Reviewing the Applications of Neural Networks in Supply Chain: Exploring Research Propositions for Future Directions

Abstract

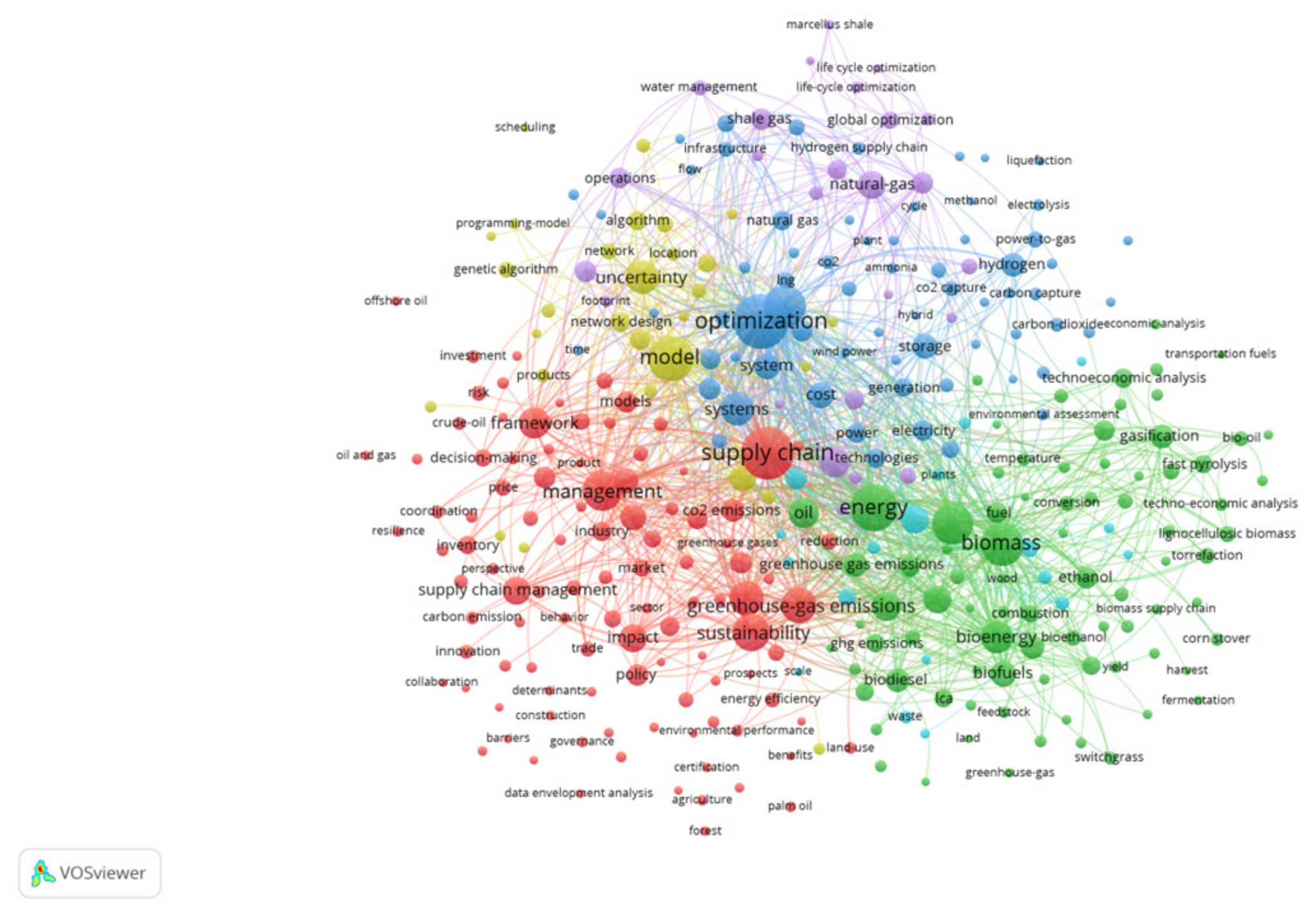

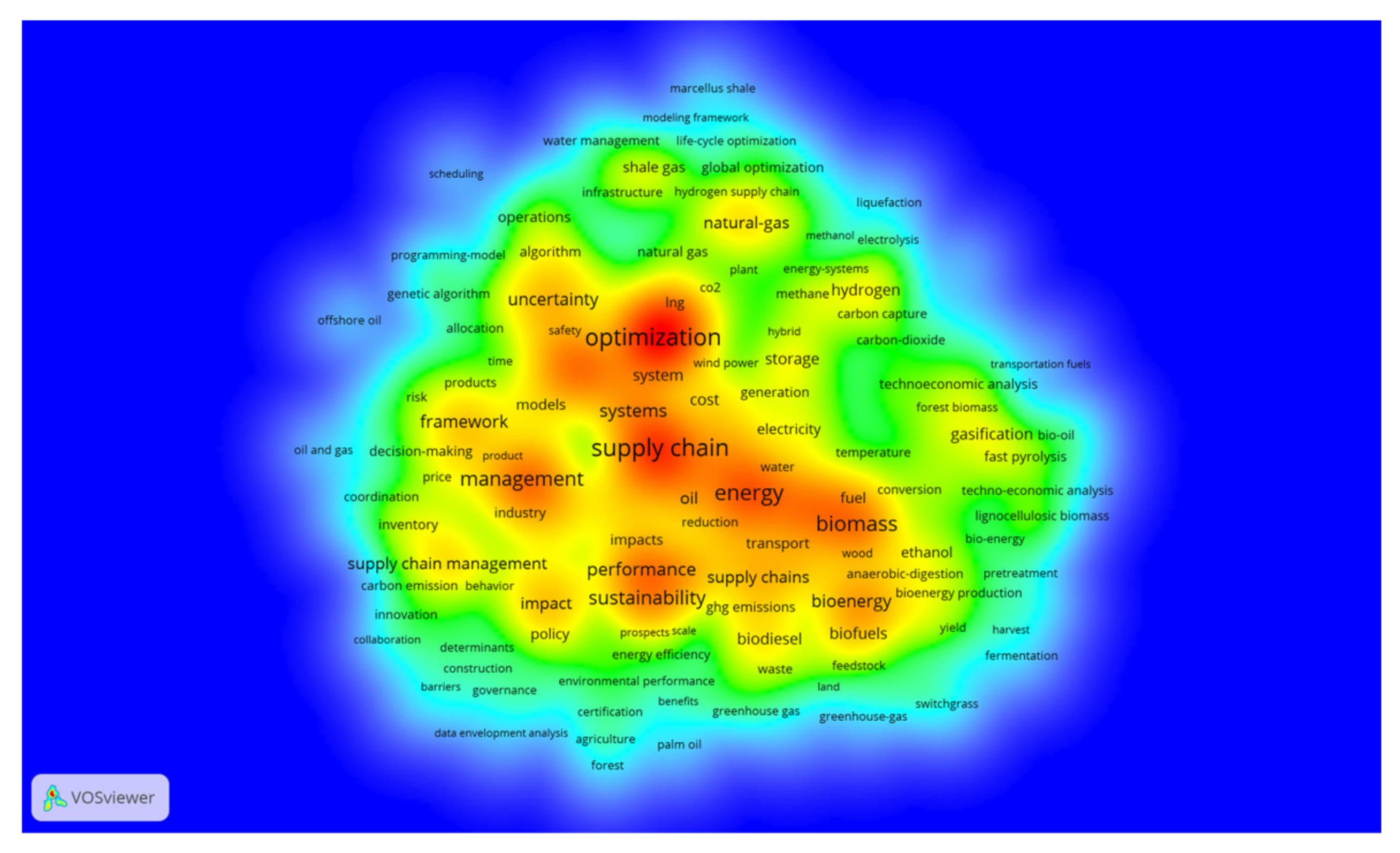

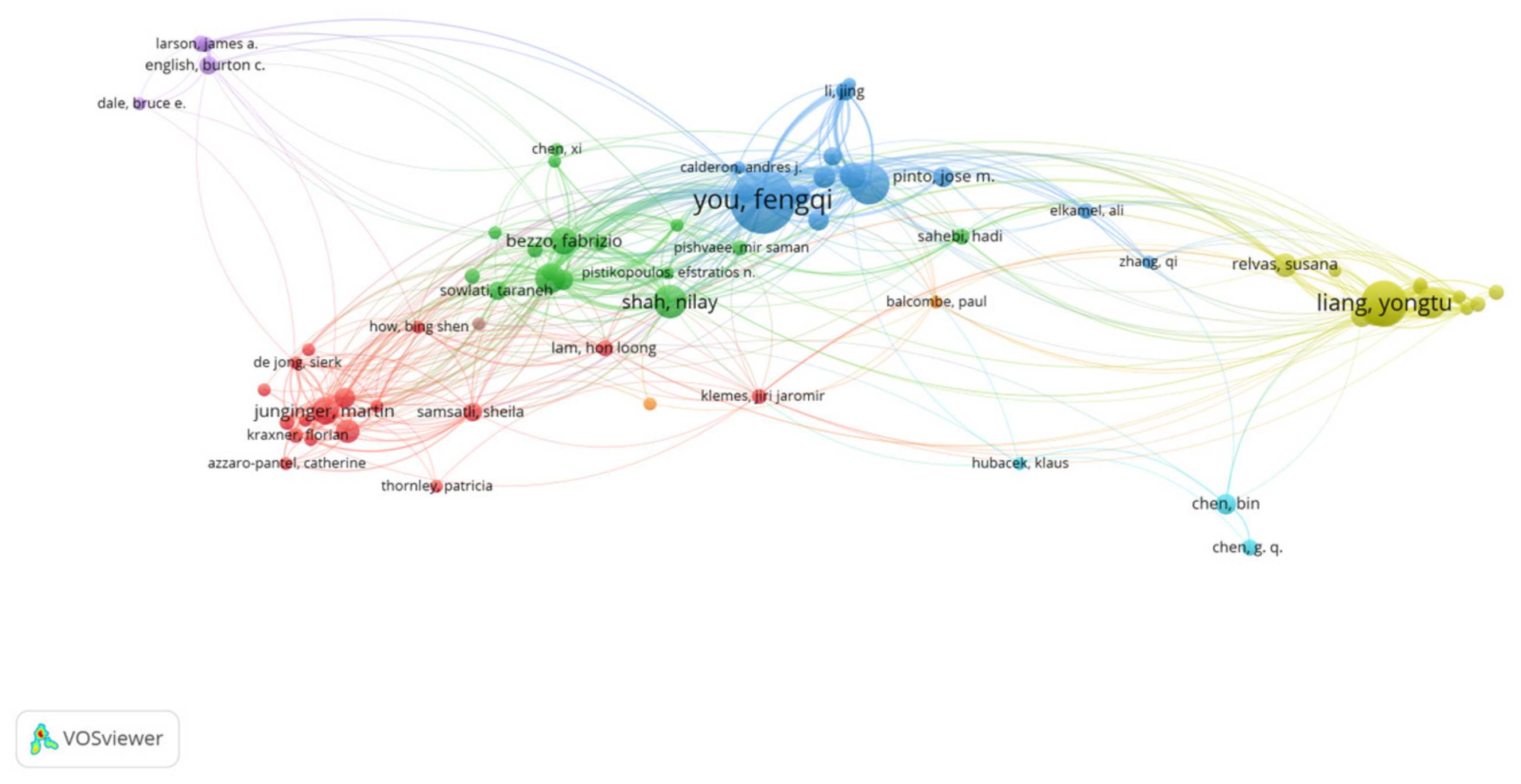

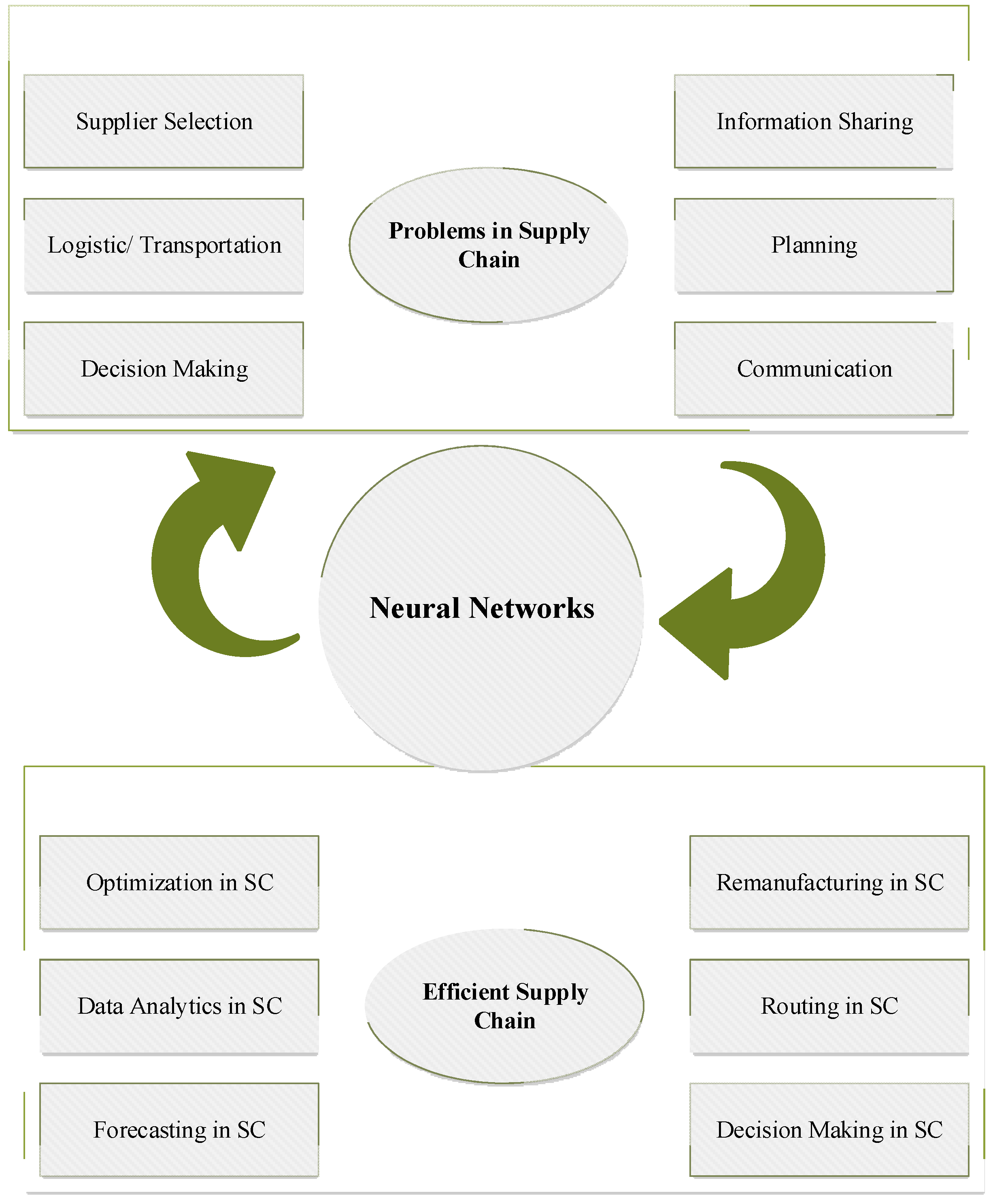

:1. Introduction

- (1)

- In which fields in supply chain management are NNs being applied?

- (2)

- What are the current research trends associated with NNs and SCM?

- (3)

- What are the future research directions for an SC based on NNs?

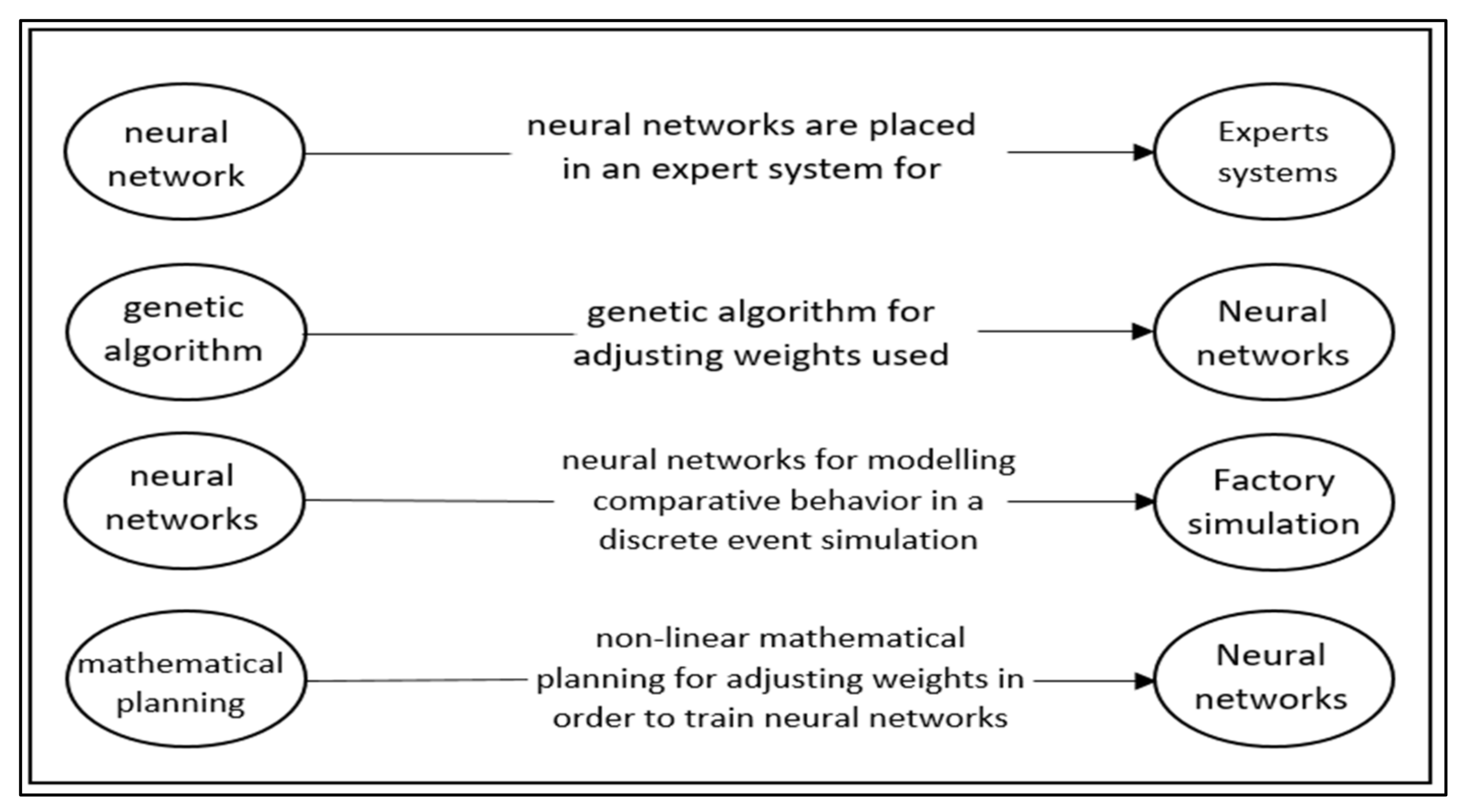

2. Methodology

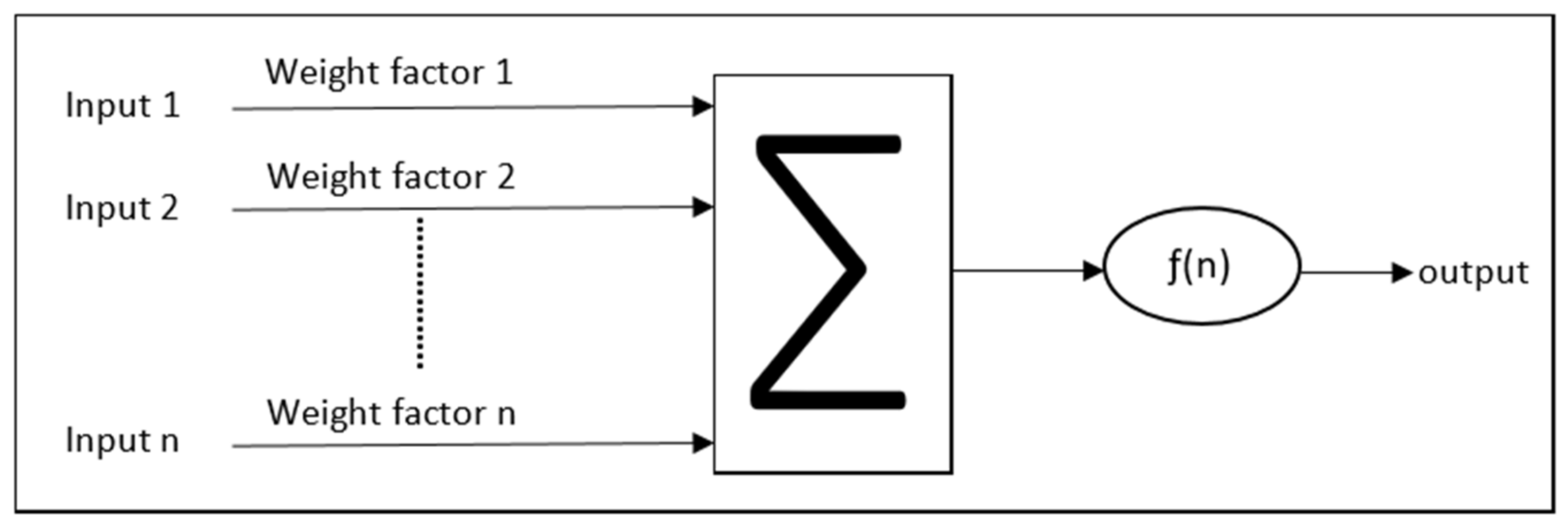

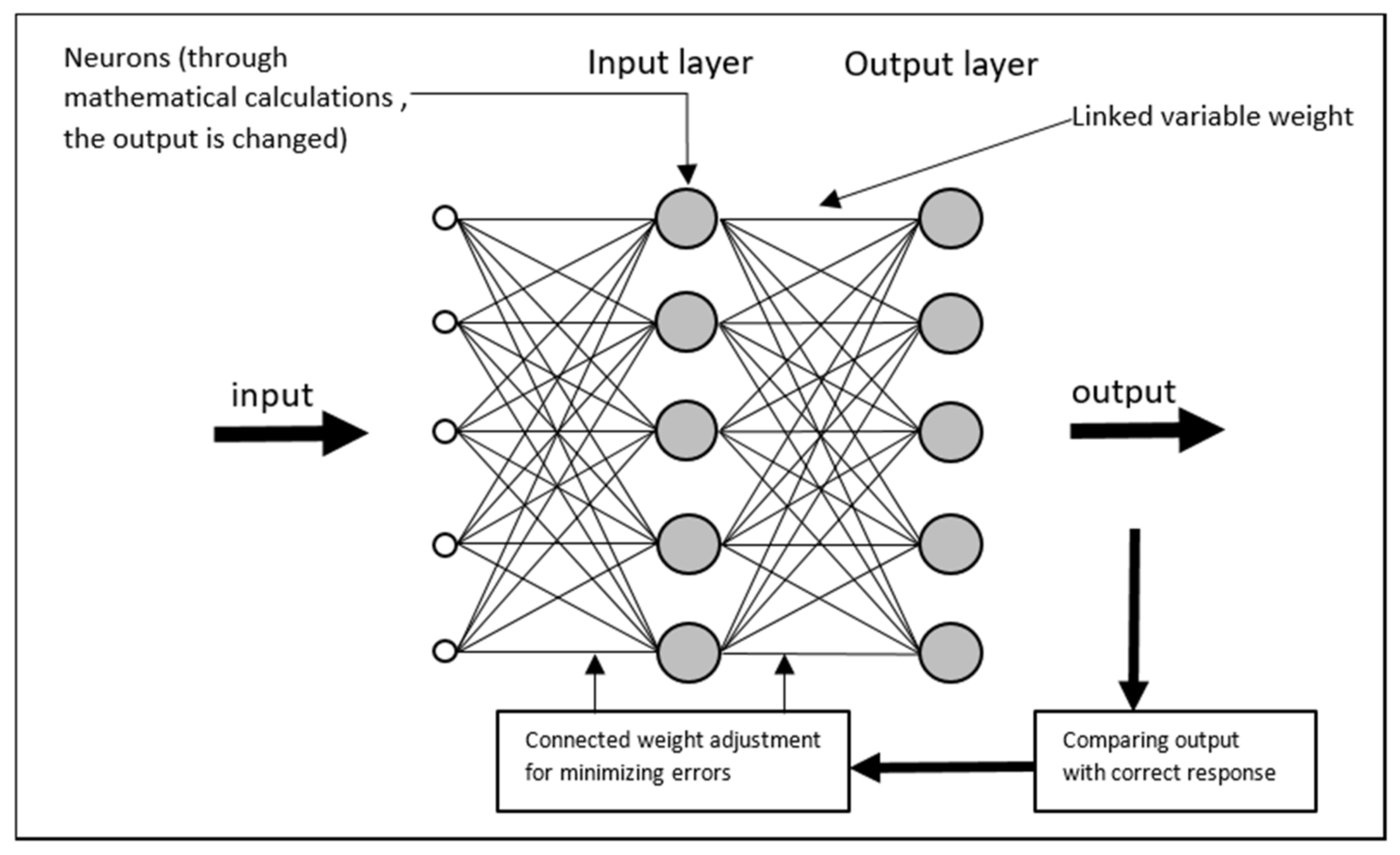

- Random values are determined for weight factors.

- Input and output samples are presented respectively to the input and output layers.

- Weighting factors are adjusted to match the input/output pair properly.

- This procedure is repeated for other input–output teams in the actual sample.

- As weight adjustment for each pair of output–input influences, steps three and four should be repeated so that each team in the sample is matched based on the predefined error rate. In other words, this is the stage for convergence of weight and network stability factors.

2.1. Optimization

2.2. Forecasting

2.3. Modeling

2.4. Clustering

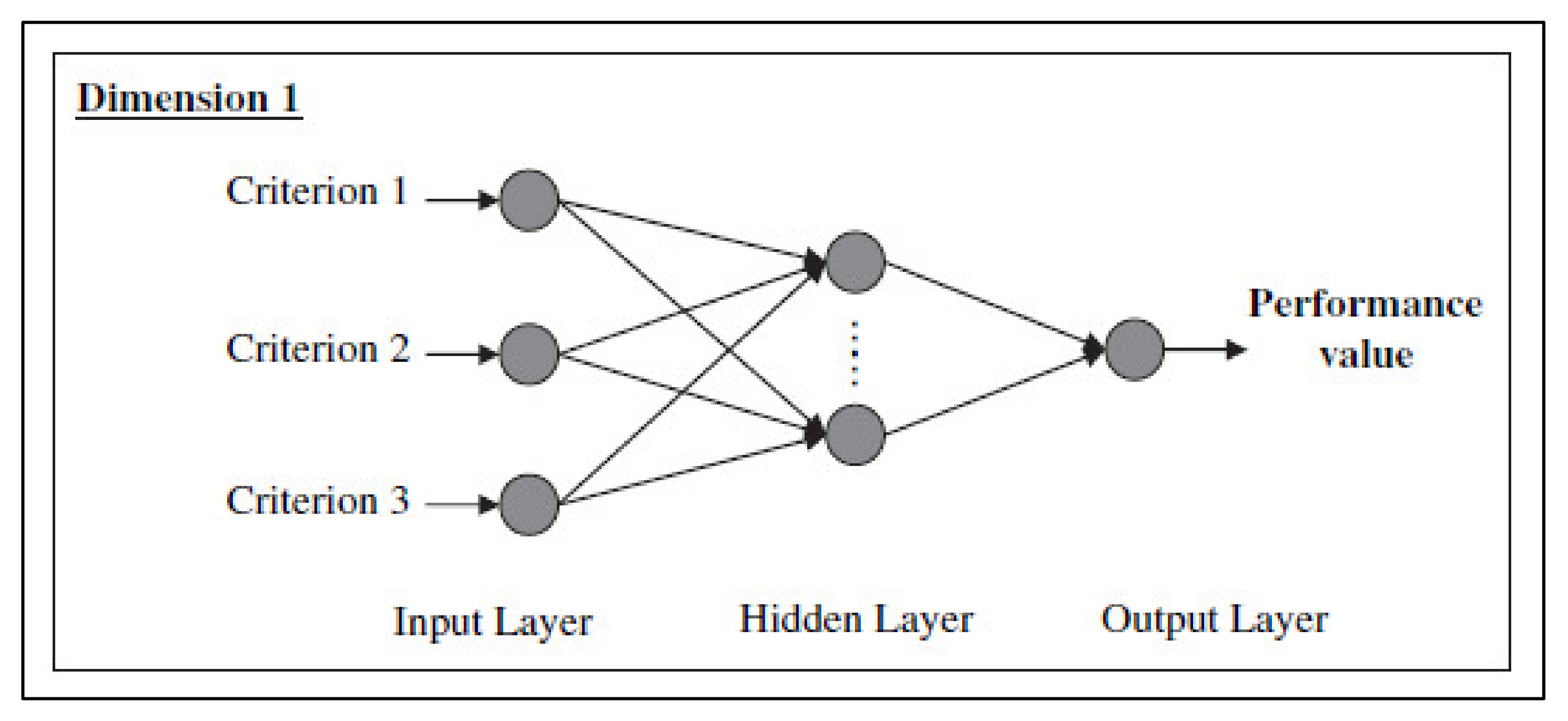

2.5. Decision Support

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sahebi, I.G.; Arab, A.; Moghadam, M.R.S. Analyzing the barriers to humanitarian supply chain management: A case study of the Tehran Red Crescent Societies. Int. J. Disaster Risk Reduct. 2017, 24, 232–241. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Prod. Plan. Control 2021, 1–18. [Google Scholar] [CrossRef]

- Sahebi, I.G.; Jafarnejad, A. Demand forecasting of emergency resource in humanitarian supply chain. In Proceedings of the 103rd IRES International Conference, Zurich, Switzerland, 16 February 2018; pp. 129–136. [Google Scholar]

- Awan, U.; Kanwal, N.; Alawi, S.; Huiskonen, J.; Dahanayake, A. Artificial Intelligence for Supply Chain Success in the Era of Data Analytics. In The Fourth Industrial Revolution: Implementation of Artificial Intelligence for Growing Business Success; Springer: Cham, Switzerland, 2021; pp. 3–21. [Google Scholar]

- Kheiravar, K.H.; Lawell, C.Y.L.; Jaffe, A.M. A Structural Econometric Model of the Dynamic Game Between Petroleum Producers in the World Petroleum Market. Economic 2015, 1–87. [Google Scholar]

- Chiu, M.; Lin, G. Collaborative supply chain planning using the artificial neural network approach. J. Manuf. Technol. Manag. 2004, 15, 787–796. [Google Scholar] [CrossRef]

- Leung, J.H. Service quality & behavioral intention: A study of Hong Kung Mobile Service Industry. In Proceedings of the POMS 21st Annual Conference, Boston, MA, USA, 28 April–1 May 2006; Volume 2, p. 28. [Google Scholar]

- Chen, J.; Zhu, Q. A stackelberg game approach for two-level distributed energy management in smart grids. IEEE Trans. Smart Grid. 2018, 9, 6554–6565. [Google Scholar] [CrossRef]

- Safari, H.; Ajali, M.; Sahebi, I.G. Determining the Strategic Position of an Educational Institution in the Organizational Life Cycle with Fuzzy Approach (Case Study: Social Sciences Faculty of Khalij Fars University). Mod. Res. Decis. Mak. 2016, 1, 117–138. [Google Scholar]

- Kuo, R.J.; Hong, S.Y.; Huang, Y. Integration of particle swarm optimization-based fuzzy neural network and artificial neural network for supplier selection. Appl. Math. Model. 2010, 34, 3976–3990. [Google Scholar] [CrossRef]

- Rydén, T. Consistent and asymptotically normal parameter estimates for hidden Markov models. Ann. Stat. 1994, 22, 1884–1895. [Google Scholar] [CrossRef]

- Tavana, M.; Abtahi, A.; Di, D.; Hashemi, R.; Youse, R. Socio-Economic Planning Sciences An integrated location-inventory-routing humanitarian supply chain network with pre- and post-disaster management considerations. Socio-Econ. Plan. Sci. 2018, 64, 21–37. [Google Scholar] [CrossRef]

- Moghadam, M.S.; Sahebi, I.G. A Mathematical Model to Improve the Quality of Demand Responding in Emergency Medical Centers in a Humanitarian Supply chain. Mod. Res. Decis. Mak. 2018, 3, 217–242. [Google Scholar]

- Masoomi, B.; Sahebi, I.G.; Fathi, M.; Yıldırım, F.; Ghorbani, S. Strategic supplier selection for renewable energy supply chain under green capabilities (fuzzy BWM-WASPAS-COPRAS approach). Energy Strateg. Rev. 2022, 40, 100815. [Google Scholar] [CrossRef]

- Hosseini, S.; Barker, K. A Bayesian network model for resilience-based supplier selection. Int. J. Prod. Econ. 2016, 180, 68–87. [Google Scholar] [CrossRef]

- Ko, M.; Tiwari, A.; Mehnen, J. A review of soft computing applications in supply chain management. Appl. Soft Comput. 2010, 10, 661–674. [Google Scholar] [CrossRef] [Green Version]

- Raut, R.D.; Kamble, S.S.; Kharat, M.G.; Joshi, H.; Singhal, C.; Kamble, S.J. A hybrid approach using data envelopment analysis and artificial neural network for optimising 3PL supplier selection. Int. J. Logist. Syst. Manag. 2017, 26, 203–223. [Google Scholar] [CrossRef]

- Sahebi, I.G.; Toufighi, S.P.; Karakaya, G.; Ghorbani, S. An intuitive fuzzy approach for evaluating financial resiliency of supply chain. OPSEARCH 2021, 1–22. [Google Scholar] [CrossRef]

- Moghadam, M.S.; Sahebi, I.G. Humanitarian Supply Chain: From Theory to Practice, 1st ed.; University of Tehran Press: Tehran, Iran, 2021. [Google Scholar]

- Anderson, J.A.; Rosenfeld, E.; Pellionisz, A. Neurocomputing; MIT Press: Cambridge, MA, USA, 1988; Volume 2. [Google Scholar]

- Kar, A.K. A hybrid group decision support system for supplier selection using analytic hierarchy process, fuzzy set theory and neural network. J. Comput. Sci. 2015, 6, 23–33. [Google Scholar] [CrossRef]

- Sahebi, I.G.; Masoomi, B.; Ghorbani, S. Expert oriented approach for analyzing the blockchain adoption barriers in humanitarian supply chain. Technol. Soc. 2020, 63, 101427. [Google Scholar] [CrossRef]

- Güneri, A.F.; Ertay, T.; Yüce, A.L. An approach based on ANFIS input selection and modeling for supplier selection problem. Expert Syst. Appl. 2011, 38, 14907–14917. [Google Scholar] [CrossRef]

- Notash, M.; Zandieh, M.; Nokorani, B.D. Using a Genetic Algorithm Approach for Designing Multi-objective Supply Chain Network. Modares J. Manag. Res. Iran 2014, 18, 183–203. [Google Scholar]

- Bansal, K.; Vadhavkar, S.; Gupta, A. Brief application description. Neural networks based forecasting techniques for inventory control applications. Data Min. Knowl. Discov. 1998, 2, 97–102. [Google Scholar] [CrossRef]

- Reyes-Aldasoro, C.C.; Ganguly, A.R.; Lemus, G.; Gupta, A. A hybrid model based on dynamic programming, neural networks, and surrogate value for inventory optimisation applications. J. Oper. Res. Soc. 1999, 50, 85–94. [Google Scholar] [CrossRef]

- Azadnia, A.H.; Saman, M.Z.M.; Wong, K.Y.; Ghadimi, P.; Zakuan, N. Sustainable supplier selection based on self-organizing map neural network and multi criteria decision making approaches. Procedia-Soc. Behav. Sci. 2012, 65, 879–884. [Google Scholar] [CrossRef] [Green Version]

- Fallahpour, A.; Olugu, E.U.; Musa, S.N. A hybrid model for supplier selection: Integration of AHP and multi expression programming (MEP). Neural Comput. Appl. 2017, 28, 499–504. [Google Scholar] [CrossRef]

- Pettit, S.J.; Beresford, A.K.C. Critical success factors in the context of humanitarian aid supply chains. Int. J. Phys. Distrib. Logist. Manag. 2009, 39, 6. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Zhao, Z. A hybrid speech recognition training method for hmm based on genetic algorithm and baum welch algorithm. In Proceedings of the Second International Conference on Innovative Computing, Informatio and Control (ICICIC 2007), Kumamoto, Japan, 5–7 September 2007; p. 572. [Google Scholar]

- Raghunathan, S. Interorganizational collaborative forecasting and replenishment systems and supply chain implications. Decis. Sci. 1999, 30, 1053–1071. [Google Scholar] [CrossRef]

- Lee, H.L.; Padmanabhan, V.; Whang, S. Information distortion in a supply chain: The bullwhip effect. Manag. Sci. 1997, 43, 546–558. [Google Scholar] [CrossRef]

- Arab, A.; Sahebi, I.G.; Alavi, S.A. Assessing the key success factors of knowledge management adoption in supply chain. Int. J. Acad. Res. Bus. Soc. Sci. 2017, 7, 401–418. [Google Scholar] [CrossRef] [Green Version]

- Dong, X.; Wen, G. An improved neural networks prediction model and its application in supply chain. Nat. Sci. 2006, 4, 23–27. [Google Scholar]

- Sahebi, I.G.; Arab, A.; Toufighi, S.P. Analyzing the barriers of organizational transformation by using fuzzy SWARA. J. Fuzzy Ext. Appl. 2020, 1, 88–103. [Google Scholar]

- Sahebi, I.G.; Mosayebi, A.; Masoomi, B.; Marandi, F. Modeling the enablers for blockchain technology adoption in renewable energy supply chain. Technol. Soc. 2022, 68, 101871. [Google Scholar] [CrossRef]

- Carbonneau, R.; Laframboise, K.; Vahidov, R. Application of machine learning techniques for supply chain demand forecasting. Eur. J. Oper. Res. 2008, 184, 1140–1154. [Google Scholar] [CrossRef]

- Meidute-Kavaliauskiene, I.; Davidaviciene, V.; Ghorbani, S.; Sahebi, I.G. Optimal Allocation of Gas Resources to Different Consumption Sectors Using Multi-Objective Goal Programming. Sustainability 2021, 13, 5663. [Google Scholar] [CrossRef]

- Gargano, M.L.; Marose, R.a.; von Kleeck, L. An application of artificial neural networks and genetic algorithms to personnel selection in the financial industry. In Proceedings of the First International Conference on Artificial Intelligence Applications on Wall Street, New York, NY, USA, 9–11 October 1991. [Google Scholar] [CrossRef]

- Bacha, H.; Meyer, W. A neural network architecture for load forecasting. In Proceedings of the 1992 IJCNN International Joint Conference on Neural Networks, Baltimore, MD, USA, 7–11 June 1992; Volume 2, pp. 442–447. [Google Scholar]

- Dejonckheere, J.; Disney, S.M.; Lambrecht, M.R.; Towill, D.R. Measuring and avoiding the bullwhip effect: A control theoretic approach. Eur. J. Oper. Res. 2003, 147, 567–590. [Google Scholar] [CrossRef]

- Chandra, C.; Grabis, J. Application of multi-steps forecasting for restraining the bullwhip effect and improving inventory performance under autoregressive demand. Eur. J. Oper. Res. 2005, 166, 337–350. [Google Scholar] [CrossRef]

- Warrender, C.; Forrest, S.; Pearlmutter, B. Detecting intrusions using system calls: Alternative data models. In Proceedings of the 1999 IEEE Symposium on Security and Privacy (Cat. No. 99CB36344), Oakland, CA, USA, 9–12 May 1999; pp. 133–145. [Google Scholar]

- Jones, M.P. Simulation: The route to excellence. Logist. Technol. Int. 1992, 57–64. [Google Scholar]

- Yao, Y.; Cao, Y. A Neural network enhanced hidden Markov model for tourism demand forecasting. Appl. Soft Comput. J. 2020, 94, 106465. [Google Scholar] [CrossRef]

- Kilmer, R.A.; Smith, A.E.; Shuman, L.J. Neural networks as a metamodeling technique for discrete event stochastic simulation. Intell. Eng. Syst. Through Artif. Neural Netw. 1994, 4, 1–6. [Google Scholar]

- Yang, X.; Chen, J.; Hao, P.; Wang, Y.J. Application of clustering for customer segmentation in private banking. In Proceedings of the Seventh International Conference on Digital Image Processing (ICDIP15), Los Angeles, CA, USA, 9 April 2015; p. 96311Z. [Google Scholar]

- Farajian, M.A.; Mohammadi, S. Mining the Banking Customer Behavior Using Clustering and Association Rules Methods. Int. J. Ind. Eng. Prod. Res. 2010, 21, 239–245. [Google Scholar]

- Hosseini, B.; Kiani, K. A big data driven distributed density based hesitant fuzzy clustering using Apache spark with application to gene expression microarray. Eng. Appl. Artif. Intell. 2019, 79, 100–113. [Google Scholar] [CrossRef]

- Kong, D.T. The pathway to unethical pro-organizational behavior: Organizational identification as a joint function of work passion and trait mindfulness. Pers. Individ. Dif. 2015, 93, 6–11. [Google Scholar] [CrossRef]

- Mikami, S.; Kakazu, Y. A Connectionist Approach to Autonomous and Distributed Manufacturing Systems. Comput. Appl. Prod. Eng. Integr. Asp. 1991, 601–608. [Google Scholar]

- Sahebi, H.; Ranjbar, S.; Teymouri, A. Investigating different reverse channels in a closed-loop supply chain: A power perspective. Oper. Res. Int. J. 2021, 1–41. [Google Scholar] [CrossRef]

- Lin, W.T.; Wu, Y.C.; Tung, C.L.; Huang, M.R.; Qin, R.S. Establishing ISO 10015 accreditation system performance model for domestic enterprises. Expert Syst. Appl. 2010, 37, 4119–4127. [Google Scholar] [CrossRef]

- Lee, C.C.; Ou-Yang, C. A neural networks approach for forecasting the supplier’s bid prices in supplier selection negotiation process. Expert Syst. Appl. 2009, 36, 2961–2970. [Google Scholar] [CrossRef]

- Gorane, S.J.; Kant, R. Modelling the SCM enablers: An integrated ISM-fuzzy MICMAC approach. Asia Pacific J. Mark. Logist. 2013, 25, 263–286. [Google Scholar] [CrossRef]

- Li, N.; Zhang, H.; Zhang, X.; Ma, X.; Guo, S. How to select the optimal electrochemical energy storage planning program? A hybrid MCDM method. Energies 2020, 13, 931. [Google Scholar] [CrossRef] [Green Version]

- Nallusamy, S.; Kumar, D.S.L.; Balakannan, K.; Chakraborty, P.S. MCDM tools application for selection of suppliers in manufacturing industries using AHP, Fuzzy Logic and ANN. Int. J. Eng. Res. Afr. 2016, 19, 130–137. [Google Scholar] [CrossRef]

- Ferreira, F.A.F.; Meidutė-Kavaliauskienė, I. Toward a sustainable supply chain for social credit: Learning by experience using single-valued neutrosophic sets and fuzzy cognitive maps. Ann. Oper. Res. 2019, 1–22. [Google Scholar] [CrossRef]

- Fallahpour, A.; Amindoust, A.; Antuchevičienė, J.; Yazdani, M. Nonlinear genetic-based model for supplier selection: A comparative study. Technol. Econ. Dev. Econ. 2017, 23, 178–195. [Google Scholar] [CrossRef]

- Hosseini, S.; al Khaled, A. A hybrid ensemble and AHP approach for resilient supplier selection. J. Intell. Manuf. 2019, 30, 207–228. [Google Scholar] [CrossRef]

- Huang, L. Recognizing real customers in e-supply chain based on SOFM neural network and corresponding marketing strategies. In Proceedings of the 2006 International Conference on Machine Learning and Cybernetics, Dalian, China, 13–16 August 2006; pp. 1592–1597. [Google Scholar]

- Madey, G.R.; Weinroth, J.; Shah, V. Hybrid intelligent systems: Tools for decision making in intelligent manufacturing. In Artificial Neural Networks for Intelligent Manufacturing; Springer: Dordrecht, Germany, 1994; pp. 67–90. [Google Scholar]

| No. | Keywords | Number of Papers |

|---|---|---|

| 1 | “Artificial neural network” AND “Supply chain” | 214 |

| 2 | “Artificial neural network” AND “Logistic network” AND “Supply chain” | 52 |

| 3 | “Artificial neural network” AND “Inventory control” AND “Supply chain” | 18 |

| 4 | “Artificial neural network” AND “Supply chain network design” | 16 |

| 5 | “Artificial neural network” AND “Demand forecasting” AND “Supply chain” | 74 |

| 6 | “Artificial neural network” AND “Supplier selection” AND “Supply chain” | 57 |

| 7 | “Artificial neural network” AND “risk” AND “Supply chain” | 11 |

| Reference | Topic | Research Method | Case Study |

|---|---|---|---|

| [53] | Supplier selection: A hybrid model using DEA, decision tree, and neural network | DEA, decision tree, and neural network | Railway industry |

| [54] | A neural networks approach for forecasting the supplier’s bid prices in the supplier selection negotiation process | neural networks and MCDM | China industry |

| [10] | Integration of particle swarm optimization-based fuzzy neural network and artificial neural network for supplier selection | particle swarm optimization and ANN | Computer company |

| [23] | An approach based on ANFIS input selection and modeling for the supplier selection problem | ANFIS and ANN | Textile firm |

| [27] | Sustainable supplier selection based on self-organizing map neural network and multi-criteria decision-making approaches | self-organizing map, fuzzy AHP, ANN | Automotive industry |

| [55] | Application of decision-making techniques in supplier selection | Artificial intelligence (A.I.) techniques | |

| [56] | Multi-Criteria Supplier Selection Using Fuzzy PROMETHEE Method | PROMETHEE and ANN | |

| [21] | A hybrid group decision support system for supplier selection using the analytic hierarchy process, fuzzy set theory, and neural network | fuzzy AHP—ANN | |

| [57] | MCDM tools application for selection of suppliers in manufacturing industries using AHP, Fuzzy Logic, and ANN | AHP, fuzzy logic, and ANN | Manufacturing industries |

| [28] | Nonlinear genetic-based model for supplier selection: a comparative study | DEA-ANN-gene expression programming | Comparative study |

| [58] | Forecasting efficiency of green suppliers by dynamic data envelopment analysis and artificial neural networks | ANN and dynamic DEA | Naniwa Co |

| [59] | A hybrid model for supplier selection: integration of AHP and multi expression programming (MEP) | AHP and MEP | |

| [17] | A hybrid approach using data envelopment analysis and an artificial neural network for optimizing 3PL supplier selection | DEA and ANN | |

| [60] | A hybrid ensemble and AHP approach for resilient supplier selection | AHP—ANN | Plastic raw material |

| Journals | Numbers | Percent |

|---|---|---|

| Expert Systems with Applications | 18 | 32.8 |

| Applied Soft Computing | 7 | 12.8 |

| Decision Support Systems | 6 | 10.9 |

| European Journal of Operational Research | 6 | 10.9 |

| Applied Intelligence | 5 | 9.1 |

| Engineering Applications of Artificial Intelligence | 4 | 7.3 |

| Expert Systems | 3 | 5.4 |

| Neural Computing & Application | 3 | 5.4 |

| International Journal of Production Research | 3 | 5.4 |

| Total | 55 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meidute-Kavaliauskiene, I.; Taşkın, K.; Ghorbani, S.; Činčikaitė, R.; Kačenauskaitė, R. Reviewing the Applications of Neural Networks in Supply Chain: Exploring Research Propositions for Future Directions. Information 2022, 13, 261. https://doi.org/10.3390/info13050261

Meidute-Kavaliauskiene I, Taşkın K, Ghorbani S, Činčikaitė R, Kačenauskaitė R. Reviewing the Applications of Neural Networks in Supply Chain: Exploring Research Propositions for Future Directions. Information. 2022; 13(5):261. https://doi.org/10.3390/info13050261

Chicago/Turabian StyleMeidute-Kavaliauskiene, Ieva, Kamil Taşkın, Shahryar Ghorbani, Renata Činčikaitė, and Roberta Kačenauskaitė. 2022. "Reviewing the Applications of Neural Networks in Supply Chain: Exploring Research Propositions for Future Directions" Information 13, no. 5: 261. https://doi.org/10.3390/info13050261

APA StyleMeidute-Kavaliauskiene, I., Taşkın, K., Ghorbani, S., Činčikaitė, R., & Kačenauskaitė, R. (2022). Reviewing the Applications of Neural Networks in Supply Chain: Exploring Research Propositions for Future Directions. Information, 13(5), 261. https://doi.org/10.3390/info13050261