Development and Application of an Additively Manufactured Calcium Chloride Nebulizer for Alginate 3D-Bioprinting Purposes

Abstract

1. Introduction

2. Results

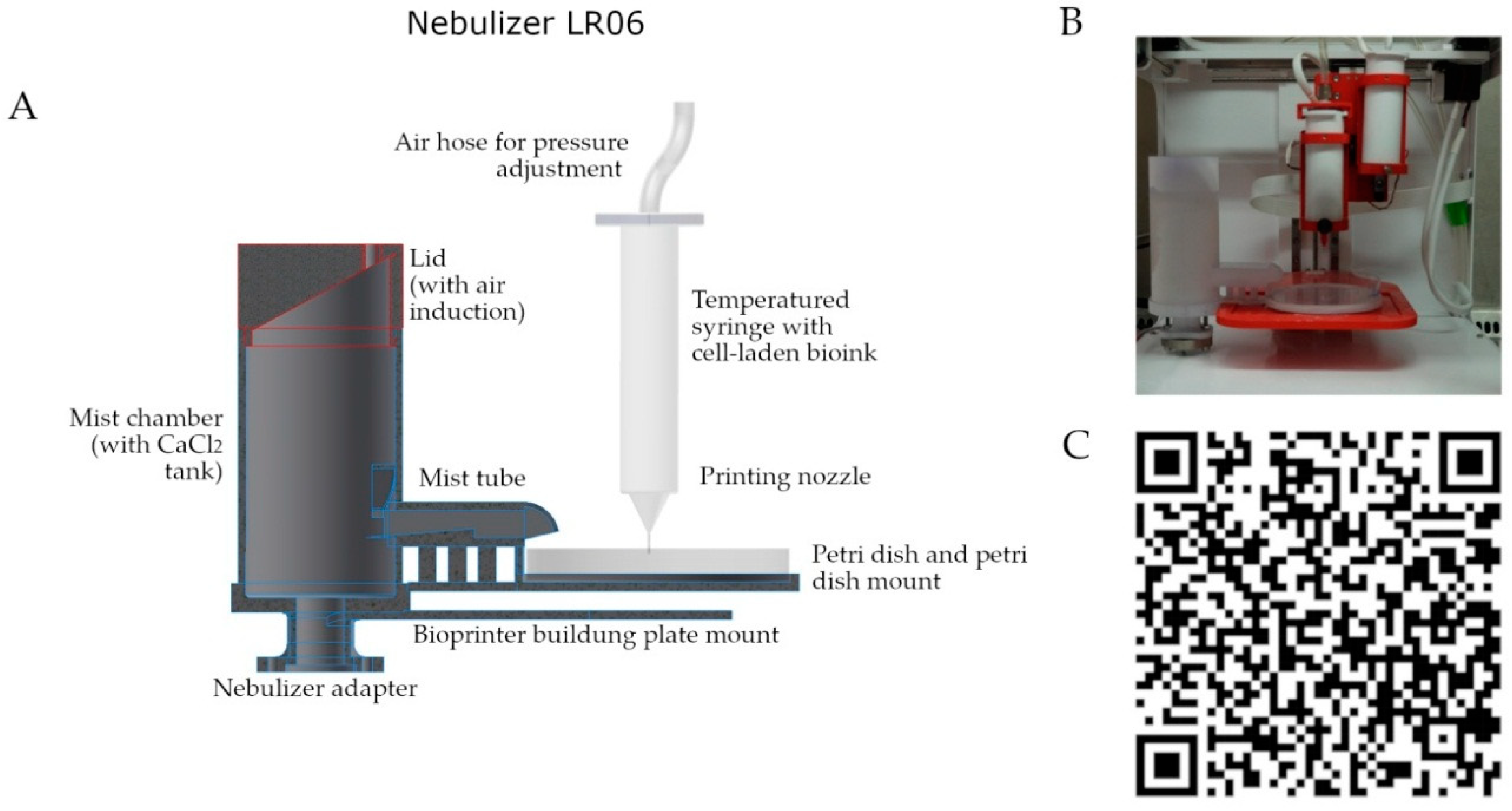

2.1. Design, Manufacturing and Functioning of the CaCl2 Nebulizer

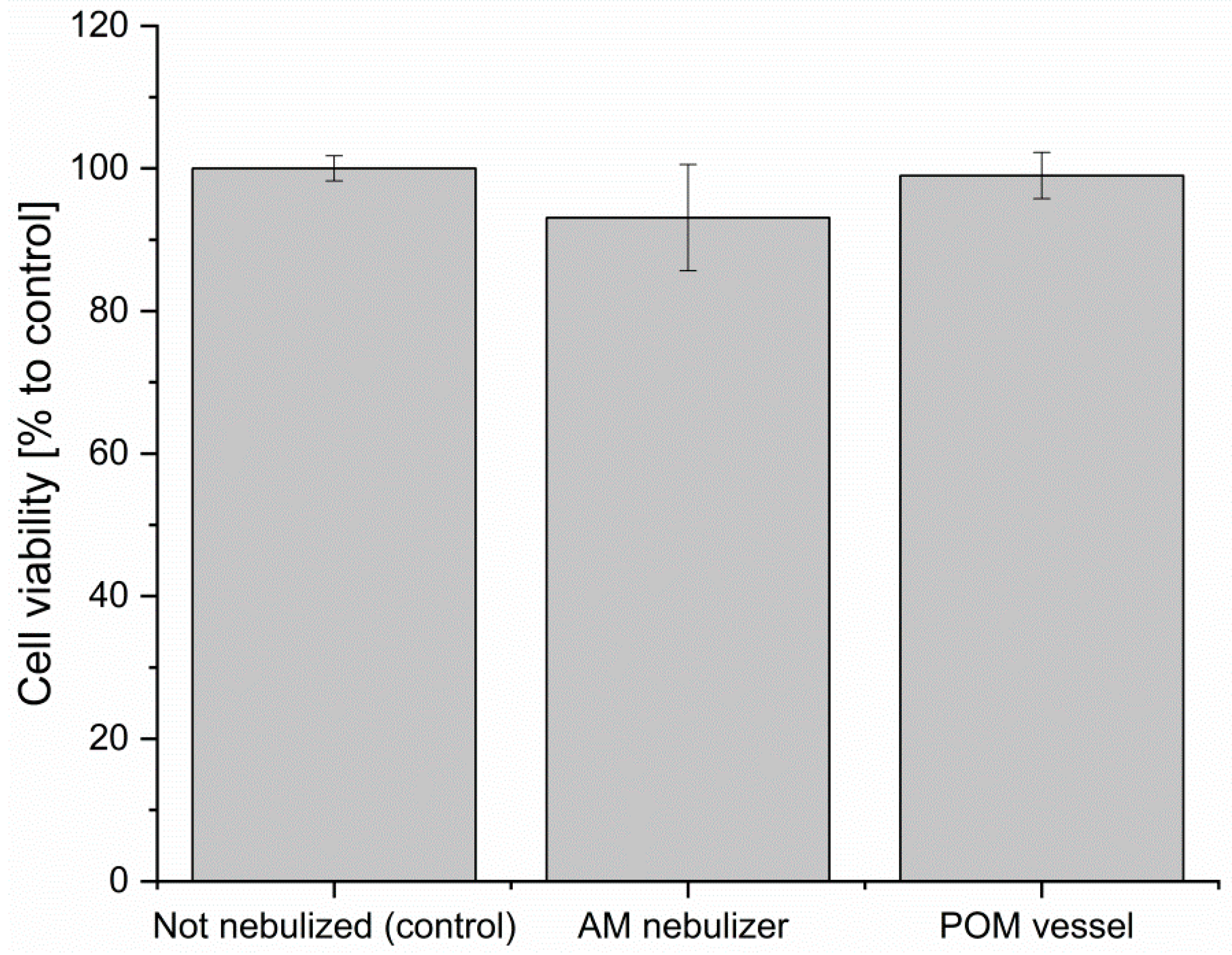

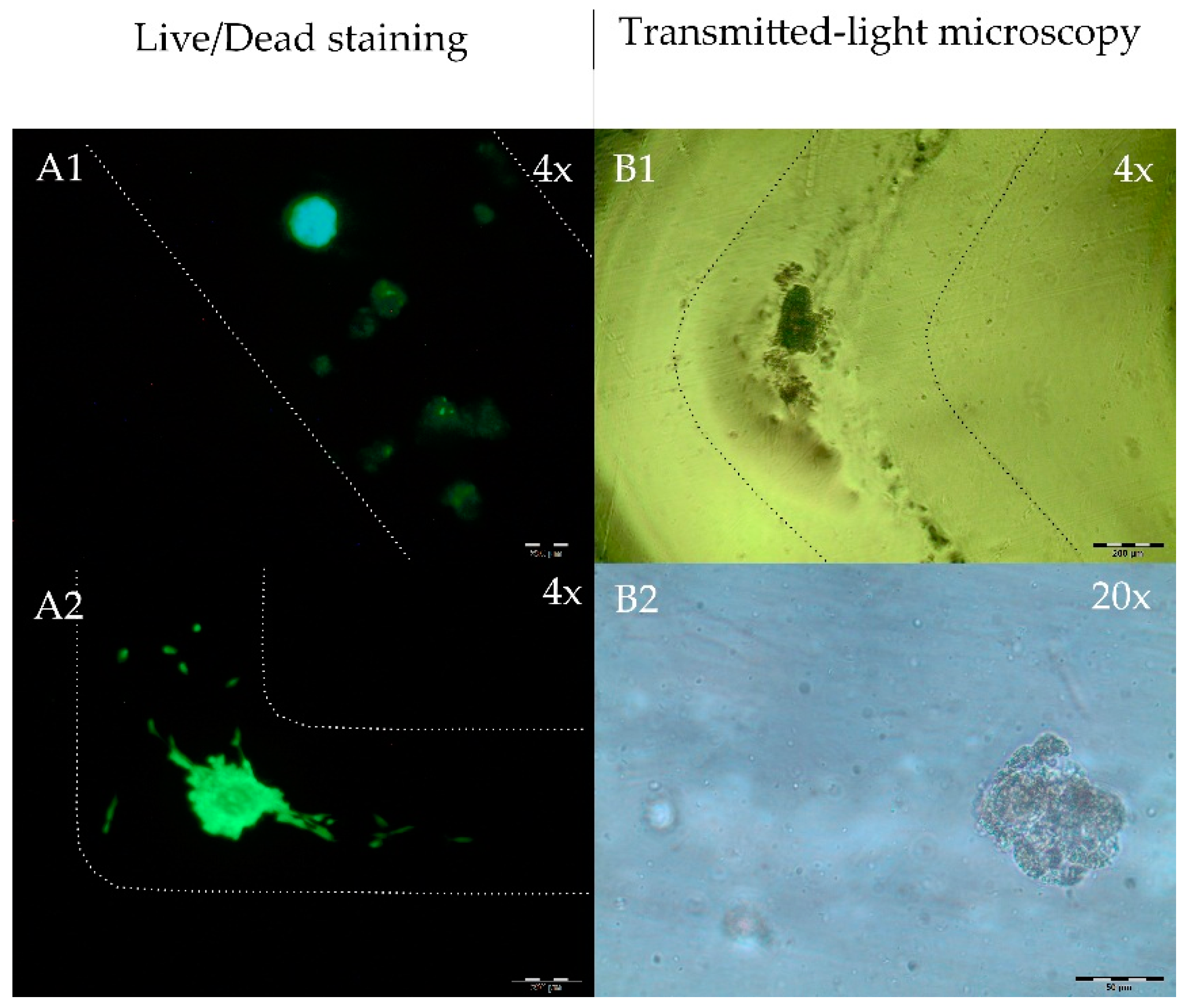

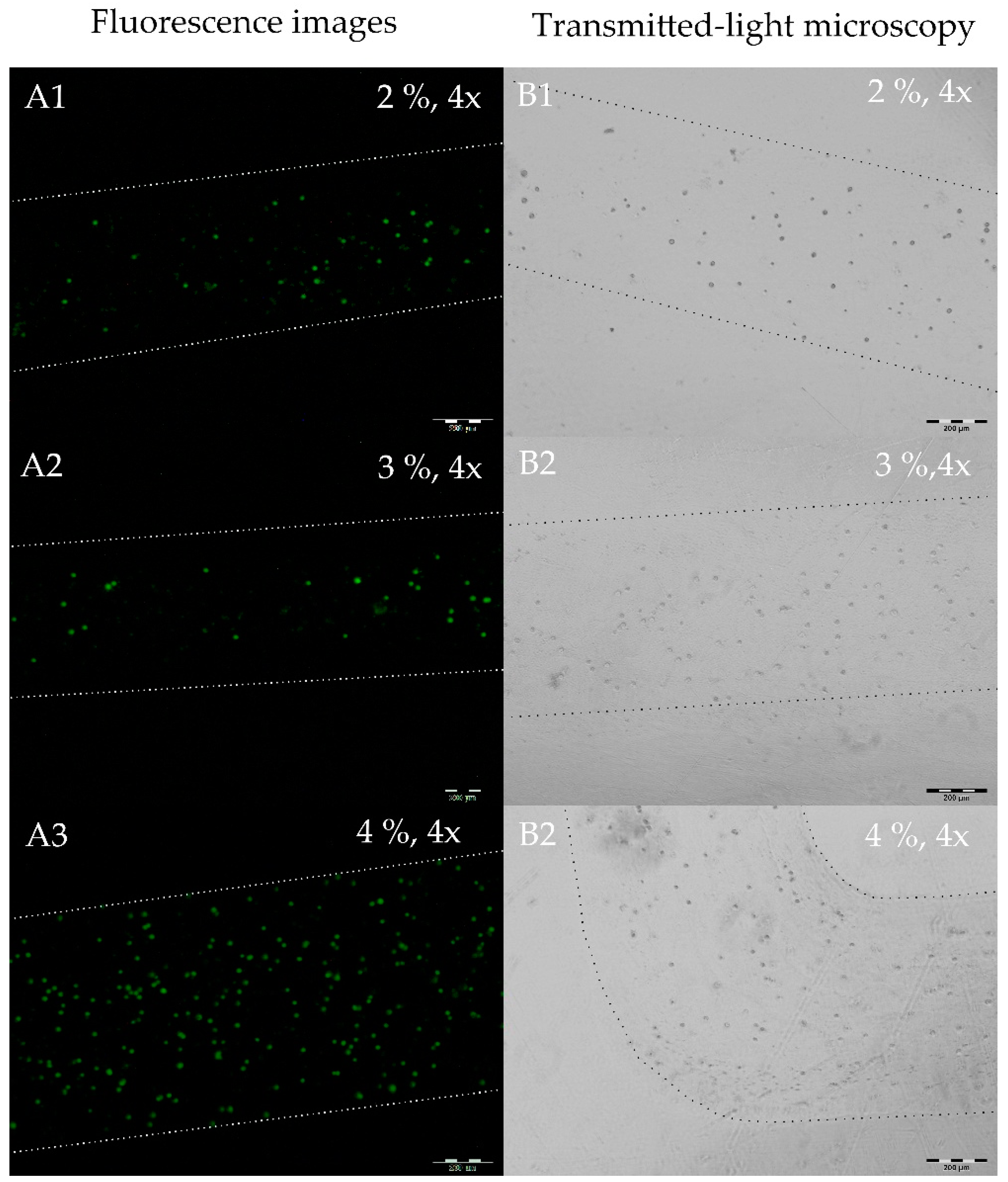

2.1.1. Toxicity Evaluation of the Printing Material and Nebulization Effect

2.2. Hydrogel Characterization

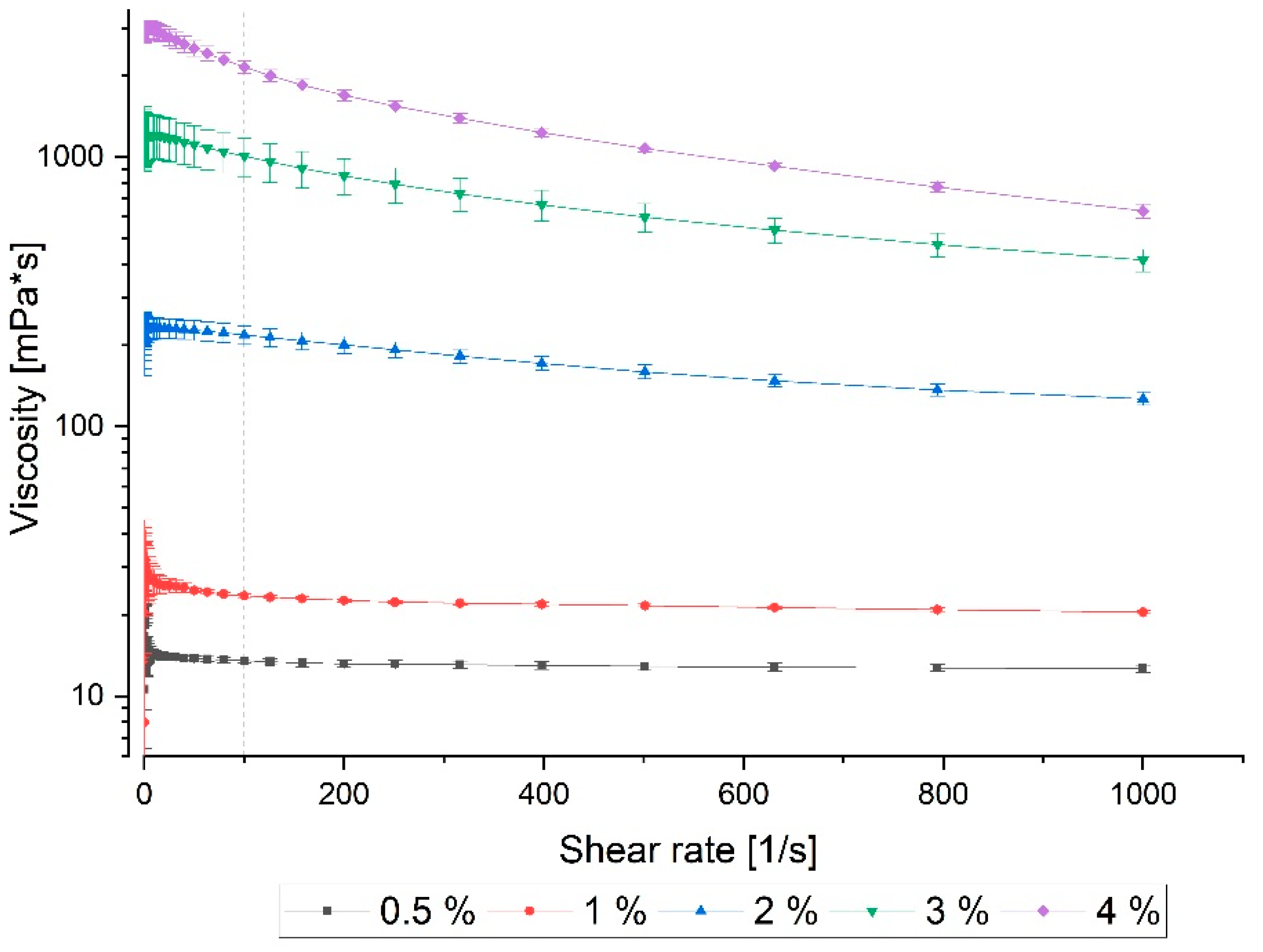

2.2.1. Viscosity

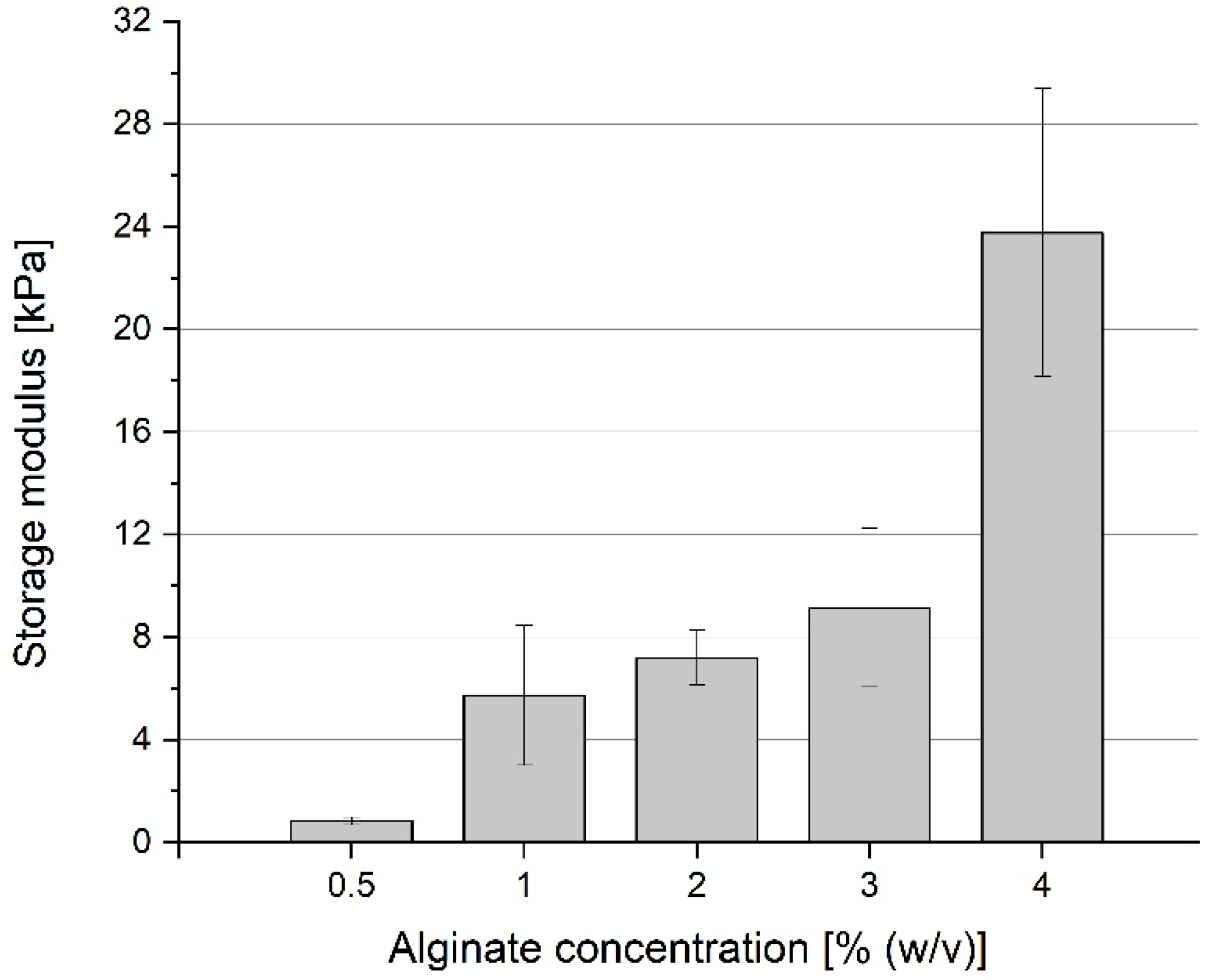

2.2.2. Storage Modulus

2.3. Bioprinting

2.3.1. Bioprinting Parameters and Shape Evaluation

2.3.2. HAD-MSC Bioprinting

2.3.3. NIH-3T3 3D Bioprinting

3. Discussion and Conclusions

4. Materials and Methods

4.1. Cell Culture

hAD-MSCs Spheroids

4.2. Cell Staining (Live/Dead Assay)

4.3. Cell Toxicity Evaluation of Nebulized Media and CellTiterBlue@ Assay

4.4. CAD Modeling and 3D Printing Techniques

4.4.1. Nebulizer

4.4.2. Bioink Preperation

4.4.3. 3D Bioprinting

4.5. Rheology

4.5.1. Viscosity

4.5.2. Storage Modulus

4.6. Chemicals

4.7. Statistical Analysis

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lehmann-Haupt, H.E. Johannes Gutenberg. German Printer. Britannica.com. Available online: https://www.britannica.com/biography/Johannes-Gutenberg (accessed on 3 May 2018).

- Johnston, G. Preaching to a Postmodern World: A Guide to Reaching Twenty-First Century Listeners; Baker Books: Ada, MI, USA, 2001; ISBN 0801063671. [Google Scholar]

- Raddatz, L.; Austerjost, J.; Beutel, S. 3D-Druck: Chancen, Möglichkeiten, Risiken. Chem. Unserer Zeit 2017. [Google Scholar] [CrossRef]

- Raddatz, L.; Vries, I.; Austerjost, J.; Lavrentieva, A.; Geier, D.; Becker, T.; Beutel, S.; Scheper, T. Additive manufactured customizable labware for biotechnological purposes. Eng. Life Sci. 2017, 17, 931–939. [Google Scholar] [CrossRef]

- Lücking, T.H.; Sambale, F.; Beutel, S.; Scheper, T. 3D-printed individual labware in biosciences by rapid prototyping: A proof of principle. Eng. Life Sci. 2015, 15, 51–56. [Google Scholar] [CrossRef]

- Lücking, T.H.; Sambale, F.; Schnaars, B.; Bulnes-Abundis, D.; Beutel, S.; Scheper, T. 3D-printed individual labware in biosciences by rapid prototyping: In vitro biocompatibility and applications for eukaryotic cell cultures. Eng. Life Sci. 2015, 15, 57–64. [Google Scholar] [CrossRef]

- Ude, C.; Hentrop, T.; Lindner, P.; Lücking, T.H.; Scheper, T.; Beutel, S. New perspectives in shake flask pH control using a 3D-printed control unit based on pH online measurement. Sensors Actuators B Chem. 2015, 221, 1035–1043. [Google Scholar] [CrossRef]

- Maltman, D.J.; Przyborski, S.A. Developments in three-dimensional cell culture technology aimed at improving the accuracy of in vitro analyses. Biochem. Soc. Trans. 2010, 38, 1072–1075. [Google Scholar] [CrossRef] [PubMed]

- Holmes, A.M.; Charlton, A.; Derby, B.; Ewart, L.; Scott, A.; Shu, W. Rising to the challenge: Applying biofabrication approaches for better drug and chemical product development. Biofabrication 2017, 9. [Google Scholar] [CrossRef] [PubMed]

- Hölzl, K.; Lin, S.; Tytgat, L.; Van Vlierberghe, S.; Gu, L.; Ovsianikov, A. Bioink properties before, during and after 3D bioprinting. Biofabrication 2016, 8, 032002. [Google Scholar] [CrossRef] [PubMed]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th anniversary article: Engineering hydrogels for biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef] [PubMed]

- Koch, L.; Gruene, M.; Unger, C.; Chichkov, B. Laser Assisted Cell Printing. Curr. Pharm. Biotechnol. 2013, 14, 91–97. [Google Scholar] [CrossRef] [PubMed]

- Gungor-Ozkerim, P.S.; Inci, I.; Zhang, Y.S.; Khademhosseini, A.; Dokmeci, M.R. Bioinks for 3D bioprinting: an overview. Biomater. Sci. 2018, 6, 915–946. [Google Scholar] [CrossRef] [PubMed]

- Derby, B. Printing and prototyping of tissues and scaffolds. Science 2012, 338, 921–926. [Google Scholar] [CrossRef] [PubMed]

- Ferris, C.J.; Gilmore, K.G.; Wallace, G.G.; in het Panhuis, M. Biofabrication: An overview of the approaches used for printing of living cells. Appl. Microbiol. Biotechnol. 2013, 97, 4243–4258. [Google Scholar] [CrossRef] [PubMed]

- De Mori, A.; Peña Fernández, M.; Blunn, G.; Tozzi, G.; Roldo, M.; De Mori, A.; Peña Fernández, M.; Blunn, G.; Tozzi, G.; Roldo, M. 3D Printing and Electrospinning of Composite Hydrogels for Cartilage and Bone Tissue Engineering. Polymers 2018, 10, 285. [Google Scholar] [CrossRef]

- Tan, Z.; Parisi, C.; Di Silvio, L.; Dini, D.; Forte, A.E. Cryogenic 3D Printing of Super Soft Hydrogels. Sci. Rep. 2017, 7, 16293. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, S.; Alm, M.; Hemmingsen, M.; Dolatshahi-Pirouz, A.; Trifol, J.; Thomsen, P.; Dufva, M.; Wolff, A.; Emnéus, J. 3D Printed Silicone-Hydrogel Scaffold with Enhanced Physicochemical Properties. Biomacromolecules 2016, 17, 1321–1329. [Google Scholar] [CrossRef] [PubMed]

- Duan, B.; Hockaday, L.A.; Kang, K.H.; Butcher, J.T. 3D Bioprinting of heterogeneous aortic valve conduits with alginate/gelatin hydrogels. J. Biomed. Mater. Res. Part A 2013, 101A, 1255–1264. [Google Scholar] [CrossRef] [PubMed]

- Shepherd, B.R.; Presnell, S.C.; Evinger, A.J. Engineered Three-Dimensional Connective Tissue Constructs and Methods of Making the Same. WO2013192290A1, 27 December 2013. [Google Scholar]

- Lipton, J.I.; Cutler, M.; Nigl, F.; Cohen, D.; Lipson, H. Additive manufacturing for the food industry. Trends Food Sci. Technol. 2015, 43, 114–123. [Google Scholar] [CrossRef]

- Jammalamadaka, U.; Tappa, K. Recent Advances in Biomaterials for 3D Printing and Tissue Engineering. J. Funct. Biomater. 2018, 9, 22. [Google Scholar] [CrossRef] [PubMed]

- Axpe, E.; Oyen, M.L. Applications of Alginate-Based Bioinks in 3D Bioprinting. Int. J. Mol. Sci. 2016, 17, 1976. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Kang, K.; Jeong, J.; Paik, S.S.; Kim, J.S.; Park, S.A.; Kim, W.D.; Park, J.; Choi, D. Three-dimensional (3D) printing of mouse primary hepatocytes to generate 3D hepatic structure. Ann. Surg. Treat. Res. 2017, 92, 67. [Google Scholar] [CrossRef] [PubMed]

- Jia, J.; Richards, D.J.; Pollard, S.; Tan, Y.; Rodriguez, J.; Visconti, R.P.; Trusk, T.C.; Yost, M.J.; Yao, H.; Markwald, R.R.; Mei, Y. Engineering alginate as bioink for bioprinting. Acta Biomater. 2014, 10, 4323–4331. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Nguyen, D.; Hägg, D.A.; Forsman, A.; Ekholm, J.; Nimkingratana, P.; Brantsing, C.; Kalogeropoulos, T.; Zaunz, S.; Concaro, S.; Brittberg, M.; Lindahl, A.; Gatenholm, P.; Enejder, A.; Simonsson, S. Cartilage Tissue Engineering by the 3D Bioprinting of iPS Cells in a Nanocellulose/Alginate Bioink. Sci. Rep. 2017, 7. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Gungor-Ozkerim, P.S.; Zhang, Y.S.; Yue, K.; Zhu, K.; Liu, W.; Pi, Q.; Byambaa, B.; Dokmeci, M.R.; Shin, S.R.; et al. Direct 3D bioprinting of perfusable vascular constructs using a blend bioink. Biomaterials 2016, 106, 58–68. [Google Scholar] [CrossRef] [PubMed]

- Williams, S.K.; Touroo, J.S.; Church, K.H.; Hoying, J.B. Encapsulation of Adipose Stromal Vascular Fraction Cells in Alginate Hydrogel Spheroids Using a Direct-Write Three-Dimensional Printing System. Biores. Open Access 2013, 2, 448–454. [Google Scholar] [CrossRef] [PubMed]

- Kyle, S.; Jessop, Z.M.; Al-Sabah, A.; Whitaker, I.S. ‘Printability’ of Candidate Biomaterials for Extrusion Based 3D Printing: State-of-the-Art. Adv. Healthc. Mater. 2017, 6, 1700264. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ramay, H.R.; Hauch, K.D.; Xiao, D.; Zhang, M. Chitosan–alginate hybrid scaffolds for bone tissue engineering. Biomaterials 2005, 26, 3919–3928. [Google Scholar] [CrossRef] [PubMed]

- Hinton, T.J.; Jallerat, Q.; Palchesko, R.N.; Park, J.H.; Grodzicki, M.S.; Shue, H.J.; Ramadan, M.H.; Hudson, A.R.; Feinberg, A.W. Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels. Sci. Adv. 2015, 1. [Google Scholar] [CrossRef] [PubMed]

- George, A.; Hu, B.; Xue, Z.; Du, Z.; Nageswar, Y.V.D.; Murthy, S.N.; Madhav, B.; Shankar, J.; Lin, T.-H.; Huang, W.-H.; et al. Biomineralization and Biomimetic Synthesis of Biomineral and Nanomaterials. In Advances in Biomimetics; InTech: Rijeka, Croatia, 2011; ISBN 978-953-307-191-6. [Google Scholar]

- Dreimann, J. Evaluierung und Optimierung Eines Neuartigen Bioreaktorsystems—Technische Informationsbibliothek (TIB); Leibniz Universität Hannover: Hannover, Germany, 2014. [Google Scholar]

- Tscheschke, B. Nebelkammerreaktoren zur Kultivierung Biotechnologisch Relevanter—Technische Informationsbibliothek (TIB); Leibniz Universität Hannover: Hannover, Germany, 2015. [Google Scholar]

- Barreras, F.; Amaveda, H.; Lozano, A. Transient high-frequency ultrasonic water atomization. Exp. Fluids 2002, 33, 405–413. [Google Scholar] [CrossRef]

- Avvaru, B.; Patil, M.N.; Gogate, P.R.; Pandit, A.B. Ultrasonic atomization: Effect of liquid phase properties. Ultrasonics 2006, 44, 146–158. [Google Scholar] [CrossRef] [PubMed]

- Wozniak, G. Zerstäubungstechnik; Springer: Berlin/Heidelberg, Germnay, 2003; ISBN 978-3-642-62509-1. [Google Scholar]

- Safety Data Sheet According to VisiJet ® M2-RCL 1; 3D Systems, Inc.: Rock Hill, SC, USA, 2015.

- Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity; ISO 10993-5:2009; ISO: Geneva, Switzerland, 2009.

- Mezger, T.G. Angewandte Rheologie—Mit Joe Flow auf der Rheologie-Straße; Anton Paar GmbH: Graz, Austria, 2014; ISBN 978-3-200-03652-9. [Google Scholar]

- Wilson, S.A.; Cross, L.M.; Peak, C.W.; Gaharwar, A.K. Shear-Thinning and Thermo-Reversible Nanoengineered Inks for 3D Bioprinting. ACS Appl. Mater. Interfaces 2017, 9, 43449–43458. [Google Scholar] [CrossRef] [PubMed]

- Tabriz, A.G.; Hermida, M.A.; Leslie, N.R.; Shu, W. Three-dimensional bioprinting of complex cell laden alginate hydrogel structures. Biofabrication 2015, 9, 45012. [Google Scholar] [CrossRef] [PubMed]

- Song, S.-J.; Choi, J.; Park, Y.-D.; Hong, S.; Lee, J.J.; Ahn, C.B.; Choi, H.; Sun, K. Sodium Alginate Hydrogel-Based Bioprinting Using a Novel Multinozzle Bioprinting System. Artif. Organs 2011, 35, 1132–1136. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yang, F.; Zhao, H.; Gao, Q.; Xia, B.; Fu, J. Research on the printability of hydrogels in 3D bioprinting. Sci. Rep. 2016, 6, 29977. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, Y.; Mao, S.; Sun, W.; Yao, R. The influence of printing parameters on cell survival rate and printability in microextrusion-based 3D cell printing technology. Biofabrication 2015, 7, 045002. [Google Scholar] [CrossRef] [PubMed]

| Na/Alg [%, (w/v)] | Printing Temperature | Printing Platform Temperature | Air Pressure for Extrusion | CaCl2 [c] | |

|---|---|---|---|---|---|

| [PSI] | [mPa] | ||||

| 0.5 | 37 °C | RT (up to 40 °C possible) | N/A | N/A | 500 mM |

| 1 | <1.5 | <10.3 | |||

| 2 | 1.8–2.4 | 12.4–16.5 | |||

| 3 | 2.1–2.8 | 14.5–19.3 | |||

| 4 | 9.9–13.1 | 68.2–90.3 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raddatz, L.; Lavrentieva, A.; Pepelanova, I.; Bahnemann, J.; Geier, D.; Becker, T.; Scheper, T.; Beutel, S. Development and Application of an Additively Manufactured Calcium Chloride Nebulizer for Alginate 3D-Bioprinting Purposes. J. Funct. Biomater. 2018, 9, 63. https://doi.org/10.3390/jfb9040063

Raddatz L, Lavrentieva A, Pepelanova I, Bahnemann J, Geier D, Becker T, Scheper T, Beutel S. Development and Application of an Additively Manufactured Calcium Chloride Nebulizer for Alginate 3D-Bioprinting Purposes. Journal of Functional Biomaterials. 2018; 9(4):63. https://doi.org/10.3390/jfb9040063

Chicago/Turabian StyleRaddatz, Lukas, Antonina Lavrentieva, Iliyana Pepelanova, Janina Bahnemann, Dominik Geier, Thomas Becker, Thomas Scheper, and Sascha Beutel. 2018. "Development and Application of an Additively Manufactured Calcium Chloride Nebulizer for Alginate 3D-Bioprinting Purposes" Journal of Functional Biomaterials 9, no. 4: 63. https://doi.org/10.3390/jfb9040063

APA StyleRaddatz, L., Lavrentieva, A., Pepelanova, I., Bahnemann, J., Geier, D., Becker, T., Scheper, T., & Beutel, S. (2018). Development and Application of an Additively Manufactured Calcium Chloride Nebulizer for Alginate 3D-Bioprinting Purposes. Journal of Functional Biomaterials, 9(4), 63. https://doi.org/10.3390/jfb9040063