Fluorescent Bulk Waveguide Sensor in Porous Glass: Concept, Fabrication, and Testing

Abstract

1. Introduction

2. Laser Procedure, Materials, and Test

2.1. Waveguides Fabrication

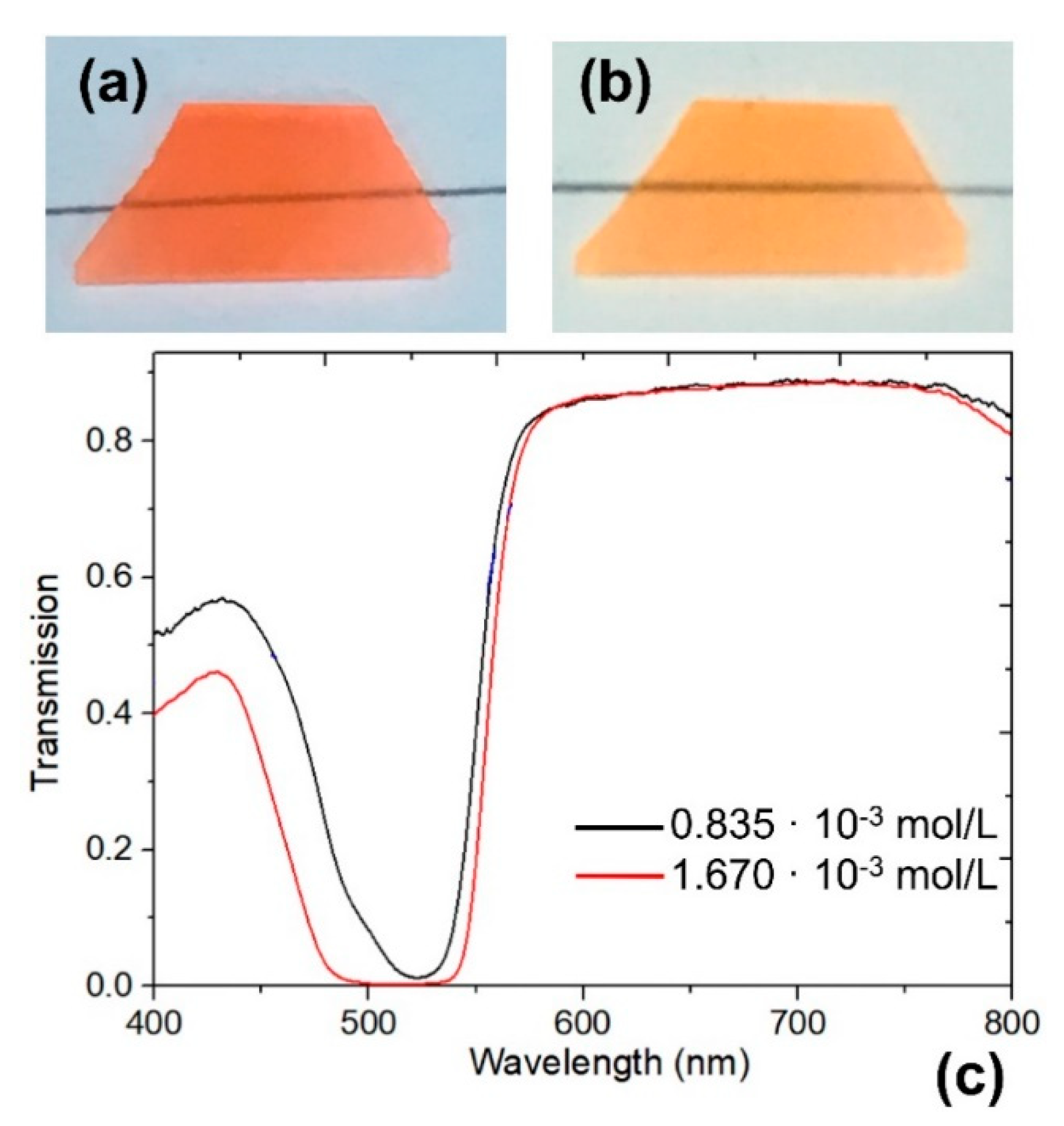

2.2. PG Impregnation Procedure

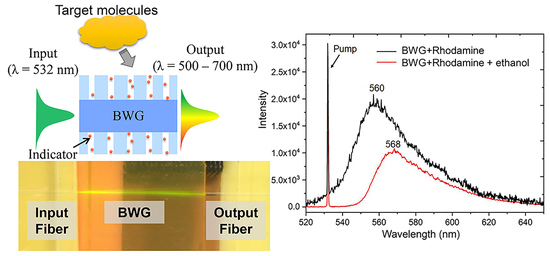

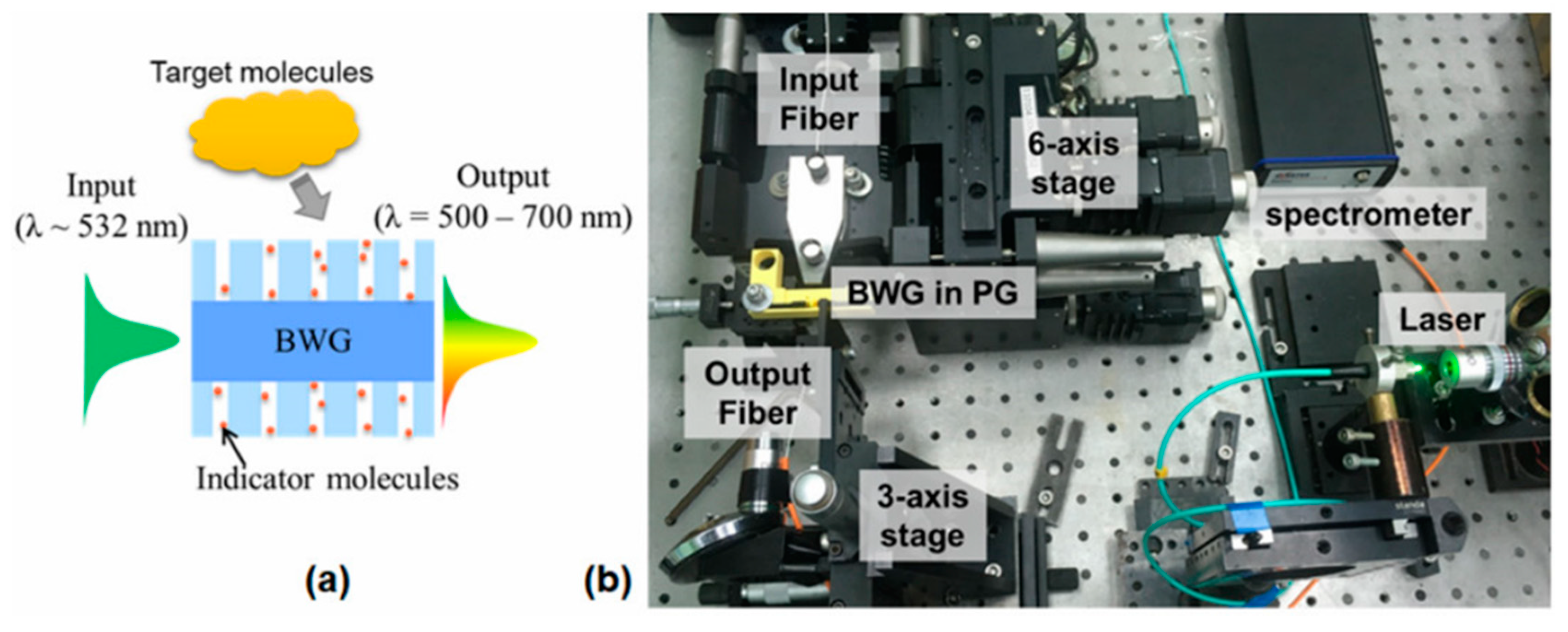

2.3. Principle Operation of BWG Sensor and Testing

3. Results and Discussion

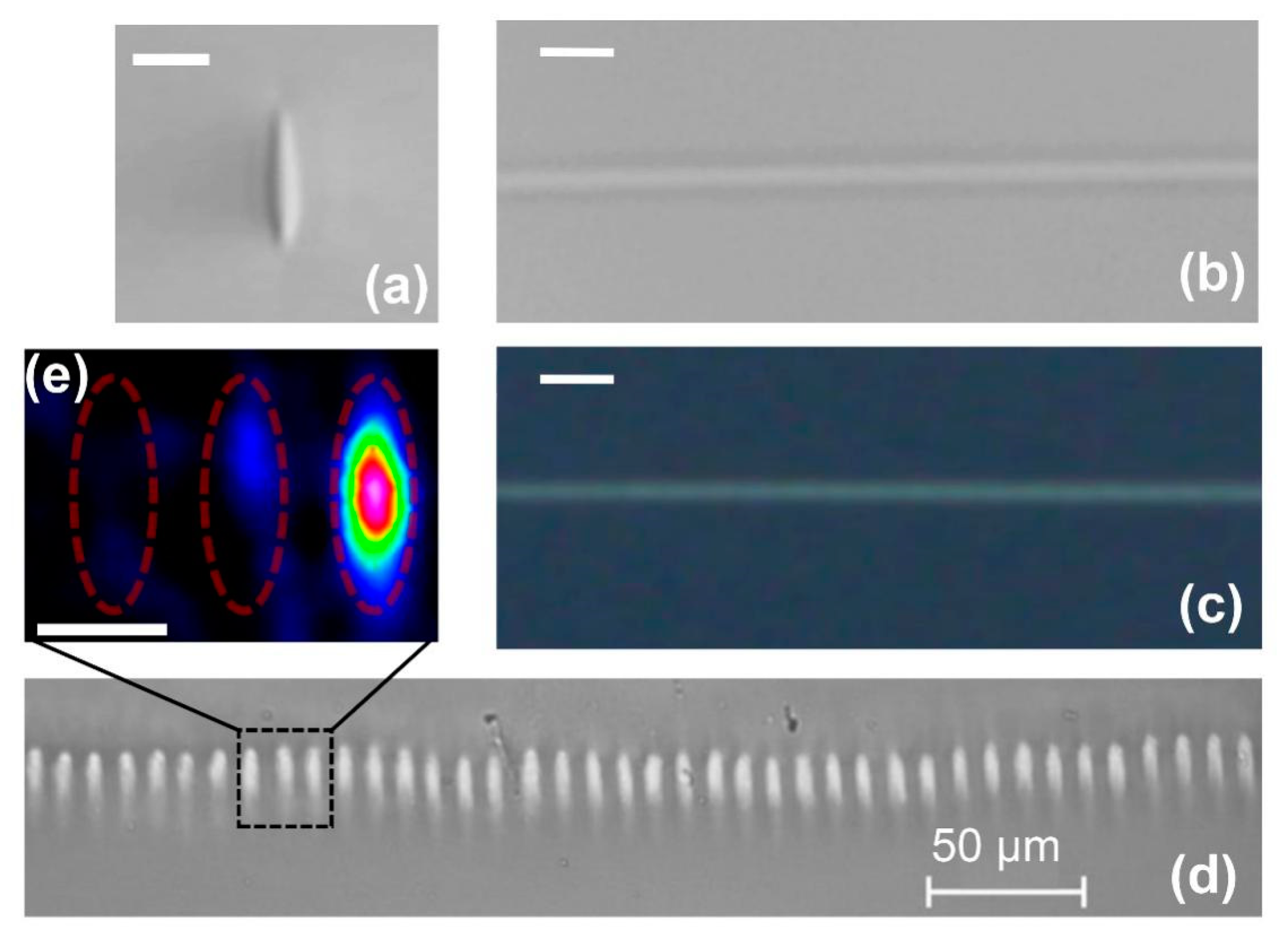

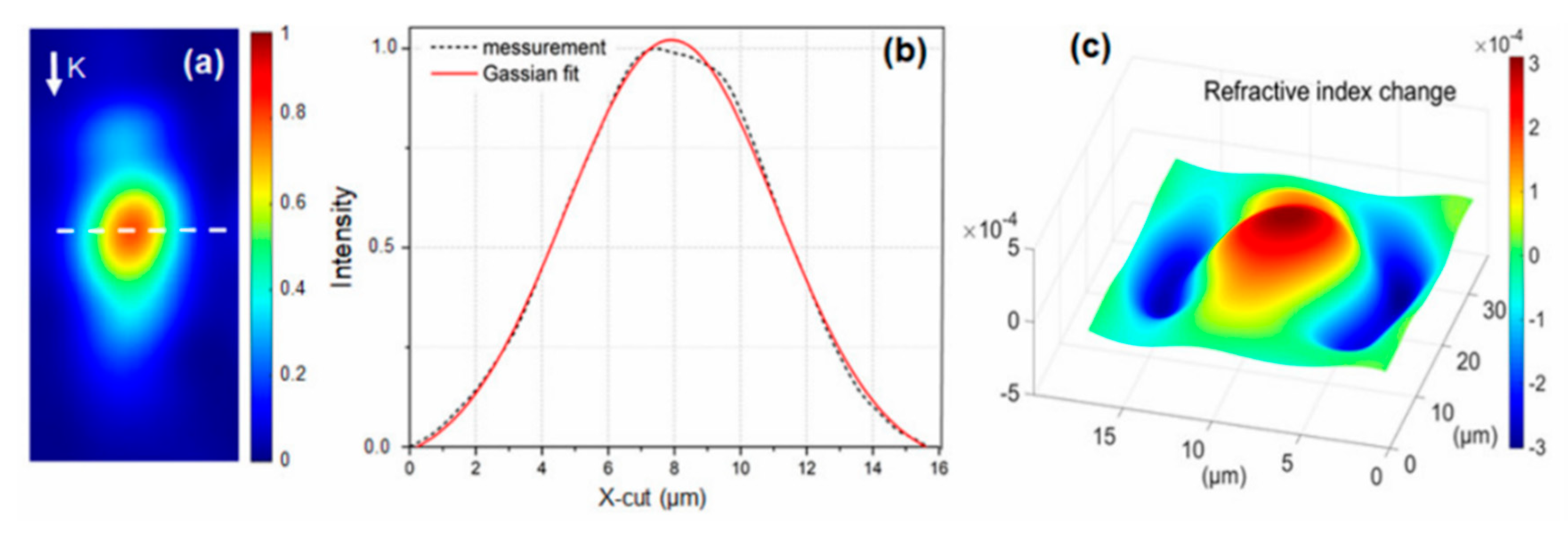

3.1. Waveguide Properties

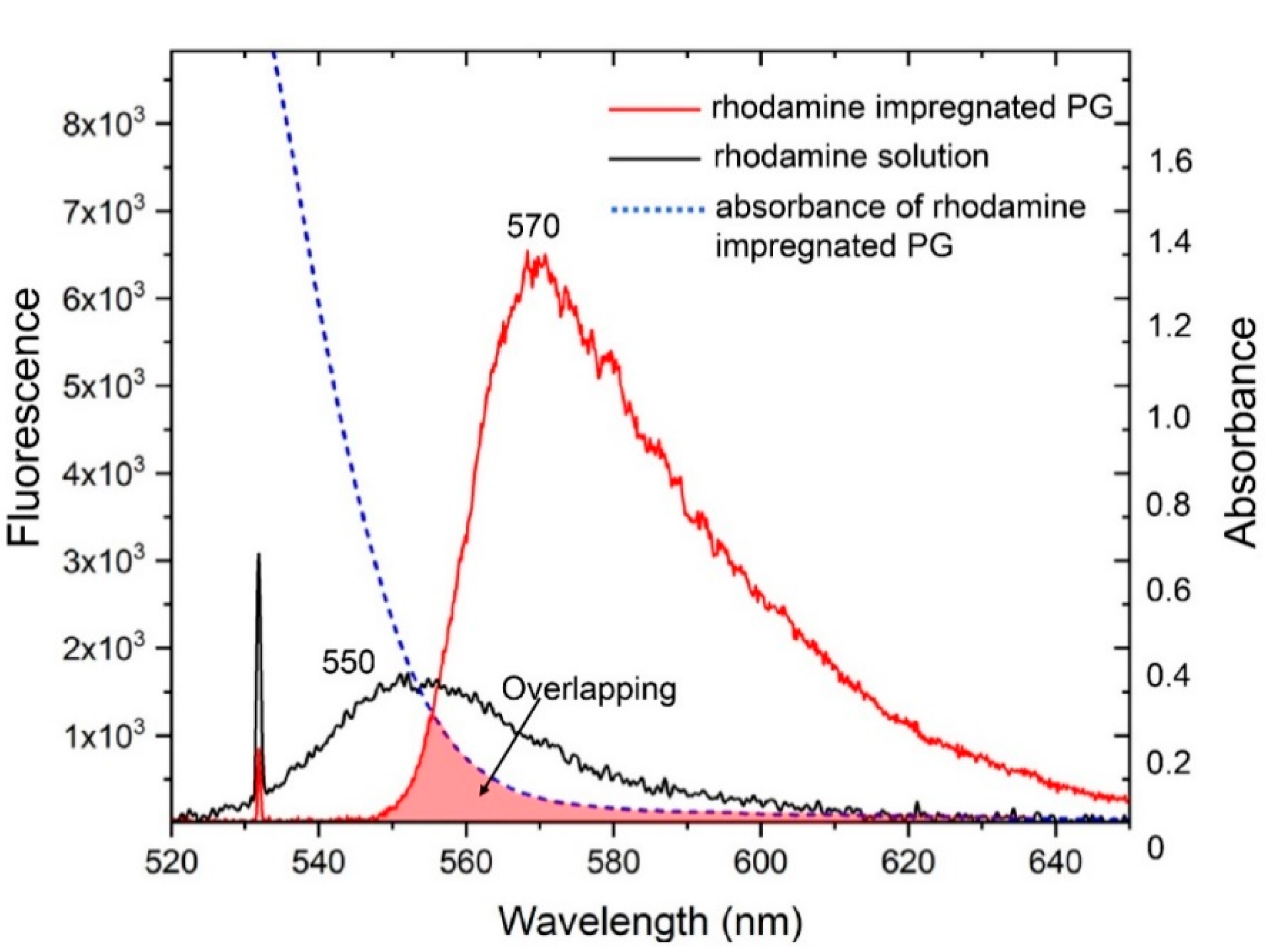

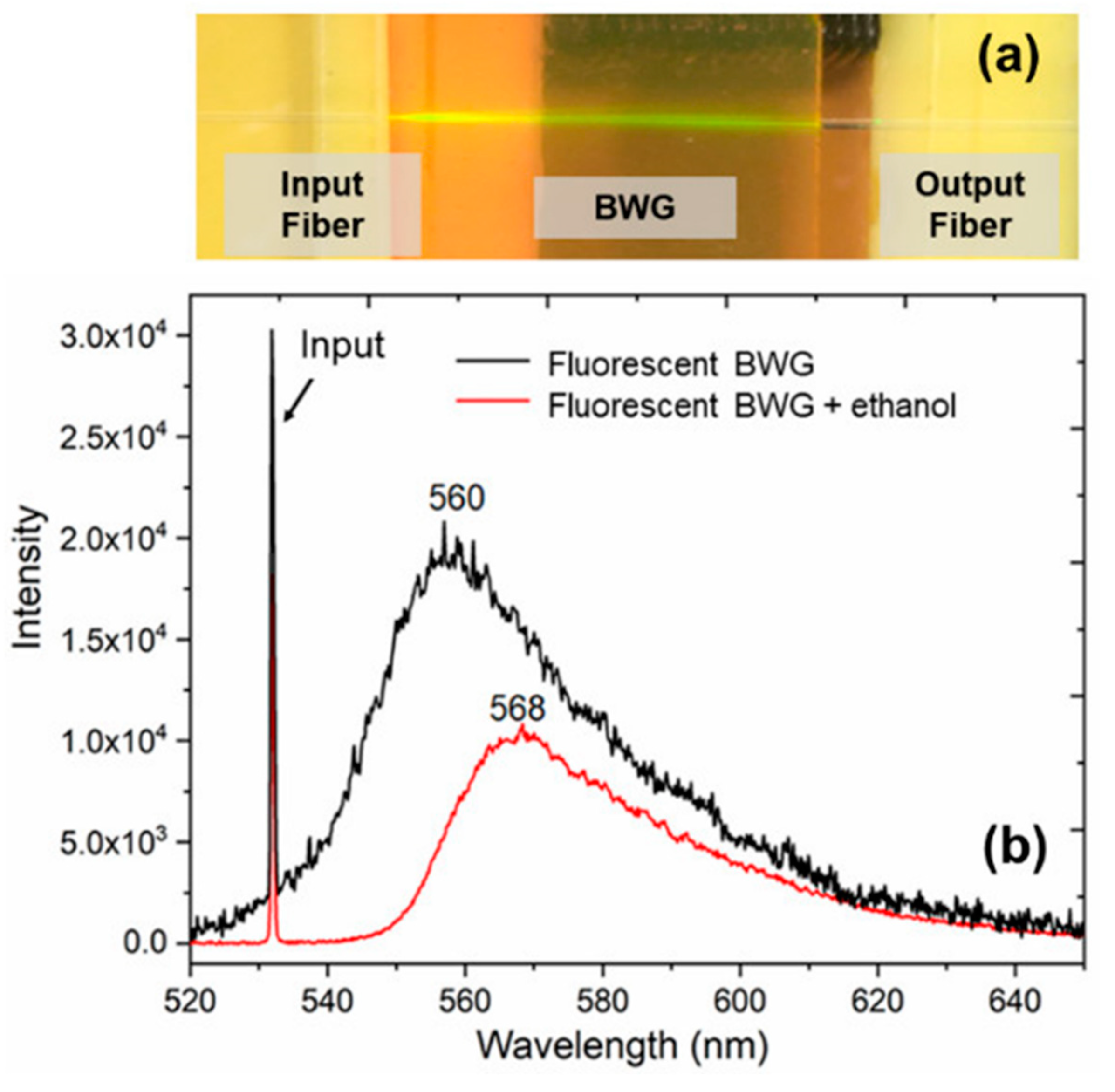

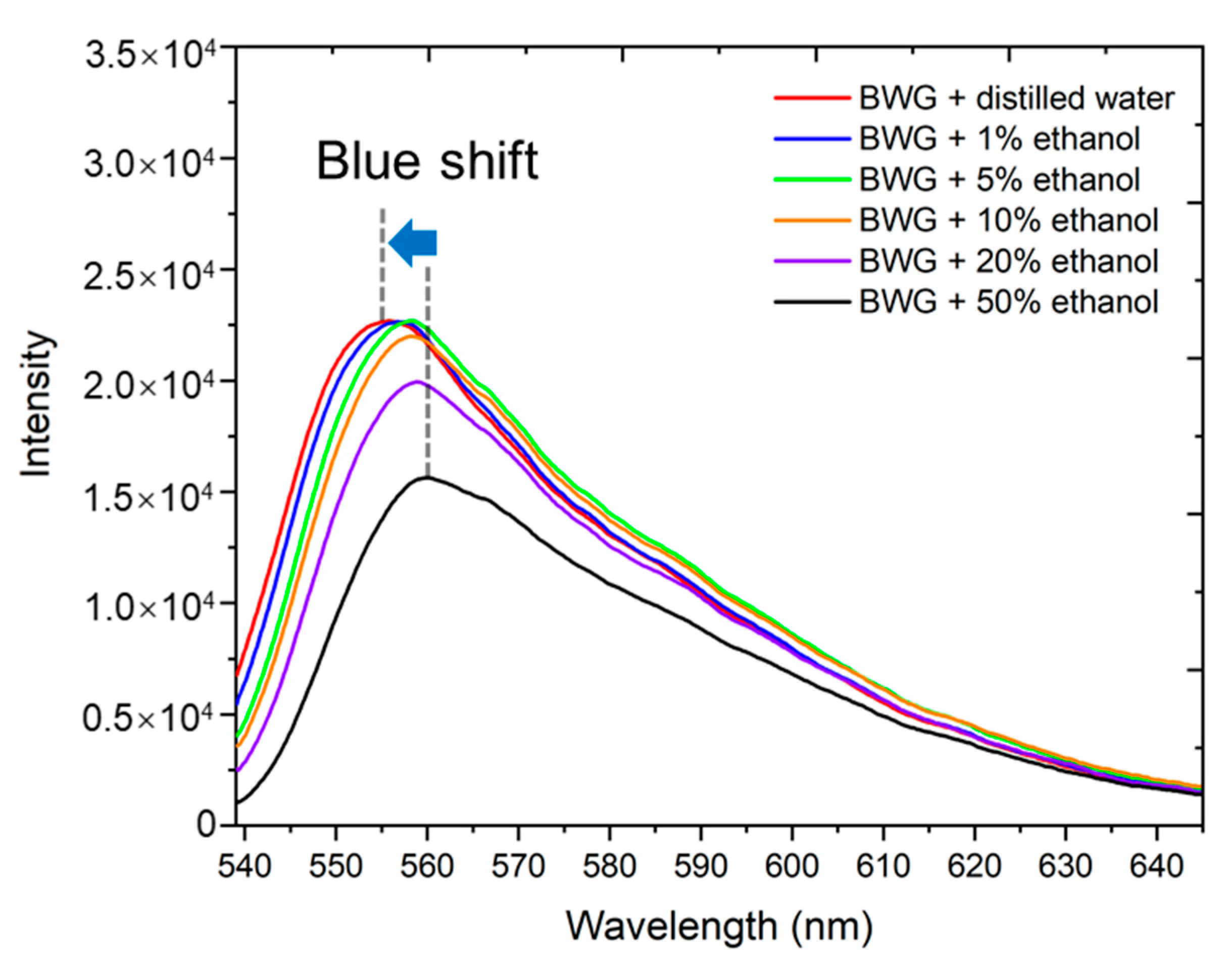

3.2. Fluorescence BWG Transducer: Proof of Concept

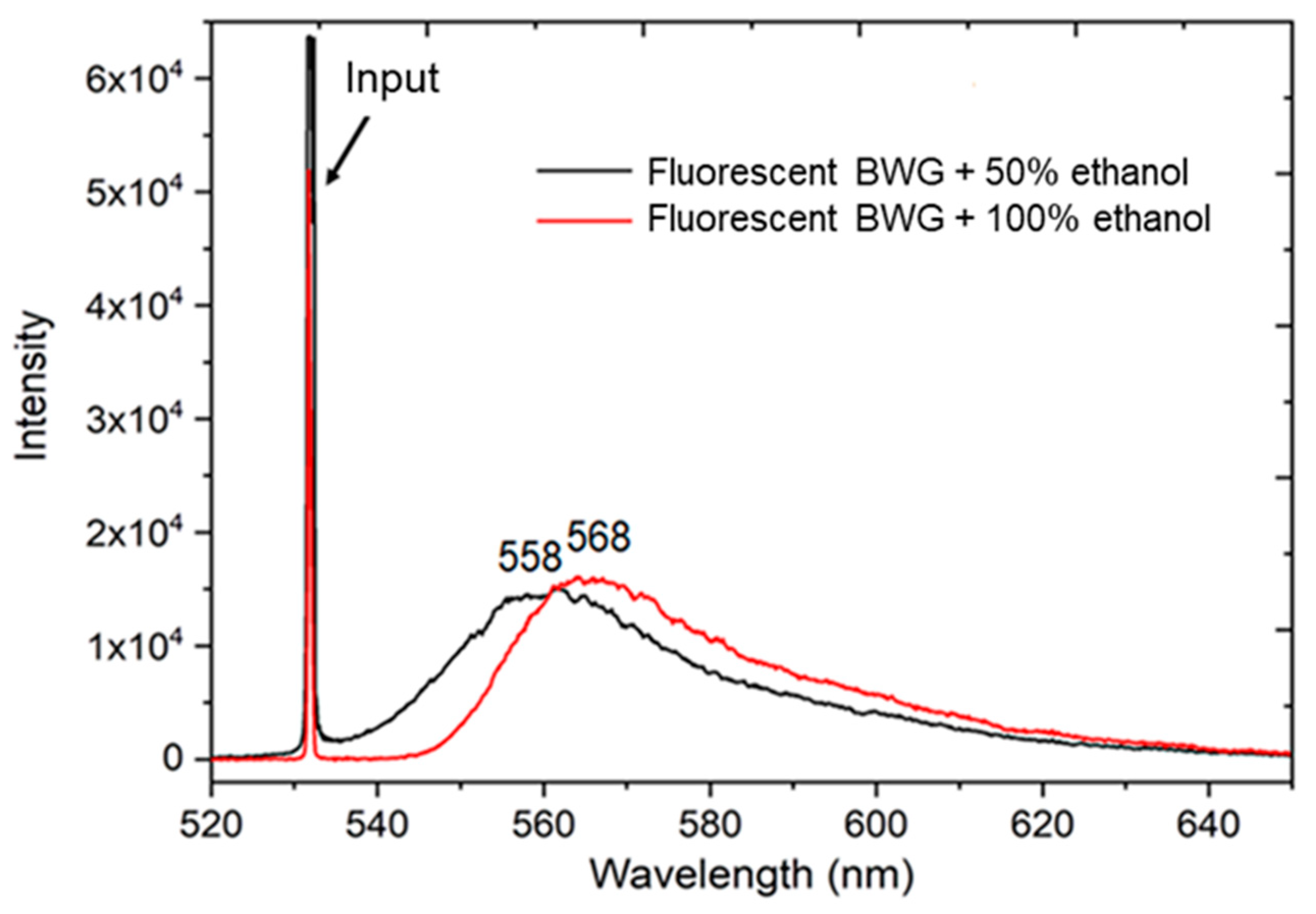

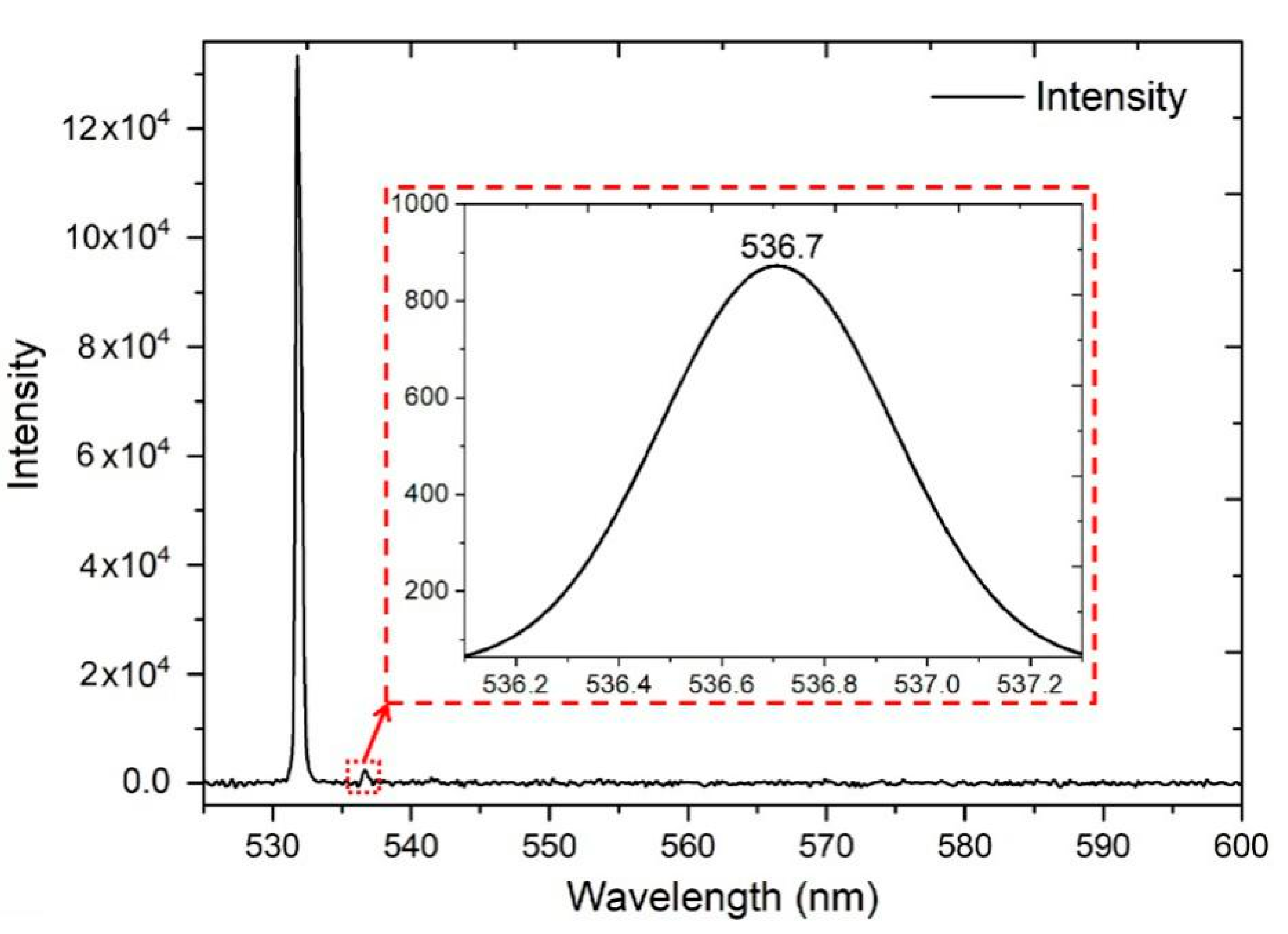

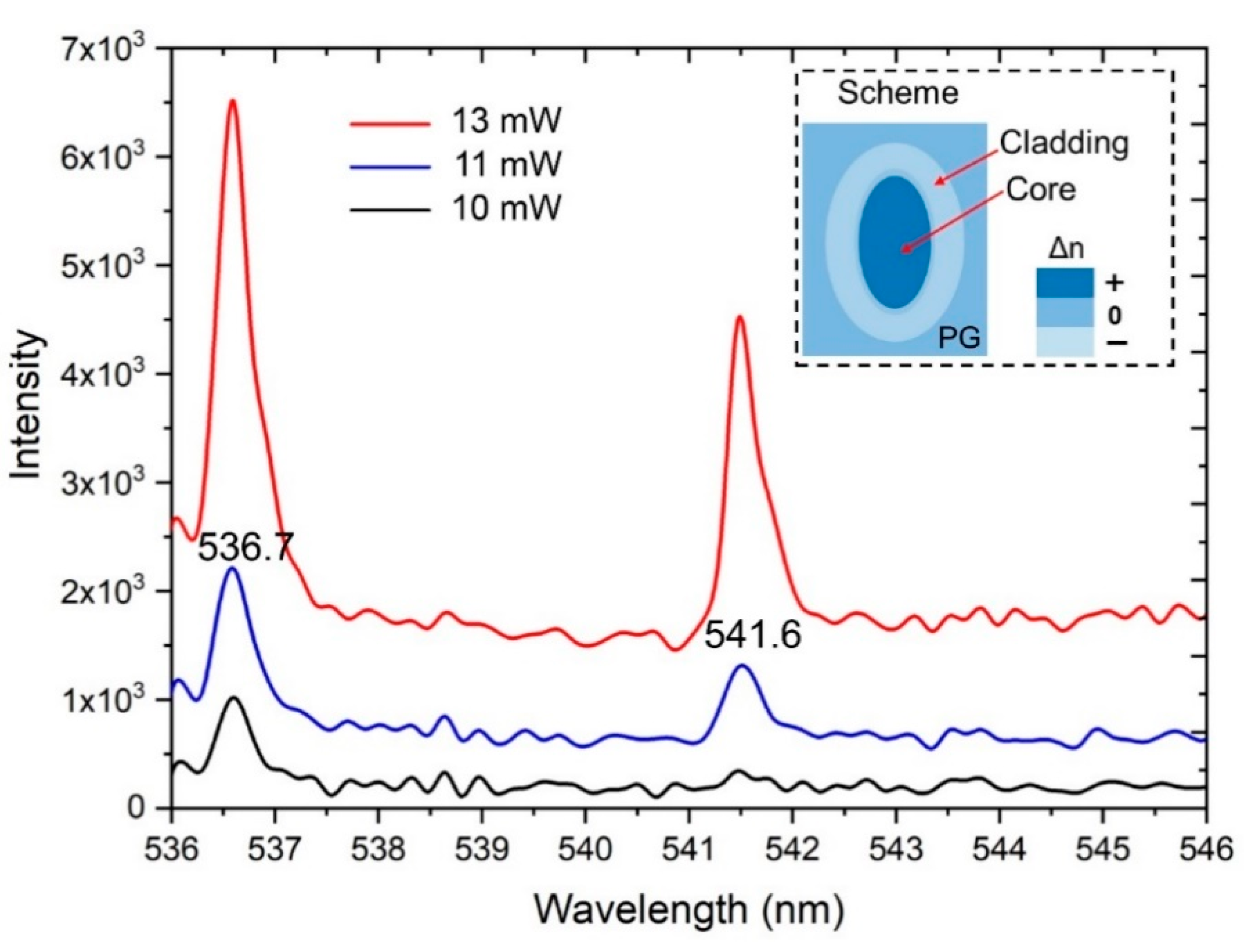

3.3. Single-Line Emission from the BWG

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McDonagh, C.; Burke, C.S.; MacCraith, B.D. Optical chemical sensors. Chem. Rev. 2008, 108, 400–422. [Google Scholar] [CrossRef]

- Borisov, S.M.; Wolfbeis, O.S. Optical biosensors. Chem. Rev. 2008, 108, 423–461. [Google Scholar] [CrossRef]

- Barrios, C.A. Optical slot-waveguide based biochemical sensors. Sensors 2009, 9, 4751–4765. [Google Scholar] [CrossRef]

- Macielag, M.J. Chemical properties of antimicrobials and their uniqueness. In Antibiotic Discovery and Development; Springer: Berlin/Heidelberg, Germany, 2012; pp. 793–820. [Google Scholar] [CrossRef]

- Hongsith, N.; Viriyaworasakul, C.; Mangkorntong, P.; Mangkorntong, N.; Choopun, S. Ethanol sensor based on ZnO and Au-doped ZnO nanowires. Ceram. Int. 2008, 34, 823–826. [Google Scholar] [CrossRef]

- Maruo, Y.Y.; Tachibana, K.; Suzuki, Y.; Shinomi, K. Development of an analytical chip for detecting acetone using a reaction between acetone and 2, 4-dinitrophenylhidrazine in a porous glass. Microchem. J. 2018, 141, 377–381. [Google Scholar] [CrossRef]

- Maruo, Y.Y.; Nakamura, J. Portable formaldehyde monitoring device using porous glass sensor and its applications in indoor air quality studies. Anal. Chim. Acta 2011, 702, 247–253. [Google Scholar] [CrossRef]

- Luo, X.; Tsai, D.; Gu, M.; Hong, M. Extraordinary optical fields in nanostructures: From sub-diffraction-limited optics to sensing and energy conversion. Chem. Soc. Rev. 2019, 48, 2458–2494. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, T.; Ohyama, T.; Maruo, Y.Y.; Hayashi, T. Coloration reactions between NO2 and organic compounds in porous glass for cumulative gas sensor. Sens. Actuators B Chem. 1998, 47, 65–69. [Google Scholar] [CrossRef]

- Izumi, K.; Utiyama, M.; Maruo, Y.Y. A porous glass-based ozone sensing chip impregnated with potassium iodide and α-cyclodextrin. Sens. Actuators B Chem. 2017, 241, 116–122. [Google Scholar] [CrossRef]

- Izumi, K.; Utiyama, M.; Maruo, Y.Y. Colorimetric NOx sensor based on a porous glass-based NO2 sensing chip and a permanganate oxidizer. Sens. Actuators B Chem. 2015, 216, 128–133. [Google Scholar] [CrossRef]

- Maruo, Y.Y. Measurement of ambient ozone using newly developed porous glass sensor. Sens. Actuators B Chem. 2007, 126, 485–491. [Google Scholar] [CrossRef]

- Tanaka, T.; Guilleux, A.; Ohyama, T.; Maruo, Y.Y.; Hayashi, T. A ppb-level NO2 gas sensor using coloration reactions in porous glass. Sens. Actuators B Chem. 1999, 56, 247–253. [Google Scholar] [CrossRef]

- Veiko, V.P.; Zakoldaev, R.A.; Sergeev, M.M.; Danilov, P.A.; Kudryashov, S.I.; Kostiuk, G.K.; Sivers, A.N.; Ionin, A.A.; Antropova, T.V.; Medvedev, O.S. Direct laser writing of barriers with controllable permeability in porous glass. Opt. Express 2018, 26, 28150–28160. [Google Scholar] [CrossRef] [PubMed]

- Avnir, D.; Levy, D.; Reisfeld, R. The nature of the silica cage as reflected by spectral changes and enhanced photostability of trapped rhodamine 6G. J. Phys. Chem. 1984, 88, 5956–5959. [Google Scholar] [CrossRef]

- Lei, S.; Zhao, X.; Yu, X.; Hu, A.; Vukelic, S.; Jun, M.B.; Joe, H.-E.; Yao, Y.L.; Shin, Y.C. Ultrafast Laser Applications in Manufacturing Processes: A State-of-the-Art Review. J. Manuf. Sci. Eng. 2020, 142. [Google Scholar] [CrossRef]

- Correa, D.S.; Almeida, J.M.; Almeida, G.F.; Cardoso, M.R.; De Boni, L.; Mendonça, C.R. Ultrafast laser pulses for structuring materials at micro/nano scale: From waveguides to superhydrophobic surfaces. Photonics 2017, 4, 8. [Google Scholar] [CrossRef]

- Lapointe, J.; Parent, F.; de Lima Filho, E.S.; Loranger, S.; Kashyap, R. Toward the integration of optical sensors in smartphone screens using femtosecond laser writing. Opt. Lett. 2015, 40, 5654–5657. [Google Scholar] [CrossRef]

- Bérubé, J.-P.; Vallée, R. Femtosecond laser direct inscription of surface skimming waveguides in bulk glass. Opt. Lett. 2016, 41, 3074–3077. [Google Scholar] [CrossRef]

- Lipatiev, A.S.; Fedotov, S.S.; Okhrimchuk, A.G.; Lotarev, S.V.; Vasetsky, A.M.; Stepko, A.A.; Shakhgildyan, G.Y.U.; Piyanzina, K.I.; Glebov, I.S.; Sigaev, V.N. Multilevel data writing in nanoporous glass by a few femtosecond laser pulses. Appl. Opt. 2018, 57, 978–982. [Google Scholar] [CrossRef]

- Sergeev, M.M.; Zakoldaev, R.A.; Itina, T.E.; Varlamov, P.V.; Kostyuk, G.K. Real-Time Analysis of Laser-Induced Plasmon Tuning in Nanoporous Glass Composite. Nanomaterials 2020, 10, 1131. [Google Scholar] [CrossRef]

- Fedotov, S.; Lipatiev, A.; Presniakov, M.Y.; Shakhgildyan, G.Y.; Okhrimchuk, A.; Lotarev, S.; Sigaev, V. Laser-induced cavities with a controllable shape in nanoporous glass. Opt. Lett. 2020, 45, 5424–5427. [Google Scholar] [CrossRef] [PubMed]

- Veiko, V.P.; Kudryashov, S.I.; Sergeev, M.M.; Zakoldaev, R.A.; Danilov, P.A.; Ionin, A.A.; Antropova, T.V.; Anfimova, I.N. Femtosecond laser-induced stress-free ultra-densification inside porous glass. Laser Phys. Lett. 2016, 13, 055901. [Google Scholar] [CrossRef]

- Zhong, L.; Zakoldaev, R.; Sergeev, M.; Veiko, V.; Li, Z. Porous glass density tailoring by femtosecond laser pulses. Opt. Quantum Electron. 2020, 52, 1–8. [Google Scholar] [CrossRef]

- Selwyn, J.E.; Steinfeld, J.I. Aggregation of equilibriums of xanthene dyes. J. Phys. Chem. 1972, 76, 762–774. [Google Scholar] [CrossRef]

- Nolte, S.; Will, M.; Burghoff, J.; Tuennermann, A. Femtosecond waveguide writing: A new avenue to three-dimensional integrated optics. Appl. Phys. A 2003, 77, 109–111. [Google Scholar] [CrossRef]

- Ams, M.; Marshall, G.; Spence, D.; Withford, M. Slit beam shaping method for femtosecond laser direct-write fabrication of symmetric waveguides in bulk glasses. Opt. Express 2005, 13, 5676–5681. [Google Scholar] [CrossRef] [PubMed]

- Szameit, A.; Blömer, D.; Burghoff, J.; Schreiber, T.; Pertsch, T.; Nolte, S.; Tünnermann, A.; Lederer, F. Discrete nonlinear localization in femtosecond laser written waveguides in fused silica. Opt. Express 2005, 13, 10552–10557. [Google Scholar] [CrossRef] [PubMed]

- Diener, R.; Nolte, S.; Pertsch, T.; Minardi, S. Effects of stress on neighboring laser written waveguides in gallium lanthanum sulfide. Appl. Phys. Lett. 2018, 112, 111908. [Google Scholar] [CrossRef]

- Shah, L.; Arai, A.Y.; Eaton, S.M.; Herman, P.R. Waveguide writing in fused silica with a femtosecond fiber laser at 522 nm and 1 MHz repetition rate. Opt. Express 2005, 13, 1999–2006. [Google Scholar] [CrossRef]

- Thomson, R.R.; Psaila, N.D.; Bookey, H.T.; Reid, D.T.; Kar, A.K. Controlling the cross-section of ultrafast laser inscribed optical waveguides. In Femtosecond Laser Micromachining; Springer: Berlin/Heidelberg, Germany, 2012; pp. 93–125. [Google Scholar] [CrossRef]

- Del Monte, F.; Mackenzie, J.D.; Levy, D. Rhodamine fluorescent dimers adsorbed on the porous surface of silica gels. Langmuir 2000, 16, 7377–7382. [Google Scholar] [CrossRef]

- Shugar, G.J.; Ballinger, J.T.; Dawkins, L.M. Chemical Technicians’ Ready Reference Handbook; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Girault, P.; Azuelos, P.; Lorrain, N.; Poffo, L.; Lemaitre, J.; Pirasteh, P.; Hardy, I.; Thual, M.; Guendouz, M.; Charrier, J. Porous silicon micro-resonator implemented by standard photolithography process for sensing application. Opt. Mater. 2017, 72, 596–601. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; Yang, X.; Wang, R.; Li, H.; Sheng, C. Evanescent-wave pumped single-mode microcavity laser from fiber of 125 μm diameter. Photonics Res. 2018, 6, 332–338. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lijing, Z.; Zakoldaev, R.A.; Sergeev, M.M.; Veiko, V.P. Fluorescent Bulk Waveguide Sensor in Porous Glass: Concept, Fabrication, and Testing. Nanomaterials 2020, 10, 2169. https://doi.org/10.3390/nano10112169

Lijing Z, Zakoldaev RA, Sergeev MM, Veiko VP. Fluorescent Bulk Waveguide Sensor in Porous Glass: Concept, Fabrication, and Testing. Nanomaterials. 2020; 10(11):2169. https://doi.org/10.3390/nano10112169

Chicago/Turabian StyleLijing, Zhong, Roman A. Zakoldaev, Maksim M. Sergeev, and Vadim P. Veiko. 2020. "Fluorescent Bulk Waveguide Sensor in Porous Glass: Concept, Fabrication, and Testing" Nanomaterials 10, no. 11: 2169. https://doi.org/10.3390/nano10112169

APA StyleLijing, Z., Zakoldaev, R. A., Sergeev, M. M., & Veiko, V. P. (2020). Fluorescent Bulk Waveguide Sensor in Porous Glass: Concept, Fabrication, and Testing. Nanomaterials, 10(11), 2169. https://doi.org/10.3390/nano10112169