Developing PMMA/Coffee Husk Green Composites to Meet the Individual Requirements of People with Disabilities: Hip Spacer Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of PMMA Composites

2.3. Characterization and Testing

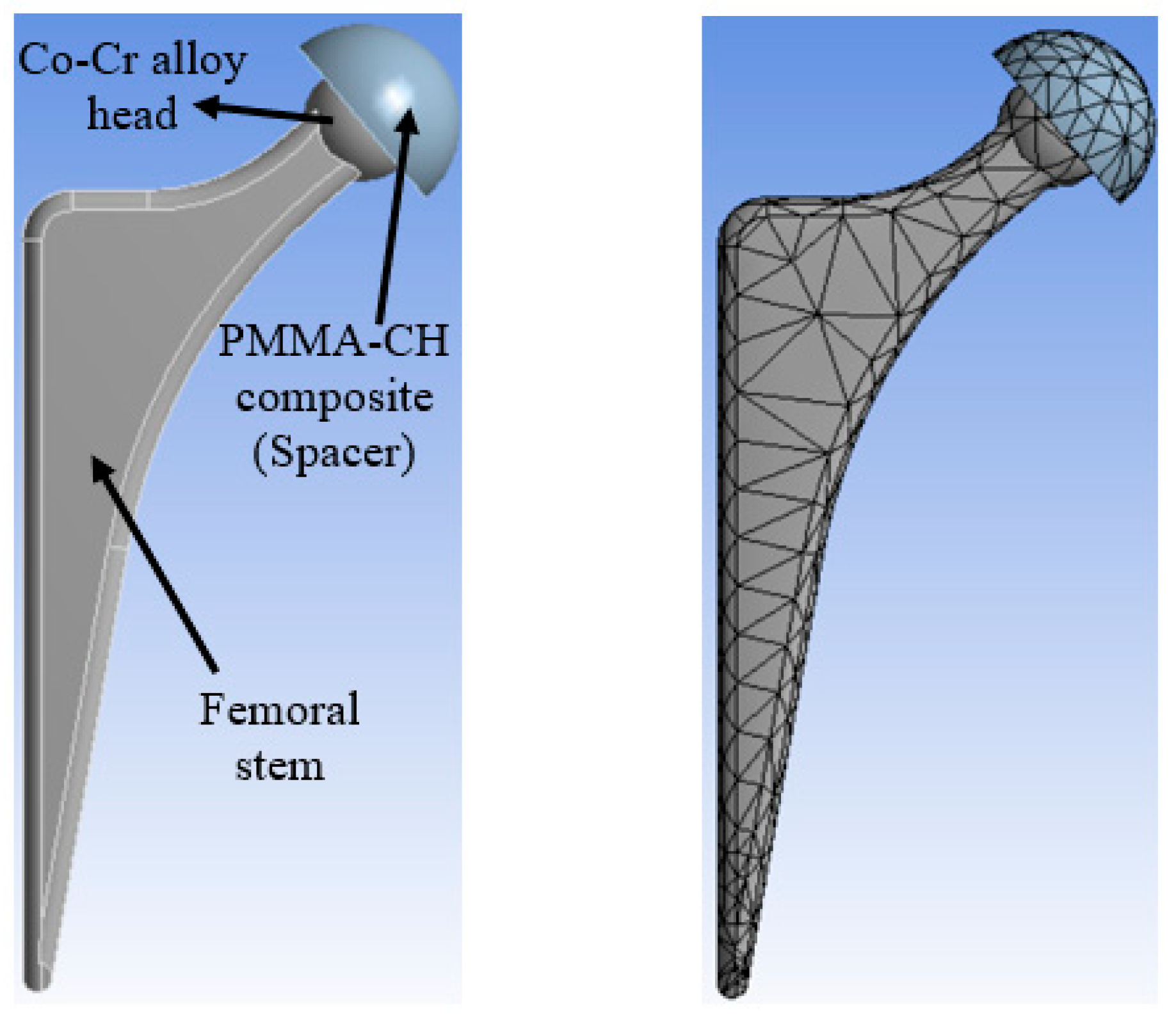

2.4. Finite Element Model

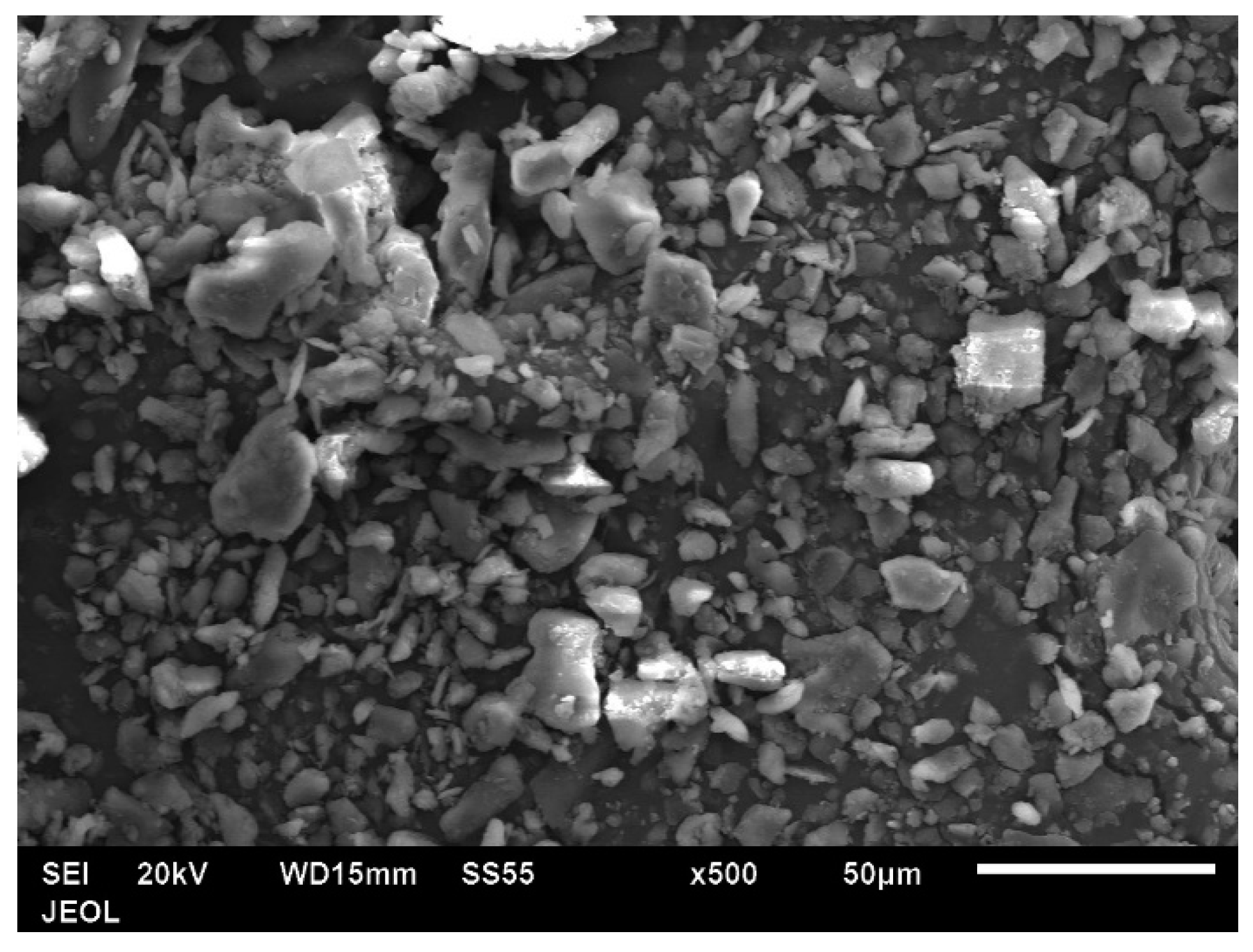

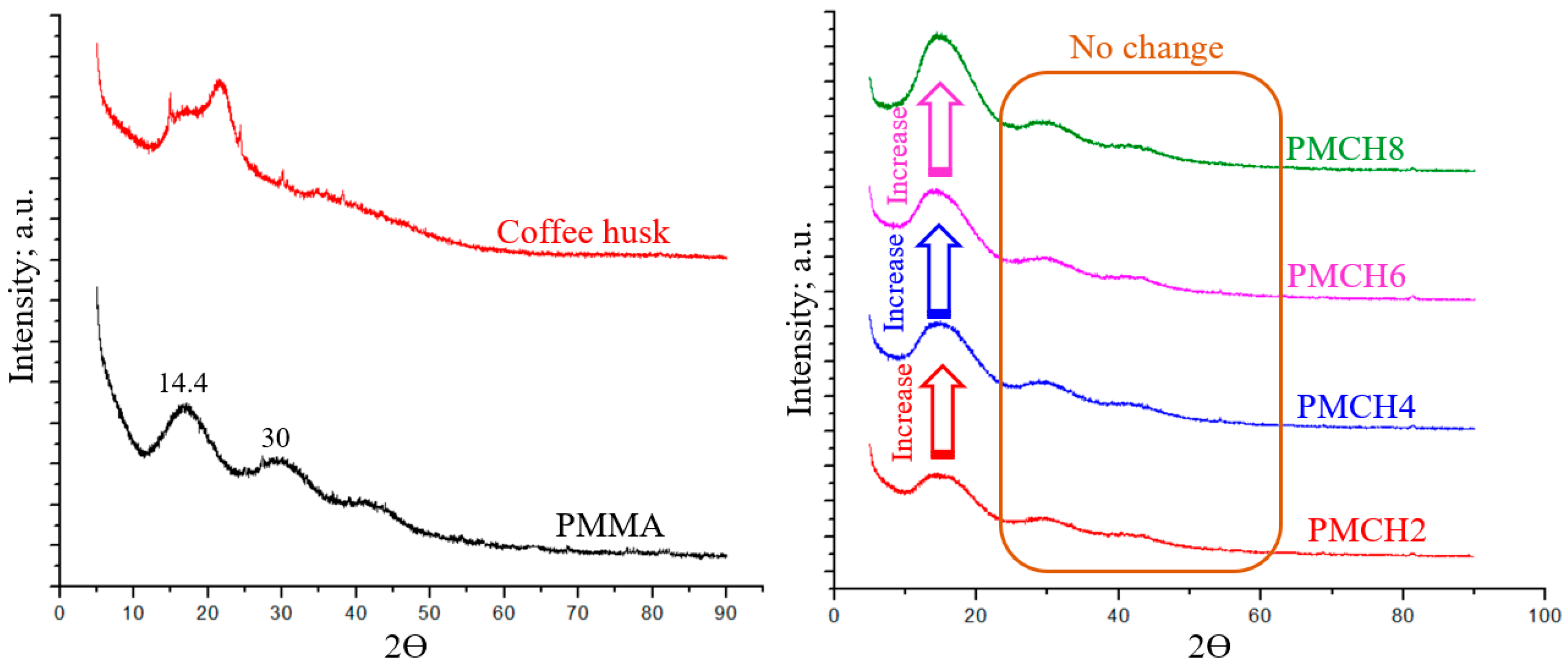

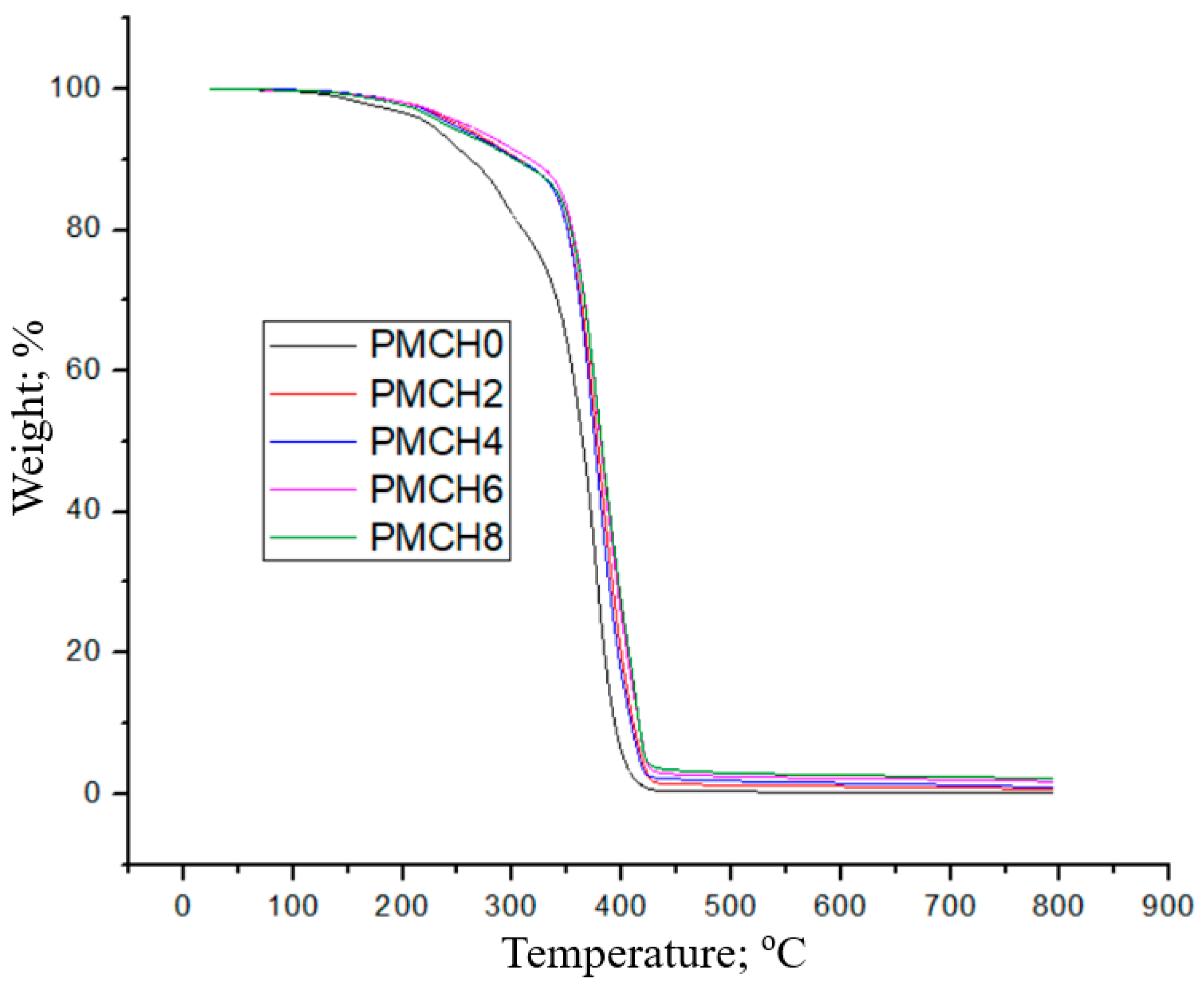

3. Results and Discussion

4. Conclusions

- Natural powder and composite materials with varying weight fractions of coffee husk were developed.

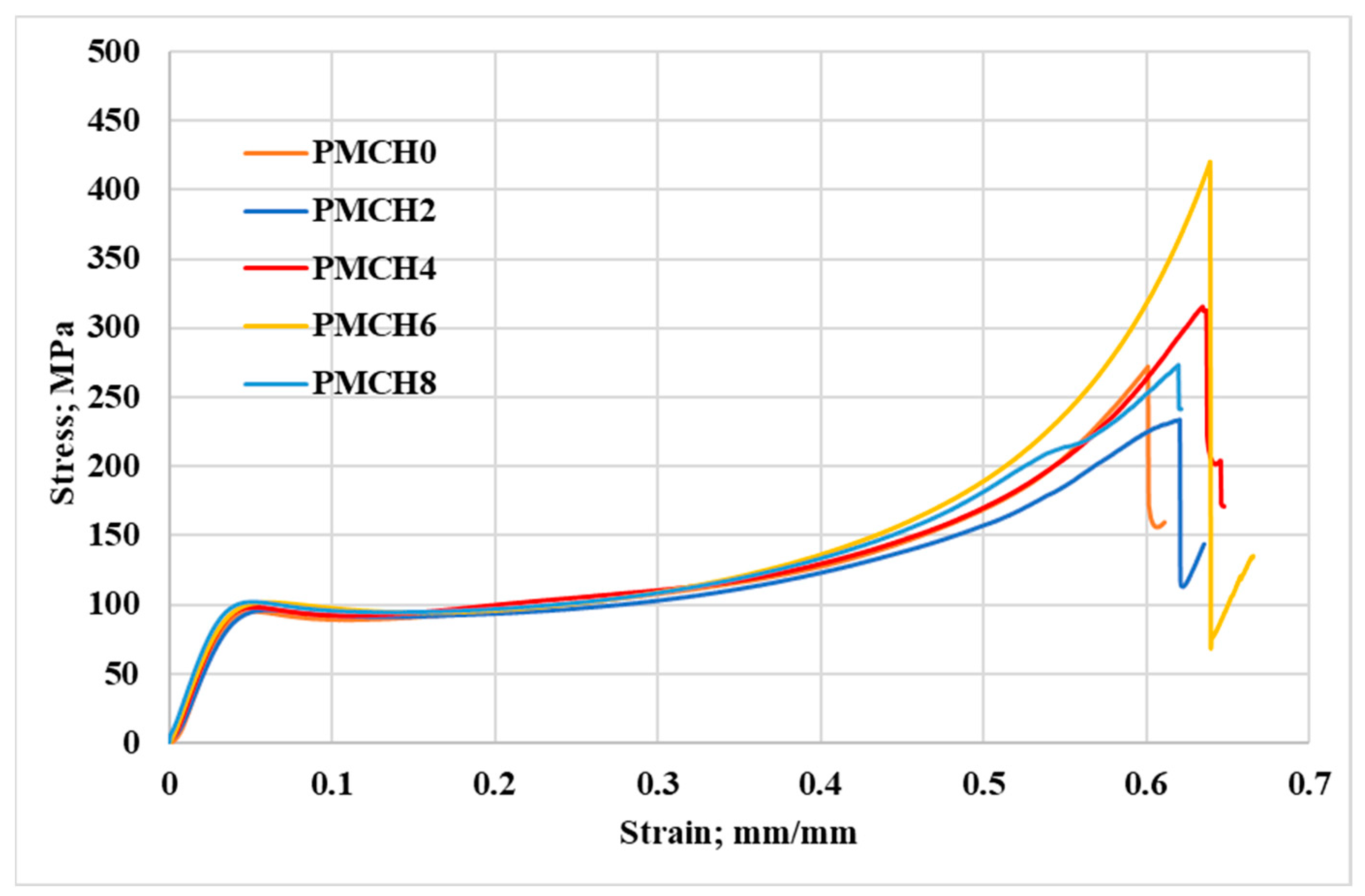

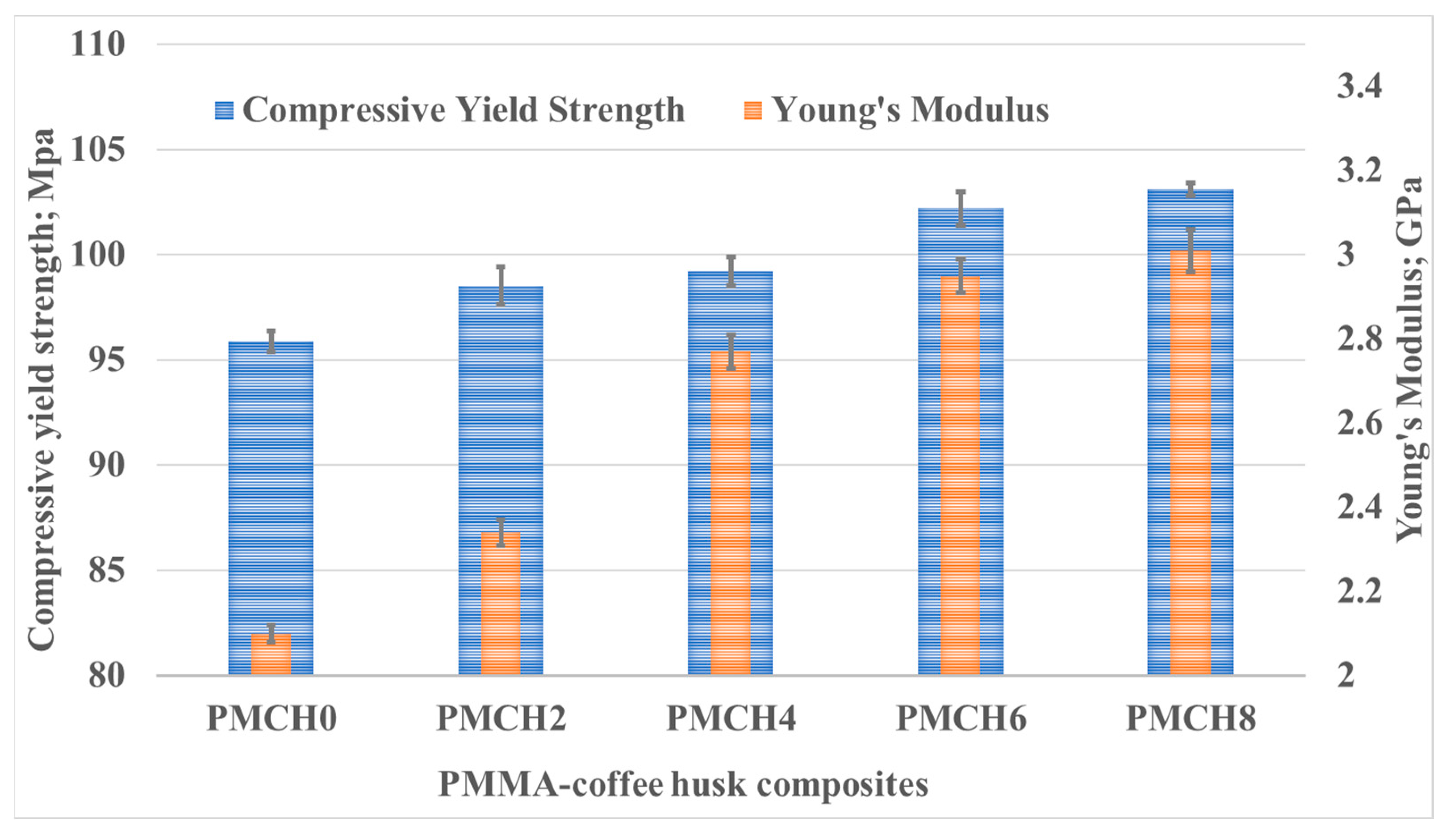

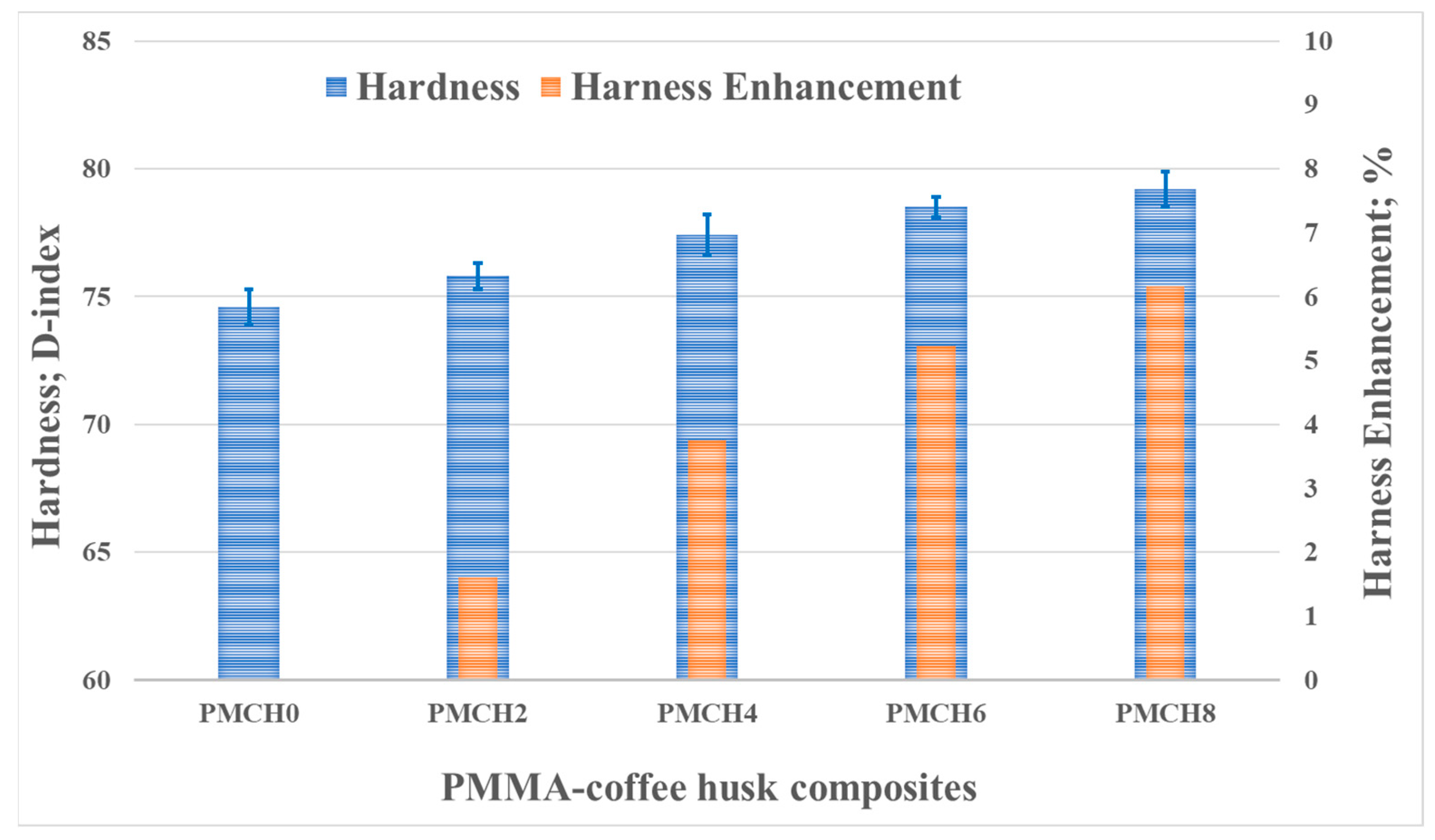

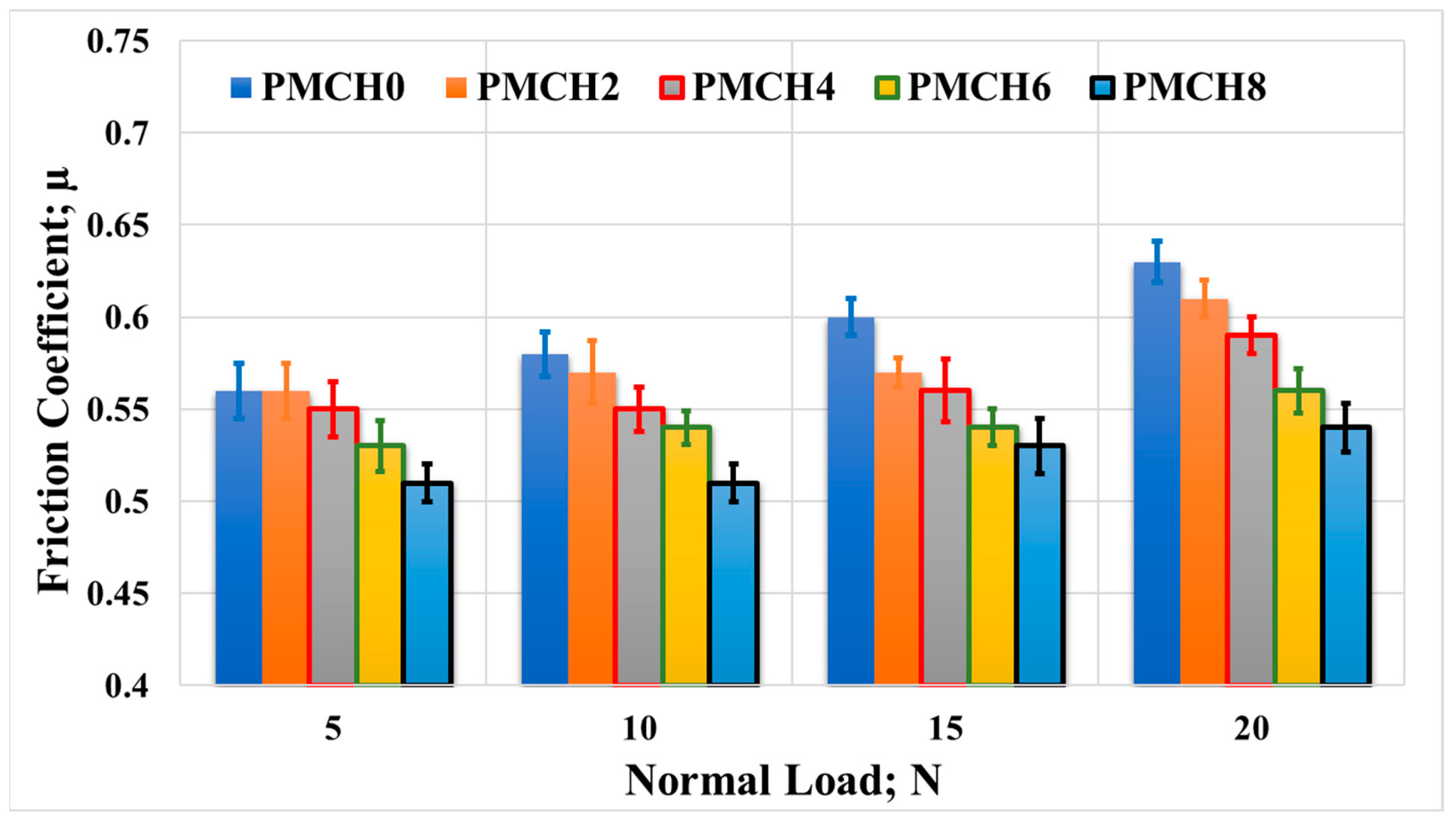

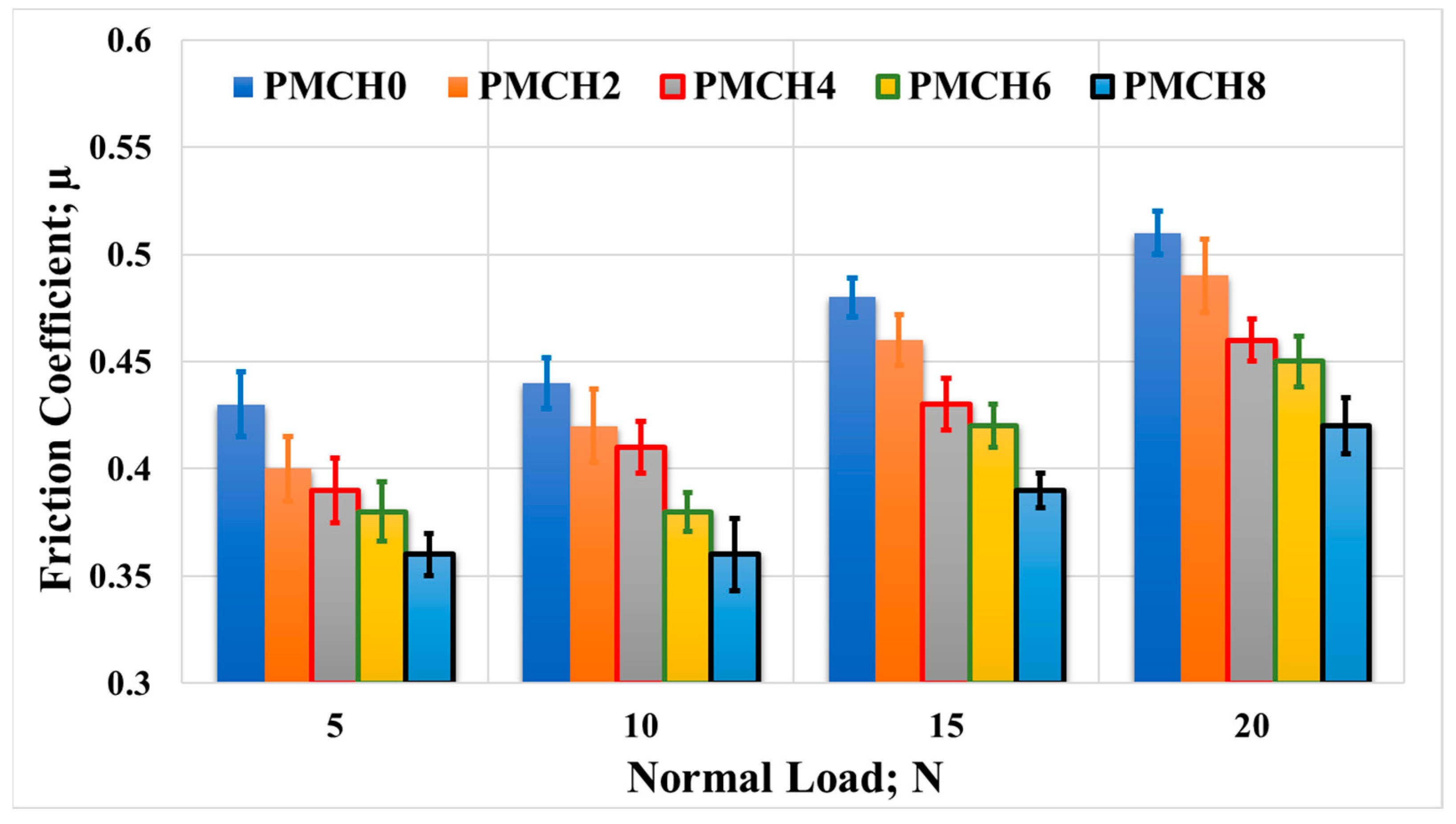

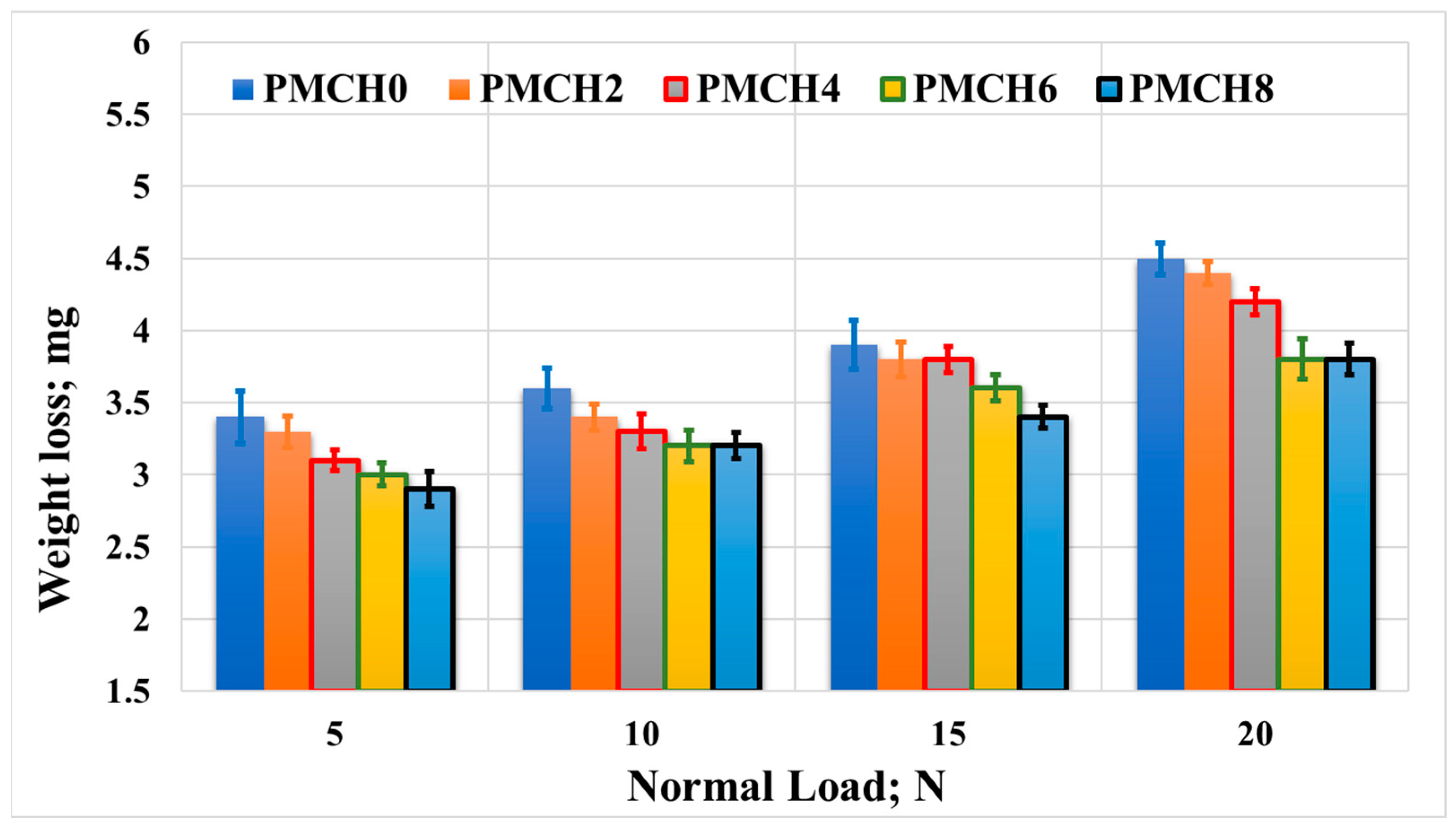

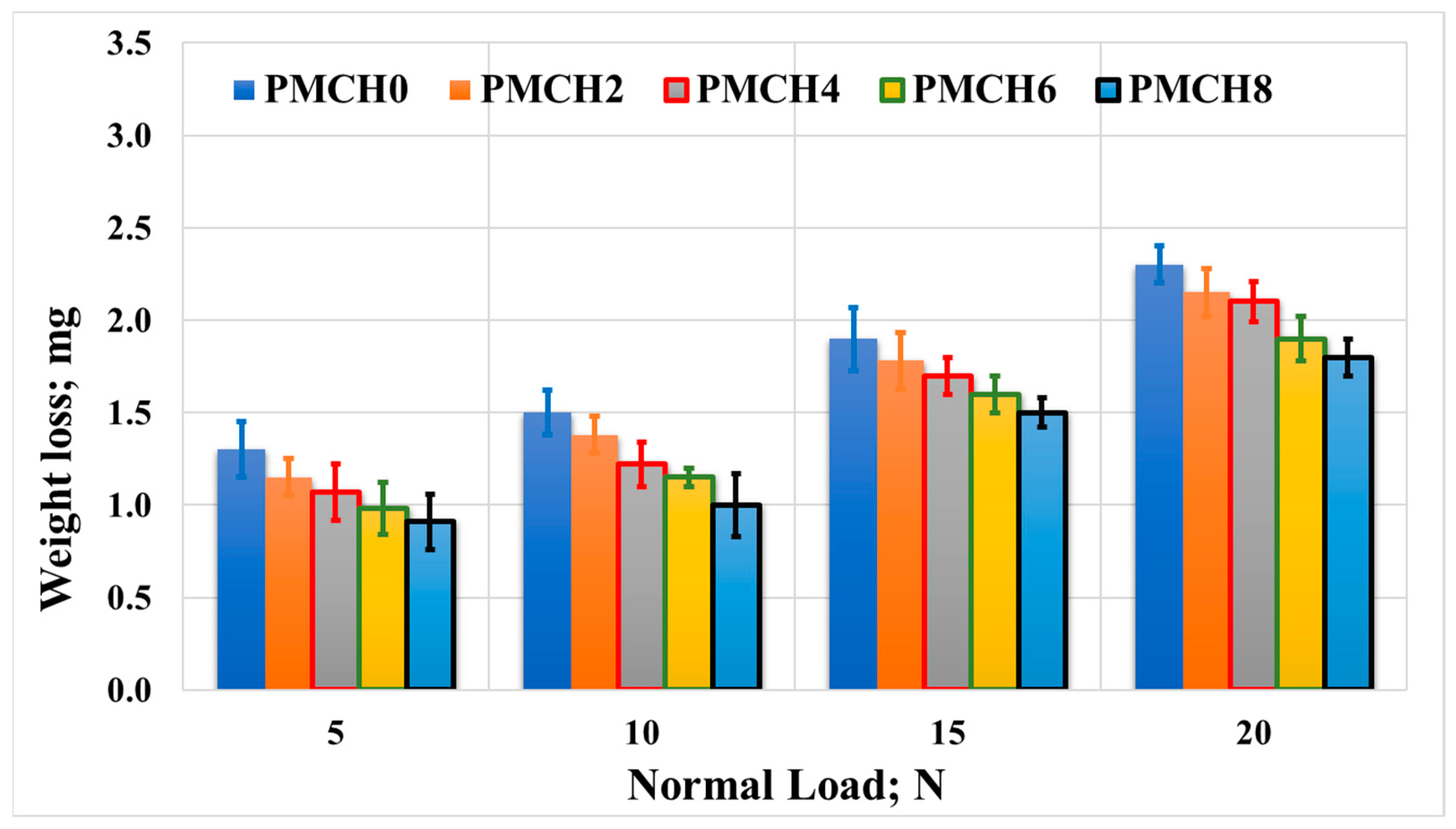

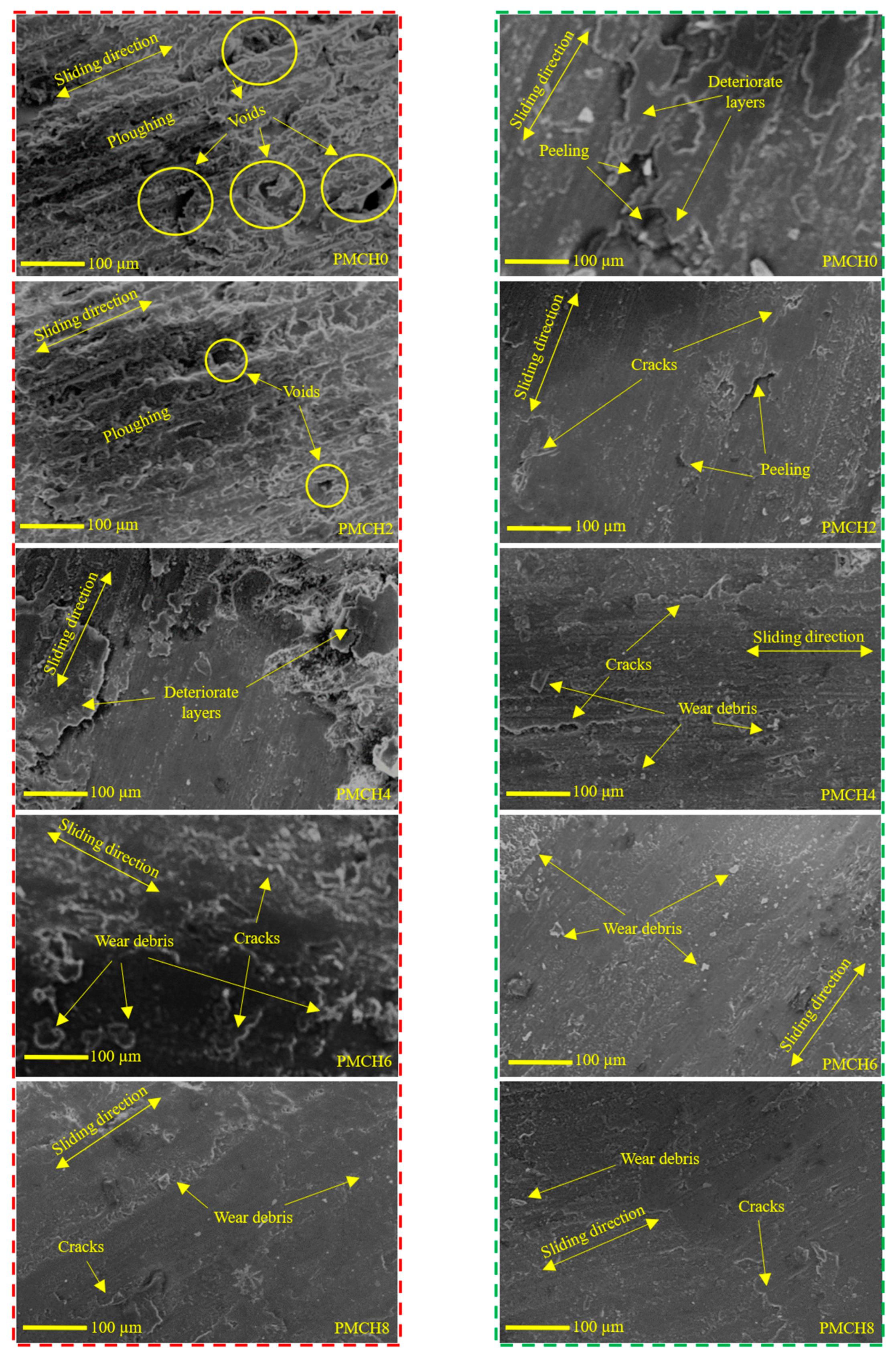

- The mechanical and tribological properties of the PMMA–coffee husk composites were evaluated.

- An ANSYS model was created to assess the performance of the spacer using the properties determined for the composites.

- The results show a noticeable improvement in the overall mechanical and tribological properties of the PMMA–coffee husk composites.

- The homogenous distribution of coffee husk particles increased the PMMA composite hardness by over 6%.

- Increasing the weight fraction of coffee husk filler up to 8 wt.% gradually improved the compressive yield strength and Young’s modulus by 7.6% and 43%, respectively, compared to pure PMMA.

- The tribological results show that incorporating coffee husk into PMMA decreased the friction coefficient and wear by 18.7% and 33%, respectively.

- The FEA analysis indicated that increasing the coffee husk content in the composite reduced the contact stresses on the spacer, enhancing its load-carrying capacity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Affatato, S.; Mattarozzi, A.; Taddei, P.; Robotti, P.; Soffiatti, R.; Sudanese, A.; Toni, A. Investigations on the wear behaviour of the temporary PMMA-based hip Spacer-G®. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2003, 217, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Lewis, G. Fatigue testing and performance of acrylic bone-cement materials: State-of-the-art review. J. Biomed. Mater. Res. Part B: Appl. Biomater. Off. J. Soc. Biomater. Jpn. Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater. 2003, 66, 457–486. [Google Scholar] [CrossRef]

- Meani, E.; Romanò, C.; Crosby, L.; Hofmann, G. Infection and Local Treatment in Orthopedic Surgery; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Rava, A.; Bruzzone, M.; Cottino, U.; Enrietti, E.; Rossi, R. Hip spacers in two-stage revision for periprosthetic joint infection: A review of literature. Joints 2019, 7, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Thielen, T.; Maas, S.; Zuerbes, A.; Waldmann, D.; Anagnostakos, K.; Kelm, J. Development of a reinforced PMMA-based hip spacer adapted to patients’ needs. Med. Eng. Phys. 2009, 31, 930–936. [Google Scholar] [CrossRef]

- Fouly, A.; Nabhan, A.; Badran, A. Mechanical and Tribological Characteristics of PMMA Reinforced by Natural Materials. Egypt. J. Chem. 2022, 65, 1–2. [Google Scholar] [CrossRef]

- Fouly, A.; Ibrahim, A.M.M.; Sherif, E.-S.M.; FathEl-Bab, A.M.; Badran, A.H. Effect of low hydroxyapatite loading fraction on the mechanical and tribological characteristics of poly (methyl methacrylate) nanocomposites for dentures. Polymers 2021, 13, 857. [Google Scholar] [CrossRef] [PubMed]

- Murakami, N.; Wakabayashi, N.; Matsushima, R.; Kishida, A.; Igarashi, Y. Effect of high-pressure polymerization on mechanical properties of PMMA denture base resin. J. Mech. Behav. Biomed. Mater. 2013, 20, 98–104. [Google Scholar] [CrossRef]

- Alhareb, A.O.; Akil, H.M.; Ahmad, Z.A. Mechanical properties of PMMA denture base reinforced by nitrile rubber particles with Al2O3/YSZ fillers. Procedia Manuf. 2015, 2, 301–306. [Google Scholar] [CrossRef]

- García-Mansilla, A.; Castro Lalín, A.; Holc, F.; Molho, N.M.; Vescovo, A.; Slullitel, P.A.; Buttaro, M.A. Intraoperative unfractionated heparin before femoral component cementation should be avoided in femoral neck fracture treated with hybrid total hip arthroplasty. Eur. J. Orthop. Surg. Traumatol. 2023, 33, 1–8. [Google Scholar] [CrossRef]

- Puri, G.; Berzins, D.W.; Dhuru, V.B.; Raj, P.A.; Rambhia, S.K.; Dhir, G.; Dentino, A.R. Effect of phosphate group addition on the properties of denture base resins. J. Prosthet. Dent. 2008, 100, 302–308. [Google Scholar] [CrossRef]

- Li, R.; Ye, L.; Mai, Y.-W. Application of plasma technologies in fibre-reinforced polymer composites: A review of recent developments. Compos. Part A Appl. Sci. Manuf. 1997, 28, 73–86. [Google Scholar] [CrossRef]

- Karthick, R.; Sirisha, P.; Sankar, M.R. Mechanical and tribological properties of PMMA-sea shell based biocomposite for dental application. Procedia Mater. Sci. 2014, 6, 1989–2000. [Google Scholar] [CrossRef]

- Alhareb, A.O.; Akil, H.M.; Ahmad, Z.A. Impact strength, fracture toughness and hardness improvement of PMMA denture base through addition of nitrile rubber/ceramic fillers. Saudi J. Dent. Res. 2017, 8, 26–34. [Google Scholar] [CrossRef]

- Asar, N.V.; Albayrak, H.; Korkmaz, T.; Turkyilmaz, I. Influence of various metal oxides on mechanical and physical properties of heat-cured polymethyl methacrylate denture base resins. J. Adv. Prosthodont. 2013, 5, 241–247. [Google Scholar] [CrossRef] [PubMed]

- Fouly, A.; Abdo, H.S.; Seikh, A.H.; Alluhydan, K.; Alkhammash, H.I.; Alnaser, I.A.; Abdo, M.S. Evaluation of mechanical and tribological properties of corn cob-reinforced epoxy-based composites—Theoretical and experimental study. Polymers 2021, 13, 4407. [Google Scholar] [CrossRef]

- Mitra, B.C. Environment Friendly composite materials: Biocomposites and Green composites. Def. Sci. J. 2014, 64. [Google Scholar] [CrossRef]

- Fouly, A.; Alnaser, I.A.; Assaifan, A.K.; Abdo, H.S. Evaluating the performance of 3D-printed PLA reinforced with date pit particles for its suitability as an acetabular liner in artificial hip joints. Polymers 2022, 14, 3321. [Google Scholar] [CrossRef]

- John, J.; Mani, S.A.; Palaniswamy, K.; Ramanathan, A.; Razak, A.A.A. Flexural properties of poly (Methyl Methacrylate) resin reinforced with oil palm empty fruit bunch fibers: A preliminary finding. J. Prosthodont. 2014, 24, 233–238. [Google Scholar] [CrossRef]

- Salih, S.I.; Oleiwi, J.K.; Fadhil, H.S. Preparation and investigation of some properties of acrylic resin reinforced with siwak fiber used for denture base applications. Kurd. J. Appl. Res. 2017, 2, 309–314. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O. Comparative Analysis of the Coffee and Cocoa Industry By-Products on the Performance of Polyethylene-Based Composites. Waste Biomass Valorization 2023, 14, 1–16. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Santoni, A.; Sbardella, F.; Calzolari, A.; Sarasini, F.; Mollica, F. Correlation between Mechanical Properties and Processing Conditions in Rubber-Toughened Wood Polymer Composites. Polymers 2020, 12, 1170. [Google Scholar] [CrossRef]

- Daglia, M.; Papetti, A.; Gregotti, C.; Bertè, F.; Gazzani, G. In vitro antioxidant and ex vivo protective activities of green and roasted coffee. J. Agric. Food Chem. 2000, 48, 1449–1454. [Google Scholar] [CrossRef]

- Ponte, S. The ‘Latte Revolution’? Regulation, Markets and Consumption in the Global Coffee Chain. World Dev. 2002, 30, 1099–1122. [Google Scholar] [CrossRef]

- Murthy, P.S.; Naidu, M.M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.; Martins, S.; Teixeira, J.A. Production, composition, and application of coffee and its industrial residues. Food Bioprocess Technol. 2011, 4, 661–672. [Google Scholar] [CrossRef]

- Zhao, H.; Allanson, D.; Ren, X.J. Use of shore hardness tests for in-process properties estimation/monitoring of silicone rubbers. J. Mater. Sci. Chem. Eng. 2015, 3, 142–147. [Google Scholar] [CrossRef]

- Radha, R.; Sreekanth, D. Mechanical, in vitro corrosion and bioactivity performance of Mg based composite for orthopedic implant applications: Influence of Sn and HA addition. Biomed. Eng. Adv. 2022, 3, 100033. [Google Scholar] [CrossRef]

- Methods, A.T. Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus1. Wear 2011, 5, 1–5. [Google Scholar]

- Bergmann, G.; Bender, A.; Dymke, J.; Duda, G.; Damm, P. Standardized Loads Acting in Hip Implants. PLoS ONE 2016, 11, e0155612. [Google Scholar] [CrossRef] [PubMed]

- Rameshkumar, C.; Sarojini, S.; Naresh, K.; Subalakshmi, R. Preparation and characterization of pristine PMMA and PVDF thin film using solution casting process for optoelectronic devices. J. Surf. Sci. Technol. 2017, 33, 12–18. [Google Scholar] [CrossRef]

- Hashem, M.; Rez, M.F.A.; Fouad, H.; Elsarnagawy, T.; Elsharawy, M.A.; Umar, A.; Assery, M.; Ansari, S.G. Influence of titanium oxide nanoparticles on the physical and thermomechanical behavior of poly methyl methacrylate (PMMA): A denture base resin. Sci. Adv. Mater. 2017, 9, 938–944. [Google Scholar] [CrossRef]

- Collazo-Bigliardi, S.; Ortega-Toro, R.; Boix, A.C. Isolation and characterisation of microcrystalline cellulose and cellulose nanocrystals from coffee husk and comparative study with rice husk. Carbohydr. Polym. 2018, 191, 205–215. [Google Scholar] [CrossRef]

- Reis, R.S.; Tienne, L.G.; de HS Souza, D.; Maria de Fátima, V.M.; Monteiro, S.N. Characterization of coffee parchment and innovative steam explosion treatment to obtain microfibrillated cellulose as potential composite reinforcement. J. Mater. Res. Technol. 2020, 9, 9412–9421. [Google Scholar] [CrossRef]

- Kallel, F.; Bettaieb, F.; Khiari, R.; García, A.; Bras, J.; Chaabouni, S.E. Isolation and structural characterization of cellulose nanocrystals extracted from garlic straw residues. Ind. Crops Prod. 2016, 87, 287–296. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric analysis properties of cellulosic natural fiber polymer composites: A review on influence of chemical treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Yang, K.; Ritchie, R.O.; Gu, Y.; Wu, S.J.; Guan, J. High volume-fraction silk fabric reinforcements can improve the key mechanical properties of epoxy resin composites. Mater. Des. 2016, 108, 470–478. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Mohamed, A.F.A.; Fathelbab, A.M.; Essa, F.A. Enhancing the tribological performance of epoxy composites utilizing carbon nano fibers additives for journal bearings. Mater. Res. Express 2018, 6, 035307. [Google Scholar] [CrossRef]

- Kuminek, T.; Anio\lek, K.; M\lyńczak, J. A numerical analysis of the contact stress distribution and physical modelling of abrasive wear in the tram wheel-frog system. Wear 2015, 328, 177–185. [Google Scholar] [CrossRef]

- Guo, R.Q.; Rohatgi, P.K.; Nath, D. Preparation of aluminium-fly ash particulate composite by powder metallurgy technique. J. Mater. Sci. 1997, 32, 3971–3974. [Google Scholar] [CrossRef]

- Effect of Nanoparticles on the Tribological Behaviour…—Google Scholar. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=Effect+of+nanoparticles+on+the+tribological+behaviour+of+short+carbon+fibre+reinforced+poly+%28etherimide%29+composites&btnG= (accessed on 19 March 2023).

- Khun, N.W.; Zhang, H.; Lim, L.H.; Yue, C.Y.; Hu, X.; Yang, J. Tribological properties of short carbon fibers reinforced epoxy composites. Friction 2014, 2, 226–239. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Shi, X.; Radwan, A.R.; Mohamed, A.F.A.; Ezzat, M.F. Enhancing the tribological properties of NiAl based nano-composites for aerospace bearing applications. Mater. Res. Express 2019, 6, 085067. [Google Scholar] [CrossRef]

- Bogdanova, L.; Lesnichaya, V.; Spirin, M.; Shershnev, V.; Irzhak, V.; Kydralieva, K.; Zarrelli, M.; Dzhardimalieva, G. Mechanical properties of polycondensate epoxy nanocomposites filled with Ag nanoparticles synthesized in situ. Mater. Today Proc. 2021, 34, 156–159. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Suh, N.P. An overview of the delamination theory of wear. Wear 1977, 44, 1–16. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fouly, A.; Alnaser, I.A.; Assaifan, A.K.; Abdo, H.S. Developing PMMA/Coffee Husk Green Composites to Meet the Individual Requirements of People with Disabilities: Hip Spacer Case Study. J. Funct. Biomater. 2023, 14, 200. https://doi.org/10.3390/jfb14040200

Fouly A, Alnaser IA, Assaifan AK, Abdo HS. Developing PMMA/Coffee Husk Green Composites to Meet the Individual Requirements of People with Disabilities: Hip Spacer Case Study. Journal of Functional Biomaterials. 2023; 14(4):200. https://doi.org/10.3390/jfb14040200

Chicago/Turabian StyleFouly, Ahmed, Ibrahim A. Alnaser, Abdulaziz K. Assaifan, and Hany S. Abdo. 2023. "Developing PMMA/Coffee Husk Green Composites to Meet the Individual Requirements of People with Disabilities: Hip Spacer Case Study" Journal of Functional Biomaterials 14, no. 4: 200. https://doi.org/10.3390/jfb14040200

APA StyleFouly, A., Alnaser, I. A., Assaifan, A. K., & Abdo, H. S. (2023). Developing PMMA/Coffee Husk Green Composites to Meet the Individual Requirements of People with Disabilities: Hip Spacer Case Study. Journal of Functional Biomaterials, 14(4), 200. https://doi.org/10.3390/jfb14040200