Correlation Between Polymerization Shrinkage and Filler Content for Universal Shade Flowable Resin-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Materials

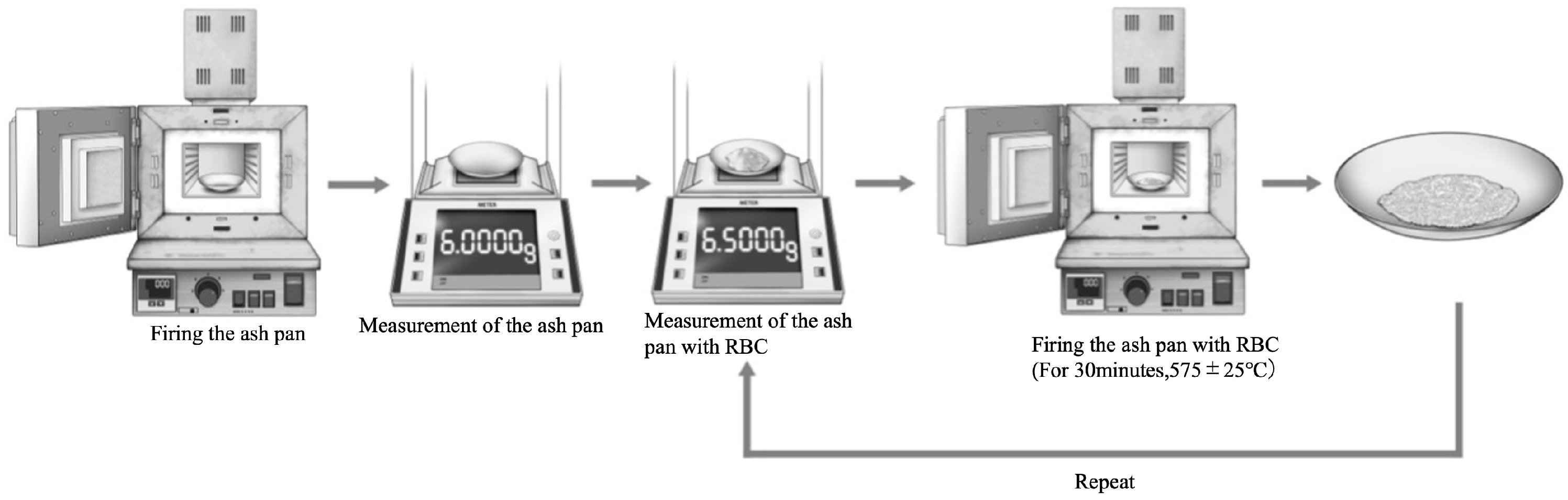

2.2. Measurement of Filler Content by Weight Percentage

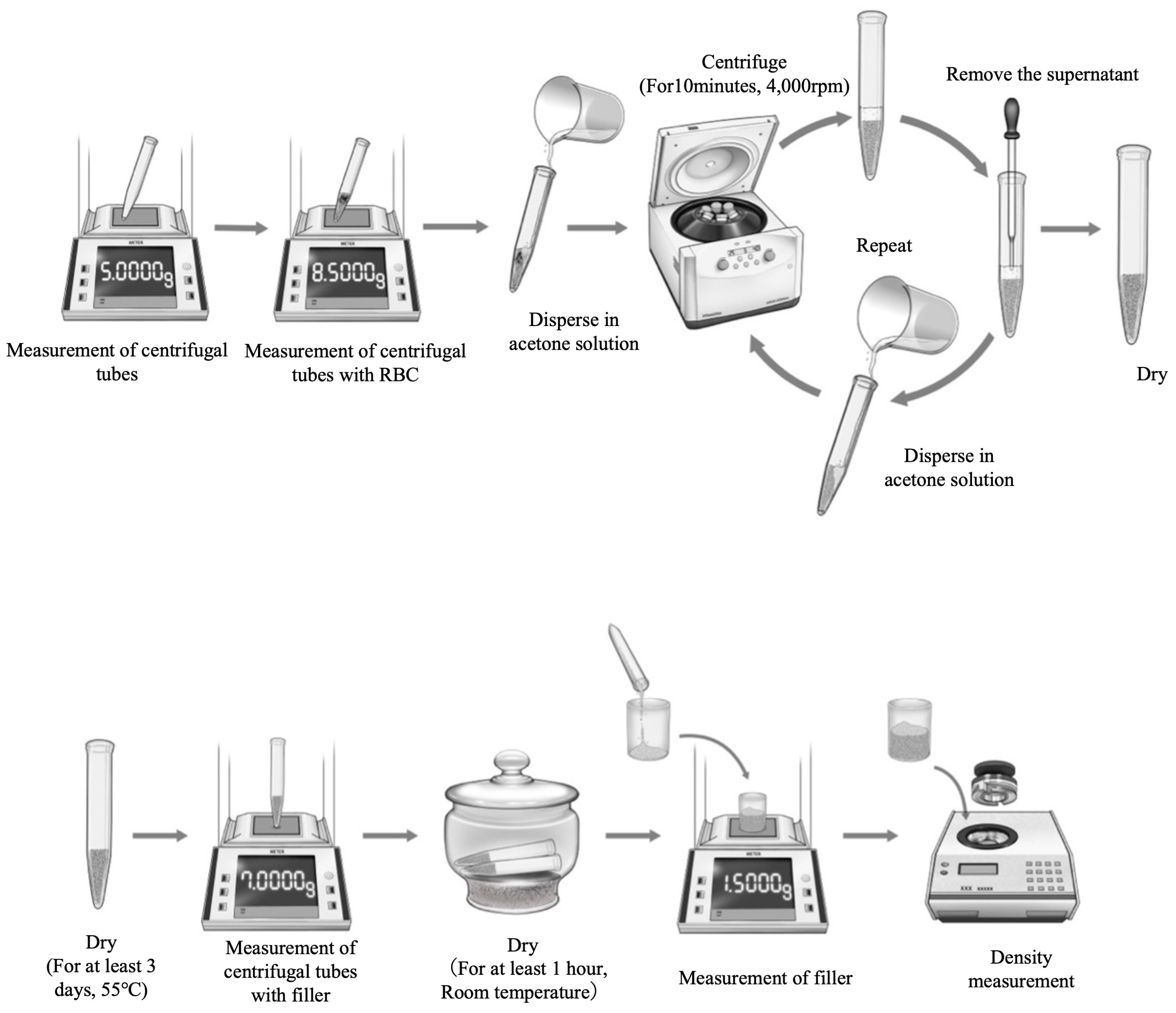

2.3. Determination of Filler Content by Volume Percentage

2.4. Statistical Analysis

3. Results

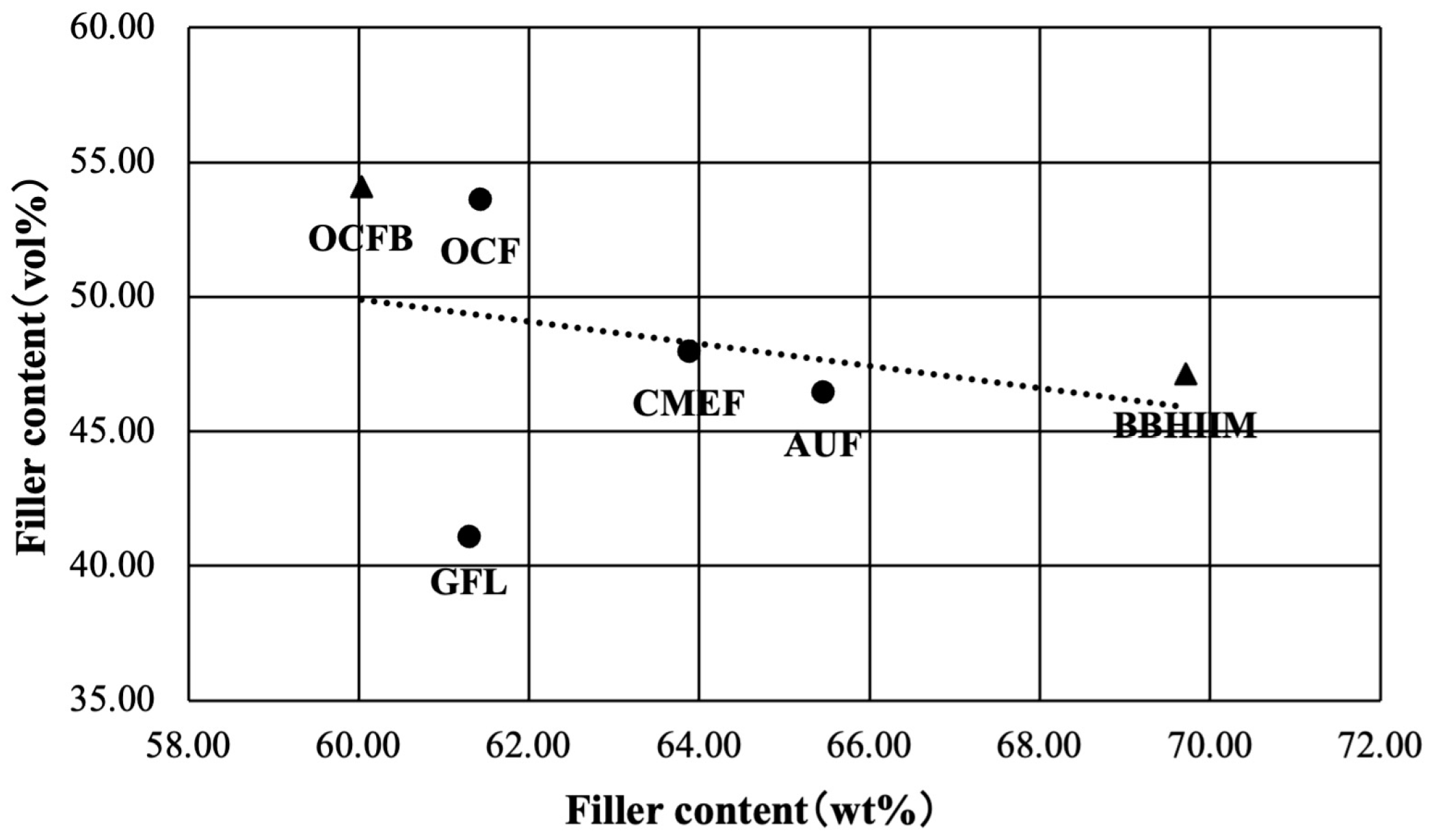

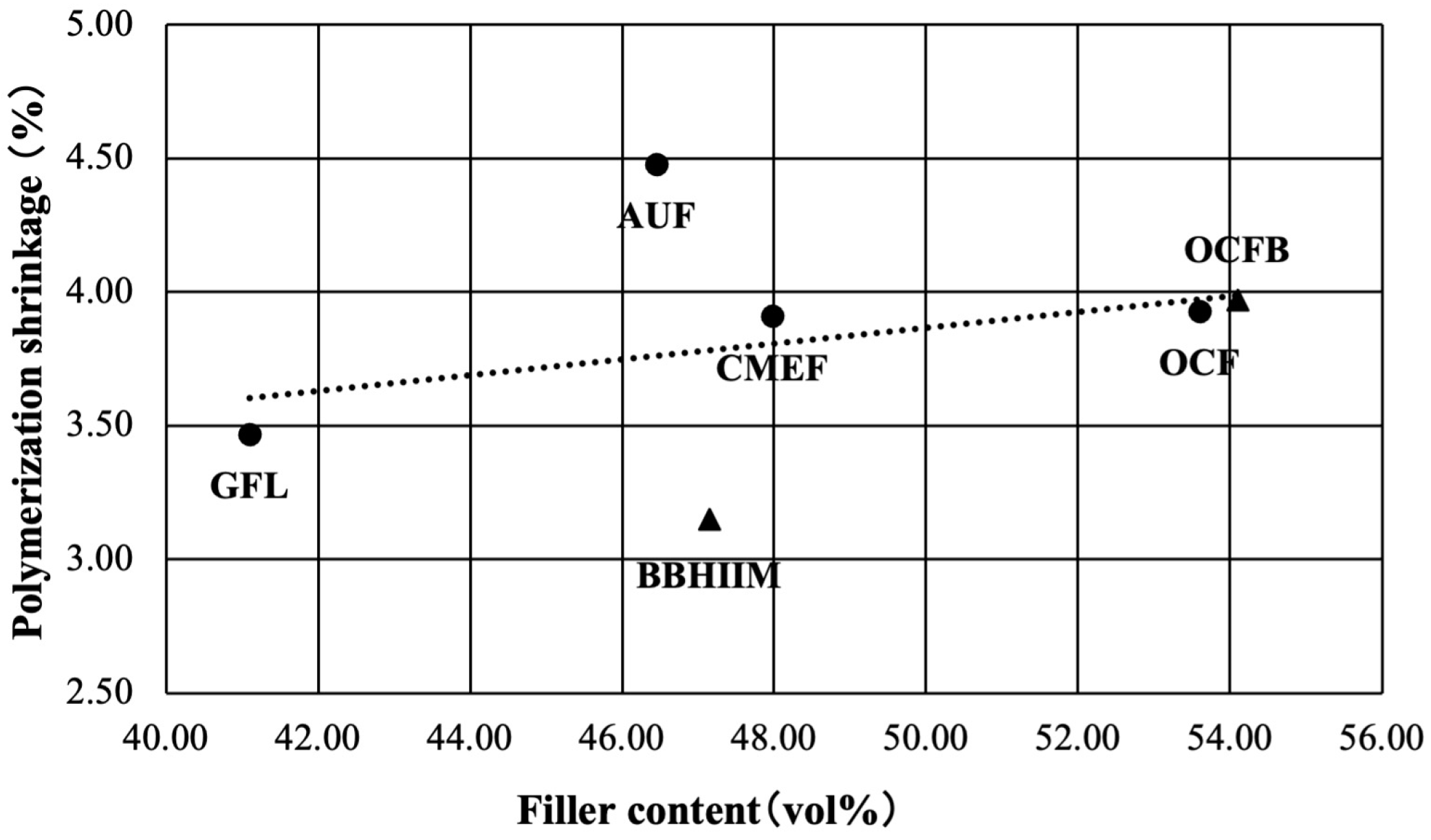

3.1. Filler Content by Weight and Volume

3.2. Correlation Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Perdigão, J.; Araujo, E.; Ramos, R.Q.; Gomes, G.; Pizzolotto, L. Adhesive dentistry: Current concepts and clinical considerations. J. Esthet. Restor. Dent. 2021, 33, 51–68. [Google Scholar] [CrossRef] [PubMed]

- Worthington, H.V.; Khangura, S.; Seal, K.; Mierzwinski-Urban, M.; Veitz-Keenan, A.; Sahrmann, P.; Schmidlin, P.R.; Davis, D.; Iheozor-Ejiofor, Z.; Rasines Alcaraz, M.G. Direct composite resin fillings versus amalgam fillings for permanent posterior teeth. Cochrane Database Syst. Rev. 2021, 8, CD005620. [Google Scholar] [CrossRef] [PubMed]

- Demarco, F.F.; Cenci, M.S.; Montagner, A.F.; de Lima, V.P.; Correa, M.B.; Moraes, R.R.; Opdam, N.J.M. Longevity of composite restorations is definitely not only about materials. Dent. Mater. 2023, 39, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Heintze, S.D.; Loguercio, A.D.; Hanzen, T.A.; Reis, A.; Rousson, V. Clinical efficacy of resin-based direct posterior restorations and glass-ionomer restorations—An updated meta-analysis of clinical outcome parameters. Dent. Mater. 2022, 38, e109–e135. [Google Scholar] [CrossRef] [PubMed]

- Schmalz, G.; Widbiller, M. Biocompatibility of amalgam vs composite—A review. Oral Health Prev. Dent. 2022, 20, 149–156. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Silikas, N.; Watts, D.C. Polymerization and shrinkage kinetics and fracture toughness of bulk-fill resin-composites. Dent. Mater. 2022, 38, 1934–1941. [Google Scholar] [CrossRef] [PubMed]

- German, M.J. Developments in resin-based composites. Br. Dent. J. 2022, 232, 638–643. [Google Scholar] [CrossRef] [PubMed]

- Maesako, M.; Fischer, N.G.; Matsui, N.; Elgreatly, A.; Mahrous, A.; Tsujimoto, A. Comparing Polymerization Shrinkage Measurement Methods for Universal Shade Flowable Resin-Based Composites. Biomimetics 2024, 9, 753. [Google Scholar] [CrossRef] [PubMed]

- Lempel, E.; Szebeni, D.; Őri, Z.; Kiss, T.; Szalma, J.; Lovász, B.V.; Kunsági-Máté, S.; Böddi, K. The effect of high-irradiance rapid polymerization on degree of conversion, monomer elution, polymerization shrinkage and porosity of bulk-fill resin composites. Dent. Mater. 2023, 39, 442–453. [Google Scholar] [CrossRef] [PubMed]

- Hayashi, J.; Espigares, J.; Takagaki, T.; Shimada, Y.; Tagami, J.; Numata, T.; Chan, D.; Sadr, A. Real-time in-depth imaging of gap formation in bulk-fill resin composites. Dent. Mater. 2019, 35, 585–596. [Google Scholar] [CrossRef]

- Maghaireh, G.A.; Taha, N.A.; Alzraikat, H. The Silorane-based Resin Composites: A Review. Oper. Dent. 2017, 42, E24–E34. [Google Scholar] [CrossRef] [PubMed]

- Tsujimoto, A.; Jurado, C.A.; Barkmeier, W.W.; Sayed, M.E.; Takamizawa, T.; Latta, M.A.; Miyazaki, M.; Garcia-Godoy, F. Effect of Layering Techniques on Polymerization Shrinkage Stress of High- and Low-viscosity Bulk-fill Resins. Oper. Dent. 2020, 45, 655–663. [Google Scholar] [CrossRef] [PubMed]

- Zotti, F.; Falavigna, E.; Capocasale, G.; De Santis, D.; Albanese, M. Microleakage of Direct Restorations—Comparison between Bulk-Fill and Traditional Composite Resins: Systematic Review and Meta-Analysis. Eur. J. Dent. 2021, 15, 755–767. [Google Scholar] [CrossRef] [PubMed]

- Maesako, M.; Matsui, N.; Fujitani, M.; Garcia-Godoy, F.; Tsujimoto, A. Comparison of surface properties of universal shade and conventional resin-based composites after degradation and repolishing. Am. J. Dent. 2024, 37, 147–153. [Google Scholar] [PubMed]

- Ruiz-López, J.; Mariano da Rocha, B.G.P.; Zemolin, N.A.M.; Altenhofen, C.S.; Durand, L.B.; Pérez, M.M. Visual evaluation of the color adjustment of single-shade and group shade resin composites in restorations with different cavity configurations. J. Dent. 2024, 149, 105262. [Google Scholar] [CrossRef] [PubMed]

- Meereis, C.T.W.; Münchow, E.A.; de Oliveira da Rosa, W.L.; da Silva, A.F.; Piva, E. Polymerization shrinkage stress of resin-based dental materials: A systematic review and meta-analyses of composition strategies. J. Mech. Behav. Biomed. Mater. 2018, 82, 268–281. [Google Scholar] [CrossRef] [PubMed]

- Furtos, G.; Baldea, B.; Silaghi-Dumitrescu, L.; Moldovan, M.; Prejmerean, C.; Nica, L. Influence of inorganic filler content on the radiopacity of dental resin cements. Dent. Mater J. 2012, 31, 266–272. [Google Scholar] [CrossRef] [PubMed][Green Version]

- ISO4049; Dentistry—Polymer-Based Restorative Materials. International Organization for Standardization: Geneva, Switzerland, 2019.

- Kaisarly, D.; Gezawi, M.E. Polymerization shrinkage assessment of dental resin composites: A literature review. Odontology 2016, 104, 257–270. [Google Scholar] [CrossRef] [PubMed]

- Ghani, S.M.A.; Hassan, M.I.A.; Abdullah, A.H.; Ghani, A.R.A.; Izra’ai, S.I.; Aregawi, W.; Chew, H.P.; Fok, A. Linear and volumetric shrinkage displacements of resin composite restorations with and without debonding. Dent. Mater. J. 2023, 42, 659–668. [Google Scholar] [CrossRef] [PubMed]

- Tsujimoto, A.; Irie, M.; Teixeira, E.C.N.; Jurado, C.A.; Maruo, Y.; Nishigawa, G.; Matsumoto, T.; Garcia-Godoy, F. Relationships between Flexural and Bonding Properties, Marginal Adaptation, and Polymerization Shrinkage in Flowable Composite Restorations for Dental Application. Polymers 2021, 13, 2613. [Google Scholar] [CrossRef] [PubMed]

- Tseng, P.C.; Chuang, S.F.; Kaisarly, D.; Kunzelmann, K.H. Simulating the shrinkage-induced interfacial damage around Class I composite resin restorations with damage mechanics. Dent. Mater. 2023, 39, 513–521. [Google Scholar] [CrossRef] [PubMed]

- Sampaio, C.S.; Garcés, G.A.; Kolakarnprasert, N.; Atria, P.J.; Giannini, M.; Hirata, R. External marginal gap evaluation of different resin-filling techniques for class II restorations-A micro-CT and SEM analysis. Oper. Dent. 2020, 45, E167–E175. [Google Scholar] [CrossRef] [PubMed]

- ISO 17304; Dentistry-Polymerization Shrinkage: Method for Determination of Polymerization Shrinkage of Polymer-Based Restorative Materials. International Organization for Standardization: Geneva, Switzerland, 2013.

- Fugolin, A.P.P.; Pfeifer, C.S. New Resins for Dental Composites. J. Dent. Res. 2017, 96, 1085–1091. [Google Scholar] [CrossRef] [PubMed]

- Pfeifer, C.S. Polymer-Based Direct Filling Materials. Dent. Clin. N. Am. 2017, 61, 733–750. [Google Scholar] [CrossRef] [PubMed]

- Nitta, K.; Nomoto, R.; Tsubota, Y.; Tsuchikawa, M.; Hayakawa, T. Characteristics of low polymerization shrinkage flowable resin composites in newly-developed cavity base materials for bulk filling technique. Dent. Mater. J. 2017, 36, 740–746. [Google Scholar] [CrossRef] [PubMed]

| Materials | Main Components | wt% | vol% | Manufacturer | Lot No. |

|---|---|---|---|---|---|

| Bulk Base HARD II Medium Flow Multi (BBH II M: Bulk-fill) | Bis-MPEPP, methacrylate monomers, barium silica glass | 74 | 54.3 | SUN MEDICAL (Moriyama, Japan) | 22062 |

| A-UNO Flow Basic (AUF: Conventional) | UDMA, Bis-GMA, DEGDMA, spherical nano filler (20–50 nm), fluoride sustained-release filler (700 nm), fluoride sustained-release filler (700 nm), ceramics cluster filler (2–8 μm) | 70 | - | YAMAKIN (Konan, Japan) | 30112314 |

| CLEARFIL MAJESTY ES Flow Low Universal (CMEF: Conventional) | Hydrophobic aromatic dimethacrylate, TEGDMA, silanated barium glass filler, silanated silica filler (0.18–3.5 μm) | 75 | 59 | Kuraray Noritake Dental (Tokyo, Japan) | 5Q0060 |

| GRACEFIL LoFlo Universal (GFL: Conventional) | Bis-MEPP, barium glass (250 nm) | 69 | - | GC (Tokyo, Japan) | 2306131 |

| OMNICHROMA Flow (OCF: Conventional) | UDMA, 1,9-nonamethylene glycol dimethacrylate, spherical silicazirconia filler (260 nm) | 71 | 57 | Tokuyama Dental (Tokyo, Japan) | 0522 |

| OMNICHROMA Flow Bulk (OCFB: Bulk-fill) | UDMA, TEGDMA, spherical silicazirconia filler (260 nm) | 69 | 55 | Tokuyama Dental (Tokyo, Japan) | 0284 |

| Materials | Polymerization Shrinkage Rate (%) | Filler Content (wt%) | Filler Content (vol%) |

|---|---|---|---|

| BBH II M | *3.15 (0.04) A | 69.71 (0.07) | 47.15 (0.29) a |

| AUF | *4.48 (0.01) B | 65.46 (0.86) | 46.45 (1.53) a |

| CMEF | *3.91 (0.12) C | 63.88 (0.75) | 47.98 (0.94) a |

| GFL | *3.47 (0.02) D | 61.30 (0.07) | 41.10 (0.39) b |

| OCF | *3.93 (0.03) C | 61.43 (0.23) | 53.60 (1.05) c |

| OCFB | *3.97 (0.02) C | 60.03 (0.54) | 54.10 (0.73) c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matsui, N.; Maesako, M.; Alkhazaleh, A.; Irie, M.; Tsujimoto, A. Correlation Between Polymerization Shrinkage and Filler Content for Universal Shade Flowable Resin-Based Composites. J. Funct. Biomater. 2025, 16, 155. https://doi.org/10.3390/jfb16050155

Matsui N, Maesako M, Alkhazaleh A, Irie M, Tsujimoto A. Correlation Between Polymerization Shrinkage and Filler Content for Universal Shade Flowable Resin-Based Composites. Journal of Functional Biomaterials. 2025; 16(5):155. https://doi.org/10.3390/jfb16050155

Chicago/Turabian StyleMatsui, Nagisa, Mayumi Maesako, Ahmad Alkhazaleh, Masao Irie, and Akimasa Tsujimoto. 2025. "Correlation Between Polymerization Shrinkage and Filler Content for Universal Shade Flowable Resin-Based Composites" Journal of Functional Biomaterials 16, no. 5: 155. https://doi.org/10.3390/jfb16050155

APA StyleMatsui, N., Maesako, M., Alkhazaleh, A., Irie, M., & Tsujimoto, A. (2025). Correlation Between Polymerization Shrinkage and Filler Content for Universal Shade Flowable Resin-Based Composites. Journal of Functional Biomaterials, 16(5), 155. https://doi.org/10.3390/jfb16050155