Polarity Control of ZnO Films Grown on Ferroelectric (0001) LiNbO3 Substrates without Buffer Layers by Pulsed-Laser Deposition

Abstract

1. Introduction

2. Experimentals

3. Results and Discussion

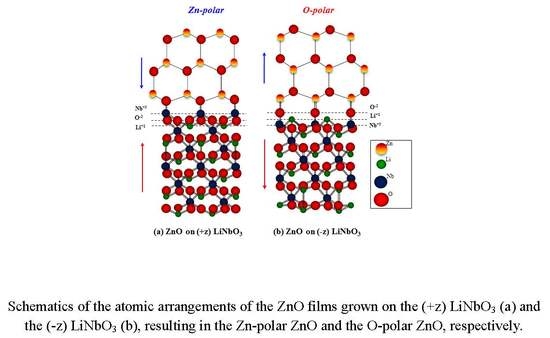

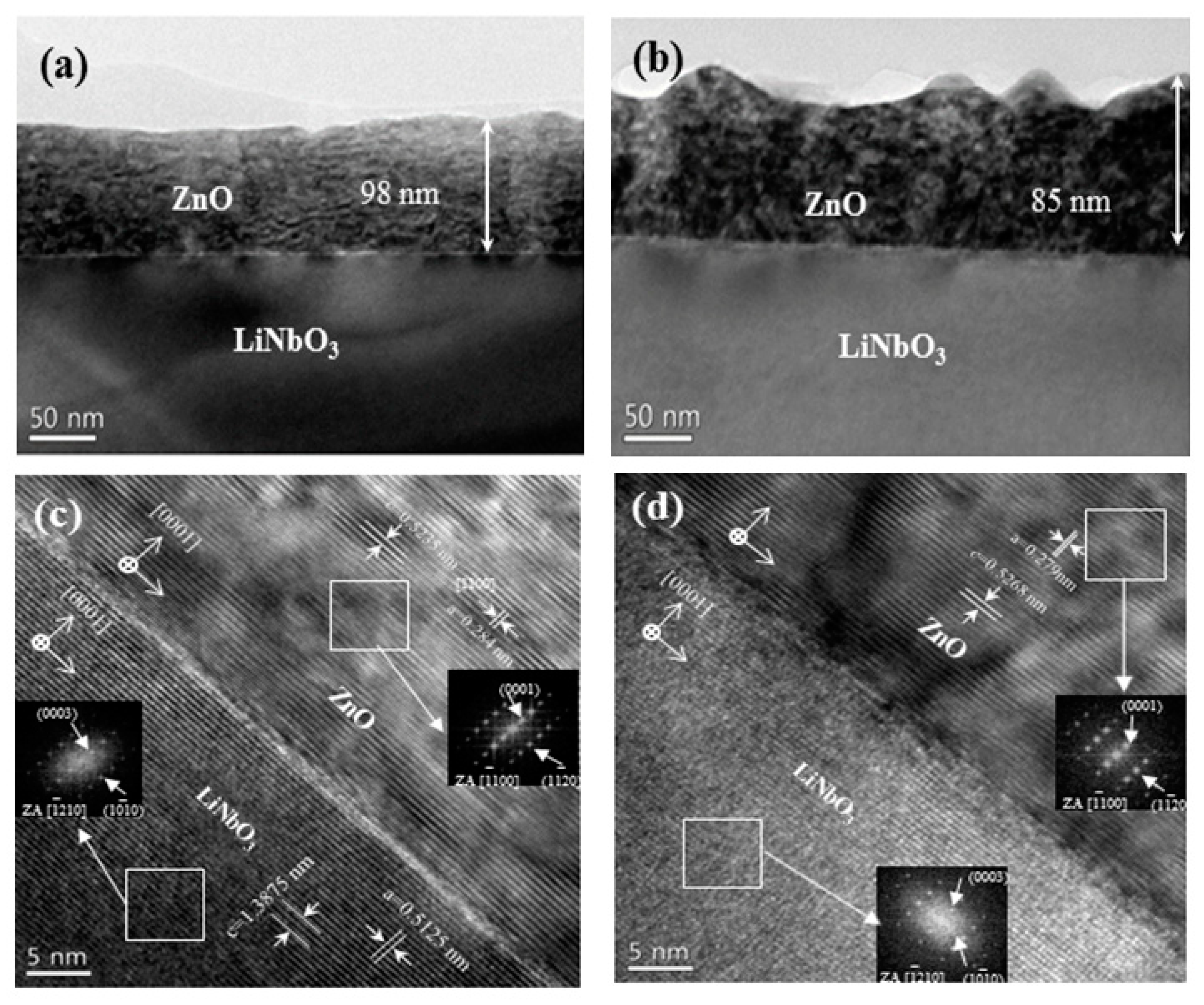

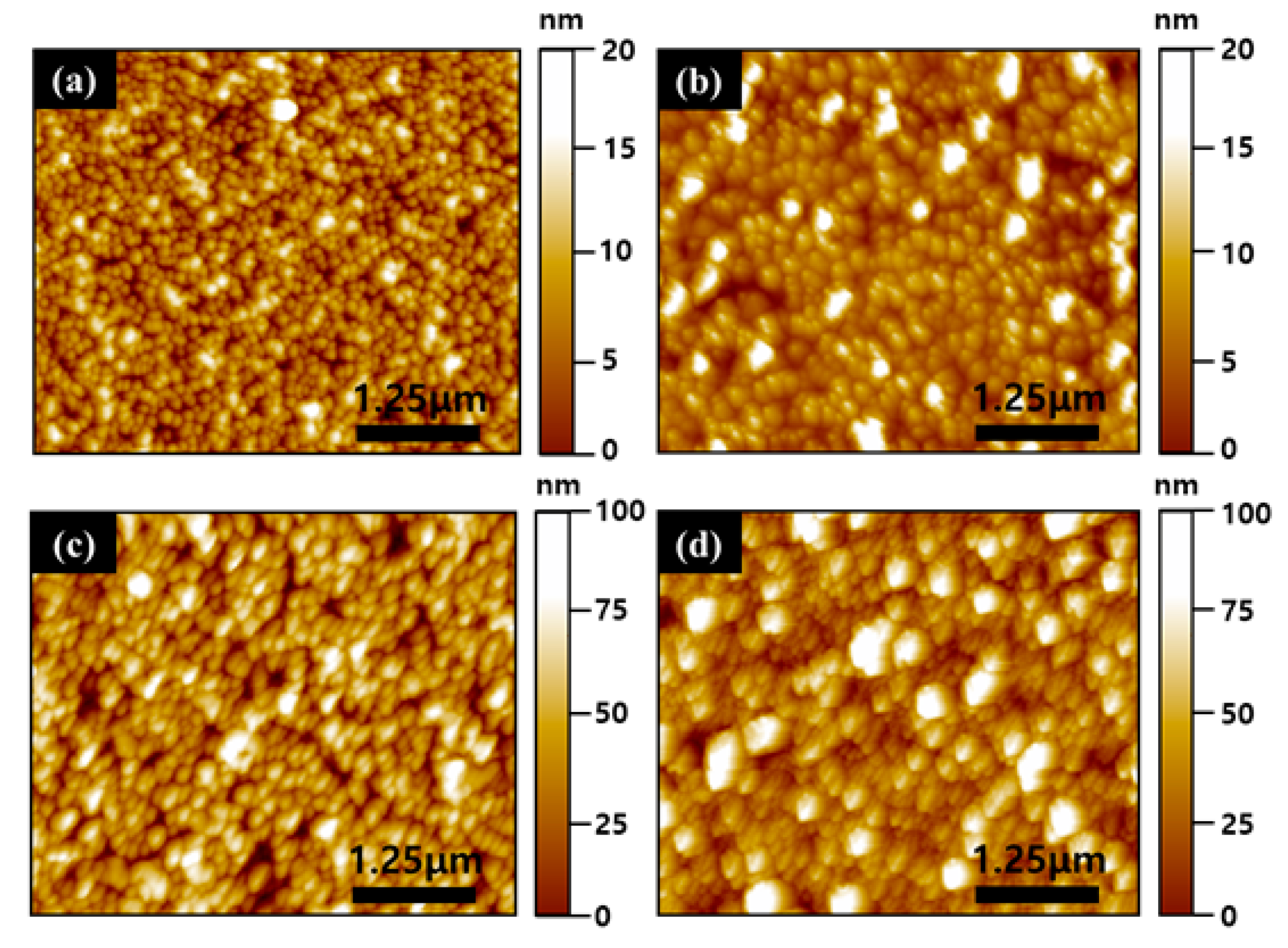

3.1. Crystal-Structure Analysis

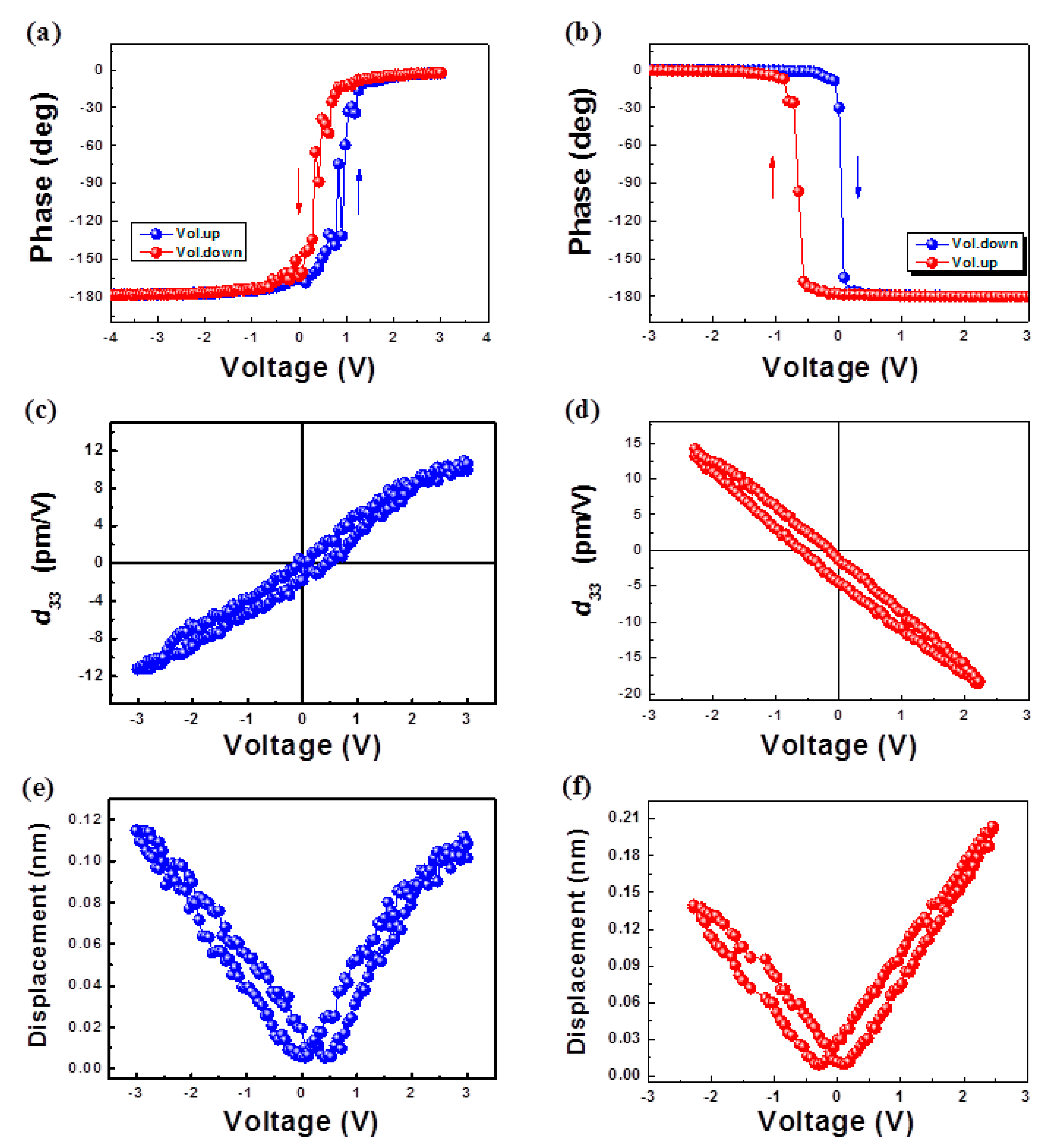

3.2. The Polarity Determination

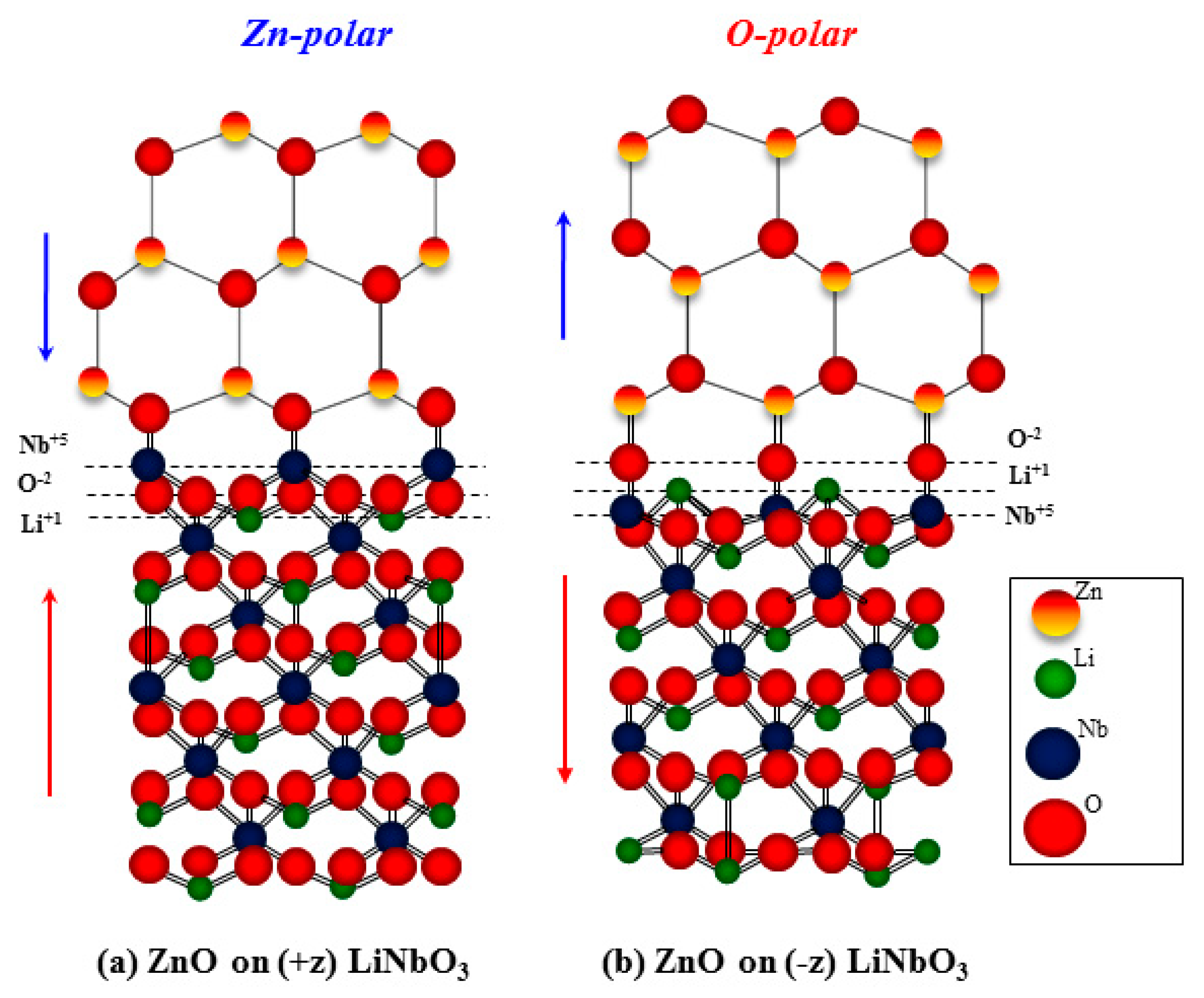

3.3. The Possible Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Tomita, Y.; Roh, O.-H.; Ohsugi, M.; Che, S.-B.; Ishitani, Y.; Yoshikawa, A. Polarity control of ZnO films grown on nitrided c-sapphire by molecular-beam epitaxy. Appl. Phys. Lett. 2005, 86, 011921. [Google Scholar] [CrossRef]

- Tampo, H.; Fons, P.; Yamada, A.; Kim, K.-K.; Shibata, H.; Matsubara, K.; Niki, S.; Yoshikawa, H.; Kanie, H. Determination of crystallographic polarity of ZnO layers. Appl. Phys. Lett. 2005, 87, 141904. [Google Scholar] [CrossRef]

- Kobayashi, A.; Kawaguchi, Y.; Ohta, J.; Fujioka, H.; Fujiwara, K.; Ishii, A. Polarity control of GaN grown on ZnO (000-1) surfaces. Appl. Phys. Lett. 2006, 88, 181907. [Google Scholar] [CrossRef]

- Guan, Z.P.; Cai, A.L.; Cabalu, J.S.; Porter, H.L.; Huang, S. Molecular beam epitaxy growth of GaN on C-terminated 6H–SiC (000-1) surface. Appl. Phys. Lett. 2000, 77, 2491. [Google Scholar] [CrossRef]

- Monroy, E.; Sarigiannidou, E.; Fossard, F.; Gogneau, N.; Bellet-Amalric, E.; Rouvière, J.-L.; Monnoye, S.; Mank, H.; Daudin, B. Growth kinetics of N-face polarity GaN by plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 2004, 84, 3684. [Google Scholar] [CrossRef]

- Fichtenbaum, N.A.; Neufeld, C.J.; Schaake, C.; Wu, Y.; Wong, M.H.; Grundmann, M.; Keller, S.; Denbaars, S.P.; Speck, J.S.; Mishra, U.K. MOCVD regrowth of InGaN on N-polar and Ga-polar pillar and stripe nanostructures. Phys. Status Solidi B 2007, 244, 1802–1805. [Google Scholar] [CrossRef]

- Ye, Z.-G. Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials; Woodhead Publishing: Cambridge, MA, USA, 2009. [Google Scholar]

- Tovstonog, S.V.; Kurimura, S.; Kitamura, K. High power continuous-wave green light generation by quasiphase matching in Mg stoichiometric lithium tantalite. Appl. Phys. Lett. 2007, 90, 051115. [Google Scholar] [CrossRef]

- Park, J.; Yamazaki, Y.; Iwanaga, M.; Ahn, S.; Jeon, H.; Fujiwara, T.; Yao, T. Second harmonic generation in periodically polarity-inverted zinc oxide. Opt. Express 2010, 18, 7851–7856. [Google Scholar] [CrossRef]

- Sasaki, E.A.; Hara, W.; Matsuda, A.; Tateda, N.; Otaka, S.; Akiba, S.; Saito, K.; Yodo, T.; Yoshimoto, M. Buffer-enhanced room-temperature growth and characterization of epitaxial ZnO thin films. Appl. Phys. Lett. 2005, 86, 231911. [Google Scholar] [CrossRef]

- Adachi, Y.; Ohashi, N.; Ohnishi, T.; Ohgaki, T.; Sakaguchi, I.; Haneda, H.; Lippmaa, M. Change in polarity of zinc oxide films grown on sapphire substrates without insertion of any buffer layer. J. Mater. Res. 2008, 23, 3269–3272. [Google Scholar] [CrossRef]

- Adachi, Y.; Ohashi, N.; Ohgaki, T.; Ohnishi, T.; Sakaguchi, I.; Ueda, S.; Yoshikawa, H.; Kobayashi, K.; Williams, J.R.; Ogino, T. Polarity of heavily doped ZnO films grown on sapphire and SiO2 glass substrates by pulsed laser deposition. Thin Solid Films 2011, 519, 5875–5881. [Google Scholar] [CrossRef]

- Williams, J.R.; Furukawa, H.; Adachi, Y.; Grachev, S.; Sondergard, E.; Ohashi, N. Polarity control of intrinsic ZnO films using substrate bias. Appl. Phys. Lett. 2013, 103, 042107. [Google Scholar] [CrossRef]

- Wang, X.Q.; Sun, H.P.; Pan, X.Q. Effect of GaN interlayer on polarity control of epitaxial ZnO thin films grown by molecular beam epitaxy. Appl. Phys. Lett. 2010, 97, 151908. [Google Scholar] [CrossRef]

- Yin, J.; Liu, Z.G.; Liu, H.; Wang, X.S.; Zhu, T.; Liu, J.M. The epitaxial growth of wurtzite ZnO films on LiNbO3 (0 0 0 1) substrates. J. Cryst. Growth 2000, 220, 281–285. [Google Scholar] [CrossRef]

- Duclère, J.-R.; Novotny, M.; Meaneya, A.; O’Hairea, R.; McGlynna, E.; Henrya, M.O.; Mosniera, J.P. Properties of Li-, P- and N-doped ZnO thin films prepared by pulsed laser deposition. Superlattices Microstruct. 2005, 38, 397–405. [Google Scholar] [CrossRef]

- Jiao, S.J.; Zhang, Z.Z.; Lu, Y.M.; Shen, D.Z.; Yao, B.; Zhang, J.Y.; Li, B.H.; Zhao, D.X.; Fan, X.W.; Tang, Z.K. ZnO p-n junction light-emitting diodes fabricated on sapphire substrates. Appl. Phys. Lett. 2006, 88, 031911. [Google Scholar] [CrossRef]

- Wan, Q.; Li, Q.H.; Chen, Y.J.; Wang, T.H.; He, X.L.; Li, J.P.; Lin, C.L. Fabrication and ethanol sensing characteristics of ZnO nanowire gas sensors. Appl. Phys. Lett. 2004, 84, 3654. [Google Scholar] [CrossRef]

- Lee, J.; Subramaniam, N.G.; Kowalik, I.A.; Nisar, J.; Lee, J.; Kwon, Y.; Lee, J.; Kang, T.; Peng, X.; Arvanitis, D.; et al. Towards a new class of heavy ion doped magnetic semiconductors for room temperature applications. Sci. Rep. 2015, 5, 17053. [Google Scholar] [CrossRef][Green Version]

- Mariano, A.N.; Hanneman, R.E. Crystallographic Polarity of Zn Crystals. J. Appl. Phys. 1963, 34, 384–388. [Google Scholar] [CrossRef]

- Park, J.S.; Hong, S.K.; Minegishi, T.; Park, S.H.; Im, L.H.; Hanada, T.; Cho, M.W.; Yao, T.; Lee, J.W.; Lee, J.Y. Polarity control of ZnO on (0001) Al2O3 by Cr -compound intermediate layers. Appl. Phys. Lett. 2007, 90, 201907. [Google Scholar] [CrossRef]

- Minj, A.; Cros, A.; Garro, N.; Colchero, J.; Auzelle, T.; Daudin, B. Assessment of Polarity in GaN Self-Assembled Nanowires by Electrical Force Microscopy. Nano Lett. 2015, 15, 6770–6776. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.G.; Wouters, D.J.; Willems, G.; Maes, H.E. Voltage shift and deformation in the hysteresis loop of Pb(Zr,Ti)O3 thin film by defects. Appl. Phys. Lett. 1996, 69, 1223. [Google Scholar] [CrossRef]

- LI, C.P.; YANG, B.H. Local Piezoelectricity and Polarity Distribution of Preferred c-Axis-Oriented ZnO Film Investigated by Piezoresponse Force Microscopy. J. Electron. Mater. 2011, 40, 253–258. [Google Scholar] [CrossRef]

- Christman, J.A.; Woolcott, R.R.; Kingon, A.I.; Nemanich, R.J. Piezoelectric measurements with atomic force microscopy. Appl. Phys. Lett. 1998, 73, 3851. [Google Scholar] [CrossRef]

- Yang, Y.C.; Song, C.; Wang, X.H.; Zeng, F.; Pan, F. Giant piezoelectric d33 coefficient in ferroelectric vanadium doped ZnO films. Appl. Phys. Lett. 2008, 92, 012907. [Google Scholar] [CrossRef]

- Park, J.S.; Minegishi, T.; Ahn, S.; Park, S.H.; Hong, S.K.; Jeon, H.; Im, I.H.; Chang, J.H.; Yao, T. Fabrication of periodically polarity-inverted ZnO structures on (0001) Al2O3. Thin Solid Films 2010, 518, 4117–4120. [Google Scholar] [CrossRef]

- Weis, R.S.; Gaylord, T.K. Lithium niobate: Summary of physical properties and crystal structure. Appl. Phys. A 1985, 37, 191–203. [Google Scholar] [CrossRef]

- Rosenman, G.; ShurYa, D.; Krasik, E.; Dunaevsky, A. Electron emission from ferroelectrics. J. Appl. Phys. 2000, 88, 6109–6161. [Google Scholar] [CrossRef]

- Kim, D.W.; Bourim, E.M.; Jeong, S.H.; Yoo, I.K. Pyroelectric electron emissions and domain inversion of LiNbO3 single crystals. Phys. B 2004, 352, 200–205. [Google Scholar] [CrossRef]

- Saito, A.; Matsumoto, H.; Ohnisi, S.; Akai-kasaya, M.; Kuwahara, Y.; Aono, M. Structure of Atomically Smoothed LiNbO3 (0001) Surface. Jpn. J. Appl. Phys. 2004, 43, 2057–2060. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, I.T.; Lee, J.; Tran, N.C.; Yang, W. Polarity Control of ZnO Films Grown on Ferroelectric (0001) LiNbO3 Substrates without Buffer Layers by Pulsed-Laser Deposition. Nanomaterials 2020, 10, 380. https://doi.org/10.3390/nano10020380

Yoon IT, Lee J, Tran NC, Yang W. Polarity Control of ZnO Films Grown on Ferroelectric (0001) LiNbO3 Substrates without Buffer Layers by Pulsed-Laser Deposition. Nanomaterials. 2020; 10(2):380. https://doi.org/10.3390/nano10020380

Chicago/Turabian StyleYoon, Im Taek, Juwon Lee, Ngoc Cuong Tran, and Woochul Yang. 2020. "Polarity Control of ZnO Films Grown on Ferroelectric (0001) LiNbO3 Substrates without Buffer Layers by Pulsed-Laser Deposition" Nanomaterials 10, no. 2: 380. https://doi.org/10.3390/nano10020380

APA StyleYoon, I. T., Lee, J., Tran, N. C., & Yang, W. (2020). Polarity Control of ZnO Films Grown on Ferroelectric (0001) LiNbO3 Substrates without Buffer Layers by Pulsed-Laser Deposition. Nanomaterials, 10(2), 380. https://doi.org/10.3390/nano10020380