Comparative Analysis of Energy Efficiency in Conventional, Modular, and 3D-Printing Construction Using Building Information Modeling and Multi-Criteria Decision-Making

Abstract

1. Introduction

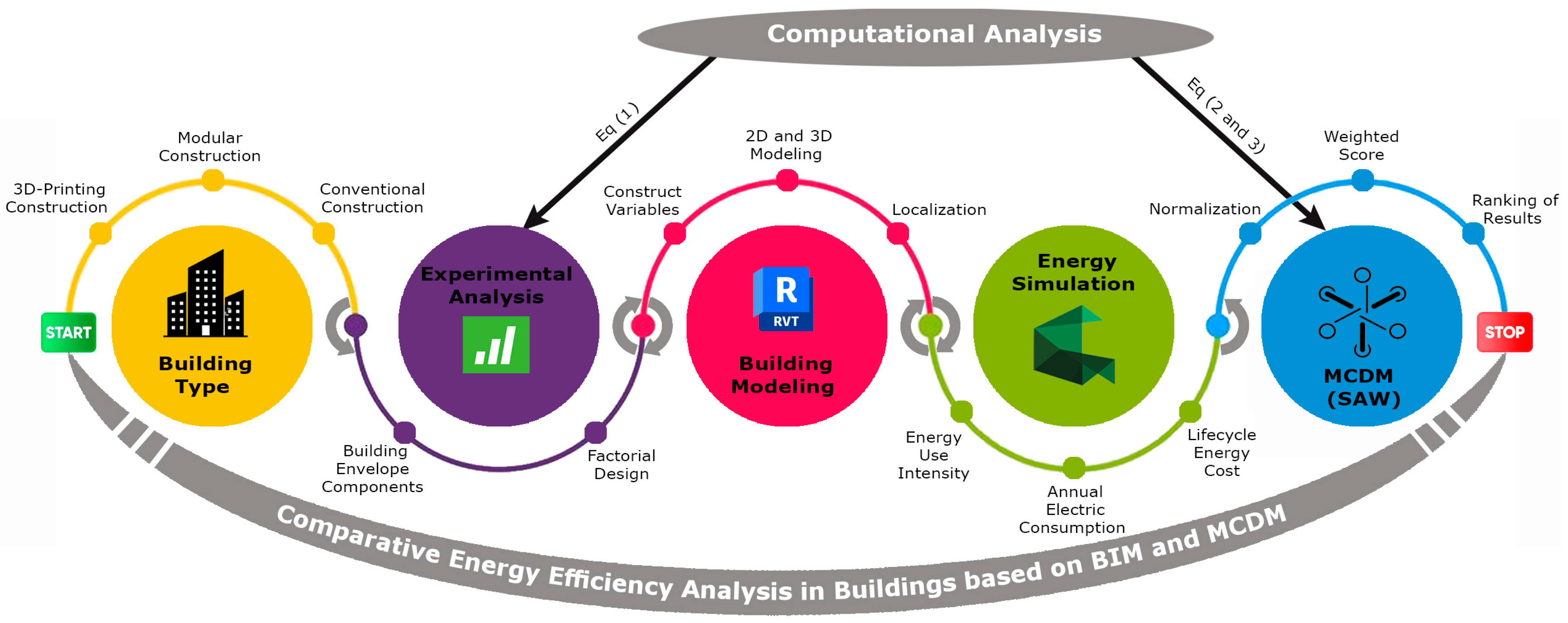

2. Materials and Methods

2.1. Building Types

2.2. Experimental Analysis

2.3. Building Modeling

2.4. Energy Simulation

2.5. Multi-Criteria Decision-Making (MCDM)

3. Case Study

3.1. Conventional Construction

3.2. Modular Construction

3.3. Three-Dimensional-Printing Construction

3.4. Experimental Design Analysis of the Case Study

4. Results and Discussions

4.1. Internal Comparison

4.2. Cross Comparison Between Construction Methods

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al Masri, A.; da Costa, B.B.F.; Vasco, D.; Boer, D.; Haddad, A.N.; Najjar, M.K. Roles of Robotics in Architectural and Engineering Construction Industries: Review and Future Trends. J. Build. Des. Environ. 2024, 3. [Google Scholar] [CrossRef]

- Labaran, Y.H.; Mathur, V.S.; Muhammad, S.U.; Musa, A.A. Carbon footprint management: A review of construction industry. Clean. Eng. Technol. 2022, 9, 100531. [Google Scholar] [CrossRef]

- Carvalho, J.P.; Bragança, L.; Mateus, R. A Systematic Review of the Role of BIM in Building Sustainability Assessment Methods.pdf. Appl. Sci. 2020, 10, 4444. [Google Scholar] [CrossRef]

- Hoeft, M.; Pieper, M.; Eriksson, K.; Bargstädt, H.J. Toward life cycle sustainability in infrastructure: The role of automation and robotics in ppp projects. Sustainability 2021, 13, 3779. [Google Scholar] [CrossRef]

- Andric, I.; Kamal, A.; Al-Ghamdi, S.G. Efficiency of green roofs and green walls as climate change mitigation measures in extremely hot and dry climate: Case study of Qatar. Energy Rep. 2020, 6, 2476–2489. [Google Scholar] [CrossRef]

- LLatas, C.; Soust-Verdaguer, B.; Hollberg, A.; Palumbo, E.; Quiñones, R. BIM-based LCSA application in early design stages using IFC. Autom. Constr. 2022, 138, 104259. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart materials and technologies for sustainable concrete construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Harputlugil, T.; de Wilde, P. The interaction between humans and buildings for energy efficiency: A critical review. Energy Res. Soc. Sci. 2021, 71, 101828. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Substantial capabilities of robotics in enhancing industry 4.0 implementation. Cogn. Robot. 2021, 1, 58–75. [Google Scholar] [CrossRef]

- Han, Y.; Yang, Z.; Ding, T.; Xiao, J. Environmental and economic assessment on 3D printed buildings with recycled concrete. J. Clean. Prod. 2021, 278, 123884. [Google Scholar] [CrossRef]

- Brankley, L.; Camci, L.; Tugrul, A.; Knight, D. Towards digital sharing of verified global warming potential data in concrete reinforcing bar. In Proceedings of the Fib Symposium, Rome, Italy, 5–7 September 2022; pp. 125–131. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85143915428&partnerID=40&md5=38ac6746f4385abf3e82ac950d580459 (accessed on 17 December 2024).

- Lu, Y.; Khan, Z.A.; Alvarez-alvarado, M.S.; Zhang, Y.; Huang, Z.; Imran, M. A Critical Review of Sustainable Energy Policies for the Promotion of Renewable Energy Sources. Sustainability 2020, 12, 5078. [Google Scholar] [CrossRef]

- Yeung, J.; J Hahn Menacho, A.; Marvuglia, A.; Navarrete Gutiérrez, T.; Beach, T.; Rezgui, Y. An open building information modelling based co-simulation architecture to model building energy and environmental life cycle assessment: A case study on two buildings in the United Kingdom and Luxembourg. Renew. Sustain. Energy Rev. 2023, 183, 113419. [Google Scholar] [CrossRef]

- Lotfabadi, P.; Hançer, P. A comparative study of traditional and contemporary building envelope construction techniques in terms of thermal comfort and energy efficiency in hot and humid climates. Sustainability 2019, 11, 3582. [Google Scholar] [CrossRef]

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D printing in the construction industry—A systematic review of the thermal performance in buildings. Renew. Sustain. Energy Rev. 2021, 141, 110794. [Google Scholar] [CrossRef]

- Wolniak, R.; Saniuk, S.; Grabowska, S. Context of the Development of Industry 4.0 Using the Polish Steel Sector as an Example. Energies 2020, 13, 2867. [Google Scholar] [CrossRef]

- Bharany, S.; Sharma, S.; Badotra, S.; Khalaf, O.I.; Alotaibi, Y.; Alghamdi, S.; Alassery, F. Energy-Efficient Clustering Scheme for Flying Ad-Hoc Networks Using an Optimized LEACH Protocol. Energies 2021, 14, 6016. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Y.; Chi, Y.; Hong, Y.; Yin, J. Shape-morphing materials and structures for energy-efficient building envelopes. Mater. Today Energy 2021, 22, 100874. [Google Scholar] [CrossRef]

- Homod, R.Z.; Almusaed, A.; Almssad, A.; Jaafar, M.K.; Goodarzi, M.; Sahari, K.S.M. Effect of different building envelope materials on thermal comfort and air-conditioning energy savings: A case study in Basra city, Iraq. J. Energy Storage 2021, 34, 101975. [Google Scholar] [CrossRef]

- Han, Y.; Fan, C.; Geng, Z.; Ma, B.; Cong, D.; Chen, K.; Yu, B. Energy efficient building envelope using novel RBF neural network integrated affinity propagation. Energy 2020, 209, 118414. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Dickson, T.; Pavía, S. Energy performance, environmental impact and cost of a range of insulation materials. Renew. Sustain. Energy Rev. 2021, 140, 110752. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A review of internal and external influencing factors on energy efficiency design of buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Elghamry, R.; Hassan, H. Impact of window parameters on the building envelope on the thermal comfort, energy consumption and cost and environment. Int. J. Vent. 2020, 19, 233–259. [Google Scholar] [CrossRef]

- Sana, S.; Hayati, A.; Salmanzadeh, M. Optimization of Window-to-Wall Ratio for Buildings Located in different climates: An IDA-indoor climate and energy simulation study. Energies 2021, 14, 1974. [Google Scholar] [CrossRef]

- Chi, F.; Wang, Y.; Wang, R.; Li, G.; Peng, C. An investigation of optimal window-to-wall ratio based on changes in building orientations for traditional dwellings. Sol. Energy 2020, 195, 64–81. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Zayed, T. A study of literature in modular integrated construction—Critical review and future directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Hořínková, D. Advantages and Disadvantages of Modular Construction, including Environmental Impacts. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1203, 32002. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, S. Dynamic thermal performance and energy-saving potential analysis of a modular pipe-embedded building envelope integrated with thermal diffusive materials. Build. Simul. 2023, 16, 2285–2305. [Google Scholar] [CrossRef]

- Sarmento, R.; Posani, M.; Fernandes, P.; Rodrigues, A.M.; Gomes, M.G. Energy efficiency in modular emergency shelters: Impact of envelope finishings and shadowing. J. Build. Eng. 2024, 94, 110029. [Google Scholar] [CrossRef]

- Mohammed, M.A.; Budaiwi, I.M.; Al-Osta, M.A.; Abdou, A.A. Thermo-Environmental Performance of Modular Building Envelope Panel Technologies: A Focused Review. Buildings 2024, 14, 917. [Google Scholar] [CrossRef]

- Chippagiri, R.; Gavali, H.R.; Ralegaonkar, R.V.; Riley, M.; Shaw, A.; Bras, A. Application of Sustainable Prefabricated Wall Technology for Energy Efficient Social Housing. Sustainability 2021, 13, 1195. [Google Scholar] [CrossRef]

- Huang, B.; Lu, W. Experimental Investigation of the Multi-Physical Properties of an Energy Efficient Translucent Concrete Panel for a Building Envelope. Appl. Sci. 2020, 10, 6863. [Google Scholar] [CrossRef]

- Pan, W.; Iturralde, K.; Bock, T.; Martinez, R.G.; Juez, O.M.; Finocchiaro, P. A Conceptual Design of an Integrated Façade System to Reduce Embodied Energy in Residential Buildings. Sustainability 2020, 12, 5730. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Shi, A.; Yang, L.; Shirowzhan, S. Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings 2020, 10, 231. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, Y.; Zhang, D.; Song, Y. 3D printing in construction: State of the art and applications. Int. J. Adv. Manuf. Technol. 2021, 115, 1329–1348. [Google Scholar] [CrossRef]

- Sotorrío Ortega, G.; Alonso Madrid, J.; Olsson, N.O.E.; Tenorio Ríos, J.A. The Application of 3D-Printing Techniques in the Manufacturing of Cement-Based Construction Products and Experiences Based on the Assessment of Such Products. Buildings 2020, 10, 144. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A critical review of 3D printing in construction: Benefits, challenges, and risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Góra, M.; Bańkosz, M.; Tyliszczak, B. Use of Innovative Methods to Produce Highly Insulating Walls Using 3D-Printing Technology. Material 2024, 17, 3990. [Google Scholar] [CrossRef] [PubMed]

- Mikhailov, S.; Mikhailova, A.; Nadyrshine, N.; Nadyrshine, L. BIM-technologies and digital modeling in educational architectural design. IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012168. [Google Scholar] [CrossRef]

- Najjar, M.; Figueiredo, K.; Hammad, A.W.A.; Haddad, A. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382. [Google Scholar] [CrossRef]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Liu, Z. Combining multi-criteria decision making (MCDM) methods with building information modelling (BIM): A review. Autom. Constr. 2021, 121, 103451. [Google Scholar] [CrossRef]

- Haruna, A.; Shafiq, N.; Montasir, O.A. Building information modelling application for developing sustainable building (Multi criteria decision making approach). Ain Shams Eng. J. 2021, 12, 293–302. [Google Scholar] [CrossRef]

- Yarramsetty, S.; Faheem, M.; Siva Kumar, M.V.N. An Integrated Approach to Building Planning Using the Multi-Criteria Decision Method (MCDM) and BIM. Int. J. Sustain. Constr. Eng. Technol. 2023, 14, 49–63. [Google Scholar] [CrossRef]

- Abdelaal, M.A.; Seif, S.M.; El-Tafesh, M.M.; Bahnas, N.; Elserafy, M.M.; Bakhoum, E.S. Sustainable assessment of concrete structures using BIM–LCA–AHP integrated approach. Environ. Dev. Sustain. 2023, 26, 25669–25688. [Google Scholar] [CrossRef]

- Namaki, P.; Vegesna, B.S.; Bigdellou, S.; Chen, R.; Chen, Q. An Integrated Building Information Modeling and Life-Cycle Assessment Approach to Facilitate Design Decisions on Sustainable Building Projects in Canada. Sustainability 2024, 16, 4718. [Google Scholar] [CrossRef]

- Desempenho Térmico de Edificações NBR 15220; Parte 3: Zoneamento Bioclimático Brasileiro e Diretrizes Construtivas Para Habitações Unifamiliares de Interesse Social; ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2005.

- Minitab Blog Regression Analysis Tutorial and Examples. Available online: https://blog.minitab.com/en/adventures-in-statistics-2/regression-analysis-tutorial-and-examples (accessed on 13 November 2024).

- Najjar, M.K.; Franco de Carvalho Willcox, L.; Khalas, M.; Da Costa, B.; Haddad, A.; Boer, D. BIM and Experimental Design Analysis Toward Sustainable Energy Efficiency in Buildings: A Modular Construction Case Study BT. Proceedings of CIRMARE 2023, Covilhã, Portugal, 5–7 December 2023; Lanzinha, J.C.G., Qualharini, E.L., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 483–495. [Google Scholar]

- Huang, X.; Liu, Y.; Huang, L.; Onstein, E.; Merschbrock, C. BIM and IoT data fusion: The data process model perspective. Autom. Constr. 2023, 149, 104792. [Google Scholar] [CrossRef]

- Najjar, M.; Figueiredo, K.; Palumbo, M.; Haddad, A. Integration of BIM and LCA: Evaluating the environmental impacts of building materials at an early stage of designing a typical office building. J. Build. Eng. 2017, 14, 115–126. [Google Scholar] [CrossRef]

- Najjar, M.K.; Tam, V.W.Y.; Di Gregorio, L.T.; Evangelista, A.C.J.; Hammad, A.W.A.; Haddad, A. Integrating parametric analysis with building information modeling to improve energy performance of construction projects. Energies 2019, 12, 1515. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Multi-Criteria Decision Making (MCDM) Methods and Concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Ibrahim, A.; Surya, R.A. The Implementation of Simple Additive Weighting (SAW) Method in Decision Support System for the Best School Selection in Jambi. J. Phys. Conf. Ser. 2019, 1338, 12054. [Google Scholar] [CrossRef]

- Fitrul Hadi, A.; Permana, R.; Syafwan, H. Decision Support System in Determining Structural Position Mutations Using Simple Additive Weighting (SAW) Method. J. Phys. Conf. Ser. 2019, 1339, 12015. [Google Scholar] [CrossRef]

- Volferda Volferda Company Catalog. Available online: https://spacecapsulehouse.com/lp-capsule-house/?gad_source=1&gclid=EAIaIQobChMI0-ba5oz4iQMVTBFECB35rwVyEAAYASAAEgLF7fD_BwE (accessed on 17 December 2024).

| External Walls | External Roof | Window-to-Wall Ratio |

|---|---|---|

| Ecological brick with high insulation | Flat insulated concrete roof | 40% |

| Areole concrete | Wood frame with high insulation | 50% |

| External Walls | External Roof | Window-to-Wall Ratio |

|---|---|---|

| Steel frames and concrete panels with high insulation | Flat roof with high insulation | 40% |

| Wood panels with high insulation | Wood frame and wood panel with high insulation | 50% |

| Brick with rigid foam for insulation | ⸻ | ⸻ |

| External Walls | External Roof | Window-to-Wall Ratio |

|---|---|---|

| Single row of 10 cm thick cork concrete mix E-PLA for insulation | Cork concrete mix and E-PLA for insulation | 40% |

| Double rows of 10 cm thick cork concrete mix E-PLA for insulation | Wood frame roof with high insulation | 50% |

| Single row of 10 cm thick sulfur concrete mix E-PLA for insulation | Sulfur concrete mix and E-PLA for insulation | ⸻ |

| Double rows of 10 cm thick sulfur concrete mix E-PLA for insulation | ⸻ | ⸻ |

| Seq. | External Walls | Roof | Window-to-Wall Ratio |

|---|---|---|---|

| 1 | Ecological brick with high insulation | Flat insulated concrete roof | 40% |

| 2 | Ecological brick with high insulation | Flat insulated concrete roof | 50% |

| 3 | Ecological brick with high insulation | Wood frame with high insulation | 40% |

| 4 | Ecological brick with high insulation | Wood frame with high insulation | 50% |

| 5 | Areole concrete | Flat insulated concrete roof | 40% |

| 6 | Areole concrete | Flat insulated concrete roof | 50% |

| 7 | Areole concrete | Wood frame with high insulation | 40% |

| 8 | Areole concrete | Wood frame with high insulation | 50% |

| Seq. | External Walls | Roof | Window-to-Wall Ratio |

|---|---|---|---|

| 1 | Concrete panels with high insulation | Flat roof with high insulation | 40% |

| 2 | Concrete panels with high insulation | Flat roof with high insulation | 50% |

| 3 | Concrete panels with high insulation | Wood frame, panels with high insulation | 40% |

| 4 | Concrete panels with high insulation | Wood frame, panels with high insulation | 50% |

| 5 | Wood panels with high insulation | Flat roof with high insulation | 40% |

| 6 | Wood panels with high insulation | Flat roof with high insulation | 50% |

| 7 | Wood panels with high insulation | Wood frame, panels with high insulation | 40% |

| 8 | Wood panels with high insulation | Wood frame, panels with high insulation | 50% |

| 9 | Brick with rigid foam for insulation | Flat roof with high insulation | 40% |

| 10 | Brick with rigid foam for insulation | Flat roof with high insulation | 50% |

| 11 | Brick with rigid foam for insulation | Wood frame, panels with high insulation | 40% |

| 12 | Brick with rigid foam for insulation | Wood frame, panels with high insulation | 50% |

| Seq. | External Walls | Roof | Window-to-Wall Ratio |

|---|---|---|---|

| 1 | Single row of insulated cork concrete mix | Cork concrete mix and E-PLA for insulation | 40% |

| 2 | Single row of insulated cork concrete mix | Cork concrete mix and E-PLA for insulation | 50% |

| 3 | Single row of insulated cork concrete mix | Wood frame roof with high insulation | 40% |

| 4 | Single row of insulated cork concrete mix | Wood frame roof with high insulation | 50% |

| 5 | Single row of insulated cork concrete mix | Sulfur concrete mix and E-PLA for insulation | 40% |

| 6 | Single row of insulated cork concrete mix | Sulfur concrete mix and E-PLA for insulation | 50% |

| 7 | Double row of insulated cork concrete mix | Cork concrete mix and E-PLA for insulation | 40% |

| 8 | Double row of insulated cork concrete mix | Cork concrete mix and E-PLA for insulation | 50% |

| 9 | Double row of insulated cork concrete mix | Wood frame roof with high insulation | 40% |

| 10 | Double row of insulated cork concrete mix | Wood frame roof with high insulation | 50% |

| 11 | Double row of insulated cork concrete mix | Sulfur concrete mix and E-PLA for insulation | 40% |

| 12 | Double row of insulated cork concrete mix | Sulfur concrete mix and E-PLA for insulation | 50% |

| 13 | Single row of insulated sulfur concrete mix | Cork concrete mix and E-PLA for insulation | 40% |

| 14 | Single row of insulated sulfur concrete mix | Cork concrete mix and E-PLA for insulation | 50% |

| 15 | Single row of insulated sulfur concrete mix | Wood frame roof with high insulation. | 40% |

| 16 | Single row of insulated sulfur concrete mix | Wood frame roof with high insulation. | 50% |

| 17 | Single row of insulated sulfur concrete mix | Sulfur concrete mix and E-PLA for insulation | 40% |

| 18 | Single row of insulated sulfur concrete mix | Sulfur concrete mix and E-PLA for insulation | 50% |

| 19 | Double row of insulated sulfur concrete mix | Cork concrete mix and E-PLA for insulation | 40% |

| 20 | Double row of insulated sulfur concrete mix | Cork concrete mix and E-PLA for insulation | 50% |

| 21 | Double row of insulated sulfur concrete mix | Wood frame roof with high insulation | 40% |

| 22 | Double row of insulated sulfur concrete mix | Wood frame roof with high insulation | 50% |

| 23 | Double row of insulated sulfur concrete mix | Sulfur concrete mix and E-PLA for insulation | 40% |

| 24 | Double row of insulated sulfur concrete mix | Sulfur concrete mix and E-PLA for insulation | 50% |

| Seq. | Conventional | Modular | 3D-Printing | ||||||

|---|---|---|---|---|---|---|---|---|---|

|

EUI [MJ/m²/Year] | Annual Electric Consumption [kWh] | Lifecycle Energy Cost [BRL] |

EUI [MJ/m²/Year] | Annual Electric Consumption [kWh] | Lifecycle Energy Cost [BRL] |

EUI [MJ/m²/Year] | Annual Electric Consumption [kWh] | Lifecycle Energy Cost [BRL] | |

| 1 | 1003.1 | 12,467 | 128,375 | 1017.80 | 12,624 | 129,304 | 789.00 | 8854 | 90,767 |

| 2 | 1058.1 | 13,182 | 135,001 | 1067.70 | 13,272 | 135,918 | 999.10 | 12,415 | 127,166 |

| 3 | 979.7 | 11,250 | 115,237 | 995.6 | 11,364 | 116,404 | 927.70 | 10,624 | 108,842 |

| 4 | 1032.5 | 11,884 | 121,715 | 1048.90 | 12,001 | 122,907 | 976.50 | 11,211 | 114,836 |

| 5 | 1003.1 | 12,467 | 127,695 | 1017.60 | 12,637 | 129,439 | 948.30 | 11,753 | 120,408 |

| 6 | 946.2 | 11,791 | 120,752 | 1066.70 | 13,275 | 135,951 | 999.10 | 12,415 | 127,166 |

| 7 | 981.7 | 11,208 | 114,812 | 762.2 | 8579 | 87,950 | 726.4 | 8151 | 83,586 |

| 8 | 1015.1 | 11,608 | 118,897 | 811.1 | 9213 | 93,605 | 805.4 | 8733 | 92,913 |

| 9 | ⸻ | ⸻ | ⸻ | 1008.50 | 11,312 | 115,868 | 954.40 | 10,677 | 109,382 |

| 10 | ⸻ | ⸻ | ⸻ | 1062.50 | 11,946 | 122,342 | 1004.30 | 11,263 | 115,367 |

| 11 | ⸻ | ⸻ | ⸻ | 1067.60 | 13,084 | 134,000 | 1008.00 | 12,321 | 126,211 |

| 12 | ⸻ | ⸻ | ⸻ | 1118.30 | 13,733 | 140,626 | 1054.90 | 12,922 | 132,342 |

| 13 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 784.10 | 9588 | 98,292 |

| 14 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 841.40 | 10,331 | 105,873 |

| 15 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 786.10 | 8860 | 90,822 |

| 16 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 840.80 | 9513 | 97,490 |

| 17 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 784.10 | 9588 | 98,292 |

| 18 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 841.40 | 10,331 | 105,873 |

| 19 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 795.00 | 8812 | 90,326 |

| 20 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 850.60 | 9464 | 96,994 |

| 21 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 793.70 | 8797 | 90,176 |

| 22 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 848.90 | 9445 | 96,800 |

| 23 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 795.00 | 8811 | 90,322 |

| 24 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 850.60 | 9464 | 96,995 |

| Normalized Values | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Seq. | Conventional | Modular | 3D-Printing | ||||||

| Normalized EUI | Normalized annual electric consumption | Normalized lifecycle energy cost | Normalized EUI | Normalized annual electric consumption | Normalized lifecycle energy cost | Normalized EUI | Normalized annual electric consumption | Normalized lifecycle energy cost | |

| 1 | 0.9480 | 0.9457 | 0.95091 | 0.9101 | 0.9192 | 0.9194 | 0.7479 | 0.6851 | 0.6858 |

| 2 | 1.00 | 1.00 | 1.00 | 0.9547 | 0.9664 | 0.9665 | 0.9471 | 0.9607 | 0.9608 |

| 3 | 0.9259 | 0.8534 | 0.8536 | 0.8902 | 0.8274 | 0.8277 | 0.8794 | 0.8221 | 0.8224 |

| 4 | 0.9758 | 0.9015 | 0.9015 | 0.9379 | 0.8738 | 0.8739 | 0.9256 | 0.8675 | 0.8677 |

| 5 | 0.9480 | 0.9457 | 0.9458 | 0.9099 | 0.9201 | 0.9204 | 0.8989 | 0.9095 | 0.9098 |

| 6 | 0.8942 | 0.8944 | 0.8944 | 0.9538 | 0.9666 | 0.9667 | 0.9471 | 0.9607 | 0.9608 |

| 7 | 0.9277 | 0.9261 | 0.8504 | 0.6815 | 0.6246 | 0.6254 | 0.6885 | 0.6307 | 0.6315 |

| 8 | 0.9593 | 0.8805 | 0.8807 | 0.7252 | 0.6708 | 0.6656 | 0.7634 | 0.6758 | 0.7020 |

| 9 | ⸻ | ⸻ | ⸻ | 0.9018 | 0.8237 | 0.8239 | 0.9047 | 0.8262 | 0.8265 |

| 10 | ⸻ | ⸻ | ⸻ | 0.9501 | 0.8698 | 0.8699 | 0.9520 | 0.8716 | 0.8717 |

| 11 | ⸻ | ⸻ | ⸻ | 0.9546 | 0.9527 | 0.9528 | 0.9555 | 0.9534 | 0.9536 |

| 12 | ⸻ | ⸻ | ⸻ | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 13 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7432 | 0.7419 | 0.7427 |

| 14 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7976 | 0.7994 | 0.7999 |

| 15 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7451 | 0.6856 | 0.6862 |

| 16 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7970 | 0.7361 | 0.7366 |

| 17 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7432 | 0.7419 | 0.7427 |

| 18 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7976 | 0.7994 | 0.7999 |

| 19 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7536 | 0.6819 | 0.6825 |

| 20 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.8063 | 0.7323 | 0.7329 |

| 21 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7523 | 0.6807 | 0.6813 |

| 22 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.8047 | 0.7309 | 0.7314 |

| 23 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.7536 | 0.6818 | 0.6824 |

| 24 | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | ⸻ | 0.8063 | 0.7323 | 0.7329 |

| Conventional | Modular | 3D-Printing | |||

|---|---|---|---|---|---|

| Seq. | Weighted score | Seq. | Weighted score | Seq. | Weighted score |

| 1 | 0.9472 | 1 | 0.9153 | 1 | 0.7056 |

| 2 | 0.9990 | 2 | 0.9616 | 2 | 0.9552 |

| 3 | 0.8767 | 3 | 0.8476 | 3 | 0.8404 |

| 4 | 0.9253 | 4 | 0.8943 | 4 | 0.8861 |

| 5 | 0.9456 | 5 | 0.9159 | 5 | 0.9051 |

| 6 | 0.8934 | 6 | 0.9614 | 6 | 0.9552 |

| 7 | 0.9005 | 7 | 0.6432 | 7 | 0.6496 |

| 8 | 0.9059 | 8 | 0.6865 | 8 | 0.7130 |

| ⸻ | ⸻ | 9 | 0.8489 | 9 | 0.8516 |

| ⸻ | ⸻ | 10 | 0.8957 | 10 | 0.8975 |

| ⸻ | ⸻ | 11 | 0.9524 | 11 | 0.9532 |

| ⸻ | ⸻ | 12 | 0.9990 | 12 | 0.9990 |

| ⸻ | ⸻ | ⸻ | ⸻ | 13 | 0.7419 |

| ⸻ | ⸻ | ⸻ | ⸻ | 14 | 0.7982 |

| ⸻ | ⸻ | ⸻ | ⸻ | 15 | 0.7049 |

| ⸻ | ⸻ | ⸻ | ⸻ | 16 | 0.7558 |

| ⸻ | ⸻ | ⸻ | ⸻ | 17 | 0.7419 |

| ⸻ | ⸻ | ⸻ | ⸻ | 18 | 0.7982 |

| ⸻ | ⸻ | ⸻ | ⸻ | 19 | 0.7053 |

| ⸻ | ⸻ | ⸻ | ⸻ | 20 | 0.7564 |

| ⸻ | ⸻ | ⸻ | ⸻ | 21 | 0.7041 |

| ⸻ | ⸻ | ⸻ | ⸻ | 22 | 0.7549 |

| ⸻ | ⸻ | ⸻ | ⸻ | 23 | 0.7052 |

| ⸻ | ⸻ | ⸻ | ⸻ | 24 | 0.7564 |

| Conventional | Modular | 3D-Printing | |||

|---|---|---|---|---|---|

| Ranking | Sequences | Ranking | Sequences | Ranking | Sequences |

| 1 | Seq 3 | 1 | Seq 07 | 1 | Seq 07 |

| 2 | Seq 6 | 2 | Seq 08 | 2 | Seq 21 |

| 3 | Seq 7 | 3 | Seq 03 | 3 | Seq 15 |

| 4 | Seq 8 | 4 | Seq 09 | 4 | Seq 23 |

| 5 | Seq 4 | 5 | Seq 04 | 5 | Seq 19 |

| 6 | Seq 5 | 6 | Seq 10 | 6 | Seq 01 |

| 7 | Seq 1 | 7 | Seq 01 | 7 | Seq 08 |

| 8 | Seq 2 | 8 | Seq 05 | 8 | Seq 13 |

| ⸻ | ⸻ | 9 | Seq 11 | 9 | Seq 17 |

| ⸻ | ⸻ | 10 | Seq 06 | 10 | Seq 22 |

| ⸻ | ⸻ | 11 | Seq 02 | 11 | Seq 16 |

| ⸻ | ⸻ | 12 | Seq 12 | 12 | Seq 20 |

| ⸻ | ⸻ | ⸻ | ⸻ | 13 | Seq 24 |

| ⸻ | ⸻ | ⸻ | ⸻ | 14 | Seq 14 |

| ⸻ | ⸻ | ⸻ | ⸻ | 15 | Seq 18 |

| ⸻ | ⸻ | ⸻ | ⸻ | 16 | Seq 03 |

| ⸻ | ⸻ | ⸻ | ⸻ | 17 | Seq 09 |

| ⸻ | ⸻ | ⸻ | ⸻ | 18 | Seq 04 |

| ⸻ | ⸻ | ⸻ | ⸻ | 19 | Seq 10 |

| ⸻ | ⸻ | ⸻ | ⸻ | 20 | Seq 05 |

| ⸻ | ⸻ | ⸻ | ⸻ | 21 | Seq 11 |

| ⸻ | ⸻ | ⸻ | ⸻ | 22 | Seq 02 |

| ⸻ | ⸻ | ⸻ | ⸻ | 23 | Seq 06 |

| ⸻ | ⸻ | ⸻ | ⸻ | 24 | Seq 12 |

| Ranking | EUI | AEC | LEC | Normalized EUI | Normalized AEC | Normalized LEC | Weighted Score |

|---|---|---|---|---|---|---|---|

| Seq 07 3D-printing | 726.4 | 8151 | 83,586 | 0.7296 | 0.6676 | 0.6922 | 0.6958 |

| Seq 07 Modular | 762.2 | 8579 | 87,950 | 0.7779 | 0.7625 | 0.7632 | 0.7671 |

| Seq 21 3D-printing | 793.70 | 8797 | 90,176 | 0.7972 | 0.7205 | 0.7467 | 0.7541 |

| Seq 15 3D-printing | 786.10 | 8860 | 90,822 | 0.7895 | 0.7257 | 0.7521 | 0.7550 |

| Seq 08 Modular | 811.1 | 9213 | 93,605 | 0.8146 | 0.7813 | 0.7751 | 0.7896 |

| Seq 3 Conventional | 979.7 | 11,250 | 115,237 | 0.9840 | 0.9541 | 0.9543 | 0.9631 |

| Seq 03 Modular | 995.6 | 11,364 | 116,404 | 1 | 0.9308 | 0.9639 | 0.9639 |

| Seq 6 Conventional | 946.2 | 11,791 | 120,752 | 0.9503 | 0.9658 | 1 | 0.9711 |

| Seq 7 Conventional | 981.7 | 12,208 | 114,812 | 0.9860 | 1 | 0.9508 | 0.9779 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Masri, A.; Haddad, A.N.; Najjar, M.K. Comparative Analysis of Energy Efficiency in Conventional, Modular, and 3D-Printing Construction Using Building Information Modeling and Multi-Criteria Decision-Making. Computation 2024, 12, 247. https://doi.org/10.3390/computation12120247

Al Masri A, Haddad AN, Najjar MK. Comparative Analysis of Energy Efficiency in Conventional, Modular, and 3D-Printing Construction Using Building Information Modeling and Multi-Criteria Decision-Making. Computation. 2024; 12(12):247. https://doi.org/10.3390/computation12120247

Chicago/Turabian StyleAl Masri, Abdullah, Assed N. Haddad, and Mohammad K. Najjar. 2024. "Comparative Analysis of Energy Efficiency in Conventional, Modular, and 3D-Printing Construction Using Building Information Modeling and Multi-Criteria Decision-Making" Computation 12, no. 12: 247. https://doi.org/10.3390/computation12120247

APA StyleAl Masri, A., Haddad, A. N., & Najjar, M. K. (2024). Comparative Analysis of Energy Efficiency in Conventional, Modular, and 3D-Printing Construction Using Building Information Modeling and Multi-Criteria Decision-Making. Computation, 12(12), 247. https://doi.org/10.3390/computation12120247