Highly Stretchable and Flexible Melt Spun Thermoplastic Conductive Yarns for Smart Textiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

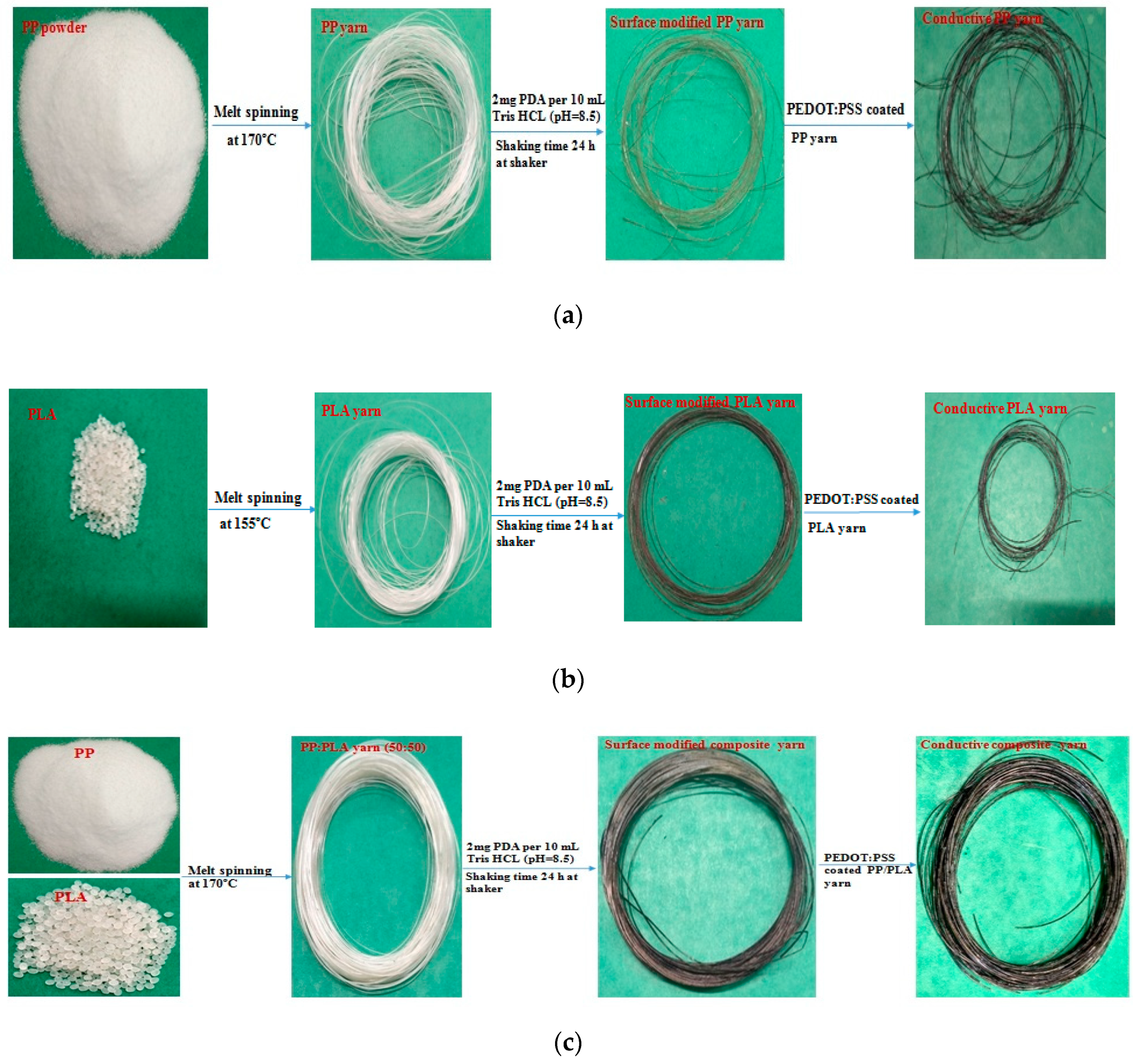

2.2. Preparation of Melt Spun Conductive Composite Yarns

2.3. Characterizations of Thermoplastic Yarns

3. Results and Discussion

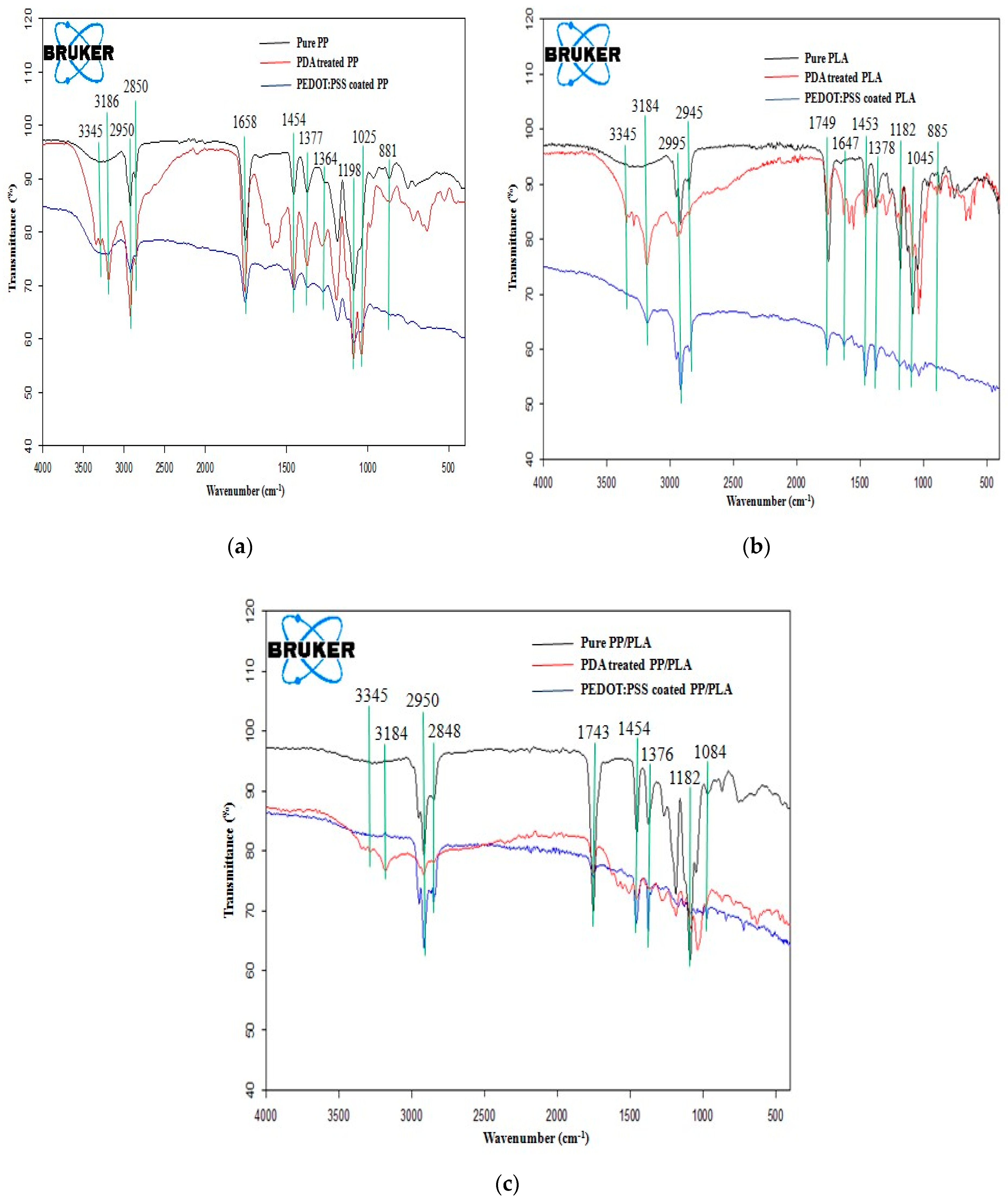

3.1. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

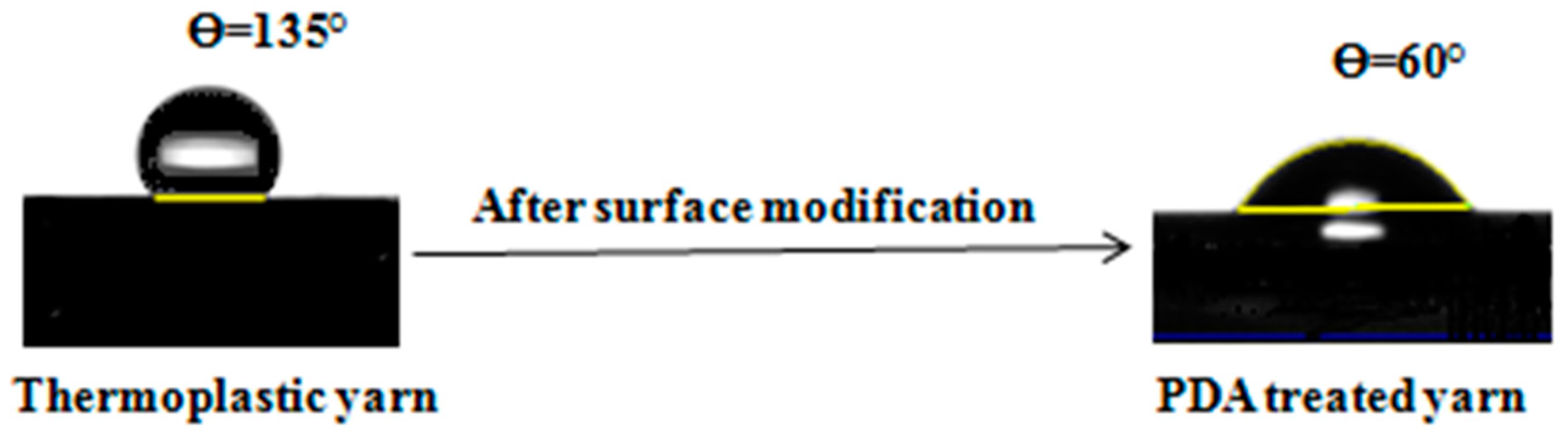

3.2. Contact Angle (CA) Analysis

3.3. Electrical Conductivity before Rinsing

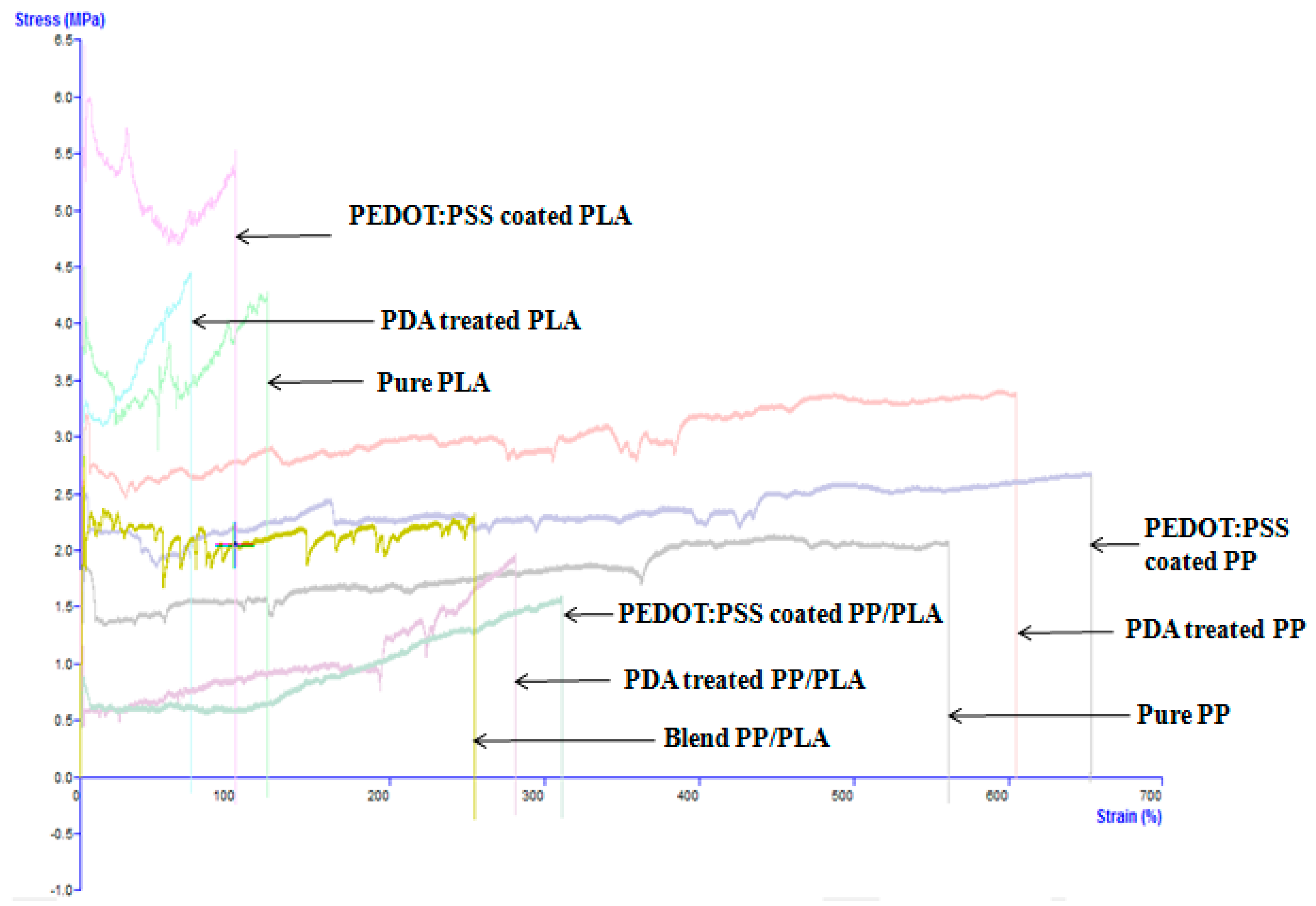

3.4. Tensile Properties Analysis

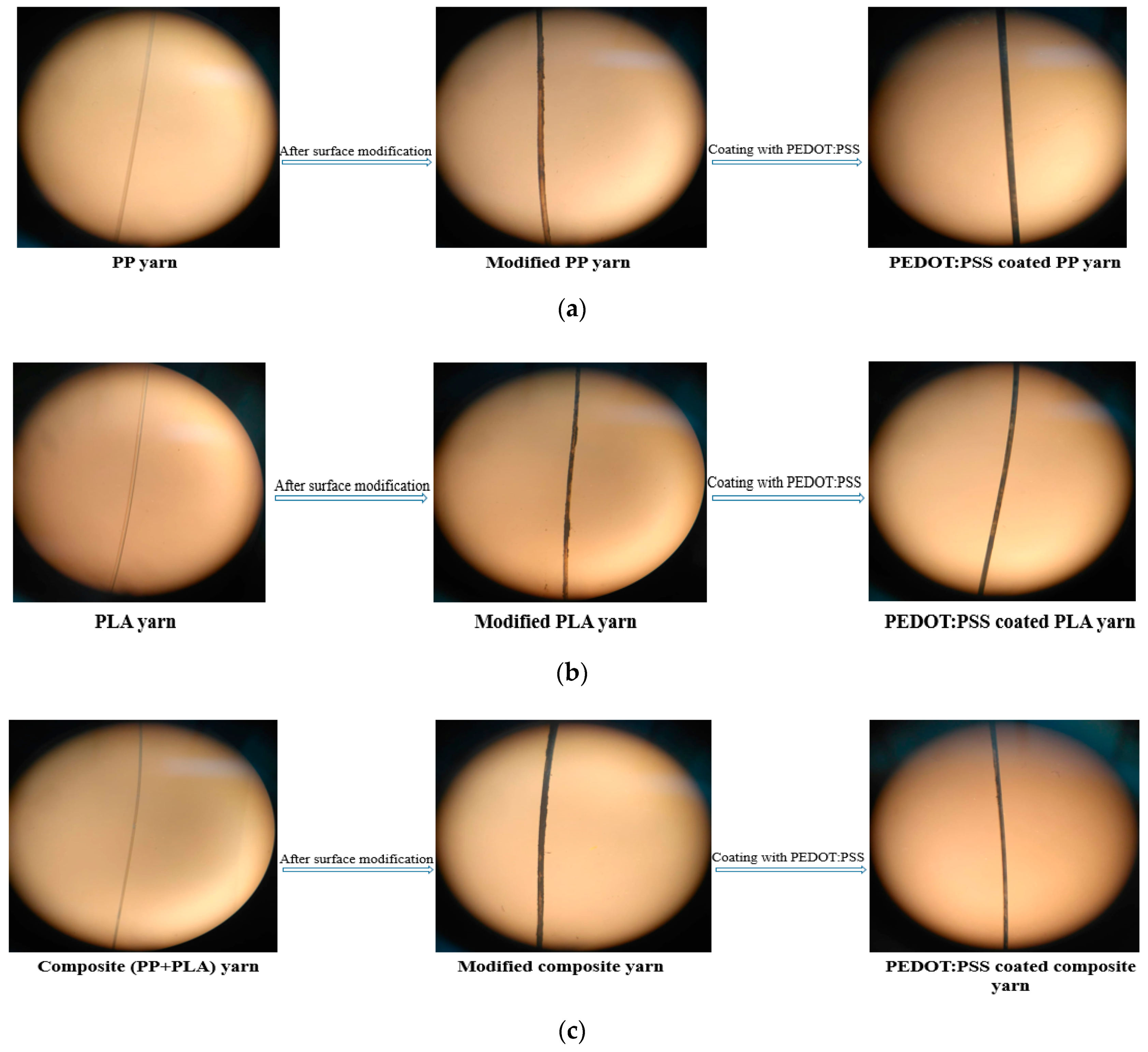

3.5. Optical Microscopy Images Analysis

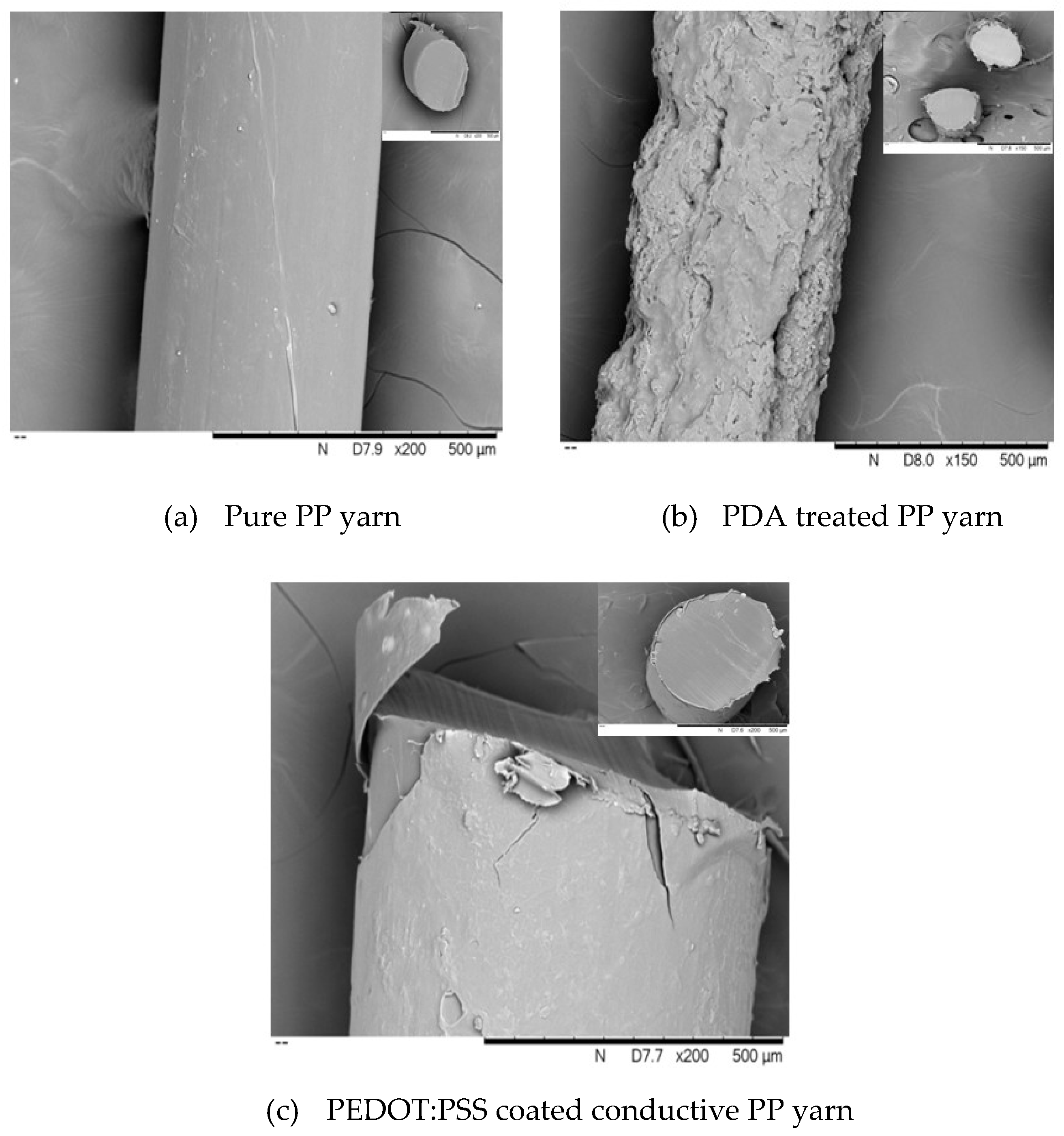

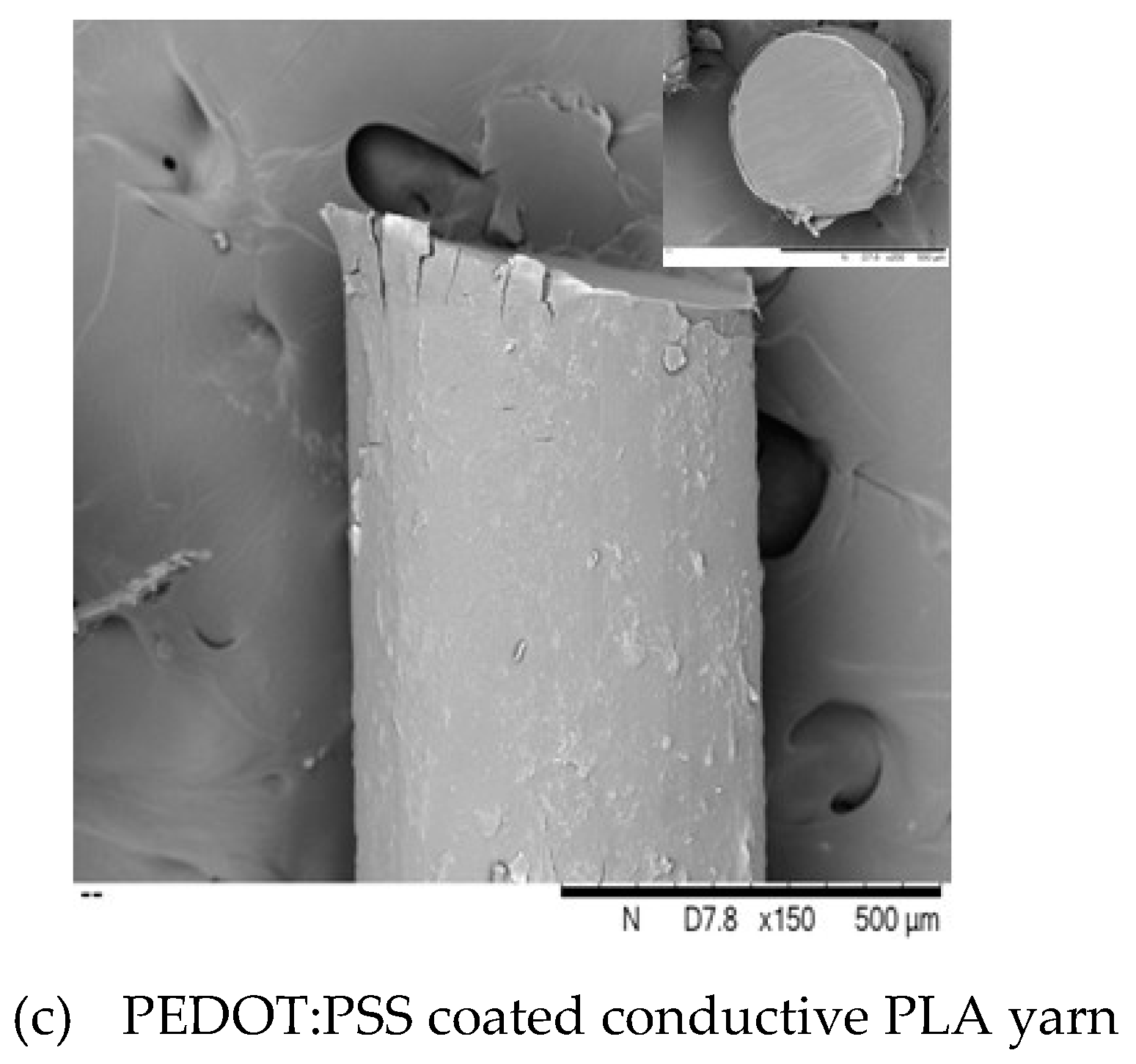

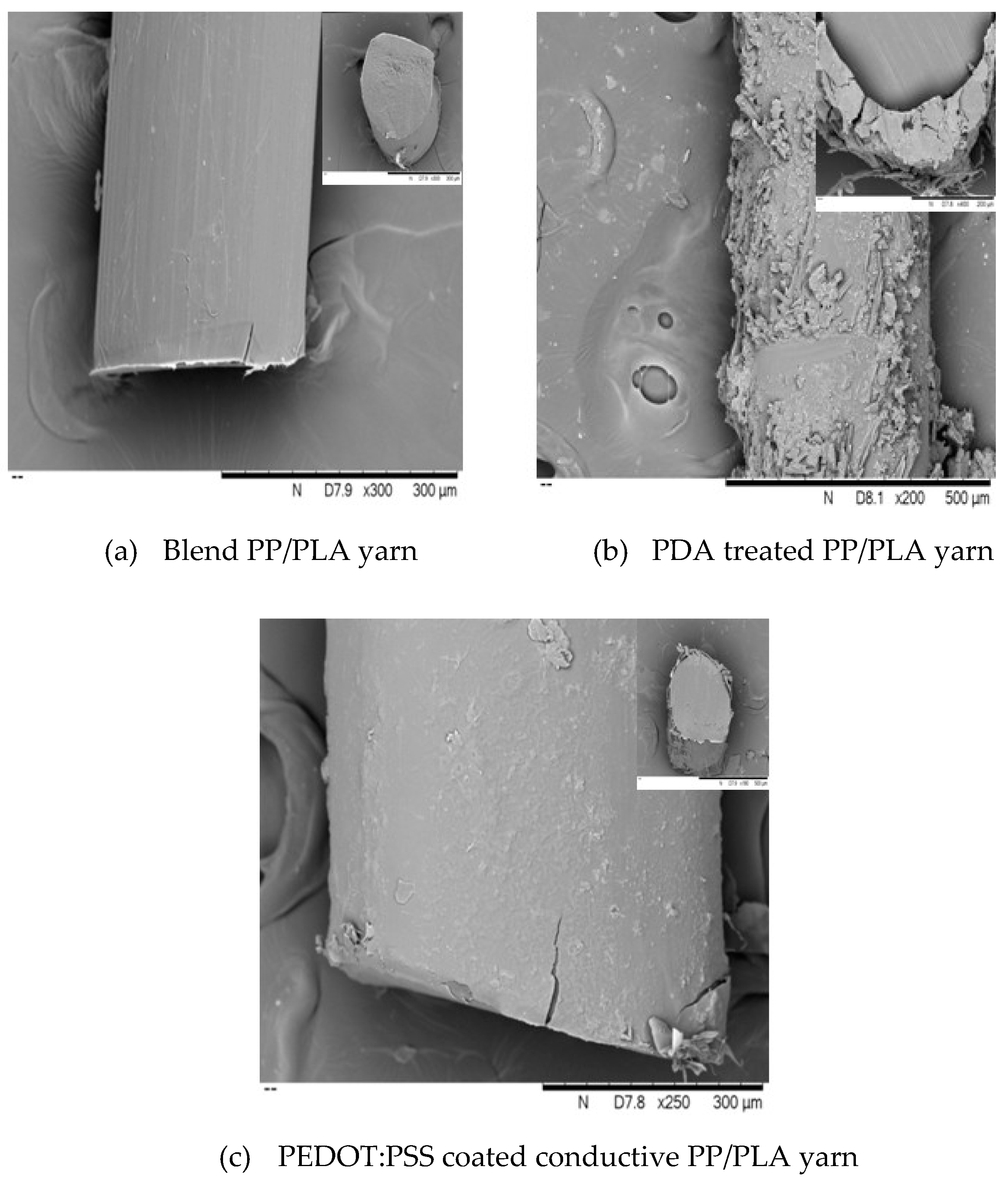

3.6. Scanning Electron Microscope (SEM) Analysis

3.7. Thermal Behavior Analysis

3.7.1. Thermo-Gravimetric Analysis (TGA)

3.7.2. Differential Scanning Calorimetry (DSC) Analysis

3.8. Aging Effect on Electrical Conductivity under Different Processing Conditions

3.9. Electrical Conductivity after Rinsing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Islam, G.M.N.; Ali, A.; Collie, S. Textile sensors for wearable applications: A comprehensive review. Cellulose 2020, 27, 6103–6131. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhu, T.; Li, S.; Huang, J.; Mao, J.; Yang, H.; Gao, S.; Chen, Z.; Lai, Y. A novel strategy for fabricating robust superhydrophobic fabrics by environmentally-friendly enzyme etching. Chem. Eng. J. 2019, 355, 290–298. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, Z.; Huang, X.; You, X.; Ye, J.; Wu, H. A Large area, stretchable, textile based tactile sensor. Adv. Mater. Technol. 2020, 5, 1901060–1901069. [Google Scholar] [CrossRef]

- Fan, X.; Zhan, Y.; Xu, H.; Hou, Z.; Liu, X.; Riedel, R. Highly flexible, light-weight and mechanically enhanced (Mo2C/PyC)f fabrics for efficient electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2020, 136, 105955–105963. [Google Scholar] [CrossRef]

- Islam, G.M.N.; Ke, G. Ultrasonic effects on the kinetics and thermodynamics of dyeing wool fiber with reactive dye. Fibers Polym. 2020, 21, 1071–1077. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, Z.; Qu, L. Graphene based fibers: Recent advances in preparation and application. Adv. Mater. 2020, 32, 1901979–1901994. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Zhang, M.; Li, J.; Luo, H.; Zhang, X.; Fu, Z. WSMS: Wearable stress monitoring system based on IoT multi-sensor platform for living sheep transportation. Electronics 2019, 8, 441. [Google Scholar] [CrossRef]

- Kayser, L.V.; Lipomi, D.J. Stretchable conductive polymers and composites based on PEDOT and PEDOT:PSS. Adv. Mater. 2019, 31, 1806133–1806145. [Google Scholar] [CrossRef]

- Mohan Bhasney, S.; Kumar, A.; Katiyar, V. Microcrystalline cellulose, polylactic acid and polypropylene biocomposites and its morphological, mechanical, thermal and rheological properties. Compos. Part B Eng. 2020, 184, 107717–107731. [Google Scholar] [CrossRef]

- Schwarz, P.A.; Obermann, M.; Weber, M.; Ehrmann, A. Smarten up garments through knitting. In Proceedings of the 48th Conference of the International Federation of Knitting Technologists (IFKT), IOP Conference Series, Moenchengladbach, Germany, 8–11 June 2016; pp. 1–8. [Google Scholar]

- Kong, X.; Zhu, C.; Lv, J.; Zhang, J.; Feng, J. Robust fluorine-free superhydrophobic coating on polyester fabrics by spraying commercial adhesive and hydrophobic fumed SiO2 nanoparticles. Prog. Org. Coat. 2020, 138, 105342–105351. [Google Scholar] [CrossRef]

- Sadi, M.S.; Pan, J.; Xu, A.; Cheng, D.; Cai, G.; Wang, X. Direct dip-coating of carbon nanotubes onto polydopamine-templated cotton fabrics for wearable applications. Cellulose 2019, 26, 7569–7579. [Google Scholar] [CrossRef]

- Baribina, N.; Baltina, I.; Oks, A. Application of additional coating for conductive yarns protection against washing. Key Eng. Mater. 2018, 762, 396–401. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, G.; Rao, W.; Fan, L.; Xu, W.; Xu, J. A simple method of fabricating nickel-coated cotton fabrics for wearable strain sensor. Cellulose 2018, 25, 4859–4870. [Google Scholar] [CrossRef]

- Li, W.; Xu, F.; Liu, W.; Gao, Y.; Zhang, K.; Zhang, X.; Qiu, Y. Flexible strain sensor based on aerogel spun carbon nanotube yarn with a core-sheath structure. Compos. Part A Appl. Sci. Manuf. 2018, 108, 107–113. [Google Scholar] [CrossRef]

- Memarian, F.; Rahmani, S.; Yousefzadeh, M.; Latifi, M. Wearable Technologies in Sportswear. In Materials in Sports Equipment; Elsevier: Amsterdam, The Netherlands, 2019; pp. 123–160. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Malandraki, A.; Butterworth, S.; Beach, C.; Rigout, M.; Novoselov, K.S.; Casson, A.J.; Yeates, S.G. All inkjet-printed graphene based conductive patterns for wearable e-textile applications. J. Mater. Chem. C 2017, 5, 11640–11648. [Google Scholar] [CrossRef]

- Aslam, S.; Bokhari, T.H.; Anwar, T.; Khan, U.; Nairan, A.; Khan, K. Graphene oxide coated graphene foam based chemical sensor. Mater. Lett. 2019, 235, 66–70. [Google Scholar] [CrossRef]

- Wu, B.; Xu, P.; Yang, W.; Hoch, M.; Dong, W.; Chen, M.; Bai, H.; Ma, P. Super toughened heat resistant poly(lactic acid) alloys by tailoring the phase morphology and the crystallization behaviors. J. Polym. Sci. 2020, 58, 500–509. [Google Scholar] [CrossRef]

- Bouchart, F.; Vidal, O.; Lacroix, J.M.; Spriet, C.; Chamary, S.; Brutel, A.; Hornez, J.C. 3D printed bioceramic for phage therapy against bone nosocomial infections. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 111, 110840–110852. [Google Scholar] [CrossRef]

- Chen, W.; Xu, Y.; Li, Y.; Jia, L.; Mo, X.; Jiang, G.; Zhou, G. 3D printing electrospinning fiber-reinforced decellularized extracellular matrix for cartilage regeneration. Chem. Eng. J. 2020, 382, 122986–122995. [Google Scholar] [CrossRef]

- Ueda, M.; Kishimoto, S.; Yamawaki, M.; Matsuzaki, R.; Todoroki, A.; Hirano, Y.; Le Duigou, A. 3D compaction printing of a continuous carbon fiber reinforced thermoplastic. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105985–105993. [Google Scholar] [CrossRef]

- Sarker, F.; Potluri, P.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Karim, N. Ultrahigh performance of nanoengineered graphene based natural jute fiber composites. ACS Appl. Mater. Interfaces 2019, 11, 21166–21176. [Google Scholar] [CrossRef]

- Afroj, S.; Tan, S.; Abdelkader, A.M.; Novoselov, K.S.; Karim, N. Highly conductive, scalable and machine washable graphene-based E-textiles for multifunctional wearable electronic applications. Adv. Funct. Mater. 2020, 30, 2000293–2000302. [Google Scholar] [CrossRef]

- Afroj, S.; Karim, N.; Wang, Z.; Tan, S.; He, P.; Holwill, M.; Ghazaryan, D.; Fernando, A.; Novoselov, K.S. Engineering graphene flakes for wearable textile sensors via highly scalable and ultrafast yarn dyeing technique. ACS Nano 2019, 13, 3847–3857. [Google Scholar] [CrossRef] [PubMed]

- Su, S.; Kang, P.M. Systemic review of biodegradable nanomaterials in nanomedicine. Nanomaterials 2020, 10, 656. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Jian, R.; Chen, H.; Tian, X.; Sun, C.; Zhu, J.; Yang, Z.; Sun, J.; Wang, C. Application of biodegradable and biocompatible nanocomposites in electronics: Current status and future directions. Nanomaterials 2019, 9, 950. [Google Scholar] [CrossRef]

- Sonseca, A.; Madani, S.; Muñoz Bonilla, A.; Fernández García, M.; Peponi, L.; Leonés, A.; Rodríguez, G.; Echeverría, C.; López, D. Biodegradable and antimicrobial PLA–OLA blends containing chitosan-mediated silver nanoparticles with shape memory properties for potential medical applications. Nanomaterials 2020, 10, 1065. [Google Scholar] [CrossRef]

- Huang, T.; Kwan, I.; Li, K.D.; Ek, M. Effect of cellulose oxalate as cellulosic reinforcement in ternary composites of polypropylene/maleated polypropylene/cellulose. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105894–105904. [Google Scholar] [CrossRef]

- Mandal, D.K.; Bhunia, H.; Bajpai, P.K. Thermal degradation kinetics of PP/PLA nanocomposite blends. J. Thermoplast. Compos. Mater. 2019, 32, 1714–1730. [Google Scholar] [CrossRef]

- Zakaria, M.; Nakane, K. Fabrication of polypropylene nanofibers from polypropylene/polyvinyl butyral blend films using laser assisted melt-electrospinning. Polym. Eng. Sci. 2020, 60, 362–370. [Google Scholar] [CrossRef]

- Zengwen, C.; Lu, Z.; Pan, H.; Bian, J.; Han, L.; Zhang, H.; Dong, L.; Yang, Y. Structuring poly (lactic acid) film with excellent tensile toughness through extrusion blow molding. Polymer 2020, 187, 122091–122098. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable compatibilized polymer blends for packaging applications: A literature review. J. Appl. Polym. Sci. 2018, 135, 45726–45760. [Google Scholar] [CrossRef]

- Cui, X.; Honda, T.; Asoh, T.A.; Uyama, H. Cellulose modified by citric acid reinforced polypropylene resin as fillers. Carbohydr. Polym. 2020, 230, 115662–115670. [Google Scholar] [CrossRef] [PubMed]

- Pivsa Art, S.; Kord Sa Ard, J.; Pivsa Art, W.; Wongpajan, R.; O-Charoen, N.; Pavasupree, S.; Hamada, H. Effect of Compatibilizer on PLA/PP Blend for Injection Molding. Energy Procedia 2016, 89, 353–360. [Google Scholar] [CrossRef]

- Mohamad, I.N.; Rohani, R.; Masdar, M.S.; Nor, M.; Tusirin, M.; Jamaliah, M.J. Permeation properties of polymeric membranes for biohydrogen purification. Int. J. Hydrogen Energy 2016, 41, 4474–4488. [Google Scholar] [CrossRef]

- Azizi, S.; Azizi, M.; Sabetzadeh, M. The role of multiwalled carbon nanotubes in the mechanical, thermal, rheological and electrical properties of PP/PLA/MWCNTs nanocomposites. J. Compos. Sci. 2019, 3, 64. [Google Scholar] [CrossRef]

- Lynge, M.E.; van der Westen, R.; Postma, A.; Städler, B. Polydopamine—A nature-inspired polymer coating for biomedical science. Nanoscale 2011, 3, 4916–4928. [Google Scholar] [CrossRef]

- El Yakhlifi, S.; Ball, V. Polydopamine as a stable and functional nanomaterial. Colloids Surf. B Biointerfaces 2020, 186, 110719–110726. [Google Scholar] [CrossRef]

- Hu, H.; Yu, B.; Ye, Q.; Gu, Y.; Zhou, F. Modification of carbon nanotubes with a nanothin polydopamine layer and polydimethylamino-ethyl methacrylate brushes. Carbon 2010, 48, 2347–2353. [Google Scholar] [CrossRef]

- Cherenack, K.; Zysset, C.; Kinkeldei, T.; Münzenrieder, N.; Tröster, G. Woven electronic fibers with sensing and display functions for smart textiles. Adv. Mater. 2010, 22, 5178–5182. [Google Scholar] [CrossRef]

- Bontapalle, S.; Varughese, S. Understanding the mechanism of ageing and a method to improve the ageing resistance of conducting PEDOT:PSS films. Polym. Degrad. Stab. 2020, 171, 1–11. [Google Scholar] [CrossRef]

- Lund, A.; van der Velden, N.M.; Persson, N.-K.; Hamedi, M.M.; Müller, C. Electrically conducting fibres for e-textiles: An open playground for conjugated polymers and carbon nanomaterials. Mater. Sci. Eng. R Rep. 2018, 126, 1–29. [Google Scholar] [CrossRef]

- Kim, S.M.; Kim, C.H.; Kim, Y.; Kim, N.; Lee, W.J.; Lee, E.H.; Kim, D.; Park, S.; Lee, K.; Rivnay, J.; et al. Influence of PEDOT:PSS crystallinity and composition on electrochemical transistor performance and long-term stability. Nat. Commun. 2018, 9, 3858–3866. [Google Scholar] [CrossRef] [PubMed]

- Yin, F.; Ye, D.; Zhu, C.; Qiu, L.; Huang, Y. Stretchable, highly durable ternary nanocomposite strain sensor for structural health monitoring of flexible aircraft. Sensors 2017, 17, 2677. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, J.; Kong, Z.; Lv, K.; Teng, C.; Zhu, Y. Conducting polymer based materials for electrochemical energy conversion and storage. Adv. Mater. 2017, 29, 1703044–1703054. [Google Scholar] [CrossRef]

- Naveen, M.H.; Gurudatt, N.G.; Shim, Y.-B. Applications of conducting polymer composites to electrochemical sensors: A review. Appl. Mater. Today 2017, 9, 419–433. [Google Scholar] [CrossRef]

- Le, T.H.; Kim, Y.; Yoon, H. Electrical and electrochemical properties of conducting polymers. Polymers 2017, 9, 150. [Google Scholar] [CrossRef]

- Eom, J.; Jaisutti, R.; Lee, H.; Lee, W.; Heo, J.S.; Lee, J.Y.; Park, S.K.; Kim, Y.H. Highly sensitive textile strain sensors and wireless user interface devices using all polymeric conducting fibers. ACS Appl. Mater. Interfaces 2017, 9, 10190–10197. [Google Scholar] [CrossRef]

- Allison, L.; Hoxie, S.; Andrew, T.L. Towards seamlessly-integrated textile electronics: Methods to coat fabrics and fibers with conducting polymers for electronic applications. Chem. Commun. 2017, 53, 7182–7193. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, M.; Kang, X.; Zhu, C.; Ge, M. Continuous wet-spinning of flexible and water-stable conductive PEDOT: PSS/PVA composite fibers for wearable sensors. Compos. Commun. 2020, 17, 134–140. [Google Scholar] [CrossRef]

- Reid, D.O.; Smith, R.E.; Garcia Torres, J.; Watts, J.F.; Crean, C. Solvent Treatment of wet-spun PEDOT: PSS fibers for fiber-based wearable pH sensing. Sensors 2019, 19, 4213. [Google Scholar] [CrossRef]

- Shan, Y.; Xu, C.; Zhang, H.; Chen, H.; Bilal, M.; Niu, S.; Cao, L.; Huang, Q. Polydopamine modified metal–organic frameworks, NH2-Fe-MIL-101, as pH-sensitive nanocarriers for controlled pesticide release. Nanomaterials 2020, 10, 2000. [Google Scholar] [CrossRef] [PubMed]

- Moraes, M.R.; Alves, A.C.; Toptan, F.; Martins, M.S.; Vieira, E.M.F.; Paleo, A.J.; Souto, A.P.; Santos, W.L.F.; Esteves, M.F.; Zille, A. Glycerol/PEDOT:PSS coated woven fabric as a flexible heating element on textiles. J. Mater. Chem. C 2017, 5, 3807–3822. [Google Scholar] [CrossRef]

- Cai, G.; Yang, M.; Xu, Z.; Liu, J.; Tang, B.; Wang, X. Flexible and wearable strain sensing fabrics. Chem. Eng. J. 2017, 325, 396–403. [Google Scholar] [CrossRef]

- Chen, H.; Lv, L.; Zhang, J.; Zhang, S.; Xu, P.; Li, C.; Zhang, Z.; Li, Y.; Xu, Y.; Wang, J. Enhanced stretchable and sensitive strain sensor via controlled strain distribution. Nanomaterials 2020, 10, 218. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; An, J.; Cai, G.; Zhang, J.; Chen, W.; Dong, X.; Zhu, L.; Tang, B.; Wang, J.; Wang, X. Environmentally friendly flexible strain sensor from waste cotton fabrics and natural rubber latex. Polymers 2019, 11, 404. [Google Scholar] [CrossRef]

- Tadesse, M.G.; Mengistie, D.A.; Chen, Y.; Wang, L.; Loghin, C.; Nierstrasz, V. Electrically conductive highly elastic polyamide/lycra fabric treated with PEDOT:PSS and polyurethane. J. Mater. Sci. 2019, 54, 9591–9602. [Google Scholar] [CrossRef]

- Strååt, M.; Toll, S.; Boldizar, A.; Rigdahl, M.; Hagström, B. Melt spinning of conducting polymeric composites containing carbonaceous fillers. J. Appl. Polym. Sci. 2011, 119, 3264–3272. [Google Scholar] [CrossRef]

- Soroudi, A.; Skrifvars, M. Melt blending of carbon nanotubes/polyaniline/polypropylene compounds and their melt spinning to conductive fibres. Synth. Met. 2010, 160, 1143–1147. [Google Scholar] [CrossRef]

- Wang, X.Y.; Feng, G.Y.; Li, M.J.; Ge, M.Q. Effect of PEDOT:PSS content on structure and properties of PEDOT:PSS/poly(vinyl alcohol) composite fiber. Polym. Bull. 2018, 76, 2097–2111. [Google Scholar] [CrossRef]

- Hassan, M.M.; Tucker, N.; Le Guen, M.J. Thermal, mechanical and viscoelastic properties of citric acid-crosslinked starch/cellulose composite foams. Carbohydr. Polym. 2020, 230, 115676–115685. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Du, M.; Guo, Y.; Li, Y.; Li, H.; Yang, Y.; Alam, F.E.; Lin, C.-T.; Fang, Y. Solid-phase coalescence of electrochemically exfoliated graphene flakes into a continuous film on copper. Chem. Mater. 2016, 28, 3360–3366. [Google Scholar] [CrossRef]

- Ploypetchara, N.; Suppakul, P.; Atong, D.; Pechyen, C. Blend of polypropylene/poly(lactic acid) for medical packaging application: Physicochemical, thermal, mechanical, and barrier properties. Energy Procedia 2014, 56, 201–210. [Google Scholar] [CrossRef]

- Boroumand, Y.; Razmjou, A.; Moazzam, P.; Mohagheghian, F.; Eshaghi, G.; Etemadifar, Z.; Asadnia, M.; Shafiei, R. Mussel inspired bacterial denitrification of water using fractal patterns of polydopamine. J. Water Process Eng. 2020, 33, 101105–101115. [Google Scholar] [CrossRef]

- Chang, H.C.; Sun, T.; Sultana, N.; Lim, M.M.; Khan, T.H.; Ismail, A.F. Conductive PEDOT:PSS coated polylactide (PLA) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) electrospun membranes: Fabrication and characterization. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 61, 396–410. [Google Scholar] [CrossRef]

- Luo, R.; Li, H.; Du, B.; Zhou, S.; Zhu, Y. A simple strategy for high stretchable, flexible and conductive polymer films based on PEDOT:PSS-PDMS blends. Org. Electron. 2020, 76, 105451–105458. [Google Scholar] [CrossRef]

- Gholampour, N.; Brian, D.; Eslamian, M. Tailoring characteristics of PEDOT:PSS coated on glass and plastics by ultrasonic substrate vibration post treatment. Coatings 2018, 8, 337. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2011, 25, 927–948. [Google Scholar] [CrossRef]

- Kowalczyk, M.; Piorkowska, E.; Kulpinski, P.; Pracella, M. Mechanical and thermal properties of PLA composites with cellulose nanofibers and standard size fibers. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1509–1514. [Google Scholar] [CrossRef]

| IR Absorption Bands (cm−1) | Description |

|---|---|

| 3184–3345 | stretching vibrations of O–H and N–H groups |

| 2945–2850 | C–H stretching |

| 1743–1454 | –CH3 stretching |

| 1647–1658 | C=C stretching |

| 1045–1182 | C=O stretching |

| 1376 | C–H bending |

| 1183 and 1025–881 | Stretching C–S |

| 1453 | Symmetric C–O–C stretching |

| Yarn Type | Radius (cm) | Area (cm2) | Coating Cycle 1 | Coating Cycle 2 | ||||

|---|---|---|---|---|---|---|---|---|

| Mean Electrical Resistance (kΩ) | SD | Conductivity (S/cm) | Mean Electrical Resistance (kΩ) | SD | Conductivity (S/cm) | |||

| PP | 0.014 | 0.000616 | 131.00 | 3.42 | 0.25 | 43.04 | 2.20 | 0.75 |

| PLA | 0.013 | 0.000531 | 223.33 | 7.77 | 0.17 | 122.67 | 5.47 | 0.36 |

| PP/PLA | 0.012 | 0.000452 | 181.13 | 3.62 | 0.24 | 65.93 | 1.23 | 0.67 |

| Types of Yarn | Tensile Strength (MPa) | SD (MPa) | Tensile/Young’s Modulus (MPa) | SD (MPa) | Elongation at Break (%) | SD |

|---|---|---|---|---|---|---|

| PP Modified PP PEDOT:PSS coated PP | 1.22 1.81 1.97 | 0.14 0.09 0.02 | 76.98 87.92 116.39 | 4.99 5.47 8.94 | 594.53 636.51 667.47 | 5.76 7.98 5.92 |

| PLA Modified PLA PEDOT:PSS coated PLA | 2.99 3.41 3.57 | 0.18 0.40 0.23 | 230.70 291.87 309.29 | 7.67 5.78 7.51 | 42.30 76.89 121.35 | 0.39 0.63 0.48 |

| PP/PLA Modified PP/PLA PEDOT:PSS coated PP/PLA | 1.35 2.08 2.56 | 0.15 0.49 0.08 | 96.164 172.11 188.40 | 7.71 5.33 5.76 | 227.17 263.64 315.33 | 1.34 1.01 0.98 |

| Yarn Type | T5% (°C) | T50% (°C) | ∆T (°C) | Remaining Ash (%) at 500°C |

|---|---|---|---|---|

| PP Modified PP PEDOT:PSS coated PP | 332 344 364 | 455 461 465 | - 6 11 | 0.93 2.16 2.72 |

| PLA Modified PLA PEDOT:PSS coated PLA | 296 307 333 | 354 372 393 | - 18 39 | 0.20 0.30 0.39 |

| PP/PLA Modified PP/PLA PEDOT:PSS coated PP/PLA | 315 317 336 | 386 412 430 | - 26 44 | 1.16 2.46 4.84 |

| Yarn Type | Tg (°C) | Tm (°C) |

|---|---|---|

| PP | - | 130.92 |

| Modified PP | - | 131.98 |

| PEDOT:PSS coated PP | - | 132.61 |

| PLA | 56.44 | 131.55 |

| Modified PLA | 56.44 | 149.49 |

| PEDOT:PSS coated PLA | 56.44 | 149.91 |

| PP/PLA | 50.55 | 132.27 |

| Modified PP/PLA | 55.50 | 149.15 |

| PEDOT:PSS coated PP/PLA | 56.18 | 150.01 |

| Conductive Yarn Type | Aging Duration (Week) | Electrical Resistance (KΩ) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| For 1st Coating | For 2nd Coating | ||||||||

| Mean | SD | Increased Electrical Resistance Every Week (%) | Total Increased Electrical Resistance (%) from Week 0–Week 5 (%) | Mean | SD | Increased Electrical Resistance (%) | Total Increased Electrical Resistance (%) from Week 0–Week 5 (%) | ||

| PP | 0 | 131.00 | 3.41 | - | 23.43 | 43.00 | 2.08 | - | 20.98 |

| 1 | 143.07 | 1.63 | 9.21 | 44.70 | 0.46 | 3.95 | |||

| 2 | 149.67 | 0.57 | 4.61 | 46.93 | 0.57 | 4.99 | |||

| 3 | 154.70 | 2.03 | 3.36 | 48.73 | 0.75 | 3.84 | |||

| 4 | 159.30 | 1.91 | 2.97 | 51.37 | 1.32 | 5.42 | |||

| 5 | 164.53 | 0.83 | 3.28 | 52.80 | 0.30 | 2.78 | |||

| PLA | 0 | 223.00 | 7.76 | - | 26.85 | 122.00 | 5.47 | - | 23.00 |

| 1 | 251.10 | 1.11 | 12.60 | 134.13 | 1.05 | 9.94 | |||

| 2 | 262.40 | 2.80 | 4.50 | 139.40 | 1.20 | 3.92 | |||

| 3 | 269.10 | 1.74 | 2.55 | 143.33 | 0.86 | 2.82 | |||

| 4 | 279.10 | 2.16 | 3.72 | 148.50 | 0.86 | 3.61 | |||

| 5 | 288.80 | 2.35 | 3.48 | 152.53 | 0.83 | 2.71 | |||

| PP/PLA | 0 | 181.00 | 3.63 | - | 25.45 | 66.00 | 1.23 | - | 21.96 |

| 1 | 199.50 | 0.79 | 10.22 | 73.43 | 0.65 | 11.26 | |||

| 2 | 210.50 | 1.12 | 5.51 | 75.67 | 0.57 | 3.05 | |||

| 3 | 215.33 | 0.96 | 2.29 | 78.50 | 0.87 | 3.74 | |||

| 4 | 223.40 | 0.79 | 3.75 | 80.80 | 0.36 | 2.93 | |||

| 5 | 231.63 | 0.42 | 3.68 | 81.63 | 0.87 | 1.03 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, G.M.N.; Collie, S.; Qasim, M.; Ali, M.A. Highly Stretchable and Flexible Melt Spun Thermoplastic Conductive Yarns for Smart Textiles. Nanomaterials 2020, 10, 2324. https://doi.org/10.3390/nano10122324

Islam GMN, Collie S, Qasim M, Ali MA. Highly Stretchable and Flexible Melt Spun Thermoplastic Conductive Yarns for Smart Textiles. Nanomaterials. 2020; 10(12):2324. https://doi.org/10.3390/nano10122324

Chicago/Turabian StyleIslam, G. M. Nazmul, Stewart Collie, Muhammad Qasim, and M. Azam Ali. 2020. "Highly Stretchable and Flexible Melt Spun Thermoplastic Conductive Yarns for Smart Textiles" Nanomaterials 10, no. 12: 2324. https://doi.org/10.3390/nano10122324

APA StyleIslam, G. M. N., Collie, S., Qasim, M., & Ali, M. A. (2020). Highly Stretchable and Flexible Melt Spun Thermoplastic Conductive Yarns for Smart Textiles. Nanomaterials, 10(12), 2324. https://doi.org/10.3390/nano10122324