Effect of ZnO and SnO2 Nanolayers at Grain Boundaries on Thermoelectric Properties of Polycrystalline Skutterudites

Abstract

1. Introduction

2. Materials and Methods

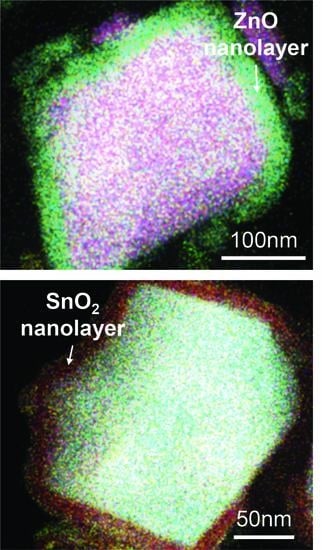

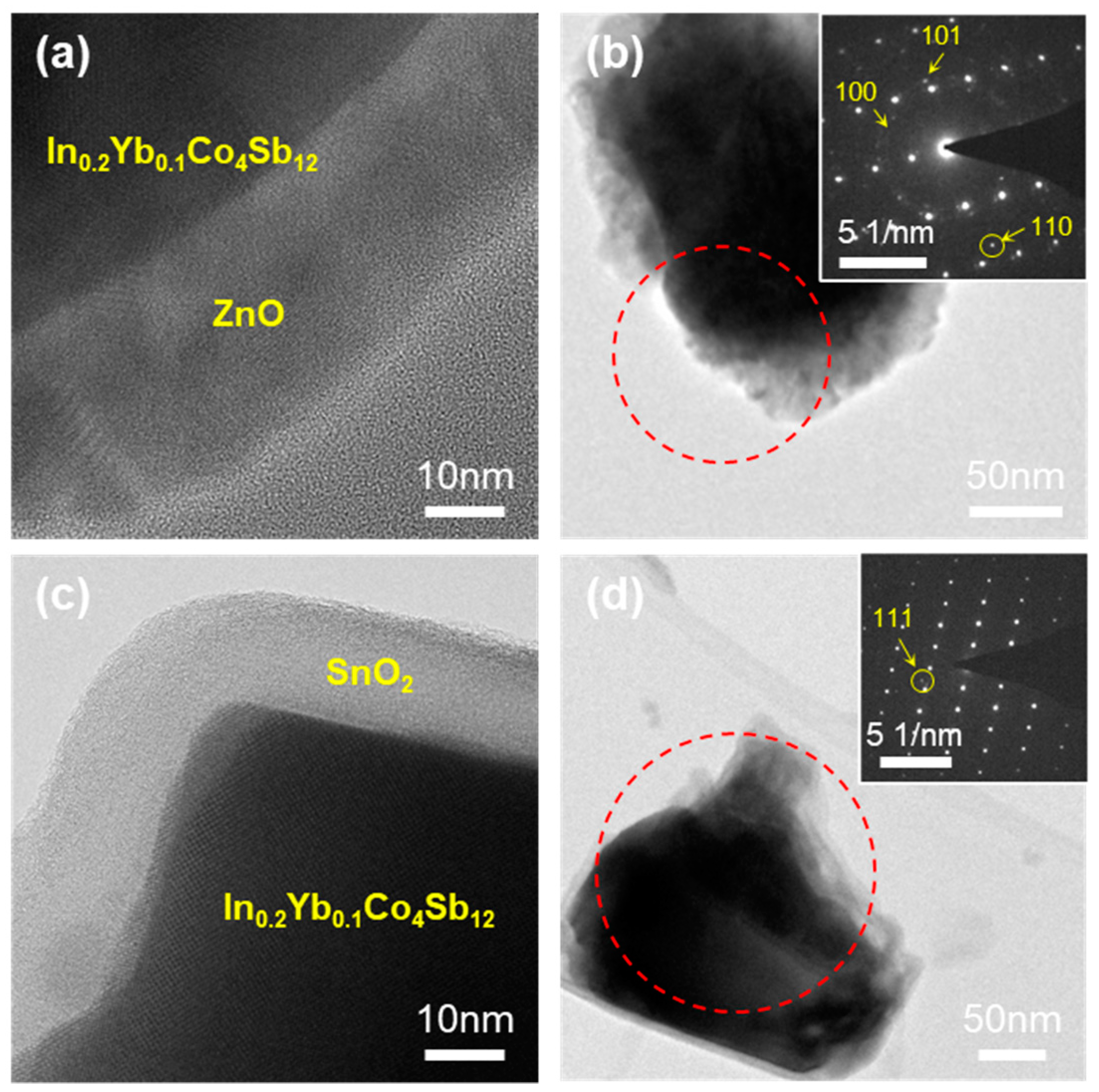

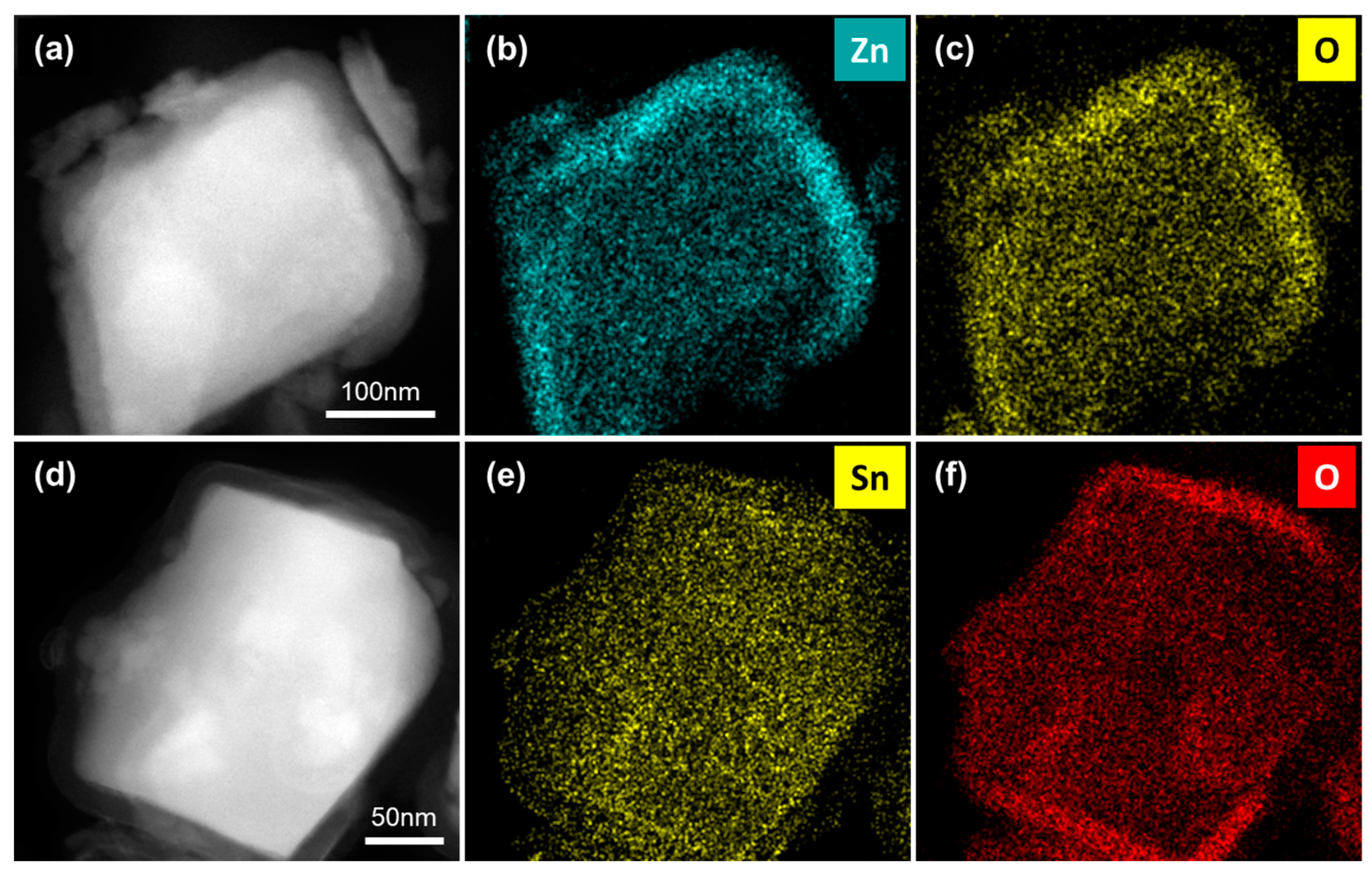

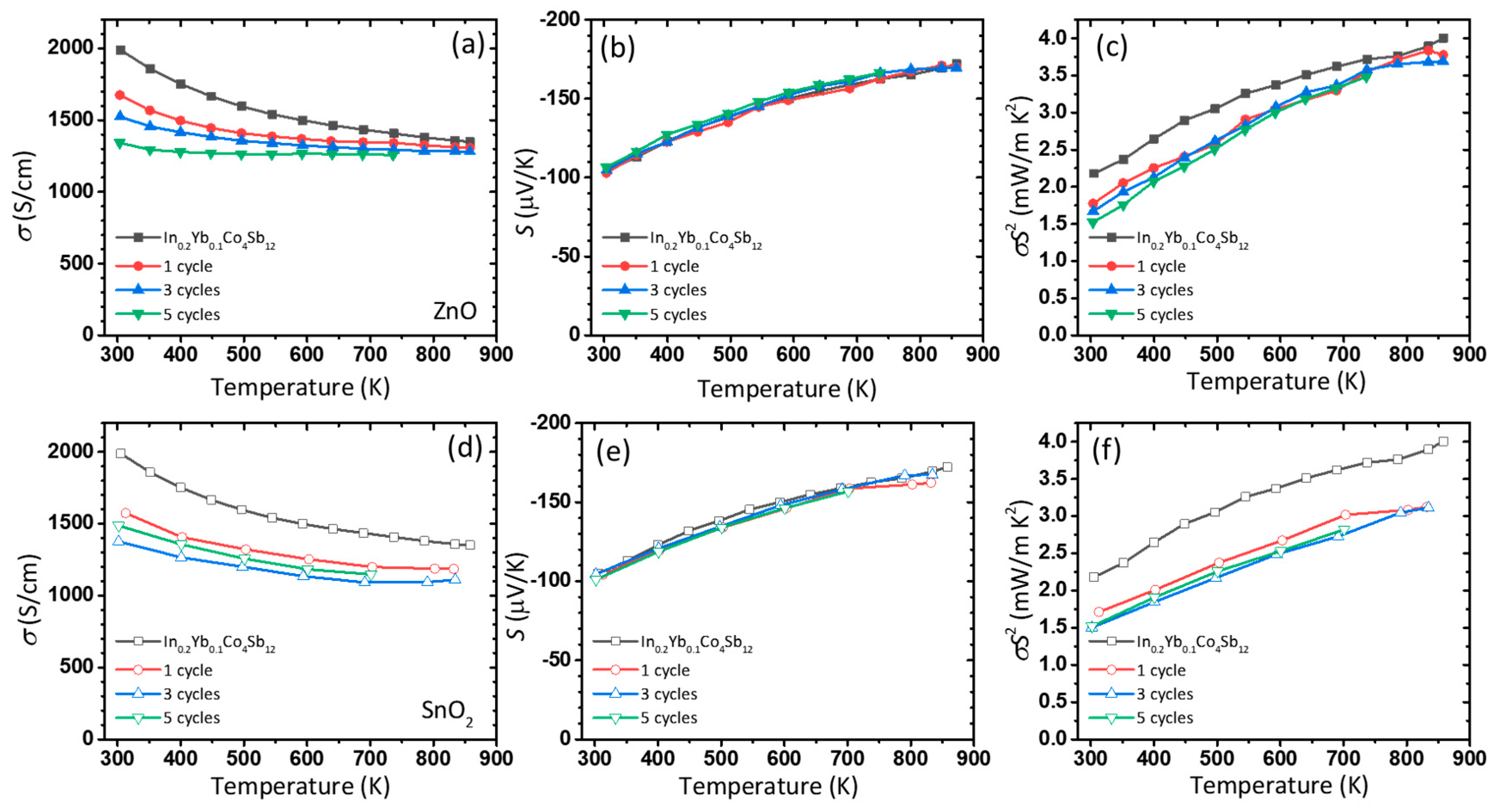

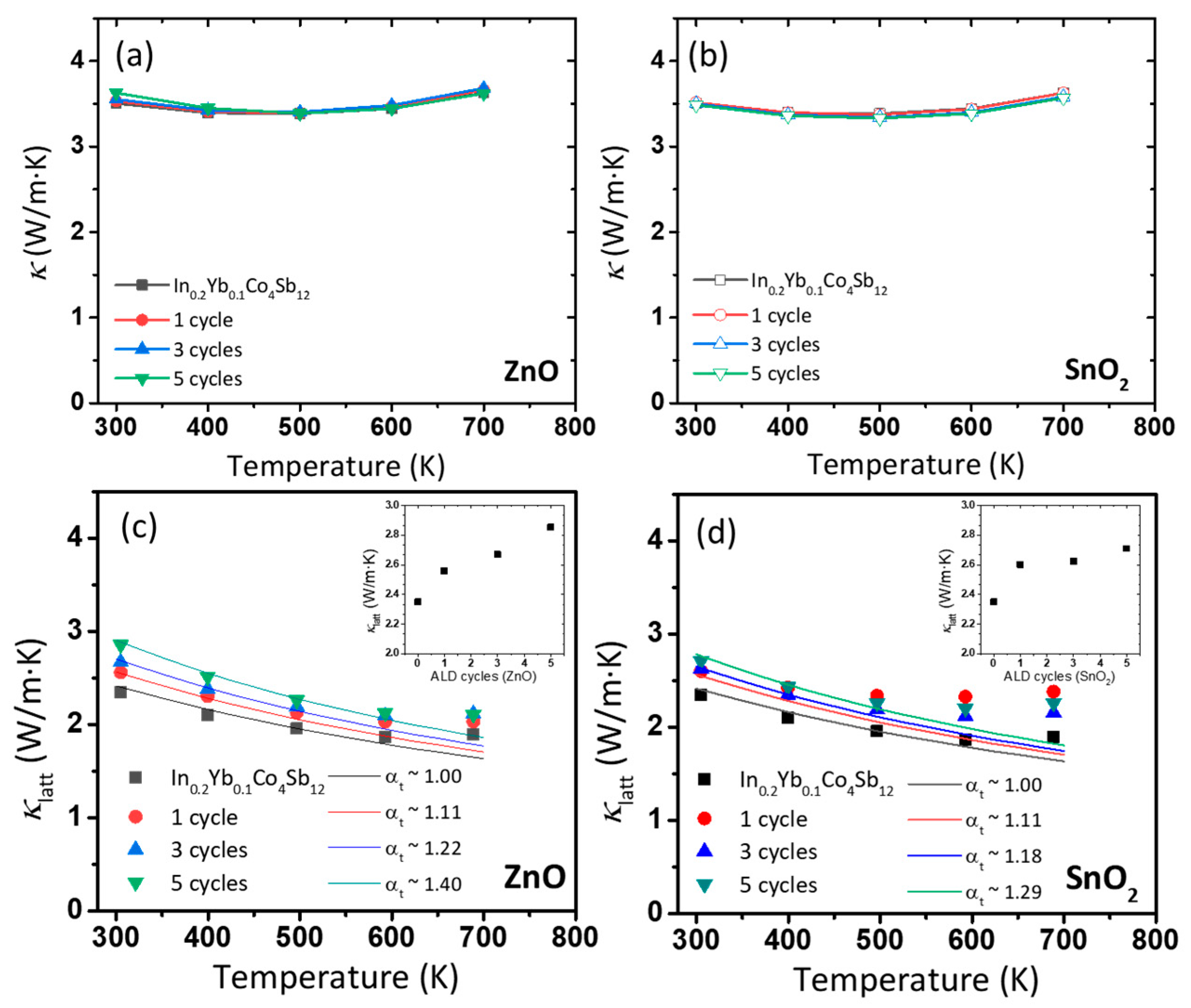

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Disalvo, F.J. Thermoelectric Cooling and Power Generation. Science 1999, 285, 703–706. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhao, L.-D. Thermoelectric materials: Energy conversion between heat and electricity. J. Mater. 2015, 1, 92–105. [Google Scholar] [CrossRef]

- Kim, S.I.; Lee, K.H.; Mun, H.A.; Kim, H.S.; Hwang, S.W.; Roh, J.W.; Yang, D.J.; Shin, W.H.; Li, X.S.; Lee, Y.H.; et al. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 2015, 348, 109–114. [Google Scholar] [CrossRef]

- Heremans, J.P.; Jovovic, V.; Toberer, E.S.; Saramat, A.; Kurosaki, K.; Charoenphakdee, A.; Yamanaka, S.; Snyder, G.J. Enhancement of Thermoelectric Efficiency in PbTe by Distortion of the Electronic Density of States. Science 2008, 321, 554–557. [Google Scholar] [CrossRef]

- Koh, Y.K.; Vineis, C.J.; Calawa, S.D.; Walsh, M.P.; Cahill, D.G. Lattice thermal conductivity of nanostructured thermoelectric materials based on PbTe. Appl. Phys. Lett. 2009, 94, 153101. [Google Scholar] [CrossRef]

- Rogl, P.; Rogl, P. Skutterudites, a most promising group of thermoelectric materials. Curr. Opin. Green Sustain. Chem. 2017, 4, 50–57. [Google Scholar] [CrossRef]

- Bravo, M.R.; Moure, A.; Fernández, J.F.; Martín-González, M.S. Skutterudites as thermoelectric materials: Revisited. RSC Adv. 2015, 5, 41653–41667. [Google Scholar] [CrossRef]

- He, T.; Chen, J.; Rosenfeld, H.D.; Subramanian, M.A. Thermoelectric Properties of Indium-Filled Skutterudites. Chem. Mater. 2006, 18, 759–762. [Google Scholar] [CrossRef]

- Tang, Y.; Qiu, Y.; Xi, L.; Shi, X.; Zhang, W.; Chen, L.; Tseng, S.-M.; Chen, S.-W.; Snyder, G.J. Phase diagram of In–Co–Sb system and thermoelectric properties of In-containing skutterudites. Energy Environ. Sci. 2014, 7, 812–819. [Google Scholar] [CrossRef]

- Wang, S.; Salvador, J.R.; Yang, J.; Wei, P.; Duan, B.; Yang, J. High-performance n-type YbxCo4Sb12: From partially filled skutterudites towards composite thermoelectrics. NPG Asia Mater. 2016, 8, e285. [Google Scholar] [CrossRef]

- Shi, X.; Bai, S.; Xi, L.; Yang, J.; Zhang, W.; Chen, L.; Yang, J. Realization of high thermoelectric performance in n-type partially filled skutterudites. J. Mater. Res. 2011, 26, 1745–1754. [Google Scholar] [CrossRef]

- Shi, X.; Yang, J.; Salvador, J.R.; Chi, M.; Cho, J.Y.; Wang, H.; Bai, S.; Yang, J.; Zhang, W.; Chen, L. Multiple-Filled Skutterudites: High Thermoelectric Figure of Merit through Separately Optimizing Electrical and Thermal Transports. J. Am. Chem. Soc. 2011, 133, 7837–7846. [Google Scholar] [CrossRef] [PubMed]

- Ballikaya, S.; Uzar, N.; Yildirim, S.; Salvador, J.R.; Uher, C. High thermoelectric performance of In, Yb, Ce multiple filled CoSb3 based skutterudite compounds. J. Solid State Chem. 2012, 193, 31–35. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, Z.; Sun, Z.; Zhang, Q.; Wei, P.; Mu, X.; Zhou, H.; Li, C.; Ma, S.; He, D.; et al. Superparamagnetic enhancement of thermoelectric performance. Nat. Cell Biol. 2017, 549, 247–251. [Google Scholar] [CrossRef]

- Shin, W.H.; Roh, J.W.; Ryu, B.; Chang, H.J.; Kim, H.S.; Lee, S.; Seo, W.S.; Ahn, K. Enhancing Thermoelectric Performances of Bismuth Antimony Telluride via Synergistic Combination of Multiscale Structuring and Band Alignment by FeTe2 Incorporation. ACS Appl. Mater. Interfaces 2018, 10, 3689–3698. [Google Scholar] [CrossRef]

- Song, J.M.; Rahman, J.U.; Cho, J.Y.; Lee, S.; Seo, W.S.; Kim, S.; Kim, S.-I.; Lee, K.H.; Roh, D.; Shin, W.H. Chemically synthesized Cu2Te incorporated Bi-Sb-Te p-type thermoelectric materials for low temperature energy harvesting. Scr. Mater. 2019, 165, 78–83. [Google Scholar] [CrossRef]

- Kim, K.-C.; Lim, S.-S.; Lee, S.H.; Hong, J.; Cho, D.-Y.; Mohamed, A.Y.; Koo, C.M.; Baek, S.-H.; Kim, J.-S.; Kim, S.K. Precision Interface Engineering of an Atomic Layer in Bulk Bi2Te3 Alloys for High Thermoelectric Performance. ACS Nano 2019, 13, 7146–7154. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Liu, F.; Zhang, C.; Hu, L.; Ao, W.; Li, Y.; Li, J.; Xie, H.; Xiao, Y.; et al. Zr vacancy interfaces: An effective strategy for collaborative optimization of ZrNiSn-based thermoelectric performance. J. Mater. Chem. A 2019, 7, 26053–26061. [Google Scholar] [CrossRef]

- Rogl, G.; Rogl, P. How nanoparticles can change the figure of merit, ZT, and mechanical properties of skutterudites. Mater. Today Phys. 2017, 3, 48–69. [Google Scholar] [CrossRef]

- Leskelä, M.; Ritala, M. Atomic Layer Deposition Chemistry: Recent Developments and Future Challenges. Angew. Chem. Int. Ed. 2003, 42, 5548–5554. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Bera, S.; Wan, Z.; Dai, W.; Bae, J.; Hong, T.E.; Kim, K.; Ahn, J.; Kwon, S.-H. Comparative study of the electrical characteristics of ALD-ZnO thin films using H2O and H2O2 as the oxidants. J. Am. Ceram. Soc. 2019, 102, 5881–5889. [Google Scholar] [CrossRef]

- Adhikari, S.; Selvaraj, S.; Kim, D.-H. Progress in Powder Coating Technology Using Atomic Layer Deposition. Adv. Mater. Interfaces 2018, 5, 1800581. [Google Scholar] [CrossRef]

- Kim, H.-S.; Gibbs, Z.M.; Tang, Y.; Wang, H.; Snyder, G.J. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-i.; An, J.; Lee, W.-J.; Kwon, S.H.; Nam, W.H.; Du, N.V.; Oh, J.-M.; Koo, S.-M.; Cho, J.Y.; Shin, W.H. Effect of ZnO and SnO2 Nanolayers at Grain Boundaries on Thermoelectric Properties of Polycrystalline Skutterudites. Nanomaterials 2020, 10, 2270. https://doi.org/10.3390/nano10112270

Kim S-i, An J, Lee W-J, Kwon SH, Nam WH, Du NV, Oh J-M, Koo S-M, Cho JY, Shin WH. Effect of ZnO and SnO2 Nanolayers at Grain Boundaries on Thermoelectric Properties of Polycrystalline Skutterudites. Nanomaterials. 2020; 10(11):2270. https://doi.org/10.3390/nano10112270

Chicago/Turabian StyleKim, Sang-il, Jiwoo An, Woo-Jae Lee, Se Hun Kwon, Woo Hyun Nam, Nguyen Van Du, Jong-Min Oh, Sang-Mo Koo, Jung Young Cho, and Weon Ho Shin. 2020. "Effect of ZnO and SnO2 Nanolayers at Grain Boundaries on Thermoelectric Properties of Polycrystalline Skutterudites" Nanomaterials 10, no. 11: 2270. https://doi.org/10.3390/nano10112270

APA StyleKim, S.-i., An, J., Lee, W.-J., Kwon, S. H., Nam, W. H., Du, N. V., Oh, J.-M., Koo, S.-M., Cho, J. Y., & Shin, W. H. (2020). Effect of ZnO and SnO2 Nanolayers at Grain Boundaries on Thermoelectric Properties of Polycrystalline Skutterudites. Nanomaterials, 10(11), 2270. https://doi.org/10.3390/nano10112270