Sensitivity-Enhanced SPR Sensor Based on Graphene and Subwavelength Silver Gratings

Abstract

1. Introduction

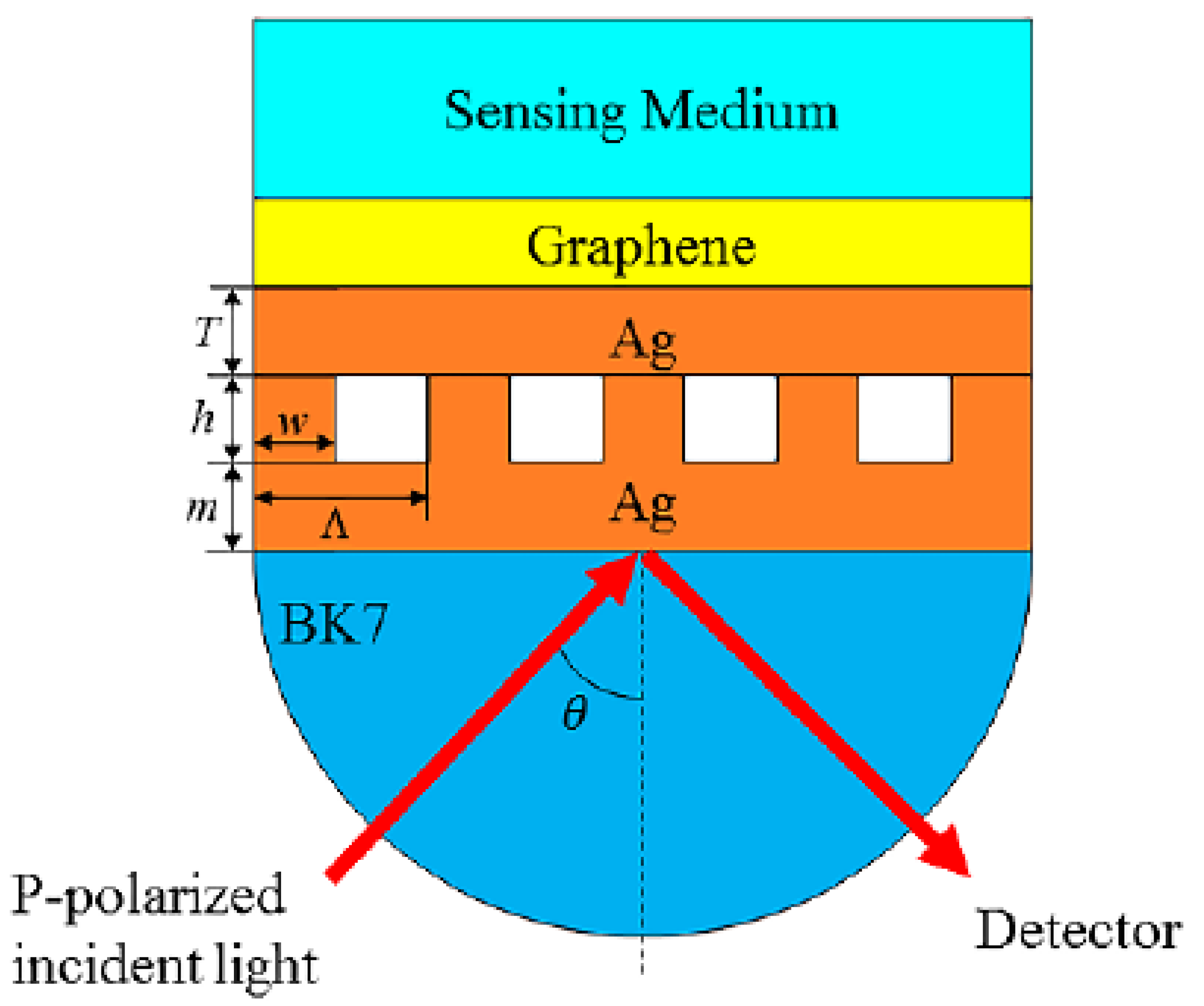

2. Theoretical Model

3. Results and Discussion

3.1. Performance Parameter Setup

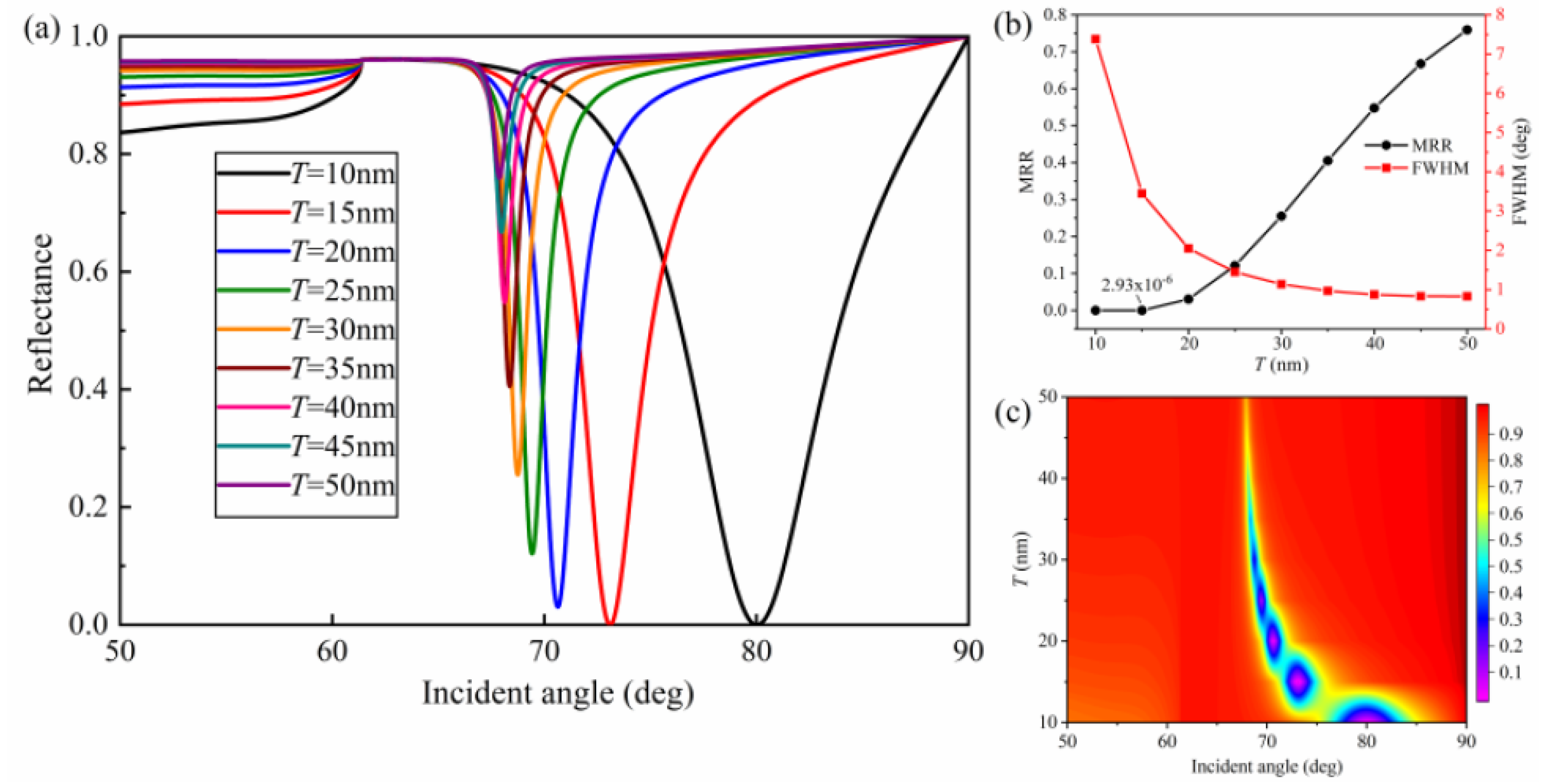

3.2. Evaluation of Metal Film Thickness on Sensor Performance

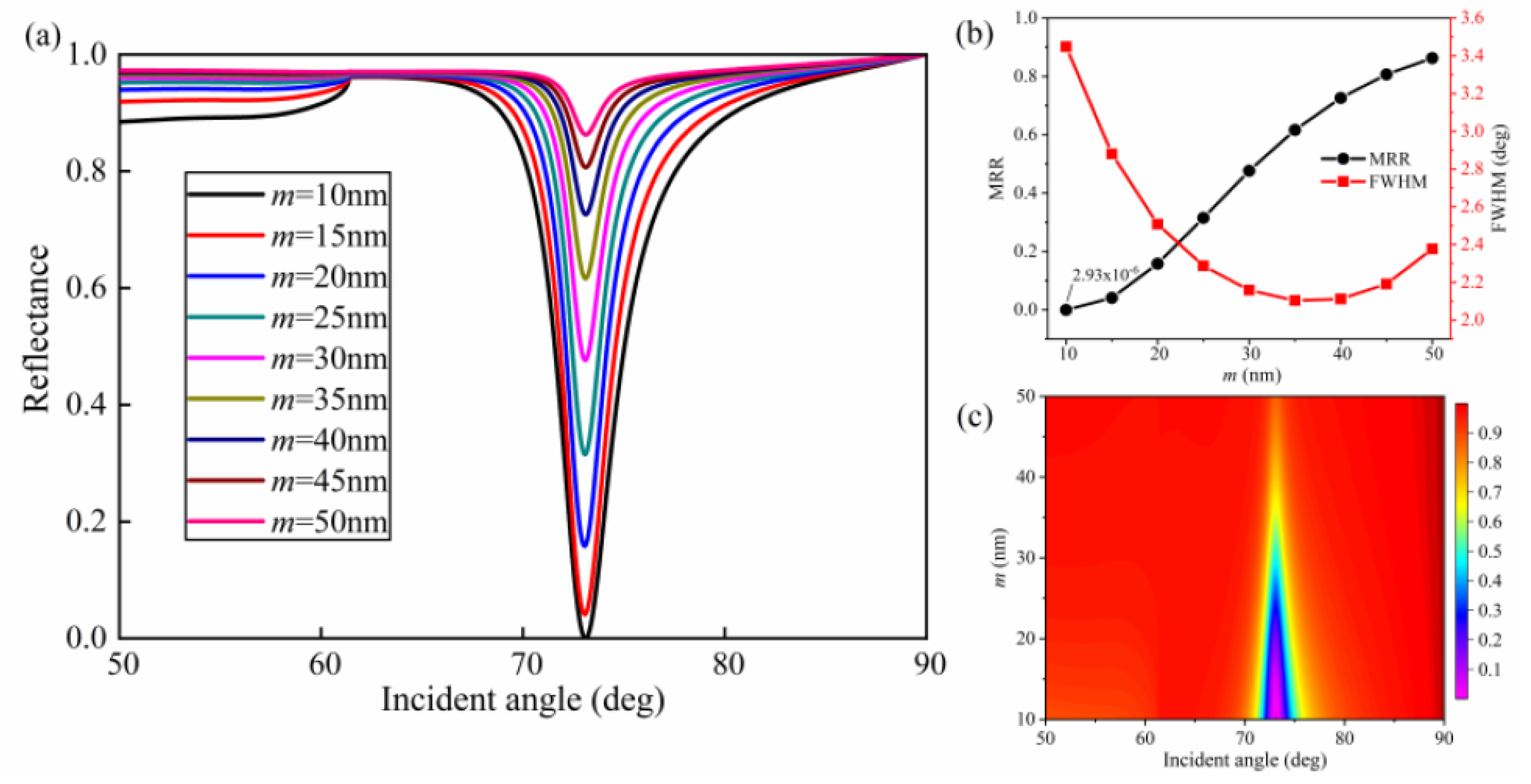

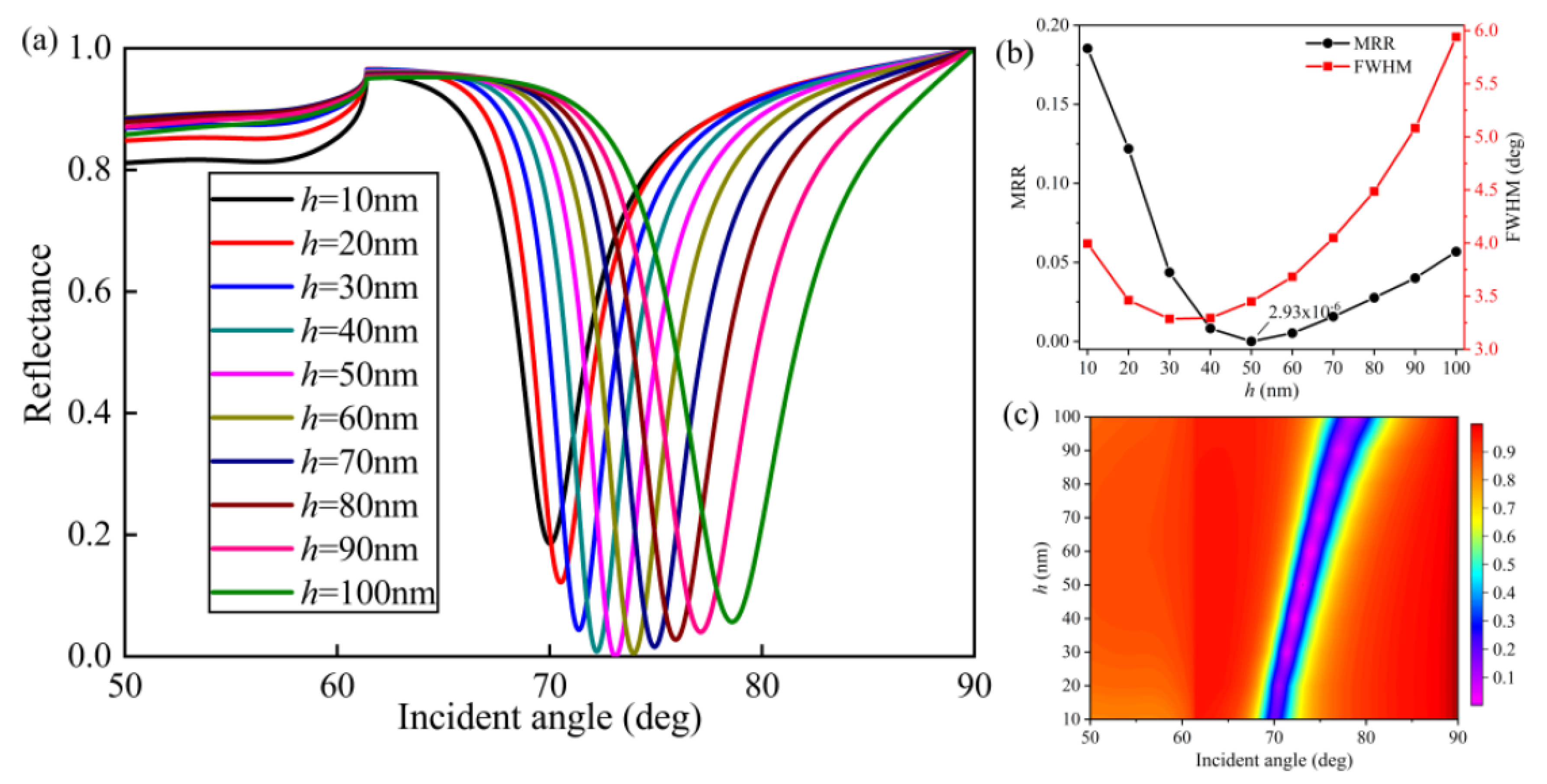

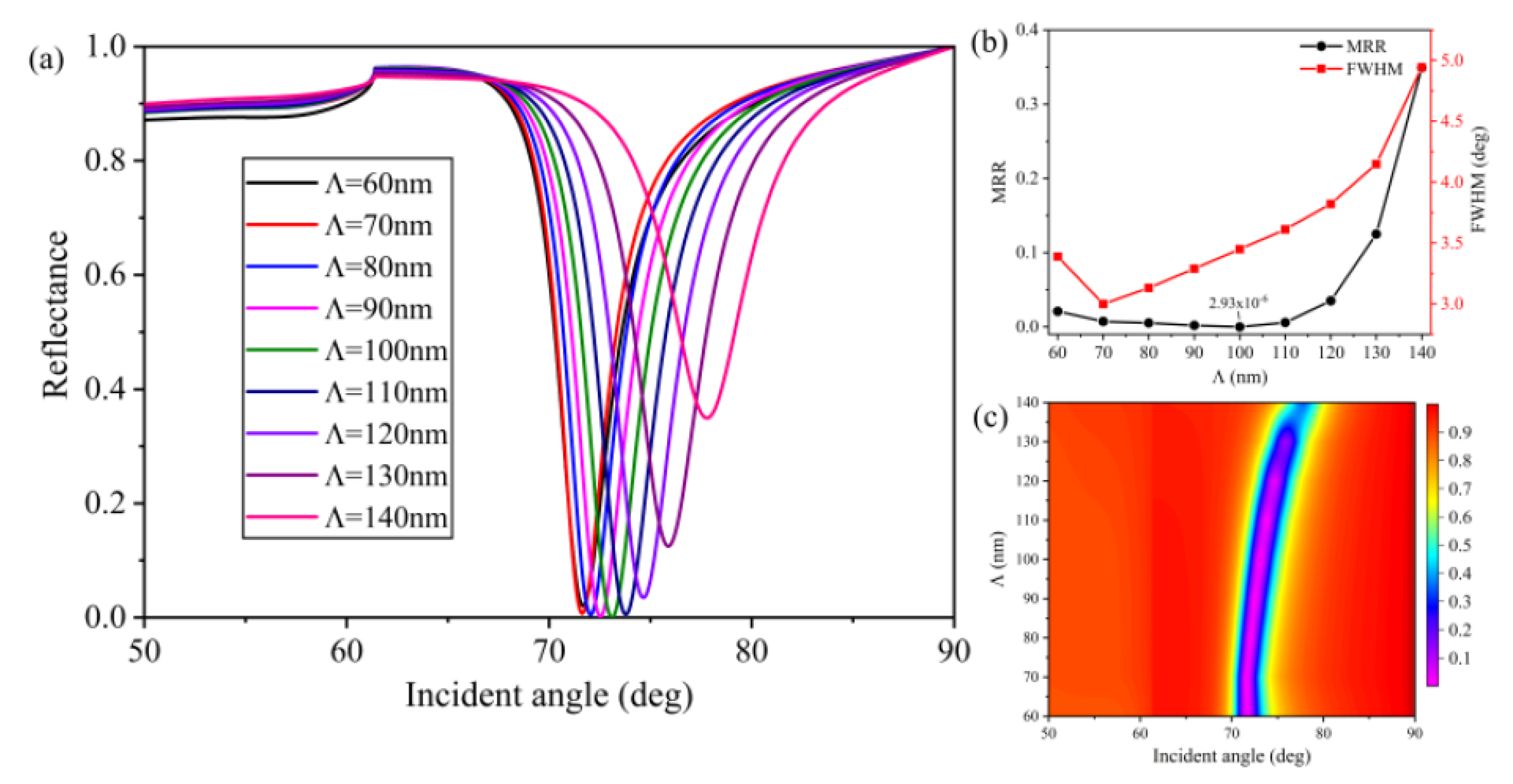

3.3. Evaluation of Grating Strutural Parameters on Sensor Performance

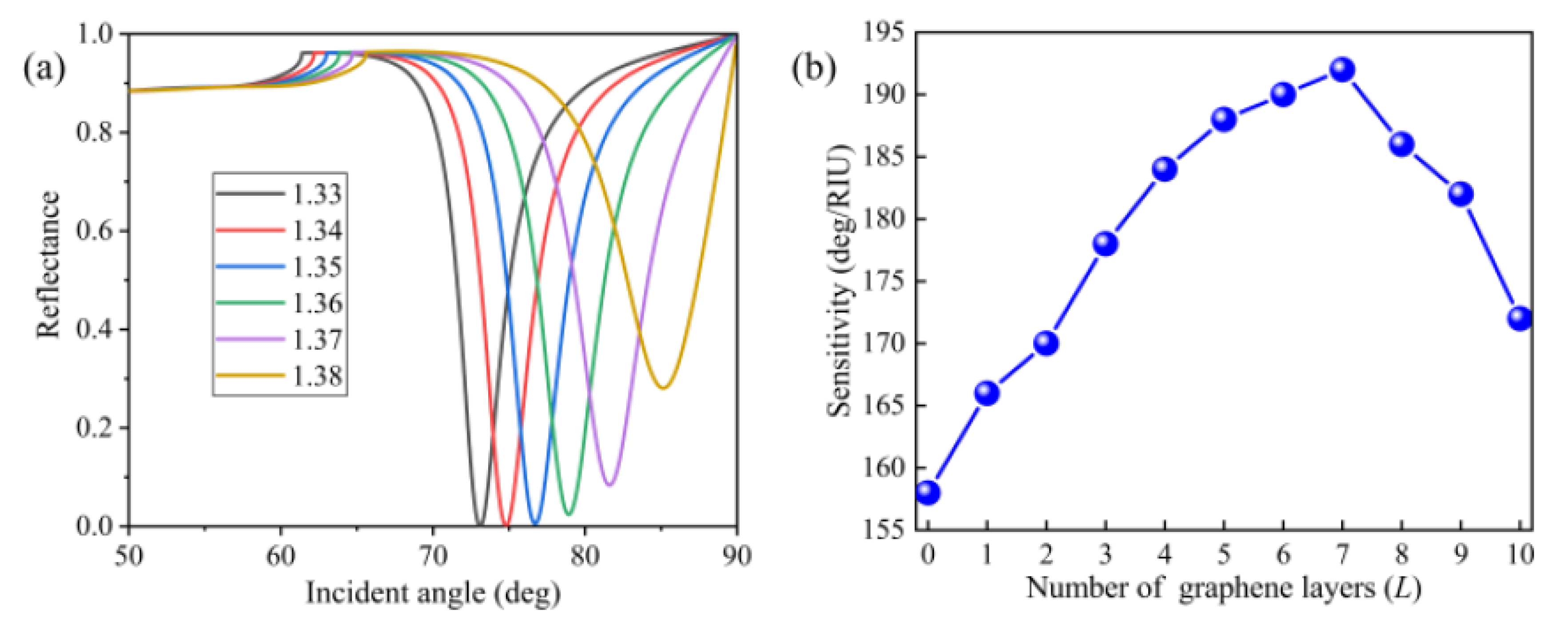

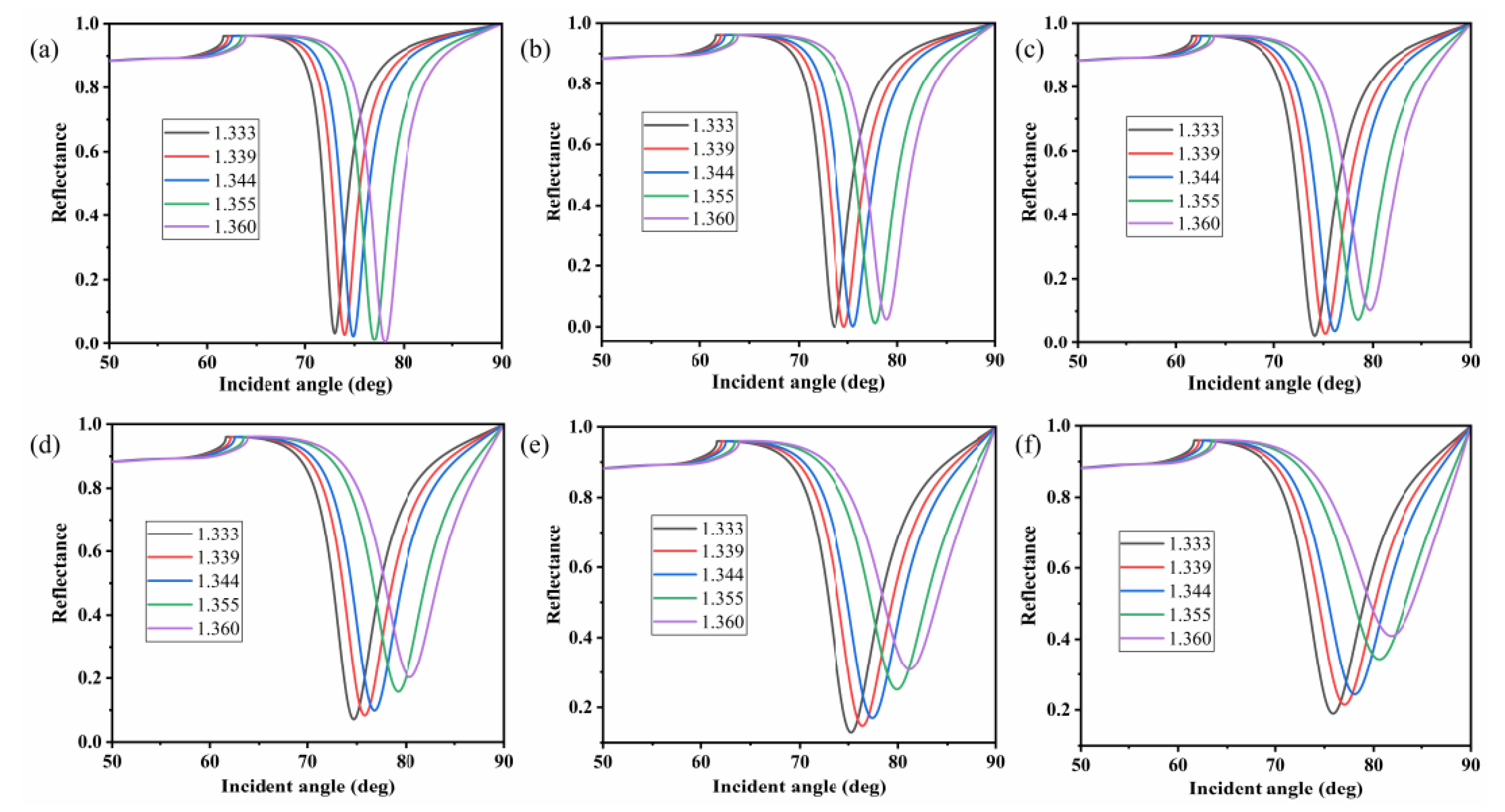

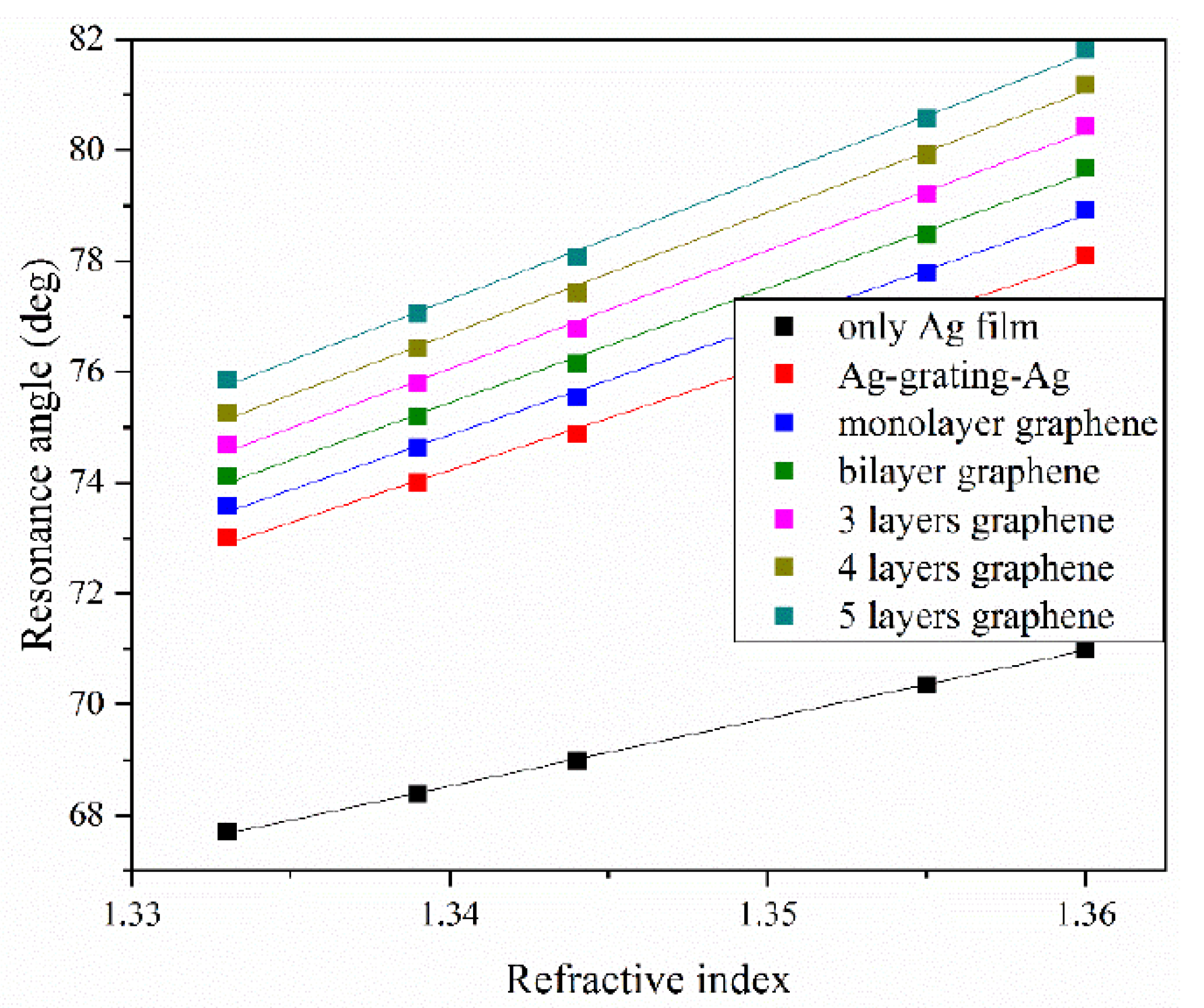

3.4. Performance Analysis and Comparison

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Homola, J. Surface plasmon resonance sensors for detection of chemical and biological species. Chem. Rev. 2008, 108, 462–493. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Cushing, S.K.; Wu, N. Plasmon-enhanced optical sensors: A review. Analyst 2015, 140, 386–406. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Chen, Y.-P.; Wang, W.; Shen, Y.; Guo, J.-S. Surface plasmon resonance for water pollutant detection and water process analysis. TrAC Trends Anal. Chem. 2016, 85, 153–165. [Google Scholar] [CrossRef]

- Couture, M.; Zhao, S.S.; Masson, J.-F. Modern surface plasmon resonance for bioanalytics and biophysics. Phys. Chem. Chem. Phys. 2013, 15, 11190–11216. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Qi, Q.; Wang, C.; Qian, Y.; Liu, G.; Wang, Y.; Fu, L. Surface plasmon resonance (SPR) biosensors for food allergen detection in food matrices. Biosens. Bioelectron. 2019, 142, 111449. [Google Scholar] [CrossRef]

- Tabassum, R.; Mishra, S.K.; Gupta, B. Surface plasmon resonance-based fiber optic hydrogen sulphide gas sensor utilizing Cu–ZnO thin films. Phys. Chem. Chem. Phys. 2013, 15, 11868–11874. [Google Scholar] [CrossRef]

- Homola, J. Present and future of surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2003, 377, 528–539. [Google Scholar] [CrossRef]

- Menon, P.S.; Mohamed, R.; Khairulazdan, N.B.; Said, F.A.; Gan, S.M.; Mohamad, N.R.; Jamil, N.A.; Tarumaraja, K.A.; Razak, N.R.; Bakar, A.A.A.; et al. Kretschmann based surface plasmon resonance for sensing in visible region. In Proceedings of the 2019 IEEE 9th International Nanoelectronics Conferences (INEC), Kuching, Malaysia, 3–5 July 2019; pp. 1–6. [Google Scholar]

- Wu, L.; Guo, J.; Xu, H.; Dai, X.; Xiang, Y. Ultrasensitive biosensors based on long-range surface plasmon polariton and dielectric waveguide modes. Photon. Res. 2016, 4, 262–266. [Google Scholar] [CrossRef]

- Kazanskiy, N.; Khonina, S.; Butt, M.A. Plasmonic sensors based on Metal-insulator-metal waveguides for refractive index sensing applications: A brief review. Phys. E 2020, 117, 113798. [Google Scholar] [CrossRef]

- Rahmatiyar, M.; Afsahi, M.; Danaie, M. Design of a refractive index plasmonic sensor based on a ring resonator coupled to a MIM waveguide containing tapered defects. Plasmonics 2020, 1–8. [Google Scholar] [CrossRef]

- Kazanskiy, N.; Butt, M.A.; Khonina, S. Nanodots decorated MIM semi-ring resonator cavity for biochemical sensing applications. Photon. Nanostructures Fundam. Appl. 2020, 42, 100836. [Google Scholar] [CrossRef]

- Vlček, J.; Pištora, J.; Lesňák, M. Design of plasmonic-waveguiding structures for sensor applications. Nanomaterials 2019, 9, 1227. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Kazanskiy, N.L.; Khonina, S.N. Highly sensitive refractive index sensor based on plasmonic bow tie configuration. Photon. Sens. 2020, 10, 223–232. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, R.-J.; Xia, F.; Peng, Y. Current status of optical fiber biosensor based on surface plasmon resonance. Biosens. Bioelectron. 2019, 142, 111505. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Pandey, A.K. Design and analysis of plasmonic sensor in communication band with gold grating on nitride substrate. Superlattices Microstruct. 2019, 130, 369–376. [Google Scholar] [CrossRef]

- Xia, L.; Yin, S.; Gao, H.; Deng, Q.; Du, C. Sensitivity enhancement for surface plasmon resonance imaging biosensor by utilizing gold–silver bimetallic film configuration. Plasmonics 2011, 6, 245–250. [Google Scholar] [CrossRef]

- Lee, K.-S.; Son, J.M.; Jeong, D.-Y.; Lee, T.S.; Kim, W.M. Resolution enhancement in surface plasmon resonance sensor based on waveguide coupled mode by combining a bimetallic approach. Sensors 2010, 10, 11390–11399. [Google Scholar] [CrossRef] [PubMed]

- Peng, W.; Liang, Y.; Li, L.; Masson, J.-F. Metallic nanowire array–polymer hybrid film for surface plasmon resonance sensitivity enhancement and spectral range enlargement. Plasmonics 2013, 9, 319–326. [Google Scholar] [CrossRef]

- Pang, L.; Hwang, G.M.; Slutsky, B.; Fainman, Y. Spectral sensitivity of two-dimensional nanohole array surface plasmon polariton resonance sensor. Appl. Phys. Lett. 2007, 91, 123112. [Google Scholar] [CrossRef]

- Piliarik, M.; Šípová, H.; Kvasnička, P.; Galler, N.; Krenn, J.R.; Homola, J. High-resolution biosensor based on localized surface plasmons. Opt. Express 2011, 20, 672–680. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, X.; Yonzon, C.R.; Haes, A.J.; Van Duyne, R.P. Localized surface plasmon resonance biosensors. Nanomedicine 2006, 1, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.J.; Kim, D. Subwavelength grating-based nanoplasmonic modulation for surface plasmon resonance imaging with enhanced resolution. J. Opt. Soc. Am. B 2010, 27, 1252–1259. [Google Scholar] [CrossRef]

- Jang, S.M.; Kim, N.; Choi, S.H.; Byun, K.M.; Kim, S.J. Enhancement of localized surface plasmon resonance detection by incorporating metal-dielectric double-layered subwavelength gratings. Appl. Opt. 2011, 50, 2846–2854. [Google Scholar] [CrossRef]

- Tahmasebpour, M.; Bahrami, M.; Asgari, A. Design study of nanograting-based surface plasmon resonance biosensor in the near-infrared wavelength. Appl. Opt. 2014, 53, 1449–1458. [Google Scholar] [CrossRef]

- Neto, A.H.C.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef]

- Vakil, A.; Engheta, N. Transformation optics using graphene. Science 2011, 332, 1291–1294. [Google Scholar] [CrossRef]

- Luo, X.; Qiu, T.; Lu, W.; Ni, Z. Plasmons in graphene: Recent progress and applications. Mater. Sci. Eng. R Rep. 2013, 74, 351–376. [Google Scholar] [CrossRef]

- Wu, L.; Chu, H.S.; Koh, W.S.; Li, E.P. Highly sensitive graphene biosensors based on surface plasmon resonance. Opt. Express 2010, 18, 14395–14400. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, Y.L.; Byun, K.M. Graphene-on-silver substrates for sensitive surface plasmon resonance imaging biosensors. Opt. Express 2011, 19, 458–466. [Google Scholar] [CrossRef]

- Verma, R.; Gupta, B.D.; Jha, R. Sensitivity enhancement of a surface plasmon resonance based biomolecules sensor using graphene and silicon layers. Sens. Actuators B Chem. 2011, 160, 623–631. [Google Scholar] [CrossRef]

- Mishra, A.K.; Mishra, S.K. Gas sensing in Kretschmann configuration utilizing bi-metallic layer of Rhodium-Silver in visible region. Sens. Actuators B Chem. 2016, 237, 969–973. [Google Scholar] [CrossRef]

- Rahman, M.S.; Rikta, K.; Abdulrazak, L.F.; Anower, S. Enhanced performance of SnSe-Graphene hybrid photonic surface plasmon refractive sensor for biosensing applications. Photon. Nanostruct. 2020, 39, 100779. [Google Scholar] [CrossRef]

- Hossain, B.; Mehedi, I.M.; Moznuzzaman, M.; Abdulrazak, L.F.; Hossain, A. High performance refractive index SPR sensor modeling employing graphene tri sheets. Res. Phys. 2019, 15, 102719. [Google Scholar] [CrossRef]

- Zeng, S.; Sreekanth, K.V.; Shang, J.; Yu, T.; Chen, C.-K.; Yin, F.; Baillargeat, D.; Coquet, P.; Ho, H.-P.; Kabashin, A.V.; et al. Graphene-gold metasurface architectures for ultrasensitive plasmonic biosensing. Adv. Mater. 2015, 27, 6163–6169. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, Z.; Shirkani, H. High-performance label-free near-infrared SPR sensor for wide range of gases and biomolecules based on graphene-gold grating. Plasmonics 2019, 14, 1179–1188. [Google Scholar] [CrossRef]

- Islam, M.; Kouzani, A. Numerical investigation of a grating and graphene-based multilayer surface plasmon resonance biosensor. J. Mod. Opt. 2014, 61, 1209–1218. [Google Scholar] [CrossRef]

- Tong, K.; Wang, Y.; Wang, F.; Sun, J.; Wu, X. Surface plasmon resonance biosensor based on graphene and grating excitation. Appl. Opt. 2019, 58, 1824–1829. [Google Scholar] [CrossRef]

- Zeng, S.; Hu, S.; Xia, J.; Anderson, T.S.; Dinh, X.-Q.; Meng, X.-M.; Coquet, P.; Yong, K.-T. Graphene–MoS2 hybrid nanostructures enhanced surface plasmon resonance biosensors. Sens. Actuators B Chem. 2015, 207, 801–810. [Google Scholar] [CrossRef]

- Sreekanth, K.V.; Zeng, S.; Yong, K.-T.; Yu, T. Sensitivity enhanced biosensor using graphene-based one-dimensional photonic crystal. Sens. Actuators B Chem. 2013, 182, 424–428. [Google Scholar] [CrossRef]

- Sun, P.; Wang, M.; Liu, L.; Jiao, L.; Du, W.; Xia, F.; Liu, M.; Kong, W.; Dongac, L.; Yun, M. Sensitivity enhancement of surface plasmon resonance biosensor based on graphene and barium titanate layers. Appl. Surf. Sci. 2019, 475, 342–347. [Google Scholar] [CrossRef]

- Bruna, M.; Borini, S. Optical constants of graphene layers in the visible range. Appl. Phys. Lett. 2009, 94, 031901. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef]

- Tahmasebpour, M.; Bahrami, M.; Asgari, A. Investigation of subwavelength grating structure for enhanced surface plasmon resonance detection. Appl. Opt. 2014, 53, 6307–6316. [Google Scholar] [CrossRef] [PubMed]

- Maharana, P.K.; Jha, R. Chalcogenide prism and graphene multilayer based surface plasmon resonance affinity biosensor for high performance. Sens. Actuators B Chem. 2012, 169, 161–166. [Google Scholar] [CrossRef]

- Wu, L.; Yue, J.; Jiang, L.; Guo, J.; Dai, X.; Xiang, Y.; Fan, D. Sensitivity improved SPR biosensor based on the MoS2/graphene–aluminum hybrid structure. J. Light. Technol. 2017, 35, 82–87. [Google Scholar] [CrossRef]

- Maharana, P.K.; Padhy, P.; Jha, R. On the field enhancement and performance of an ultra-stable SPR biosensor based on graphene. IEEE Photon Technol. Lett. 2013, 25, 2156–2159. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Dong, J.; Hu, S.; Zhu, W.; Qiu, W.; Lu, H.; Yu, J.; Guan, H.; Gao, S.; et al. Sensitivity-enhanced surface plasmon resonance sensor utilizing a tungsten disulfide (WS2) nanosheets overlayer. Photon. Res. 2018, 6, 485–491. [Google Scholar] [CrossRef]

| Design | Sensitivity (deg/RIU) | FWHM (deg) | MRR | References |

|---|---|---|---|---|

| Au–Ag bimetallic film | 54.84 | -- | 0.1 | [17] |

| Au–Si–graphene | 134.6 | 17.975 | -- | [33] |

| Rh–Ag–graphene | 220 | 10.204 | -- | [34] |

| SnSe–graphene | 94.29 | 7.454 | 0.0032 | [35] |

| Graphene tri sheets | 121.67 | 3.30 | -- | [36] |

| Au–graphene | 46 | 5.52 | -- | [47] |

| Graphene–MoS2–Al | 190.36 | -- | -- | [48] |

| Ag–graphene | 91.76 | 1.754 | -- | [49] |

| Graphene–Ag grating | 220.67 | 7.093 | 0.19 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, L.; Lv, J.; Gu, Q.; Ying, Y.; Jiang, X.; Si, G. Sensitivity-Enhanced SPR Sensor Based on Graphene and Subwavelength Silver Gratings. Nanomaterials 2020, 10, 2125. https://doi.org/10.3390/nano10112125

Kong L, Lv J, Gu Q, Ying Y, Jiang X, Si G. Sensitivity-Enhanced SPR Sensor Based on Graphene and Subwavelength Silver Gratings. Nanomaterials. 2020; 10(11):2125. https://doi.org/10.3390/nano10112125

Chicago/Turabian StyleKong, Lu, Jiangtao Lv, Qiongchan Gu, Yu Ying, Xiaoxiao Jiang, and Guangyuan Si. 2020. "Sensitivity-Enhanced SPR Sensor Based on Graphene and Subwavelength Silver Gratings" Nanomaterials 10, no. 11: 2125. https://doi.org/10.3390/nano10112125

APA StyleKong, L., Lv, J., Gu, Q., Ying, Y., Jiang, X., & Si, G. (2020). Sensitivity-Enhanced SPR Sensor Based on Graphene and Subwavelength Silver Gratings. Nanomaterials, 10(11), 2125. https://doi.org/10.3390/nano10112125