A Fuzzy Evaluation Model for Sustainable Modular Supplier

Abstract

1. Introduction

2. Literature Review

2.1. An Overview of Supplier Evaluation

2.2. An Overview of Sustainable Modular Supplier Evaluation

2.3. An Overview of Organizational Identity

3. Empirical Study of Evaluation Criteria

3.1. Item Primary Selection

3.2. Item Optimization

4. Fuzzy Evaluation Method and Stability Analysis

4.1. Determining the Weights

4.2. Establishing Membership and Conducting Comprehensive Evaluation

4.3. Calculating the Dispersion Degree

4.4. Stability Analysis

- (1)

- Both positive and negative errors have impact on Equations (1) and (2). Namely, , .

- (2)

- The positive error has an impact on Equation (1), both positive and negative errors have impact on Equation (2). Namely, , .

- (3)

- The negative error has an impact on Equation (1), both positive and negative error have impact on Equation (2). Namely, , .

- (4)

- Both positive and negative errors do not have an impact on Equation (1), the negative error has an impact on Equation (2). Namely, , .

- (5)

- Both positive and negative errors do not have impact on Equation (1), the positive error has an impact on Equation (2). Namely, , .

- (6)

- Both positive and negative errors do not have impact on the two equations. Namely, , .

5. Case Analysis

5.1. Case Description

5.2. Calculating the Weights

5.3. Establishing Membership and Conducting Comprehensive Evaluation

5.4. Stability Analysis

6. Conclusions

- (1)

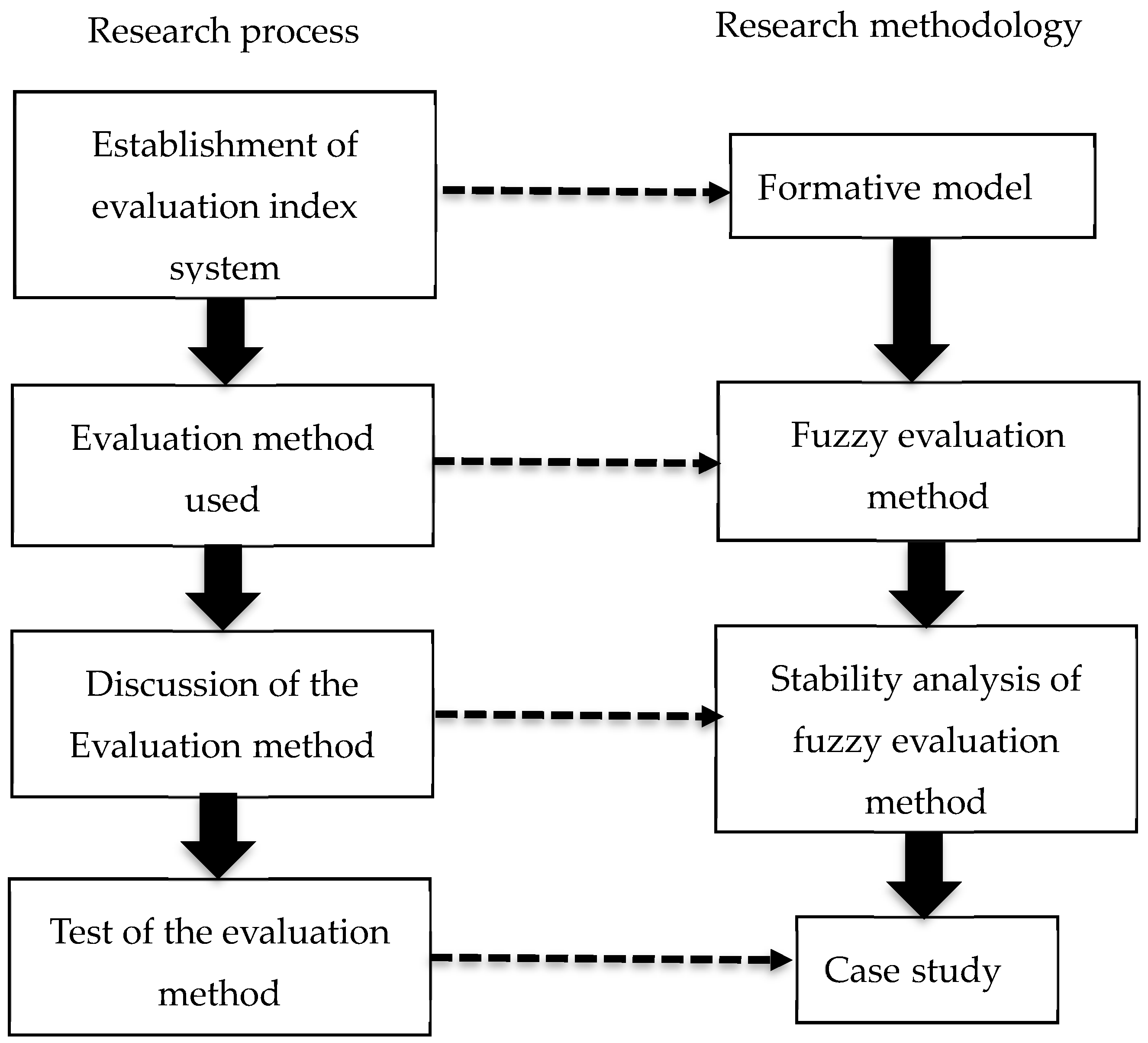

- This paper introduces an organizational identity perspective into the design of the evaluation index system. According to the organizational identity theory, organizational identity is the unanimous understanding of most members of an organization about “who we are as an organization” [1]. It is the central, enduring and distinctive understanding about an organization [2]. An organization categorizes itself and accordingly takes actions by the cognition of its organizational identity. As such, the study proposes that by taking the supplier’s cognition of its organizational identity into account, a manufacturer can learn more about a supplier and therefore better forecast the supplier’s behaviors and reduce risk. Therefore, in designing the evaluation index system, the study adds the organizational identity perspective, which has not been discussed before.

- (2)

- The study uses the formative model to evaluate the validity and reliability of the index system. In designing the index system, the author decomposes the concept of sustainable modular supplier into its three aspects: modular competency, sustainability, and organizational identity cognition. Based on a literature review and interviews, the author designs the indexes for each aspect. Different from previous factor analyses of the index system, the study adopts a formative model to build the index system, which better follows the design logic and is more appropriate for the index analysis.

- (3)

- In this paper a fuzzy evaluation method is adopted to evaluate and select sustainable modular suppliers. Considering that this method depends largely on an expert’s subjective judgment, the stability of the method is discussed. By introducing the dispersion degree, the study modifies the comprehensive evaluation vector. Based on this, the study discusses the different circumstances and the range of subjective judgment errors in each circumstance. Such stability analysis helps us to understand the degree to which results can be trusted. Lastly, by applying this method to a practical case, the author shows how the fuzzy evaluation method can help to evaluate sustainable modular suppliers and how stability analysis can help to test the reliability of the results.

Funding

Conflicts of Interest

Appendix A

| 1 | 3 | 4 | |

| 1/3 | 1 | 2 | |

| 1/4 | 1/2 | 1 |

| Total | Weight | ||||

|---|---|---|---|---|---|

| 6 | 8.5 | 14.5 | 0.322 | ||

| 9 | 10 | 19 | 0.422 | ||

| 6.5 | 5 | 11.5 | 0.256 |

| Total | Weight | ||||

|---|---|---|---|---|---|

| 6.5 | 8 | 14.5 | 0.322 | ||

| 8.5 | 9 | 17.5 | 0.389 | ||

| 7 | 6 | 13 | 0.289 |

| Total | Weight | ||||||

|---|---|---|---|---|---|---|---|

| 8 | 6.5 | 9 | 8.5 | 32 | 0.213 | ||

| 7 | 8 | 6 | 9 | 30 | 0.2 | ||

| 8.5 | 7 | 9 | 9 | 33.5 | 0.223 | ||

| 6 | 9 | 6 | 8 | 29 | 0.194 | ||

| 6.5 | 6 | 6 | 7 | 25.5 | 0.17 |

| Total | Weight | |||||

|---|---|---|---|---|---|---|

| 8 | 6 | 6 | 20 | 0.222 | ||

| 7 | 6 | 6 | 19 | 0.211 | ||

| 9 | 9 | 8.5 | 26.5 | 0.294 | ||

| 9 | 9 | 6.5 | 24.5 | 0.273 |

| Total | Weight | |||

|---|---|---|---|---|

| 9 | 9 | 0.6 | ||

| 6 | 6 | 0.4 |

| Total | Weight | |||

|---|---|---|---|---|

| 9 | 9 | 0.6 | ||

| 6 | 6 | 0.4 |

| Total | Weight | |||

|---|---|---|---|---|

| 8 | 8 | 0.533 | ||

| 7 | 7 | 0.467 |

| Total | Weight | |||

|---|---|---|---|---|

| 6.5 | 6.5 | 0.433 | ||

| 8.5 | 8.5 | 0.567 |

| Total | Weight | |||

|---|---|---|---|---|

| 7 | 7 | 0.533 | ||

| 8 | 8 | 0.467 |

| Total | Weight | ||||

|---|---|---|---|---|---|

| 9 | 8.5 | 17.5 | 0.389 | ||

| 6 | 7 | 13 | 0.289 | ||

| 6.5 | 8 | 14.5 | 0.322 |

Appendix B

| Evaluated Supplier: | Code of supplier: | ||||

| Evaluating department or representative | |||||

| Purchasing and procurement department and representative | Production department and representative | Other departments and representative | |||

| Grades and definition of comments | |||||

| 1 good (implement well, have good effect, obvious advantage) 2 general (implement basically, have general effect, partly advantage) 3 fairly weak (partly implement, have fairly weak effect, no advantage) 4 weak (no implementation, have weak effect, disadvantage) | |||||

| Evaluation Item | |||||

| Modular Competency (first tier index) | |||||

| Second tier index | Third tier index | Specific way | Comment | ||

| Modular design and production competency | Professional industry knowledge | Questionnaire | |||

| Technical development capability | Questionnaire | ||||

| Value analysis capability | Questionnaire | ||||

| Global item of MCD0 | Questionnaire | ||||

| Modular management competency | Engineering support | Questionnaire | |||

| Integration capability | Questionnaire | ||||

| Relationship management capability | Questionnaire | ||||

| Global item of MCM0 | Questionnaire | ||||

| MC01 | Questionnaire | ||||

| MC02 | Questionnaire | ||||

| Sustainability (first tier index) | |||||

| Second tier index | Third tier index | Specific way | Comment | ||

| Social responsibility implementation | Contribution to the government | National tax paid on time | |||

| Local tax paid on time | |||||

| Number of people employed | |||||

| Contribution to the investors | Dividends distributed | ||||

| Return of investment | |||||

| Contribution to the employees | Satisfied salaries and benefits paid | ||||

| Sense of belonging | |||||

| Sense of achievement | |||||

| Contribution to the suppliers | Satisfied returns and profits | ||||

| Long-term cooperation relationship | |||||

| Contribution to the community | Money donated | ||||

| Community activities undertaken | |||||

| Global item of SCR0 | Questionnaire | ||||

| Environmental management | Having environmental management certification | Questionnaire | |||

| Protecting environmental resources | Questionnaire | ||||

| Implementing clean production | Questionnaire | ||||

| Passing ISO14000 certification | Questionnaire | ||||

| Global item of SCM0 | Questionnaire | ||||

| SC01 | Questionnaire | ||||

| SC02 | Questionnaire | ||||

| Organizational identity cognition (first tier index) | |||||

| Second tier index | Third tier index | Specific way | Comment | ||

| Cognition of the core features | Cognition of the enterprise’s core value | Questionnaire | |||

| Cognition of the enterprise’s vision and mission | Questionnaire | ||||

| Global item of OIC0 | Questionnaire | ||||

| Cognition of the distinctive features | Cognition of the enterprise’s core competitiveness and businesses | Questionnaire | |||

| Cognition of the resources needed in the enterprise’s core businesses | Questionnaire | ||||

| Global item of OID0 | Questionnaire | ||||

| OI01 | Questionnaire | ||||

| OI02 | Questionnaire | ||||

Appendix C

References

- Nag, R.; Corley, K.G.; Gioia, D.A. The intersection of organizational identity, knowledge, and practice: Attempting strategic change via knowledge grafting. Acad. Manag. J. 2007, 50, 821–847. [Google Scholar] [CrossRef]

- Dutton, J.E.; Dukerich, J.M. Keeping an eye on the mirror: Image and identity in organizational adaptation. Acad. Manag. J. 1991, 34, 517–554. [Google Scholar]

- Dickson, G.W. An analysis of vendor selection systems and decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Choi, T.Y.; Hartley, J.L. An exploration of supplier selection practices across the supply chain. J. Oper. Manag. 1996, 14, 333–343. [Google Scholar] [CrossRef]

- Li, W.; Humphreys, P.K.; Yeung, A.C.; Cheng, T.C.E. The impact of supplier development on buyer competitive advantage: A path analytic model. Int. J. Prod. Econ. 2012, 135, 353–366. [Google Scholar] [CrossRef]

- He, W. Coevolution of Inter-organizational Psychological Contract and Inter-organizational Relationship-A Case Study of Manufacturing Company in China. Discret. Dyn. Nat. Soc. 2017, 2017, 9370969. [Google Scholar] [CrossRef]

- Chen, S.H. The Influencing Factors of Enterprise Sustainable Innovation: An Empirical Study. Sustainability 2016, 8, 425. [Google Scholar] [CrossRef]

- Ordoobadi, M.S. Application of AHP and Taguchi loss functions in supply chain. Ind. Manag. Data Syst. 2010, 110, 1251–1269. [Google Scholar] [CrossRef]

- Ou, P.Y.; Wang, Y.L.; Wang, P.X. The study of supplier selection and evaluation based on ABC approach. Manag. Rev. 2007, 19, 46–51. [Google Scholar]

- Amin, H.S.; Razmi, J. An integrated fuzzy model for supplier management: A case study of ISP selection and evaluation. Expert Syst. Appl. 2009, 36, 8639–8648. [Google Scholar] [CrossRef]

- Wang, E.J.; Chen, Y.C.; Wang, W.S.; Su, T.S. Analysis of outsourcing cost-effectiveness using a linear programming model with fuzzy multiple goals. Int. J. Prod. Res. 2010, 48, 501–523. [Google Scholar] [CrossRef]

- Jia, Y.N.; Sun, P. Algorithm for the evaluation of supplier quality based on BP neural network. Stat. Decis. 2015, 4, 172–174. [Google Scholar]

- He, W. An inventory controlled supply chain model based on improved BP neural network. Discret. Dyn. Nat. Soc. 2013, 2013, 537675. [Google Scholar] [CrossRef]

- Talluri, S.; Narasimhan, R.; Nair, A. Vendor performance with supply risk: A chance-constrained DEA approach. Int. J. Prod. Econ. 2006, 100, 212–222. [Google Scholar] [CrossRef]

- Rasmus, L.; Ruy, Q.; Hubert, S. Reorganising global value chains and building innovation capabilities in Brazil and India. Res. Policy 2015, 44, 1376–1386. [Google Scholar]

- He, W. A Dynamic Evolutionary Game Model of Modular Production Network. Discret. Dyn. Nat. Soc. 2016, 2016, 6425158. [Google Scholar] [CrossRef]

- He, W.; Chen, S.H. Game analysis of determinants of stability of semiconductor modular production networks. Sustainability 2014, 6, 4772–4794. [Google Scholar] [CrossRef]

- Wang, H.J.; Feng, J.Z.; Zou, H. A research on the evaluation of strategic module suppliers and management mechanism from the perspective of collaborative innovation. Sci. Res. Manag. 2016, 37, 1–12. [Google Scholar]

- Eggers, J.E.; Hofman, E.; Schiele, H.; Holschbach, E. Identifying the “right” supplier for module developments-a cross-industrial case analysis. Int. J. Innov. Manag. 2017, 21, 1750026. [Google Scholar] [CrossRef]

- Feng, S.C.; Joung, C.; Li, G. Development Overview of Sustainable Manufacturing Metrics. In Proceedings of the 17th CIRP International Conference on Life Cycle Engineering, Hefei, China, 19–21 May 2010; pp. 6–12. [Google Scholar]

- Chen, S.H. The game analysis of negative externality of environmental logistics and governmental regulation. Int. J. Environ. Pollut. 2013, 51, 143–155. [Google Scholar] [CrossRef]

- Chen, S.H. An Evolutionary Game Study of an Ecological Industry Chain Based on Multi-Agent Simulation: A Case Study of the Poyang Lake Eco-Economic Zone. Sustainability 2017, 9, 1165. [Google Scholar] [CrossRef]

- Chen, S.H. An Evolutionary Game Model of Knowledge Workers’ Counterproductive Work Behaviors Based on Preferences. Complexity 2017, 2017, 3295436. [Google Scholar] [CrossRef]

- Walton, S.V.; Handfield, R.B.; Melnyk, S.A. The green supply chain: Integrating suppliers into environmental management processes. Int. J. Purch. Mater. Manag. 1998, 34, 2–11. [Google Scholar] [CrossRef]

- Bai, C.A.; Sarkis, J. Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 2010, 124, 252–264. [Google Scholar] [CrossRef]

- Büyükozkan, G.; Çifçi, G. A novel fuzzy multi-criteria decision framework for sustainable supplier selection with incomplete information. Comput. Ind. 2011, 23, 164–174. [Google Scholar] [CrossRef]

- Sarkis, J.; Dhavale, D.G. Supplier selection for sustainable operations: A triple-bottom-line approach using a Bayesian framework. Int. J. Prod. Econ. 2015, 166, 177–191. [Google Scholar] [CrossRef]

- Ji, Y.J.; Jiao, J.R.; Chen, L.; Wu, C.L. Green modular design for material efficiency: A leader-follower joint optimization model. J. Clean. Prod. 2013, 41, 187–201. [Google Scholar] [CrossRef]

- Ma, J.F.; Kremer, G.A. systematic literature review of modular product design (MPD) from the perspective of sustainability. Int. J. Adv. Manuf. Technol. 2016, 81, 1509–1539. [Google Scholar] [CrossRef]

- Albert, S.; Whetten, D.A. Organizational Identity; Research in Organizational Behavior; JAI Press: Greenwich, CT, USA, 1985; pp. 263–295. [Google Scholar]

- Foreman, P.; Whetten, D.A. Member’s identification with multiple-identity organizations. Organ. Sci. 2002, 13, 618–635. [Google Scholar] [CrossRef]

- Gioia, D.A.; Schultz, M.; Corley, K.G. Organizational identity, image, and adaptive instability. Acad. Manag. Rev. 2000, 25, 63–81. [Google Scholar] [CrossRef]

- Rousseau, D.M. Why workers still identify with organizations. J. Organ. Behav. 1998, 19, 217–233. [Google Scholar] [CrossRef]

- Kreiner, G.E.; Ashforth, B.E. Evidence toward an expanded model of organizational identification. J. Organ. Behav. 2004, 25, 1–27. [Google Scholar] [CrossRef]

- Empson, L. Organizational identity change: Managerial regulation and member identification in an accounting firm acquisition. Acc. Organ. Sci. 2004, 29, 759–781. [Google Scholar] [CrossRef]

- Carlsen, A. Organizational becoming as dialogic imagination of practice: The case of the indomitable Gauls. Organ. Sci. 2006, 17, 132–149. [Google Scholar] [CrossRef]

- Lowe, M.; George, G.; Alexy, O. Organizational identity and capability development in internationalization: Transference, splicing and enhanced imitation in Tesco’s US market entry. J. Econ. Geogr. 2012, 12, 1021–1054. [Google Scholar] [CrossRef]

- Albert, S.; Whetten, D.A. Organizational identity. In Organizational Identity: A Reader; Hatch, M.J., Schultz, M., Eds.; Oxford University Press: London, UK, 2004; pp. 89–118. [Google Scholar]

- Pratt, M.G.; Foreman, P.O. Classifying managerial responses to multiple organizational identities. Acad. Manag. Rev. 2000, 25, 18–42. [Google Scholar] [CrossRef]

- Scott, S.G.; Lane, V. A stakeholder approach to organizational identity. Acad. Manag. Rev. 2000, 25, 43–62. [Google Scholar] [CrossRef]

- Miller, T.L.; Wesley, C.L., II. Assessing mission and resources for social change: An organizational identity perspective on social venture capitalists’ decision criteria. Entrep. Theory Pract. 2010, 34, 705–733. [Google Scholar] [CrossRef]

- Whetten, D.A.; Mackey, A. A social actor conception of organizational identity and its implication for the study of organizational reputation. Bus. Soc. 2002, 1, 393–414. [Google Scholar] [CrossRef]

- Zachary, M.A.; McKenny, A.F.; Short, J.C.; Davis, K.M.; Wu, D. Franchise branding: An organizational identity perspective. J. Acad. Mark. Sci. 2011, 39, 629–645. [Google Scholar] [CrossRef]

- Lamberson, R.L.; Diederich, D.; Wuori, J. Quantitative vendor evaluation. J. Supply Chain Manag. 1976, 12, 19–28. [Google Scholar] [CrossRef]

- Sezhiyan, M.D.; Nambirajan, T. Development of scale to measure supplier selection, supply effort management and organizational performance. Asia Pac. Bus. Rev. 2010, 6, 26–37. [Google Scholar] [CrossRef]

- Soukup, W.R. Supplier selection strategies. J. Purch. Mater. Manag. 1987, 23, 7–12. [Google Scholar] [CrossRef]

- Monczka, R.M.; Trent, R.J. Evolving sourcing strategies for the 1990s. Int. J. Phys. Distrib. Logist. Manag. 1991, 21, 4–12. [Google Scholar] [CrossRef]

- Kannan, V.R.; Tan, K.C. Buyer-supplier relationships: The impact of supplier selection and buyer-supplier engagement on relationship and firm performance. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 755–775. [Google Scholar] [CrossRef]

- Wu, D.; Olson, D.L. A comparison of stochastic dominance and stochastic DEA for vendor evaluation. Int. J. Prod. Res. 2008, 46, 2313–2327. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Azadi, M.; Jafarian, M.; Saen, R.F.; Mirhedayatian, S.M. A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers in sustainable supply chain management context. Comput. Oper. Res. 2015, 54, 274–285. [Google Scholar] [CrossRef]

- Azadnia, A.H.; Saman, M.Z.M.; Wong, K.Y. Sustainable supplier selection and order lot-sizing: An integrated multi-objective decision-making process. Int. J. Prod. Res. 2015, 53, 383–408. [Google Scholar] [CrossRef]

- Amindoust, A.; Ahmed, S.; Saghafinia, A.; Bahreininejad, A. Sustainable supplier selection: A ranking model based on fuzzy inference system. Appl. Soft Comput. 2012, 12, 1668–1677. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, K.; Zeng, B.; Xu, H.; Yang, Y. Supplier selection in nuclear power industry with extended VIKOR method under linguistic information. Appl. Soft Comput. 2016, 48, 444–457. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Bondi, C.A.M. Applying the precautionary principle to consumer household cleaning product development. J. Clean. Prod. 2011, 19, 429–437. [Google Scholar] [CrossRef]

- Hudson, J.; Orviska, M. Firms’ adoption of international standards: One size fits all? J. Policy Model. 2013, 35, 289–306. [Google Scholar] [CrossRef]

- Sammarra, A.; Biggiero, L. Identity and identification in industrial districts. J. Manag. Gov. 2001, 5, 61–82. [Google Scholar] [CrossRef]

- Cheng, C.; Xie, H.M.; Yang, Y.N.; Cao, B.L.; Cheng, X.M. Is it reason or feeling? The effect of the status area of the competitive behavior of “the attack-the reacting” in the enterprises in the dynamic competition. Manag. World 2015, 8, 132–169. [Google Scholar]

- Wang, C.C.; Ni, Q.; Shi, C.S.; Li, M. The differences of innovative enterprises growth in China: A quantitative analysis based on organizational identity theory. Sci. Technol. Prog. Policy 2015, 32, 100–104. [Google Scholar]

- DeVellis, R.F. Scale Development Theory and Applications, 2nd ed.; Sage Publications: London, UK, 2003. [Google Scholar]

- Bollen, K.A. Structural Equations with Latent Variables; Wiley: New York, NY, USA, 1989. [Google Scholar]

- Diamantopoulos, A.; Winklhofer, H. Index construction with formative indicators: An alternative to scale development. J. Mark. Res. 2001, 38, 269–277. [Google Scholar] [CrossRef]

- Fornell, C.; Bookstein, F.I. Two structural equation models: LISREL and PLS applied to consumer exit-voice theory. J. Mark. Res. 1982, 19, 440–452. [Google Scholar] [CrossRef]

- Bollen, K.A.; Davis, W.R. Causal indicator models: Identification, estimation, and testing. Struct. Equ. Model. 2009, 16, 498–522. [Google Scholar] [CrossRef]

- Diamantopoulos, A. The error term in formative measurement models: Interpretation and modeling implications. J. Model. Manag. 2005, 1, 7–17. [Google Scholar] [CrossRef]

- Chen, S.H. Construction of an Early Risk Warning Model of Organizational Resilience: An Empirical Study Based on Samples of R&D Teams. Discret. Dyn. Nat. Soc. 2016, 2016, 4602870. [Google Scholar]

- He, W. A Study on Evaluation of Modular Suppliers and Discussion of stability. Discret. Dyn. Nat. Soc. 2018, 2018, 4950740. [Google Scholar] [CrossRef]

| No | Firm Name | Industry | Interviewees |

|---|---|---|---|

| 1 | BYD Company Limited | Automobile, new energy and rail transit | Executive director, deputy purchasing director, production director |

| 2 | Shenzhen Huaxun ark Science & Technology Co., Ltd. | Semiconductor devices, microwave systems, millimeter wave systems, and terahertz micro electronics systems | General manager, purchasing directors |

| 3 | Hasee Computer Co., Ltd. | Laptops, desktops, LCD computers, LCD LCDs, and smart TVs | Head of purchasing department, head of production department |

| 4 | Sunwoda Electronic Co., Ltd. | Lithium ion battery module | General manager, head of purchasing department, head of quality management department |

| 5 | Changan PSA Automobiles Co. Ltd. | Automobile | General manager, purchasing deputy directors, supply section chief |

| First Tier Index | Second Tier Index | Third Tier Index | References |

|---|---|---|---|

| Modular Competency Criteria (MC) | Modular design and production competency (MCD) | Professional industry knowledge (MC1) | [44] |

| Technical development capability (MC2) | [45,46] | ||

| New technological identification (MC3) | [45] | ||

| Value analysis capability (MC4) | [47] | ||

| Modular management competency (MCM) | Engineering support (MC5) | [19] | |

| Integration capability (MC6) | [48] | ||

| Relationship management capability (MC7) | [14,49] | ||

| Compatibility capability (MC8) | [46] | ||

| Sustainability Criteria (SC) | Social responsibility implementation (SCR) | Contribution to the government (SC1) | [25,50] |

| Contribution to the investors (SC2) | [25,50] | ||

| Contribution to the employees (SC3) | [51,52] | ||

| Contribution to the suppliers (SC4) | [53] | ||

| Contribution to the community (SC5) | [25,50] | ||

| Environmental management (SCM) | Having environmental management certification (SC6) | [53,54] | |

| Protecting environmental resources (SC7) | [50,55] | ||

| Implementing clean production (SC8) | [56] | ||

| Passing ISO (International Organization for Standardization)14000 certification (SC9) | [57] | ||

| Organizational Identity Cognition Criteria (OI) | Cognition of the core features (OIC) | Cognition of the enterprise’s core value (OI1) | [58,59,60] |

| Cognition of the enterprise’s vision and mission (OI2) | [58,59,60] | ||

| Cognition of the distinctive features (OID) | Cognition of the enterprise’s core competitiveness and businesses (OI3) | [58,59,60] | |

| Cognition of the resources needed in the enterprise’s core businesses (OI4) | [58,59,60] |

| Dimension | Indicator | Weight (γ Coefficient) | t Value | Dimension | Indicator | Weight (γ Coefficient) | t Value | Dimension | Indicator | Weight (γ Coefficient) | t Value |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Modular competency (MC) | MC1 | 0.6539 | 4.503 | Sustainability (SC) | SC1 | 0.7247 | 5.421 | Organizational identity cognition (OI) | OI1 | 0.6739 | 4.363 |

| MC2 | 0.7841 | 6.364 | SC2 | 0.6338 | 2.836 | OI2 | 0.6224 | 3.048 | |||

| MC3 | 0.2753 | 2.067 | SC3 | 0.5842 | 2.369 | OI3 | 0.6593 | 4.604 | |||

| MC4 | 0.6037 | 2.573 | SC4 | 0.6421 | 3.073 | OI4 | 0.5881 | 2.348 | |||

| MC5 | 0.6439 | 2.936 | SC5 | 0.5903 | 2.410 | ||||||

| MC6 | 0.6328 | 2.745 | SC6 | 0.6741 | 4.588 | ||||||

| MC7 | 0.6080 | 2.594 | SC7 | 0.6194 | 2.974 | ||||||

| MC8 | 0.0710 | 0.7318 | SC8 | 0.7003 | 5.422 | ||||||

| SC9 | 0.6148 | 2.681 |

| Path | Correlation | T Value | Path | Correlation | T Value | ||

|---|---|---|---|---|---|---|---|

| MCD → MCD0 | 0.6035 | 13.6841 | 0.3538 | SCR → SCR0 | 0.6538 | 15.6372 | 0.3143 |

| MCM → MCM0 | 0.6763 | 14.8935 | 0.3790 | SCM → SCM0 | 0.5134 | 13.5129 | 0.3273 |

| MCD0 → MC | 0.2864 | 3.7042 | 0.3593 | SCR0 → SC | 0.2463 | 3.6937 | 0.3236 |

| MCM0 → MC | 0.1860 | 2.1743 | SCM0 → SC | 0.2153 | 3.4943 | ||

| OIC → OIC0 | 0.5283 | 11.3804 | 0.2639 | ||||

| OID → OID0 | 0.5672 | 12.0319 | 0.2973 | ||||

| OIC0 → OI | 0.3045 | 5.2984 | 0.2851 | ||||

| OID0 → OI | 0.2841 | 3.7640 |

| Category | Content | Standard |

|---|---|---|

| Statistical significance indicator | Significance of coefficient | T value should be bigger than 1.96 |

| Significance of path coefficient | T value should be bigger than 1.96 | |

| Significance of Chi-Square test | It should not be significant | |

| GFI | It should be bigger than 0.9 | |

| Statistical validity indicator | coefficient | Generally, it should be bigger than 0.6. The ideal value should be bigger than 0.7. |

| Path coefficient | Generally, it should be bigger than 0.2. The ideal value should be bigger than 0.3. | |

| Generally, it should be bigger than 0.2 |

| 1 | 0 | 0 | ||

| 0 | 1 | 1 | ||

| 1 | 0 | 0 | ||

| 1 | 0 | 1 |

| Sum | |||||

|---|---|---|---|---|---|

| The Target Layer | The First Layer | The Second Layer | The Third Layer |

|---|---|---|---|

| The index system of sustainable modular supplier selection | Modular competency | Modular design and production competency | Professional industry knowledge |

| Technical development capability | |||

| Value analysis capability | |||

| Modular management competency | Engineering support | ||

| Integration capability | |||

| Relationship management capability | |||

| Sustainability | Social responsibility implementation | Contribution to the government | |

| Contribution to the investors | |||

| Contribution to the employees | |||

| Contribution to the suppliers | |||

| Contribution to the community | |||

| Environmental management | Having environmental management certification | ||

| Protecting environmental resources | |||

| Implementing clean production | |||

| Passing ISO14000 certification | |||

| Organizational identity cognition | Cognition of the core features | Cognition of the enterprise’s core value | |

| Cognition of the enterprise’s vision and mission | |||

| Cognition of the distinctive features | Cognition of the enterprise’s core competitiveness and businesses | ||

| Cognition of the resources needed in the enterprise’s core businesses |

| Factor | First Tier Weight | Second Tier Weight | Third Tier Weight | Synthetic Weight |

|---|---|---|---|---|

| Professional industry knowledge | 0.322 | 0.533 | 0.389 | 0.0668 |

| Technical development capability | 0.422 | 0.533 | 0.389 | 0.0875 |

| Value analysis capability | 0.256 | 0.533 | 0.389 | 0.0531 |

| Engineering support | 0.322 | 0.467 | 0.389 | 0.0585 |

| Integration capability | 0.389 | 0.467 | 0.389 | 0.0707 |

| Relationship management capability | 0.289 | 0.467 | 0.389 | 0.0525 |

| Contribution to the government | 0.213 | 0.433 | 0.289 | 0.0267 |

| Contribution to the investors | 0.2 | 0.433 | 0.289 | 0.0250 |

| Contribution to the employees | 0.223 | 0.433 | 0.289 | 0.0279 |

| Contribution to the suppliers | 0.194 | 0.433 | 0.289 | 0.0243 |

| Contribution to the community | 0.17 | 0.433 | 0.289 | 0.0213 |

| Having environmental management certification | 0.222 | 0.567 | 0.289 | 0.0364 |

| Protecting environmental resources | 0.211 | 0.567 | 0.289 | 0.0346 |

| Implementing clean production | 0.294 | 0.567 | 0.289 | 0.0482 |

| Passing ISO14,000 certification | 0.273 | 0.567 | 0.289 | 0.0447 |

| Cognition of the enterprise’s core value | 0.6 | 0.533 | 0.322 | 0.1030 |

| Cognition of the enterprise’s vision and mission | 0.4 | 0.533 | 0.322 | 0.0687 |

| Cognition of the enterprise’s core competitiveness and businesses | 0.6 | 0.467 | 0.322 | 0.0902 |

| Cognition of the resources needed in the enterprise’s core businesses | 0.4 | 0.467 | 0.322 | 0.0601 |

| 0.3 | 0.4 | 0.2 | 0.5 | 0.3 | 0.2 | 0.4 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.2 | 0.3 | 0.6 | 0.3 | 0.4 | 0.3 | 0.4 | |

| 0.5 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 | 0.3 | 0.3 | 0.2 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 | 0.3 | 0.4 | 0.3 | |

| 0.2 | 0.2 | 0.3 | 0.2 | 0.2 | 0.3 | 0.2 | 0.2 | 0.3 | 0.3 | 0.2 | 0.3 | 0.3 | 0.3 | 0 | 0.3 | 0.2 | 0.2 | 0.3 | |

| 0 | 0.1 | 0.2 | 0 | 0.1 | 0.2 | 0 | 0.2 | 0.2 | 0.1 | 0.3 | 0 | 0.1 | 0 | 0 | 0 | 0.1 | 0.1 | 0 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, W. A Fuzzy Evaluation Model for Sustainable Modular Supplier. Information 2018, 9, 330. https://doi.org/10.3390/info9120330

He W. A Fuzzy Evaluation Model for Sustainable Modular Supplier. Information. 2018; 9(12):330. https://doi.org/10.3390/info9120330

Chicago/Turabian StyleHe, Wei. 2018. "A Fuzzy Evaluation Model for Sustainable Modular Supplier" Information 9, no. 12: 330. https://doi.org/10.3390/info9120330

APA StyleHe, W. (2018). A Fuzzy Evaluation Model for Sustainable Modular Supplier. Information, 9(12), 330. https://doi.org/10.3390/info9120330