Investigation on the Flow and Heat Transfer Behavior of Molten Steel During Continuous Casting

Abstract

1. Introduction

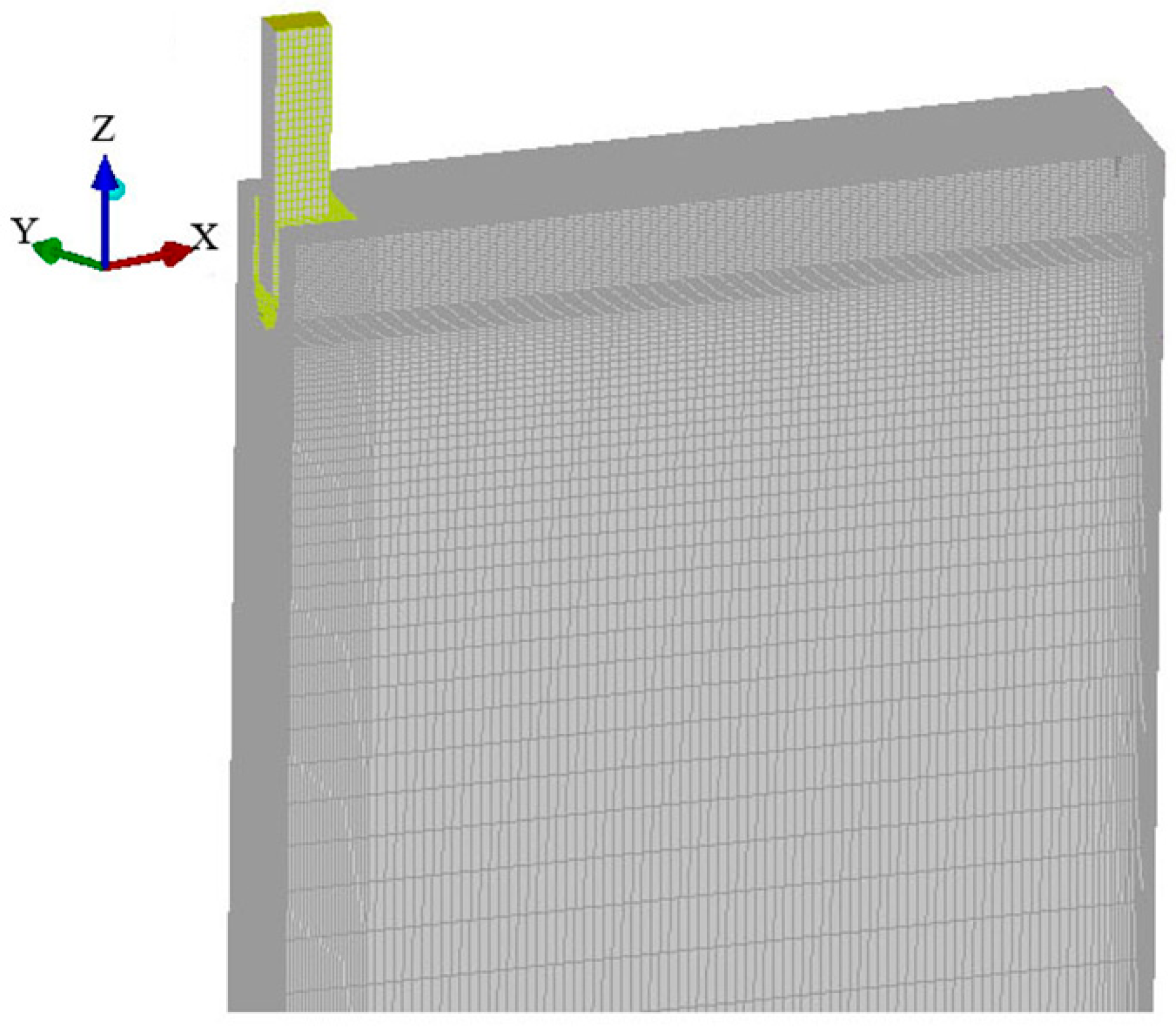

2. Model Description

2.1. Model

2.2. Assumption

- (1)

- The liquid steel is an incompressible Newtonian fluid, so the influence of mold vibration is ignored.

- (2)

- The calculation boundary is a non-slip boundary, where the velocity, turbulent kinetic energy, and turbulent energy dissipation rate are all zero.

- (3)

- The influence of the phase transition is neglected.

- (4)

- The solidification shrinkage of the billet and the natural convection caused by density changes are ignored. The rapid outflow of molten steel from the nozzle impinges on the molten steel in the mold, causing forced convection; however, the density change of molten steel is very small, and the natural convection caused by the density change is far smaller than the forced convection caused by the impact of molten steel, so it can be ignored. The displacement caused by the contraction of the casting slab is very small, and its disturbance to the flow is negligible.

2.3. Governing Equation

- (1)

- Mass-conservation equation:

- (2)

- Momentum conservation equation:

- (3)

- Energy equation:

- (4)

- Turbulence control equation:

2.4. Boundary Condition

- (1)

- The nozzle inlet is defined as the velocity inlet.

- (2)

- The computational domain exit is defined as the speed exit, while the speed is equal to the casting speed.

- (3)

- The mold liquid level is set as the free liquid level, and the shear force is null.

- (4)

- Both the mold wall and nozzle wall are treated as non-slip solid walls, while the flow field near the wall is treated as a standard wall function. The temperature boundary condition of the nozzle wall is treated as adiabatic. The mold wall is calculated using the second type of heat transfer boundary condition, and the heat flow is applied to the surface of the billet in the mold using a profile file.

3. Results and Discussion

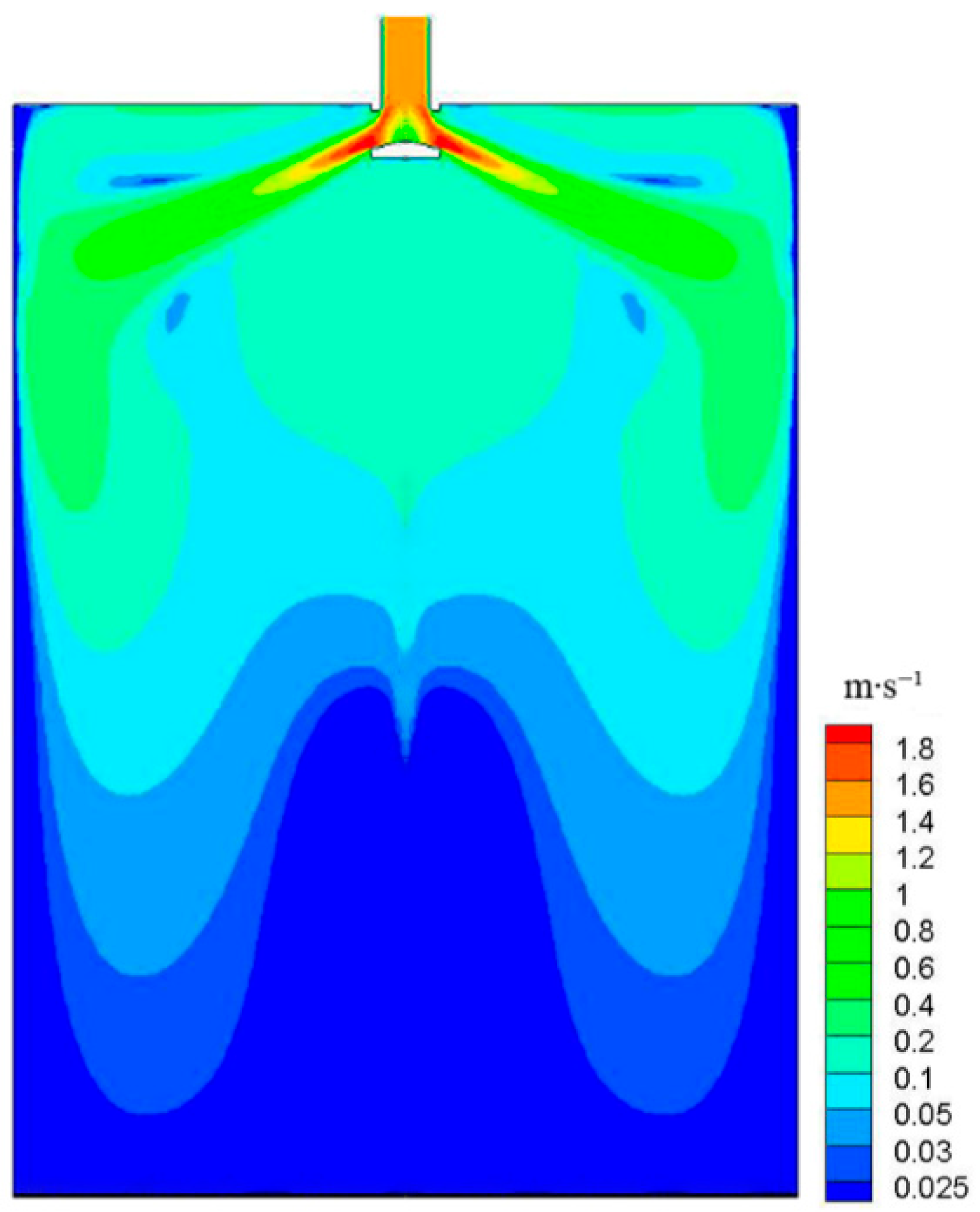

3.1. Narrow Impact Point

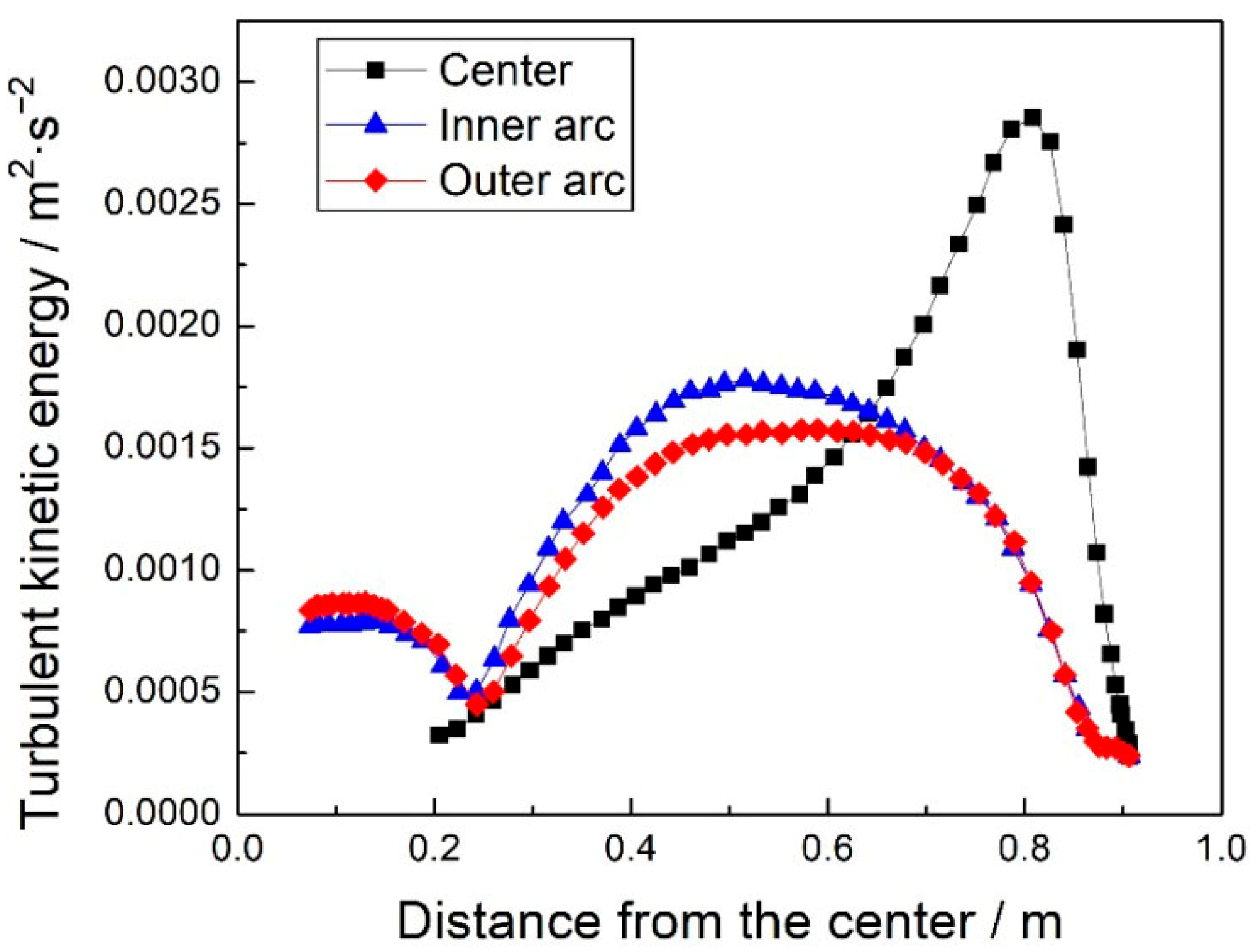

3.2. Turbulent Kinetic Energy

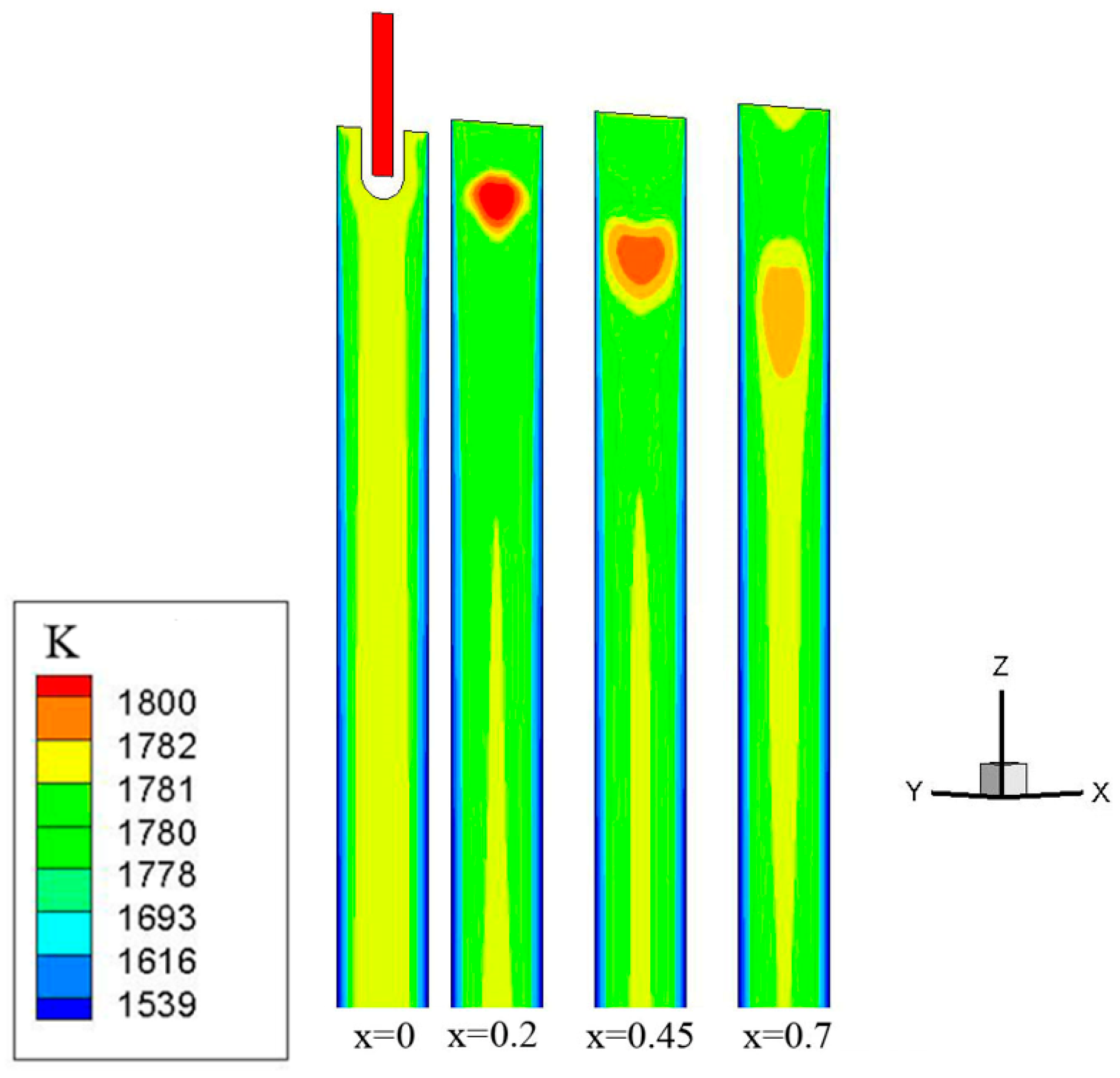

3.3. Temperature Distribution of Molten Steel

3.3.1. Temperature of Cross-Section

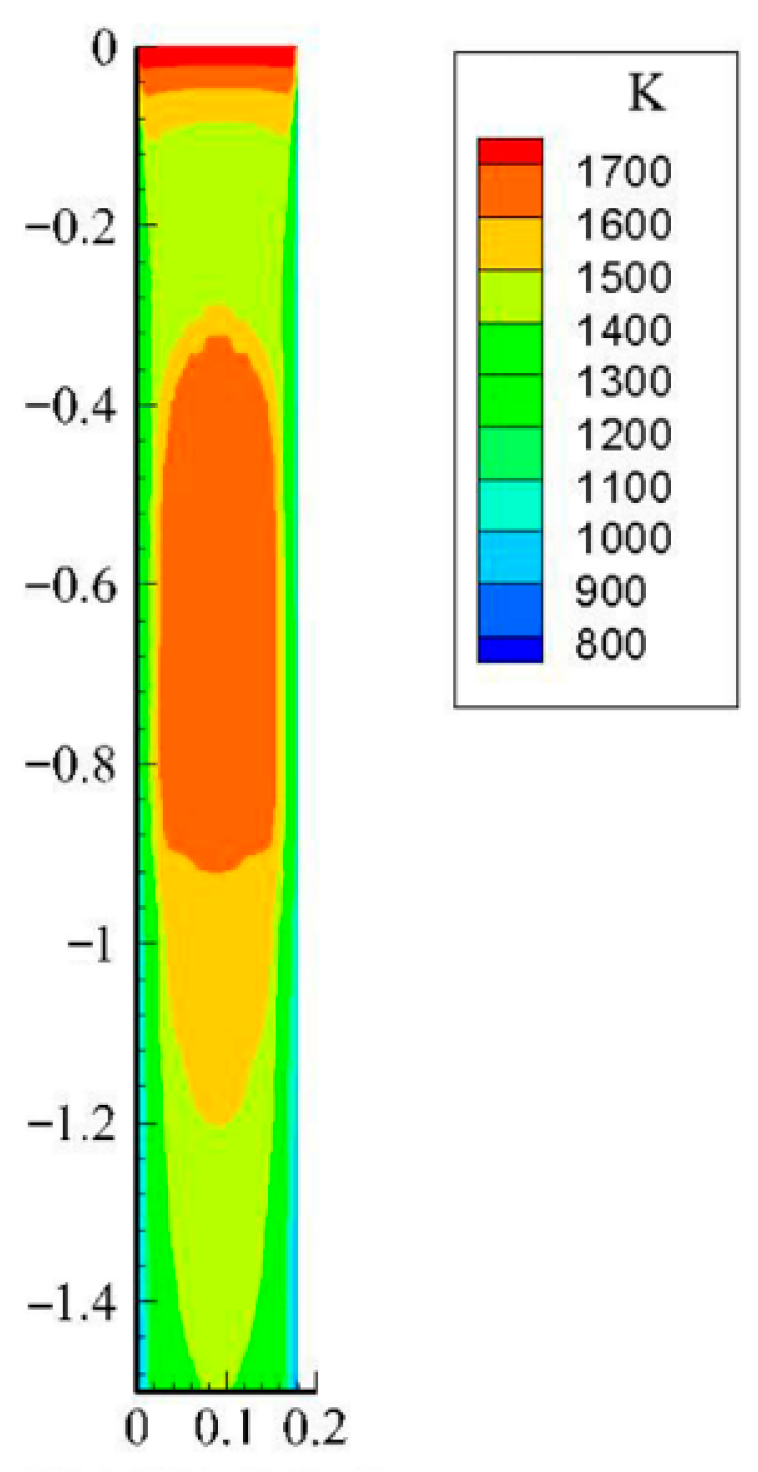

3.3.2. Temperature of Longitudinal Section

3.3.3. Temperature of Wide Surface

3.3.4. Temperature of Narrow Surface

4. Conclusions

- (1)

- After the steel liquid reached the narrow surface and formed a certain impact on it, some of the steel liquid flowed towards the meniscus while the other part moved towards the outlet of the mold, forming two main streams: upward flow and downward flow. The vortex center position in the upper reflux zone was (0.565 m, −0.179 m), and the vortex center position in the lower reflux zone was (0.524 m, −0.455 m). The impact position of the narrow surface was 315 mm from the meniscus.

- (2)

- When the steel liquid reached the meniscus in the upper annular flow zone, the velocity component perpendicular to the liquid surface direction reached a local extreme value, and the horizontal flow velocity parallel to the liquid surface direction was also higher, resulting in the maximum turbulence kinetic energy of the centerline reaching 0.00284 m2∙s−2, 108 mm from the narrow surface. In the area from the narrow surface to 1/4 width of the billet, the turbulent kinetic energy of the center line and the near inner and outer arc copper plate steel liquid was high, and the fluctuation of the liquid level and the inflow of slag were easily disturbed. It was a high-incidence area for longitudinal cracking and bonding of the billet, and attention should be paid to this in the design of the nozzle and flow field optimization.

- (3)

- The temperature of the steel liquid on the path of the two splitting strands located in the upper and lower circulation zones was relatively high, above 1781 K. The temperature range from the center of the billet to the narrow 1/4 section, which was enclosed by the upper annular flow zone and 400 mm below the liquid level, was relatively low and lower than the liquidus temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Srinivas, P.S.; Mishra, D.K.; Kulkarni, A.B.; Gupta, R.; Korath, J.M.; Jana, A.K. Investigation of vortex flow patterns at the meniscus in a water caster mold. Can. Metall. Q. 2020, 59, 211–232. [Google Scholar] [CrossRef]

- Zhao, P.; Piao, R.X. Lattice boltzmann method modeling of the evolution of coherent vortices and periodic flow in a continuous casting mold. Metals 2022, 12, 572. [Google Scholar] [CrossRef]

- Zhi, Q.; Niu, J.P.; Tan, X.R.; Rong, P.; Liu, Y.; Chen, Y.Q.; Liu, W.H. Effect of scanning process and heat treatment on microstructure and mechanical property of inconel 718 fabricated by selective laser melting. J. Mater. Eng. Perform. 2024, 32, 9515–9524. [Google Scholar] [CrossRef]

- Saeedipour, M.; Pirker, S. Analysis of hysteresis in the regime transition of cocurrent liquid-gas flow. Steel Res. Int. 2022, 93, 2100800. [Google Scholar] [CrossRef]

- Chen, W.; Ren, Y.; Zhang, L.F. Large eddy simulation on the two-phase flow in a water model of continuous casting strand with gas injection. Steel Res. Int. 2019, 90, 1800287. [Google Scholar] [CrossRef]

- Glavinic, I.; Galindo, V.; Stefani, F.; Wondrak, T. Contactless inductive flow tomography for real-time control of electromagnetic actuators in metal casting. Sensors 2022, 22, 4155. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.J.; Xu, P.; Zhou, Y.Z.; Duan, H.M.; Chen, D.F.; Long, M.J. The effect of mold structure and cooling parameters on heat transfer during billet high-speed continuous casting. Materials 2023, 16, 3361. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Kim, J.J.; Oh, K.S. A simplified model for semi-continuous casting of steel. J. Mater. Eng. Perform. 2023, 32, 4064–4070. [Google Scholar] [CrossRef]

- Pujol, S.; Bedirhanoglu, I.; Donmez, C.; Dowgala, J.D.; Eryilmaz-Yildirim, M.; Klaboe, K.; Koroglu, F.B.; Lequesne, R.D.; Ozturk, B.; Pledger, L.; et al. Quantitative evaluation of the damage to RC buildings caused by the 2023 southeast Turkey earthquake sequence. Earthq. Spectra 2024, 40, 505–530. [Google Scholar] [CrossRef]

- Narayan, N.M.; Gopalkrishna, S.B.; Mehdi, B.; Ryll, S.; Specht, E.; Fritsching, U. Multiphase numerical modeling of boiling flow and heat transfer for liquid jet quenching of a moving metal plate. Int. J. Therm. Sci. 2023, 194, 108587. [Google Scholar] [CrossRef]

- Yang, Y.W.; Luo, S.; Wang, W.L.; Zhu, M.Y. Multiphase solidification modeling of solidification structure evolution and macrosegregation of round bloom continuous casting process with mold electromagnetic stirring and final electromagnetic stirring. Steel Res. Int. 2023, 95, 2300446. [Google Scholar] [CrossRef]

- Lu, J.Z.; Pan, W.M.; Wang, W.L.; Dou, K. Full-process numerical simulation of flow, heat transfer and solidification for hot stamping steel manufactured via thin slab continuous casting process. MMTB 2024, 55, 3237–3253. [Google Scholar] [CrossRef]

- Xie, Q.H.; Ni, P.Y.; Tanaka, T.; Ersson, M.; Li, Y. Flow field, heat transfer and inclusion behavior in a round bloom mold under effect of a swirling flow submerged entry nozzle. J. Iron Steel Res. Int. 2023, 30, 1211–1221. [Google Scholar] [CrossRef]

- Li, G.; Tu, L.F.; Wang, Q.Q.; Zhang, X.B.; He, S.P. Fluid flow in continuous casting mold for ultra-wide slab. Materials 2023, 16, 1135. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.Y.; Sun, Y.W.; Liu, Z.Y.; Sun, M.J.; Liu, X.M.; Mu, W.Z.; Liu, T.; Wang, Q. Mechanism of inclusions control influenced by electromagnetic swirling flow in nozzle compared to mold electromagnetic stirring. Materialstoday 2025, 44, 112003. [Google Scholar] [CrossRef]

- Wang, S.B.; Cai, Z.Z.; Zhu, M.Y. Behavior of shell initial solidification in ultra-large beam blank continuous casting mold. MMTB 2025, 56, 1588–1604. [Google Scholar] [CrossRef]

- Takatani, K. Effects of electromagnetic brake and meniscus electromagnetic stirrer on transient molten steel flow at meniscus in a continuous casting mold. ISIJ Int. 2003, 6, 915–922. [Google Scholar] [CrossRef]

- Li, B.K.; Tsukihashi, F. Effects of electromagnetic brake on whirlpool flows in thin slab continuous casting mold. ISIJ Int. 2006, 12, 1833–1838. [Google Scholar] [CrossRef]

- Shamsi, M.R.R.I.; Ajmani, S.K. Three dimensional turbulent fluid flow and heat transfer mathematical model for the analysis of a continuous slab caster. ISIJ Int. 2007, 3, 433–442. [Google Scholar] [CrossRef]

- Lu, B.W.; Yuan, F.L.; Wang, H.L.; Bai, H. Water model experimental study on the behavior of fluid flow in slab caster mold. Res. Iron Steel 2015, 43, 24–27. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Mold height (mm) | 1000 |

| Slab width (mm) | 1800 |

| Slab thickness (mm) | 180 |

| Nozzle immersion depth (mm) | 120 |

| Casting speed (m·min−1) | 1.3 |

| Density of steel (kg·m−3) | 7080 |

| Viscosity of steel (kg·m−1·s−1) | 0.0055 |

| Pour point (°C) | 1530 |

| Liquidius temperature (°C) | 1510 |

| Solidus temperature (°C) | 1420 |

| Specific heat of steel (J∙kg−1∙°C −1) | 740 |

| Latent heat (J∙kg−1) | 274,950 |

| Steel thermal conductivity(W∙m−1∙K−1) | 31 |

| Average heat flux (MW∙m−2) | 1.35 |

| entrance flow rate (m/s) | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Du, F.; Li, T.; Zhang, S. Investigation on the Flow and Heat Transfer Behavior of Molten Steel During Continuous Casting. Computation 2025, 13, 257. https://doi.org/10.3390/computation13110257

Li G, Du F, Li T, Zhang S. Investigation on the Flow and Heat Transfer Behavior of Molten Steel During Continuous Casting. Computation. 2025; 13(11):257. https://doi.org/10.3390/computation13110257

Chicago/Turabian StyleLi, Guohui, Fengming Du, Tianyi Li, and Shuai Zhang. 2025. "Investigation on the Flow and Heat Transfer Behavior of Molten Steel During Continuous Casting" Computation 13, no. 11: 257. https://doi.org/10.3390/computation13110257

APA StyleLi, G., Du, F., Li, T., & Zhang, S. (2025). Investigation on the Flow and Heat Transfer Behavior of Molten Steel During Continuous Casting. Computation, 13(11), 257. https://doi.org/10.3390/computation13110257