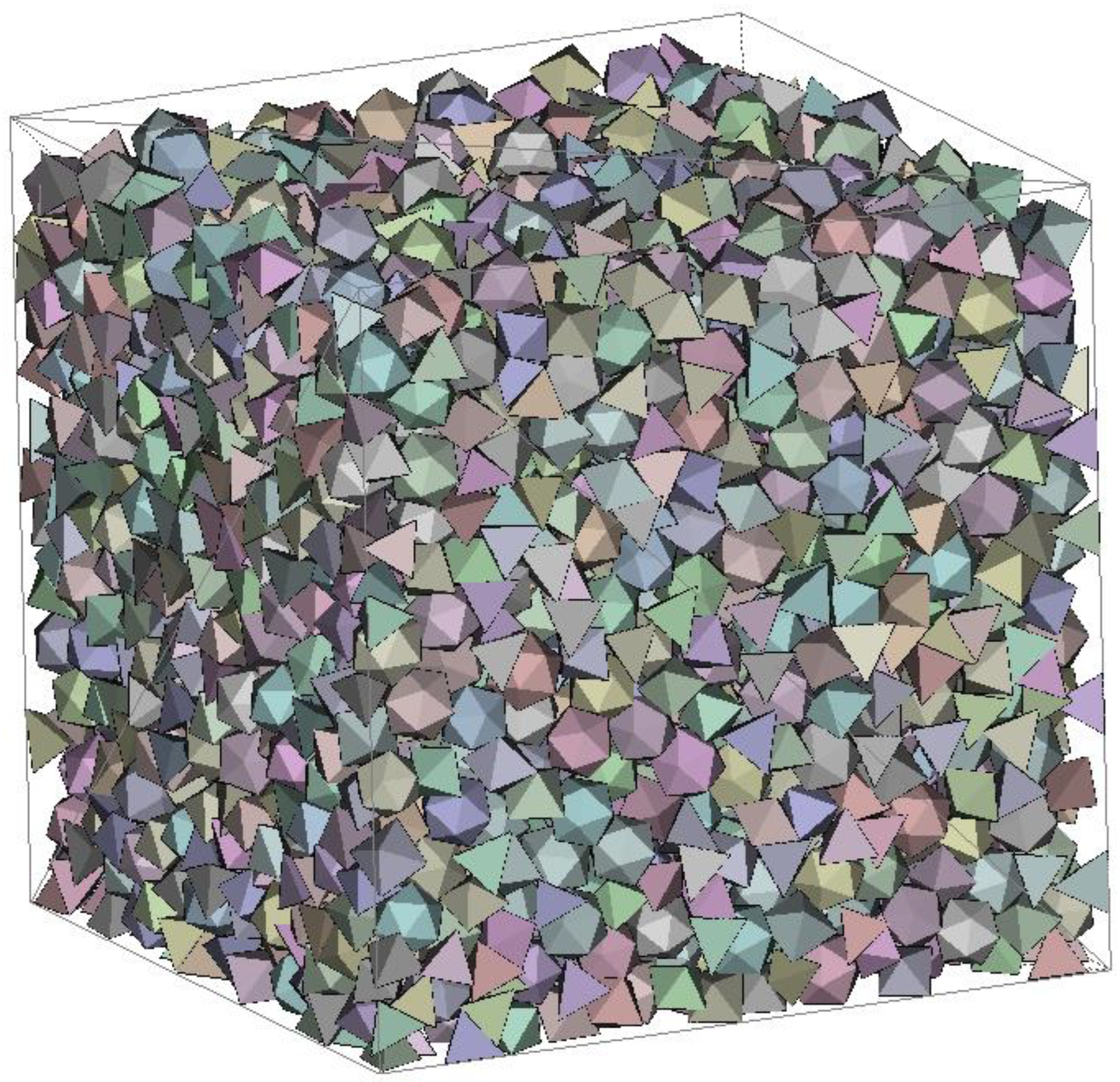

Optimized Packing Titanium Alloy Powder Particles

Abstract

1. Introduction

- Optimizing characteristics of titanium alloys used for 3D printing.

- Nonlinear programming model for filling a working volume with polyhedral particles.

- Fast solution approach based on a flexible active layer strategy.

- Comparing numerical and experimental findings.

2. Formulation of the Packing Problem

3. Geometric Tools and Mathematical Model

4. Solution Approach

4.1. The Principal Steps of the Approach

- Step 1. “Normalizing” objects and the container Ω.

- Define

- Next, consider packing polyhedra of type associated with the appropriate radii into a cuboid of sizes .

- Step 2. Set , , , . Define , , . Set , where .

- Step 3. Randomly generate the radius (see algorithm Q) associated with the polyhedron of type (see algorithm G).

- Step 4. Place the center of the polyhedron at a point , . Assume Euler angles are random variables.

- Step 5. Create the arrangement of the object with the center at a random point in a cuboid with dimensions , providing non-overlapping with already packed polyhedra (algorithm S). If a feasible point cannot be found, then go to step 9.Step 6. Solve the nonlinear programming problem to search for the minimum of (coordinate of the gravity center of the polyhedron ):where , , is the quasi-phi-function (3) for fixed , is the phi-function (4), (algorithm S). The corresponding optimal solution gives the appropriate placement parameters of the polyhedron and is considered as the initial point for the algorithm D below.

- Step 7. Updating the size of the active layer:

- Change the thickness of the active layer: if then define (increasing the thickness if the lower limit of the active layer is attained) and set , while and (see Figure 1);

- Set (the maximal height of the active layer). If then set , otherwise set to determine the upper bound of the active layer.

- Polyhedra that are arranged under the active layer are not considered: set for (Figure 2).

- Step 8. If , set and go to step 4, otherwise, go to step 9.

- Step 9. Recalculate corresponding coordinates for the centers of polyhedra, multiplying them by while updating the original size of the polyhedra and the cuboid.

- Step 10. Delete from the set of polyhedra that are not completely packed in a cuboid with dimensions .

4.2. Description of Algorithms Q, G, S, and D Used in This Optimization Procedure

- Algorithm Q. Generating a discrete value of the radius R depending on vectors and P.

- Step Q1. Find random value of .

- Step Q2. Find the minimum index m for which .

- Step Q3. Set .

- Algorithm G. Generating a discrete value of the type T with distribution law defined by vectors and F.

- Step G1. Find random value of .

- Step G2. Find the minimum index m for which .

- Step G3. Set .

- Algorithm S. Generating a feasible packing of polyhedra (with radius R) of the active layer of the cuboid with size subject to i already packed polyhedra.

- Step S1. Select to determine the “gravity” that affects the particles and define .

- Step S2. Set , (a large number) and fix the angles of rotation of the object.

- Step S3. Form and fix randomly chosen values of variables , .

- Step S4. Define an index set

- Step S5. Solve the nonlinear programming problemwhere is the quasi-phi-function of the form (2) provided that are fixed, q is the cardinality of the set .

- Step S6. If then set .

- Step S7. Set . If , then terminate algorithm S, otherwise go to step S2.

- The output of algorithm S is a point .

- If , then the current polyhedron cannot be placed in a cuboid with dimensions .

- Algorithm D. Finding the minimal value of the z-th coordinate of a polyhedron using as a starting feasible point.

- Step D1. Set k = 0 and perform the decomposition step δ = 2 for the problem with normalized dimensions of the polyhedron.

- Step D2. Define

- Step D3. Obtain the zth-coordinate of the i-th polyhedron by solving the following nonlinear programming problem:where , , is the quasi-phi-function (1), provided that the vector is fixed, is the phi-function (2), q is the cardinality of the set .

- Take as a starting point.

- Step D4. Find a vector of coordinates of the center of the polyhedra.

- Step D5. If , then algorithm D is terminated, otherwise, set and go to step D2.

5. Computational Results and Comparison with Experimental Findings

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies, 1st ed.; Springer: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- Romanova, T.; Stoyan, Y.; Pankratov, A.; Litvinchev, I.; Avramov, K.; Chernobryvko, M.; Yanchevskyi, I.; Mozgova, I.; Bennell, J. Optimal layout of ellipses and its application for additive manufacturing. Int. J. Prod. Res. 2019, 59, 560–575. [Google Scholar] [CrossRef]

- Milewski, J.O. Additive Manufacturing of Metals, 1st ed.; Springer: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies, 3rd ed.; Springer: New York, NY, USA, 2021. [Google Scholar]

- Qian, M.; Froes, F.H. Titanium Powder Metallurgy: Science, Technology and Applications; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Duriagina, Z.A.; Lemishka, I.A.; Trostianchyn, A.M.; Kulyk, V.V.; Shvachko, S.G.; Tepla, T.L.; Pleshakov, E.I.; Kovbasyuk, T.M. The Effect of Morphology and Particle-Size Distribution of VT20 Titanium Alloy Powders on the Mechanical Properties of Deposited Coatings. Sov. Powder Met. Met. Ceram. 2019, 57, 697–702. [Google Scholar] [CrossRef]

- Duriagina, Z.; Holyaka, R.; Tepla, T.; Kulyk, V.; Arras, P.; Eyngorn, E. Identification of Fe3O4 Nanoparticles Biomedical Purpose by Magnetometric Methods; InTech: Rijeka, Croatia, 2018; Chapter 17. [Google Scholar] [CrossRef]

- Izonin, I.; Trostianchyn, A.; Duriagina, Z.; Tkachenko, Z.; Tepla, R.; Lotoshynska, T.N. The combined use of the wiener poly-nomial and SVM for material classification task in medical implants production. Int. J. Intell. Syst. Appl. 2018, 10, 40–47. [Google Scholar]

- Tepla, T.; Izonin, I.; Duriagina, Z.; Tkachenko, R.; Trostianchyn, A.; Lemishka, I.; Kulyk, V.; Kovbasyuk, T. Alloys selection based on the supervised learning technique for design of biocompatible medical materials. Arch. Mater. Sci. Eng. 2018, 1, 32–40. [Google Scholar] [CrossRef]

- Vastola, G.; Pei, Q.; Zhang, Y.-W. Predictive model for porosity in powder-bed fusion additive manufacturing at high beam energy regime. Addit. Manuf. 2018, 22, 817–822. [Google Scholar] [CrossRef]

- Bayat, M.; Dong, W.; Thorborg, J.; To, A.C.; Hattel, J.H. A review of multi-scale and multi-physics simulations of metal additive manufacturing processes with focus on modeling strategies. Addit. Manuf. 2021, 47, 102278. [Google Scholar] [CrossRef]

- Hebert, R.J.; Sun, Y.; Aindow, M.; Garboczi, E.J. Three-dimensional particle size, shape, and internal porosity characterization: Application to five similar titanium alloy (Ti–6Al–4V) powders and comparison to two-dimensional measurements. Addit. Manuf. 2021, 44, 102060. [Google Scholar] [CrossRef]

- Liu, R.; Liu, S.; Zhang, X. A physics-informed machine learning model for porosity analysis in laser powder bed fusion additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 1943–1958. [Google Scholar] [CrossRef]

- Wang, W.; Ning, J.; Liang, S.Y. Analytical prediction of keyhole porosity in laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2022, 119, 6995–7002. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.-M.; Cao, A.-X.; Yao, Z.-L. HAPE3D—A new constructive algorithm for the 3D irregular packing problem. Front. Inf. Technol. Electron. Eng. 2015, 16, 380–390. [Google Scholar] [CrossRef]

- Leao, A.A.; Toledo, F.M.; Oliveira, J.F.; Carravilla, M.A.; Alvarez-Valdés, R. Irregular packing problems: A review of mathematical models. Eur. J. Oper. Res. 2019, 282, 803–822. [Google Scholar] [CrossRef]

- Kallrath, J. Business Optimization Using Mathematical Programming, 2nd ed.; Springer: New York, NY, USA, 2021; Chapter 15. [Google Scholar] [CrossRef]

- Stoyan, Y.; Pankratov, A.; Romanova, T. Placement Problems for Irregular Objects: Mathematical Modeling, Optimization and Applications; Springer: Cham, Germany, 2017; Volume 130, pp. 521–559. [Google Scholar] [CrossRef]

- Stoyan, Y.; Pankratov, A.; Romanova, T.; Fasano, G.; Pintér, J.D.; Stoian, Y.E.; Chugay, A. Optimized Packings in Space Engineering Applications: Part I; Springer: Cham, Germany, 2019; Volume 144, pp. 395–437. [Google Scholar] [CrossRef]

- Pankratov, A.; Romanova, T.; Litvinchev, I. Packing ellipses in an optimized convex polygon. J. Glob. Optim. 2019, 75, 495–522. [Google Scholar] [CrossRef]

- Romanova, T.; Litvinchev, I.; Pankratov, A. Packing ellipsoids in an optimized cylinder. Eur. J. Oper. Res. 2020, 285, 429–443. [Google Scholar] [CrossRef]

- Duriagina, Z.; Lemishka, I.; Litvinchev, I.; Marmolejo, J.A.; Pankratov, A.; Romanova, T.; Yaskov, G. Optimized Filling of a Given Cuboid with Spherical Powders for Additive Manufacturing. J. Oper. Res. Soc. China 2020, 9, 853–868. [Google Scholar] [CrossRef]

- Wächter, A.; Biegler, L.T. On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math. Program. 2005, 106, 25–57. [Google Scholar] [CrossRef]

- Duriagina, Z.A.; Tkachenko, R.O.; Trostianchyn, A.M.; Lemishka, I.A.; Kovalchuk, A.M.; Kulyk, V.V.; Kovbasyuk, T.M. Deter-mination of the best microstructure and titanium alloy powders properties using neural network. J. Ach. Mater. Manuf. Eng. 2018, 87, 25–31. [Google Scholar]

- Verguet, A.; Messaoudi, C.; Marco, S.; Donnadieu, P. An ImageJ tool for simplified post-treatment of TEM phase contrast images (SPCI). Micron 2019, 121, 90–98. [Google Scholar]

- OriginLab. Available online: http://www.originlab.com/doc/User-Guide (accessed on 3 December 2022).

- Zhao, B.; An, X.; Wang, Y.; Zhao, H.; Shen, L.; Sun, X.; Zou, R. Packing of different shaped tetrahedral particles: DEM simulation and experimental study. Powder Technol. 2019, 360, 21–32. [Google Scholar] [CrossRef]

- Zhao, B.; An, X.; Zhao, H.; Gou, D.; Shen, L.; Sun, X. DEM simulation on random packings of binary tetrahedron-sphere mixtures. Powder Technol. 2019, 361, 160–170. [Google Scholar] [CrossRef]

- Li, J.; An, X.; Wang, J.; Zhao, H.; Zou, R.; Dong, K.; Gou, D. Experimental study on 3D vibrated packing densification of mono-sized dodecahedral particles. Powder Technol. 2020, 367, 703–712. [Google Scholar] [CrossRef]

- Wang, H.; Lim, J.Y. Metal-ceramic bond strength of a cobalt chromium alloy for dental prosthetic restorations with a porous structure using metal 3D printing. Comput. Biol. Med. 2019, 112, 103364. [Google Scholar] [CrossRef] [PubMed]

- Litvinchev, I.; Infante, L.; Espinosa, E.L.O. Approximate Circle Packing in a Rectangular Container: Integer Programming Formulations and Valid Inequalities. In Computational Logistics. ICCL 2014. Lecture Notes in Computer Science; González-Ramírez, R.G., Schulte, F., Voß, S., Ceroni Díaz, J.A., Eds.; Springer: Cham, Switzerland, 2014; Volume 8760, pp. 47–60. [Google Scholar] [CrossRef]

- Litvinchev, I.; Espinosa, E.L.O. Integer Programming Formulations for Approximate Packing Circles in a Rectangular Container. Math. Probl. Eng. 2014, 2014, 317697. [Google Scholar] [CrossRef]

- Michaelis, A.; Scheithauer, U.; Moritz, T.; Weingarten, S.; Abel, J.; Schwarzer, E.; Kunz, W. Advanced Manufacturing for Advanced Ceramics. Procedia CIRP 2020, 95, 18–22. [Google Scholar] [CrossRef]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of Metal-Ceramic Components. J. Vis. Exp. 2018, 143, e57693. [Google Scholar] [CrossRef]

| Powder Fraction | Experimentally Determined Particle Sizes by Ferret Diameter, μm | Number of Particles | |

|---|---|---|---|

| Pcs. | % | ||

| Fraction 1 (200–250 μm) | 96.6 | 1 | 2.3 |

| 156.9 | 2 | 4.7 | |

| 199.7 | 12 | 27.9 | |

| 214.5 | 17 | 39.5 | |

| 228.3 | 5 | 11.6 | |

| 241.3 | 6 | 14.0 | |

| Fraction 2 (160–200 μm) | 178.8 | 14 | 19.2 |

| 183.4 | 7 | 9.6 | |

| 187.6 | 18 | 24.7 | |

| 193.6 | 14 | 19.2 | |

| 200.1 | 20 | 27.4 | |

| Fraction 3 (100–160 μm) | 75.9 | 5 | 6.6 |

| 92.3 | 3 | 3.9 | |

| 106.2 | 7 | 9.2 | |

| 118.4 | 6 | 7.9 | |

| 129.5 | 5 | 6.6 | |

| 139.8 | 2 | 2.6 | |

| 149.3 | 7 | 9.2 | |

| 158.3 | 20 | 26.3 | |

| 166.8 | 21 | 27.6 | |

| Powder Fraction | Experimental Filling Factor, % | Calculated Filling Factor, % | Error, % |

|---|---|---|---|

| Fraction 1 (200–250 μm) | 62.07 | 59.43 | 2.64 |

| Fraction 2 (160–200 μm) | 67.18 | 62.21 | 4.97 |

| Fraction 3 (100–160 μm) | 73.56 | 68.77 | 4.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duriagina, Z.; Pankratov, A.; Romanova, T.; Litvinchev, I.; Bennell, J.; Lemishka, I.; Maximov, S. Optimized Packing Titanium Alloy Powder Particles. Computation 2023, 11, 22. https://doi.org/10.3390/computation11020022

Duriagina Z, Pankratov A, Romanova T, Litvinchev I, Bennell J, Lemishka I, Maximov S. Optimized Packing Titanium Alloy Powder Particles. Computation. 2023; 11(2):22. https://doi.org/10.3390/computation11020022

Chicago/Turabian StyleDuriagina, Zoia, Alexander Pankratov, Tetyana Romanova, Igor Litvinchev, Julia Bennell, Igor Lemishka, and Sergiy Maximov. 2023. "Optimized Packing Titanium Alloy Powder Particles" Computation 11, no. 2: 22. https://doi.org/10.3390/computation11020022

APA StyleDuriagina, Z., Pankratov, A., Romanova, T., Litvinchev, I., Bennell, J., Lemishka, I., & Maximov, S. (2023). Optimized Packing Titanium Alloy Powder Particles. Computation, 11(2), 22. https://doi.org/10.3390/computation11020022