A Fuzzy EWMA Attribute Control Chart to Monitor Process Mean

Abstract

:1. Introduction and Literature Review

2. The Fuzzy Attribute and Variable Schemes

2.1. Fuzzy Transformation Approaches

2.2. Some Fuzzy Formulae

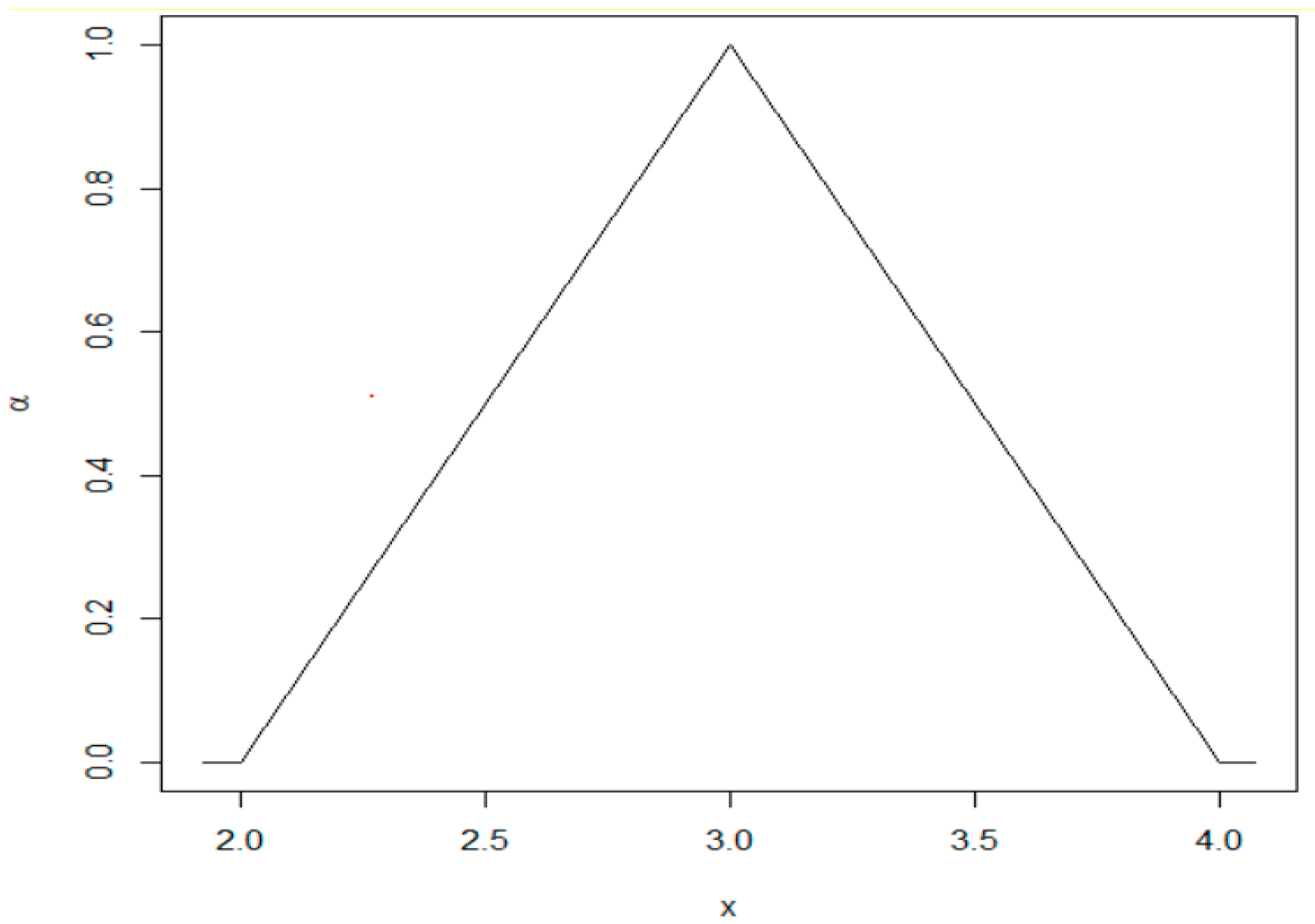

2.3. Triangular Fuzzy Number

3. The EWMA Control Chart to Monitor Process Mean

The Existing Fuzzy EMWA Control Chart

4. The Proposed FEWMA Scheme Based on the chart

4.1. Is Unknown and Is Small

4.2. Is Unknown and Is Large

4.3. The Control Limits in the α-Cuts Fuzzy EWMA Control Chart

4.4. The Control Limits in the α-Cut Fuzzy Median EWMA Scheme

5. The Application

The Simulation

- Generate a binomial random variable.

- Determine the in-control limits using K = 2.58, P = 0.65, λ = 0.2 so as the in-control ARL, ARL0, as a function of K, P1, and λ, becomes 371 using 10,000 simulations, each with 25 samples.

- Similarly, to estimate the ARL1, the process is simulated 100,000 times for an out-of-control process with P1 = 0.65. In this case, the ARL1, which is a function of K, P1, and λ, becomes 2.34.

- The same simulation process is repeated in a fuzzy environment, the difference being the use of fuzzy random variables.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Devor, R.E.; Chang, T.; Sutherland, J.W. Statistical Quality Design and Control, Contemporary Concepts and Methods; Pearson Education, Inc.: London, UK, 2007. [Google Scholar]

- Yang, S.F.; Tsai, W.C.; Huang, T.M.; Yang, C.C.; Cheng, S. Monitoring process mean with a new EWMA control chart. Production 2011, 21, 217–222. [Google Scholar]

- Raz, T.; Wang, J.H. Probabilistic and membership approaches in the construction of control chart for linguistic data. Prod. Plan. Control 1990, 1, 147–157. [Google Scholar] [CrossRef]

- Kanagawa, A.; Tamaki, F.; Ohta, H. Control charts for process average and variability based on linguistic data. Intell. J. Prod. Res. 1993, 31, 913–922. [Google Scholar] [CrossRef]

- Wang, J.H.; Raz, T. On the construction of control charts using linguistic variables. Intell. J. Prod. Res. 1990, 28, 477–487. [Google Scholar] [CrossRef]

- El-Shal, S.M.; Morris, A.S. A fuzzy rule-based algorithm to improve the performance of statistical process control in quality systems. J. Intell. Fuzzy Syst. 2000, 9, 207–223. [Google Scholar]

- Rowlands, H.; Wang, L.R. An approach of fuzzy logic evaluation and control in SPC. Qual. Reliab. Eng. Int. 2000, 16, 91–98. [Google Scholar] [CrossRef]

- Gülbay, M.; Kahraman, C.; Ruan, D. α-cut Fuzzy control charts for linguistic data. Int. J. Intell. Syst. 2004, 19, 1173–1196. [Google Scholar] [CrossRef]

- Cheng, C.B. Fuzzy process control: Construction of control charts with fuzzy numbers. Fuzzy Sets Syst. 2005, 154, 287–303. [Google Scholar] [CrossRef]

- Gülbay, M.; Kahraman, C. An alternative approach to fuzzy control charts: Direct fuzzy approach. Inf. Sci. 2007, 77, 1463–1480. [Google Scholar] [CrossRef]

- Faraz, A.; Moghadam, M.B. Fuzzy control chart a better alternative for Shewhart average chart. Qual. Quant. 2007, 41, 375–385. [Google Scholar] [CrossRef]

- Erginel, N. Fuzzy individual and moving range control charts with α-cuts. J. Intell. Fuzzy Syst. 2008, 19, 373–383. [Google Scholar]

- Sentürk, S.; Erginel, N. Development of fuzzy and control charts using α-cuts. Inf. Sci. 2009, 179, 1542–1551. [Google Scholar] [CrossRef]

- Sentürk, S. Fuzzy regression control chart based on α-cut approximation. Int. J. Comput. Intell. Syst. 2010, 3, 123–140. [Google Scholar] [CrossRef]

- Kaya, İ.; Kahraman, C. Process capability analyses based on fuzzy measurements and fuzzy control charts. Expert Syst. Appl. 2011, 38, 3172–3177. [Google Scholar] [CrossRef]

- Sentürk, S.; Erginel, N.; Kaya, İ.; Kahraman, C. Design of Fuzzy (u)over-tilde Control Charts. J. Mult. Valued Logic Soft Comput. 2011, 17, 459–473. [Google Scholar]

- Alipour, H.; Noorossana, R. Fuzzy multivariate exponentially weighted moving average control chart. Int. J. Adv. Manuf. Technol. 2010, 48, 1001–1007. [Google Scholar] [CrossRef]

- Sentürk, S.; Erginel, N.; Kaya, İ.; Kahraman, C. Fuzzy exponentially weighted moving average Control chart for univariate data with a real case application. Appl. Soft Comput. 2014, 22, 1–10. [Google Scholar] [CrossRef]

- Khademi, M.; Amirzadeh, V. Fuzzy rules for fuzzy and R control charts. Iran. J. Fuzzy Syst. 2014, 11, 55–56. [Google Scholar]

- Kahraman, C.; Gülbay, M.; Boltürk, E. Fuzzy Shewhart Control Charts. In Fuzzy Statistical Decision-Making. Studies in Fuzziness and Soft Computing; Springer: Cham, Switzerland, 2016; Volume 343. [Google Scholar]

- Zadeh, L.A. Information and control. Fuzzy Sets 1965, 8, 338–353. [Google Scholar]

- Ross, T.J. Fuzzy Logic with Engineering Applications; John Wiley & Sons: Singapore, 2004. [Google Scholar]

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons: New York, NY, USA, 1991; Volume 351. [Google Scholar]

| Sample | Fuzzy Proportion | α-Cuts for the Proportion | Fuzzy EWMAs | Fuzzy (EWMA-med) | |

|---|---|---|---|---|---|

| 1 | (4,5,6) | (4.65,5,5.35) | (3.6,4.84,6.32) | 4.92 | In-control |

| 2 | (3,4,5) | (3.65,4,4.35) | (3.8,4.8,5.8) | 4.80 | In-control |

| 3 | (5,6,7) | (5.65,6,6.35) | (3.4,4.4,5.4) | 4.40 | In-control |

| 4 | (2,3,4) | (2.65,3,3.35) | (5.05,5.4,5.75) | 5.40 | In-control |

| 5 | (6,5,7) | (6.65,6,6.35) | (4.80,6.3,6.46) | 4.60 | In control |

| 6 | (3,4,5) | (3.65,4,4.35) | (4.6,5.6,6.6) | 4.93 | In-control |

| 7 | (4,6,7) | (4.65,3,2,3.25) | (3.40,4.6,4.7) | 4.63 | In-control |

| 8 | (3,4,5) | (3.65,4,4.35) | (4.6,5.6,6.6) | 4.93 | In-control |

| 9 | (4,5,6) | (4.65,5,5.35) | (3.2,4.2,5.2) | 4.20 | In-control |

| 10 | (6,7,8) | (6.65,7,7.35) | (4.4,5.4,6.4) | 5.40 | In-control |

| P | 0.25 | 0.35 | 0.45 | 0.55 | 0.613 | 0.65 | 0.75 | 0.85 | 0.95 |

|---|---|---|---|---|---|---|---|---|---|

| n | |||||||||

| 9 | 1.0 | 1.0 | 1.0 | 1.00 | 3.61 | 5.57 | 3.04 | 1.02 | 1.0 |

| 10 | 1.0 | 1.0 | 1.0 | 1.55 | 4.11 | 3.06 | 3.45 | 1.06 | 1.0 |

| 11 | 1.0 | 1.0 | 1.0 | 4.70 | 3.61 | 3.48 | 3.12 | 1.05 | 1.0 |

| 12 | 1.0 | 1.0 | 1.0 | 1.37 | 1.37 | 3.15 | 3.06 | 1.30 | 1.0 |

| 13 | 1.0 | 1.0 | 1.0 | 1.02 | 1.50 | 2.82 | 2.37 | 1.23 | 1.0 |

| 14 | 1.0 | 1.0 | 1.0 | 1.005 | 1.13 | 2.99 | 2.87 | 1.05 | 1.0 |

| 15 | 1.0 | 1 | 1.003 | 3.07 | 4.26 | 16.91 | 2.26 | 1.01 | 1.0 |

| P | 0.25 | 0.35 | 0.45 | 0.55 | 0.613 | 0.65 | 0.75 | 0.85 | 0.95 |

|---|---|---|---|---|---|---|---|---|---|

| n | |||||||||

| 9 | 1.0 | 1.0 | 1.34 | 5.41 | 48.06 | 188.53 | 6.35 | 1.32 | 1.0 |

| 10 | 1.0 | 1.0 | 1.14 | 5.40 | 86.40 | 330.32 | 6.17 | 1.07 | 1.0 |

| 11 | 1.0 | 1.0 | 1.23 | 4.26 | 105.68 | 575.78 | 5.48 | 1.04 | 1.0 |

| 12 | 1.0 | 1.0 | 1.11 | 4.54 | 101.57 | 743.43 | 4.56 | 1.08 | 1.0 |

| 13 | 1.0 | 1.0 | 1.21 | 4.41 | 104.52 | 1000.35 | 4.64 | 1.10 | 1.0 |

| 14 | 1.0 | 1.0 | 1.05 | 3.32 | 181.62 | 1200.14 | 3.79 | 1.0 | 1.0 |

| 15 | 1.0 | 3.33 | 1.03 | 3.21 | 178.23 | 1330.43 | 3.87 | 1.0 | 1.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.Z.; Khan, M.F.; Aslam, M.; Niaki, S.T.A.; Mughal, A.R. A Fuzzy EWMA Attribute Control Chart to Monitor Process Mean. Information 2018, 9, 312. https://doi.org/10.3390/info9120312

Khan MZ, Khan MF, Aslam M, Niaki STA, Mughal AR. A Fuzzy EWMA Attribute Control Chart to Monitor Process Mean. Information. 2018; 9(12):312. https://doi.org/10.3390/info9120312

Chicago/Turabian StyleKhan, Muhammad Zahir, Muhammad Farid Khan, Muhammad Aslam, Seyed Taghi Akhavan Niaki, and Abdur Razzaque Mughal. 2018. "A Fuzzy EWMA Attribute Control Chart to Monitor Process Mean" Information 9, no. 12: 312. https://doi.org/10.3390/info9120312

APA StyleKhan, M. Z., Khan, M. F., Aslam, M., Niaki, S. T. A., & Mughal, A. R. (2018). A Fuzzy EWMA Attribute Control Chart to Monitor Process Mean. Information, 9(12), 312. https://doi.org/10.3390/info9120312