1. Introduction

The rapidly changing marketplace leads to companies seeking competitiveness for their products with respect to innovation, higher performance, lower prices and more functionality. Since companies’ resources are limited, the top-level management tends to set-up the main competiveness with minimum resources. Therefore, it is very important to establish a systematic approach for designing solutions in the early phases of design, since solutions in the early design stages play a critical role for the competitiveness of product development.

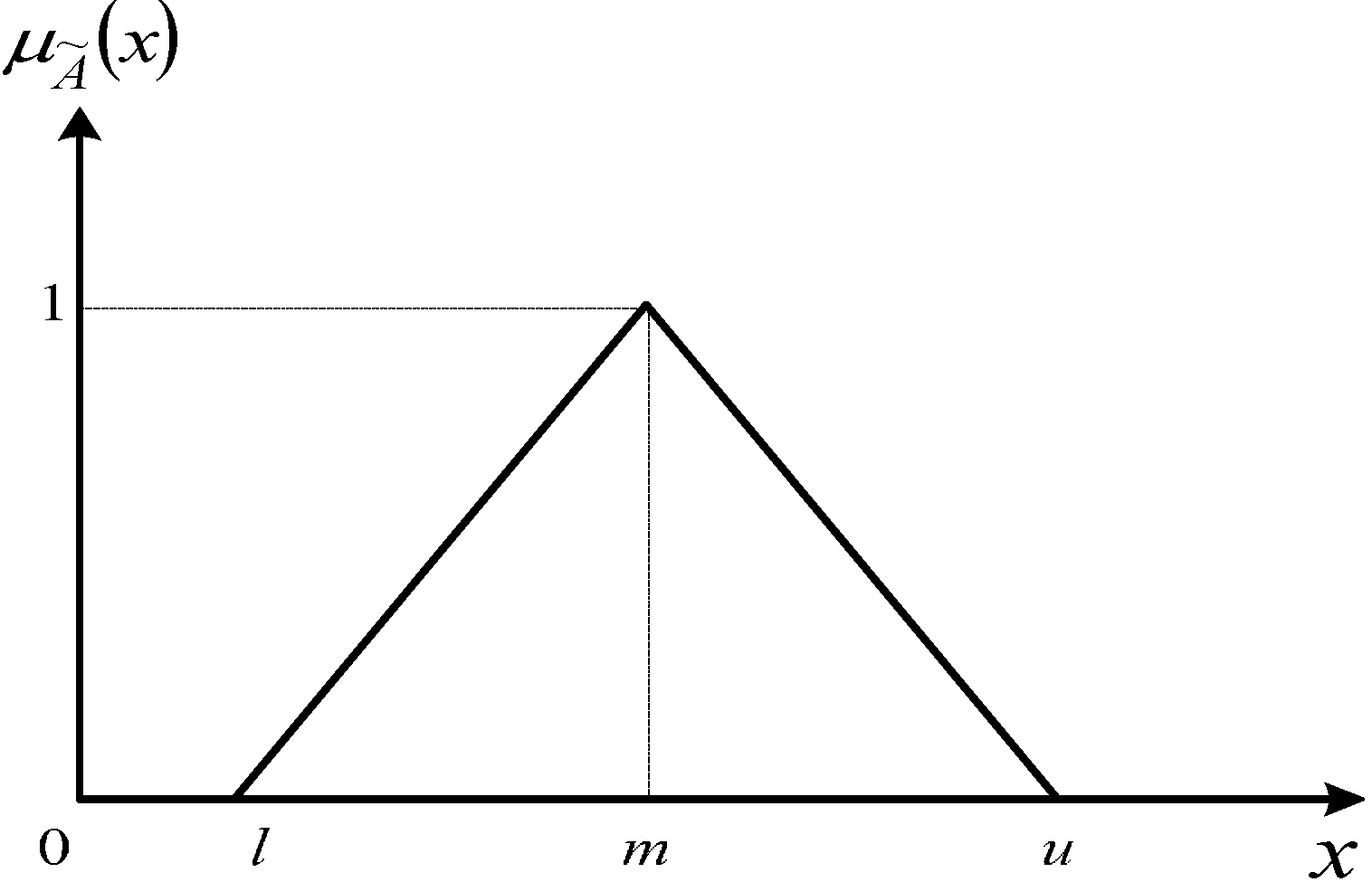

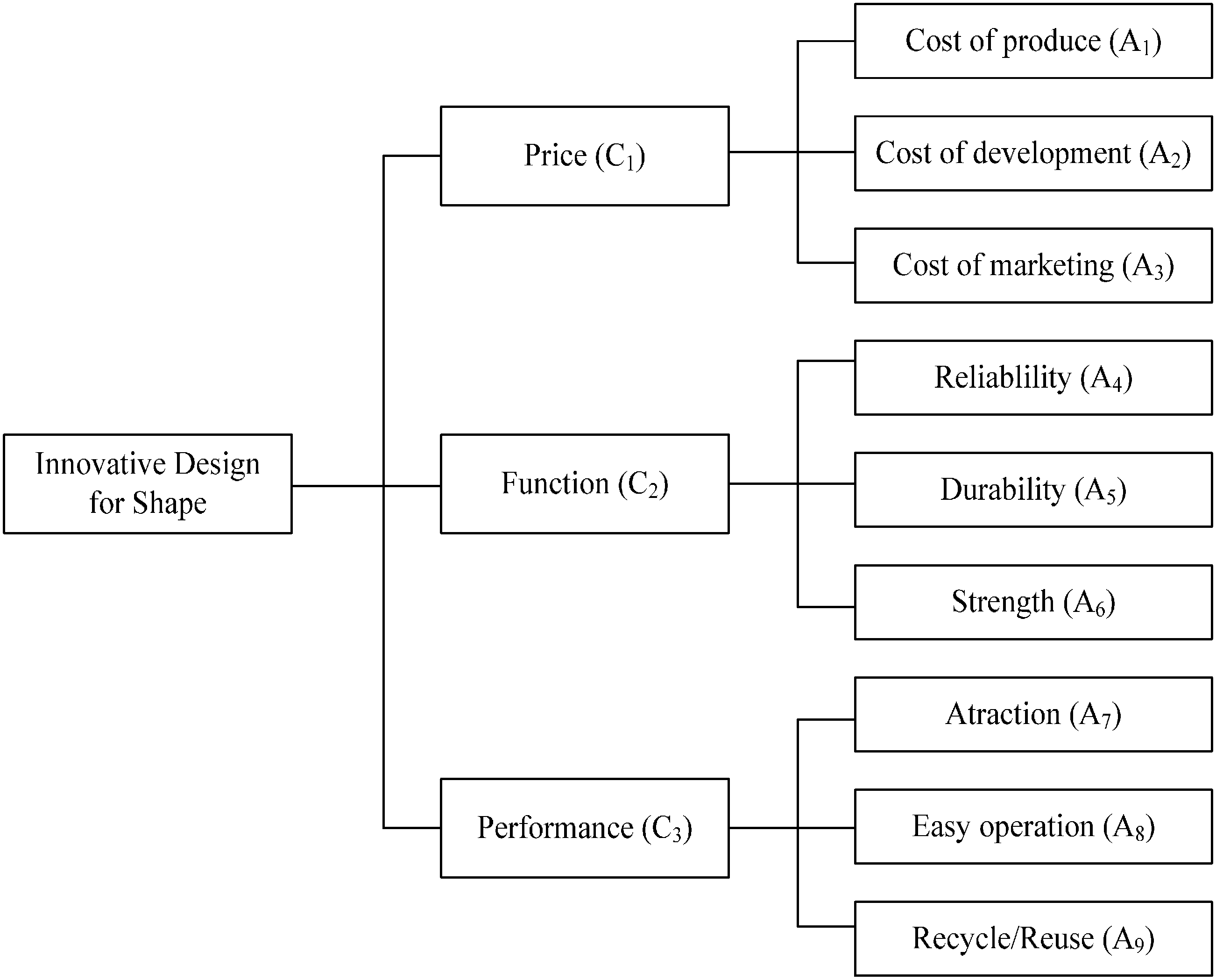

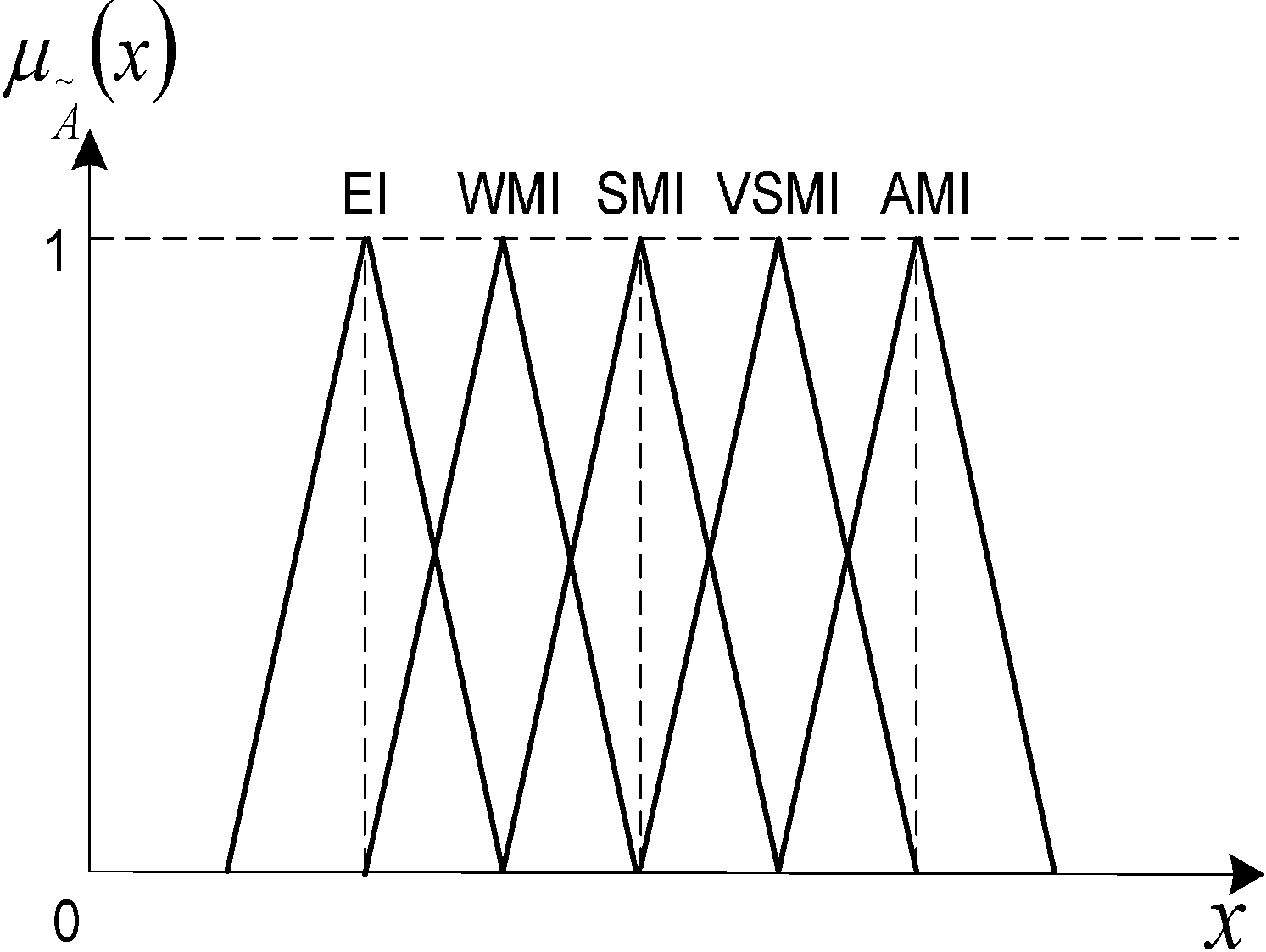

Innovation is a new idea, device or process. It can be viewed as the application of better solutions to meet new requirements, unarticulated needs or existing market needs. TRIZ is a knowledge-based method of inventive problem-solving. It can offer concepts and tools to facilitate the concept creation and problem-solving. On the other hand, lean production is a management philosophy and a systematic method for the elimination of waste within a manufacturing process. In practice, both the lean production concept and innovative design concept cannot be quantified precisely. However, fuzzy set theory can be employed to deal with the uncertainty due to imprecision or vagueness, and the AHP can be applied to solve multiple criteria decision-making problems. Hence, in this research, we apply the TRIZ and FAHP based on the lean production concept to design an innovative shape for machine tools to meet the requirement of the companies’ competitiveness.

Our review of the literature shows that TRIZ and fuzzy, as well as multiple-criteria decision-making (MCDM) are widely used to deal with many issues of enterprise. The applications of these tools are briefly discussed in the following. Rosli

et al. [

1] use an AHP-TRIZ innovation method to design an automotive door panel. Chen [

2] takes an application of a hybrid dynamic MCDM to explore the key factors for the internal control of procurement circulation. Tompkins

et al. [

3] use the TRIZ method to derive the technology forecasting of CCD and CMOS digital imaging technology. Ding

et al. [

4] use the MCDM method to develop a model for optimal maintenance policy selection. Dong

et al. [

5] use an automatic method to reach consensus in a local context for AHP group decision-making. Ishizaka [

6] applied fuzzy logic and AHP for supplier selection. Ishizaka and Nguyen [

7] use the method of calibrated fuzzy AHP to develop a model for current bank account selection. A review of the literature [

1,

2,

3,

4,

5,

6,

7] shows that most research in the applicability of TRIZ or FAHP is focused on the improvement of manufacturing, quality and procurement management of innovative designs. From the review of the literature, we know from Rosli

et al. [

1] that the factors of AHP were independence and certainty. However, in our study, we assume that the innovative design concept and lean production concept are vague. We demonstrate how to apply the TRIZ and FAHP to make new innovative changes in the design for a new product under the concept of lean production. This study applies the contradiction matrix table, 40 innovative principles and 39 engineering parameters to tackle the trade-off between design contradictions and engineering parameters, while at the same time, the project team can acquire more inspiration and feasible solutions through the proposed approach. However, due to vagueness and uncertainty in the decision-makers’ judgments, we adopted a FAHP method as a decision support tool that can adequately represent qualitative and subjective assessments for the independent factors under the multiple criteria decision-making environment. Based on the TRIZ-FAHP synergy, the authors selected the top five criteria (cost of production, cost of development, reliability, costs of marketing, attractiveness) from the AHP method as the main objectives and in view of certain subjective and objective aspects to collect the relevant principles from the TRIZ matrix, in order to complete the innovative design of a new shape for machine tools.

This paper is composed of the following:

Section 2 shows the introduction of the hybrid-method about TRIZ, and a FAHP method is illustrated.

Section 3 provides an application of innovative design for a new shape of machine tools. Finally, the last section highlights the most relevant results of the authors’ work and proposes possible extensions.

4. Conclusions

This is the first time, a TRIZ is used to propose the alternatives of a shape’s design under innovative design considerations and using a FAHP to evaluate and select the best feasible alternative under a multiple criteria decision-making environment in the machine tools industry. This work applied TRIZ-FAHP to develop the new shape of machine tools and demonstrates the development of innovative design for a new shape. If a design project includes a contradiction structure to be overcome, it is necessary to generate a novel solution from the systems point of view. For this purpose, an idea generation approach has been proposed in which the TRIZ contradiction matrix was adopted based on expert knowledge. The method enables the knowledge incorporated in TRIZ to be used in innovation design. The system of shape design is followed with an innovative approach, TRIZ. Although more than one design is probable, a multi-criteria decision-making, FAHP, is able to evaluate and suggest the most suitable design. The integration of an innovative design tool, TRIZ, and multi-criteria decision-making, FAHP, is used in this research and indicates that it is likely to be a reliable and promising form of hybrid method in new shape design. According to the TRIZ-FAHP synergy and the concept of lean production, the authors selected the top five criteria (cost of production, cost of development, reliability, cost of marketing, attractiveness) from the FAHP method as the main design objectives, and in view of certain subjective and objective aspects, to collect the relevant principles from the TRIZ matrix and to complete the innovative shape design of machine tools. From this case study, the benefits of this new innovative design shape, used with TRIZ-FAHP, are better than the old design for machine tools based on the concept of lean production.

In summary, we applied the TRIZ and FAHP to design an innovative new shape of machine tools for machine tools based on the concept of lean production. Our research has demonstrated that the use of an integrated hybrid-method of innovative design and multi-criteria decision-making tools for new shape design has enabled shape designers to improve the efficiency of the design task. Designing the best shape for a new product and expanding knowledge to the other industries is the contribution of our research.

Acknowledgments

This research was supported by The Vetica Group Company, 2F, No.11-1 Sec., Chongqing S. Rd., Taipei, Taiwan. Much appreciation goes to Sampaio Rui and Min Hau Lee for taking part in the project of innovation design of new shape for machine tools. This research was funded by the National Science Council of Taiwan under Grant No. MOST 103-2221-E-035-052.

Author Contributions

Ho-Nien Hsieh initiated the idea of the work. Jeng-Fung Chen conducted the literature review. Quang Hung Do collected the experts’ opinions. All of the authors developed the research design and implemented the research. All authors have read and approved the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rosli, M.U.; Ariffin, M.K.A.; Sapuan, S.M.; Sulaiman, S. Integrated AHP-TRIZ innovation method for automotive door panel design. Int. J. Eng. Technol. 2013, 5, 3158–3167. [Google Scholar]

- Chen, F.H. Application of a hybrid dynamic MCDM to explore the key factors for the internal control of procurement circulation. Int. J. Prod. Res. 2014. [Google Scholar] [CrossRef]

- Tompkins, M.; Price, T.; Clapp, T. Technology forecasting of CCD and CMOS digital imaging technology using TRIZ. Available online: http://www.triz-journal.com/archives/year/ (accessed on 30 October 2014).

- Dong, Y.; Xu, W.; Xu, W. An automatic method to reach consensus in a local context for AHP group decision making. Eur. J. Ind. Eng. 2013, 7, 456–474. [Google Scholar] [CrossRef]

- Yuluğkural, Y.; Yörür, B.; Akman, G.; Aladağ, Z. Assessment of model validity of analytic network process using structural equations modelling: An application of supplier evaluation problem. Eur. J. Ind. Eng. 2013, 7, 55–77. [Google Scholar] [CrossRef]

- Ishizaka, A. Combining fuzzy logic and AHP for supplier selection. Int. J. Integr. Supply Manag. 2014, 9, 1–22. [Google Scholar] [CrossRef]

- Ishizaka, A.; Nguyen, N.H. Calibrated fuzzy AHP for current bank account selection. Expert Syst. Appl. 2013, 40, 3775–3783. [Google Scholar] [CrossRef]

- Savranksy, S.D. Materiality, design, and creativity. In Materials and Design, 3rd ed.; Ashby, M., Johnson, K., Eds.; CRC Press: Boca Raton, FL, USA, 2000; pp. 34–61. [Google Scholar]

- Souchkov, V. Accelerate Innovation with TRIZ. Available online: http://www.xtriz.com/publications/Accelerate Innovation with TRIZ (accessed on 22 October 2014).

- Altshuller, G. The Innovation Algorithm: TRIZ, Systematic Innovation, and Technical Creativity; Technical Innovation Centre: Worcester, MA, USA, 1999. [Google Scholar]

- Gadd, K. TRIZ for Engineers; John Wiley & Sons: West Sussex, UK, 2011. [Google Scholar]

- Livotov, P. TRIZ and Innovation Management. Available online: http://www.triz.it/triz_papers 20% TRIZ 20% and 20%Innovation 20%Management (accessed on 15 October 2014).

- Barry, K.; Domb, E.; Slocum, M.S. What is TRIZ? TRIZ J. 2011. Available online: http://www.triz-journal.com/archives/what_is_triz/ (accessed on 19 October 2014).

- Nakagawa, T. Introduction to TRIZ (Theory of Inventive Problem Solving): A technological philosophy for creative problem solving. Jpn. Creat. Soc. 2001. Available online: http://www.osakagu.ac.jp/php/nakagawa/TRIZ/eTRIZ/epapers/eIntro011223/eIntroJCS011104.htmlS (accessed on 17 October 2014).

- Rantanen, K.; Domb, E. Simplified TRIZ—New Problem Solving Applications for Engineers and Manufacturing Professionals; Auerbach Publications: New York, NY, USA, 2008. [Google Scholar]

- Souchkov, V. A Brief History of TRIZ. Available online: http://www.xtriz.com/BriefHistoryOfTRIZ.pdf (accessed on 30 October 2014).

- Moehrle, M.G. What is TRIZ: From conceptual basics to a framework for research. Creat. Innov. Manag. 2005, 14, 3–13. [Google Scholar] [CrossRef]

- Pannenbaecker, T. Methodisches Erfinden in Unternehmen; Gabler-Verlag: Wiesbaden, Germany, 2001. [Google Scholar]

- Zlotin, B.; Zusman, A.; Kaplan, L.; Visnepolschi, S.; Proseanic, V.; Malking, S. TRIZ beyond technology: The theory and practice of applying TRIZ to non-technical areas. Available online: http://www.trizmantra.com/Learning20%Resource20%files/TRIZ_Beyond_Technology (accessed on 27 October 2014).

- Zadeh, L.A. Fuzzy set. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Zimmermann, H.J. Fuzzy Set Theory and its Applications; Kluwer: Boston, MA, USA, 1992. [Google Scholar]

- Kaufmann, A.; Gupta, M.M. Introduction to Fuzzy Arithmetic: Theory and Applications; Van Nostrand Reinhold Co.: New York, NY, USA, 1991. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; Mc Graw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Van-Laarhoven, P.J.M.; Pedrycz, W. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst. 1983, 11, 229–241. [Google Scholar] [CrossRef]

- Buckley, J.J.; Feuring, T.; Hayashi, Y. Proceedings of the International Fuzzy Systems Conference on Fuzzy Hierarchy Analysis, Seoul, Korea, 22–25 August 1999; pp. 402–408.

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Op. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Buyukozkan, G.; Kahraman, C.; Ruan, D. A fuzzy multi-criteria decision approach for software development strategy selection. Int. J. Gen. Syst. 2004, 33, 259–280. [Google Scholar] [CrossRef]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Kahraman, C.; Ertay, T.; Buyukozkan, G. A fuzzy optimization model for QFD planning process using analytic network approach. Eur. J. Op. Res. 2006, 171, 390–411. [Google Scholar] [CrossRef]

- Chen, C.F. Determining the attribute weights of professional conference organizer selection: An application of the fuzzy AHP approach. Tour. Econ. 2011, 17, 1129–1139. [Google Scholar] [CrossRef]

- Lee, E.S.; Li, R.J. Comparison of fuzzy numbers based on the probability measure of fuzzy events. Comput. Math. Appl. 1998, 15, 887–896. [Google Scholar] [CrossRef]

- Golden, B.L. The Analytic Hierarchy Process: Applications and Studies; Springer-Verlag: New York, NY, USA, 1989. [Google Scholar]

- Forman, E.; Peniwati, K. Aggregating individual judgments and priorities with the AHP. Eur. J. Op. Res. 1998, 108, 165–169. [Google Scholar] [CrossRef]

- Davies, M.A.P. A Multi-criteria Decision Model Application for Managing Group Decisions. J. Op. Res. Soc. 1994, 45, 47–58. [Google Scholar] [CrossRef]

- Aczel, J.; Roberts, F.S. On the possible merging functions. Math. Soc. Sci. 1989, 17, 205–243. [Google Scholar] [CrossRef]

- Buyukozkam, G.; Feyzioglu, O. A fuzzy logic based decision-making approach for new product development. Int. J. Prod. Econ. 2004, 90, 27–45. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).