1. Introduction

Injury prevention in the sports industry is a very important aspect of research with emotional, health, and financial contributions to the sports organizations and the players. The football industry is rapidly evolving with a revenue growth rate of approximately 8–10% on a yearly basis and total produced revenue of around 40 billion euros, especially in the most prestigious European Football Leagues Associations. The total number of professional, amateur, and youth league football players is constantly on the rise, and the need for assessing and minimizing the injury risks is evident not only in the big market teams but also in the lower divisions where funding is limited [

1,

2]. Based on the fast-paced philosophy of modern football, the majority of those injuries (70–80% of the total injuries) refer to the lower limb region and are mainly contact injuries, varying from bruises and contusions to more serious injuries that can be caused by ligament tears and bone and tendon fractures. Roughly 60% of the aforementioned leg injuries involve below-knee injuries, mainly in the ankle region and the tibia/fibula bones [

3,

4,

5]. Fractures in the fibula and tibia are mainly evident in football, and along with them, the danger of permanent damage to the bones, tendons, or neighboring ligaments may occur based on the severity of the injury. The injury severity is mainly split into four basic categories depending on the recovery time and complexity. In an effort to minimize contact injuries and enhance safety, the insertion of shin guards as protective equipment was included in the game of football and in other contact sports, and this equipment stands as a mandatory part of the overall athletic gear, according to the recent regulations [

6,

7,

8,

9]. In

Table 1, a brief overview of the possible leg injuries in football is presented, along with their severity based on the estimated recovery timeline.

Conventionally developed injection-molded shin guards tended to minimize light to moderate contact injuries, but the bulky, heavy design did not provide enough shock absorption to mitigate the active stresses and lower the risk of more severe injuries such as bone fractures. This inability could lead to higher stress distribution and allocation to other articulations, such as the knee or the ankle, and lead to long-term permanent damage due to cumulative fatigue. As is visible from

Table 1, the existing designs do not resolve the injury issue at a satisfying rate and are also responsible for the development of some minor injuries related to the wearable that could be minimized with an improved, optimized design. In

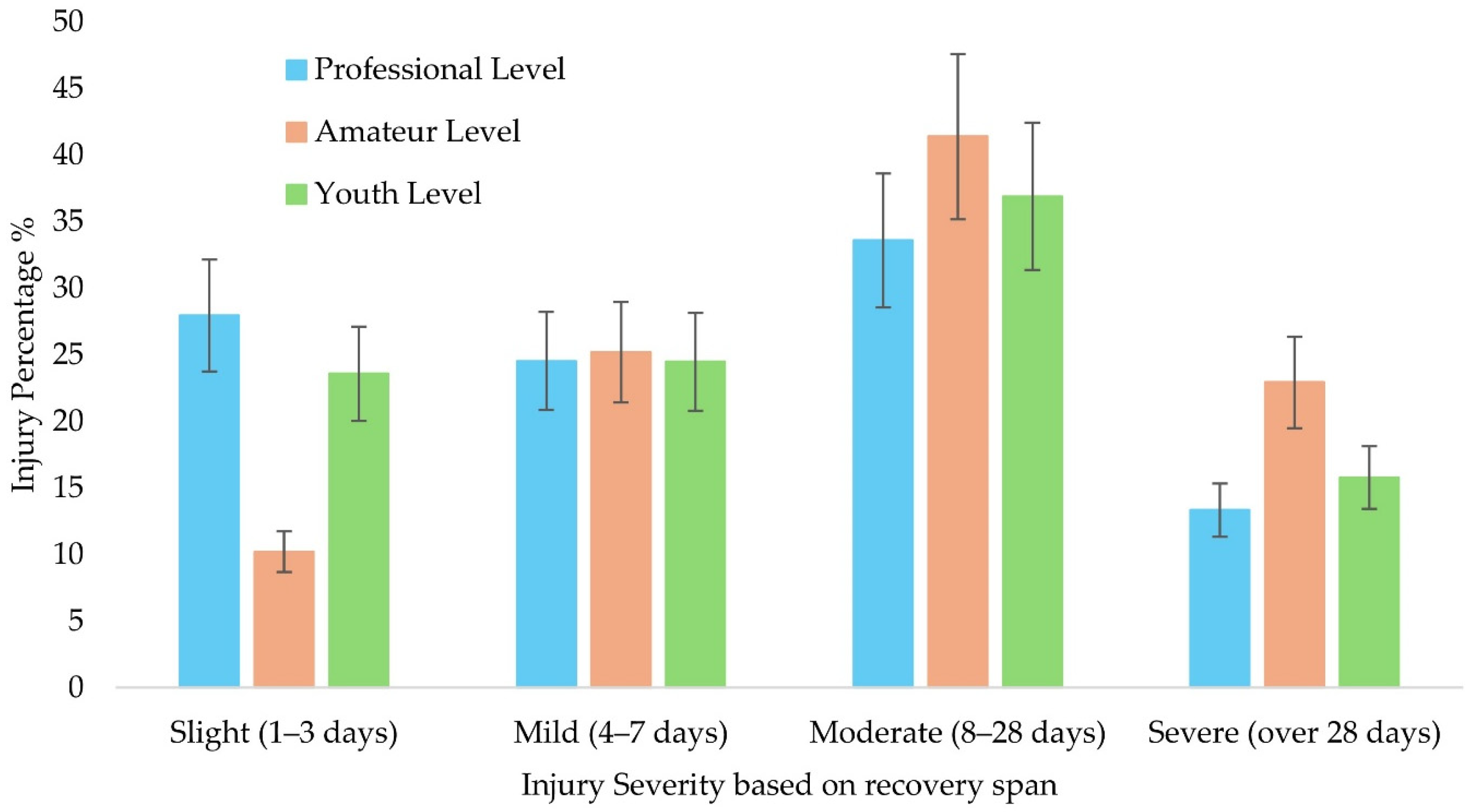

Figure 1, an overview of the different injuries’ severity allocation is presented based on the estimated recovery time according to recent metrics for the calendar year of 2023.

As is visible from

Figure 1, especially in amateur-level athletes, where the emphasis on the recovery process after the activities is not the proposed one and the conditioning of the athletes is worse compared to the professional athletes, the injury risk and severity are elevated. A slight elevation in the more severe injuries is also observed in the youth-level leagues. The reevaluation and optimization of the conventionally designed shin guards could lead to a decreased number of serious injuries with results on the physical and social life of the athletes while simultaneously allowing the better development of their skill level, especially for youth players where the projected growth and potential is still higher and based mainly on the availability factor (fit for football activities) and the frequent efficient training [

10,

11,

12,

13].

In this context, many optimization strategies based on design, material selection, and manufacturing processes have been studied with the aim of providing tailored mechanical properties, shape, size, and weight for each unique athlete. Additive manufactured shin guards have been studied at the prototype level, utilizing different composite materials, with the reinforcement being mainly in fiber form (carbon, glass). The results indicated the final structure presented slightly more suitable mechanical properties regarding the overall stiffness and the impact capabilities and overall improved strength-to-weight ratio [

14,

15,

16,

17]. Besides the non-eco-friendly conventional fibers, alternatives such as the reused tire rubbers could enhance the damping and the energy absorption capabilities, leading to structures that ensure maximum comfort and reduce the cases of mild injuries due to poor manufacturing while simultaneously helping address the more severe ones with effective stress distribution, as it was shown in the previous literature [

18,

19,

20,

21].

It was also observed that in all cases, the initial bulk solid design was inadequate for constant use, and therefore strategic material removal processes (density-based removal or truss-based removal) for the development of repetitive geometric patterns were analyzed, with the ultimate goal of achieving a lightweight structure with maximized performance metrics compatible and tailored for the demands of the high-strength shock impacts. This process is widely known as topology optimization, with many applications in industrial processes and products in the automotive and aerospace industries. Lattice geometries have proved to enhance the structure’s elasticity and result in more unified stress distribution and energy absorption efficiency, especially in the case of the Triply Periodic Minimal Surface (TPMS) structures. Combined with high-precision manufacturing techniques that allow the rapid transformation of a design to a prototype, could help enhance the compatibility of this structure to the human leg, allowing maximum comfort due to light bumps and high crashworthiness in the more extreme cases of hits, such as the stud kicks incidents in competitive games [

22,

23,

24].

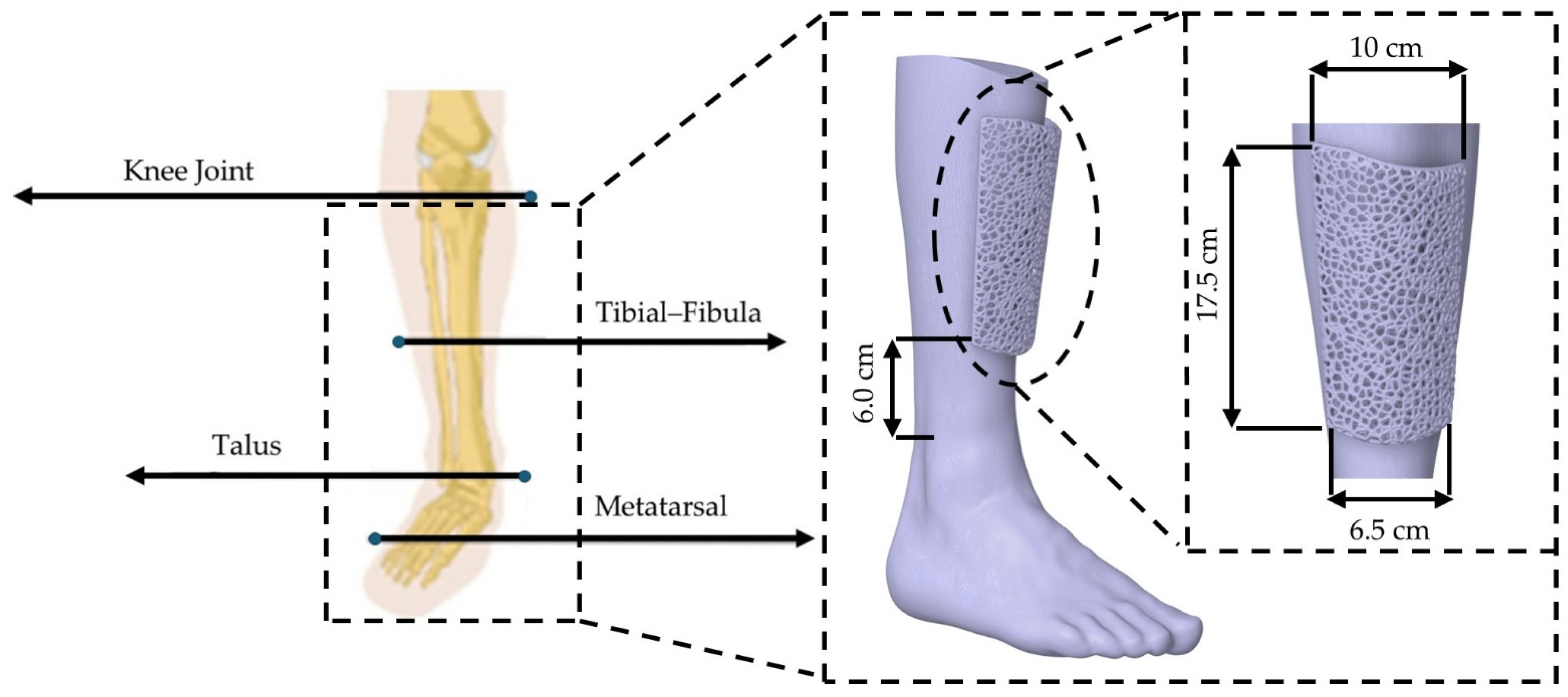

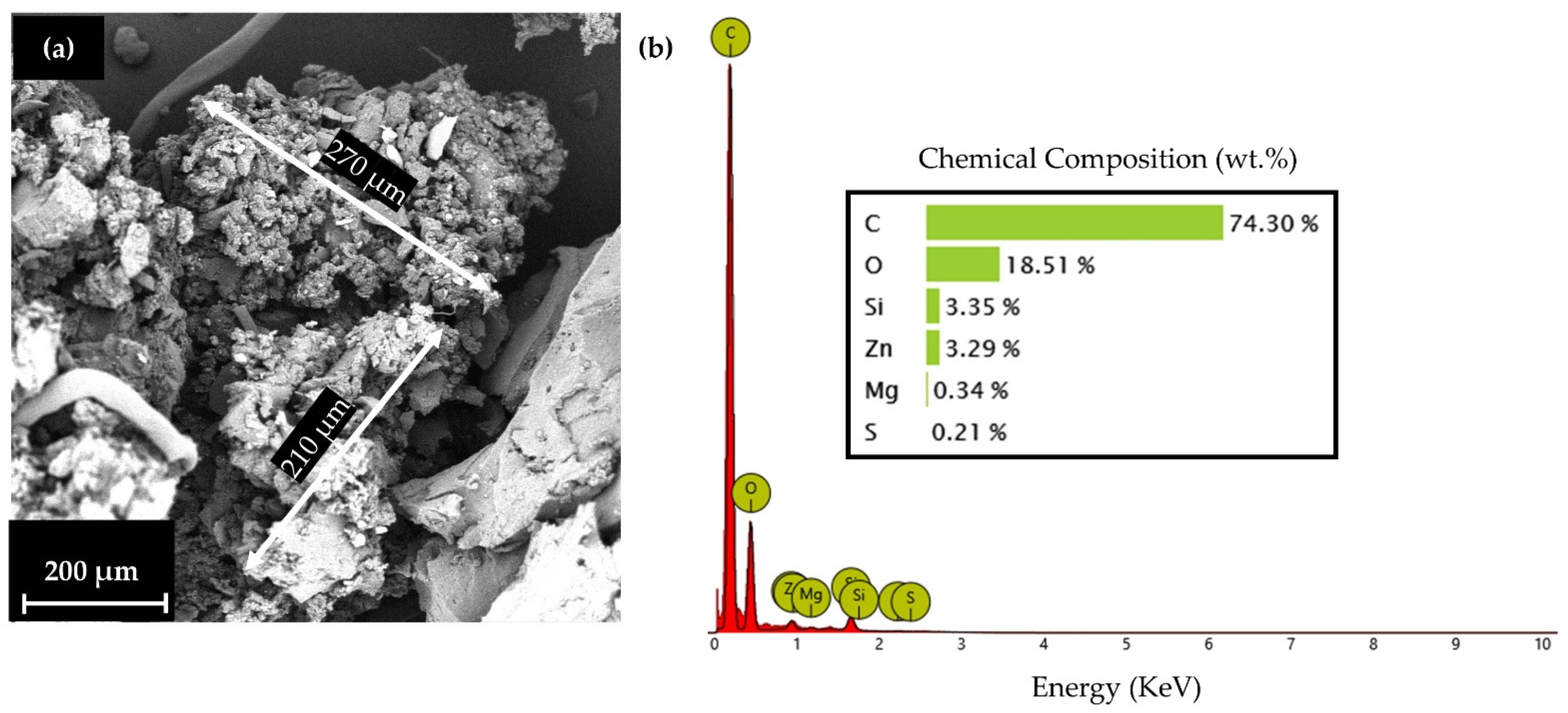

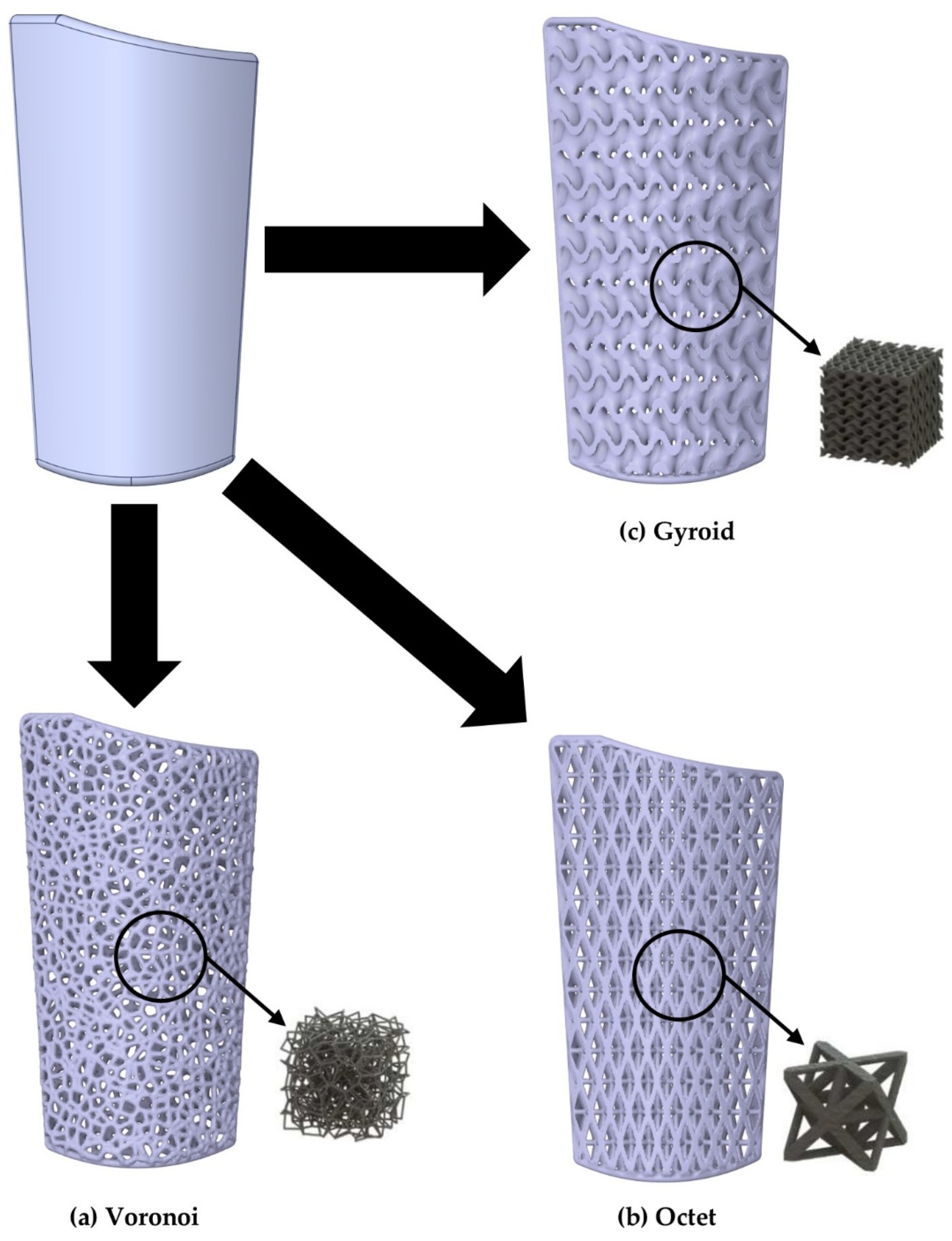

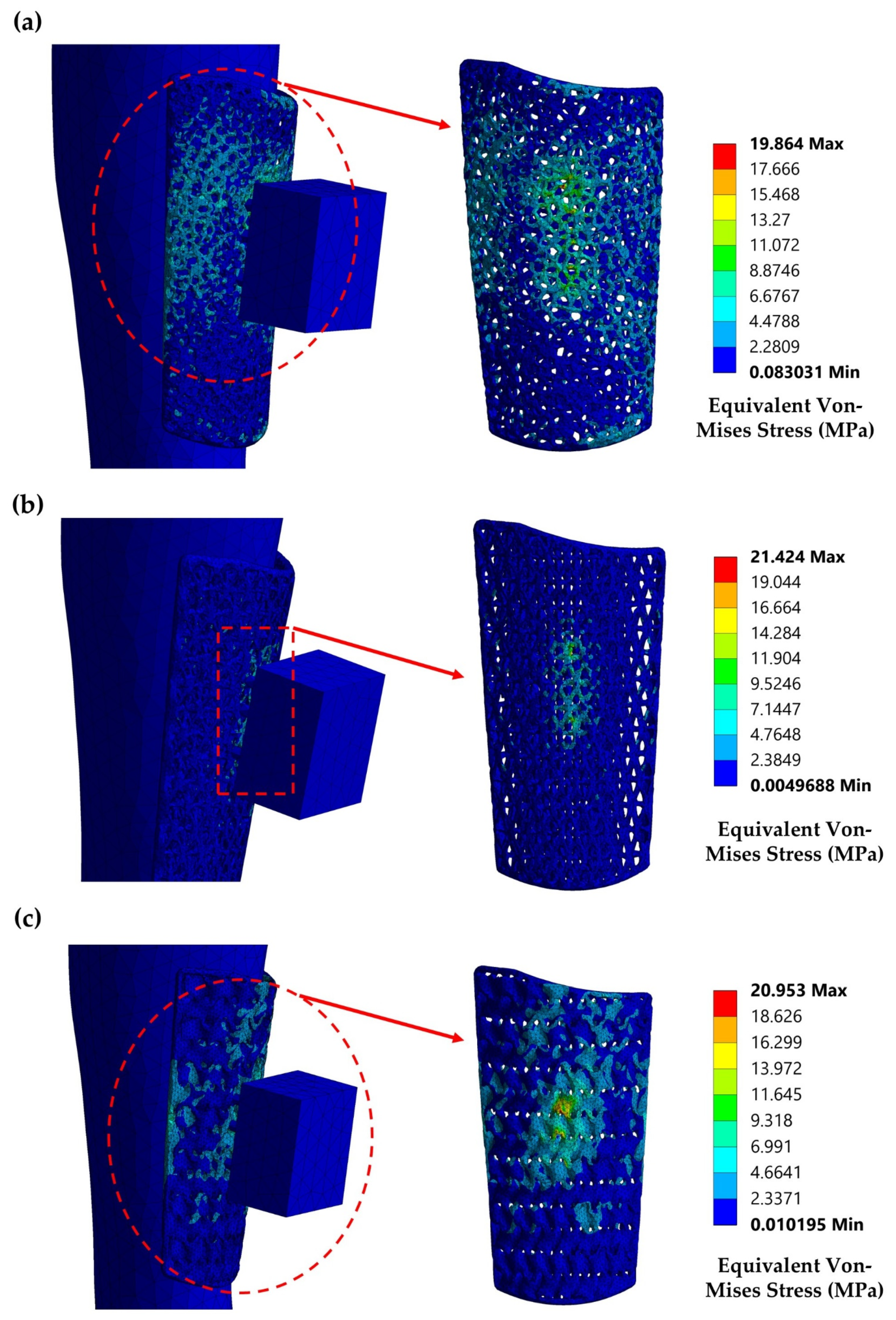

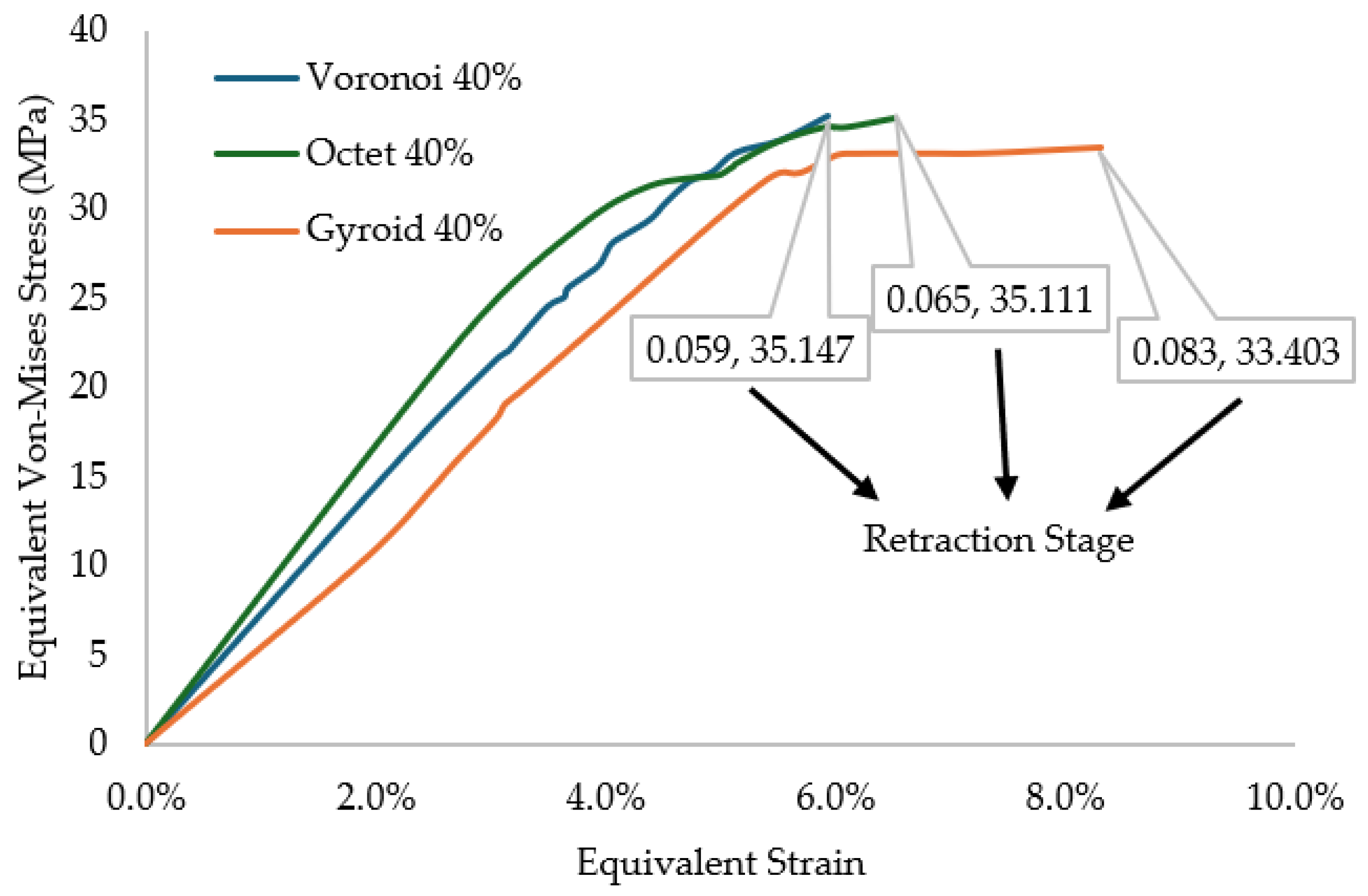

In this paper, a computational investigation of topologically optimized shin guards is conducted to assess the optimal lattice geometry with a focus on efficient impact absorption and damping capabilities, ensuring maximum comfort and minimization of severe tibia-fibula injuries due to hard kicks on the regions during sports activities. In this context, an initial draft bulk design was designed aligned with the shape of an average male athlete’s leg, and with the aid of 3D scanning, three different lattice geometries, (2.5D Voronoi, Strut Octet, and TPMS gyroid) were utilized for the customized prototypes on the same relative density (40%), which was confirmed in previous cases as the solution for optimal energy absorption combined with adequate enough overall strength. For the material selection, a PA-12-based composite was selected with ground tire rubber (GTR) insertion of 10 wt.%. The GTR insertion was proved in a different study that improved crucial elasticity properties, and the matrix material presented similar mechanical properties to other thermoplastics that were already studied in the literature [

14,

15,

19,

21,

22,

24]. The three aforementioned prototypes underwent impact testing with the aid of Finite Element Analysis (FEA) to assess the dynamic mechanical response in real-life based scenarios in the extreme case of a stud kick to the shin area, which was described as the condition where the maximum forces were generated. An assessment of the overall stresses and the distribution of those was conducted, providing valuable insights regarding the structures’ elasticity, force tolerance, energy dissipation, and shock absorption properties. The results indicated that the gyroid structure shin guard presented the most unified stress distributions and ensured the maximum comfort and safety and was proposed as the go-to solution in this use case. The novelty in this paper lies in the proper material selection that can promote environmental sustainability, the utilization of complex lattice geometries for the provision of tailored dynamic properties, and the real-life simulation of the stud’s kick impact testing, providing results that can be used directly for possible upcycling with rapid manufacturing technologies such as 3D printing. An indicative flowchart of this current study is presented in

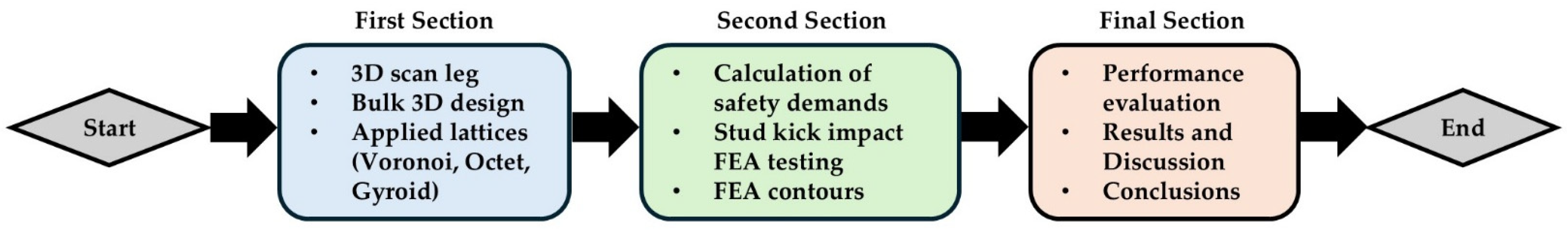

Figure 2.