Multi-Fault Diagnosis Approach Based on Updated Interacting Multiple Model for Aviation Hydraulic Actuator

Abstract

1. Introduction

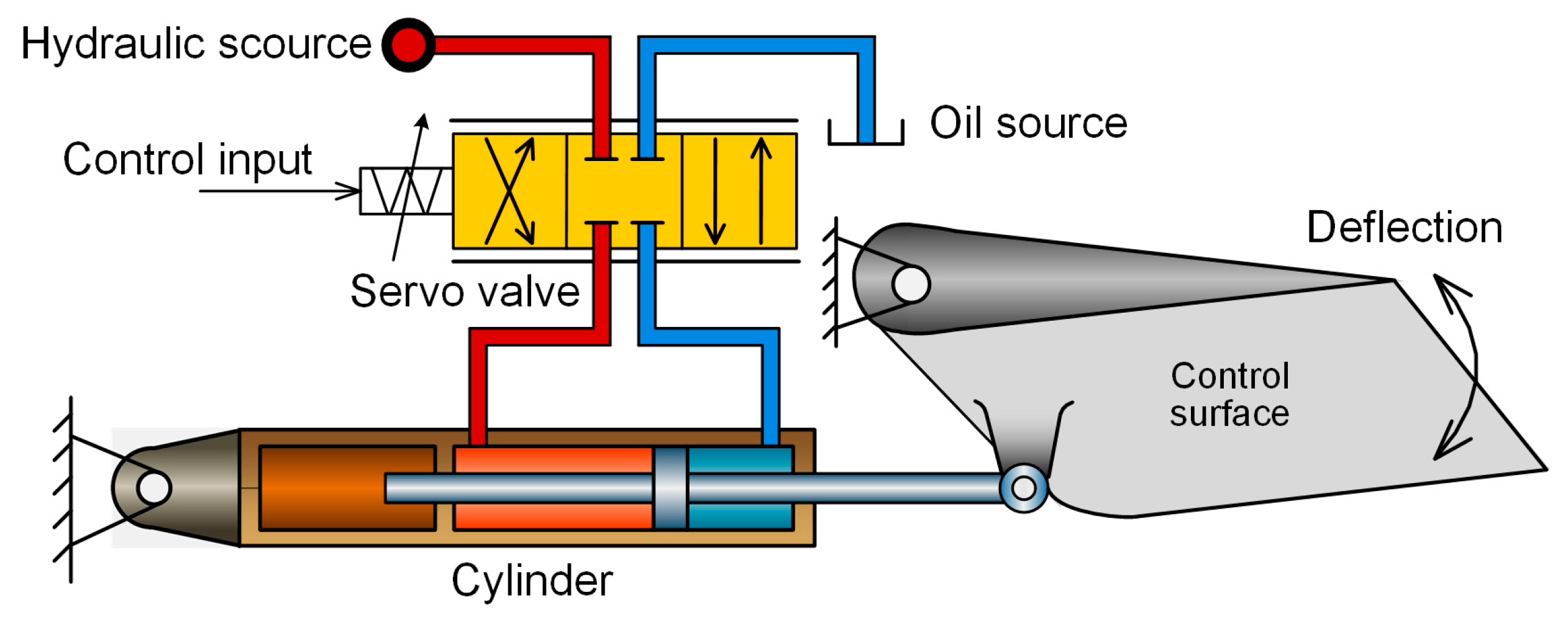

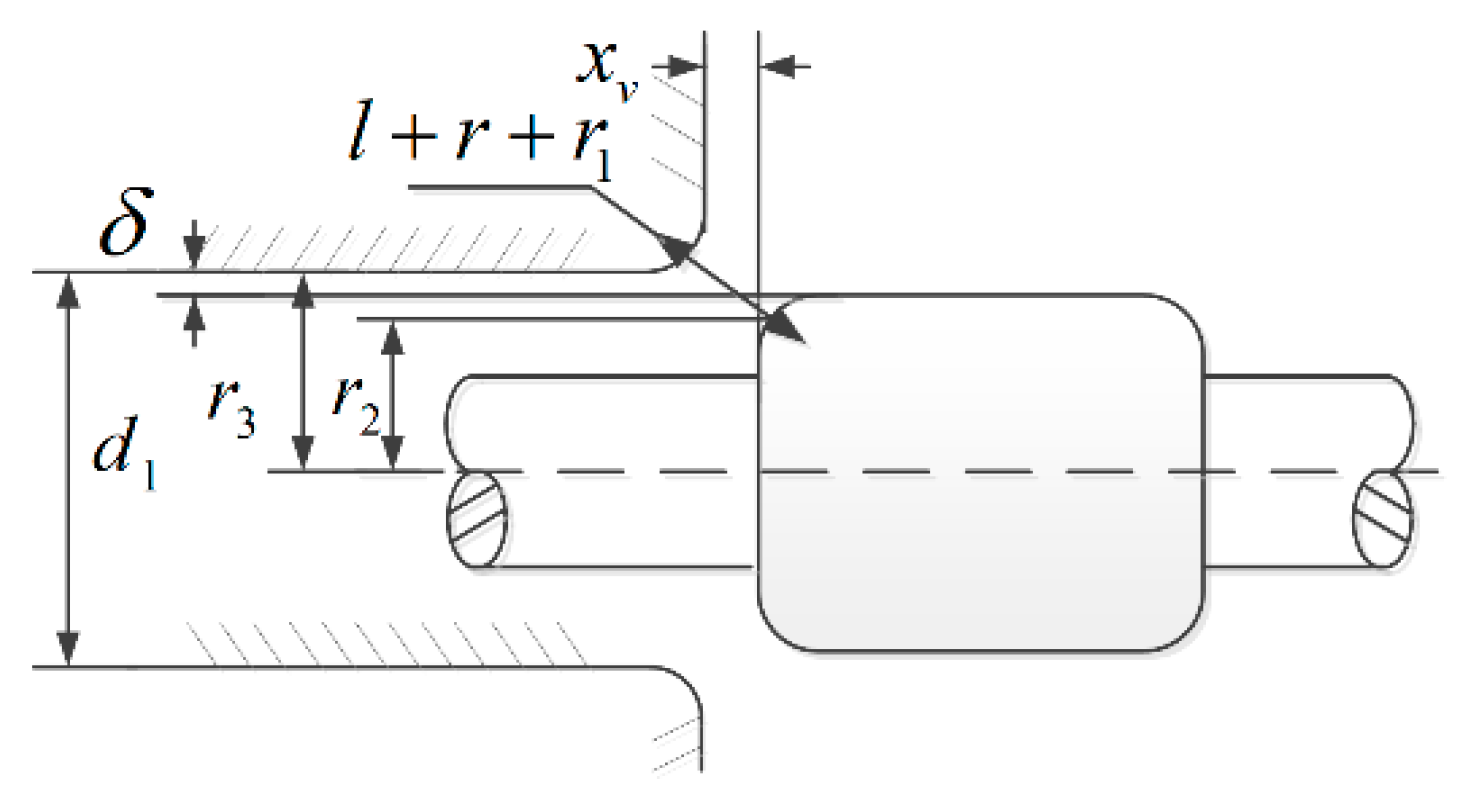

2. Failure Mode and Mechanical Analysis

2.1. Mathematical Model of HA under Fault-Free State

2.2. Mathematical Model of HA under Fault State

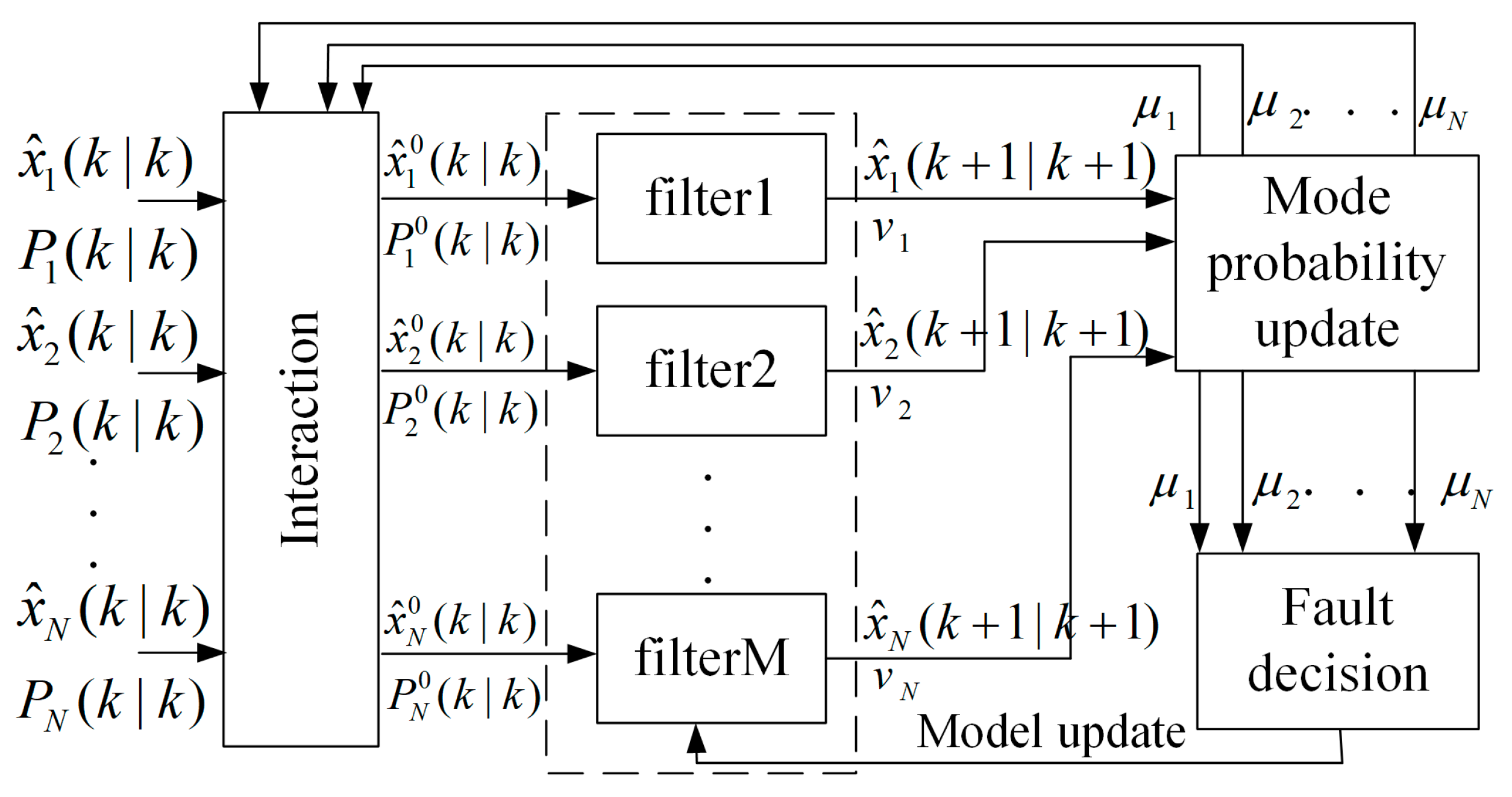

3. UIMM Algorithm

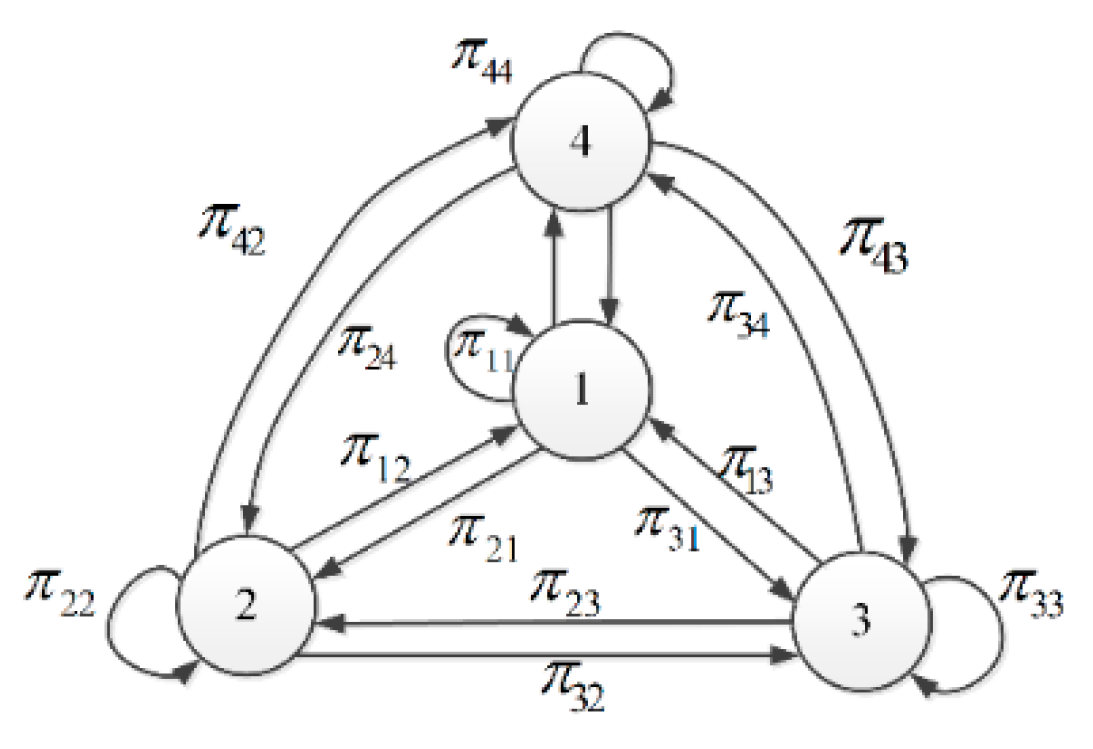

3.1. Model Set Design

3.2. The Updated Interacting Multiple Model

3.3. Comparison of IMM and UIMM

4. Simulation Results and Discussion

4.1. Simulation Environment Settings

4.2. Simulation 1—Wear of the Servo Valve and Leakage of the Hydraulic Cylinder

4.3. Simulation 2—Wear of the Servo Valve and Oil Mixed with the Air

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ahn, K.K.; Nam, D.N.C.; Jin, M. Adaptive backstepping control of an electrohydraulic actuator. IEEE/ASME Trans. Mechatron. 2014, 19, 987–995. [Google Scholar] [CrossRef]

- Cochoy, O.; Hanke, S.; Carl, U.B. Concepts for position and load control for hybrid actuation in primary flight controls. Aerosp. Sci. Technol. 2007, 11, 194–201. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S. High performance adaptive control of mechanical servo system with LuGre friction model: Identification and compensation. J. Dyn. Syst. Meas. Control 2012, 134, 011021. [Google Scholar] [CrossRef]

- Yao, J.; Deng, W.; Jiao, Z. RISE-based adaptive control of hydraulic systems with asymptotic tracking. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1524–1531. [Google Scholar] [CrossRef]

- Shi, C.; Wang, X.; Wang, S.; Wang, J.; Tomovic, M.M. Adaptive decoupling synchronous control of dissimilar redundant actuation system for large civil aircraft. Aerosp. Sci. Technol. 2015, 47, 114–124. [Google Scholar] [CrossRef]

- Byington, C.S.; Watson, M.; Edwards, D.; Stoelting, P. A model-based approach to prognostics and health management for flight control actuators. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 6–13 March 2004; pp. 3551–3562. [Google Scholar]

- Singh, M.; Lathkar, G.S.; Basu, S.K. Failure prevention of hydraulic system based on oil contamination. J. Inst. Eng. C 2012, 93, 269–274. [Google Scholar] [CrossRef]

- Greeley, M.; Rajagopalan, N. Impact of environmental contaminants on machining properties of metalworking fluids. Tribol. Int. 2004, 37, 327–332. [Google Scholar] [CrossRef]

- LinariC, D.; Koroman, V. Fault diagnosis of a hydraulic actuator using neural network. In Proceedings of the 2003 IEEE International Conference on Industrial Technology, Maribor, Slovenia, 10–12 December 2003; pp. 108–111. [Google Scholar]

- Goharrizi, A.Y.; Sepehri, N. A wavelet-based approach to internal seal damage diagnosis in hydraulic actuators. IEEE Trans. Ind. Electron. 2010, 57, 1755–1763. [Google Scholar] [CrossRef]

- Isermann, R. Fault diagnosis of machines via parameter estimation and knowledge processing—tutorial paper. Automatica 1993, 29, 815–835. [Google Scholar] [CrossRef]

- Yang, H.; Saif, M. Observer design and fault diagnosis for state-retarded dynamical systems. Automatica 1998, 34, 217–227. [Google Scholar] [CrossRef]

- Garcia, E.A.; Frank, P.M. Deterministic nonlinear observer-based approaches to fault diagnosis: A survey. Control Eng. Pract. 1997, 5, 663–670. [Google Scholar] [CrossRef]

- Wang, H.; Daley, S. Actuator fault diagnosis: An adaptive observer-based technique. IEEE Trans. Autom. Control 1996, 41, 1073–1078. [Google Scholar] [CrossRef]

- Yu, D. Fault diagnosis for a hydraulic drive system using a parameter-estimation method. Control Eng. Pract. 1997, 5, 1283–1291. [Google Scholar] [CrossRef]

- An, L.; Sepehri, N. Hydraulic actuator leakage fault detection using extended Kalman filter. Int. J. Fluid Power 2005, 6, 41–51. [Google Scholar] [CrossRef]

- Du, J.; Wang, S.; Zhang, H. Layered clustering multi-fault diagnosis for hydraulic piston pump. Mech. Syst. Signal Process. 2013, 36, 487–504. [Google Scholar] [CrossRef]

- Garimella, P.; Yao, B. Model based fault detection of an electro-hydraulic cylinder. In Proceedings of the 2005 American Control Conference Proceedings, Portland, OR, USA, 8–10 June 2005; pp. 484–489. [Google Scholar]

- Blom, H.A.; Bar-Shalom, Y. The interacting multiple model algorithm for systems with Markovian switching coefficients. IEEE Trans. Autom. Control 1988, 33, 780–783. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, J. Fault tolerant control system design with explicit consideration of performance degradation. IEEE Trans. Aerosp. Electron. Syst. 2003, 39, 838–848. [Google Scholar] [CrossRef]

- Tudoroiu, N.; Khorasani, K. Fault detection and diagnosis for satellite’s attitude control system (ACS) using an interactive multiple model (IMM) approach. In Proceedings of the 2005 IEEE Conference on Control Applications, Toronto, ON, Canada, 28–31 August 2005; pp. 1287–1292. [Google Scholar]

- Gadsden, S.A.; McCullough, K.; Habibi, S.R. Fault detection and diagnosis of an electrohydrostatic actuator using a novel interacting multiple model approach. In Proceedings of the American Control Conference (ACC), San Francisco, CA, USA, 29 June–1 July 2011; pp. 1396–1401. [Google Scholar]

- Chen, H.M.; Renn, J.C.; Su, J.P. Sliding mode control with varying boundary layers for an electro-hydraulic position servo system. Int. J. Adv. Manuf. Technol. 2005, 26, 117–123. [Google Scholar] [CrossRef]

- Zhang, K.; Yao, J.; Jiang, T. Degradation assessment and life prediction of electro-hydraulic servo valve under erosion wear. Eng. Fail. Anal. 2014, 36, 284–300. [Google Scholar] [CrossRef]

- Fang, X.; Yao, J.; Yin, X.; Chen, X.; Zhang, C. Physics-of-failure models of erosion wear in electrohydraulic servovalve, and erosion wear life prediction method. Mechatronics 2013, 23, 1202–1214. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, J. Integrated active fault-tolerant control using IMM approach. IEEE Trans. Aerosp. Electron. Syst. 2001, 37, 1221–1235. [Google Scholar] [CrossRef]

- Rago, C.; Prasanth, R.; Mehra, R.K.; Fortenbaugh, R. Failure detection and identification and fault tolerant control using the IMM-KF with applications to the Eagle-Eye UAV. In Proceedings of the 37th IEEE Conference on Decision and Control, Tampa, FL, USA, 18 December 1998; Volume 4, pp. 4208–4213. [Google Scholar]

- Cork, L.; Walker, R. Sensor fault detection for UAVs using a nonlinear dynamic model and the IMM-UKF algorithm. In Proceedings of the Information, Decision and Control, Adelaide, QLD, Australia, 12–14 February 2007; pp. 230–235. [Google Scholar]

- Zhang, Y.; Li, X.R. Detection and diagnosis of sensor and actuator failures using IMM estimator. IEEE Trans. Aerosp. Electron. Syst. 1998, 34, 1293–1313. [Google Scholar] [CrossRef]

| Parameter (Unit) | Normal Value | Faulty Value |

|---|---|---|

| Operating Mode | |

|---|---|

| fault-free (model 1) | |

| wear of the servo valve (model 2) | |

| wear of the servo valve and leakage of the hydraulic cylinder (model 3) |

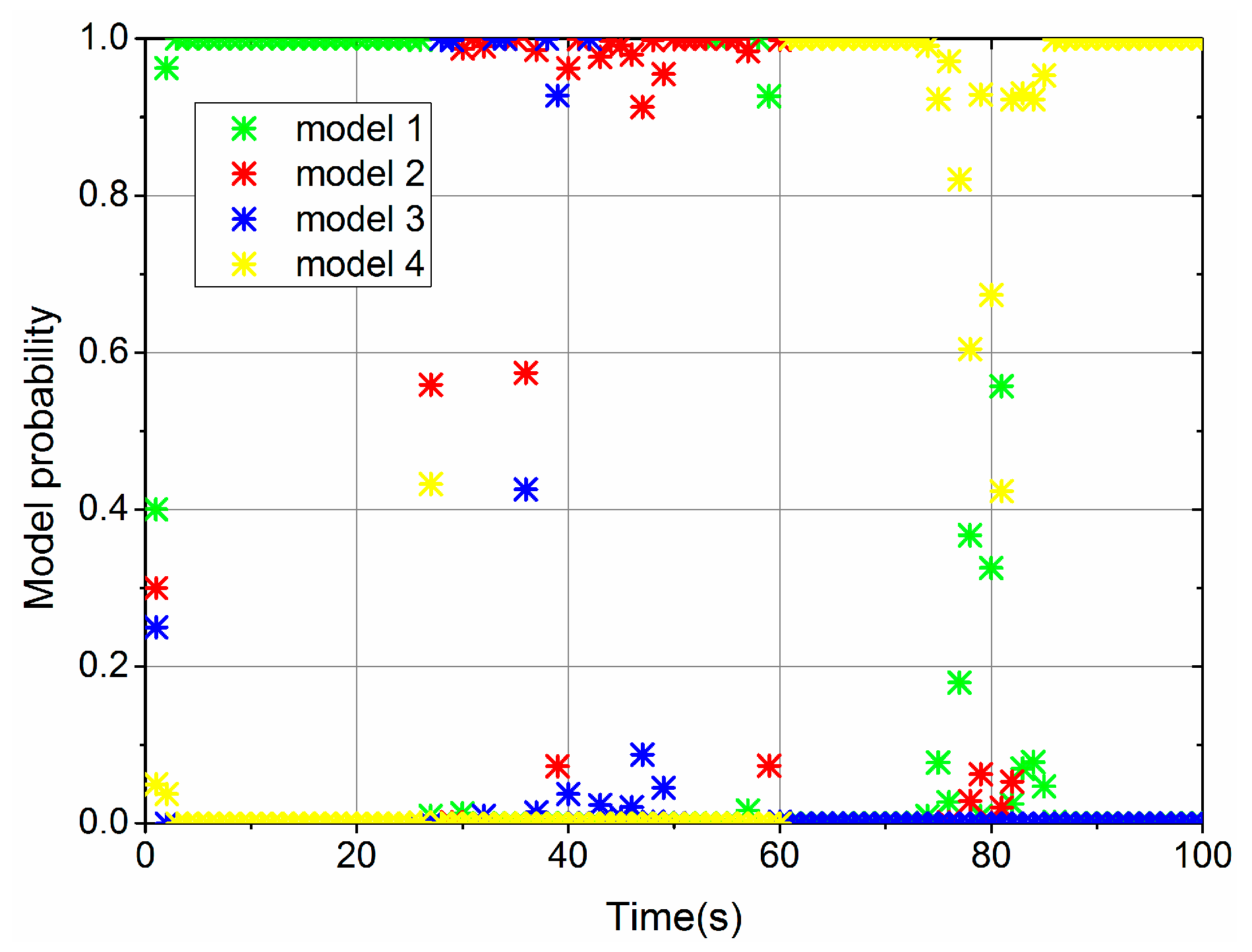

| Operating Mode | |

|---|---|

| fault-free (model 1) | |

| wear of the servo valve (model 2) | |

| wear of the servo valve and oil mixed with the air (model 4) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Wang, X.; Lin, S. Multi-Fault Diagnosis Approach Based on Updated Interacting Multiple Model for Aviation Hydraulic Actuator. Information 2020, 11, 410. https://doi.org/10.3390/info11090410

Sun X, Wang X, Lin S. Multi-Fault Diagnosis Approach Based on Updated Interacting Multiple Model for Aviation Hydraulic Actuator. Information. 2020; 11(9):410. https://doi.org/10.3390/info11090410

Chicago/Turabian StyleSun, Xiaozhe, Xingjian Wang, and Siru Lin. 2020. "Multi-Fault Diagnosis Approach Based on Updated Interacting Multiple Model for Aviation Hydraulic Actuator" Information 11, no. 9: 410. https://doi.org/10.3390/info11090410

APA StyleSun, X., Wang, X., & Lin, S. (2020). Multi-Fault Diagnosis Approach Based on Updated Interacting Multiple Model for Aviation Hydraulic Actuator. Information, 11(9), 410. https://doi.org/10.3390/info11090410