Leveraging Generative AI for Modelling and Optimization of Maintenance Policies in Industrial Systems

Abstract

1. Introduction

- Understand and re-formulate traditional maintenance models: instead of simply optimizing predefined models, generative AI can adapt, restructure, and improve models based on real-time data or shifting operational needs [4].

- Combine multiple policies dynamically: it offers a unique capability to overlap various maintenance strategies (e.g., preventive overhauls, corrective interventions, minimal repairs, imperfect maintenance, etc.), creating hybrid strategies that are more adaptable to industrial complexities [5].

- Offer enhanced interaction with optimization models: by enabling users to interact with the AI, it allows for adjustments not just in policy but also in the visualization of outcomes, the re-formulation of the model in finite time periods, and other exploratory tasks that go beyond traditional optimization techniques [5].

- Real-time adaptability: the AI’s ability to learn and refine strategies dynamically allows for real-time problem-solving in maintenance operations, unlike static models that require frequent manual updates [4].

2. The Maintenance Policy Concept

- The age-dependent preventive maintenance (PM) policy for a single unit system is a common approach where a unit is replaced at a predetermined age T or upon failure, whichever occurs first [7]. This policy has evolved to include concepts like minimal, imperfect, or perfect repair for CMs [15] or imperfect maintenance for PMs [15,16,17], leading to various extensions and modifications (failure limit policy, failure cost limit policy, etc.).

- A very useful extension of previous policies was the partial replacement policy [18], which is based on the idea that in most cases where a system fails, a full replacement of the system is not necessary to restore it to proper operating conditions. Instead, a partial preventive replacement (PPR) of some components is sufficient. PPRs are interventions, often named overhauls in industry, performed when the system reaches a certain age, which restore the system’s failure rate to its initial level. After a certain number of partial preventive replacements (to be determined), the accumulated costs of these interventions may exceed the cost of performing a total replacement of the system.

- A random age-dependent maintenance policy addresses scenarios where it is impractical to maintain a unit on a strictly periodic basis. Instead, maintenance is performed at random intervals, taking advantage of available free time [8,14]. In this context, a unit’s age is measured from the time of the last replacement, and minimal repairs are undertaken upon failure, leading to a periodic replacement with a minimal repair at failure policy.

- Recently, ref. [2] introduced an imperfect maintenance policy that defines a reliability improvement factor according to the intervention level of maintenance actions. This assumes the intervention level to be independent of the time between consecutive maintenance actions, removing the common constraint that longer intervals necessitate higher intervention levels. Additionally, it optimizes not only the number of maintenance activities and their timing but also the intervention levels of maintenance activities.

- Selective maintenance: maintenance prioritizes specific units based on their criticality or condition to optimize overall system reliability [19].

3. Criteria for Maintenance Policies’ Optimization

4. The Problem Statement

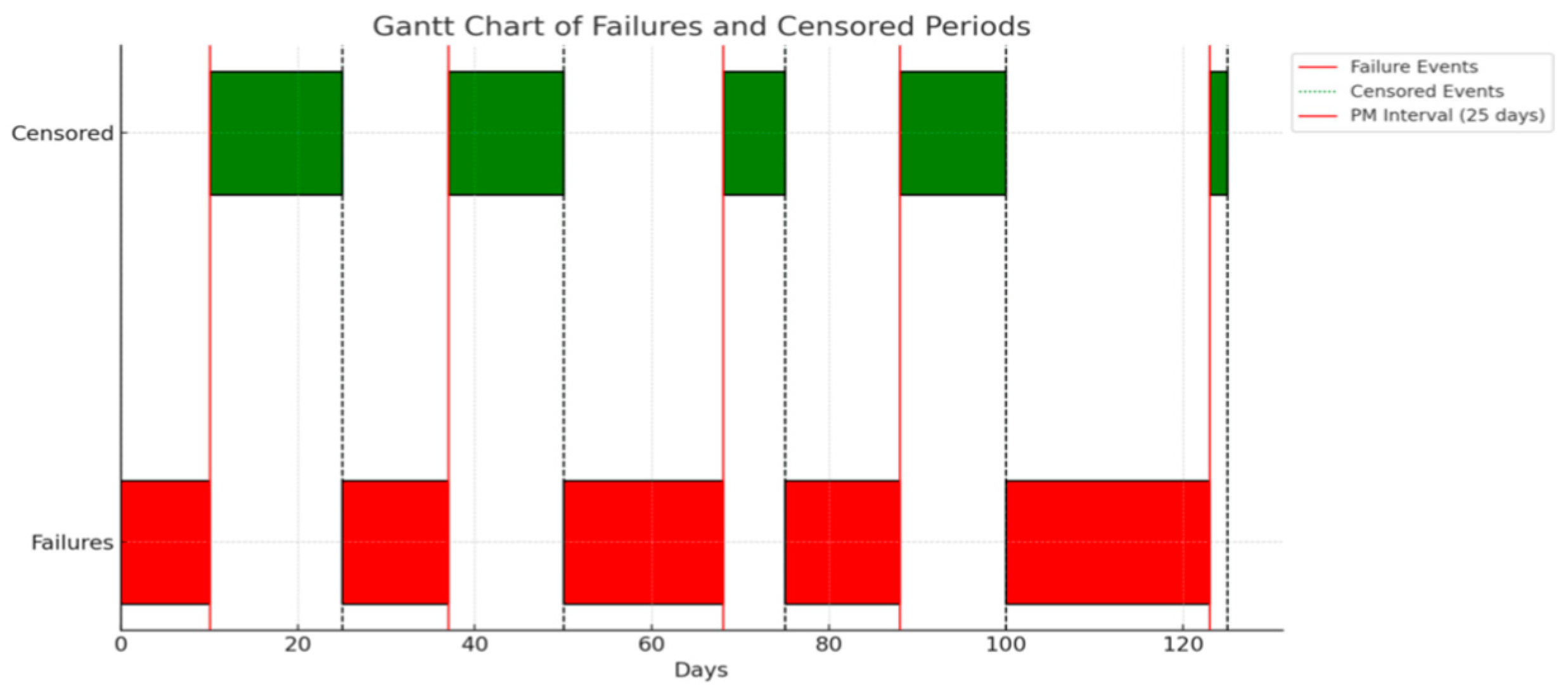

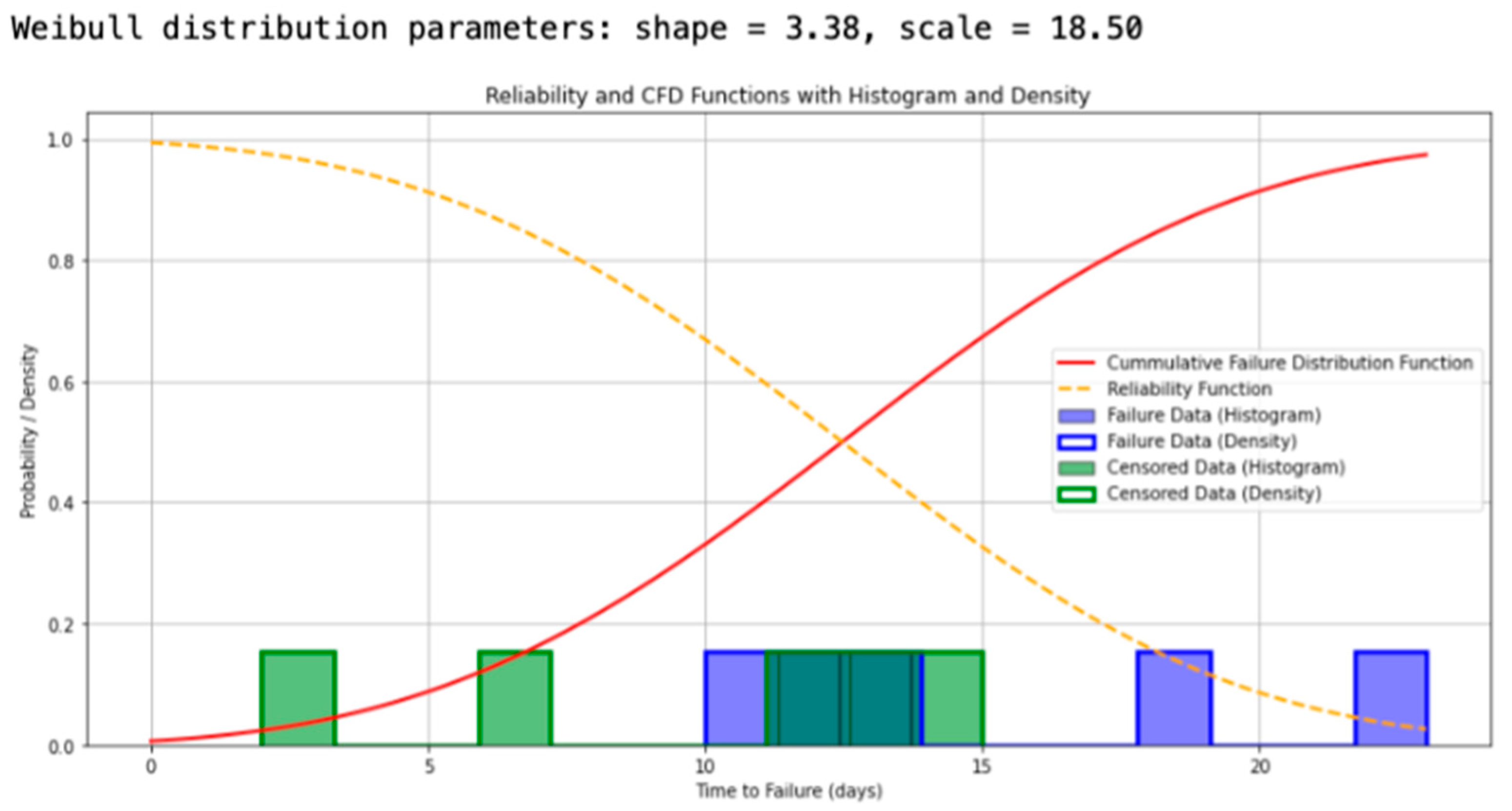

- Prompt 1. Fitting the failure data to a Weibull distribution using the MLE.

- Blue: Histogram and density of failure data.

- Green: Histogram and density of censored data.

- Red Line: Cumulative distribution function.

- Orange Dashed Line: Reliability function.

- Shape (β): 3.38

- Scale (): 18.50

5. Optimization Using Total Replacement Policies

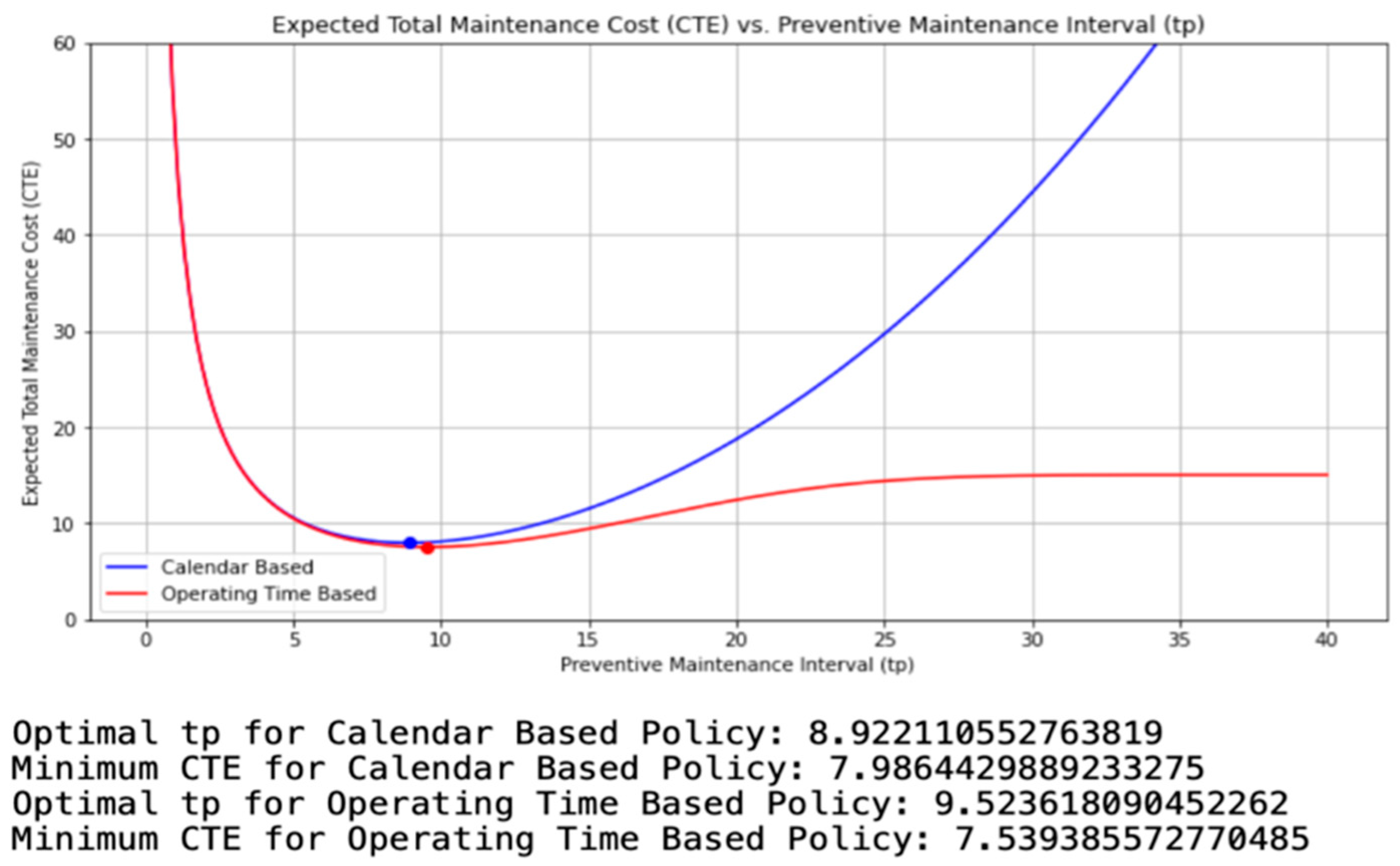

- Prompt 2. Properly formulating the maintenance optimization problem.

- -

- Equipment reliability: Weibull (3.38, 18.5)

- -

- Cp: Preventive maintenance cost = 50

- -

- Cc: Corrective maintenance cost = 250

- F(tp) is the cumulative failure probability at time tp, i.e., the integral of f(t) from 0 to tp; f(t) is the probability density function of failures.

- R(tp) is the survival probability at time tp, i.e., R(tp) = 1 − F(tp).

- M(tp) = integral of t * f(t) from 0 to tp.

- Prompt 3. Ordering to solve the maintenance optimization problem.

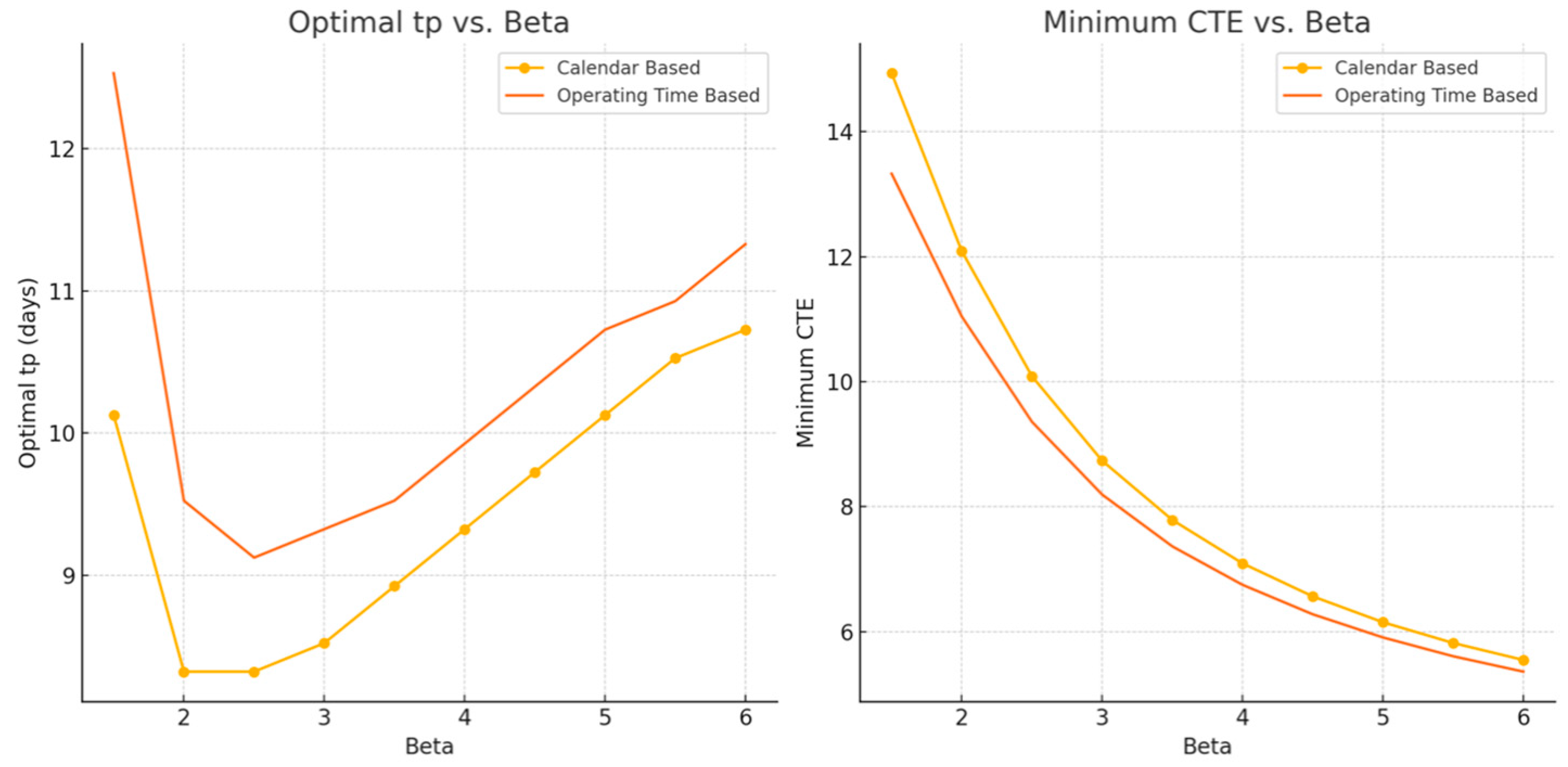

- Prompt 4. Gaining knowledge to face potential failure scenarios.

- Optimal tp vs. β: This graph shows how the optimal preventive maintenance interval (tp) changes with different values of β for both calendar-based and operating time-based policies. Both policies show a decrease in optimal tp as β increases, reflecting the higher failure rates associated with higher β values.

- Minimum CTE vs. β: This graph illustrates how the minimum expected total maintenance cost (CTE) varies with different values of β. The operating time-based policy consistently results in a lower minimum CTE compared to the calendar-based policy across the range of β values.

- Prompt 5. Gaining more knowledge to face potential cost scenarios.

6. Optimization Using Partial Replacement Policies

- Prompt 6. Transferring principles of partial replacement policy.

- [1].

- Models with partial preventive replacements (preventive overhauls) and minimal repairs; and

- [2].

- Models with partial preventive replacements (preventive overhauls) and corrective interventions (corrective overhauls).

- Partial Replacement with Minimal Repairs. Conceptual Framework:

- We consider a system that undergoes partial preventive replacements (SPPs or overhauls) and minimal repairs.

- A total system replacement (ST) occurs after k − 1 overhauls.

- Each overhaul ii takes place after Ti calendar time, with ii ranging from 1 to k − 1.

- In case of failure within the i-th interval, a minimal repair is performed, returning the system to an “as bad as old” condition (i.e., the failure rate remains unchanged after the repair).

- After an SPP or ST, the system is restored to an “as good as new” condition.

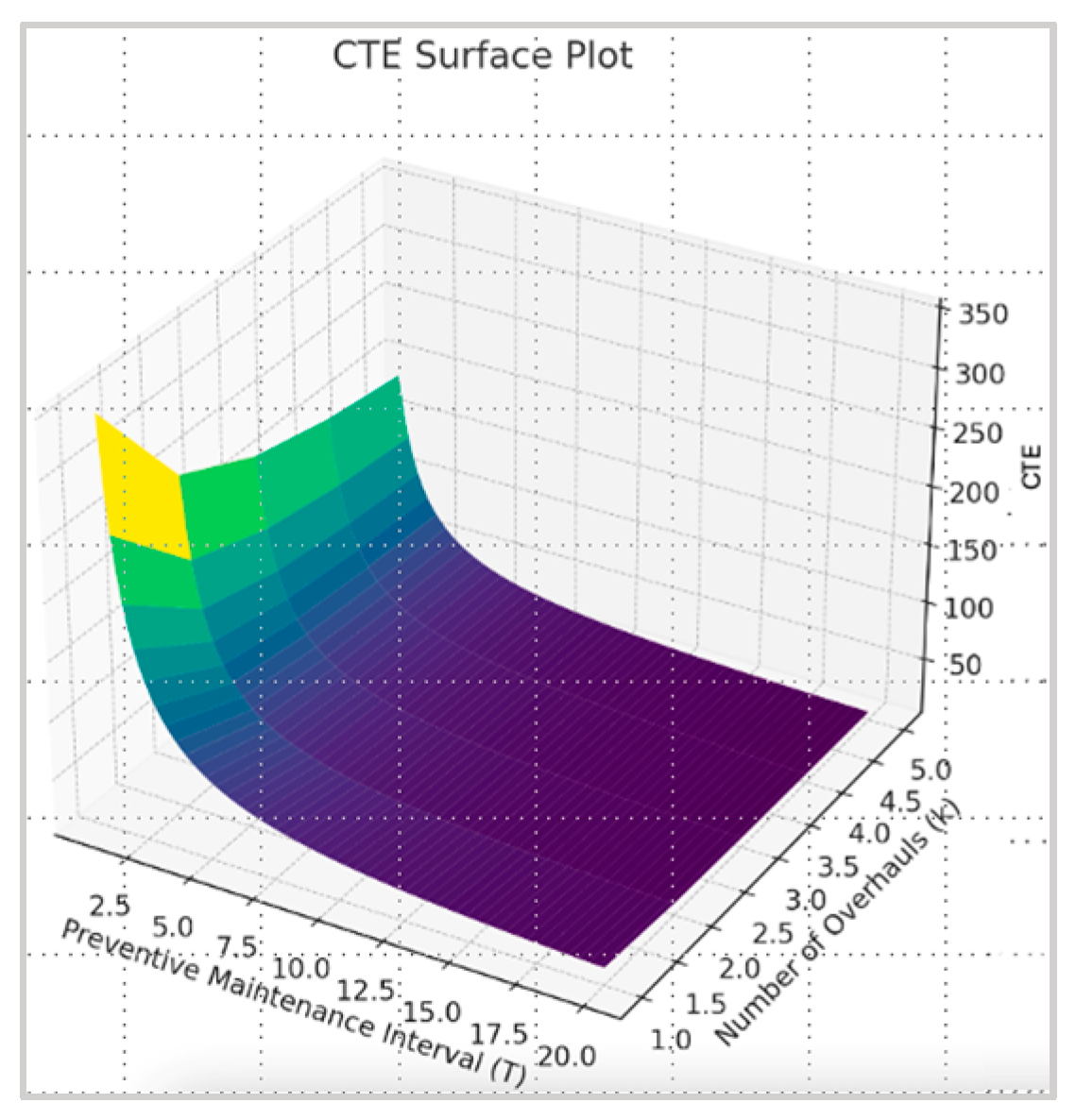

- Objective: Minimize the total expected maintenance cost CTE(k,T1,…,Tk).

- Formulation:where:

- is the total number of intervals, including the interval after the last overhaul leading to the total replacement.

- is the cost of each partial preventive replacement (overhaul).

- is the cost of total system replacement.

- is the cost of minimal repairs.

- is the number of minimal repairs in the ii-th interval.

- is the calendar time length of the i-th interval.

- Failure Rate and Minimal Repairs:

- Let denote the failure rate of the system during the ii-th interval.

- is dependent on , which changes after each overhaul.

- Steps to Solve the Problem:

- Define Failure Rate : Determine how evolves within each interval Ti. This may involve fitting a failure rate model for each interval based on historical data or assumptions.

- Calculate : Integrate the failure rate over each interval to find the expected number of minimal repairs:

- Formulate CTE Expression: Substitute the values of and the corresponding costs into the expression to obtain the expected total maintenance cost.

- Optimize : Optimize the intervals to minimize the total expected maintenance cost .

- Other Important Considerations:

- Cost Parameters: Ensure accurate estimation of , , and .

- Failure Rate Modeling: Accurate modeling of for each interval is crucial for precise calculation of .

- Optimization Method: Choose an appropriate optimization method (e.g., gradient descent, genetic algorithms) to minimize .

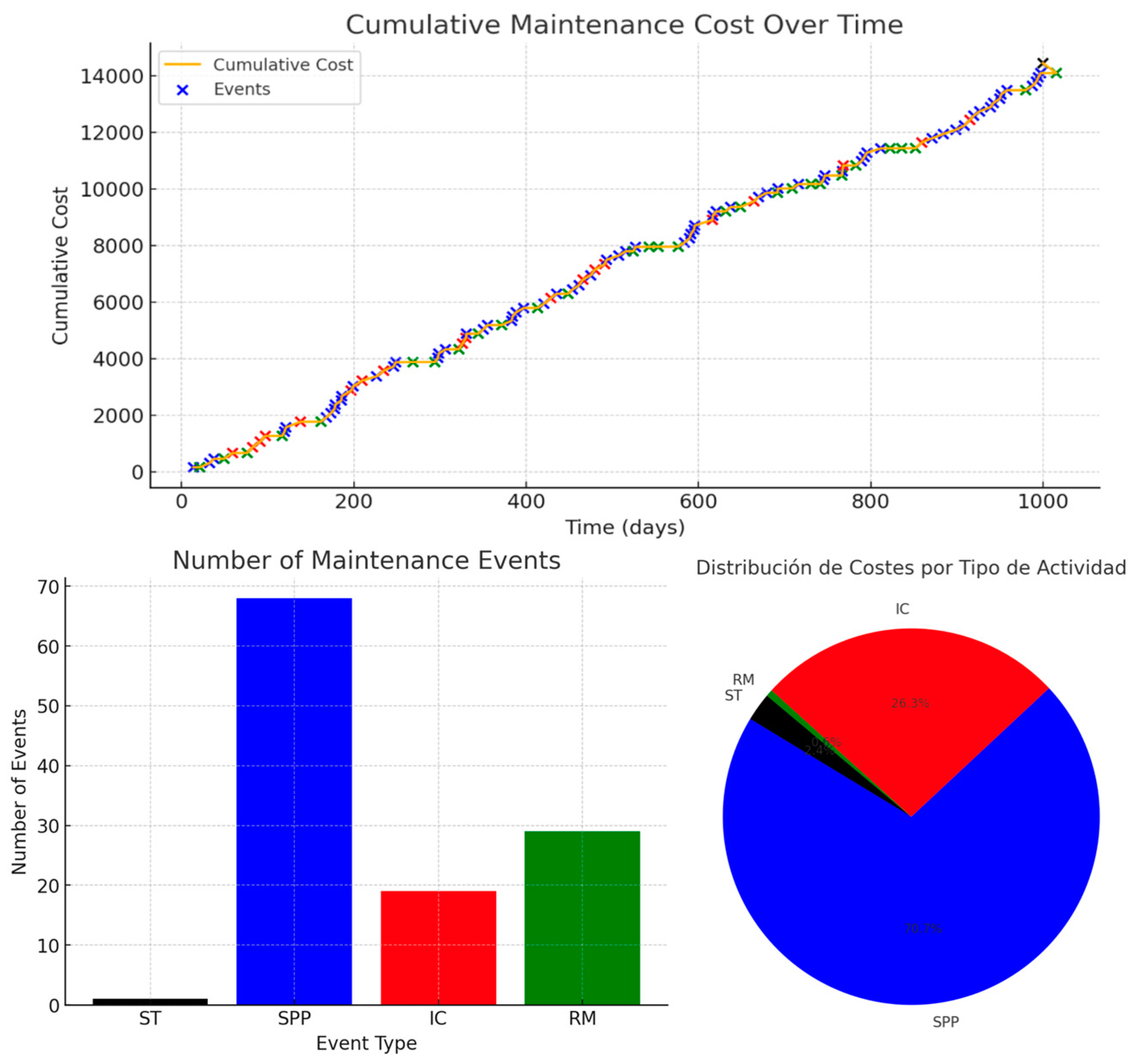

- Prompt 7. Outputs of the first partial replacement policy cost calculation

- Prompt 8. Transferring principles of the second partial replacement policy.

- Preventive Overhauls (SPP): These are scheduled preventive replacements that occur after a certain time interval . After each preventive overhaul, the system is considered “as good as new”.

- Corrective Overhauls (IC): These occur when a failure happens that necessitates a complete overhaul before the next scheduled preventive overhaul. The cost of an IC includes the cost of a preventive overhaul plus an additional cost, represented as After an IC, the system is also considered “as good as new”.

- The probability of requiring a corrective overhaul (IC) is modeled by a Weibull distribution with parameters and . This distribution will have a lower failure rate compared to minimal repairs.

- The cost of each corrective overhaul (IC) is , which includes the standard overhaul cost CsppCspp and an additional cost .

- Reliability Function (Survival Probability) : This indicates the probability that the system does not fail by time tt in the i-th interval.

- Probability of Corrective Overhaul : The probability that a corrective overhaul is needed by time t in the i-th interval.

- Integral of Time-Weighted Density: This represents the expected value of time until failure for each interval.

- Total cost of k−1 preventive overhauls.

- Cost of the final total system replacement after the last preventive overhaul.

- Total additional cost due to corrective overhauls.

- Expected time without failure for the i-th interval.

- Expected time to failure weighted by the density function for the ii-th interval.

7. AI-Designed Model of Hybrid Policies’ Optimization

- Prompt 9. Designing the prompt to combine models

- Preventive Overhauls (SPP): These are scheduled overhauls that are performed after a certain interval of time. Ti, leaving the system “as new”. Costo f each SPP is Cspp.

- Corrective Overhauls (CI): These are unscheduled interventions due to serious failures that require a complete repair before the next scheduled SPP. Costo f an IC is Cic = Cspp + Ceic, with Ceic named additional cost. The probability of the occurrence of a CI is modeled by a Weibull distribution with parameters βic and ηic.

- Minimal Repairs: These repairs occur when minor failures occur, returning the system to an “as bad as before” state without altering the failure rate. The cost of each minimal repair is Crm. The number of minimal repairs is N(Ti) is determined by integrating the failure rate over the interval adjusted by the expected duration.

- The reliability function for IC Ric(t), which represents the probability that a corrective intervention does not occur until time t.

- The cumulative probability of failure for IC Fic(t), which is the probability that a corrective intervention occurs in the interval.

- The time-weighted density integral for CI Mi(Ti), based on the probability density of CIs.

- The number of minimum repairs N(Ti), which considers the expected duration of the interval, calculated as TiRic(Ti) + Mi(Ti).

- Prompt 10. Validating hybrid model formulation corrections

- Reliability Function for CI Ric(t): represents the probability that a corrective intervention does not occur until time t.

- Time-weighted density integral for IC Mi(Ti): Based on the probability density function for corrective interventions fic(t):

- Number of Minimum Repairs Ni(Ti): Calculated using Rrm (Ti) instead of Ric(Ti) and the expected duration of the interval, considering that minimum repairs can occur before a corrective intervention (CI) is performed: . Where λrm(t) is the failure rate of the minimum repairs.

8. AI-Designed Discrete Event Simulation Model for Finite-Time Period Analysis of the Previous Problem

- Prompt 11. Simulating the finite time problem for potential optimization

9. The AI Generated Code per Case Study—Considerations

- Effectiveness: the accuracy and completeness with which users achieve specified goals.

- Efficiency: resources expended in relation to the accuracy and completeness with which users achieve goals.

- Satisfaction: the degree to which user needs are satisfied when a product or system is used in a specified context of use.

- Freedom from risk: the degree to which a product or system mitigates the potential risk to economic status, human life, health, or the environment.

- Context coverage: the degree to which a product or system can be used with effectiveness, efficiency, freedom from risk, and satisfaction in both specified contexts of use and in contexts beyond those initially explicitly identified.

Quality-in-Use Assessment

- Effectiveness: Concerning goal’s satisfaction, the chatbot is proven useful when it comes to assessing simple tasks. It has to be noted that the model might usually behave in a narrow-minded way. For example, when defining functions, parameters such as alpha or costs will not be included as function inputs but as simple constants, unless explicitly told to do so.When it comes to more complex tasks, the model may start to provide wrong answers. One example is Prompt 11; when asked to develop a fairly simple simulation model, several attempts are necessary until a decent solution is achieved—the main failures in this case were wrong logical rules when inputting costs, a misunderstanding of concepts clearly stated when deterministic parameters, such as scheduled preventive maintenance time intervals, was randomized, and a not-so-reliable method for generating random time intervals. Similarly, when performing stochastic simulations, the chatbot does not consider the necessity of statistical analysis to obtain reliable results, unless explicitly told to.

- Efficiency: The time consumption of the chatbot’s processing is negligible. However, there are some further issues that need to be addressed when it comes to resource consumption. First of all, it is important to consider that many companies will not be able to/want to upload sensitive data to an external cloud-based data system, such as OpenAI’s ChatGPT platform. Running extensive AI models might require high-end hardware, posing an elevated cost that might not be so efficient if this is the only task it will be used for. Also, it is necessary to provide very specific and detailed instructions, and colloquial speech should be avoided at any costs—this usually leads to the need of thoroughly review the written prompts. If personnel with decent programming skills is available, the same task could be achieved as fast as with the chatbot but avoiding any extensive hardware requirements and the use of the AI itself, as the task is fairly simple.

- Satisfaction: Personal user satisfaction has been evaluated from two different Points of View: a skilled programmer perspective and a non-skilled programming one.On the one hand, for a person with little knowledge of programming, the use of the chatbot is highly satisfactory, as it leverages programming tools overtaking the lack of knowledge.On the other, a person with enough programming knowledge to develop these models in Python might find uncomfortable the use of the chatbot because of several reasons: these are, for example, the necessity of explicitly mentioning rather trivial things, such as the inclusion of parameters as inputs rather than as constants of functions.It is very important to consider trust implications. Users may trust or distrust the chatbot because of very different reasons. If a person with enough programming knowledge considers the source code provided simple or notices flaws, they might feel discouraged to continue using the tool. However, the chatbot can be asked to provide the mathematical formulation being used, so it can be checked and can improve users trust when simply prompting the chatbot to develop models (not source codes). Nevertheless, this option is not always suitable (it might not be as simple to mathematically formulate and revise a simulation model).

- Freedom from risk: As stated before, the chatbot might sometimes commit errors that can only be checked by looking at the source code that the chatbot generated and used to accomplish the task. This means that a user unexperienced in coding might consider these as valid wrong solutions, posing a potential risk. This also leads to an ironic situation where a programmer might be requested to check the source code and carry out necessary corrections but could have been tasked before to develop the model from scratch, making this potentially more efficient.

- Context coverage: Chatbots like ChatGPT allow the user to interact using different languages—this entails that language barriers might be easily surpassed when the user’s mother tongue is supported. Also, it is possible to generate models dynamically and update input data through interaction with the chatbot. However, it has been proven that in certain cases, the chatbot might give wrong answers, leading to potential risks. Also, the nuances defining the barrier between a good or a bad answer might be unclear; therefore, the context coverage might be considered as unclear, or null in the worst case, based on the inability of potential users to judge the correctness of answers.

10. Conclusions Regarding the Use of AI for Modelling Policies

11. Conclusions Regarding the Code Generated

12. Limitations and Future Work

12.1. Risks of AI-Driven Maintenance Optimization

- Oversimplification of constraints—AI may overlook factors like workforce availability, spare parts, or regulatory requirements, leading to impractical recommendations.

- Limited consideration of critical variables—AI may fail to account for industry-specific factors that influence maintenance decisions.

- Bias in decision-making—unbalanced training data may cause AI to favor certain maintenance strategies while neglecting others.

- Suboptimal recommendations—AI-generated policies may appear optimal in simulations but fail when applied to real-world conditions.

12.2. Computational Considerations and Deployment Costs

- Processing power and data requirements—AI models require high-performance computing for training and optimization. Their accuracy depends on access to high-quality maintenance records, which may not always be available.

- Cloud vs. on-premise deployment—cloud-based AI offers scalability but raises security concerns, while on-premise solutions provide more control but demand greater infrastructure investment.

- Computational cost vs. optimization accuracy—While AI can refine maintenance strategies, running complex models may not always justify the computational expense. Balancing cost and performance is crucial for practical adoption.

12.3. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shafiee, M.; Finkelstein, M. An optimal age-based group maintenance policy for multi-unit degrading systems. Reliab. Eng. Syst. Saf. 2015, 134, 230–238. [Google Scholar] [CrossRef]

- Pereira, F.H.; Melani, A.H.d.A.; Kashiwagi, F.N.; da Rosa, T.G.; dos Santos, U.S.; de Souza, G.F.M. Imperfect Preventive Maintenance Optimization with Variable Age Reduction Factor and Independent Intervention Level. Appl. Sci. 2023, 13, 10210. [Google Scholar] [CrossRef]

- Haridasan, P.K.; Kumar, V. Generative AI in Manufacturing: A Review of Innovations, Challenges, and Future Prospects. J. Artif. Intell. Mach. Learn. 2024, 2, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, A. Generative AI for Predictive Maintenance: Predicting Equipment Failures and Optimizing Maintenance Schedules Using AI. Int. J. Sci. Res. Manag. (IJSRM) 2024, 12, 1648–1672. [Google Scholar] [CrossRef]

- Ćelić, J.; Bronzin, T.; Horvat, M.; Jović, A.; Stipić, A.; Prole, B.; Maričević, M.; Pavlović, I.; Pap, K.; Mikota, M.; et al. Generative AI in E-maintenance: Myth or Reality? Int. J. Adv. Comput. Sci. Appl. 2024, 15, 45–52. [Google Scholar]

- Electropedia 192-06-02:2015; Maintenance Policy. IEC: Geneva, Switzerland, 2015. Available online: https://www.electropedia.org/iev/iev.nsf/display?openform&ievref=192-06-02 (accessed on 3 February 2025).

- Barlow, R.; Hunter, L. Optimum Preventive Maintenance Policies. Oper. Res. 1960, 8, 90–100. [Google Scholar] [CrossRef]

- Chang, C.C. Optimum preventive maintenance policies for systems subject to random working times, replacement, and minimal repair. Comput. Ind. Eng. 2014, 67, 185–194. [Google Scholar] [CrossRef]

- Cho, D.I.; Parlar, M. A survey of maintenance models for multi-unit systems. Eur. J. Oper. Res. 1991, 51, 1–23. [Google Scholar] [CrossRef]

- Ding, S.H.; Kamaruddin, S. Maintenance policy optimization—Literature review and directions. Int. J. Adv. Manuf. Technol. 2014, 76, 1263–1283. [Google Scholar] [CrossRef]

- Journal, E.; Pham, H.; Wang, H. Imperfect maintenance. Eur. J. Oper. Res. 1996, 94, 425–438. [Google Scholar]

- Pierskalla, W.P.; Voelker, J.A. A survey of maintenance models: The control and surveillance of deteriorating systems. Nav. Res. Logist. Q. 1976, 23, 353–388. [Google Scholar] [CrossRef]

- de Jesus Santos, A.C.; Cavalcante, C.A.V.; Wu, S. Maintenance policies and models: A bibliometric and literature review of strategies for reuse and remanufacturing. Reliab. Eng. Syst. Saf. 2023, 231, 108983. [Google Scholar] [CrossRef]

- Valdez-Flores, C.; Feldman, R.M. A survey of preventive maintenance models for stochastically deteriorating single-unit systems. Nav. Res. Logist. (NRL) 1989, 36, 419–446. [Google Scholar] [CrossRef]

- Wang, H.; Pham, H. Optimal maintenance policies for several imperfect repair models. Int. J. Syst. Sci. 1996, 27, 543–549. [Google Scholar] [CrossRef]

- Coster, M.; Liu, Q. An Imperfect Preventive Maintenance Policy Considering Reliability Limit. J. Eng. Res. Appl. 2015, 5, 49–56. [Google Scholar]

- Nakagawa, T. Optimum policies when preventive maintenance is imperfect. IEEE Trans. Reliab. 1979, R-28, 331–332. [Google Scholar] [CrossRef]

- Nguyen, D.G.; Murthy, D.N.P. Optimal Preventive Maintenance Policies for Repairable Systems. Oper. Res. 1981, 29, 1181–1194. [Google Scholar] [CrossRef]

- Xu, Q.Z.; Guo, L.M.; Wang, N.; Fei, R. Recent advances in selective maintenance from 1998 to 2014. J. Donghua Univ. (Engl. Ed.) 2015, 32, 986–994. [Google Scholar]

- Jafari, L.; Naderkhani, F.; Makis, V. Joint optimization of maintenance policy and inspection interval for a multi-unit series system using proportional hazards model. J. Oper. Res. Soc. 2017, 69, 36–48. [Google Scholar] [CrossRef]

- Tian, Z.; Liao, H. Condition based maintenance optimization for multi-component systems using proportional hazards model. Reliab. Eng. Syst. Saf. 2011, 96, 581–589. [Google Scholar] [CrossRef]

- Wakiru, J.; Pintelon, L.; Muchiri, P.N.; Chemweno, P.K.; Mburu, S. Towards an innovative lubricant condition monitoring strategy for maintenance of ageing multi-unit systems. Reliab. Eng. Syst. Saf. 2020, 204, 107200. [Google Scholar] [CrossRef]

- Laggoune, R.; Chateauneuf, A.; Aissani, D. Opportunistic policy for optimal preventive maintenance of a multi-component system in continuous operating units. Comput. Chem. Eng. 2009, 33, 1499–1510. [Google Scholar] [CrossRef]

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Alfarhood, S. Explainable Predictive Maintenance of Rotating Machines Using LIME, SHAP, PDP, ICE. IEEE Access 2024, 12, 29345–29361. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, S.; Zhao, C.; Xu, Z. TelOps: AI-Driven Operations and Maintenance for Telecommunication Networks. IEEE Commun. Mag. 2024, 62, 104–110. [Google Scholar] [CrossRef]

- Kirschbaum, L.; Roman, D.; Singh, G.; Bruns, J.; Robu, V.; Flynn, D. AI-Driven maintenance support for downhole tools and electronics operated in dynamic drilling environments. EEE Access 2020, 8, 78683–78701. [Google Scholar] [CrossRef]

- Dhyani, B. Predicting Equipment Failure in Manufacturing Plants: An AI-driven Maintenance Strategy. Math. Stat. Eng. Appl. 2021, 70, 1326–1334. [Google Scholar] [CrossRef]

- Chareonsuk, C.; Nagarur, N.; Tabucanon, M.T. A multicriteria approach to the selection of preventive maintenance intervals. Int. J. Prod. Econ. 1997, 49, 55–64. [Google Scholar] [CrossRef]

- Sharma, A.; Yadava, G.S.; Deshmukh, S.G. A literature review and future perspectives on maintenance optimization. J. Qual. Maint. Eng. 2011, 17, 5–25. [Google Scholar] [CrossRef]

- Anders, G.J.; Sugier, J. Risk assessment tool for maintenance selection. In Proceedings of the International Conference on Dependability of Computer Systems, DepCoS-RELCOMEX, Szklarska Poreba, Poland, 25–27 May 2006. [Google Scholar] [CrossRef]

- Samrout, M.; Châtelet, E.; Kouta, R.; Chebbo, N. Optimization of maintenance policy using the proportional hazard model. Reliab. Eng. Syst. Saf. 2009, 94, 44–52. [Google Scholar] [CrossRef]

- Marais, K.B.; Saleh, J.H. System value trajectories, maintenance, and its present value. In Safety, Reliability and Risk Analysis: Theory, Methods and Applications—Proceedings of the Joint ESREL and SRA-Europe Conference, 1st ed.; Taylor & Francis Group: London, UK, 2009. [Google Scholar] [CrossRef]

- OpenAI. Hello GPT-4o. 2024. Available online: https://openai.com/index/hello-gpt-4o/ (accessed on 1 December 2024).

- Pérez, F.; Granger, B.E. IPython: A System for Interactive Scientific Computing. Comput. Sci. Eng. 2007, 9, 21–29. [Google Scholar] [CrossRef]

- ISO 25000. SQuaRE—System and Software Quality Requirements and Evaluation. Available online: https://iso25000.com/index.php/en/iso-25000-standards (accessed on 3 February 2025).

- Pereira, D.S.; Bezerra, L.F.V.; Nunes, J.S.; Barroca Filho, I.M.; Lopes, F.A.S. Performance Efficiency Evaluation based on ISO/IEC 25010:2011 applied to a Case Study on Load Balance and Resilient. In Workshop de Testes e Tolerância a Falhas (WTF); Sociedade Brasileira de Computação: Porto Alegre, Brazil, 2023. [Google Scholar] [CrossRef]

- Prabowo, W.A. Developing Compliant Audit Information System for Information Security Index: A Study on Enhancing Institutional and Organizational Audits Using Web-based Technology and ISO 25010:2011 Total Quality of Use Evaluation. Int. J. Inform. Vis. 2024, 8, 343. [Google Scholar] [CrossRef]

| Advantages | Disadvantages |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Pros | Cons |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crespo Márquez, A.; Pérez Oliver, D. Leveraging Generative AI for Modelling and Optimization of Maintenance Policies in Industrial Systems. Information 2025, 16, 217. https://doi.org/10.3390/info16030217

Crespo Márquez A, Pérez Oliver D. Leveraging Generative AI for Modelling and Optimization of Maintenance Policies in Industrial Systems. Information. 2025; 16(3):217. https://doi.org/10.3390/info16030217

Chicago/Turabian StyleCrespo Márquez, Adolfo, and Diego Pérez Oliver. 2025. "Leveraging Generative AI for Modelling and Optimization of Maintenance Policies in Industrial Systems" Information 16, no. 3: 217. https://doi.org/10.3390/info16030217

APA StyleCrespo Márquez, A., & Pérez Oliver, D. (2025). Leveraging Generative AI for Modelling and Optimization of Maintenance Policies in Industrial Systems. Information, 16(3), 217. https://doi.org/10.3390/info16030217