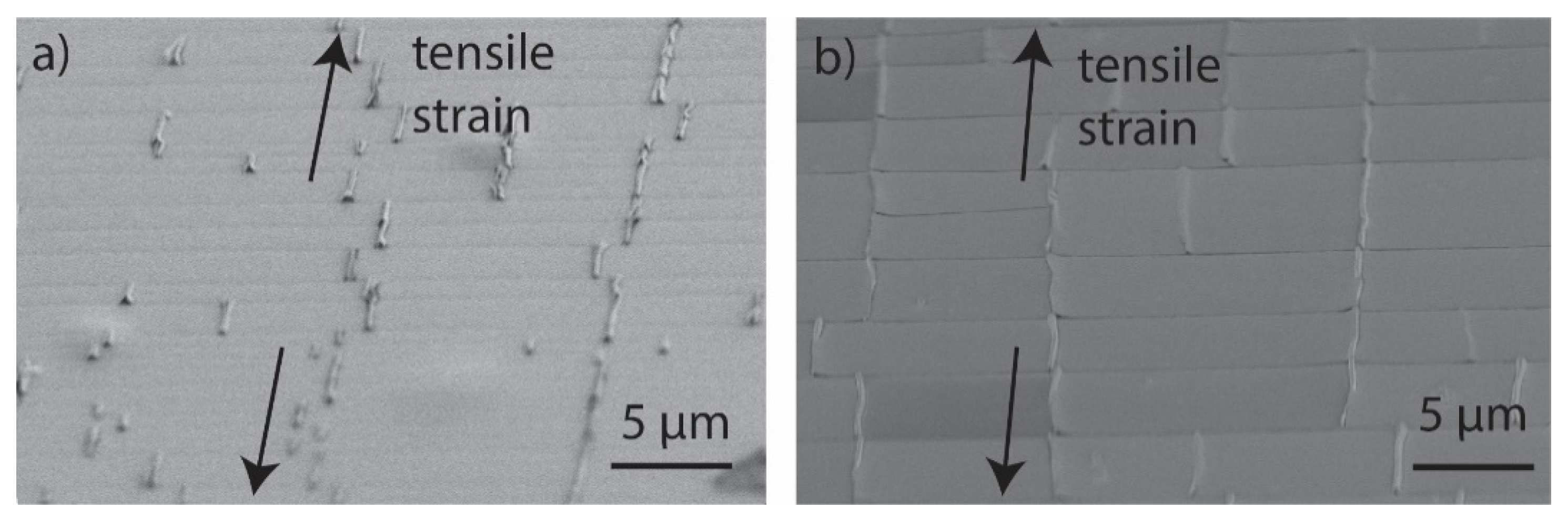

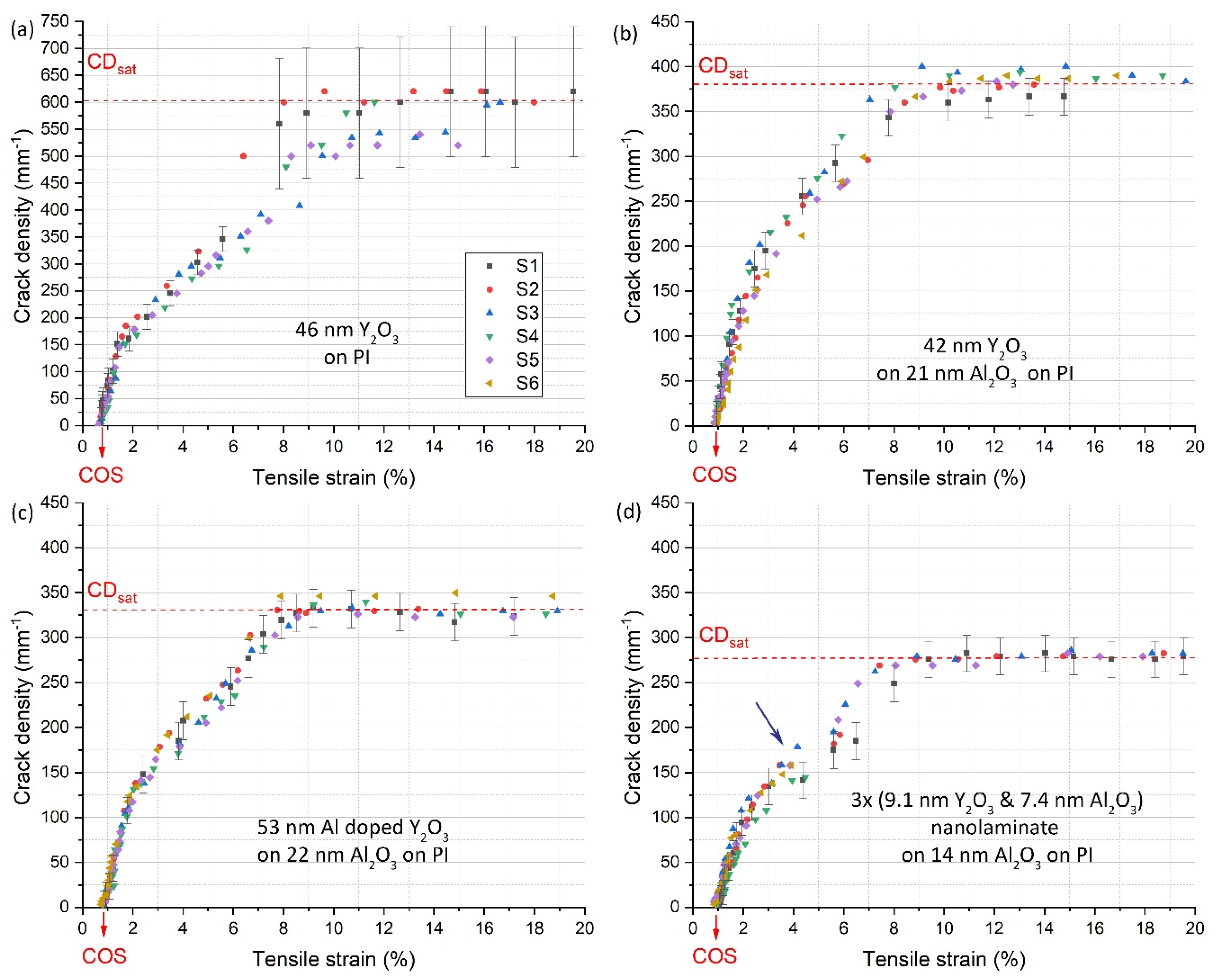

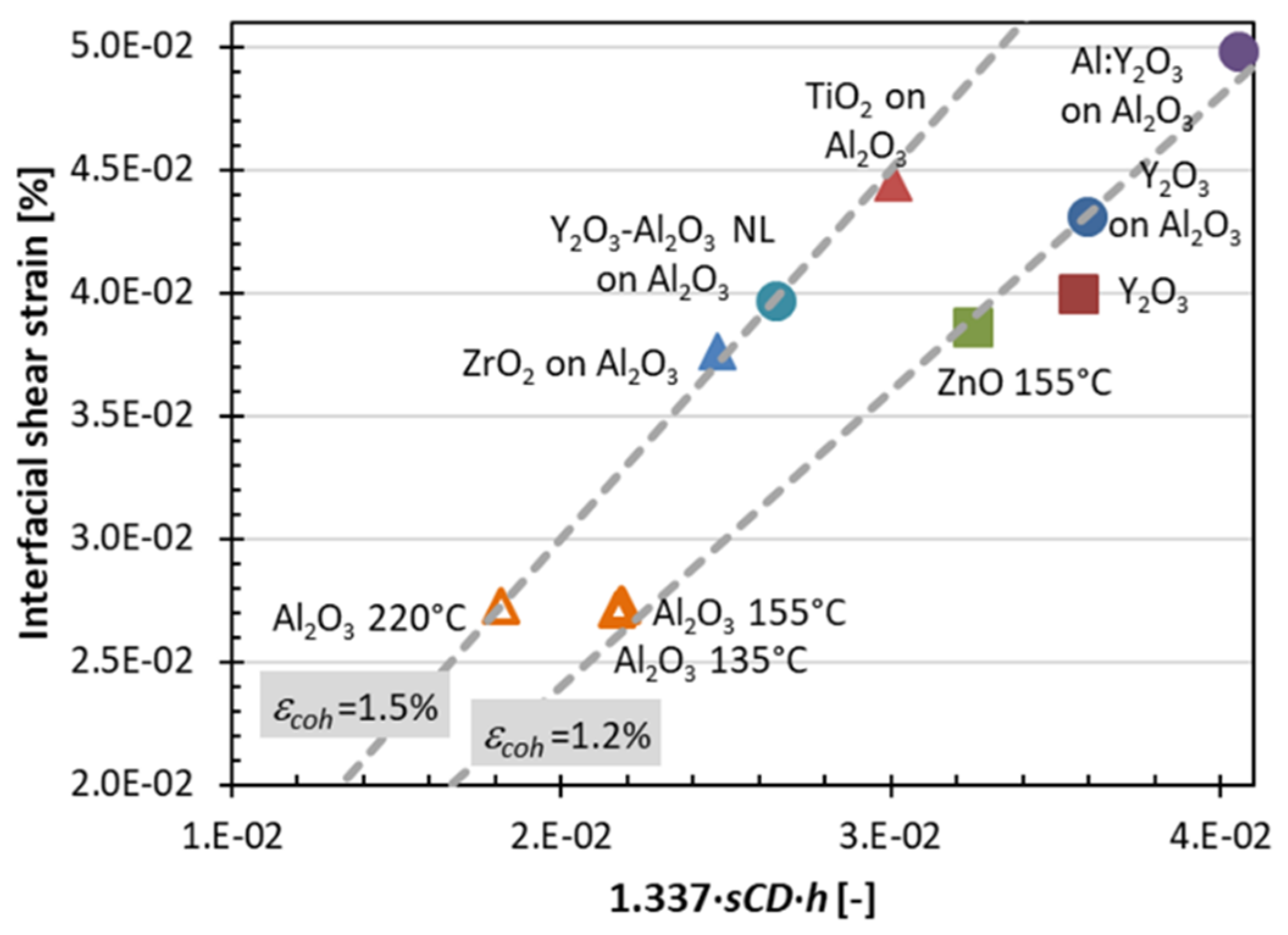

3.2. Fragmentation of the Films

3.3. Mechanical Properties of the Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Meyer, J.; Görrn, P.; Bertram, F.; Hamwi, S.; Winkler, T.; Johannes, H.-H.; Weimann, T.; Hinze, P.; Riedl, T.; Kowalsky, W. Al2O3/ZrO2 Nanolaminates as Ultrahigh Gas-Diffusion Barriers-A Strategy for Reliable Encapsulation of Organic Electronics. Adv. Mater. 2009, 21, 1845–1849. [Google Scholar] [CrossRef]

- Jen, S.-H.; Lee, B.H.; George, S.M.; McLean, R.S.; Carcia, P.F. Critical tensile strain and water vapor transmission rate for nanolaminate films grown using Al2O3 atomic layer deposition and alucone molecular layer deposition. Appl. Phys. Lett. 2012, 101, 234103. [Google Scholar] [CrossRef]

- Jarvis, K.L.; Evans, P.J. Growth of thin barrier films on flexible polymer substrates by atomic layer deposition. Thin Solid Film. 2017, 624, 111–135. [Google Scholar] [CrossRef]

- Groner, M.D.; George, S.M.; McLean, R.S.; Carcia, P.F. Gas diffusion barriers on polymers using Al2O3 atomic layer deposition. Appl. Phys. Lett. 2006, 88, 051907. [Google Scholar] [CrossRef]

- Meyer, J.; Schneidenbach, D.; Winkler, T.; Hamwi, S.; Weimann, T.; Hinze, P.; Ammermann, S.; Johannes, H.-H.; Riedl, T.; Kowalsky, W. Reliable thin film encapsulation for organic light emitting diodes grown by low-temperature atomic layer deposition. Appl. Phys. Lett. 2009, 94, 233305. [Google Scholar] [CrossRef]

- Kim, L.H.; Kim, K.; Park, S.; Jeong, Y.J.; Kim, H.; Chung, D.S.; Kim, S.H.; Park, C.E. Al2O3/TiO2 nanolaminate thin film encapsulation for organic thin film transistors via plasma-enhanced atomic layer deposition. ACS Appl. Mater. Interfaces 2014, 6, 6731–6738. [Google Scholar] [CrossRef]

- Shih, H. A Systematic Study and Characterization of Advanced Corrosion Resistance Materials and Their Applications for Plasma Etching Processes in Semiconductor Silicon Wafer Fabrication. In Corrosion Resistance; IntechOpen: London, UK, 2012. [Google Scholar]

- Matero, R.; Ritala, M.; Leskela, M.; Salo, T.; Aromaa, J.; Forsen, O. Atomic layer deposited thin films for corrosion protection. J. Phys. IV 1999, 9, 493–499. [Google Scholar] [CrossRef]

- Härkönen, E.; Diaz, B.; Światowska, J.; Maurice, V.; Seyeux, A.; Vehkamaki, M.; Sajavaara, T.; Fenker, M.; Marcus, P.; Ritala, M. Corrosion Protection of Steel with Oxide Nanolaminates Grown by Atomic Layer Deposition. J. Electrochem. Soc. 2011, 158, C369. [Google Scholar] [CrossRef]

- Härkönen, E.; Kolev, I.; Díaz, B.; Światowska, J.; Maurice, V.; Seyeux, A.; Marcus, P.; Fenker, M.; Toth, L.; Radnoczi, G.; et al. Sealing of Hard CrN and DLC Coatings with Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2014, 6, 1893–1901. [Google Scholar] [CrossRef]

- Daubert, J.S.; Hill, G.T.; Gotsch, H.N.; Gremaud, A.P.; Ovental, J.S.; Williams, P.S.; Oldham, C.J.; Parsons, G.N. Corrosion protection of copper using Al2O3, TiO2, ZnO, HfO2, and ZrO2 Atomic layer deposition. ACS Appl. Mater. Interfaces 2017, 9, 4192–4201. [Google Scholar] [CrossRef]

- Lin, Y.Y.; Hsu, C.C.; Tseng, M.H.; Shyue, J.J.; Tsai, F.Y. Stable and High-Performance Flexible ZnO Thin-Film Transistors by Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2015, 7, 22610–22617. [Google Scholar] [CrossRef] [PubMed]

- Sheng, J.; Park, J.; Choi, D.; Lim, J.; Park, J.-S. A Study on the Electrical Properties of Atomic Layer Deposition Grown InOx on Flexible Substrates with Respect to N2O Plasma Treatment and the Associated Thin-Film Transistor Behavior under Repetitive Mechanical Stress. ACS Appl. Mater. Interfaces 2016, 8, 31136–31143. [Google Scholar] [CrossRef] [PubMed]

- Jen, S.-H.; Bertrand, J.A.; George, S.M. Critical tensile and compressive strains for cracking of Al2O3 films grown by atomic layer deposition. J. Appl. Phys. 2011, 109, 084305. [Google Scholar] [CrossRef]

- Sun, Y.; Padbury, R.P.; Akyildiz, H.I.; Goertz, M.P.; Palmer, J.A.; Jur, J.S.; Sun, B.Y.; Padbury, R.P.; Akyildiz, H.I.; Goertz, M.P.; et al. Influence of subsurface hybrid material growth on the mechanical properties of atomic layer deposited thin films on polymers. Chem. Vap. Depos. 2013, 19, 134–141. [Google Scholar] [CrossRef]

- Miller, D.C.; Foster, R.R.; Zhang, Y.; Jen, S.-H.; Bertrand, J.A.; Lu, Z.; Seghete, D.; O’Patchen, J.L.; Yang, R.; Lee, Y.-C.; et al. The mechanical robustness of atomic-layer- and molecular-layer-deposited coatings on polymer substrates. J. Appl. Phys. 2009, 105, 093527. [Google Scholar] [CrossRef]

- Bulusu, A.; Graham, S.; Bahre, H.; Behm, H.; Böke, M.; Dahlmann, R.; Hopmann, C.; Winter, J.J.; Böke, M.; Dahlmann, R.; et al. The Mechanical Behavior of ALD-Polymer Hybrid Films Under Tensile Strain. Adv. Eng. Mater. 2015, 17, 1057–1067. [Google Scholar] [CrossRef]

- Latella, B.A.; Triani, G.; Evans, P.J. Toughness and adhesion of atomic layer deposited alumina films on polycarbonate substrates. Scr. Mater. 2007, 56, 493–496. [Google Scholar] [CrossRef]

- Triani, G.; Campbell, J.A.; Evans, P.J.; Davis, J.; Latella, B.A.; Burford, R.P. Low temperature atomic layer deposition of titania thin films. Thin Solid Film. 2010, 518, 3182–3189. [Google Scholar] [CrossRef]

- Song, S.H.; Lee, M.Y.; Lee, G.B.; Choi, B.-H. Characterization of Al2O3 and ZnO multilayer thin films deposited by low temperature thermal atomic layer deposition on transparent polyimide. J. Vac. Sci. Technol. A Vac. Surf. Film. 2017, 35, 01B110. [Google Scholar] [CrossRef]

- Ruoho, M.; Juntunen, T.; Tittonen, I. Large-area thermoelectric high-aspect-ratio nanostructures by atomic layer deposition. Nanotechnology 2016, 27, 355403. [Google Scholar] [CrossRef]

- Ruoho, M.; Juntunen, T.; Alasaarela, T.; Pudas, M.; Tittonen, I. Transparent, Flexible, and Passive Thermal Touch Panel. Adv. Mater. Technol. 2016, 1, 1600204. [Google Scholar] [CrossRef]

- Guerra-Nuñez, C.; Döbeli, M.; Michler, J.; Utke, I. Reaction and Growth Mechanisms in Al2O3 deposited via Atomic Layer Deposition: Elucidating the Hydrogen Source. Chem. Mater. 2017, 29, 8690–8703. [Google Scholar] [CrossRef]

- Ruoho, M.; Tarasiuk, N.; Rohbeck, N.; Kapusta, C.; Michler, J.; Utke, I. Stability of mechanical properties of molecular layer–deposited alucone. Mater. Today Chem. 2018, 10, 187–194. [Google Scholar] [CrossRef]

- Leterrier, Y.; Boogh, L.; Andersons, J.; Månson, J.A.E. Adhesion of silicon oxide layers on poly(ethylene terephthalate). I: Effect of substrate properties on coating’s fragmentation process. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 1449–1461. [Google Scholar] [CrossRef]

- Leterrier, Y.; Andersons, J.; Pitton, Y.; Månson, J.A.E. Adhesion of silicon oxide layers on poly(ethylene terephthalate). II: Effect of coating thickness on adhesive and cohesive strengths. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 1463–1472. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Dundurs, J. Discussion: “Edge-Bonded Dissimilar Orthogonal Elastic Wedges Under Normal and Shear Loading” (Bogy, D.B., 1968, ASME J. Appl. Mech., 35, pp. 460–466). J. Appl. Mech. 1969, 36, 650. [Google Scholar] [CrossRef]

- Beuth, J.L. Cracking of thin bonded films in residual tension. Int. J. Solids Struct. 1992, 29, 1657–1675. [Google Scholar] [CrossRef]

- Ylivaara, O.M.E.; Liu, X.; Kilpi, L.; Lyytinen, J.; Schneider, D.; Laitinen, M.; Julin, J.; Ali, S.; Sintonen, S.; Berdova, M.; et al. Aluminum oxide from trimethylaluminum and water by atomic layer deposition: The temperature dependence of residual stress, elastic modulus, hardness and adhesion. Thin Solid Film. 2014, 552, 124–135. [Google Scholar] [CrossRef]

- Lewis, J. Material challenge for flexible organic devices. Mater. Today 2006, 9, 38–45. [Google Scholar] [CrossRef]

- Raghavan, R.; Bechelany, M.; Parlinska, M.; Frey, D.; Mook, W.M.; Beyer, A.; Michler, J.; Utke, I. Nanocrystalline-to-amorphous transition in nanolaminates grown by low temperature atomic layer deposition and related mechanical properties. Appl. Phys. Lett. 2012, 100, 191912. [Google Scholar] [CrossRef]

- Niinistö, J.; Putkonen, M.; Niinistö, L. Processing of Y2O3 Thin Films by Atomic Layer Deposition from Cyclopentadienyl-Type Compounds and Water as Precursors. Chem. Mater. 2004, 16, 2953–2958. [Google Scholar] [CrossRef]

- Lin, K.Y.; Young, L.B.; Cheng, C.K.; Chen, K.H.; Lin, Y.H.; Wan, H.W.; Cai, R.F.; Lo, S.C.; Li, M.Y.; Kwo, J.; et al. Enhancement of effective dielectric constant using high-temperature mixed and sub-nano-laminated atomic layer deposited Y2O3/Al2O3 on GaAs(001). Microelectron. Eng. 2017, 178, 271–274. [Google Scholar] [CrossRef]

- Elam, J.W.; George, S.M. Growth of ZnO/Al2O3 Alloy Films Using Atomic Layer Deposition Techniques. Chem. Mater. 2003, 15, 1020–1028. [Google Scholar] [CrossRef]

- Jensen, J.M.; Oelkers, A.B.; Toivola, R.; Johnson, D.C.; Elam, J.W.; George, S.M. X-ray Reflectivity Characterization of ZnO/Al2O3 Multilayers Prepared by Atomic Layer Deposition. Chem. Mater. 2002, 14, 2276–2282. [Google Scholar] [CrossRef]

- Karvonen, L.; Säynätjoki, A.; Chen, Y.; Jussila, H.; Rönn, J.; Ruoho, M.; Alasaarela, T.; Kujala, S.; Norwood, R.A.; Peyghambarian, N.; et al. Enhancement of the third-order optical nonlinearity in ZnO/Al2O3 nanolaminates fabricated by atomic layer deposition. Appl. Phys. Lett. 2013, 103, 031903. [Google Scholar] [CrossRef]

- Niemelä, J.-P.; Marin, G.; Karppinen, M. Titanium dioxide thin films by atomic layer deposition: A review. Semicond. Sci. Technol. 2017, 32, 093005. [Google Scholar] [CrossRef]

- Kukli, K.; Ritala, M.; Leskelä, M. Low-Temperature Deposition of Zirconium Oxide-Based Nanocrystalline Films by Alternate Supply of Zr[OC(CH3)3]4 and H2O. Chem. Vap. Depos. 2000, 6, 297–302. [Google Scholar] [CrossRef]

- Kukli, K.; Ritala, M.; Leskelä, M. Properties of (Nb1-xTax)2O5 solid solutions and (Nb1-xTax)2O5-ZrO2 nanolaminates grown by Atomic Layer Epitaxy. Nanostruct. Mater. 1997, 8, 785–793. [Google Scholar] [CrossRef]

- Djurado, E.; Bouvier, P.; Lucazeau, G. Crystallite Size Effect on the Tetragonal-Monoclinic Transition of Undoped Nanocrystalline Zirconia Studied by XRD and Raman Spectrometry. J. Solid State Chem. 2000, 149, 399–407. [Google Scholar] [CrossRef]

- Frank, S.; Handge, U.A.; Olliges, S.; Spolenak, R. The relationship between thin film fragmentation and buckle formation: Synchrotron-based In Situ studies and two-dimensional stress analysis. Acta Mater. 2009, 57, 1442–1453. [Google Scholar] [CrossRef]

- Chawla, V.; Ruoho, M.; Weber, M.; Chaaya, A.A.; Taylor, A.A.; Charmette, C.; Miele, P.; Bechelany, M.; Michler, J.; Utke, I. Fracture Mechanics and Oxygen Gas Barrier Properties of Al2O3/ZnO Nanolaminates on PET Deposited by Atomic Layer Deposition. Nanomaterials 2019, 9, 88. [Google Scholar] [CrossRef]

- Laws, N.; Dvorak, G.J. Progressive Transverse Cracking In Composite Laminates. J. Compos. Mater. 1988, 22, 900–916. [Google Scholar] [CrossRef]

- Leterrier, Y.; Mottet, A.; Bouquet, N.; Gilliéron, D.; Dumont, P.; Pinyol, A.; Lalande, L.; Waller, J.H.; Månson, J.A.E. Mechanical integrity of thin inorganic coatings on polymer substrates under quasi-static, thermal and fatigue loadings. Thin Solid Film. 2010, 519, 1729–1737. [Google Scholar] [CrossRef]

- Bull, S.J. Mechanical response of atomic layer deposition alumina coatings on stiff and compliant substrates. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 01A160. [Google Scholar] [CrossRef]

- DUPONTTM KAPTON® HN. Available online: https://www.dupont.com/content/dam/dupont/products-and-services/membranes-and-films/polyimde-films/documents/DEC-Kapton-HN-datasheet.pdf (accessed on 11 November 2019).

- Tripp, M.K.; Stampfer, C.; Miller, D.C.; Helbling, T.; Herrmann, C.F.; Hierold, C.; Gall, K.; George, S.M.; Bright, V.M. The mechanical properties of atomic layer deposited alumina for use in micro- and nano-electromechanical systems. Sens. Actuators A Phys. 2006, 130–131, 419–429. [Google Scholar] [CrossRef]

- Hahtela, O.; Sievila, P.; Chekurov, N.; Tittonen, I. Atomic layer deposited alumina Al2O3 thin films on a high-Q mechanical silicon oscillator. J. Micromech. Microeng. 2007, 17, 737–742. [Google Scholar] [CrossRef][Green Version]

- Miller, D.C.; Foster, R.R.; Jen, S.H.; Bertrand, J.A.; Cunningham, S.J.; Morris, A.S.; Lee, Y.C.; George, S.M.; Dunn, M.L. Thermo-mechanical properties of alumina films created using the atomic layer deposition technique. Sens. Actuators A Phys. 2010, 164, 58–67. [Google Scholar] [CrossRef]

- Jõgiaas, T.; Zabels, R.; Tamm, A.; Merisalu, M.; Hussainova, I.; Heikkilä, M.; Mändar, H.; Kukli, K.; Ritala, M.; Leskelä, M. Mechanical properties of aluminum, zirconium, hafnium and tantalum oxides and their nanolaminates grown by atomic layer deposition. Surf. Coat. Technol. 2015, 282, 36–42. [Google Scholar] [CrossRef]

- Tapily, K.; Jakes, J.; Stone, D.; Shrestha, P.; Gu, D.; Baumgart, H.; Elmustafa, A. Nanomechanical Properties of High-K Dielectrics Grown by Atomic Layer Deposition. ECS Trans. 2007, 11, 123–130. [Google Scholar]

- Rochat, G.; Delachaux, A.; Leterrier, Y.; Månson, J.-A.A.E.; Fayet, P. Influence of substrate morphology on the cohesion and adhesion of thin PECVD oxide films on semi-crystalline polymers. Surf. Interface Anal. 2003, 35, 948–952. [Google Scholar] [CrossRef]

- Dameron, A.A.; Miller, D.C.; George, N.; To, B.; Ginley, D.S.; Simpson, L. Tensile strain and water vapor transport testing of flexible, conductive and transparent indium-zinc-oxide/silver/indium-zinc-oxide thin films. Thin Solid Film. 2011, 519, 3177–3184. [Google Scholar] [CrossRef]

- Munro, R.G.; Freiman, S.W.; Baker, T.L. Fracture Toughness Data for Brittle Materials; NISTIR 6153; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1998. [Google Scholar]

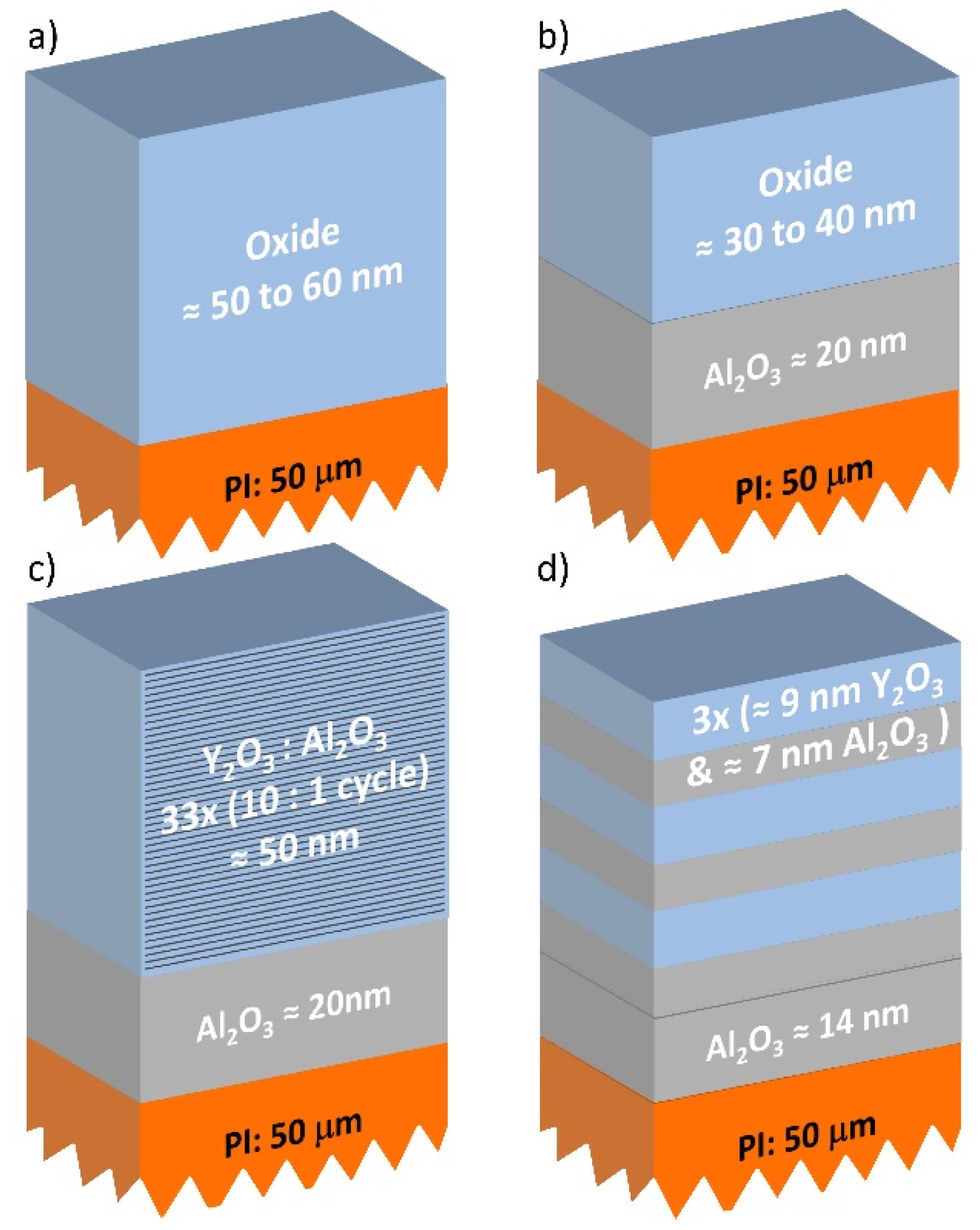

| Sample | Metal Precursor (1) and Temperature | ALD (°C) | Number of ALD Cycles | Total Film Thickness (nm) on Si | Thickness Top Oxide (nm) | Interfacial Al2O3 (nm) | Density (g cm−3) |

|---|---|---|---|---|---|---|---|

| Al2O3 | TMA 25 °C | 135 | 440 | 53 | - | - | 3.00 |

| Al2O3 | TMA 25 °C | 155 | 440 | 55 | - | - | 3.2 |

| Al2O3 | TMA 25 °C | 220 | 440 | 49 | - | - | 3.3 [23] |

| ZnO | DEZn 25 °C | 155 | 500 | 46 | - | - | 5.60 |

| Y2O3 | YMeCp 150 °C | 220 | 400 | 55 | - | - | 4.50 |

| Y2O3 on Al2O3 | YMeCp 150 °C | 220 | 190 + 280 | 63 | 42 | 21 | (2) |

| Al-doped Y2O3 on Al2O3 | YMeCp 150 °C | 220 | 195 + 33 × (1:10) | 75 | 53 | 22 | (2) |

| TiO2 on Al2O3 | TTIP 75 °C | 200 | 190 + 1000 | 58 | 37 | 21 | (2) |

| ZrO2 on Al2O3 | ZrBuO 75 °C | 220 | 190 + 340 | 50 | 32 | 22 | (2) |

| 3 × NL Y2O3/Al2O3 on Al2O3 | YMeCp 150 °C and TMA 25 °C | 220 | 115 + (75/57) × 3 | 63 | 3 × (9.1/7.4) | 14 | (2) |

| Sample | Total Thickness (nm) | Crack Onset Strain (%) | Normalized COS (%) (50 nm) | Saturation Crack Density (mm−1) | Normalized sCD (mm−1) (50 nm) | Bend Radii (mm) | Cohesive Strain (%) | Interfacial Shear Strain (‰) |

|---|---|---|---|---|---|---|---|---|

| Al2O3 135 °C | 53 | 0.77 ± 0.1 | 0.79 | 300 ± 28 | 310 | 3.2 | 1.3 ± 0.3 | 0.26 ± 0.07 |

| Al2O3 155 °C | 55 | 0.99 ± 0.12 | 1.0 | 280 ± 30 | 300 | 2.5 | 1.3 ± 0.1 | 0.25 ± 0.04 |

| Al2O3 220 °C | 49 | 1.2 ± 0.16 | 1.2 | 280 ± 28 | 280 | 2.1 | 1.5 ± 0.23 | 0.28 ± 0.06 |

| ZnO | 46 | 1.0 ± 0.12 | 0.98 | 550 ± 35 | 530 | 2.4 | 1.2 ± 0.12 | 0.4 ± 0.06 |

| Y2O3 | 46 | 0.70 ± 0.09 | 0.67 | 610 ± 90 | 580 | 3.6 | 1.1 ± 0.26 | 0.42 ± 0.12 |

| Y2O3 on Al2O3 | 63 | 0.93 ± 0.12 | 1.0 | 380 ± 36 | 430 | 2.7 | 1.2 ± 0.25 | 0.38 ± 0.1 |

| Al/Y2O3 on Al2O3 | 75 | 0.85 ± 0.12 | 1.0 | 330 ± 31 | 400 | 3.0 | 1.2 ± 0.2 | 0.41 ± 0.09 |

| TiO2 on Al2O3 | 58 | 1.2 ± 0.15 | 1.3 | 360 ± 25 | 390 | 2.1 | 1.5 ± 0.3 | 0.41 ± 0.09 |

| ZrO2 on Al2O3 | 50 | 1.3 ± 0.15 | 1.3 | 370 ± 28 | 370 | 2.0 | 1.6 ± 0.2 | 0.38 ± 0.07 |

| Y2O3–Al2O3 NL on Al2O3 | 63 | 0.93 ± 0.11 | 1.0 | 280 ± 24 | 310 | 2.5 | 1.5 ± 0.2 | 0.41 ± 0.07 |

| Al2O3 ALD (°C) | E (GPa) | (%) | (%) | (%) | Cohesive Strength (GPa) | Interfacial Shear Strength (MPa) | Fracture Energy (J m−2) | Fracture Toughness (MPa·m0.5) |

|---|---|---|---|---|---|---|---|---|

| 135 | 150 | 0.27 | −0.19 | 0.07 | 2.1 ± 0.5 | 45 ± 11 | 12 ± 6 | 1.3 ± 0.7 |

| 155 | 170 | 0.19 | −0.25 | −0.05 | 2.2 ± 0.2 | 43 ± 4 | 17 ± 8 | 1.7 ± 0.9 |

| 220 | 170 | 0.16 | −0.44 | −0.29 | 2.6 ± 0.4 | 48 ± 7 | 12 ± 6 | 1.4 ± 0.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruoho, M.; Niemelä, J.-P.; Guerra-Nunez, C.; Tarasiuk, N.; Robertson, G.; Taylor, A.A.; Maeder, X.; Kapusta, C.; Michler, J.; Utke, I. Thin-Film Engineering of Mechanical Fragmentation Properties of Atomic-Layer-Deposited Metal Oxides. Nanomaterials 2020, 10, 558. https://doi.org/10.3390/nano10030558

Ruoho M, Niemelä J-P, Guerra-Nunez C, Tarasiuk N, Robertson G, Taylor AA, Maeder X, Kapusta C, Michler J, Utke I. Thin-Film Engineering of Mechanical Fragmentation Properties of Atomic-Layer-Deposited Metal Oxides. Nanomaterials. 2020; 10(3):558. https://doi.org/10.3390/nano10030558

Chicago/Turabian StyleRuoho, Mikko, Janne-Petteri Niemelä, Carlos Guerra-Nunez, Natalia Tarasiuk, Georgina Robertson, Aidan A. Taylor, Xavier Maeder, Czeslaw Kapusta, Johann Michler, and Ivo Utke. 2020. "Thin-Film Engineering of Mechanical Fragmentation Properties of Atomic-Layer-Deposited Metal Oxides" Nanomaterials 10, no. 3: 558. https://doi.org/10.3390/nano10030558

APA StyleRuoho, M., Niemelä, J.-P., Guerra-Nunez, C., Tarasiuk, N., Robertson, G., Taylor, A. A., Maeder, X., Kapusta, C., Michler, J., & Utke, I. (2020). Thin-Film Engineering of Mechanical Fragmentation Properties of Atomic-Layer-Deposited Metal Oxides. Nanomaterials, 10(3), 558. https://doi.org/10.3390/nano10030558