Abstract

The rapid shift toward electric vehicles (EVs) has underscored the critical importance of battery pack crashworthiness, creating a demand for lightweight, energy-absorbing protective systems. This review systematically explores bio-inspired cellular structures as promising solutions for improving the impact resistance of EV battery packs. Inspired by natural geometries, these designs exhibit superior energy absorption, controlled deformation behavior, and high structural efficiency compared to conventional configurations. A comprehensive analysis of experimental, numerical, and theoretical studies published up to mid-2025 was conducted, with emphasis on design strategies, optimization techniques, and performance under diverse loading conditions. Findings show that auxetic, honeycomb, and hierarchical multi-cell architectures can markedly enhance specific energy absorption and deformation control, with improvements often exceeding 100% over traditional structures. Finite element analyses highlight their ability to achieve controlled deformation and efficient energy dissipation, while optimization strategies, including machine learning, genetic algorithms, and multi-objective approaches, enable effective trade-offs between energy absorption, weight reduction, and manufacturability. Persistent challenges remain in structural optimization, overreliance on numerical simulations with limited experimental validation, and narrow focus on a few bio-inspired geometries and thermo-electro-mechanical coupling, for which engineering solutions are proposed. The review concludes with future research directions focused on geometric optimization, multi-physics modeling, and industrial integration strategies. Collectively, this work provides a comprehensive framework for advancing next-generation crashworthy battery pack designs that integrate safety, performance, and sustainability in electric mobility.

1. Introduction

Electric vehicles (EVs) are becoming more and more popular as the world shifts to more environmentally friendly modes of transportation. This shift is driven by environmental concerns and stricter regulations on emissions. Climate change has led governments worldwide to reduce greenhouse gas emissions and decrease dependency on fossil fuels [1], and the transportation sector is a significant contributor to these emissions. The automotive industry is undergoing a major transformation as EVs are rapidly adopted [2,3,4]. EVs offer a cleaner alternative to conventional internal combustion engine vehicles, contributing to lower environmental pollution and enhanced energy security [5]. Transitioning to electric mobility can significantly cut pollution, promoting a more sustainable and healthier future [6].

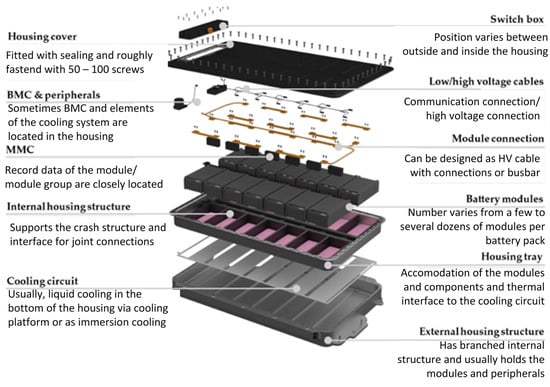

As the EV market expands, efforts to optimize battery pack materials and structures are crucial for improving vehicle performance and sustainability [7]. Battery packs, the primary power source in EVs, consist of multiple cells housed in an enclosure that provides structural support, thermal management, and impact protection, as shown in Figure 1. The battery pack is also vital for EV safety, particularly during crashes. A robust enclosure shields cells from impact, reducing the risk of serious incidents like thermal runaway, fires, or explosions, which are significant concerns with lithium-ion batteries [3,8,9]. Well-designed battery packs, therefore, contribute to structural integrity, occupant protection, and environmental safety.

Figure 1.

Electric vehicle and battery pack components (Reused from [10] with permission in accordance with Creative Common CC BY license, open access).

As the automotive industry shifts toward electrification, the safety of battery packs in electric vehicles has become a paramount concern. The battery pack must not only provide energy but also withstand impact forces without compromising the integrity of the cells. Lithium-ion batteries, the primary energy source for EVs, are more efficient and cleaner than conventional fossil fuels. However, they pose a significant fire risk during crashes. Large deformations of the battery during a crash can lead to thermal runaway, causing fires or explosions that pose severe risks to occupants and components [9]. Crashworthiness, or the ability to absorb impact energy while maintaining structural integrity, is paramount for protecting occupants and preventing catastrophic outcomes. Energy absorption systems are vital components of vehicle crashworthiness designs [11,12], as they dissipate kinetic energy during collisions, reducing the severity of impact forces and minimizing the risk of injury or fatality by resisting deformation [13,14].

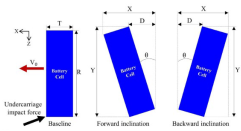

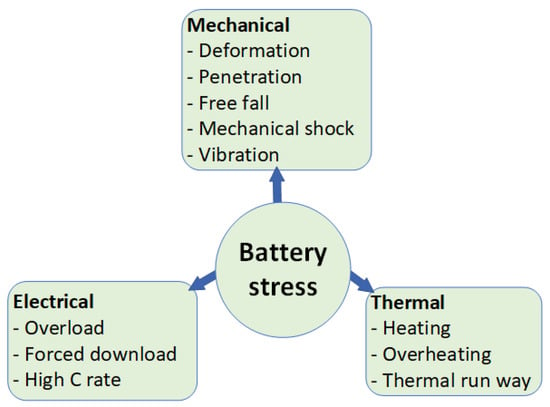

In numerous studies, detailed analyses have been conducted on responses to safety incidents involving energy sources subjected to overloading. From these analyses, external stresses impacting the energy sources have been categorized, as referenced in [15,16,17] and depicted in Figure 2.

Figure 2.

Stresses in lithium-ion batteries during operation and accidents.

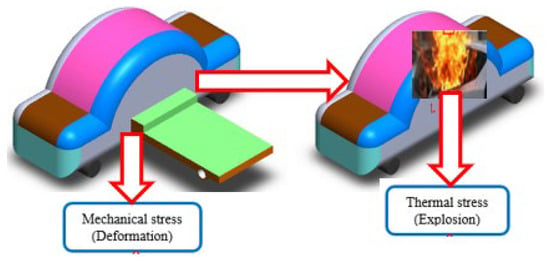

Mechanical stresses from car accidents can trigger additional electrical and thermal stresses, making it essential to prioritize mechanical stress analysis. Studying the crashworthiness of EV batteries is therefore crucial for mitigating these stresses [18]. Battery packs are not only heavy but also highly susceptible to damage, which can lead to catastrophic failures such as fires or explosions due to thermal runaway from collisions and deformation, as shown in Figure 3. Therefore, crashworthiness, which ensures that a structure protects its occupants and critical components during an impact, has become a vital research focus. According to the USA National Highway Traffic Safety Administration (NHTSA), side-impact collisions make up 25% of all fatal accidents [19], posing a significant risk to EV batteries. As battery packs become larger and more powerful, improving safety in side-impact collisions is critical to maintaining battery integrity during both normal operation and crashes.

Figure 3.

Side impact collision causes on mechanical and thermal stress.

In addition, evolving safety regulations and the growing need for safety of occupants make protection of batteries and the crashworthiness of EV battery packs critical [20]. With the rising adoption of EVs, manufacturers face heightened scrutiny to ensure the safety of battery systems, which are vital for overall vehicle safety. A crashworthy vehicle needs a structure that can absorb impact energy, reducing the deceleration load on occupants. Despite advancements, the safety of EV batteries during collisions remains a significant concern, prompting researchers to explore bio-inspired cellular structures based on natural forms evolved to absorb energy effectively, presenting a promising solution.

Recent advancements in materials science have introduced lightweight carbon fiber reinforced polymer (CFRP) structures, auxetic structures, composite materials, and metamaterials, which offer unique properties for energy absorption and structural integrity. For instance, metamaterials have tailored microstructures and exhibit exceptional energy absorption capabilities and mechanical properties that can be optimized for crashworthiness [21]. In particular, CFRP structures are reported to be widely used in automotive applications to improve crashworthiness and enhance efficiency [22]. Similarly, foam composites, which combine lightweight properties with high energy dissipation, are seen as promising materials in enhancing the impact protection engineering [23].

Auxetic structures, known for their negative Poisson’s ratio, effectively distribute stress and resist impact forces, making them ideal for crashworthiness applications [24]. Integrating these materials with bio-inspired cellular structures, such as honeycomb and lattice designs, obviously enhances EV battery pack crashworthiness by mimicking natural energy-absorbing forms, advancing both safety and sustainability in electric vehicle design.

This review systematically examines recent experimental, numerical, and theoretical studies on bio-inspired cellular structures for EV battery pack protection, aiming to synthesize current knowledge on the design, optimization, and performance of such architectures for enhanced battery safety during impacts. The focus is on lightweight, energy-absorbing protective systems that mitigate mechanical damage and thermal risks. Numerical methods, including finite element analysis and other optimization techniques, address key evaluation metrics, emphasizing energy absorption, deformation mitigation, and structural efficiency. By integrating these findings, the review provides a comprehensive framework for developing high-performance battery protection systems and highlights emerging trends in bio-inspired crashworthiness research.

2. Bio-Inspired Cellular Structures

The biomimetic approach, first used in an energy absorption application in 2000, has been widely applied in various systems, including front components of cars and trains [25,26], aircraft wings, and defensive armor [27]. Naturally occurring cellular structures are commonly found in human bone, honeycomb structures, fungi mushrooms, Voronoi structures in bubbles, dragonfly wings, leaf structures, toucan beaks, turtle shells, bird bones, and antlers [28].

Acknowledging the superior energy absorption capability of bio-inspired structures compared to conventional structures, the remarkable properties, such as low density, high strength, and high energy absorption, of structures from plants and animals serve as inspiration for constructing new structures [29]. Different materials have been utilized to manufacture these bio-inspired structures from aluminum alloys and mild steel [30], polymers [31], fiber-reinforced composite and concrete [32], and glass.

2.1. Forms and Applications

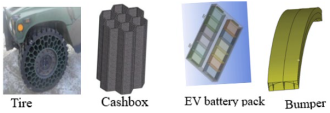

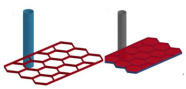

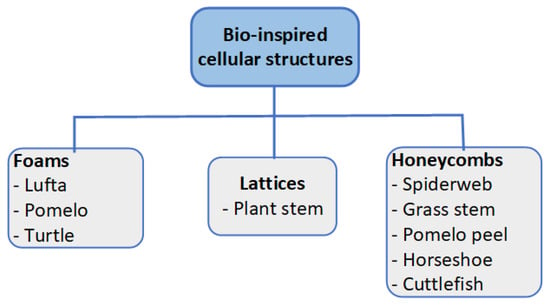

Nature-inspired cellular structures provide a promising solution by mimicking nature’s efficient designs to enhance energy absorption and structural integrity during collisions. Cellular structures are ideal to improve the crashworthiness of vehicles, especially in EV battery packs, because of their form and porous nature that makes them ideal for lightweight components [33], improving energy absorption and impact resistance [34]. Moreover, the arrangement of pores is essential for effectively responding to dynamic stresses. These structures can be engineered to collapse in a controlled manner, absorbing energy and safeguarding the components beneath. Cellular structures are generally classified into three primary types: foams, honeycombs, and lattice structures, as shown in Figure 4, each offering distinct features and applications, especially in areas such as crashworthiness in aerospace and automotive engineering [35].

Figure 4.

Categorization of bio-inspired cellular structures for energy absorption.

Honeycomb structures: Honeycomb structures, with their hexagonal cell pattern, offer high strength-to-weight ratios and exceptional stiffness, making them ideal for aerospace, vehicle parts, and packaging materials [36]. They efficiently distribute loads, are lightweight, and maintain high structural integrity under compression, making them particularly valuable for crashworthiness applications [37]. Research has shown that honeycomb crash absorbers, when reinforced or foam-filled, significantly enhance energy absorption without increasing force levels, and that increasing wall thickness improves mean crushing force, thereby enhancing crashworthiness and passenger safety [38].

Another study by [39] investigated concave I-shaped honeycomb structures, showing that design parameters like cell size and geometry significantly impact crashworthiness. Through multi-objective optimization, improvements in peak crushing force and specific energy absorption were achieved, indicating that refined designs enhance crash performance. Curved designs also prove effective in maximizing energy absorption of honeycombs with curved cell walls exhibiting superior energy absorption performance under quasi-static compression compared to standard designs [40].

D’Mello et al. [41] conducted in-plane compression experiments on circular cell honeycombs filled with elastomer, finding that elastomer filling significantly enhances energy absorption capacity. Additionally, studies show that replacing traditional straight cell walls with circular arc walls in auxetic honeycombs further improves energy absorption [42]. This design approach aligns with the optimal hierarchical honeycomb concept, yielding structures with superior mechanical properties. Reports also highlight that additive manufacturing enables the creation of energy-absorbing devices with tunable mechanical characteristics and improved crashworthiness. The mechanical behavior and crushing performance of five polymer-based honeycomb structures under in-plane loads were analyzed, revealing that polyethylene terephthalate glycol (PET-G) honeycombs exhibit the best crushing performance [43].

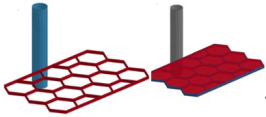

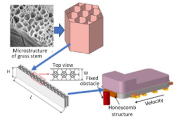

Hexagonal honeycombs, known for their efficiency [44], have inspired the creation of various man-made honeycomb configurations like triangular, square, and circular [45]. While traditional honeycombs typically exhibit a positive Poisson’s ratio, recent research has focused on negative Poisson’s ratio (NPR) structures, such as re-entrant, star-shaped, and double arrowhead honeycombs. These NPR structures have demonstrated significant improvements in crashworthiness compared to traditional designs, making them promising candidates for applications requiring enhanced energy absorption and impact resistance [46,47]. Recent research carried out by [3] investigated the effects of 7 different bio-inspired honeycomb structures, such as conventional honeycomb (Hc), beetle forewings (Hb1, Hb2), spider web (Hs1, Hs2), pomelo peel (Hp), and grass stems (Hg), on the crashworthiness of a battery-pack system during frontal impact.

Foam Structures: Foams consist of gas dispersed within a solid or liquid matrix, creating a network of interconnected cells. Renowned for their exceptional energy absorption, they are commonly used for impact protection in automotive crash safety, padding, and insulation [48]. Their benefits include being lightweight, having high energy absorption per unit weight, and providing effective thermal insulation. Foams are categorized as open-cell or closed-cell, with the structure influencing energy absorption properties.

Recent advancements in foam structures for crashworthiness have been significant. A comprehensive review by Baroutaji et al. [49] highlights the dynamic and mechanical performance of foam-filled systems, emphasizing how foam can modify deformation modes to enhance energy absorption, making them ideal for thin-walled automotive absorbers.

Research by Renreng et al. [50] showed that different foam-filling designs in crash boxes notably influence energy absorption, with fully filled configurations generally offering superior performance compared to partially filled ones. Yet, optimized partial fills can improve efficiency and minimize weight. Experimental investigations by [51] reveal that foam-filled structures excel under various loading scenarios, such as axial and lateral impacts, by lowering peak forces and regulating deformation to boost crashworthiness.

Metal foams have also been extensively researched for energy absorption and structural enhancement. They are commonly used as fillers in beams to increase rigidity and impact resistance. Studies on aluminum foam-filled tubes with diverse cross-sections (ellipse, circle, square, and conical) have explored their energy absorption capabilities and specific properties [52].

Lattice Structures: Lattice structures are 3D frameworks made of interconnected struts designed to optimize mechanical properties while minimizing material use [53]. They are used in 3D printing, lightweight vehicle components, and biomedical implants, offering customizable geometries for improved energy absorption and reduced weight. There are three types: randomized, uniform, and pseudo-periodic lattices [54]. Randomized lattices have irregular cell shapes, uniform lattices have identical cells, and pseudo-periodic lattices have varying cells but the same topology.

Recent research shows that truss-based lattices outperform traditional materials in energy absorption under dynamic impact forces, with strut alignment optimizing crashworthiness parameters like plateau stress and absorbed energy [55]. The use of modern manufacturing techniques such as additive manufacturing enabled customizable lattice structures that enhanced crashworthiness, with thin-walled tubes combined with lattices improving energy absorption by up to 84% [56]. This study also claims that key design parameters like wall thickness and lattice density are critical for optimizing energy absorption and crushing force, with gradient lattices achieving 3.3 times higher specific energy absorption compared to uniform designs.

2.2. Design and Engineering Models of Bionic Structures

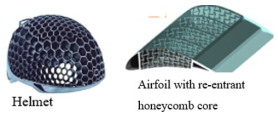

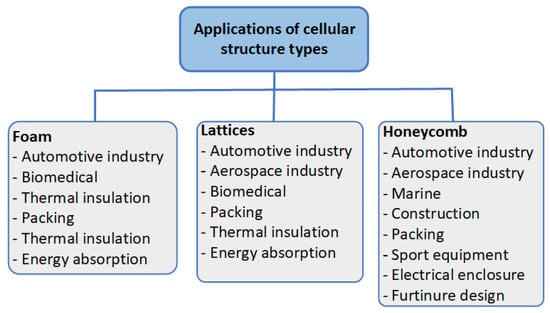

Bio-inspired cellular structures are characterized by their efficient use of materials and unique geometries that enhance mechanical performance. The design of cellular structures is bio-inspired, which means that these designs often draw from natural forms such as animals like human bone [57,58], turtle shells, antlers, toucan beaks [28] and various plants like grass stems, pomelo peel [59], bamboo, leaves [60], as well as fungi like mushrooms and insects like honeycomb bees, dragonflies, beetle elytron, and spider webs [28,61]. Applications of each cellular structure based on the data collected from open publications are summarized in Figure 5.

Figure 5.

Applications of cellular structure types.

As previously noted by numerous researchers, manmade structures are often inspired by nature. Table 1 highlights examples of bionic structures alongside their corresponding engineering models.

Table 1.

Bionic structures with engineering models.

Honeycomb structures represent the most extensively studied bio-inspired cellular designs for battery protection applications. Characterized by their hexagonal cell geometry, they provide optimal strength-to-weight ratios and excellent energy absorption properties [3]. Traditional hexagonal honeycombs serve as a baseline, offering controlled plastic deformation and buckling mechanisms for energy absorption. Numerical investigations have shown that the incorporation of honeycomb cores leads to a marked reduction in internal energy dissipation during collisions, highlighting their potential to safeguard battery cells against catastrophic failure [4]. More advanced bio-inspired variants, such as grass stem-inspired designs, have demonstrated superior performance, reducing battery pack deformation by up to 30% and maximum stress by 10% [3]. The study in [70] introduces a cactus-inspired bionic tube with enhanced energy absorption, validated through experiments and numerical simulations, achieving a 15.84% boost in specific energy absorption and outperforming contemporary structures by 28.3–127.9%. Hierarchical honeycombs, which consist of self-similar nested structures, further enhance crashworthiness, with higher-order configurations achieving up to 88.63% improvement in energy absorption compared to first-order designs [71].

In addition to honeycombs, auxetic structures, defined by their negative Poisson’s ratio, offer unique deformation mechanisms that enhance energy dissipation efficiency. Recent studies report that auxetic lattices can mitigate battery damage by up to 35.2% compared with conventional protective designs while maintaining a lightweight profile that supports vehicle energy efficiency [72]. Beyond these cellular configurations, interlaced battery cell arrangements inspired by natural honeycomb systems have been explored as a means to optimize load distribution. Such bio-inspired layouts not only reduced intrusion deformation by 3.8% but also lowered battery cell damage by 7.3% under high-energy impact scenarios [73].

Auxetic lattice configurations demonstrate excellent crashworthiness, with specific energy absorption values reaching 35 kJ/kg [74]. Recent developments in optimized auxetic designs, including those enhanced through machine learning techniques, have achieved specific energy absorption values of 47,997.84 J while effectively maintaining battery stress below critical thresholds [9].

Another promising category includes lattice and foam structures, which rely on three-dimensional cellular arrangements to improve crash performance. Triply Periodic Minimal Surface (TPMS) structures such as Primitives, FRD, IWP, and Gyroid have been widely investigated, with FRD-sheet structures showing the highest energy absorption capacity [75]. Foam-filled honeycombs, particularly those using aluminum foams, enable better control of densification zones under varying impact energies, thereby improving adaptability and protection [76,77]. Furthermore, multi-stage structures that vary cell wall thickness and inclination have demonstrated enhanced performance under high-velocity impact conditions, making them valuable approaches for advanced battery protection systems [78].

Collectively, studies underscored the potential of bio-inspired geometries in advancing EV safety through improved energy absorption and load management. Nevertheless, critical challenges remain, particularly in achieving an optimal balance between lightweight design and structural resilience. Thus, future work should focus on multi-objective optimization approaches, incorporating material heterogeneity, graded geometries, and large-scale crash validation to accelerate the translation of these bio-inspired concepts into practical EV battery pack applications.

2.3. Comparative Analysis of Nature-Inspired Design Optimizations

Many design optimization approaches have been developed to mimic natural forms. The comparative analysis of bio-inspired cellular structures summarized in Table 2 addresses key findings of energy absorption efficiency, deformation mitigation, and optimization strategies, providing a comprehensive synthesis that informs future development of lightweight, high-performance protective systems for electric vehicle batteries.

Table 2.

Comparative analysis of bionic cellular structures.

As the summary given above indicates, studies consistently demonstrated that bio-inspired designs significantly improved crashworthiness performance in EV applications. Many investigations report notable gains in energy absorption, particularly with honeycomb, auxetic, and multi-cell configurations, which effectively dissipate impact energy [3,82,99]. Foam-filled and hierarchical designs further stabilize deformation modes and increase crushing forces [86,100] while experimental validations confirm that composite and lattice structures outperform conventional counterparts [97,101]. Moreover, structural geometry and material gradients emerge as key factors in maximizing absorption efficiency [84,88]. In terms of SEA, optimized auxetic and meta-structure designs achieve improvements exceeding 1000% relative to baseline models [78,81]. Bio-inspired multi-cell and hierarchical tubes, often combined with foam filling, provide additional enhancements [92,102]. For battery deformation reduction, optimized honeycomb and auxetic structures consistently limit intrusion by 20–35% or more [4,35]. Sandwich panels with lattice cores successfully reduce ground impact penetration below safety thresholds [80,82], while innovative layouts such as interleaved battery cell arrangements further mitigate deformation [73]. Integration of bio-inspired geometries with composite materials enhances both energy absorption and mechanical protection, ensuring safer battery enclosures under crash conditions [97,103].

3. Deformation and Energy Absorption Mechanisms of Nature-Inspired Cellular Structures

Nature-inspired cellular structures have attracted increasing attention for their exceptional energy absorption capabilities, particularly in applications such as automotive crashworthiness, protective gear, and impact mitigation systems. These structures replicate natural designs that have evolved to efficiently dissipate energy and resist mechanical failure. A clear understanding of their underlying energy absorption mechanisms and their geometrical forms is essential for optimizing the performance in engineering applications like EV battery pack protection.

3.1. Deformation Mechanisms

The key mechanisms of energy absorption of cellular structure include progressive crushing, densification, buckling and bending (stretching).

Progressive Crushing: Bio-inspired cellular structures often exhibit a progressive crushing behavior, where the material deforms gradually under load. This allows for a more extended energy absorption phase compared to traditional materials, which may fail suddenly. For example, structures like the Weaire and Floret honeycombs demonstrate this behavior, absorbing energy through controlled deformation patterns as they collapse under stress [104]. Additionally, in cellular materials like honeycombs and re-entrant structures, crushing mechanisms play a vital role in energy absorption. The geometry of these cells allows for progressive crushing, which maximizes energy dissipation over time [105,106].

Densification: As the structure undergoes deformation, it eventually reaches a densification phase, where the material becomes compacted. This phase contributes significantly to the total energy absorbed, as the force required for compressing the material increases sharply, allowing for additional energy dissipation [74].

Buckling: Many bio-inspired designs utilize buckling as a means of energy dissipation. In the report of [107], a novel super hexagonal honeycomb (SHH) structure was developed from the traditional hexagonal honeycomb (THH) using an edge-based strategy to improve the energy absorption capacity of honeycomb materials. Tubular and hierarchical structures can absorb energy through controlled buckling modes, which distribute loads more effectively across the structure.

Bending (Stretching): Deformation mechanisms like bending and tensile-dominated behaviors have different effects on energy absorption. Bending-dominated structures typically absorb more energy due to plastic deformation without failing immediately, making them ideal for applications that require significant energy dissipation, such as crash structures. In contrast, tensile-dominated structures are better suited for applications that demand high strength and stiffness [108].

Whether a structure is bending-dominated or stretching-dominated based on its geometry and material properties is analyzed using the Maxwell rule. This offers a straightforward method using the mathematical equation m = b − 3j + 6, where b and j represent the number of struts and nodes in the lattice, respectively, and m is used to identify if the lattice is stretching-dominated (m ≥ 0) or bending-dominated (m < 0) [108]. Accordingly, lattice structures can be classified as either tensile or bending structures, based on their internal configuration and node count, using this Maxwell rule [109,110].

Nature-inspired cellular structures enhance crashworthiness by combining lightweight design with efficient energy dissipation. Biomorphic designs, such as cedar-inspired wood microstructures, show superior compressive performance due to vertically aligned cell walls [111]. Gyroidal shell–core composites further improve toughness by exploiting hard–soft phase interactions within their periodic topology [112].

In terms of deformation, re-entrant honeycombs utilize negative Poisson’s ratio behavior to achieve stable collapse and high energy absorption [113], while lotus root lattices with hourglass-shaped cells exhibit sequential deformation modes optimized for crashworthiness, strongly influenced by wall thickness [114].

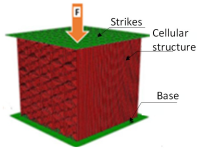

3.2. Criteria Affecting Energy Absorption

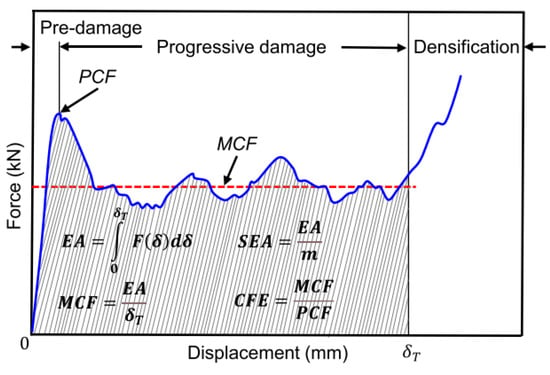

Energy absorption is crucial in structures designed to absorb impact energy. It involves converting kinetic energy into strain energy through mechanisms like plasticity, friction, and viscoelasticity. Material characteristics, loading circumstances, deformation modes, and structural arrangement are some of the variables that affect energy absorption [108]. Energy absorption (EA), specific energy absorption (SEA), peak crash force (PCF), mean crash force (MCF), and crash force efficiency (CFE) are important metrics to evaluate structures for their energy-absorbing characteristics. These indicators, derived from the load-displacement curve, provide insights into how effectively structures dissipate impact energy, and they are analytically formulated as shown in Figure 6, which depicts a typical force-displacement curve for materials that absorb energy during dynamic compression.

Figure 6.

Schematic diagram illustrating energy absorption characteristics and damage zones.

These metrics are crucial for evaluating structural performance under varying loading conditions, influenced by material properties, deformation, and structural configurations. Ultimately, crashworthiness, defined as a vehicle’s ability to protect occupants from serious injury during collisions, depends on how well these energy-absorbing structures mitigate impact forces [115].

Among the most important indicators of crashworthiness performance metrics is SEA, which measures the absorbed energy per unit mass and has reached values of 35–48 kJ/kg in optimized designs [9,74]. Peak crushing force reflects the maximum force sustained during impact, and advanced designs demonstrate controlled force profiles to avoid damaging sensitive battery components [39]. Crushing force efficiency is another important parameter, which is defined as the ratio of mean crushing force to peak force (Figure 6) and provides insight into deformation stability. This parameter is significantly improved in optimized bio-inspired designs [107]. Total energy absorption is another vital metric, with lattice-filled structures showing 62.6–79.1% improvements compared to empty tubes [116].

Comparative performance analysis highlights the superiority of bio-inspired geometries over traditional configurations. For instance, super hexagonal honeycombs demonstrate 106% improvement in MCF, 62% in CFE, 104% in SEA, and 162% in volumetric energy absorption compared to standard hexagonal designs [116]. Similarly, auxetic structures integrated into battery cases can reduce damaged cells by up to 35.2% while maintaining lower mass than conventional designs [72]. Honeycomb-integrated battery packs also show remarkable reductions in internal energy during impact, decreasing from 1021.8 mJ to just 0.80376 mJ [4].

In terms of applications, bio-inspired cellular structures are integrated into EV battery pack protection through several strategies. Direct enclosure protection involves incorporating honeycomb structures into the battery housing [3,4], while interlaced cell arrangements optimize cell positioning and reduce deformation intrusion by more than 3.8%, lowering cell damage by over 7.3% [73]. Sandwich panel configurations with multi-layer cellular cores and protective face sheets further enhance impact resistance [9]. Additionally, energy-absorbing modules have been successfully implemented for lateral pole impact protection, showing significant improvements in crashworthiness [117].

Optimization methods further enhance structural crashworthiness. Multi-objective optimization techniques, such as NSGA-II combined with TOPSIS, balance weight reduction with energy absorption [39,118]. Machine learning approaches, including artificial neural networks, are increasingly used for predicting and optimizing crash performance [9]. Parametric studies systematically explore the effects of geometric parameters such as wall thickness, cell size, and hierarchy on structural efficiency [71].

Compared to conventional protection methods, bio-inspired structures provide clear advantages, including weight reductions of up to 4.31% while simultaneously improving crashworthiness by 5.97% [118]. They achieve superior energy absorption per unit mass, predictable deformation patterns that safeguard battery cells, and overall enhanced structural stability [74,119]. Traditional protection methods, in contrast, often suffer from limited energy absorption capacity, unpredictable failure modes, and difficulty achieving optimal strength-to-weight ratios, especially for complex geometries.

Current research demonstrates notable strengths, such as comprehensive performance evaluation across multiple crashworthiness indicators [39,107], advanced simulation capabilities using ABAQUS and ANSYS [4,120], and experimental validations that confirm numerical predictions [71,89]. Moreover, multi-scale optimization strategies address both material-level and structural-level enhancements [9,75]. However, limitations persist, including limited real-world crash validations, variations in material properties, manufacturing scalability challenges, and integration complexities with existing vehicle architectures [88,96,119,120].

Overall, bio-inspired cellular structures represent a rapidly evolving field with significant potential to improve EV battery safety, reduce structural weight, and advance sustainable vehicle design. Continued efforts toward practical implementation, real-world validation, and standardization will be crucial for transforming these promising concepts into widely deployed safety solutions.

4. Finite Element Analysis of Cellular Structures in EV Battery Pack Design

Finite element analysis is a powerful tool for assessing the mechanical behavior of bio-inspired cellular structures, especially in applications like crashworthiness for EV battery packs. It enables the simulation of how these structures respond to impacts and loads, optimizing designs for better performance. Bio-inspired structures, which mimic natural forms, can be accurately modeled in FEA to examine stress distribution and deformation under load.

Lithium-ion batteries, the primary energy source for EVs, are more efficient and cleaner than conventional fossil fuels. However, they pose a significant fire risk during crashes. Large deformations of the battery during a crash lead to thermal runaway, causing fires or explosions that pose severe risks to occupants and components [3,8,9].

Li-ion batteries offer high energy density but require ongoing design improvements [121]. Moreover, ensuring crashworthiness of battery protective casings is crucial for vehicle safety [122]. One downside of protective casings is that they can add weight and may not fully protect batteries in collisions. Due to their susceptibility to temperature, pressure, and dynamic loads, Li-ion batteries may also malfunction during impacts, resulting in explosions and fires [123].

Crashworthiness refers to a vehicle’s capacity to safeguard occupants during collisions. Damaged battery cells can pose safety risks [124]. Hence, enhancing battery pack crashworthiness is crucial for EV design. Crashworthiness tests include various impact scenarios, with side impact tests being the most studied for Li-ion battery safety. International standards use a pole to simulate side impacts on battery packs. Researchers have explored various pack enclosures to improve energy absorption. Some proposed designs include hexagonal structures and negative Poisson’s ratio blocks [125]. The goal is to create lightweight, anti-collision structures to reduce battery pack weight and minimize damage during impacts.

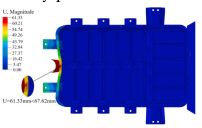

A study reported in [3] investigated seven bio-inspired honeycomb structures, finding that a grass stem-inspired design improved battery pack safety. This design reduced deformation and stress in the bottom shell. Another study [4] using ANSYS analysis showed that incorporating honeycomb structures reduces internal cell energy. A study reported in [9] optimized sandwich-based auxetic honeycomb structures for battery cell protection. The optimized design showed high specific energy absorption and low stress on the battery, effectively absorbing impact energy.

A study reported in [122] investigated lightweight, nature-inspired cellular structures for protecting EV batteries. These structures were assessed through numerical evaluations, revealing that shell thickness plays a crucial role in their energy absorption. The top-performing structure achieved specific energy absorption of 35 kJ/kg, similar to the current design. Honeycomb structures are another popular energy-absorbing material due to their strength, low cost, and effectiveness. They have been used in various industries, including battery packs [72]. A study [126] assessed the performance of different battery pack structures, including hexagonal, trapezoidal, and rectangular configurations. The results showed that hexagonal packs, both empty and foam-filled, had better energy absorption characteristics compared to the other shapes.

A study [86] explored lightweight, nature-inspired cellular structures for EV battery protection, which were evaluated numerically, and the results showed that shell thickness significantly influences their energy absorption. The best-performing structure achieved specific energy absorption of 35 kJ/kg, comparable to existing designs. A study investigated NPR tubular structures and optimized them using a multi-objective optimization method. The optimized design showed superior crashworthiness and heat dissipation compared to other battery pack designs [127]. Researchers studied a structural honeycomb battery pack, which includes a honeycomb core and embedded cylindrical batteries. In order to safeguard the internal battery, they also created a unique thin-walled honeycomb for Li-ion battery packing [128]. A study analyzed a battery pack enclosure’s (BPE) crashworthiness and weight reduction. While still fulfilling crush criteria, the BPE’s weight was lowered by 11.73% with the use of the response surface approach and an orthogonal experimental design [129].

Numerical methods like FEA are important for studying cellular structures. A study [130] compared three honeycomb topologies: hexagon, half-concave hexagon, and concave hexagon. The results showed that the hexagon had the highest impact force, while the dual-wall hexagon structure improved rear panel protection displacement by 30–50%.

Another study [118] combined the TOPSIS approach, contribution analysis, and a modified Genetic Algorithm (NSGA-II) to present an effective lightweight solution for EV battery packs. This method was created to reduce mass and increase the BPE crashworthiness. According to numerical simulations, the revised BPE produced a lighter, crash-resistant design by reducing total weight by 4.31% and crushing deformation by 5.97%.

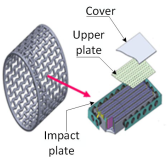

In addition to cellular structures, non-cellular structures are also considered by researchers for EV battery pack protection (where some examples are listed in Table 3). While cellular structures focus on energy absorption through honeycomb or lattice designs, non-cellular structures provide an alternative approach like battery cell layout, structural optimization, etc.

Table 3.

Summary of some cellular structure-based energy absorbers for EV battery pack.

Finite element analysis enables the simplification of complex battery pack models by deriving equivalent homogeneous materials that represent multiple cells, thereby reducing computational demands [132]. Advanced modeling techniques, including 3D simulations, facilitate both static and dynamic analyses under various operational conditions, ensuring that the battery pack meets mechanical strength requirements [133].

Electric vehicles rely on high-energy-density lithium-ion batteries (LIBs) to meet the requirements of range, performance, and cost [134]. However, during crashes, mechanical loads can deform the battery system, compromising both LIB and vehicle safety [135,136,137]. Various mechanical abuse tests assess LIB safety and mechanical behavior, including nail penetration [138], axial compression [139], indentation [9], and bending [140]. These tests are conducted by loading direction, i.e., out-of-plane (along the cell thickness) and in-plane (perpendicular to thickness).

When developing FEA models for battery packs, it is essential to distinguish between isotropic and anisotropic materials. Isotropic materials, such as AA6063 or AA2024, are often assumed for honeycomb cores, pack enclosures, and foams. In contrast, anisotropic behavior arises in pouch cells due to their layered structure and manufacturing process. Lithium-ion pouch cells, consisting of anode, cathode, separator, and polymer laminates, exhibit directional stiffness, strength, and failure strains. Accurately capturing this anisotropy, often through representative volume element (RVE) modeling under fully constrained conditions, is critical for predicting in-plane and out-of-plane mechanical responses [141,142,143].

Crash-induced deformation of lithium-ion battery packs involves strong interactions between mechanical, electrical, and thermal fields. Therefore, thermal–electrical–mechanical (T–E–M) coupled finite element modeling is essential for evaluating battery performance and safety during crashes [144]. Early studies often assumed isotropic behavior for components such as aluminum enclosures or honeycomb cores. However, the layered architecture of LIBs makes anisotropic constitutive modeling necessary for accurate simulation of mechanical response under compression, tension, and impact.

The study in [145] investigated the anisotropic mechanical behavior and fracture of lithium-ion pouch cell components using tensile tests to develop and validate a layered finite element model. Significant anisotropy was observed, highlighting the need for advanced modeling to predict failure accurately. The findings provide guidance for material selection and structural reinforcement to enhance battery safety and prevent short circuits or thermal runaway.

The study in [146] also demonstrated the practicality of employing a representative battery model to predict thermal runaway during full-vehicle crash analysis. By integrating multiphysics simulations, the approach effectively captured the complex interactions within the battery system. Detailed 3D models of battery cells, including components like cathodes and anodes, allow for the evaluation of failure modes under different loading scenarios, such as crush loading [147]. Furthermore, crash propagation models capture mechanical pressure effects and the resulting electrical and thermal responses in automotive battery packs, with validation against crash events [148]. The integration of structural and thermal analyses helps predict battery behavior during extreme conditions, enhancing safety measures against thermal runaway during crashes [146].

Recent studies on the mechanical behavior and modeling of lithium-ion batteries (LIBs) have significantly enhanced the understanding of mechanical–thermal–electrical coupling and FEA-based crashworthiness analyses. To address these aspects, several key works have been highlighted. The study reported in [149] analyzed the stress–strain behavior of pouch cells under static and dynamic loading, capturing anisotropic and rate-dependent mechanical properties, which are critical for evaluating battery safety.

For instance, the investigation in [150] focused on 21,700 cylindrical cells under dynamic loads and varying states of charge using FEA to predict deformation and failure, emphasizing the influence of loading velocity and state of charge. The analysis in [151] examined battery pack crashworthiness under impact and drop scenarios, combining experimental and numerical methods to assess stress distribution, deformation, and energy absorption. The research in [152] explored the dynamic response and failure evolution of pouch cells under impact, providing insights into high-strain-rate behavior and failure mechanisms.

Further, the approach presented in [153] integrated a thermo-mechanical FEA framework for 4680 cells, capturing coupled thermal and mechanical effects during crash events. Finally, [144] applied a two-way mechanical–electrical–thermal coupled analysis to predict internal short-circuit initiation and subsequent electrical and thermal response. Advanced finite element software like LS-DYNA, ABAQUS, and ANSYS Multiphysics are used for coupled simulations, integrating mechanical deformation results with thermal and electrical modeling to understand complex battery failure mechanisms. Incorporating these studies strengthens our discussion and provides a comprehensive and up-to-date perspective on LIB crashworthiness and multiphysics behavior.

Nature-inspired cellular structures exhibit exceptional energy absorption by mimicking biological designs and employing mechanisms such as progressive crushing, densification, controlled buckling, and bending-dominated deformation to dissipate impact energy efficiently while maintaining structural stability. Designs including Weaire, Floret, super hexagonal, re-entrant honeycombs, and grass stem- or lotus root-inspired lattices achieve high specific energy absorption, mean crushing force, and crushing force efficiency, consistently outperforming conventional configurations. For example, super hexagonal honeycombs demonstrate over 100% improvements in SEA, CFE, and volumetric energy absorption, while auxetic battery-case structures reduce damaged cells by 35% with lower mass. In electric vehicle battery packs, these cellular designs reduce stress, deformation, and internal energy during impacts, enhancing crashworthiness without excessive weight. Finite element analysis, often integrated with thermal–electrical–mechanical simulations, enables accurate prediction of deformation, energy dissipation, and thermal risks such as battery thermal runaway, while multi-objective optimization and machine learning further enhance performance. Overall, bio-inspired cellular structures offer a transformative approach to vehicle safety, combining lightweight design, predictable impact behavior, and high energy absorption, although real-world validation, manufacturing feasibility, and integration with vehicle architectures remain key challenges.

5. Optimization Techniques for Cellular Structures

In this review, optimization of cellular structures, such as bio-inspired honeycombs, is focused on enhancing energy absorption and improving crashworthiness through algorithmic and geometric techniques.

5.1. Optimization Approches Using Algorithms

Design optimization for crashworthiness and lightweight structures is essential for enhancing safety and reducing costs. A typical optimization framework involves defining the problem, creating a model, and applying an algorithm to solve it [67]. Various studies have applied optimization techniques to battery pack enclosures and similar structures. For example, a multi-objective genetic algorithm (MOGA) was used to optimize a battery pack enclosure with cold-sprayed materials, improving performance over bulk aluminum [154]. Pareto solutions were used for multi-objective topology optimization, achieving a 9.42% mass reduction. Furthermore, to improve structural performance in an air-cooled battery pack, multi-objective particle-swarm optimization (MOPSO) and surrogate-based optimization were used to optimize frequency and decrease mass [155]. In Table 4, optimization objectives and optimized parameters are summarized.

Table 4.

Summary of design optimization methods and parameters as reported in the literature.

ANSYS and MATLAB, combined with genetic programming, were used to optimize battery pack enclosures by focusing on minimizing mass, maximizing frequency, and reducing deformation [162]. Researchers [156] employed artificial neural networks (ANN) with NSGA-II and central composite design (CCD), achieving a 2.22% reduction in deformation, a 3.18% increase in frequency, and an 11.61% mass reduction. Scholars [80] utilized LS-DYNA for crash simulations of battery pack enclosures made from steel and carbon-fiber-reinforced plastic, resulting in a 6.6% weight reduction and enhanced crashworthiness.

The multi-objective optimization of an air-cooled battery module using ANSYS, CFD, design of experiments (DoE), and surrogate models resulted in reduced temperature rises and enhanced cooling efficiency, making it appropriate for industrial EVs with large cell counts, according to the paper in [158]. To improve dependability, researchers [163] emphasized the crucial roles that modular packaging architecture and thermal management play in EV battery packs. A further study [159] described a surrogate-based optimization framework for battery packs that uses MOPSO and metamodel techniques to maximize frequency and reduce mass under shock limitations.

The study used Finite Element Method (FEM) simulations, and 100 design samples produced using Latin Hypercube Sampling (LHS) to investigate several auxetic cell shapes (Re-entrant, Double Arrow, Star-shaped, Double-U), materials (GFRP, CFRP, aluminum, and carbon steel), and geometries. To mitigate battery deformation and failure, machine learning techniques such as an Artificial Neural Network (ANN) and Non-dominated Sorting Genetic Algorithm-II (NSGA-II) found that aluminum star-shaped auxetic cells with a thickness of 2.95 mm achieved a 1220% increase in specific energy absorption compared to the baseline, with a 6.7% prediction error [79].

Bird flock behavior serves as the inspiration for the heuristic global optimization algorithm known as Particle Swarm Optimization (PSO). To discover the best answer, iterations are performed starting with random solutions. PSO, which is renowned for its quick convergence and capacity to generate a well-distributed Pareto frontier, is extended by MOPSO, which selects elite individuals from sparse regions as global optimal solutions and uses a crowded degree method to manage non-dominated solutions while maintaining uniformity in the solution distribution using an external archive [155].

In recent engineering applications, deep learning has emerged as a powerful tool for optimizing complex, multi-objective engineering problems like crashworthiness. Due to their powerful prediction capacities, recent studies have focused on the use of deep learning techniques to predict the crashworthiness behavior of energy-absorbing structures [164,165]. Particularly, artificial neural networks (ANNs) are the rapidly developing field of deep learning in machine learning that is being employed in the crashworthiness performance of, for instance, composite rectangular tubes, where, based on experimentally obtained values of different crashworthiness parameters under various loading conditions, the ANN models were constructed to identify the optimum cross-sectional aspect ratio of cotton fiber/epoxy laminated composite [166].

Among the available techniques, generative adversarial networks (GANs) are a class of deep learning algorithms that can generate synthetic data from latent space. In this algorithm, reinforcement learning-based optimization techniques are tuned using finite element simulations, and synthetic data are generated by the GAN to optimize and select the optimal model parameters for vehicle crashworthiness analysis [167].

Machine learning (ML) techniques, including artificial neural networks (ANNs) and evolutionary algorithms such as NSGA-II, have been widely applied to optimize the geometry and material parameters of bio-inspired structures to achieve maximum energy absorption and minimal deformation [79,80,82].

Multi-objective optimization algorithms, such as particle swarm optimization (PSO) and TOPSIS, are effective in balancing competing crashworthiness metrics, enabling designers to achieve optimal performance under multiple criteria [84,88]. Complementing numerical simulations, theoretical models provide predictive insights into crushing behavior, guiding design decisions and improving structural performance [67,86,90]. Collectively, these optimization approaches have demonstrated substantial improvements in specific energy absorption (SEA) and overall crashworthiness, highlighting their critical role in the development of bio-inspired cellular designs [85].

5.2. Geometric Optimization Approch

Prior studies have explored many geometric configurations of thin-walled structures for square [168,169,170,171], circular [172,173], triangular, and polygonal shapes such as hexagonal and octagonal [174,175], double hat [176], tapered [177,178], new concave polygon [179], and corrugated [180], which have been extensively studied in the literature for improving crashworthiness capacity. Additional structural enhancements such as filling with foam [181], employing multi-cell designs [182], hybrid structures [177], hierarchical configuration designs [102], and re-entrant honeycomb [42,183,184,185,186] can significantly enhance their energy absorption capabilities. Beyond geometry, bio-inspired design has emerged as an innovative strategy to enhance mechanical performance.

Cell Geometry: The geometry of bio-inspired structures is key to their energy absorption efficiency. Honeycomb designs inspired by nature can be optimized for increased strength and stiffness while reducing weight. Studies show that bio-inspired honeycombs achieve specific energy absorption (SEA) values up to 44% higher than traditional designs, thanks to their optimized geometries. Research on weaire, floret, and kagome-shaped honeycombs reveals that they outperform conventional thin-walled structures in energy absorption due to their unique shape [107].

Hierarchical Design: Hierarchical structures found in biological materials span many length scales, such as beetle elytron [62], spider web [61], bone [58], pomelo peel [57,59], and bamboo [30]. These multi-scale designs enable various levels of the structure to work together to dissipate energy effectively. For instance, bamboo offers rigidity along one axis while maintaining flexibility in others, enhancing its energy absorption capabilities. The above-mentioned structures found in nature have shown remarkable impact resistance and energy dissipation due to their hierarchical structures. According to research, hierarchical structures have greater energy dissipation performance, absorbing up to 2.5 times as much energy as traditional honeycomb structures [187,188].

The structure of spider webs, which exhibit multiple hierarchies, was studied by [189]. The study found that the specific energy absorption (SEA) of a first-order spider-web hierarchical honeycomb increased by 62.1%, while the SEA of a second-order spider-web hierarchical honeycomb increased by 82.4%. Hierarchical configurations can be categorized into vertex-based and edge-based hierarchies. Edge-based hierarchies involve replacing the sides of structure with smaller sub-cells. Sandwich walled tubes are a notable example of edge-based hierarchical structure [190]. A study by [102] focused on bionics inspired by beetle forewings, using quadrilateral, hexagonal, and octagonal sections, with analytical models and crashworthiness design implemented.

Hybrid Structures: Recent advancements have resulted in hybrid bio-inspired designs that integrate different structural elements to optimize energy absorption. For example, combining tubular structures with honeycomb cores has demonstrated enhanced performance under dynamic loading conditions, improving both strength and energy dissipation. A study revealed that a hybrid bio-inspired sandwich structure significantly outperformed conventional designs in terms of energy absorption, achieving notably higher SEA values due to the synergistic effects of the integrated structure [103].

Gradient hierarchical structure: Numerous studies highlight the superior energy absorption of functionally graded configurations compared to traditional uniform structures. This section focuses on metallic cellular structures with functionally graded designs, categorized into four types: graded sectional dimensions, graded wall thickness, graded foam fillers, and tailored properties. Graded sectional dimensions refer to variations in the diameter or width of a thin-walled structure along the axial direction. Tapered thin-walled tubes or frusta are common examples, offering improved peak crushing force reduction and stability under oblique loading. An early study on tapered square cellular structures examined the effects of wall thickness, taper angle, and loading angle, followed by multi-objective optimization to determine optimal dimensions [191]. The energy absorption performance of graded foam-filled thin-walled structures under axial crushing and lateral bending was reported [192] to have enhanced the axial crashworthiness performance of thin-walled structures by filling graded lattice structures.

Optimization of bio-inspired cellular structures integrates algorithmic and geometric approaches to maximize energy absorption and crashworthiness. Algorithmic methods, including multi-objective genetic algorithms (NSGA-II, MOGA), particle swarm optimization (PSO/MOPSO), surrogate-based models, and machine learning techniques like artificial neural networks (ANNs) and generative adversarial networks (GANs), enable systematic tuning of material and geometric parameters, achieving substantial improvements in crashworthiness. Geometric optimization explores diverse cell shapes, hierarchical arrangements, hybrid designs, and gradient structures to enhance energy dissipation and structural stability. Hierarchical and gradient designs, inspired by natural structures such as beetle elytra, bamboo, and spider webs, allow multiple scales of deformation to work synergistically, increasing SEA by up to 82% compared to conventional designs. Hybrid configurations, such as tubular cores combined with honeycomb or foam-filled lattices, further boost crash performance under dynamic loading. Collectively, these optimization strategies provide a robust framework for designing high-performance cellular structures that balance lightweight design, predictable impact behavior, and superior energy absorption.

6. Summary and Future Outlook

This paper addresses the safety of EV battery packs by reviewing recent research on bio-inspired cellular structures aimed at enhancing impact resistance. The key findings can be summarized as follows:

- ○

- Studies consistently show that bio-inspired multi-cell and hierarchical tubes like honeycomb, auxetic, and multi-cell configurations significantly improve energy absorption and deformation control, with foam-filled and hierarchical designs or optimized cell shapes further stabilizing crushing behavior [3,82,86,99,100].

- ○

- Numerous studies report significant reductions in battery deformation, with optimized honeycomb and auxetic structures reducing deformation by 20–35% or more [3,79,81,83] and layout innovations, such as interleaved battery cell arrangements, also contributing to deformation mitigation [73].

- ○

- There is broad agreement that structural geometry and hierarchical design play a critical role in enhancing energy absorption and overall crashworthiness. Bio-inspired configurations such as honeycomb, auxetic, bamboo, grass stem, and lotus leaf patterns demonstrate superior performance compared to conventional designs, offering improved impact resistance and deformation control [3,84,87,88].

- ○

- Integration of composite materials and bio-inspired designs enhances mechanical protection while controlling deformation [103,193]. Advanced computational methods, including FEA coupled with machine learning, including ANN and NSGA-II, have emerged as vital tools for optimizing structural configurations and material properties [79,81,82], and different optimization approaches have demonstrated substantial improvements in crashworthiness, validating their critical role in bio-inspired design development [85]. Additionally, manufacturing techniques such as additive manufacturing enable the practical realization of complex bio-inspired architectures, facilitating improvements in lightweight, impact-resistant battery protection systems.

To enhance the crashworthiness of EV battery packs, future improvements will require advancements in the following key areas:

- ○

- Many studies rely heavily on numerical simulations and finite element models without extensive experimental validation, which limits the external validity and practical applicability of the findings. This methodological constraint may affect the reliability of crashworthiness predictions [3,4,79,82,88,94].

- ○

- Many investigations concentrate on particular bio-inspired geometries (e.g., honeycomb, auxetic) without exploring a broader variety of natural structures, which restricts the comprehensiveness of design strategies and may overlook potentially superior configurations [3,79,84,85,86,89].

- ○

- Most research focuses on specific impact types (e.g., axial or frontal impacts) and velocities, often neglecting diverse real-world crash scenarios such as oblique, side, or multi-directional impacts, which reduces the ecological validity of the findings [3,73,83,96,121,193].

- ○

- While mechanical crashworthiness is well-studied, integration of thermal management and fire safety considerations remains limited, which is critical for comprehensive battery pack protection in electric vehicles. This gap affects the holistic safety assessment [90,98,194,195].

7. Conclusions

Research on bio-inspired cellular structures highlights their significant potential for improving the crashworthiness of EV battery packs. Designs such as honeycombs, auxetic cells, multi-cell tubes, and hierarchical configurations consistently offer superior energy absorption and deformation mitigation compared to conventional structures, achieving lightweighting without compromising safety. Structural geometry is a key performance driver, with auxetic and meta structures demonstrating high specific energy absorption due to negative Poisson’s ratio and multi-scale hierarchy. Multi-cell and foam-filled architectures further stabilize deformation and limit battery intrusion.

Optimization methods, particularly those combining machine learning and genetic algorithms, effectively tailor cell shape, wall thickness, and material distribution to balance crashworthiness with manufacturability. While mechanical protection is well-studied, thermal management and fire safety integration remain limited. Multifunctional materials and system-level design approaches show promise but require experimental validation.

In summary, bio-inspired cellular structures enhance EV battery safety through optimized geometry and intelligent design. Future research should focus on bridging simulations with experiments, scalable manufacturing, and integrating thermal protection to develop robust, multifunctional battery pack systems for real-world crashes.

Author Contributions

Conceptualization, T.D. and Y.R.; methodology, H.G.L. and Y.R.; software, T.D.; validation, H.G.L. and Y.R.; formal analysis, T.D.; investigation, T.D.; resources, Y.R.; data curation, T.D. and H.G.L.; writing—original draft preparation, T.D.; writing—review and editing, H.G.L.; visualization, Y.R.; supervision, H.G.L. and Y.R.; project administration, Y.R.; funding acquisition, Y.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AA | Aluminum Alloy |

| AHSS | Advanced High Strength Steel |

| ANN | Artificial Neural Network |

| BPE | Battery Pack Enclosure |

| BPS | Battery Pack System |

| CC BY | Creative Commons Attribution |

| CCD | Central Composite Design |

| CFE | Crash Force Efficiency |

| CFD | Computational Fluid Dynamics |

| CFRP | Carbon Fiber Reinforced Polymer |

| CTP | Crashworthy Tube Pack |

| DoE/DOE | Design of Experiments |

| EA | Energy Absorption |

| EV | Electric Vehicle |

| FEA | Finite Element Analysis |

| FEM | Finite Element Method |

| GA | Genetic Algorithm |

| GAN | Generative Adversarial Network |

| GFRP | Glass Fiber Reinforced Polymer |

| IPF | Intrusion Peak Force |

| LIB | Lithium-Ion Battery |

| Li-ion | Lithium-Ion |

| LHS | Latin Hypercube Sampling |

| LS-DYNA | Livermore Software for Dynamic Analysis |

| MCF | Mean Crash Force |

| MOGA | Multi-Objective Genetic Algorithm |

| MOO | Multi-Objective Optimization |

| MOPSO | Multi-Objective Particle Swarm Optimization |

| NHTSA | National Highway Traffic Safety Administration |

| NPR | Negative Poisson’s Ratio |

| NSGA-II | Non-dominated Sorting Genetic Algorithm II |

| NSGA-III | Non-dominated Sorting Genetic Algorithm III |

| OED | Orthogonal Experimental Design |

| PET-G | Polyethylene Terephthalate Glycol |

| PCF | Peak Crash Force |

| PSO | Particle Swarm Optimization |

| PSO-RBF | Particle Swarm Optimization—Radial Basis Function |

| RBF | Radial Basis Function |

| RSM | Response Surface Method |

| RVE | Representative Volume Element |

| SEA | Specific Energy Absorption |

| SHH | Super Hexagonal Honeycomb |

| THH | Traditional Hexagonal Honeycomb |

| T–E–M | Thermal–Electrical–Mechanical |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| TPMS | Triply Periodic Minimal Surface |

References

- Mawuntu, N.N.; Mu, B.Q.; Doukhi, O.; Lee, D.J. Modeling of the Battery Pack and Battery Management System towards an Integrated Electric Vehicle Application. Energies 2023, 16, 7165. [Google Scholar] [CrossRef]

- Capasso, C.; Iannucci, L.; Patalano, S.; Veneri, O.; Vitolo, F. Design approach for electric vehicle battery packs based on experimentally tested multi-domain models. J. Energy Storage 2024, 77, 109971. [Google Scholar] [CrossRef]

- Li, R.; Zhao, Z.; Bao, H.; Pan, Y.; Wang, G.; Liu, B.; Liao, T.; Li, J. Bio-inspired honeycomb structures to improve the crashworthiness of a battery-pack system. Eng. Fail. Anal. 2024, 158, 108041. [Google Scholar] [CrossRef]

- Agarwal, A.; Batista, R.C.; Tashi, T. Crashworthiness evaluation of electric vehicle battery packs using honeycomb structures and explicit dynamic analysis. In Proceedings of the 5th Talenta Conference on Engineering, Science and Technology (TALENTA CEST-5 2024), Medan, Indonesia, 6–7 March 2024; Volume 519, p. 04010. [Google Scholar] [CrossRef]

- Dua, S.; Khatri, H.; Naveen, J.; Jawaid, M.; Jayakrishna, K.; Norrrahim, M.; Rashedi, A. Potential of natural fiber based polymeric composites for cleaner automotive component production a comprehensive review. J. Mater. Res. Technol. 2023, 25, 1086–1104. [Google Scholar] [CrossRef]

- Brătucu, G.; Trifan, A.; Dovleac, L.; Chiţu, I.B.; Todor, R.D.; Brătucu, R. Acquisition of electric vehicles-A step towards green consumption. Empirical research among Romanian students. Sustainability 2019, 11, 6639. [Google Scholar] [CrossRef]

- Azzopardi, B.; Hapid, A.; Kaleg, S.; Onggo, D.; Budiman, A.C. Recent advances in battery pack polymer composites. Energies 2023, 16, 6223. [Google Scholar] [CrossRef]

- Belingardi, G.; Scattina, A. Battery pack and underbody: Integration in the structure design for battery electric vehicles—Challenges and solutions. Vehicles 2023, 5, 498–514. [Google Scholar] [CrossRef]

- Biharta, M.A.S.; Santosa, S.P.; Widagdo, D. Design and optimization of lithium-ion battery protector with auxetic honeycomb for in-plane impact using machine learning method. Front. Energy Res. 2023, 11, 1114263. [Google Scholar] [CrossRef]

- Chen, P.; Xia, Y.; Zhou, Q. Inclined battery cells for mitigating damage in undercarriage collision. Int. J. Crashworthiness 2024, 29, 508–520. [Google Scholar] [CrossRef]

- Albak, E.I. Thin-walled structures crashworthiness design and optimization of nested structures with a circumferentially corrugated circular outer wall and inner ribs. Thin Walled Struct. 2021, 167, 108219. [Google Scholar] [CrossRef]

- Baroutaji, A.; Sajjia, M.; Olabi, A.-G. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments. Thin Walled Struct. 2017, 118, 137–163. [Google Scholar] [CrossRef]

- El-Baky, M.A.A.; AHegazy, D.; Hassan, M.A. Novel energy absorbent composites for crashworthiness applications. Compos. Struct. 2022, 51, 6403–6442. [Google Scholar] [CrossRef]

- Tao, C.; Wang, Z.; Liu, Z.; Wang, Y.; Zhou, X.; Liang, X.; Li, H. Crashworthiness of additively manufactured lattice reinforced thin-walled tube hybrid structures. Aerospace 2023, 10, 524. [Google Scholar] [CrossRef]

- Lavine, M.S. A solid electrolyte. Science 2018, 359, 1115–1116. [Google Scholar] [CrossRef][Green Version]

- Chombo, P.V.; Laoonual, Y. A review of safety strategies of a Li-ion battery. J. Power Sources 2020, 478, 228649. [Google Scholar] [CrossRef]

- Klink, J.; Hebenbrock, A.; Grabow, J.; Orazov, N.; Nylén, U.; Benger, R.; Beck, H.-P. Comparison of model-based and sensor-based detection of thermal runaway in Li-Ion battery modules for automotive application. Batteries 2022, 8, 34. [Google Scholar] [CrossRef]

- Szabo, I.; Scurtu, L.I.; Raboca, H.; Mariasiu, F. Topographical optimization of a battery module case that equips an electric vehicle. Batteries 2023, 9, 77. [Google Scholar] [CrossRef]

- Traffic Safety Facts 2011 Data. NHTSA’s National Center for Statistics and Analysis DOT HS 811 754: Washington, DC, USA, 2013. Available online: https://crashstats.nhtsa.dot.gov/Api/Public/ViewPublication/811751 (accessed on 22 March 2025).

- Chombo, P.V.; Laoonual, Y.; Wongwises, S. Lessons from the electric vehicle crashworthiness leading to battery fire. Energies 2021, 14, 4802. [Google Scholar] [CrossRef]

- Zhong, J.; Zhao, C.; Chen, C.; Lai, W.L.; Wang, Q. Mechanical behaviors of composite auxetic structures under quasi-static compression and dynamic impact. J. Mech. A/Solids 2024, 109, 105454. [Google Scholar] [CrossRef]

- Hussain, N.N.; Regalla, S.P.; Rao, Y.V.D.; Mohammed, A.M. Mohammed, An experimental and numerical analysis on influence of triggering for composite automotive crash boxes under compressive impact loads. Int. J. Crashworthiness 2022, 27, 1152–1166. [Google Scholar] [CrossRef]

- Zhao, C.; Zhong, J.; Wang, H.; Liu, C.; Li, M.; Liu, H. Impact behavior and protection performance of a CFRP NPR skeleton filled with aluminum foam. Mater. Des. 2024, 246, 113295. [Google Scholar] [CrossRef]

- Shen, J.; Liu, K.; Zeng, Q.; Ge, J.; Dong, Z.; Liang, J. Design and mechanical property studies of 3D re-entrant lattice auxetic structure. Aerosp. Sci. Technol. 2021, 118, 106998. [Google Scholar] [CrossRef]

- Xu, T.; Liu, N.; Yu, Z.; Xu, T.; Zou, M. Crashworthiness design for bionic bumper structures inspired by cattail and bamboo. Appl. Bionics Biomech. 2017, 2017, 5894938. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Zhao, W.; Zou, S.; Zhou, G.; Wang, Y. Structure design and multi-objective optimization of a novel crash box based on biomimetic structure. Int. J. Mech. Sci. 2018, 138, 489–501. [Google Scholar] [CrossRef]

- Islam, M.K.; Hazell, P.J.; Escobedo, J.P.; Wang, H. Biomimetic armour design strategies for additive manufacturing: A review. Mater. Des. 2021, 109730, 10973. [Google Scholar] [CrossRef]

- Zheng, Y. Bioinspired Design of Materials Surfaces Materials Today; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. A Review of Recent Research on Bio-Inspired Structures and Materials for Energy Absorption Applications. Compos. Part B Eng. 2019, 181, 107496. [Google Scholar] [CrossRef]

- Hu, D.; Wang, Y.; Song, B.; Dang, L.; Zhang, Z. Energy-absorption characteristics of a bionic honeycomb tubular nested structure inspired by bamboo under axial crushing. Compos. Part B Eng. 2019, 162, 21–32. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, J.; Chen, J.; Okabe, Y.; Pan, L.; Xu, M. The beetle elytron plate: A lightweight, high-strength and buffering functional-structural bionic material. Sci. Rep. 2017, 7, 4440. [Google Scholar] [CrossRef] [PubMed]

- Toader, N.; Sobek, W.; Nickel, K.G. Energy absorption in functionally graded concrete bioinspired by sea urchin spines. J. Bionic Eng. 2017, 14, 369–378. [Google Scholar] [CrossRef]

- Wang, D.; Chen, D.; Chen, Z. Recent progress in 3D printing of bio inspired structures. Front. Mater. 2020, 7, 286. [Google Scholar] [CrossRef]

- Lazarus, B.S.; Velasco-Hogan, A.; Tdel Rio, G.; Meyers, M.A. A review of impact resistant biological and bio inspired materials and structures. J. Mater. Res. Technol. 2020, 9, 15705–15738. [Google Scholar] [CrossRef]

- Komara, A.I.; Budiwantoro, B.; Setiawan, R. Cellular structure design and manufacturability for electric vehicle: A review. Int. J. Sustain. Transp. Technol. 2022, 5, 70–79. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332. [Google Scholar] [CrossRef]

- Zhang, X.; Zahng, H. Theoretical. and numerical investigation on the crush resistance of rhombic and kagome honeycombs. Compos. Struct. 2013, 96, 143. [Google Scholar] [CrossRef]

- Ghasemnejad, G.N.H.; SWatson, S.J.W. Crashworthiness of foam-filled and reinforced honeycomb crash absorbers in transverse direction. Appl. Compos. Mater. 2024, 31, 489–509. [Google Scholar] [CrossRef]

- Wang, T.; Li, M.; Qin, D.; Chen, J.; Wu, H. Crashworthiness analysis and multi-objective optimization for concave I-shaped honeycomb structure. Appl. Sci. 2022, 12, 10420. [Google Scholar] [CrossRef]

- Feng, G.; Li, S.; Xiao, L.; Song, W. Energy absorption performance of honeycombs with curved cell walls under quasi-static compression. Int. J. Mech. Sci. 2021, 210, 106746. [Google Scholar] [CrossRef]

- D’Mello, R.J.; Waas, A.M. Inplane crush response and energy absorption of circular cell honeycomb filled with elastomer. Compos. Struct. 2013, 106, 491–501. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Remennikov, A.; Pei, L.-Z.; Liu, J.; Wang, J.-S.; Liao, X.-W.; Yang, S. Quasi-static crushing behavior of novel re-entrant circular auxetic honeycombs. Compos. Part B Eng. 2020, 197, 108117. [Google Scholar] [CrossRef]

- Isaac, C.W.; Sokołowski, A.; Duddeck, F.; Adamiak, M.; Pakieła, W.; Aremu, A. Mechanical characterisation and crashworthiness performance of additively manufactured polymer-based honeycomb structures under in-plane quasi-static loading. Virtual Phys. Prototyp. 2023, 18, 1–23. [Google Scholar] [CrossRef]

- Hales, T.C. The honeycomb conjecture. Discret. Comput. Geom. 2011, 25, 1–22. [Google Scholar] [CrossRef]

- Sun, G.; Huo, X.; Wang, H.; Hazell, P.J.; Li, Q. On the structural parameters of honeycomb-core sandwich panels against low-velocity impact. Compos. Part B Eng. 2021, 216, 10888. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, Z.; Liu, X.; Tang, Z.; Zhang, K.; Zhang, P.; Ren, J.; Liu, Z.; Le, G.; Zhong, J. The in-plane stretching and compression mechanics of negative Poisson’s ratio structures: Concave hexagon, star shape, and their combination. J. Alloy Compd. 2021, 859, 157840. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Yang, J.; Li, S.; Schröder, K.-U. Mechanical response and auxetic properties of composite double-arrow corrugated sandwich panels with defects. Mech. Adv. Mater. Struct. 2021, 29, 6517–6529. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; He, Z.; Zong, Z.; Fang, J. Dynamic impact response of aluminum honeycombs filled with expanded polypropylene foam. Compos. Part B Eng. 2019, 156, 17–27. [Google Scholar] [CrossRef]

- Baroutaji, A.; Arjunan, A.; Niknejad, A.; Tran, T.; Olabi, A.-G. Application of cellular material in crashworthiness applications: An overview. Ref. Modul. Mater. Sci. Mater. Eng. 2019, 6, 157840. [Google Scholar] [CrossRef]

- Renreng, I.; Djamaluddin, F.; Mar’uf, M.; Li, Q. Optimization of crashworthiness design of foam-filled crash boxes under oblique loading for electric vehicles. Front. Mech. Eng. 2024, 10, 1449476. [Google Scholar] [CrossRef]

- Djamaluddin, F. Review: Deformation and optimisation crashworthiness method for foam filled structures. Lat. Am. J. Solids Struct. 2019, 16, 213. [Google Scholar] [CrossRef]

- Kumar, A.P.; Maneiah, D. Crashworthiness behavior of capped cylindrical aluminum tubular structures subjected to lateral compression. Int. J. Mech. Prod. 2019, 9, 1167–1172. [Google Scholar]

- Helou, M.; Kara, S. Design, analysis and manufacturing of lattice structures: An overview. Int. J. Comput. Integr. Manuf. 2018, 31, 243–261. [Google Scholar] [CrossRef]

- Tang, Y.; Dong, G.; Zhao, Y.F. A hybrid geometric modeling method for lattice structures fabricated by additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 102, 4011–4030. [Google Scholar] [CrossRef]

- Bernard, A.R.; ElSayed, M.S.A. Crashworthiness of 3D Lattice Topologies under Dynamic Loading: A Comprehensive Study. Materials 2024, 17, 1597. [Google Scholar] [CrossRef] [PubMed]

- Tao, C.; Zhou, X.; Liu, Z.; Liang, X.; Zhou, W.; Li, H. Crashworthiness study of 3D printed lattice reinforced thin—walled tube hybrid structures. Materials 2023, 16, 1871. [Google Scholar] [CrossRef] [PubMed]

- Audibert, C.; Chaves-Jacob, J.; Linares, J.-M.; Lopez, Q.-A. Bio-inspired method based on bone architecture to optimize the structure of mechanical workspieces. Mater. Des. 2018, 160, 708–717. [Google Scholar] [CrossRef]

- Ghazlan, A.; Nguyen, T.; Ngo, T.; Linforth, S.; Le, V.T. Performance of a 3D printed cellular structure inspired by bone. Thin-Walled Struct. 2020, 151, 106713. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, S.; Yu, T.X.; Jun, X. Crushing resistance. and energy absorption of pomelo peel inspired hierarchical honeycomb. Int. J. Impact Eng. 2019, 125, 163–172. [Google Scholar] [CrossRef]