The Future Is Organic: A Deep Dive into Techniques and Applications for Real-Time Condition Monitoring in SASO Systems—A Systematic Review

Abstract

1. Introduction

- Overview of real-time CM techniques with SASO properties.

- Taxonomy and categorization of existing studies based on the implemented techniques, application domains, input data, and predictive approaches for CM in SASO systems.

- Analysis of self-* properties and the extent to which SASO system requirements are fulfilled.

- Exploration of high-frequency monitoring and CM system processing time

- Deriving research gaps and proposing a structured research agenda for future investigation

2. Related Works

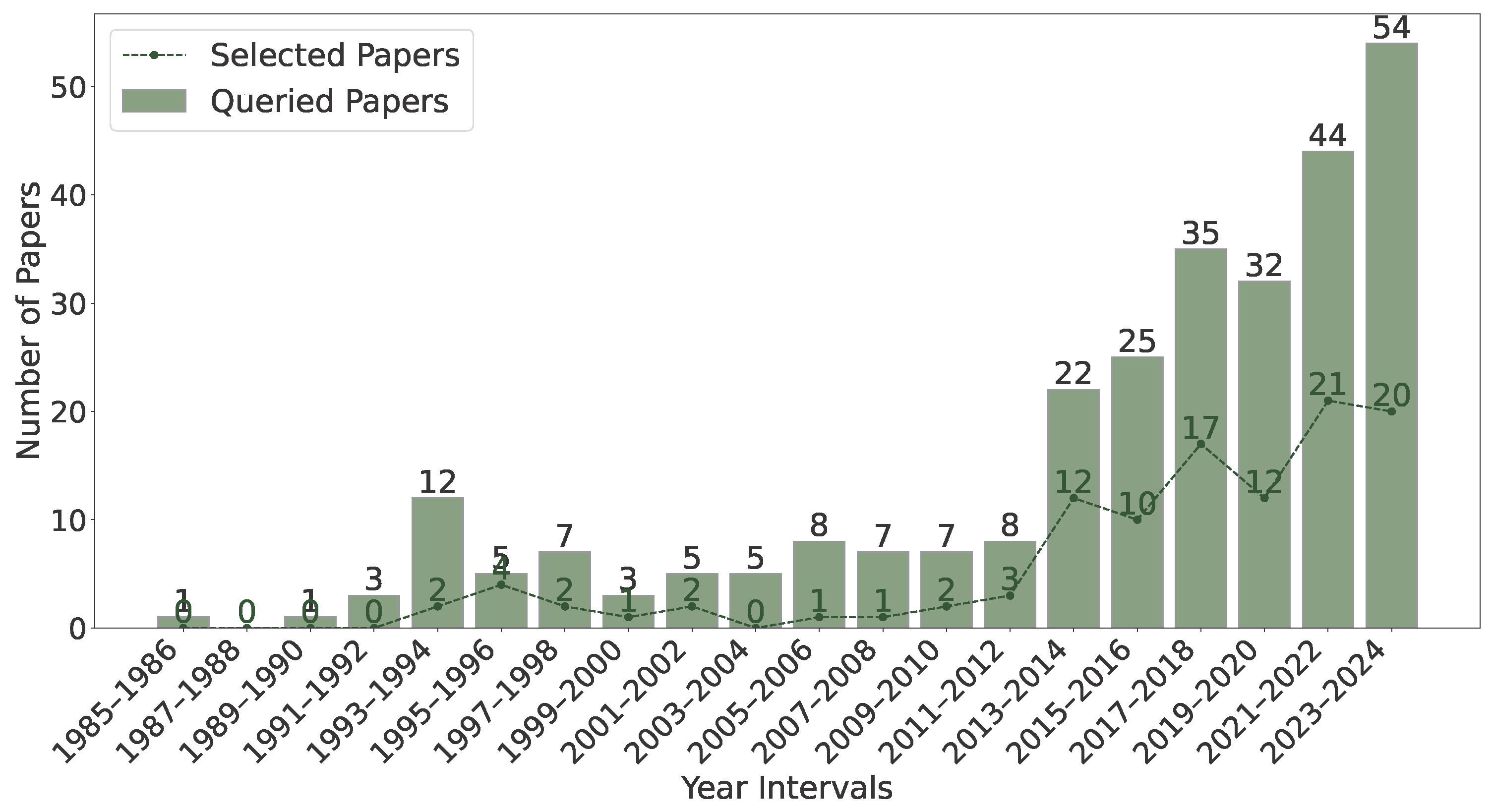

3. Methodology

- Defined research questions to guide the direction of the review.

- Designed a search strategy, including the specific search terms and the contribution sources.

- Created selection criteria to identify studies to exclude from the review.

- Established a systematic procedure to apply the selection criteria consistently.

3.1. Research Questions and Search Strategy

- In which application domains is CM employed in SASO systems and how are the applied methods influenced by specific applications?

- To what extent do the presented CM approaches implement self-* properties, and how well do they meet the requirements of a SASO system?

- What technologies and methods are utilized for CM in SASO systems, and what is the role of ML and DL in this context?

- What types of sensor data and features are used for CM, and how frequently is the data processed?

- What challenges and open research questions exist in integrating CM into SASO systems, particularly with the use of DL techniques?

(“condition monitoring”) AND (“self-adaptive” OR “self-organization” OR “self-aware” OR “self-correcting”) AND (“real-time”) AND NOT (“framework”)

3.2. Selection Criteria and Process

4. Results

4.1. Taxonomy

4.1.1. Application Domain

- Manufacturing/Process: Papers that focus on CM of manufacturing processes or procedures, such as cutting, drilling, or milling operations, as well as the examination of the produced object, are classified in this category.

- Structure: Studies categorized here address CM of static objects, including buildings and other structures.

- System: This category includes the monitoring of system parameters, such as machines, circuits, or autonomous vehicles.

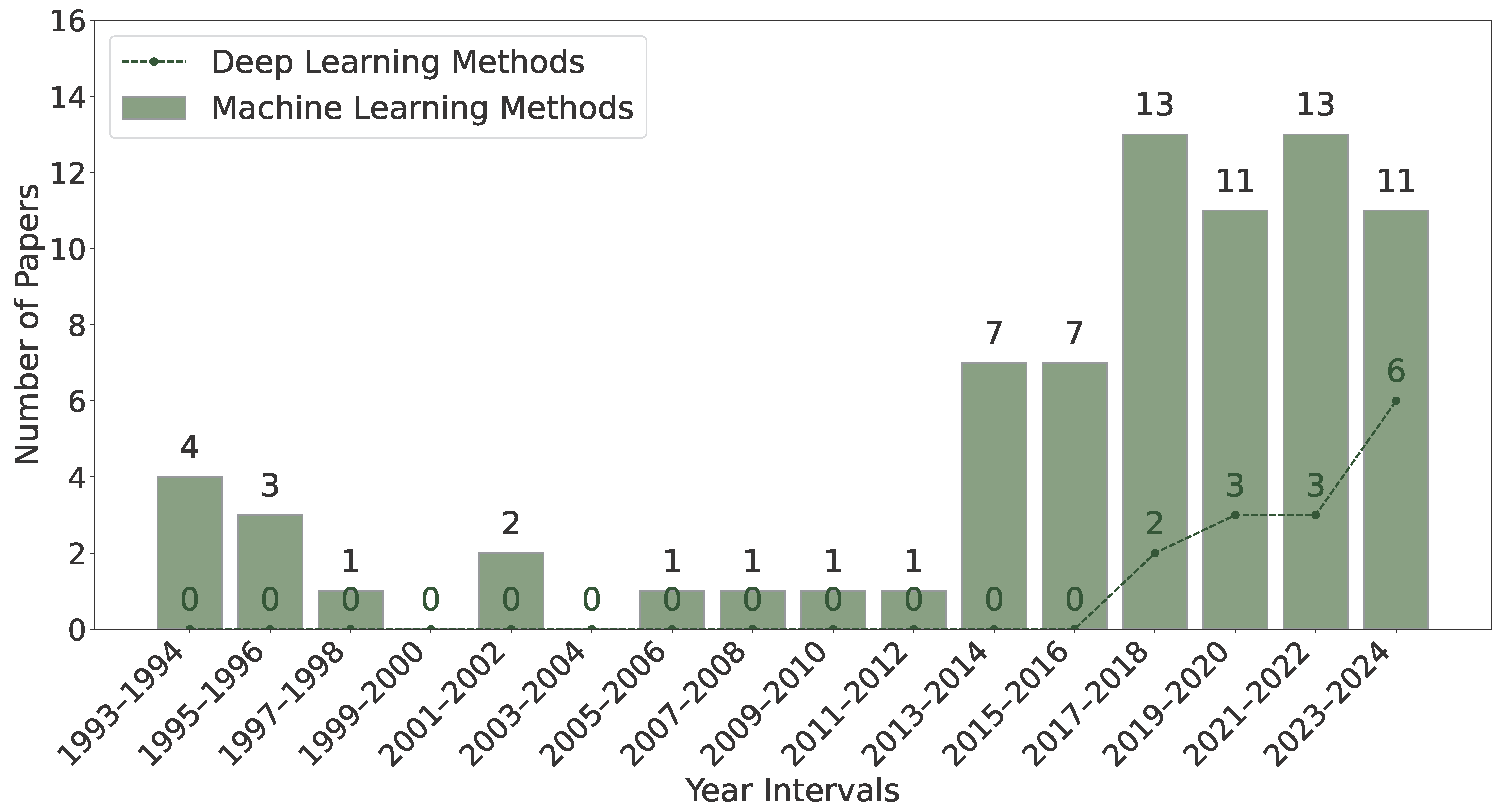

4.1.2. Technique

- Machine Learning: This category includes papers that utilize ML techniques for CM, with a further distinction made between DL and traditional ML.

- Non-Machine Learning: Contributions in this category rely on traditional techniques such as signal processing or statistical methods for CM.

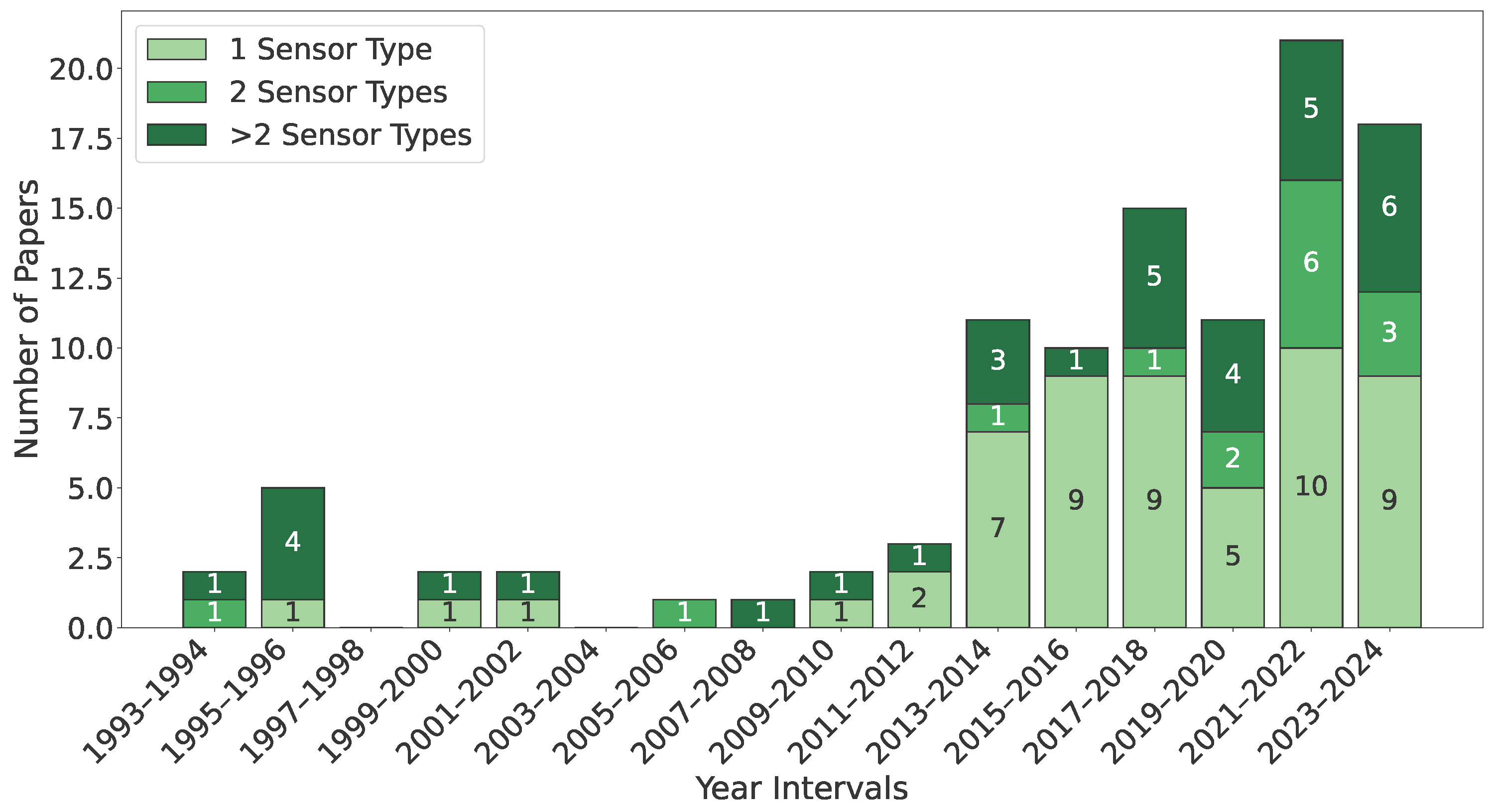

4.1.3. Input Data

4.1.4. Type of Condition Monitoring

- Predictive Approach: This category includes papers that focus on predictive approaches to monitoring states, such as forecasting the lifespan of a machine or estimating maintenance intervals.

- Anomaly Detection: Contributions in this category examine the current state, specifically identifying existing faults or changes within the system or process.

- Combination of Both Approaches: This category encompasses papers that integrate both predictive methods and current state monitoring techniques in their approaches.

4.1.5. Self-* Properties

4.2. Application Domain

4.2.1. Manufacturing and Process Monitoring

4.2.2. System-Level Monitoring

4.2.3. Full-System Monitoring

4.2.4. Structural Monitoring

4.3. Techniques

4.3.1. Machine Learning

4.3.2. Deep Learning

4.3.3. Non-Machine Learning

4.4. Input Data

4.5. Types of Condition Monitoring

4.6. Self-* Properties

5. Discussion

5.1. Machine Learning and Application Domains

5.2. Type of Condition Monitoring and Applications

5.3. Distinction Between Real-Time Categories

5.4. Self-* Properties

6. Research Agenda

- Is it possible to develop a concept that performs equally well across different application domains and scenarios?

- Can the fusion of more than three heterogeneous sensor types improve the performance of CM systems compared to systems with fewer sensor types?

- Can more efficient and faster DL models be developed to address all aspects of CM in real time?

- Is a comparison of processing time and performance feasible across proposed methods despite varying application domains and hardware components?

- What processing time requirements must CM systems meet to be sufficiently fast for different application areas and real-time scenarios?

- What constitutes “high-frequency” processing in the context of real-time, and how can real-time be meaningfully categorized based on processing time thresholds?

- How can a CM system be designed to meet the requirements of a full SASO system?

- Can such a system be integrated into a complete SASO framework with a feedback mechanism or MAPE-K loop, enabling real-time, autonomous adaptation and reconfiguration?

- Can a SASO system be designed in such a way that its actions and decisions are inherently self-explainable?

- How can unlabeled real-world datasets be accurately labeled in an unsupervised manner?

- How can the lack of rare anomalies, which are crucial for robust model performance, be addressed?

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 2SND | Two-Stage Novelty Detector |

| AFFGMM | Adaptive Forgetting Factor Gaussian Mixture Model |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| ANN | Artificial Neural Network |

| AMSC | Average Magnitude Coherence Coefficient |

| AVMD | Adaptive Variational Mode Decomposition |

| AVSMF | Adaptive Variable Scale Morphological Filter |

| BN | Bayesian Network |

| BRNHMM | Bayesian Robust New Hidden Markov Model |

| CEEMDAN | Complete Ensemble Empirical Mode Decomposition with Adaptive Noise |

| CHMM | Continuous Hidden Markov Model |

| CMF | Combined Mode Functions |

| CMI | Common-Mode Interference |

| CR | Contribution Ratio |

| CSWVS | Wigner–Ville Spectrum Based on Cyclic Spectral Density |

| DDS | Dynamic Data System |

| DFV | Dependent Feature Vector |

| DNN | Deep Neural Network |

| ED | Energy Distribution |

| EDC | Entropy Drift Coefficient |

| ELM | Extreme Learning Machine |

| EMI | Electromagnetic Interference |

| EnKF | Ensemble Kalman Filter |

| ESRIR | Enhanced Sparse Representation-Based Intelligent Recognition |

| ET | Ensemble Tree |

| FBLMS | Fast Block LMS |

| FCM | Fuzzy C-Means |

| FrFT-Mel Filter | Fractional Fourier Transform-Mel Filter |

| Fuzzy ARTMAP | Adaptive Resonance Theory MAP |

| GG | Gath-Geva |

| GASF | Gramian Angular Summation Fields |

| GEFS | Generalized Evolving Fuzzy Systems |

| GARCH-MD | Generalized Autoregressive Conditional Heteroskedasticity-Mahalanobis Distance |

| GPR | Gaussian Process Regression |

| GTM | Generative Topographic Mapping |

| HMM | Hidden Markov Model |

| Higuchi’s FD | Higuchi’s Fractal Dimension |

| ICIELMD | Improved Compound Interpolation LMD |

| IHDGWO | Improved Hybrid Differential Grey Wolf Optimization |

| IPLS | Incremental Partial Least Squares |

| IPSO-SDUPF-AFFRLS | Improved Particle Swarm Optimization-Singular Value Decomposition Unscented Particle Filter-Adaptive Forgetting Factor Recursive Least Squares |

| IWTD | Improved Wavelet Threshold Denoising |

| Katz’s FD | Katz’s Fractal Dimension |

| KPCA | Kernel Principal Component Analysis |

| KNN | k-Nearest Neighbors |

| LCD-TEO-MF-DFA | Local Characteristic-Scale Decomposition–Teager Energy Operator-Multifractal Detrended Fluctuation Analysis |

| LGC | Local Gravitational Clustering |

| LOD | Local Oscillatory-Characteristic Decomposition |

| LMS | Least Mean Squares |

| LSSVM | Least Squares Support Vector Machine |

| LVQ | Learning Vector Quantization |

| M-PH-SF-HAT | Statistic Filter-Hilbert Transform-Moving-Peak-Hold |

| MB-CNN | Multi-Sensor Data Fusion and Bottleneck Layer Optimized Convolutional Neural Network |

| MCCC | Maximum Cross-Correlation Coefficient |

| Maximin LHDs | Space-Filling Maximin Latin Hypercube Design |

| MODWT | Maximal Overlap Discrete Wavelet Transform |

| MTS | Mahalanobis–Taguchi System |

| NB | Naive-Bayes |

| NLLP | Negative Likelihood Probability |

| NPSHa | Net Positive Suction Head Available |

| NPVLR | Negative Pressure Wave Method Based on Logical Reasoning |

| OCIGIVMD | Operating Condition Information-Guided Iterative VMD |

| OD | Online Dynamic |

| OS | Online Sequential |

| PNN | Probabilistic Neural Network |

| PLSR | Partial Least Squares Regression |

| QTA | Quantitative Trend Analysis |

| RBF | Radial Basis Function |

| RCE | Restricted Coulomb Energy |

| RF | Random Forest |

| SCNN | Self-Correcting Neural Network |

| SCA-Hamming | State Coupling Analysis-Hamming |

| SAKF-AR | Square-Root Unscented Kalman Filter-Autoregressive |

| SANC | Self-Adaptive Noise Cancellation |

| SFAM | Simplified Fuzzy Adaptive Resonance Theory Map |

| SK-COT | Spectral Kurtosis-Computed Order Tracking |

| SNN | Spiking Neural Network |

| SOFM | Self-Organizing Feature Map |

| SSGB | Semi-Supervised Graph-Based Model |

| SVR | Support Vector Regression |

| STFT | Short-Time Fourier Transform |

| WPT | Wavelet Packet Transform |

| WMRA | Wavelet Multi-Resolution Analysis |

| XGBoost | Extreme Gradient Boosting |

Appendix A. Tables Showing the Relationship Between Applications, Implemented Techniques, Types of Data Used, Preprocessing Methods, and Sampling Rates of Sensors

| Reference | Category | Application | Technique | Pre-Processing | Data | Sample Rate (kHz) |

|---|---|---|---|---|---|---|

| [103] | Additive manufacturing | Defect detection in additive manufacturing processes | ±3 principle | - | Temperature (IR-Sensor) data | - |

| [68] | Milling | Machining quality prediction (CNC machine/milling process) | PCA-models (LR, RF, DNN, and XGBoost) | Data segmentation and fusion, FFT | Time, vibration (3-axis) and noise data | 10 |

| [34] | Chatter monitoring (CNC machine/milling process) | Katz’s FD, Higuchi’s FD, and PSE (with EMD) | (EMD) | Vibration data (3-axis) | 12.8 (PCB 356A24) and 0.8 (ADXL345) | |

| [134] | Chatter detection (CNC machine/milling process) | AVMD-GA-EDC | - | Vibration data (3-axis) | 5.12 | |

| [98] | Stability analysis in milling process | SBLMD | LMD | Acoustic data | 8 | |

| [67] | Machine tool anomaly detection (milling process) | Mean shift clustering-SOM | Time series segmentation, FFT | Drive signal data (PLC signals) | 0.5 | |

| [135] | Energy efficiency state identification (milling process) | HMM | Feature extraction | Force (3-axis), tool temperature and cutting area temperature data | - | |

| [108] | Tool wear prediction (CNC machine/milling process) | CNN | GASF | Force (3-axis) data | 50 | |

| [64] | Tool life predictions (milling process) | ANN | Normalizing and RMS (power) | RMS power, in the time domain | - | |

| [91] | Milling cutter breakage detection (CNC machine/milling process) | SGW | - | Acoustic emission data | 2500 | |

| [80] | Tool failure detection (milling process) | DWT-ART2 | DWT | Force (3-axis) data | - | |

| [79] | Tool wear monitoring (milling) | EEMD-ANFIS | EEMD, feature extraction | Vibration, acoustic emission and motor current (AC/DC) data | 0.25 | |

| [90] | Tool wear monitoring (milling/CNC) | Boundary mathematical model (self-learning) and ±3 principle of normal distribution | RMS | Spindle current data | 3 | |

| [111] | Cutting | Cutting process monitoring | SNN | - | Vertical vibration, acoustic emission and force data | 20 |

| [100] | Tool life transition and wear monitoring (cutting) | WMRA-EMD | WMRA | Vibration data (3-axis) | 32.768 | |

| [102] | Tool wear monitoring (cutting) | ANN | - | Force (3-axis), cutting and feed data | - | |

| [86] | Identifying working status (CNC machine) | 1D-CNN/2D-CNN | Anti-aliasing filter, averaging, median filter and PCA | 5-axes servomotor data | 1000; 100 (different devices) | |

| [88] | Thermal error prediction in machining process | IWTD-LSTM | IWTD | Armature current, rotational speed, and temperature | 20 | |

| [136] | Drilling | Material recognition (drilling process) | Random forest | Nan handling, signal segmentation, FFT | Thrust force, torque (z-axis), acceleration (3-axis), pressure and flow rate data | 20 |

| [110] | Monitoring drill process (CNC machine/drilling process) | DWT-ART2 | DWT | Force (3-axis) and thrust force data | - | |

| [71] | Hole cleaning analysis | Linear regression | - | Low rate, inclination angle, rotation speed, rate of penetration, relative pellet density and equivalent fluid viscosity data | - | |

| [73] | Abrasive tool wear prediction | IHDGWO-SVM | Feature extraction (time-, frequency- and wavelet domain analysis) | Grinding force signal and vibration data | 10 | |

| [37] | FMS | Fault diagnosis of flexible manufacturing systems | SAKF-AR | - | Power, vibration, spindle temperature, acceleration feed axes (3-axis), as well hydraulic oil and pneumatic supply pressure data | - |

| [137] | Industry 4.0 | Remaining usable life prediction in industry 4.0 (conveyor chains) | Prophet | - | Ultrasonic data | - |

| [106] | Micro-fluidic chip | Micro-fluidic chip quality prediction | IPLS-GEFS | Re-dundancy removal, missing value replacement, feature extraction | Time-series data of process parameters from the micro-fluidic chip production | - |

| [138] | Pickling | Pickling process anomaly detection | PCA-SOM | PCA | Speed and length loop target value, as well as measured length loop value data | - |

| [36] | Machine surface | Machine surface analysis | ANN | - | Light intensity distribution data (diffraction image) | 1 |

| [87] | Tapping | Tapping process fault identification (CNC machine) | LSTM | - | Force data (2-way) | - |

| [109] | Welding | Welding process monitoring | MLP | - | Current, voltage (AC and DC components), time and weld tip age/acoustic emission data | - |

| [35] | Welding process porosity defect detection | GA-SVM | EMD | Spectrum; Voltage and current data | 0.03; 0.5 | |

| [139] | Semi-conductor manufacturing | Prescriptive maintenance for etching equipment | (SVM, DT, RF)-BN | Re-dundancy removal, missing value replacement, feature extraction, normalization | Automated Process Control (APC) data, limit violations | - |

| Reference | Category | Application | Technique | Pre-Processing | Data | Sample Rate (kHz) |

|---|---|---|---|---|---|---|

| [95] | Lithium battery | SOC estimation of Li-ion ternary battery | IPSO-SDUPF-AFFRLS | IPSO-SDUPF | Battery voltage and current data | - |

| [140] | Fluidized bed boilers | Fouling monitoring of Fluidized bed boilers | EnKF, PLSR | - | Vibration and CFB boiler data | 1 |

| [118] | Circuit | IGBT module solder layer aging | EMI and spectrum analyzer (Cauer model) | - | Common mode interference current signal data | - |

| [54] | Analog circuit fault analysis | PSO-LSSVM | Feature extraction (Mahalanobis distance) | Resistor and capacitor data | - | |

| [141] | Network intrusion | Computer network intrusion detection | 2SND and parametric density estimation (GMM) | Dimension reduction | KDD Cup 1999 network intrusion data set | - |

| [96] | Energy harvesting | Piezoelectric energy harvesting (synchronous extraction circuits) | SSHI-SAMS | - | Vibration data | - |

| [70] | Internet of things | Industrial Internet of Things (devices fault detection) | DT-SSGB (DT, SVM, SSGB, and NB) | - | Device metric data (Id, macaddress, messagetime, logid, funcid, time, energy, and cpu) | - |

| [116] | Oil refining | Early warning and anomaly detection in oil refining process | QTA (DT, Siegel’s repeated median filter) | Normalization, segmentation | Outlet temperature of the second side of the column, bottom level of the column and outlet temperature of the vacuum furnace | - |

| [117] | Spinning | Roller path defect detection (Spinning) | SVM, GPR and DNN (and PSO) | Maximin LHDs | Inner radius and flange width, roller path half cone angle, roller feed ratio and mandrel speed data | - |

| [115] | PEMFC | Monitoring for proton exchange membrane fuel cell (PEMFC) humidity | OS-ELM-FCM | - | Tiplet resistance data | - |

| [57] | Satellit | Long-term degradation prediction of satellite | GRU-GARCH-MD | - | Temperature data | - |

| [105] | Power plant | Fault diagnosis in power plant | MLP, RBF, KNN | - | Pressure, temperature and flow data | - |

| [52] | Wind farm failure analysis | Fuzzy clustering-mahalanobis distance | - | Sensor data of wind farm components and operating conditions (operating, environmental and system monitoring data) | - |

| Reference | Category | Application | Technique | Pre-Processing | Data | Sample Rate (kHz) |

|---|---|---|---|---|---|---|

| [93] | Bearing | Analysis of wear resistance for bearing coating | VMD | - | Vibration data | - |

| [42] | Rolling bearing fault of aero engine | wavelet band envelope-CNN-PF | - | Vibration data | 20.48 | |

| [75] | Rolling bearing analysis (Flywheel energy storage system (FESS)) | PCA-EMD-Kriging model-based prediction | - | Vibration, temperature sensor and torque data | 25.6 | |

| [41] | AUV motor fault detection (propeller, eccentric and bearing) | DT, SVM, and KNN | Normalization, feature extraction | Acoustic data | 44 | |

| [142] | Bearing fault diagnosis | ANN, ANFIS-DA | - | Vibration data | 50 | |

| [43] | RBE fault diagnosis (whirlpool turbine generators) | CWT-M-PH-SF-HAT-FNN | CWT, M-PH, SF, and HT | Vibration data | 100 | |

| [89] | Rolling bearing fault detection | S4VM | HHT, SDAE | IEEE PHM Challenge 2012, IMS and XJTU-SY dataset | 25.6 and 0.001 (temperature); 20; 25.6 | |

| [92] | Rolling bearing analysis | ICIELMD | LMD | Vibration data (CWRU and NASA dataset) | 12; 20 | |

| [72] | Bearing fault classification | GA-SVM | - | Acoustic emission data | 25-530 | |

| [143] | Bearing fault detection | BRNHMM | - | Acoustic emission data | 25-530 | |

| [112] | Machinery fault diagnosis (gear and roller bearing fault) | LOD | - | Vibration data | 4.096 | |

| [85] | Rolling bearing fault diagnosis | CNN-CMF-EEMD | - | Vibration data (CWRU and NASA dataset) | 100 | |

| [40] | REB fault condition diagnostics (rotating machine) | EEMD-SVD-GG | EEMD-SVD | Vibration data | 10 | |

| [144] | Bearing fault diagnosis | Linear Prediction, SANC, LMS and FBLMS | - | Vibration data | 5 | |

| [145] | Rolling element bearing residual life prediction | CHMM-based NLLP-SVR | - | Vibration data (NASA dataset) | 20 | |

| [78] | Rolling bearing fault diagnosis | LCD-TEO-MF-DFA-PCA | LCD-TEO | Vibration data (CWRU dataset) | 12 | |

| [56] | REB remaining life prediction | GMM-based NLLP-SVR | - | Vibration data (NASA dataset) | 20 | |

| [81] | Bearing fault diagnosis | EMD-LDA-PNN-SFAM | EMD-LDA | Vibration data (NASA and IMS dataset) | 20 | |

| [74] | REB remaining life prediction | GTM-based NLLP-markov model | Feature extraction | Vibration data (NASA dataset) | 20 | |

| [114] | REB fault diagnosis | DFV–PNN | DVF | Vibration data (CWRU dataset) | 12 | |

| [146] | Bearing fault (machine health condition prediction) | OD-FNN | - | Vibration data | - | |

| [147] | Bearing faults diagnosis | Linear prediction, SK, LMS and FBLMS | - | Vibration data | 5 | |

| [97] | Bearing faults diagnosis | BSEMD | EMD | Vibration data (CWRU dataset) | 12 | |

| [69] | Bearing faults and fatigue crack detection | ASK | PSD and normalization | Acoustic emission signal data | 6250 | |

| [148] | REB damage detection | Schur filter | - | Vibration data | 19.2 | |

| [66] | REB degradation identification | MTS–SOM | Basic noise reduction, feature extraction | Vibration data | 20 | |

| [38] | REB fault detection | SK-COT | - | Vibration data | 40 | |

| [39] | REB fault diagnosis | CSWVS | Wigner–Ville spectrum based on cyclic spectral density | Vibration data | 25.6; 48 (University of Wales) and 24 (3 different scenarios) | |

| [82] | Rotating mechanical system fault analysis | GA-ANN | Feature extraction | Vibration and acoustic emission data | - | |

| [44] | Planet bearing fault diagnosis in wind turbines | ESRIR (self-similarity, shift-invariance, parsity-based diagnosis strategy) | - | Vibration data | 20.48 | |

| [45] | Ball bearing fault diagnosis | WPT-ANN | WPT | Vibration data (CWRU dataset) | - | |

| [107] | Bearing defect detection (wind turbine shaft line) | SVR | - | Angular speed data | 97.656 | |

| [149] | Bearing fault detection (wind turbine gearbox) | Multiple signal processing techniques | - | Vibration data | - | |

| [94] | Rotor-bearing system fault detection (rotating machine) | SSA-NM | - | Vibration data | - | |

| [99] | Rotor-bearing system fault diagnosis (rotating machine) | LMD-FFT | ICIE | Vibration data | 5 | |

| [119] | Gear | Planetary gear fault diagnosis | CNN | SAE | Electrical signal data of the TPGS | - |

| [76] | Intelligent gearbox early stage fault detection | MODWT-VMD-PCA-(SVM, DT, ET, NB, kNN) | MODWT, VMD | Vibration data | 25.8 | |

| [77] | Gear fault diagnosis | ITD-SVD-SVM | ITD-SVD | Vibration data | - | |

| [120] | Planetary gearbox fault detection | LVQ | filtration (low-pass and band-pass), estimation and normalization (min–max) | Vibration data | 5 | |

| [46] | Wind turbines gearbox degradation analysis | CEEMDAN-KPCA-ELM-FOA | CEEMDAN | Vibration data | 4.096 | |

| [150] | Fault recognition in rotating machinery | MB-CNN | Image conversion | Vibration sensor (3-axis) | - | |

| [47] | Shaft | Rotor shaft crack detection | CSA-DEA | - | Vibration data | - |

| [151] | Shaft fault diagnosing (PVEH) | Time domain-based statistical features, FFT and WT | - | Vibration data | 12.8 | |

| [50] | Aircraft engine | Tool wear recognition (aircraft turbine disc) | GWO-SVM | Wavelet packet threshold, feature extraction | Vibration data (3-axis) | - |

| [65] | Industrial environment in general | Automatic fault detection and diagnosis in industrial environments (chemical reactor and machinery system of rotary elements) | DWT-SAGNN | DWT | Reactor pressure and cooling temperature, as well vibration data | - |

| [83] | Wear particle | Wear particle detection (machine defects) | CNN-SVM (WP-DRnet) | Translation, cropping and rotation of images | Ferrograph image data (oil lubrication) | - |

| [152] | Inverter-fed machine | State perception of inverter-fed machine turn insulation | FrFT-Mel filter | FrFT | Switching oscillation current data | - |

| [49] | Induction machine | Induction machine fault diagnosis | FFT | - | Three phase current data | 10 |

| [84] | ATV | Industrial autonomous transfer vehicle fault diagnosis | LeNet-5 model (CNN)-STFT | STFT signal transformation | Vibration and sound data | 0.1 |

| [53] | AUV | System CM with fuzzy neural network | FNN | - | Propeller size, yaw, velocity and acceleration fuzzy data | - |

| [104] | Pressure system | Fault diagnosis in air pressure system | ANN | Normalization | Temperature and pressure distribution data | - |

| [153] | Reciprocating compressors intelligent fault diagnosis | AVSMF | IPB | Vibration data | 10.24 | |

| [113] | Early surge state of centrifugal compressors | OCIGIVMD | - | Vibration data (for evaluation exhaust and noise sound pressure data) | 12.8 (10; 48) | |

| [154] | Inter turn fault detection in pumping system | ANN, ANFIS | Feature extraction | Stator current data | - | |

| [101] | Centrifugal pump analysis | EMD-NPSHa-based cavitation model | - | Acoustic data | 1000 | |

| [48] | Condition classification of small reciprocating refrigerator compressor | SVM, SOFM and LVQ | DWT, feature extraction | Vibration and noise (acoustic) data | 10 | |

| [155] | Complete machinery system | Detection and diagnosis of faults in industrial systems | DWT-SAGNN | DWT | Vibration, reactor pressure and reactor cooling temperature data | - |

| [51] | Oil plant | Predictive maintenance of turbomachinery | ANN | - | Vibration data | - |

| [55] | Nuclear plant | Reactor component diagnostics | ANN (RCE, Cascade correlation, Backpropagation, and Fuzzy ARTMAP) and CR-DDS | Normalization (ANN) | Pump power, pump speed, and pump pressure data | 0.01; 0.1; 0.01 |

| Reference | Application | Technique | Pre-Processing | Data | Sample Rate (kHz) |

|---|---|---|---|---|---|

| [58] | Nonparametric damage detection (civil structure) | LGC | LMD, SV | Acceleration data | 1.24 |

| [59] | Damage detection (steel structure) | CWT | CWT, MCCC, AMSC and ED | Acoustic emission data | 1.000 |

| [62] | Crack detection (steel beams) | Fuzzy relational clustering | FFT, CWT and feature extraction | Vibration data | 1 |

| [63] | Wheel polygonization detection (heavy haul locomotive) | CNN-LSTM | FFT, data augmentation, windowing | Axle box acceleration data | 4.096 |

| [60] | Leak detection (long transportation pipeline) | SCA-Hamming approach degree analysis, NPVLR | - | Pressure data | - |

| [121] | Road pavement diagnostics | SCNN | - | Image data (and vibration and GPS data) | 0.003 (30 fps) |

| [61] | Foreign object debris detection (rocket tank final assembly process) | EDAWF-AFFGMM | EDAWF | Acoustic data | - |

| Reference | Technique | Prediction Topic | Type of CM | Data | Category |

|---|---|---|---|---|---|

| [139] | SVM, DT, RF | Prescriptive maintenance | CBA | Automated Process Control (APC) data, limit violations | Semi-conductor manufacturing |

| [68] | LR, RF, DNN, XGBoost | Machining quality prediction | PA | Time, vibration (3-axis) and noise data | Milling |

| [88] | LSTM | Error prediction | CBA | Armature current, rotational speed, and temperature | Cutting |

| [75] | Kriging model-based prediction | Remaining useful life | PA (actual state monitoring) | Vibration, temperature sensor, and torque data | Bearing |

| [73] | SVM | Abrasive tool wear prediction | PA (actual state monitoring) | Grinding force signal and vibration data | Drilling |

| [137] | Prophet | Predictive maintenance | PA (actual state monitoring) | Ultrasonic data | Industry 4.0 |

| [57] | GRU-GARCH-MD | Degradation prediction | PA (actual state monitoring) | Temperature data | Satellite |

| [64] | ANN | Tool life prediction | PA (actual state monitoring) | RMS power (time domain) | Milling |

| [51] | ANN | Predictive maintenance | CBA | Vibration data | Oil plant |

| [46] | FOA-ELM | Remaining useful life | CBA | Vibration data | Bearing |

| [79] | ANFIS | Remaining useful life | PA (actual state monitoring) | Vibration, acoustic emission, and motor current (AC/DC) data | Milling |

| [146] | OD-FNN | Machine health condition prediction | CBA | Vibration data | Bearing |

| [106] | IPLS-GEFS | Predictive maintenance | PA (actual state monitoring) | Time-series data of process parameters from the micro-fluidic chip production | Micro-fluidic chip |

| [108] | CNN | Tool wear prediction | CBA | Force (3-axis) data | Milling |

| [85] | CNN | Compound fault prediction | CBA | Vibration data (CWRU and NASA dataset) | Bearing |

| [145] | SVR | Residual life prediction | PA (actual state monitoring) | Vibration data (NASA dataset) | Bearing |

| [56] | SVR | Remaining life prediction | PA (actual state monitoring) | Vibration data (NASA dataset) | Bearing |

| [74] | Markov model | Remaining life prediction | PA (actual state monitoring) | Vibration data (NASA dataset) | Bearing |

Appendix B. Tabular Analysis of Self-* Properties in Relation to Control Integration, Processing Time, Data Type, Number of Sensors, and Feature Size in Condition Monitoring Approaches

| Reference | Category | Number of Sensors (Feature) | Processing Time (in s) | Data | Control Loop | Self-* Properties |

|---|---|---|---|---|---|---|

| [103] | Additive manufacturing | 2 (4) | R | No | No | |

| [68] | Milling | 1–4 (128) | R | No | SA | |

| [34] | 2 (2) | 0.840 (pre-process + send data) | R | No | SA (EMD) | |

| [134] | 1 (3) | R/S | No | Only adaptive | ||

| [98] | 1 (12 statistical) | R | No | No | ||

| [67] | 3 (3) | 1.3 (mean shift clustering complete dataset) without SOM | R | No | SO (SOM) | |

| [135] | 7 (7) | R | No | No | ||

| [108] | 1 (3 channel) | R | Yes | SA | ||

| [64] | 1 (1) | 0.5 | R | No | SA learning rate algorithm | |

| [91] | 1 (4) | 0.250 (decompensation) | R | No | SA (SGW) | |

| [80] | 1–2 (23 WC) | R | No | SO network (ART2) | ||

| [79] | 6 (66 statistical) | R | No | SA (EEMD) | ||

| [90] | 1 (1) | R | No | SA learning | ||

| [111] | Cutting | 2–3 (14–15) | R/S | No | SO | |

| [100] | 1 (2) | R | No | SA (EMD) | ||

| [102] | 5 (5) | R | No | No | ||

| [86] | 1 (6) | R | No | No | ||

| [88] | 3 (8) | 138 | R | No | SA | |

| [136] | Drilling | 5 (114 statistical/-frequency domain) | R | No | No | |

| [110] | 2 (6-22 WC) | R | No | SO network (ART2) | ||

| [71] | 6 (6) | R | No | No | ||

| [73] | 2 (5 time, frequency and wavelet domain) | R | No | SA scaling factor | ||

| [37] | FMS | 7 (72) | R | No | SA Kalman wave filter | |

| [137] | Industry 4.0 | 1 (1) | R | No | No | |

| [106] | Micro-fluidic chip | 63 parameter (63) | R | No | SA | |

| [138] | Pickling | 3 (3) | R | No | SO (SOM) | |

| [36] | Machine surface | 1 (1 channel) | R | No | SO | |

| [87] | Tapping | 1 (3) | R | No | No | |

| [109] | Welding | 1–3 (1–3) | R | No | SA | |

| [35] | 3 (8) | R | No | SA (EMD) | ||

| [139] | Semi-conductor manufacturing | (1–4) | R | No | No |

| Reference | Category | Number of Sensors (Feature) | Processing Time (in s) | Data | Control Loop | Self-* Properties |

|---|---|---|---|---|---|---|

| [95] | Lithium battery | 2 (2) | R | No | SA (SANC) | |

| [140] | Fluidized bed boilers | 2 (4) | R | No | No | |

| [118] | Circuit | 1 (1) | R | Yes | SC | |

| [54] | 16 (21 statistical) | R | No | No | ||

| [141] | Network intrusion | 41 parameter (6) | R | No | No | |

| [96] | Energy harvesting | R | Yes | SA | ||

| [70] | Internet of things | R | No | No | ||

| [116] | Oil refining | 3 (3) | R | No | SA | |

| [117] | Spinning | R/S | Yes | SA control | ||

| [115] | PEMFC | 3 (3) | R | No | SA | |

| [57] | Satellite | 1 (3) | R | No | SA baseline | |

| [105] | Power plant | 15 (15) | S | No | No | |

| [52] | R | No | No | |||

| [93] | Bearing | 1 (7 statistical) | R | No | No | |

| [42] | 1 (1 channel) | R | No | No | ||

| [75] | 2 (71) | R | No | SA (EMD) | ||

| [41] | 1 (6 statistical) | R | No | No | ||

| [142] | 1 (9 statistical) | R | No | Only adaptive | ||

| [43] | 1 (21 statistical and autoregression) | R | No | SA (SF) | ||

| [89] | 1 (30) | R | No | Only adaptive | ||

| [92] | 2 (1) | R | No | SA threshold | ||

| [72] | 2 (13) | R | No | No | ||

| [143] | 1 (13) | R | No | No | ||

| [112] | 1 (3) | R | No | SA (LOD) | ||

| [85] | 1 (1) | R | No | SA (EEMD) | ||

| [40] | 1 (3) | R | No | SA (EMD) | ||

| [144] | 1 (1) | R | No | SA (SANC) | ||

| [74] | 1 (1 statistical) | R | No | SA (SANC) | ||

| [78] | 1 (15) | R | No | SA (LCD) | ||

| [56] | 1 (4 statistical) | R | No | SA (LMS) | ||

| [81] | 1 (13) | R | No | SA (EMD) and SD | ||

| [74] | 1 (3) | R | No | SA (LMS) | ||

| [114] | 1 (100) | R | No | Self-adapting sample representation (DFV) | ||

| [146] | 1 (1 statistical) | R | No | SO | ||

| [147] | 1 (1) | R | No | No | ||

| [97] | 1 (8) | R | No | SA (EMD) | ||

| [69] | 1 (PSD feature vector) | R | No | SA | ||

| [148] | 1 (5) | R/S | No | SA (SANC) | ||

| [66] | 1-3 (9-27) | R | No | SO (SOM) | ||

| [38] | 1 (1 statistical) | R/S | No | SA envelope extraction | ||

| [39] | 1 (1) | R/S | No | SA (SANC) | ||

| [82] | 4 (242 statistical and spectral) | R | No | No | ||

| [44] | 4 (4) | R | No | SS | ||

| [45] | 1 (4 statistical) | R | No | No | ||

| [107] | 1 (1) | R | No | No | ||

| [149] | 1 (5) | R | No | No | ||

| [94] | 2 (8) | R/S | No | Only adaptive | ||

| [99] | 1 (3) | R/S | No | SA (LMD) | ||

| [119] | Gear | 1 (1 channel) | R | No | SAW and SR | |

| [76] | 1 (12 statistical) | R | No | SA (VMD) | ||

| [77] | 1 (8) | R | No | SA (SVD) | ||

| [120] | 1 (3) | R | No | SO (SOM) | ||

| [46] | 4 (8) | R | No | SA (EEMD) | ||

| [150] | 3 (3) | R | No | No | ||

| [47] | Shaft | 3 (9) | R | No | SA (DEA) | |

| [151] | 1 (8) | R/S | No | No | ||

| [50] | Aircraft engine | 4 (11-57) | R | No | No | |

| [65] | Industrial environment in general | 1-2 (3-6) | R/S | No | SA and SS (SAGNN) | |

| [83] | Wear particle | 1 (3) | 0.0234 | R | No | No |

| [152] | Inverter-fed machine | 1 (10) | R | No | No | |

| [49] | Induction machine | 3 (1 spectral) | R/S | No | No | |

| [84] | Auto-nomous transfer vehicles (ATV) | 1-4 (1-4) | R | No | No | |

| [53] | Auto-nomous underwater vehicle (AUV) | 4 (4) | R/S | No | No | |

| [104] | Pressure system | 5 (5) | R | No | No | |

| [153] | 1 (10-120 statistical and IPB) | R | No | SA (EEMD) | ||

| [113] | 2 (4 statistical) | R/S | No | SA (VMD) | ||

| [154] | 2 (12 statistical) | R/S | No | No | ||

| [101] | 1 (1) | R/S | No | SA (EMD) | ||

| [48] | 2 (16) | R/S | No | SO (SOFM) | ||

| [155] | Complete machinery system | 1-5 (2-5) | R/S | No | SA (SAGNN) | |

| [51] | Oil plant | 1 (2) | R | No | No | |

| [55] | Nuclear plant | 1 (55) | R/S | No | SO (ART) |

| Reference | Number of Sensors (Feature) | Processing Time | Data | Control Loop | Self-* Properties |

|---|---|---|---|---|---|

| [58] | 1–30 (6–180) | R | No | SA | |

| [59] | 1 (5) | R | No | No | |

| [62] | 1 (6) | R | No | No | |

| [63] | 1 (2000) | R/S | No | SA (Adam optimization) | |

| [121] | (12) | R/S | No | No | |

| [121] | 2 (6) | R | No | SC | |

| [61] | 8 (4) | R | No | Only adaptive |

Appendix C. Summary of Papers Excluded Following Selection Criteria and Process

| Exclusion Criterion ID | Excluded Contributions |

|---|---|

| E1 | [26,156,157,158,159,160,161,162,163,164], |

| [21,165,166,167,168,169,170,171,172,173], | |

| [18,174,175,176,177,178,179,180,181,182], | |

| [25,183,184,185,186,187,188,189,190,191], | |

| [22,192,193,194,195,196,197,198,199,200], | |

| [201,202,203,204,205,206,207,208,209,210], | |

| [19,20,24,211,212,213,214,215,216,217], | |

| [23,218,219,220,221] | |

| E2 | [18,222] |

| E3 | [223,224,225,226,227,228,229,230,231,232], |

| [233,234,235,236,237,238,239,240,241,242], | |

| [243,244,245,246,247,248,249,250,251,252], | |

| [253,254,255,256,257,258,259,260,261,262], | |

| [263,264,265,266,267,268,269,270,271,272], | |

| [273,274,275,276,277,278,279,280,281,282], | |

| [283,284,285,286,287,288,289,290,291,292], | |

| [293,294,295,296,297,298] | |

| E4 | [299,300,301,302,303,304,305,306,307,308] |

| E5 | [309,310,311,312,313,314,315] |

Appendix D. PRISMA Checklists and Flow Diagram

| Section and Topic | Item # | Checklist Item | Location |

|---|---|---|---|

| Information sources and methods | |||

| Database name | 1 | Name each individual database searched, stating the platform for each. | M |

| Multi-database searching | 2 | If databases were searched simultaneously on a single platform, state the name of the platform, listing all of the databases searched. | M |

| Study registries | 3 | List any study registries searched. | M |

| Online resources and browsing | 4 | Describe any online or print source purposefully searched or browsed (e.g., tables of contents, print conference proceedings, websites), and how this was done. | M |

| Citation searching | 5 | Indicate whether cited references or citing references were examined, and describe any methods used for locating cited/citing references (e.g., browsing reference lists, using a citation index, setting up email alerts for references citing included studies). | (Not utilized)/M |

| Contacts | 6 | Indicate whether additional studies or data were sought by contacting authors, experts, manufacturers, or others. | (Not utilized)/M |

| Other methods | 7 | Describe any additional information sources or search methods used. | (Not utilized)/M |

| Search strategies | |||

| Full search strategies | 8 | Include the search strategies for each database and information source, copied and pasted exactly as run. | M |

| Limits and restrictions | 9 | Specify that no limits were used, or describe any limits or restrictions applied to a search (e.g., date or time period, language, study design) and provide justification for their use. | M |

| Search filters | 10 | Indicate whether published search filters were used (as originally designed or modified), and if so, cite the filter(s) used. | (Not utilized)/M |

| Prior work | 11 | Indicate when search strategies from other literature reviews were adapted or reused for a substantive part or all of the search, citing the previous review(s). | (Not utilized)/M |

| Updates | 12 | Report the methods used to update the search(es) (e.g., rerunning searches, email alerts). | (Not utilized)/M |

| Dates of searches | 13 | For each search strategy, provide the date when the last search occurred. | M |

| Peer review | |||

| Peer review | 14 | Describe any search peer review process. | Not applicable |

| Managing records | |||

| Total records | 15 | Document the total number of records identified from each database and other information sources. | M |

| Deduplication | 16 | Describe the processes and any software used to deduplicate records from multiple database searches and other information sources. | M |

| Section and Topic | Item # | Checklist Item | Location |

|---|---|---|---|

| Title | 1 | Identify the report as a systematic review. | Title |

| Abstract | 2 | See the PRISMA 2020 for Abstracts checklist. | Abstract |

| Introduction | 3 | Describe the rationale for the review in the context of existing knowledge. | I/RW |

| 4 | Provide an explicit statement of the objective(s) or question(s) the review addresses. | M | |

| Methods | 5 | Specify the inclusion and exclusion criteria for the review and how studies were grouped for the syntheses. | M |

| 6 | Specify all databases, registers, websites, organisations, reference lists and other sources searched or consulted to identify studies. Specify the date when each source was last searched or consulted. | M | |

| 7 | Present the full search strategies for all databases, registers and websites, including any filters and limits used. | M | |

| 8 | Specify the methods used to decide whether a study met the inclusion criteria, including how many reviewers screened each record and each report retrieved, whether they worked independently, and if applicable, details of automation tools used. | M | |

| 9 | Specify the methods used to collect data, including how many reviewers collected data, whether they worked independently, any processes for obtaining or confirming data, and if applicable, details of automation tools used. | M | |

| 10a | List and define all outcomes for which data were sought; specify whether all compatible results were sought, and if not, describe how results were selected. | R | |

| 10b | List and define all other variables sought (e.g., participant characteristics, funding sources); describe assumptions about missing/unclear info. | R | |

| 11 | Specify methods used to assess risk of bias in included studies, including tool(s) used, number of reviewers, whether they worked independently, and any automation tools. | M | |

| 12 | Specify effect measures used for each outcome. | R | |

| 13a | Describe processes used to decide study eligibility for each synthesis. | R | |

| 13b | Describe methods used to prepare data for presentation/synthesis, such as handling missing stats or conversions. | Not applicable | |

| 13c | Describe methods used to tabulate or visually display results. | Not required | |

| 13d | Describe methods used to synthesize results and rationale; if meta-analysis, include model(s), heterogeneity methods, and software used. | R | |

| 13e | Describe methods used to explore causes of heterogeneity. | Not required | |

| 13f | Describe any sensitivity analyses. | M | |

| 14 | Describe methods used to assess risk of bias due to missing results (reporting biases). | M | |

| 15 | Describe methods used to assess certainty/confidence in the evidence. | M | |

| Results | 16a | Describe search and selection results, ideally using a flow diagram. | M |

| 16b | Cite studies excluded despite appearing eligible, and explain why. | M/A | |

| 17 | Cite each included study and present characteristics. | M/R/A | |

| 18 | Present risk of bias assessments for each included study. | M | |

| 19 | For all outcomes, present summary stats and effect estimates with precision (e.g., confidence interval), ideally in tables/plots. | R | |

| 20a | Summarize characteristics and risk of bias in contributing studies for each synthesis. | M/R/D | |

| 20b | Present statistical synthesis results; if meta-analysis, report summary estimate, precision, heterogeneity, direction of effect. | R/D | |

| 20c | Present results of heterogeneity investigations. | R/D | |

| 20d | Present sensitivity analysis results. | Not required / M | |

| 21 | Present risk of bias assessments due to missing results (reporting biases) for each synthesis. | Not required / M | |

| 22 | Present certainty/confidence assessments for each outcome. | Not required / M | |

| Discussion | 23a | Provide a general interpretation of results in context of other evidence. | D |

| 23b | Discuss limitations of the evidence. | D | |

| 23c | Discuss limitations of the review process. | D | |

| 23d | Discuss implications for practice, policy, future research. | D/RA | |

| Other information | 24a | Provide registration info (register name, number), or state unregistered. | M |

| 24b | Indicate where protocol can be accessed or state that none was prepared. | M | |

| 24c | Describe/explain amendments to registration or protocol. | M | |

| 25 | Describe sources of financial/non-financial support and role of funders/sponsors. | BA | |

| 26 | Declare any competing interests of authors. | BA | |

| 27 | Report availability and location of data, code, and other materials (e.g., extraction forms, analytic code). | Not applicable/BA |

References

- Schweizer, P. Many-Objective Centralized Adaptation Planning: Towards Hybrid Self-Adaptive and Self-Organizing Systems. In Proceedings of the 2024 IEEE International Conference on Autonomic Computing and Self-Organizing Systems Companion (ACSOS-C), Aarhus, Denmark, 16–20 September 2024; pp. 167–169. [Google Scholar] [CrossRef]

- Müller-Schloer, C.; Tomforde, S. Organic Computing—Technical Systems for Survival in the Real World; Autonomic Systems; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Kephart, J.; Chess, D. The vision of autonomic computing. Computer 2003, 36, 41–50. [Google Scholar] [CrossRef]

- Goller, M.; Tomforde, S. Identifying Adaptation Changes in Collections of Self-Adaptive Systems. In Proceedings of the 2022 IEEE International Conference on Autonomic Computing and Self-Organizing Systems Companion (ACSOS-C), Los Angeles, CA, USA, 19–23 September 2022; pp. 101–106. [Google Scholar] [CrossRef]

- Tomforde, S.; Rudolph, S.; Bellman, K.; Würtz, R. An Organic Computing Perspective on Self-Improving System Interweaving at Runtime. In Proceedings of the 2016 IEEE International Conference on Autonomic Computing (ICAC), Wuerzburg, Germany, 17–22 July 2016; pp. 276–284. [Google Scholar] [CrossRef]

- Wong, T.; Wagner, M.; Treude, C. Self-adaptive systems: A systematic literature review across categories and domains. Inf. Softw. Technol. 2022, 148, 106934. [Google Scholar] [CrossRef]

- Salehie, M.; Tahvildari, L. Self-adaptive software: Landscape and research challenges. ACM Trans. Auton. Adapt. Syst. 2009, 4, 1–42. [Google Scholar] [CrossRef]

- Würtz, R.P. Organic Computing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Müller-Schloer, C.; Schmeck, H.; Ungerer, T. Organic Computing—A Paradigm Shift for Complex Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Arcaini, P.; Riccobene, E.; Scandurra, P. Modeling and Analyzing MAPE-K Feedback Loops for Self-Adaptation. In Proceedings of the 2015 IEEE/ACM 10th International Symposium on Software Engineering for Adaptive and Self-Managing Systems, Florence, Italy, 18–19 May 2015; pp. 13–23. [Google Scholar] [CrossRef]

- Iglesia, D.G.D.L.; Weyns, D. MAPE-K Formal Templates to Rigorously Design Behaviors for Self-Adaptive Systems. ACM Trans. Auton. Adapt. Syst. 2015, 10, 1–31. [Google Scholar] [CrossRef]

- Weyns, D.; Schmerl, B.; Grassi, V.; Malek, S.; Mirandola, R.; Prehofer, C.; Wuttke, J.; Andersson, J.; Giese, H.; Göschka, K.M. On Patterns for Decentralized Control in Self-Adaptive Systems. In Software Engineering for Self-Adaptive Systems II: International Seminar, Dagstuhl Castle, Germany, October 24-29, 2010 Revised Selected and Invited Papers; de Lemos, R., Giese, H., Müller, H.A., Shaw, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 76–107. [Google Scholar] [CrossRef]

- Tomforde, S.; Prothmann, H.; Branke, J.; Hähner, J.; Mnif, M.; Müller-Schloer, C.; Richter, U.; Schmeck, H. Observation and Control of Organic Systems. In Organic Computing—A Paradigm Shift for Complex Systems; Müller-Schloer, C., Schmeck, H., Ungerer, T., Eds.; Springer: Basel, Switzerland, 2011; pp. 325–338. [Google Scholar] [CrossRef]

- Jamshidi, S.; Amirnia, A.; Nikanjam, A.; Khomh, F. Enhancing Security and Energy Efficiency of Cyber-Physical Systems using Deep Reinforcement Learning. Procedia Comput. Sci. 2024, 238, 1074–1079. [Google Scholar] [CrossRef]

- Grimmelius, H.; Meiler, P.; Maas, H.; Bonnier, B.; Grevink, J.; van Kuilenburg, R. Three state-of-the-art methods for condition monitoring. IEEE Trans. Ind. Electron. 1999, 46, 407–416. [Google Scholar] [CrossRef]

- Shahzad, K.; O’Nils, M. Condition Monitoring in Industry 4.0-Design Challenges and Possibilities: A Case Study. In Proceedings of the 2018 Workshop on Metrology for Industry 4.0 and IoT, Brescia, Italy, 16–18 April 2018; pp. 101–106. [Google Scholar] [CrossRef]

- Correa, J.C.A.J.; Guzman, A.A.L. Mechanical Vibrations and Condition Monitoring; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Hodge, V.; Austin, J. A Survey of Outlier Detection Methodologies. Artif. Intell. Rev. 2004, 22, 85–126. [Google Scholar] [CrossRef]

- Sun, H.C.; Huang, Y.C.; Huang, C.M. Fault Diagnosis of Power Transformers Using Computational Intelligence: A Review. Energy Procedia 2012, 14, 1226–1231. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X.; Chen, X. Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Process. 2014, 96, 1–15. [Google Scholar] [CrossRef]

- El-Thalji, I.; Jantunen, E. A summary of fault modelling and predictive health monitoring of rolling element bearings. Mech. Syst. Signal Process. 2015, 60–61, 252–272. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S.H. A review on signal processing techniques utilized in the fault diagnosis of rolling element bearings. Tribol. Int. 2016, 96, 289–306. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, W. Review of tool condition monitoring methods in milling processes. Int. J. Adv. Manuf. Technol. 2018, 96, 2509–2523. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration based condition monitoring and fault diagnosis of wind turbine planetary gearbox: A review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Kumar, A.; Gandhi, C.P.; Zhou, Y.; Kumar, R.; Xiang, J. Latest developments in gear defect diagnosis and prognosis: A review. Measurement 2020, 158, 107735. [Google Scholar] [CrossRef]

- Chaupal, P.; Rajendran, P. A review on recent developments in vibration-based damage identification methods for laminated composite structures: 2010–2022. Compos. Struct. 2023, 311, 116809. [Google Scholar] [CrossRef]

- Piliuk, K.; Tomforde, S. Artificial intelligence in emergency medicine. A systematic literature review. Int. J. Med. Inform. 2023, 180, 105274. [Google Scholar] [CrossRef]

- Google Scholar. Google Scholar Homepage. n.d. Available online: https://scholar.google.com (accessed on 15 November 2024).

- ACM Digital Library. ACM Digital Library Homepage. n.d. Available online: https://dl.acm.org (accessed on 15 November 2024).

- IEEE Xplore. IEEE Xplore Digital Library. n.d. Available online: https://ieeexplore.ieee.org (accessed on 15 November 2024).

- SpringerLink. Search Page on SpringerLink. n.d. Available online: https://link.springer.com/search (accessed on 15 November 2024).

- ScienceDirect | Science, Health and Medical Journals, Full Text Articles and Books. n.d. Available online: https://www.sciencedirect.com/ (accessed on 15 November 2024).

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Mei, X.; Xu, H.; Feng, P.; Yuan, M.; Xu, C.; Ma, Y.; Feng, F. Online chatter monitor system based on rapid detection method and wireless communication. Int. J. Adv. Manuf. Technol. 2022, 122, 1321–1337. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, D.; Zhang, Z.; Chen, H.; Chen, S. EMD-based pulsed TIG welding process porosity defect detection and defect diagnosis using GA-SVM. J. Mater. Process. Technol. 2017, 239, 92–102. [Google Scholar] [CrossRef]

- Lonardo, P.M.; Bruzzone, A.A.; Lonardo, A.M. Analysis of Machined Surfaces through Diffraction Patterns and Neural Networks. CIRP Ann. 1995, 44, 509–512. [Google Scholar] [CrossRef]

- Hu, W.; Starr, A.G.; Zhou, Z.; Leung, A.Y.T. A systematic approach to integrated fault diagnosis of flexible manufacturing systems. Int. J. Mach. Tools Manuf. 2000, 40, 1587–1602. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, T.W.; Na, J.; Fung, R.F. Envelope order tracking for fault detection in rolling element bearings. J. Sound Vib. 2012, 331, 5644–5654. [Google Scholar] [CrossRef]

- Dong, G.; Chen, J. Noise resistant time frequency analysis and application in fault diagnosis of rolling element bearings. Mech. Syst. Signal Process. 2012, 33, 212–236. [Google Scholar] [CrossRef]

- Yu, K.; Lin, T.R.; Tan, J.W. A bearing fault diagnosis technique based on singular values of EEMD spatial condition matrix and Gath-Geva clustering. Appl. Acoust. 2017, 121, 33–45. [Google Scholar] [CrossRef]

- Altinors, A.; Yol, F.; Yaman, O. A sound based method for fault detection with statistical feature extraction in UAV motors. Appl. Acoust. 2021, 183, 108325. [Google Scholar] [CrossRef]

- Liu, X.; Chen, G.; Wei, X.; Liu, Y.; Wang, H. A rolling bearing fault evolution state indicator based on deep learning and its application. J. Mech. Sci. Technol. 2023, 37, 2755–2769. [Google Scholar] [CrossRef]

- Mubaraali, L.; Kuppuswamy, N.; Muthukumar, R. Intelligent fault diagnosis in microprocessor systems for vibration analysis in roller bearings in whirlpool turbine generators real time processor applications. Microprocess. Microsyst. 2020, 76, 103079. [Google Scholar] [CrossRef]

- Kong, Y.; Qin, Z.; Wang, T.; Han, Q.; Chu, F. An enhanced sparse representation-based intelligent recognition method for planet bearing fault diagnosis in wind turbines. Renew. Energy 2021, 173, 987–1004. [Google Scholar] [CrossRef]

- Chen, Q.; Hu, Y.; Xia, J.; Chen, Z.; Tseng, H.W. Data fusion of wireless sensor network for prognosis and diagnosis of mechanical systems. Microsyst. Technol. 2021, 27, 1187–1199. [Google Scholar] [CrossRef]

- Pan, Y.; Hong, R.; Chen, J.; Singh, J.; Jia, X. Performance degradation assessment of a wind turbine gearbox based on multi-sensor data fusion. Mech. Mach. Theory 2019, 137, 509–526. [Google Scholar] [CrossRef]

- Yadao, A.; Mishra, K. A Hybridization of CSA DEA Approach for Detection of Multiple Transverse Crack Rotor Shaft Rotating in Fluid Environment under Axial and Bending Loading. Mech. Solids 2024, 59, 2100–2126. [Google Scholar] [CrossRef]

- Yang, B.S.; Hwang, W.W.; Kim, D.J.; Chit Tan, A. Condition classification of small reciprocating compressor for refrigerators using artificial neural networks and support vector machines. Mech. Syst. Signal Process. 2005, 19, 371–390. [Google Scholar] [CrossRef]

- Guesmi, H.; Ben Salem, S.; Bacha, K. Smart wireless sensor networks for online faults diagnosis in induction machine. Comput. Electr. Eng. 2015, 41, 226–239. [Google Scholar] [CrossRef]

- Ying, S.; Sun, Y.; Fu, C.; Lin, L.; Zhang, S. Grey wolf optimization based support vector machine model for tool wear recognition in fir-tree slot broaching of aircraft turbine discs. J. Mech. Sci. Technol. 2022, 36, 6261–6273. [Google Scholar] [CrossRef]

- Piedras Lopes, T.A.; Troyman, A.C.R. Neural Networks on Predictive Maintenance of Turbomachinery. IFAC Proc. Vol. 1997, 30, 983–988. [Google Scholar] [CrossRef]

- Ruiz de la Hermosa González-Carrato, R. Wind farm monitoring using Mahalanobis distance and fuzzy clustering. Renew. Energy 2018, 123, 526–540. [Google Scholar] [CrossRef]

- Wang, Y.j.; Zhang, M.j. Study of fuzzy neural networks model for system condition monitoring of AUV. J. Mar. Sci. Appl. 2002, 1, 42–45. [Google Scholar] [CrossRef]

- Long, B.; Xian, W.; Li, M.; Wang, H. Improved diagnostics for the incipient faults in analog circuits using LSSVM based on PSO algorithm with Mahalanobis distance. Neurocomputing 2014, 133, 237–248. [Google Scholar] [CrossRef]

- Keyvan, S. Traditional signal pattern recognition versus artificial neural networks for nuclear plant diagnostics. Prog. Nucl. Energy 2001, 39, 1–29. [Google Scholar] [CrossRef]

- Wang, X.l.; Gu, H.; Xu, L.; Hu, C.; Guo, H. A SVR-Based Remaining Life Prediction for Rolling Element Bearings. J. Fail. Anal. Prev. 2015, 15, 548–554. [Google Scholar] [CrossRef]

- Tao, L.; Zhang, T.; Peng, D.; Hao, J.; Jia, Y.; Lu, C.; Ding, Y.; Ma, L. Long-term degradation prediction and assessment with heteroscedasticity telemetry data based on GRU-GARCH and MD hybrid method: An application for satellite. Aerosp. Sci. Technol. 2021, 115, 106826. [Google Scholar] [CrossRef]

- Kaloni, S.; Singh, G.; Tiwari, P. Nonparametric damage detection and localization model of framed civil structure based on local gravitation clustering analysis. J. Build. Eng. 2021, 44, 103339. [Google Scholar] [CrossRef]

- Mukherjee, A.; Banerjee, A. Analysis of Acoustic Emission Signal for Crack Detection and Distance Measurement on Steel Structure. Acoust. Aust. 2021, 49, 133–149. [Google Scholar] [CrossRef]

- Liang, W.; Kang, J.; Zhang, L. Leak detection for long transportation pipeline using a state coupling analysis of pump units. J. Loss Prev. Process Ind. 2013, 26, 586–593. [Google Scholar] [CrossRef]

- Lin, T.; Zhu, Y.; Zhang, X.; Huang, K.; Yan, K. A robust FOD acoustic detection method for rocket tank final assembly process. Appl. Acoust. 2023, 211, 109479. [Google Scholar] [CrossRef]

- Abu-Mahfouz, I.; Banerjee, A. Crack Detection and Identification Using Vibration Signals and Fuzzy Clustering. Procedia Comput. Sci. 2017, 114, 266–274. [Google Scholar] [CrossRef]

- Dong, M.; Chen, S.; Xie, B.; Wang, K.; Zhai, W. A quantitative detection method for wheel polygonization of heavy-haul locomotives based on a hybrid deep learning model. Measurement 2024, 227, 114206. [Google Scholar] [CrossRef]

- Drouillet, C.; Karandikar, J.; Nath, C.; Journeaux, A.C.; El Mansori, M.; Kurfess, T. Tool life predictions in milling using spindle power with the neural network technique. J. Manuf. Process. 2016, 22, 161–168. [Google Scholar] [CrossRef]

- Barakat, M.; Lefebvre, D.; Khalil, M.; Druaux, F.; Mustapha, O. Parameter selection algorithm with self adaptive growing neural network classifier for diagnosis issues. Int. J. Mach. Learn. Cybern. 2013, 4, 217–233. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, L.; Liang, W. Dynamic degradation observer for bearing fault by MTS–SOM system. Mech. Syst. Signal Process. 2013, 36, 385–400. [Google Scholar] [CrossRef]

- Netzer, M.; Michelberger, J.; Fleischer, J. Intelligent Anomaly Detection of Machine Tools based on Mean Shift Clustering. Procedia CIRP 2020, 93, 1448–1453. [Google Scholar] [CrossRef]

- Sheng, Y.; Zhang, G.; Zhang, Y.; Luo, M.; Pang, Y.; Wang, Q. A multimodal data sensing and feature learning-based self-adaptive hybrid approach for machining quality prediction. Adv. Eng. Inform. 2024, 59, 102324. [Google Scholar] [CrossRef]

- Pomponi, E.; Vinogradov, A. A real-time approach to acoustic emission clustering. Mech. Syst. Signal Process. 2013, 40, 791–804. [Google Scholar] [CrossRef]

- Garcés-Jiménez, A.; Rodrigues, A.; Gómez-Pulido, J.M.; Raposo, D.; Gómez-Pulido, J.A.; Silva, J.S.; Boavida, F. Industrial Internet of Things embedded devices fault detection and classification. A case study. Internet Things 2024, 25, 101042. [Google Scholar] [CrossRef]

- Zhang, F.; Li, B.; Yu, C.; Chen, J.; Peng, T.; Wang, X. A new real-time hole cleaning monitoring method based on downhole multi-point pressure measurement and data driven approach. Nat. Gas Ind. B 2023, 10, 312–321. [Google Scholar] [CrossRef]

- Omoregbee, H.O.; Heyns, P.S. Fault Classification of Low-Speed Bearings Based on Support Vector Machine for Regression and Genetic Algorithms Using Acoustic Emission. J. Vib. Eng. Technol. 2019, 7, 455–464. [Google Scholar] [CrossRef]

- Liang, Y.; Hu, S.; Guo, W.; Tang, H. Abrasive tool wear prediction based on an improved hybrid difference grey wolf algorithm for optimizing SVM. Measurement 2022, 187, 110247. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Zhu, J. An Adaptive Remaining Life Prediction for Rolling Element Bearings. J. Fail. Anal. Prev. 2015, 15, 82–89. [Google Scholar] [CrossRef]

- Wen, Z.; Fang, P.; Yin, Y.; Królczyk, G.; Gardoni, P.; Li, Z. A novel machine learning model for safety risk analysis in flywheel-battery hybrid energy storage system. J. Energy Storage 2022, 49, 104072. [Google Scholar] [CrossRef]

- Mansi; Saini, K.; Vanraj; Dhami, S.S. MODWT and VMD Based Intelligent Gearbox Early Stage Fault Detection Approach. J. Fail. Anal. Prev. 2021, 21, 1821–1837. [Google Scholar] [CrossRef]

- Xing, Z.; Qu, J.; Chai, Y.; Tang, Q.; Zhou, Y. Gear fault diagnosis under variable conditions with intrinsic time-scale decomposition-singular value decomposition and support vector machine. J. Mech. Sci. Technol. 2017, 31, 545–553. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Lu, C. Rolling bearing fault diagnosis based on LCD–TEO and multifractal detrended fluctuation analysis. Mech. Syst. Signal Process. 2015, 60–61, 273–288. [Google Scholar] [CrossRef]

- Wu, J.; Su, Y.; Cheng, Y.; Shao, X.; Deng, C.; Liu, C. Multi-sensor information fusion for remaining useful life prediction of machining tools by adaptive network based fuzzy inference system. Appl. Soft Comput. 2018, 68, 13–23. [Google Scholar] [CrossRef]

- Tansel, I.N.; Mekdeci, C.; Mclaughlin, C. Detection of tool failure in end milling with wavelet transformations and neural networks (WT-NN). Int. J. Mach. Tools Manuf. 1995, 35, 1137–1147. [Google Scholar] [CrossRef]

- Ben Ali, J.; Saidi, L.; Mouelhi, A.; Chebel-Morello, B.; Fnaiech, F. Linear feature selection and classification using PNN and SFAM neural networks for a nearly online diagnosis of bearing naturally progressing degradations. Eng. Appl. Artif. Intell. 2015, 42, 67–81. [Google Scholar] [CrossRef]

- Saxena, A.; Saad, A. Evolving an artificial neural network classifier for condition monitoring of rotating mechanical systems. Appl. Soft Comput. 2007, 7, 441–454. [Google Scholar] [CrossRef]

- Peng, Y.; Cai, J.; Wu, T.; Cao, G.; Kwok, N.; Peng, Z. WP-DRnet: A novel wear particle detection and recognition network for automatic ferrograph image analysis. Tribol. Int. 2020, 151, 106379. [Google Scholar] [CrossRef]

- Gültekin, Ö.; Cinar, E.; Özkan, K.; Yazıcı, A. Multisensory data fusion-based deep learning approach for fault diagnosis of an industrial autonomous transfer vehicle. Expert Syst. Appl. 2022, 200, 117055. [Google Scholar] [CrossRef]

- Singh, S.K.; Kumar, S.; Dwivedi, J.P. Compound fault prediction of rolling bearing using multimedia data. Multimed. Tools Appl. 2017, 76, 18771–18788. [Google Scholar] [CrossRef]

- Selvaraj, V.; Xu, Z.; Min, S. Intelligent Operation Monitoring of an Ultra-Precision CNC Machine Tool Using Energy Data. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 59–69. [Google Scholar] [CrossRef]

- Chen, T.; Zheng, J.; Peng, C.; Zhang, S.; Jing, Z.; Wang, Z. Tapping process fault identification by LSTM neural network based on torque signal singularity feature. J. Mech. Sci. Technol. 2024, 38, 1123–1133. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Gui, H.; Wang, S. Intelligent digital-twin prediction and reverse control system architecture for thermal errors enabled by deep learning and cloud-edge computing. Expert Syst. Appl. 2023, 225, 120122. [Google Scholar] [CrossRef]

- Mao, W.; Tian, S.; Fan, J.; Liang, X.; Safian, A. Online detection of bearing incipient fault with semi-supervised architecture and deep feature representation. J. Manuf. Syst. 2020, 55, 179–198. [Google Scholar] [CrossRef]

- Ma, P.; Lan, X.; Tong, S.; Zheng, X.; Wang, W. The method of self-learning based online tool wear monitoring in semi-finishing or finishing working step. Int. J. Adv. Manuf. Technol. 2023, 124, 4649–4661. [Google Scholar] [CrossRef]

- He, Z.; Cao, H.; Li, Z.; Zi, Y.; Chen, X. The principle of second generation wavelet for milling cutter breakage detection. Sci. China Ser. E Technol. Sci. 2009, 52, 1312–1322. [Google Scholar] [CrossRef]

- Li, X.; Ma, J.; Wang, X.; Wu, J.; Li, Z. An improved local mean decomposition method based on improved composite interpolation envelope and its application in bearing fault feature extraction. ISA Trans. 2020, 97, 365–383. [Google Scholar] [CrossRef]

- Cambow, R.; Singh, M. Comparative Analysis of Wear Resistance for Bearing Coating Using VMD. J. Vib. Eng. Technol. 2024, 12, 93–108. [Google Scholar] [CrossRef]

- Abbasi, A.; Firouzi, B.; Sendur, P.; Ranjan, G.; Tiwari, R. Identification of unbalance characteristics of rotating machinery using a novel optimization-based methodology. Soft Comput. 2022, 26, 4831–4862. [Google Scholar] [CrossRef]

- Li, Z.; Wang, S.; Yu, C.; Qi, C.; Shen, X.; Fernandez, C. An improved adaptive weights correction-particle swarm optimization-unscented particle filter method for high-precision online state of charge estimation of lithium-ion batteries. Ionics 2024, 30, 311–334. [Google Scholar] [CrossRef]

- Liu, W.; Qin, G.; Zhu, Q.; Hu, G. Synchronous extraction circuit with self-adaptive peak-detection mechanical switches design for piezoelectric energy harvesting. Appl. Energy 2018, 230, 1292–1303. [Google Scholar] [CrossRef]

- Saidi, L.; Ali, J.B.; Fnaiech, F. Bi-spectrum based-EMD applied to the non-stationary vibration signals for bearing faults diagnosis. ISA Trans. 2014, 53, 1650–1660. [Google Scholar] [CrossRef]

- Mishra, R.; Singh, B. Stability analysis in milling process using spline based local mean decomposition (SBLMD) technique and statistical indicators. Measurement 2021, 174, 108999. [Google Scholar] [CrossRef]

- Deng, L.; Zhao, R. A vibration analysis method based on hybrid techniques and its application to rotating machinery. Measurement 2013, 46, 3671–3682. [Google Scholar] [CrossRef]

- Babouri, M.K.; Ouelaa, N.; Djebala, A. Experimental study of tool life transition and wear monitoring in turning operation using a hybrid method based on wavelet multi-resolution analysis and empirical mode decomposition. Int. J. Adv. Manuf. Technol. 2016, 82, 2017–2028. [Google Scholar] [CrossRef]

- Li, H.; Yu, B.; Qing, B.; Luo, S. Cavitation pulse extraction and centrifugal pump analysis. J. Mech. Sci. Technol. 2017, 31, 1181–1188. [Google Scholar] [CrossRef]

- Das, S.; Roy, R.; Chattopadhyay, A.B. Evaluation of wear of turning carbide inserts using neural networks. Int. J. Mach. Tools Manuf. 1996, 36, 789–797. [Google Scholar] [CrossRef]

- Hossain, R.E.N.; Lewis, J.; Moore, A.L. In situ infrared temperature sensing for real-time defect detection in additive manufacturing. Addit. Manuf. 2021, 47, 102328. [Google Scholar] [CrossRef]

- Juuma, T.; Parkkinen, R. Application of a Neural Network to Condition Monitoring and Fault Diagnosis in an Pressure System. IFAC Proc. Vol. 1994, 27, 603–609. [Google Scholar] [CrossRef]

- Guglielmi, G.; Parisini, T.; Rossi, G. Keynote paper: Fault diagnosis and neural networks: A power plant application. Control Eng. Pract. 1995, 3, 601–620. [Google Scholar] [CrossRef]

- Lughofer, E.; Pollak, R.; Zavoianu, A.C.; Pratama, M.; Meyer-Heye, P.; Zörrer, H.; Eitzinger, C.; Haim, J.; Radauer, T. Self-adaptive evolving forecast models with incremental PLS space updating for on-line prediction of micro-fluidic chip quality. Eng. Appl. Artif. Intell. 2018, 68, 131–151. [Google Scholar] [CrossRef]

- André, H.; Allemand, F.; Khelf, I.; Bourdon, A.; Rémond, D. Improving the monitoring indicators of a variable speed wind turbine using support vector regression. Appl. Acoust. 2020, 166, 107350. [Google Scholar] [CrossRef]

- Gouarir, A.; Martínez-Arellano, G.; Terrazas, G.; Benardos, P.; Ratchev, S. In-process Tool Wear Prediction System Based on Machine Learning Techniques and Force Analysis. Procedia CIRP 2018, 77, 501–504. [Google Scholar] [CrossRef]

- Skitt, P.J.C.; Javed, M.A.; Sanders, S.A.; Higginson, A.M. Process monitoring using auto-associative, feed-forward artificial neural networks. J. Intell. Manuf. 1993, 4, 79–94. [Google Scholar] [CrossRef]

- Tansel, I.N.; Mekdeci, C.; Rodriguez, O.; Uragun, B. Monitoring drill conditions with wavelet based encoding and neural networks. Int. J. Mach. Tools Manuf. 1993, 33, 559–575. [Google Scholar] [CrossRef]

- Silva, R.G. Condition monitoring of the cutting process using a self-organizing spiking neural network map. J. Intell. Manuf. 2010, 21, 823–829. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, X.; Liao, L.; Tang, M.; Wu, J. A new rotating machinery fault diagnosis method based on local oscillatory-characteristic decomposition. Digit. Signal Process. 2018, 78, 98–107. [Google Scholar] [CrossRef]

- Hou, Y.; Wu, P.; Wu, D. An operating condition information-guided iterative variational mode decomposition method based on Mahalanobis distance criterion for surge characteristic frequency extraction of the centrifugal compressor. Mech. Syst. Signal Process. 2023, 186, 109836. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, J.; Xiao, J.; Zhang, X.; Xiao, H.; Zhu, W.; Fu, W. Fault diagnosis based on dependent feature vector and probability neural network for rolling element bearings. Appl. Math. Comput. 2014, 247, 835–847. [Google Scholar] [CrossRef]

- Dong, Q.; Zhou, Y.; Lian, J.; Li, L. Online adaptive humidity monitoring method for proton exchange membrane fuel cell based on fuzzy C-means clustering and online sequence extreme learning machine. Electrochim. Acta 2022, 429, 141059. [Google Scholar] [CrossRef]

- Zhang, L.; Cai, S.; Hu, J. An adaptive pre-warning method based on trend monitoring: Application to an oil refining process. Measurement 2019, 139, 163–176. [Google Scholar] [CrossRef]

- Gao, P.; Yan, X.; Wang, Y.; Li, H.; Zhan, M.; Ma, F.; Fu, M. An online intelligent method for roller path design in conventional spinning. J. Intell. Manuf. 2023, 34, 3429–3444. [Google Scholar] [CrossRef]

- Liu, Y.; Du, M.; Yin, J.; Dong, C. A parameter self-correcting thermal network model considering IGBT module solder layer aging. Microelectron. J. 2023, 134, 105741. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, Y.; Yu, M.; Yu, D.; Lv, J.; Yin, J.; Liu, J.; Wu, R. Triboelectric sensor for planetary gear fault diagnosis using data enhancement and CNN. Nano Energy 2022, 103, 107804. [Google Scholar] [CrossRef]

- Dabrowski, D. Condition monitoring of planetary gearbox by hardware implementation of artificial neural networks. Measurement 2016, 91, 295–308. [Google Scholar] [CrossRef]

- Staniek, M.; Czech, P. Self-correcting neural network in road pavement diagnostics. Autom. Constr. 2018, 96, 75–87. [Google Scholar] [CrossRef]

- Gopali, S.; Abri, F.; Siami-Namini, S.; Namin, A.S. A Comparison of TCN and LSTM Models in Detecting Anomalies in Time Series Data. In Proceedings of the 2021 IEEE International Conference on Big Data (Big Data), Orlando, FL, USA, 15–18 December 2021; pp. 2415–2420. [Google Scholar] [CrossRef]

- Taha, H.A.; Yacout, S.; Shaban, Y. Autonomous self-healing mechanism for a CNC milling machine based on pattern recognition. J. Intell. Manuf. 2023, 34, 2185–2205. [Google Scholar] [CrossRef]

- Chang, B.R.; Tsai, H.F.; Chen, G.R. Self-Adaptive Server Anomaly Detection Using Ensemble Meta-Reinforcement Learning. Electronics 2024, 13, 2348. [Google Scholar] [CrossRef]

- Li, W.; Zhan, J.; Wang, J.; Xia, B.; Gao, B.B.; Liu, J.; Wang, C.; Zheng, F. Towards Continual Adaptation in Industrial Anomaly Detection. In Proceedings of the 30th ACM International Conference on Multimedia, Lisboa, Portugal, 10–14 October 2022; pp. 2871–2880. [Google Scholar] [CrossRef]

- Huertas Celdrán, A.; Gil Pérez, M.; García Clemente, F.J.; Martínez Pérez, G. Towards the autonomous provision of self-protection capabilities in 5G networks. J. Ambient Intell. Humaniz. Comput. 2019, 10, 4707–4720. [Google Scholar] [CrossRef]

- Schönberner, C.; Rothenburger, K.M.; Mackensen, A.; Tomforde, S. Neural Rules for Reinforcement Learning with XCSF as Controller in Organic Computing Systems. In Proceedings of the ARCS ’25, Kiel, Germany, 22–24 April 2025. [Google Scholar]

- Heider, M.; Pätzel, D.; Stegherr, H.; Hähner, J. A Metaheuristic Perspective on Learning Classifier Systems. In Metaheuristics for Machine Learning: New Advances and Tools; Eddaly, M., Jarboui, B., Siarry, P., Eds.; Springer Nature: Singapore, 2023; pp. 73–98. [Google Scholar] [CrossRef]

- Ziesche, F.; Klös, V.; Glesner, S. Anomaly Detection and Classification to enable Self-Explainability of Autonomous Systems. In Proceedings of the 2021 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 1–5 February 2021; pp. 1304–1309. [Google Scholar] [CrossRef]

- Wang, Y.; Li, P.; Bai, C.; Leskovec, J. TEDIC: Neural Modeling of Behavioral Patterns in Dynamic Social Interaction Networks. In Proceedings of the Web Conference 2021, Ljubljana, Slovenia, 19–23 April 2021; pp. 693–705. [Google Scholar] [CrossRef]

- Nolte, L.; Finck, M.J.; Pirk, S.; Tomforde, S. Feedback-guided Dataset Shaping for Automated Downstream Task Optimization. In Proceedings of the GI Workshop on Organic Computing (OC); Supported by the IDIR-Project (Digital Implant Research), a cooperation financed by Kiel University, University Hospital Schleswig-Holstein and Helmholtz Zentrum Hereon; Gesellschaft für Informatik: Kiel, Germany, 2025. [Google Scholar]

- Wu, R.; Das, N.; Chaba, S.; Gandhi, S.; Chau, D.H.; Chu, X. A Cluster-then-label Approach for Few-shot Learning with Application to Automatic Image Data Labeling. J. Data Inf. Qual. 2022, 14, 1–23. [Google Scholar] [CrossRef]

- NVIDIA Corporation. Isaac Sim. n.d. Available online: https://developer.nvidia.com/isaac-sim (accessed on 2 June 2025).

- Chen, Q.; Zhang, C.; Hu, T.; Zhou, Y.; Ni, H.; Wang, T. Online chatter detection in robotic machining based on adaptive variational mode decomposition. Int. J. Adv. Manuf. Technol. 2021, 117, 555–577. [Google Scholar] [CrossRef]

- Cai, Y.; Shi, X.; Shao, H.; Wang, R.; Liao, S. Energy efficiency state identification in milling processes based on information reasoning and Hidden Markov Model. J. Clean. Prod. 2018, 193, 397–413. [Google Scholar] [CrossRef]

- Haoua, A.A.; Rey, P.A.; Cherif, M.; Abisset-Chavanne, E.; Yousfi, W. Material recognition method to enable adaptive drilling of multi-material aerospace stacks. Int. J. Adv. Manuf. Technol. 2024, 131, 779–796. [Google Scholar] [CrossRef]

- Einabadi, B.; Baboli, A.; Rother, E. A new methodology for estimation of dynamic Remaining Useful Life: A case study of conveyor chains in the automotive industry. Procedia Comput. Sci. 2022, 201, 461–469. [Google Scholar] [CrossRef]

- Salah, B.; Dit Leksir Yazid, L.; Jurgen, B. Evaluation-based closed-loop errors using principal component analysis and self-organisation map with an application to a pickling process. Int. J. Adv. Manuf. Technol. 2014, 70, 1033–1041. [Google Scholar] [CrossRef]

- Biebl, F.; Glawar, R.; Jalali, A.; Ansari, F.; Haslhofer, B.; Boer, P.d.; Sihn, W. A conceptual model to enable prescriptive maintenance for etching equipment in semiconductor manufacturing. Procedia CIRP 2020, 88, 64–69. [Google Scholar] [CrossRef]

- Ikonen, E.; Liukkonen, M.; Hansen, A.H.; Edelborg, M.; Kjos, O.; Selek, I.; Kettunen, A. Fouling monitoring in a circulating fluidized bed boiler using direct and indirect model-based analytics. Fuel 2023, 346, 128341. [Google Scholar] [CrossRef]

- Gruhl, C.; Sick, B. Novelty detection with CANDIES: A holistic technique based on probabilistic models. Int. J. Mach. Learn. Cybern. 2018, 9, 927–945. [Google Scholar] [CrossRef]

- Kumbhar, S.G.; Sudhagar P, E. An integrated approach of Adaptive Neuro-Fuzzy Inference System and dimension theory for diagnosis of rolling element bearing. Measurement 2020, 166, 108266. [Google Scholar] [CrossRef]

- Omoregbee, H.O.; Heyns, P.S. Fault detection in roller bearing operating at low speed and varying loads using Bayesian robust new hidden Markov model. J. Mech. Sci. Technol. 2018, 32, 4025–4036. [Google Scholar] [CrossRef]

- Elasha, F.; Mba, D.; Ruiz-Carcel, C. A comparative study of adaptive filters in detecting a naturally degraded bearing within a gearbox. Case Stud. Mech. Syst. Signal Process. 2016, 3, 1–8. [Google Scholar] [CrossRef][Green Version]

- Zhang, S.; Zhang, Y.; Zhu, D. Residual Life Prediction for Rolling Element Bearings Based on an Effective Degradation Indicator. J. Fail. Anal. Prev. 2015, 15, 722–729. [Google Scholar] [CrossRef]

- Pan, Y.; Er, M.J.; Li, X.; Yu, H.; Gouriveau, R. Machine health condition prediction via online dynamic fuzzy neural networks. Eng. Appl. Artif. Intell. 2014, 35, 105–113. [Google Scholar] [CrossRef]

- Elasha, F.; Ruiz-Carcel, C.; Mba, D.; Chandra, P. A Comparative Study of the Effectiveness of Adaptive Filter Algorithms, Spectral Kurtosis and Linear Prediction in Detection of a Naturally Degraded Bearing in a Gearbox. J. Fail. Anal. Prev. 2014, 14, 623–636. [Google Scholar] [CrossRef]

- Makowski, R.; Zimroz, R. A procedure for weighted summation of the derivatives of reflection coefficients in adaptive Schur filter with application to fault detection in rolling element bearings. Mech. Syst. Signal Process. 2013, 38, 65–77. [Google Scholar] [CrossRef]

- Shanbr, S.; Elasha, F.; Elforjani, M.; Teixeira, J. Detection of natural crack in wind turbine gearbox. Renew. Energy 2018, 118, 172–179. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Song, L.; Cui, L. A novel convolutional neural network based fault recognition method via image fusion of multi-vibration-signals. Comput. Ind. 2019, 105, 182–190. [Google Scholar] [CrossRef]

- Debnath, B.; Kumar, R. A Piezoelectric Energy Harvester Designed for Vibration Energy Scavenging and Shaft Fault Diagnosing-Based Applications. J. Vib. Eng. Technol. 2021, 9, 1387–1398. [Google Scholar] [CrossRef]

- Fan, R.; Lei, X.; Jia, T.; Qin, M.; Li, H.; Xiang, D. High-sensitive state perception method for inverter-fed machine turn insulation based on FrFT-Mel. Glob. Energy Interconnect. 2024, 7, 155–165. [Google Scholar] [CrossRef]

- Fang, Z.; Wang, W.; Cao, Y.; Li, Q.; Lin, Y.; Li, T.; Wu, D.; Wu, S. Reciprocating compressors intelligent fault diagnosis under multiple operating conditions based on adaptive variable scale morphological filter. Measurement 2024, 224, 113778. [Google Scholar] [CrossRef]

- Dutta, N.; Kaliannan, P.; Shanmugam, P. Application of machine learning for inter turn fault detection in pumping system. Sci. Rep. 2022, 12, 12906. [Google Scholar] [CrossRef]

- Barakat, M.; Druaux, F.; Lefebvre, D.; Khalil, M.; Mustapha, O. Self adaptive growing neural network classifier for faults detection and diagnosis. Neurocomputing 2011, 74, 3865–3876. [Google Scholar] [CrossRef]

- Abualigah, L.; Sheikhan, A.; Ikotun, A.M.; Zitar, R.A.; Alsoud, A.R.; Al-Shourbaji, I.; Hussien, A.G.; Jia, H. 1—Particle swarm optimization algorithm: Review and applications. In Metaheuristic Optimization Algorithms; Abualigah, L., Ed.; Morgan Kaufmann: Burlington, MA, USA, 2024; pp. 1–14. [Google Scholar] [CrossRef]