Reliability Analysis of the High-speed Train Bearing Based on Wiener Process

Abstract

:1. Introduction

2. Random Degradation Model

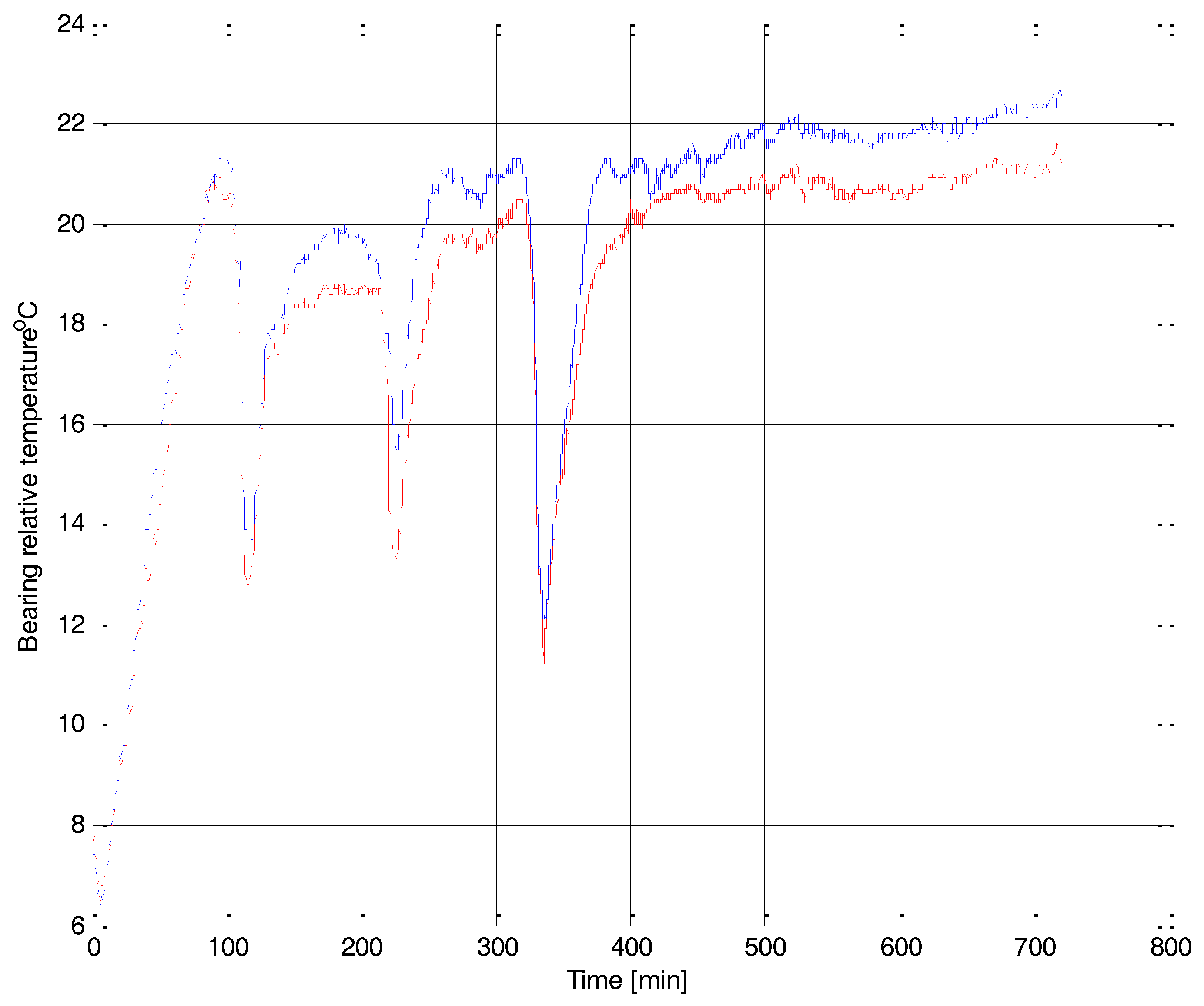

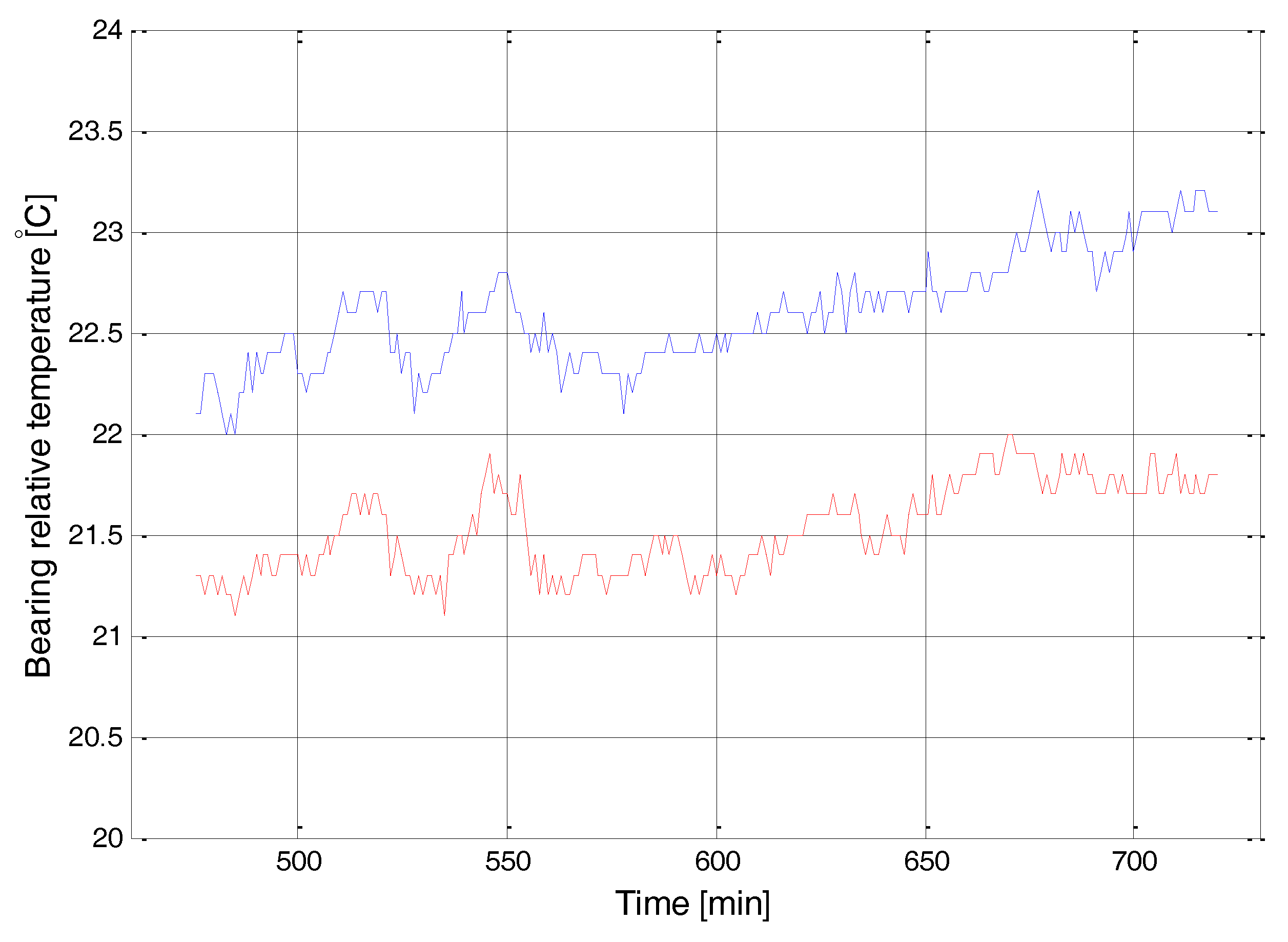

2.1. Model Assumption

- Product failure is caused by degradation, and degradation failure shows that the change trend of a certain performance parameter is monotonous over time. Let Z(t) denote the performance parameter value at time t. The measured data, written as X(t), corresponding to Z(t), are called “degraded.” The measured error is written as ε(t). Thus, we have Z(t) = X(t) + ε(t). In this paper, we would not consider the measured error, i.e., Z(t) = X(t).

- The tested samples are randomly selected. The test condition and the measurement errors of all products are the same.

- The observed values of the performance parameters obey the independent and identical distribution at all times, whether it is continuous damage or is discrete. The measure is nondestructive.

- The product is identified as a failure when the performance degradation value increases to the failure threshold l.

2.2. Degradation Model

X2(t1), X2(t2), …, X2(tm)

… … … …

Xn(t1), Xn(t2), …, Xn(tm)

- (1)

- Collect the degradation data, make the statistical analysis, remove the anomalous data, and judge which distribution is coincident with the performance degradation value at every moment.

- (2)

- Solve the average and variance of performance degradation value at all times and finally computing the reliability of the tested bearings.

3. Parameter Estimation

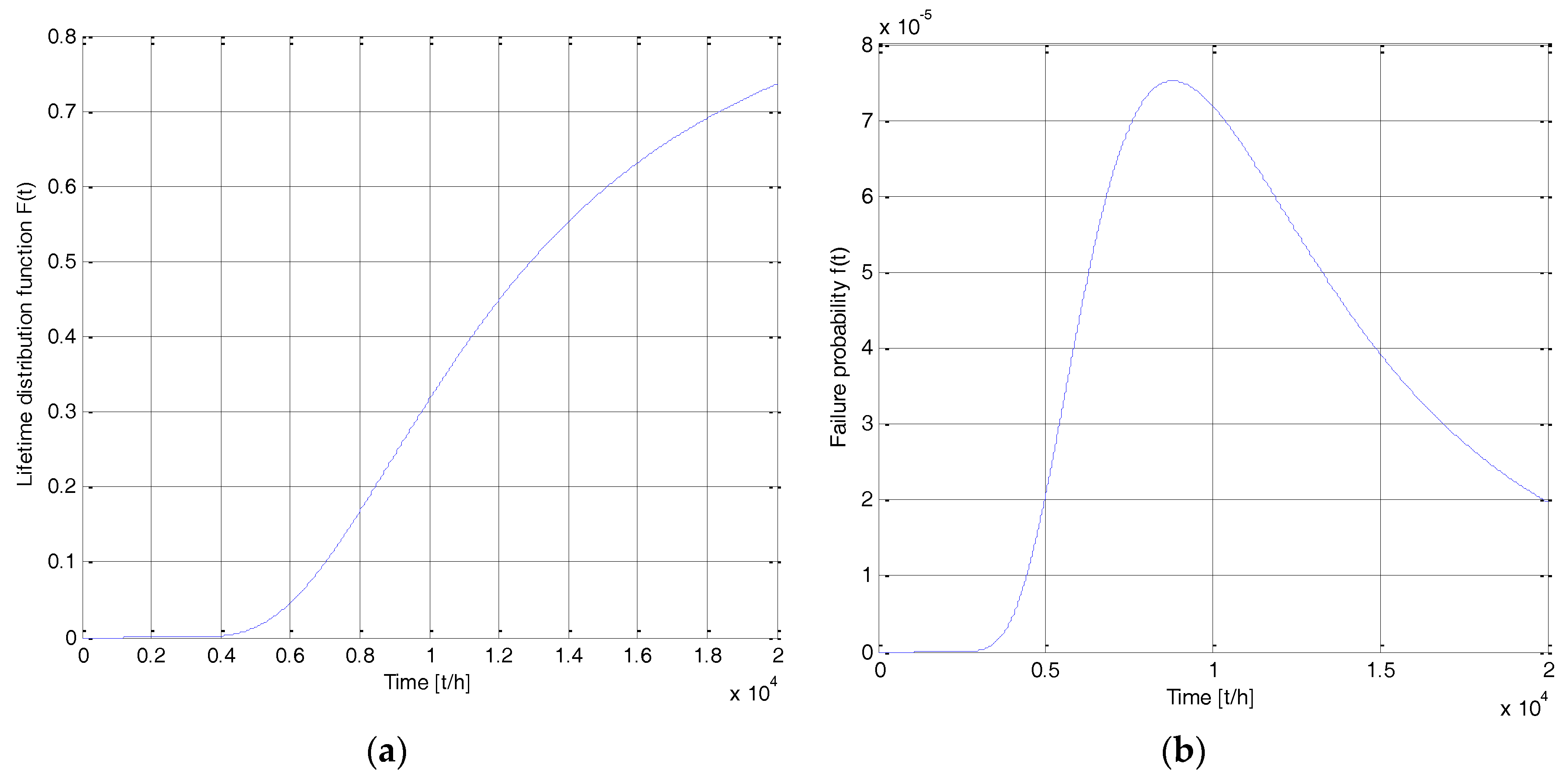

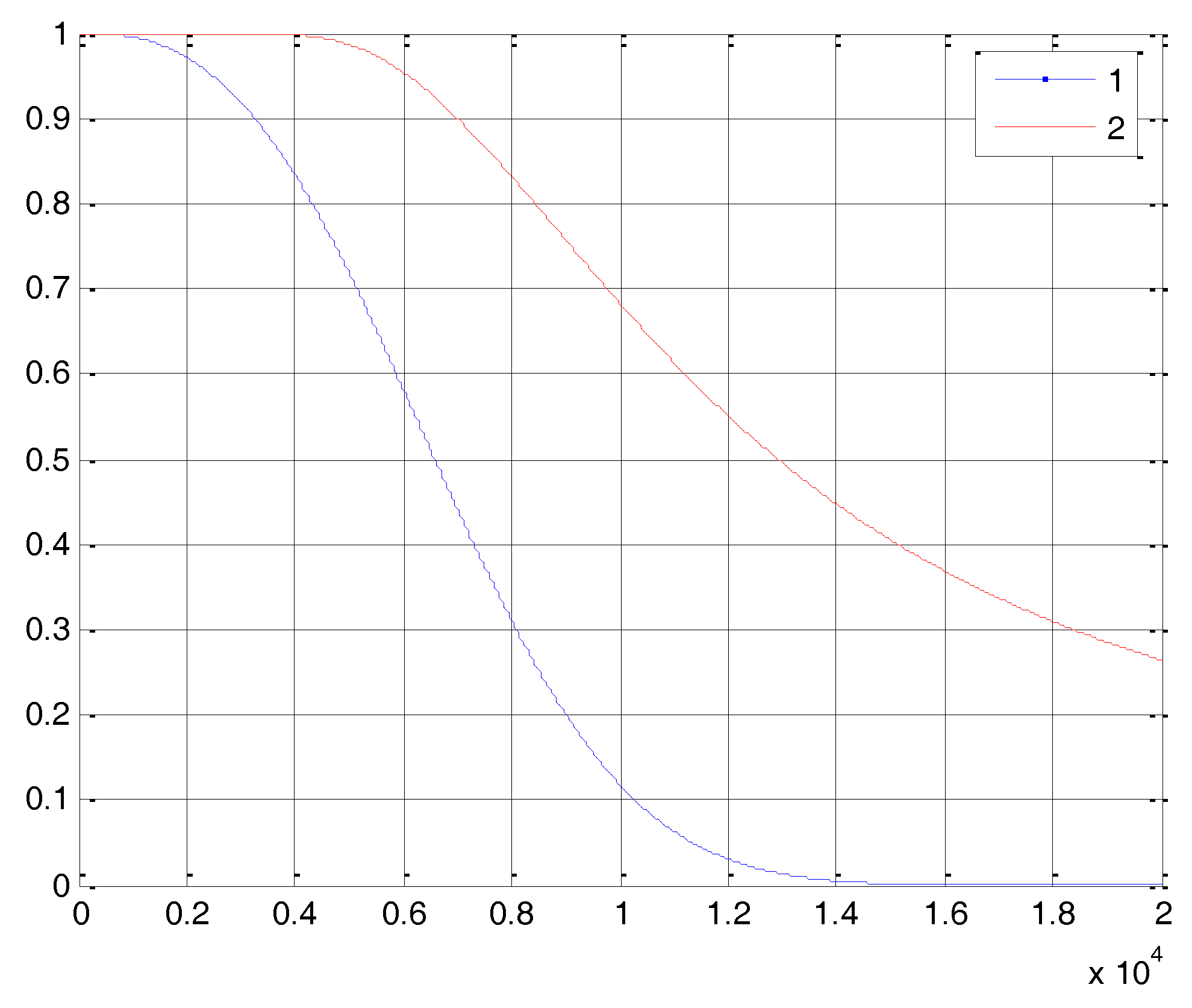

4. Example Analysis

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Si, X.; Wang, W.; Hu, C.; Zhou, D. Estimating remaining useful life with three-source variability in degradation modeling. IEEE Trans. Reliab. 2014, 63, 167–190. [Google Scholar] [CrossRef]

- Jiang, X.; Liu, H.; Zi, J.; Liu, J. Extremely small sample’s reliability of motorized spindle based on Bayes method. J. Vib. Shock 2015, 34, 121–127. [Google Scholar]

- Cai, Z.; Chen, Y.; Li, S.; Wang, Z. Residual Lifetime Prediction Method with Random Degradation and Information Fusion. J. Shanghai Jiao Tong Univ. 2016, 50, 1778–1783. [Google Scholar]

- Zhang, Z.; Si, X.; Hu, C.; Pecht, M. A Prognostic Model for Stochastic Degrading Systems with State Recovery: Application to Li-Ion Batteries. IEEE Trans. Reliab. 2017, 66, 1293–1308. [Google Scholar] [CrossRef]

- Zheng, J.; Hu, C.; Si, X.; Zhang, X. Remaining Useful Life Estimation for Nonlinear Stochastic Degrading Systems with Uncertain Measurement and Unit-to-unit Variability. Acta Autom. Sin. 2017, 43, 259–270. [Google Scholar]

- Pan, Z.; Balakrishnan, N. Multiple-steps step-stress accelerated degradation modeling based on Wiener and gamma processes. Commun. Stat. Simul. Comput. 2010, 39, 1384–1402. [Google Scholar] [CrossRef]

- Pan, Z.; Balakrishnan, N.; Sun, N. Bivariate degradation analysis of products based on Wiener processes and copulas. J. Stat. Comput. Simul. 2013, 83, 1316–1329. [Google Scholar] [CrossRef]

- Pan, Z.; Zhou, J.; Peng, B. Optimal design for accelerated degradation tests with several stresses based on Wiener process. Syst. Eng. Theory Pract. 2009, 29, 64–71. [Google Scholar] [CrossRef]

- Wang, H.; Xu, T.; Mi, Q. Lifetime prediction based on Gamma processes from accelerated degradation data. Chin. J. Aeronaut. 2015, 28, 172–179. [Google Scholar] [CrossRef]

- Tsai, C.C.; Tseng, S.T.; Balakrishnan, N. Optimal design for degradation tests based on Gamma processes with random effects. IEEE Trans. Reliab. 2012, 61, 604–613. [Google Scholar] [CrossRef]

- Lee, M.L.T.; Whitmore, G.A. Threshold regression for survival analysis: Modeling event times by a stochastic process reaching a boundary. Stat. Sci. 2006, 21, 501–513. [Google Scholar] [CrossRef]

- Tsai, C.C.; Tseng, S.T.; Balakrishnan, N. Mis-specification analyses of Gamma and Wiener degradation processes. J. Stat. Plan. Inference 2011, 141, 3725–3735. [Google Scholar] [CrossRef]

- Kim, Y.S.; Sung, S. Practical lifetime estimation strategy based on partially step-stress-accelerated degradation tests. Proc. Instit. Mech. Eng. J. Risk Reliab. 2017, 231, 605–614. [Google Scholar] [CrossRef]

- Balka, J.; Desmond, A.F.; McNicholas, P.D. Review and implementation of cure models based on first hitting times for Wiener Processes. Lifetime Data Anal. 2009, 15, 147–176. [Google Scholar] [CrossRef] [PubMed]

- Chikkara, R.S.; Folks, J.L. The Inverse Gaussian Distribution; Marcell Dekker: New York, NY, USA, 1989. [Google Scholar]

- Yang, X. Overview of High Speed Rail Bearings. Bearings 2011, 10, 59–61. [Google Scholar]

- Zhu, D.; Liu, H.; Yuan, D. Time determination and life assessment of high-speed railway bearing reliability test. China Mech. Eng. 2014, 25, 2886–2891. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, D.; Nan, C. Reliability Analysis of the High-speed Train Bearing Based on Wiener Process. Information 2018, 9, 15. https://doi.org/10.3390/info9010015

Zhu D, Nan C. Reliability Analysis of the High-speed Train Bearing Based on Wiener Process. Information. 2018; 9(1):15. https://doi.org/10.3390/info9010015

Chicago/Turabian StyleZhu, Dexin, and Cui Nan. 2018. "Reliability Analysis of the High-speed Train Bearing Based on Wiener Process" Information 9, no. 1: 15. https://doi.org/10.3390/info9010015

APA StyleZhu, D., & Nan, C. (2018). Reliability Analysis of the High-speed Train Bearing Based on Wiener Process. Information, 9(1), 15. https://doi.org/10.3390/info9010015