Surface Heparinization of a Magnesium-Based Alloy: A Comparison Study of Aminopropyltriethoxysilane (APTES) and Polyamidoamine (PAMAM) Dendrimers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Self-Assembly and Immobilization of Biomolecules

2.3. Surface Characterizations

2.4. Corrosion Behavior

2.5. Cell Culture and Morphological Study

2.6. Cell Viability

2.7. Clotting Time

3. Results and Discussion

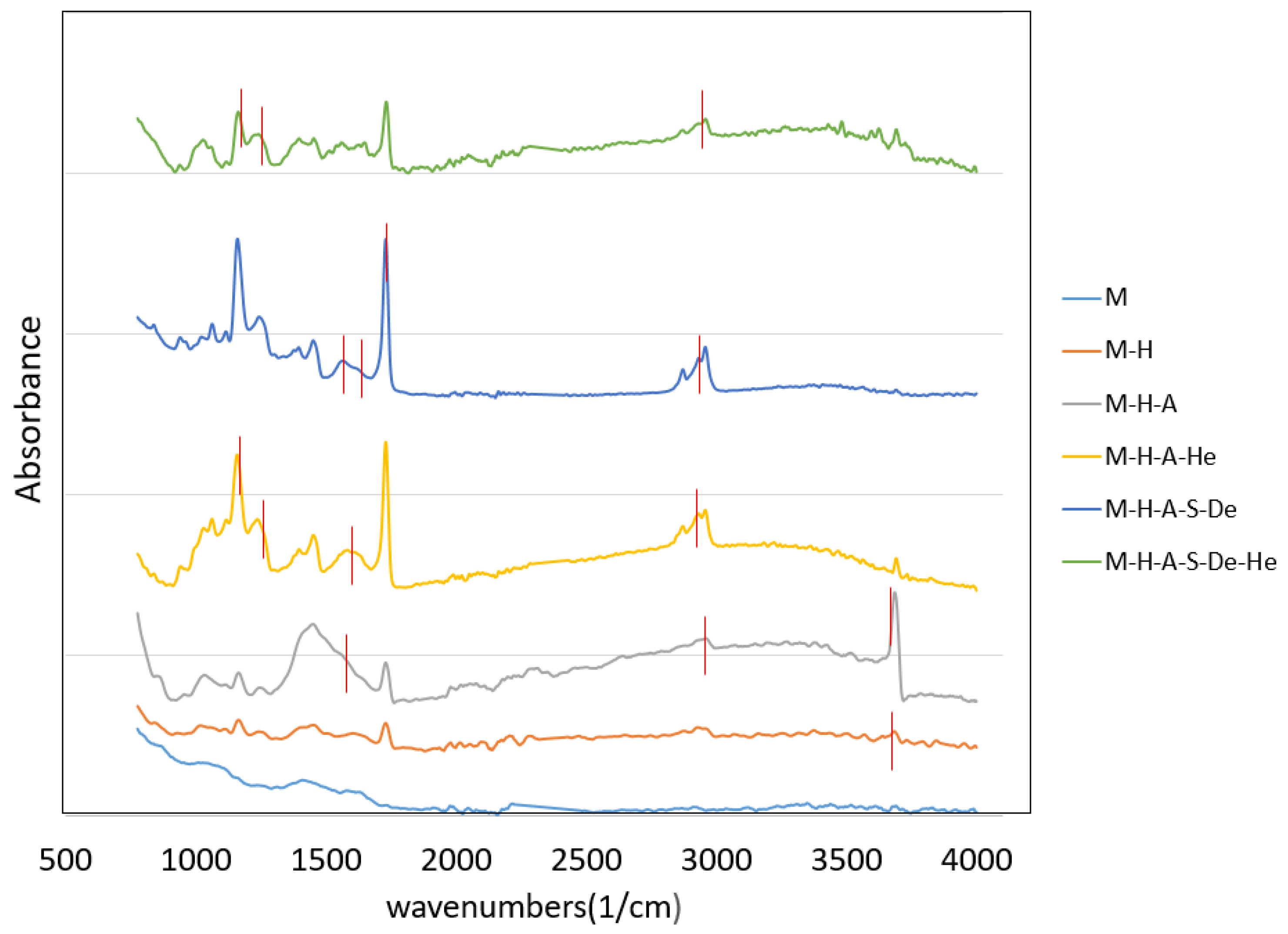

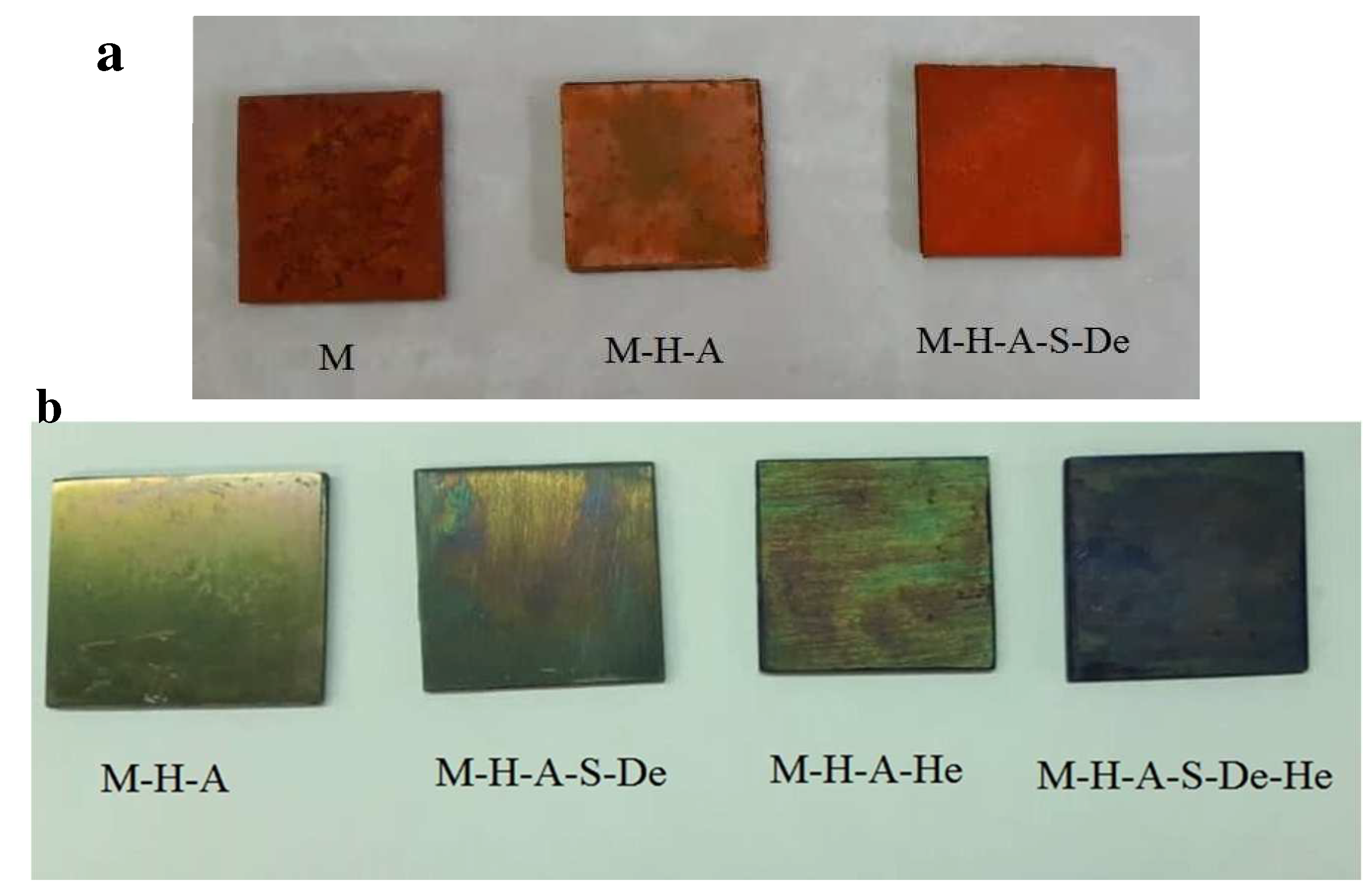

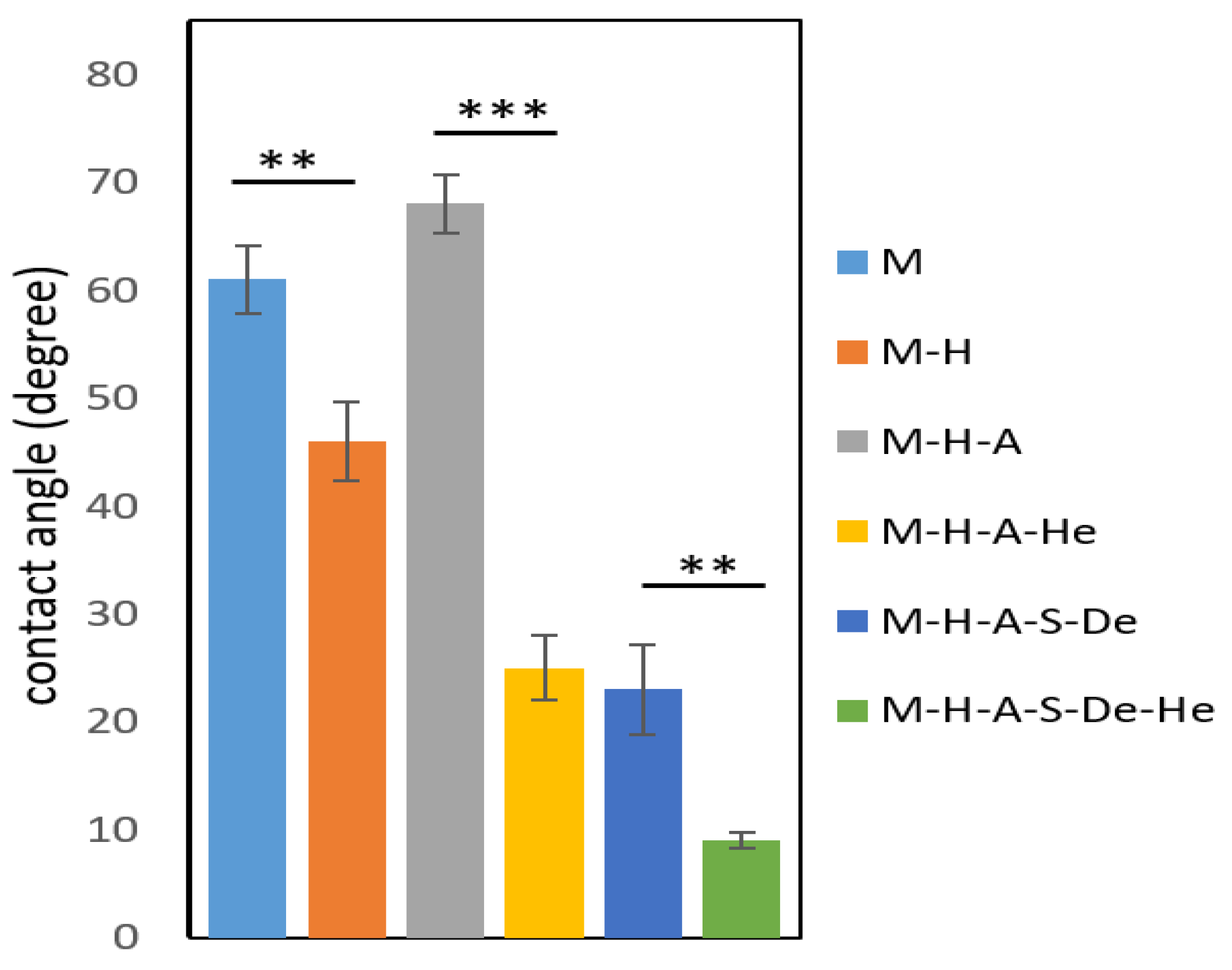

3.1. Surface Characterizations

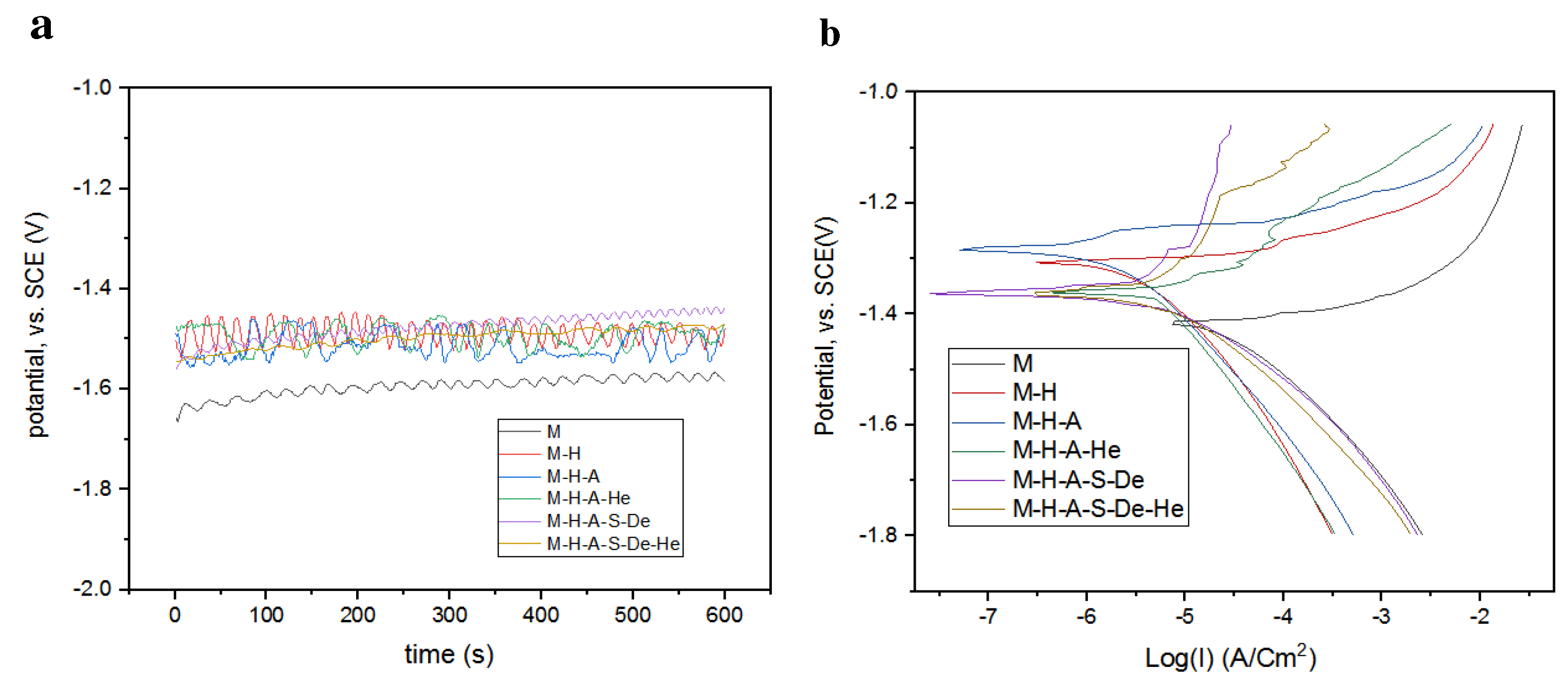

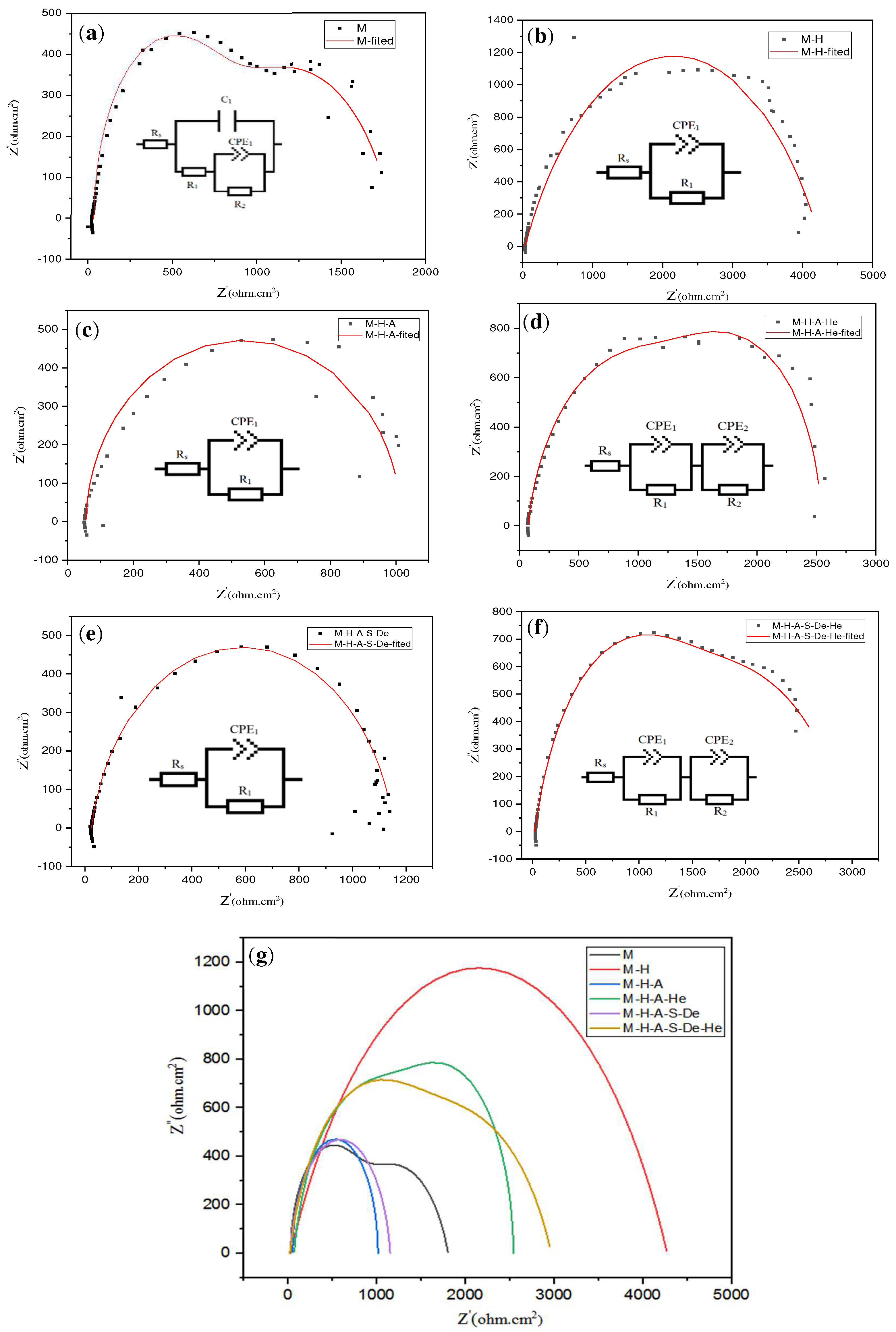

3.2. In Vitro Electrochemical Tests

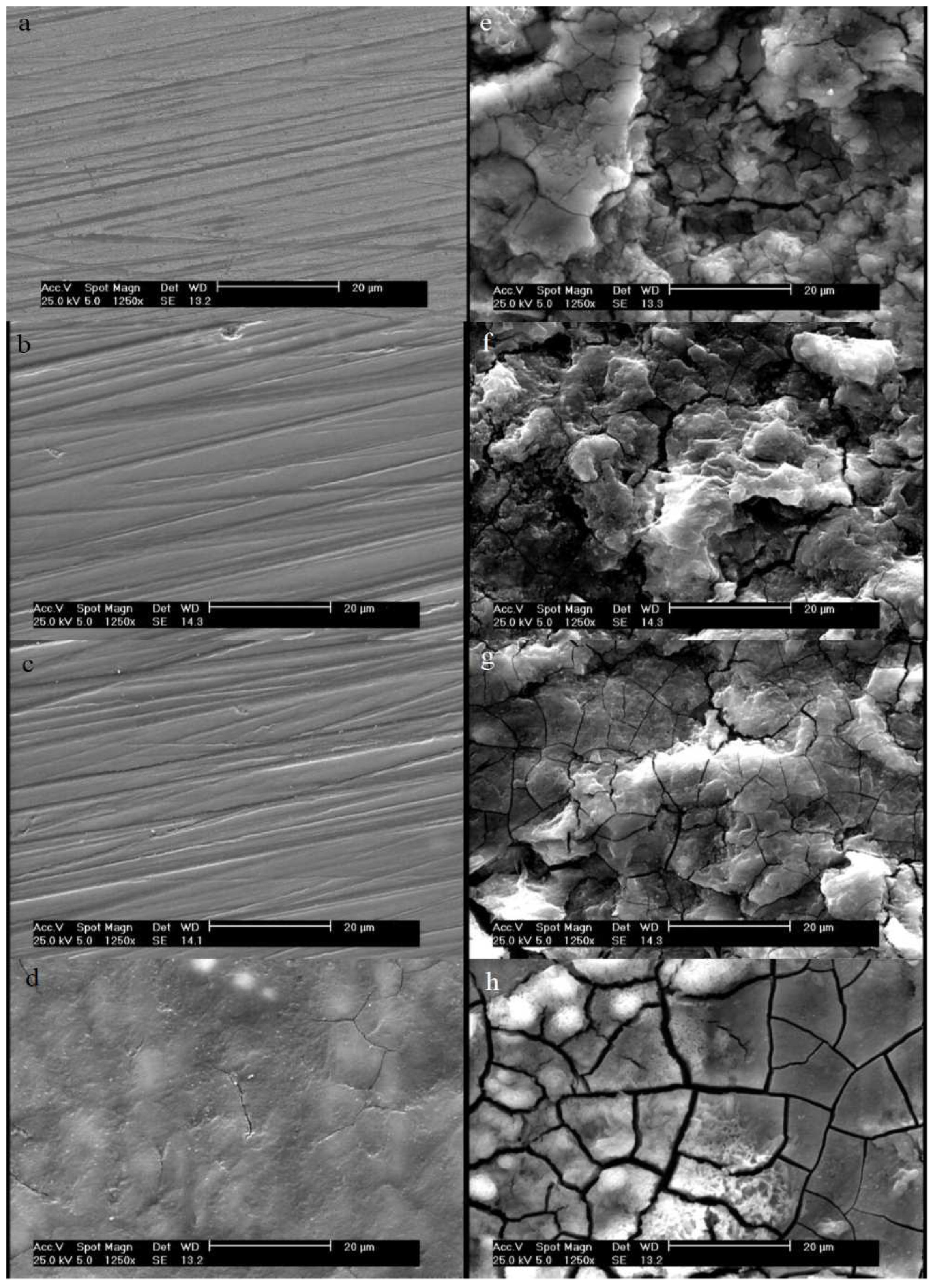

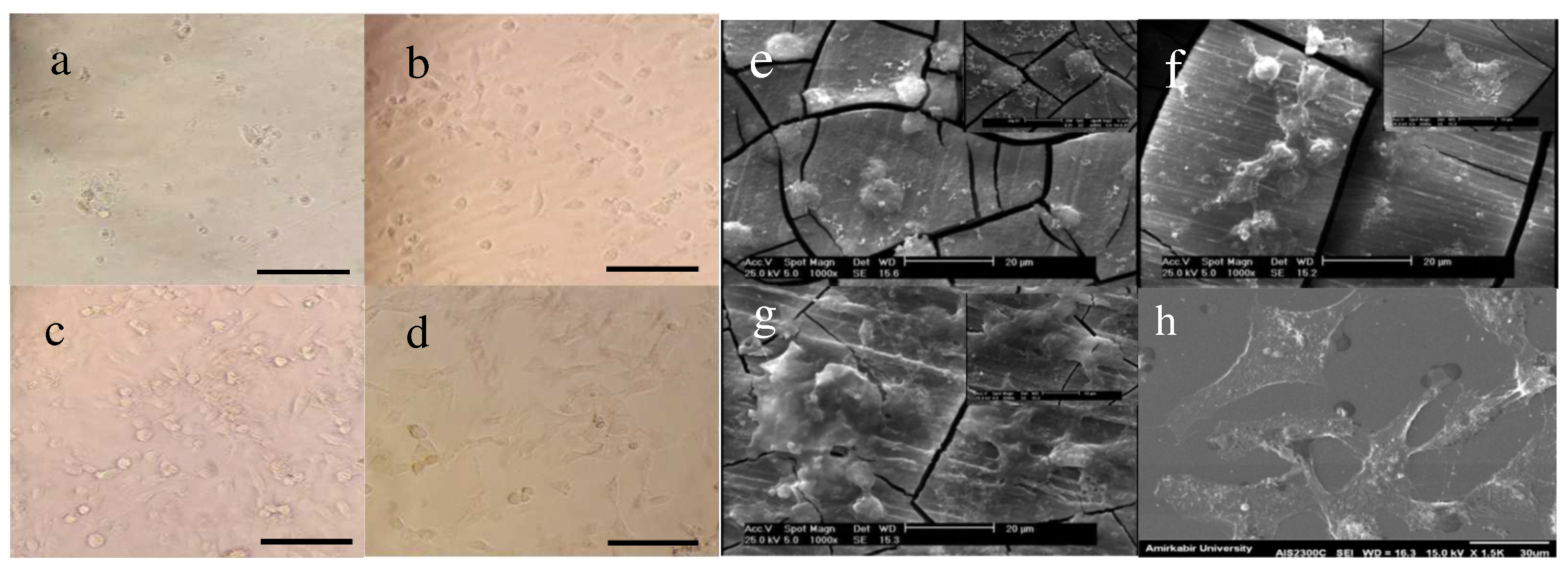

3.3. Cell Culture and Morphological Investigation

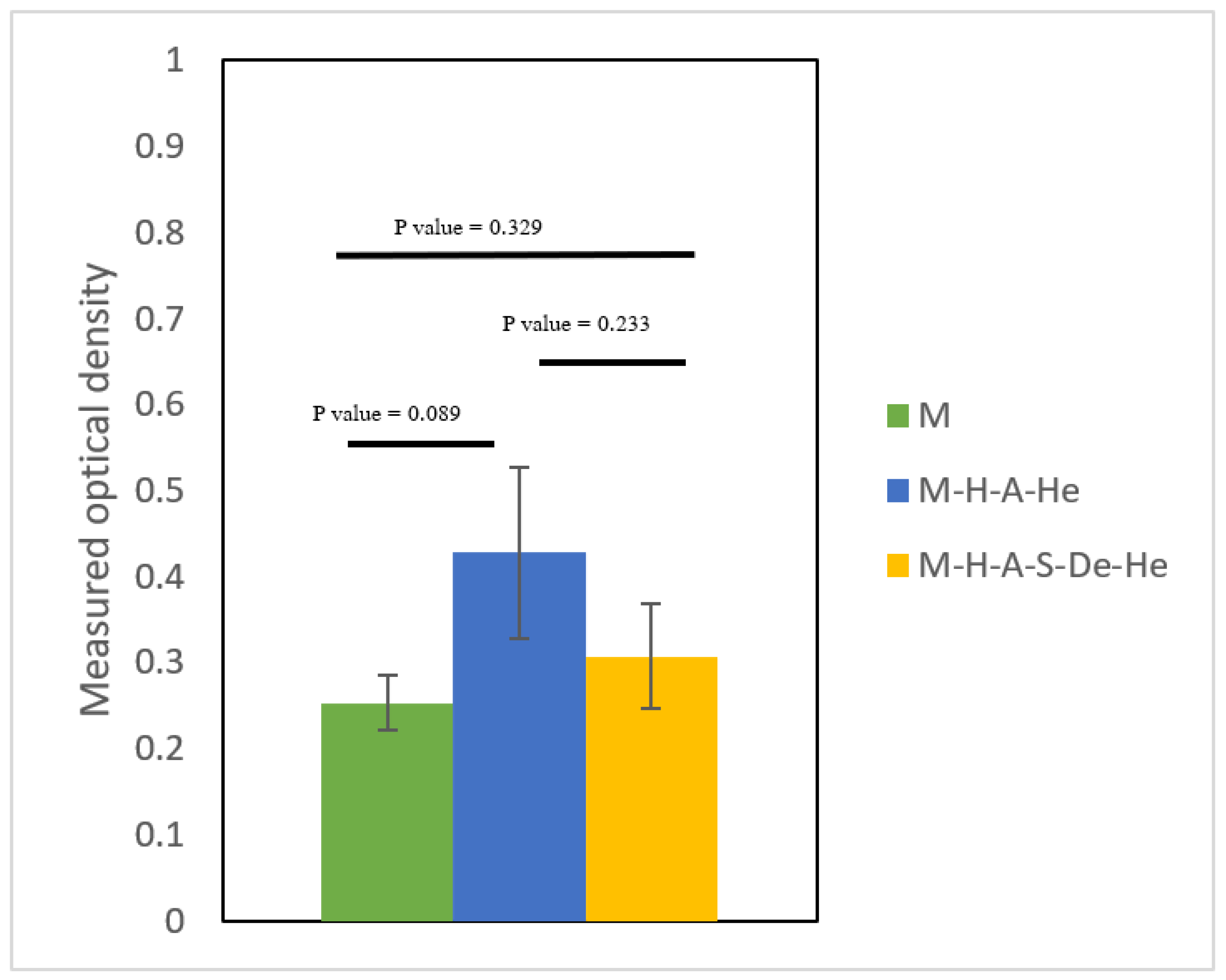

3.4. Cell Viability

3.5. Clotting Time Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Tan, L.; Yang, K. Cytocompatibility and Hemolysis of AZ31B Magnesium Alloy with Si-containing Coating. J. Mater. Sci. Technol. 2015, 31, 845–851. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, B.; Wang, P.; Wang, X.; Zhang, B.; Shi, Q.; Xi, T.; Chen, M.; Guan, S. Enhanced in Vitro and in Vivo Performance of Mg–Zn–Y–Nd Alloy Achieved with APTES Pretreatment for Drug-Eluting Vascular Stent Application. ACS Appl. Mater. Interfaces 2016, 8, 17842–17858. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, P.; Chu, C.C.; Xi, T. Arginine-leucine based poly (ester urea urethane) coating for Mg-Zn-Y-Nd alloy in cardiovascular stent applications. Colloids Surf. B Biointerfaces 2017, 159, 78–88. [Google Scholar] [CrossRef]

- Wu, G.; Ibrahim, J.M.; Chu, P.K. Surface design of biodegradable magnesium alloys—A review. Surf. Coat. Technol. 2012, 233, 2–12. [Google Scholar] [CrossRef]

- Lu, P.; Fan, H.; Liu, Y.; Cao, L.; Wu, X.; Xu, X. Controllable biodegradability, drug release behavior and hemocompatibility of PTX-eluting magnesium stents. Colloids Surf. B Biointerfaces 2011, 83, 23–28. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Hu, Y.; Li, G.; Liu, S.; Quan, L.; Yang, Z.; Wei, Y.; Pan, C. Layer-by-layer deposition of bioactive layers on magnesium alloy stent materials to improve corrosion resistance and biocompatibility. Bioact. Mater. 2020, 5, 611–623. [Google Scholar] [CrossRef] [PubMed]

- Nouri, A.; Wen, C. 1-Introduction to surface coating and modification for metallic biomaterials. In Surface Coating and Modification of Metallic Biomaterials; Wen, C., Ed.; Woodhead Publishing: Sawston, UK, 2015; pp. 3–60. [Google Scholar]

- Heimann, R.B. Magnesium alloys for biomedical application: Advanced corrosion control through surface coating. Surf. Coat. Technol. 2021, 405, 126521. [Google Scholar] [CrossRef]

- Wang, P.; Xiong, P.; Liu, J.; Gao, S.; Xi, T.; Cheng, Y. A silk-based coating containing GREDVY peptide and heparin on Mg–Zn–Y–Nd alloy: Improved corrosion resistance, hemocompatibility and endothelialization. J. Mater. Chem. B 2018, 6, 966–978. [Google Scholar] [CrossRef]

- Wei, Z.; Tian, P.; Liu, X.; Zhou, B. Hemocompatibility and selective cell fate of polydopamine-assisted heparinized PEO/PLLA composite coating on biodegradable AZ31 alloy. Colloids Surf. B Biointerfaces 2014, 121, 451–460. [Google Scholar] [CrossRef]

- Zhao, N.; Zhu, D. Collagen Self-Assembly on Orthopedic Magnesium Biomaterials Surface and Subsequent Bone Cell Attachment. PLoS ONE 2014, 9, e110420. [Google Scholar] [CrossRef]

- Pan, C.-J.; Hou, Y.; Wang, Y.-N.; Gao, F.; Liu, T.; Hou, Y.-H.; Zhu, Y.-F.; Ye, W.; Wang, L.-R. Effects of self-assembly of 3-phosphonopropionic acid, 3-aminopropyltrimethoxysilane and dopamine on the corrosion behaviors and biocompatibility of a magnesium alloy. Mater. Sci. Eng. C 2016, 67, 132–143. [Google Scholar] [CrossRef] [PubMed]

- Brusciotti, F.; Snihirova, D.; Xue, H.; Montemor, F.; Lamaka, S.; Ferreira, M. Hybrid epoxy–silane coatings for improved corrosion protection of Mg alloy. Corros. Sci. 2013, 67, 82–90. [Google Scholar] [CrossRef]

- Pan, C.; Hu, Y.; Hou, Y.; Liu, T.; Lin, Y.; Ye, W.; Hou, Y.; Gong, T. Corrosion resistance and biocompatibility of magnesium alloy modified by alkali heating treatment followed by the immobilization of poly (ethylene glycol), fibronectin and heparin. Mater. Sci. Eng. C 2017, 70, 438–449. [Google Scholar] [CrossRef] [PubMed]

- Majumder, O.; Bankoti, A.K.S.; Kaur, T.; Thirugnanam, A.; Mondal, A.K. The influence of silane and silane–PMMA coatings on the in vitro biodegradation behavior of AE42 magnesium alloy for cardiovascular stent applications. RSC Adv. 2016, 6, 107344–107354. [Google Scholar] [CrossRef]

- Golshan, M.; Rostami-Tapeh-Esmail, E.; Salami-Kalajahi, M.; Roghani-Mamaqani, H. A review on synthesis, photophysical properties, and applications of dendrimers with perylene core. Eur. Polym. J. 2020, 137, 109933. [Google Scholar] [CrossRef]

- Cloninger, M.J. Biological applications of dendrimers. Curr. Opin. Chem. Biol. 2002, 6, 742–748. [Google Scholar] [CrossRef]

- Fana, M.; Gallien, J.; Srinageshwar, B.; Dunbar, G.L.; Rossignol, J. PAMAM Dendrimer Nanomolecules Utilized as Drug Delivery Systems for Potential Treatment of Glioblastoma: A Systematic Review. Int. J. Nanomed. 2020, 15, 2789–2808. [Google Scholar] [CrossRef]

- Delyanee, M.; Akbari, S.; Solouk, A. Amine-terminated dendritic polymers as promising nanoplatform for diagnostic and therapeutic agents’ modification: A review. Eur. J. Med. Chem. 2021, 221, 113572. [Google Scholar] [CrossRef]

- Zhang, B.; He, C.; Chen, X.; Tian, Z.; Li, F. The synergistic effect of polyamidoamine dendrimers and sodium silicate on the corrosion of carbon steel in soft water. Corros. Sci. 2015, 90, 585–596. [Google Scholar] [CrossRef]

- Gao, F.; Hu, Y.; Gong, Z.; Liu, T.; Gong, T.; Liu, S.; Zhang, C.; Quan, L.; Kaveendran, B.; Pan, C. Fabrication of chitosan/heparinized graphene oxide multilayer coating to improve corrosion resistance and biocompatibility of magnesium alloys. Mater. Sci. Eng. C 2019, 104, 109947. [Google Scholar] [CrossRef]

- Li, H.; Peng, F.; Wang, D.; Qiao, Y.; Xu, D.; Liu, X. Layered double hydroxide/poly-dopamine composite coating with surface heparinization on Mg alloys: Improved anticorrosion, endothelialization and hemocompatibility. Biomater. Sci. 2018, 6, 1846–1858. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.; Cui, Y.; Zeng, Z.; Wei, L.; Li, L.; Wang, H.; Hu, H.; Liu, T.; Huang, N.; Chen, J.; et al. Heparin/poly-l-lysine nanoplatform with growth factor delivery for surface modification of cardiovascular stents: The influence of vascular endothelial growth factor loading. J. Biomed. Mater. Res. Part A 2020, 108, 1295–1304. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Xi, T. Enhanced Anti-corrosion Ability and Biocompatibility of PLGA Coatings on MgZnYNd Alloy by BTSE-APTES Pre-treatment for Cardiovascular Stent. J. Mater. Sci. Technol. 2016, 32, 845–857. [Google Scholar] [CrossRef]

- Solouk, A.; Cousins, B.G.; Mirahmadi, F.; Mirzadeh, H.; Nadoushan, M.R.J.; Shokrgozar, M.A.; Seifalian, A. Biomimetic modified clinical-grade POSS-PCU nanocomposite polymer for bypass graft applications: A preliminary assessment of endothelial cell adhesion and haemocompatibility. Mater. Sci. Eng. C 2015, 46, 400–408. [Google Scholar] [CrossRef] [PubMed]

- Jafari, S.; Hosseini Salekdeh, S.S.; Solouk, A.; Yousefzadeh, M. Electrospun polyethylene terephthalate (PET) nanofibrous conduit for biomedical application. Polym. Adv. Technol. 2020, 31, 284–296. [Google Scholar] [CrossRef]

- Pavia, D.L.; Lampman, G.M.; Kriz, G.S.; Vyvyan, J.A. Introduction to Spectroscopy: A Guide for Students of Organic Chemistry; Cengage Learning: Boston, MA, USA, 1996. [Google Scholar]

- Chauhan, A.S. Dendrimers for Drug Delivery. Molecules 2018, 23, 938. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Yue, Z.; Romeo, T.; Weber, J.; Scheuermann, T.; Moulton, S.; Wallace, G. Biofunctionalized anti-corrosive silane coatings for magnesium alloys. Acta Biomater. 2013, 9, 8671–8677. [Google Scholar] [CrossRef]

- Lazghab, M.; Saleh, K.; Guigon, P. Functionalisation of porous silica powders in a fluidised-bed reactor with glycidoxypropyltrimethoxysilane (GPTMS) and aminopropyltriethoxysilane (APTES). Chem. Eng. Res. Des. 2010, 88, 686–692. [Google Scholar] [CrossRef]

- Yu, S.; Yu, Z.; Wang, G.; Matthew, S.D.; Zhang, M. Evaluation of Haemocompatibility of TLM Titanium Alloy with Surface Heparinization. Rare Met. Mater. Eng. 2009, 38, 384–388. [Google Scholar] [CrossRef]

- Verma, C.; Ebenso, E.E.; Vishal, Y.; Quraishi, M.A. Dendrimers: A new class of corrosion inhibitors for mild steel in 1M HCl: Experimental and quantum chemical studies. J. Mol. Liq. 2016, 224, 1282–1293. [Google Scholar] [CrossRef]

- Banerjee, P.C.; Raman, R.S. Electrochemical impedance spectroscopic investigation of the role of alkaline pre-treatment in corrosion resistance of a silane coating on magnesium alloy, ZE41. Electrochim. Acta 2011, 56, 3790–3798. [Google Scholar] [CrossRef]

- Diallo, M.S.; Christie, S.; Swaminathan, P.; Balogh, L.; Shi, X.; Um, W.; Papelis, C.; Goddard, W.A.; Johnson, J.H. Dendritic Chelating Agents. 1. Cu(II) Binding to Ethylene Diamine Core Poly (amidoamine) Dendrimers in Aqueous Solutions. Langmuir 2004, 20, 2640–2651. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Yang, Y.; Zhao, Y.; Gao, F.; Guo, X.; Yang, M.; Hong, Q.; Yang, Z.; Dai, J.; Pan, C. Incorporation of heparin/BMP2 complex on GOCS-modified magnesium alloy to synergistically improve corrosion resistance, anticoagulation, and osteogenesis. J. Mater. Sci. Mater. Med. 2021, 32, 24. [Google Scholar] [CrossRef]

- Delyanee, M.; Solouk, A.; Akbari, S.; Daliri Joupari, M. Engineered hemostatic bionanocomposite of Poly (lactic acid) electrospun mat amino-modified halloysite for potential application in wound healing. Polym. Adv. Technol. 2021, 32, 3934–3947. [Google Scholar] [CrossRef]

| Sample Code | Definition | Top Coating | Surface Functional Groups |

|---|---|---|---|

| M | Unmodified Mg alloy | None | --- |

| M-H | Hydroxidized Mg alloy | Mg(OH)2 | OH |

| M-H-A | APTES-coated hydroxidized Mg alloy | APTES | NH2 |

| M-H-A-He | Heparinized APTES-coated hydroxidized Mg alloy | Heparin | --- |

| M-H-A-S-De | Dendrimers (PAMAM) grafted onto APTES-coated hydroxidized Mg alloy | PAMAM | NH2 |

| M-H-A-S-De-He | Heparinized dendrimers (PAMAM) grafted onto APTES-coated hydroxidized Mg alloy | Heparin | --- |

| Sample | Peak Wavelength (cm−1) | Bonding |

|---|---|---|

| M | − | − |

| M-H | 3684 | O–H |

| M-H-A | 1030, 1150 | O–Si |

| 1556 | N–H | |

| M-H-A-He | 1613 | C=O |

| 1240, 1164 | S=O, S–O | |

| M-H-A-S-De | 1563 | N–H |

| 1613 | C=O | |

| 3000–3500 | O–H | |

| M-H-A-S-De-He | 1168, 1240 | S=O, S–O |

| Sample | M | M-H-A | M-H-A-S-De | M-H-A-He | M-H-A-S-De-He | Blank |

|---|---|---|---|---|---|---|

| Acid Orange 7 optical density (OD) | 1.168 ± 0.02 | 1.267 ± 0.07 | 0.877 ± 0.06 | - | - | 1.595 ± 0.01 |

| NH2 density | 4.3 × 10−7 | 3.3 × 10−7 | 7.2 × 10−7 | - | - | − |

| Methylene blue optical density (OD) | - | 1.23 ± 0.02 | 1.24 ± 0.05 | 1.18 ± 0.09 | 1.16 ± 0.07 | 1.24 ± 0.02 |

| Heparin density | - | 1.04 × 10−7 | 2.41 × 10−8 | 5.23 × 10−7 | 6.52 × 10−7 | − |

| Sample | M | M-H | M-H-A | M-H-A-S-De | M-H-A-He | M-H-A-S-De-He |

|---|---|---|---|---|---|---|

| Icorr (µA) | 25 ± 1.2 | 3.7 ± 0.7 | 0.62 ± 1.08 | 0.53 ± 4.96 | 0.014 ± 0.50 | 5.55 ± 0.37 |

| Ecorr (mV) | −1420 ± 23 | −1300 ± 19 | −1250 ± 14 | −1350 ± 25 | −1360 ± 15 | −1350 ± 6 |

| CPE2 | 1.5 × 10−4 | − | 0− | − | 4.46 × 10−6 | 2.6 × 10−4 |

| n2 | 0.7 | − | − | − | 1 | 0.83 |

| Q2 | 2.00 × 10−6 | − | − | − | 4.46 × 10−6 | 3.20 × 10−5 |

| R2 | 944.2 | − | − | − | 1100 | 1284.7 |

| CPE1 | 6.30 × 10−6 | 5.1 × 10−5 | 3.14 × 10−7 | 7.90 × 10−6 | 4.4 × 10−6 | 2.0 × 10−4 |

| n1 | 1 | 0.64 | 0.98 | 0.88 | 0.85 | 0.65 |

| Q1 | 6.30 × 10−6 | 2.05 × 10−5 | 3.73 × 10−7 | 1.49 × 10−5 | 1.34 × 10−6 | 3.00 × 10−4 |

| R1 | 829.5 | 4240 | 960.4 | 1130 | 1371.6 | 1663.4 |

| Rs | 33.22 | 33.2 | 55.6 | 24.38 | 71.9 | 20.5 |

| Sample | M | M-H | M-H-A | M-H-A-He | M-H-A-S-De | M-H-A-S-De-He |

|---|---|---|---|---|---|---|

| Clotting time (s) | 480 ± 10 | 445 ± 7 | 530 ± 12 | 630 ± 8 | 585 ± 11 | 715 ± 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahimi, M.; Solouk, A.; Davoodi, A.; Akbari, S.; Nazarpak, M.H.; Nouri, A. Surface Heparinization of a Magnesium-Based Alloy: A Comparison Study of Aminopropyltriethoxysilane (APTES) and Polyamidoamine (PAMAM) Dendrimers. J. Funct. Biomater. 2022, 13, 296. https://doi.org/10.3390/jfb13040296

Ebrahimi M, Solouk A, Davoodi A, Akbari S, Nazarpak MH, Nouri A. Surface Heparinization of a Magnesium-Based Alloy: A Comparison Study of Aminopropyltriethoxysilane (APTES) and Polyamidoamine (PAMAM) Dendrimers. Journal of Functional Biomaterials. 2022; 13(4):296. https://doi.org/10.3390/jfb13040296

Chicago/Turabian StyleEbrahimi, Masoumeh, Atefeh Solouk, Ali Davoodi, Somaye Akbari, Masoumeh Haghbin Nazarpak, and Alireza Nouri. 2022. "Surface Heparinization of a Magnesium-Based Alloy: A Comparison Study of Aminopropyltriethoxysilane (APTES) and Polyamidoamine (PAMAM) Dendrimers" Journal of Functional Biomaterials 13, no. 4: 296. https://doi.org/10.3390/jfb13040296

APA StyleEbrahimi, M., Solouk, A., Davoodi, A., Akbari, S., Nazarpak, M. H., & Nouri, A. (2022). Surface Heparinization of a Magnesium-Based Alloy: A Comparison Study of Aminopropyltriethoxysilane (APTES) and Polyamidoamine (PAMAM) Dendrimers. Journal of Functional Biomaterials, 13(4), 296. https://doi.org/10.3390/jfb13040296