Production Challenges in Least Developed Countries

Abstract

:1. Introduction

2. Production Sites in Least Developed Countries

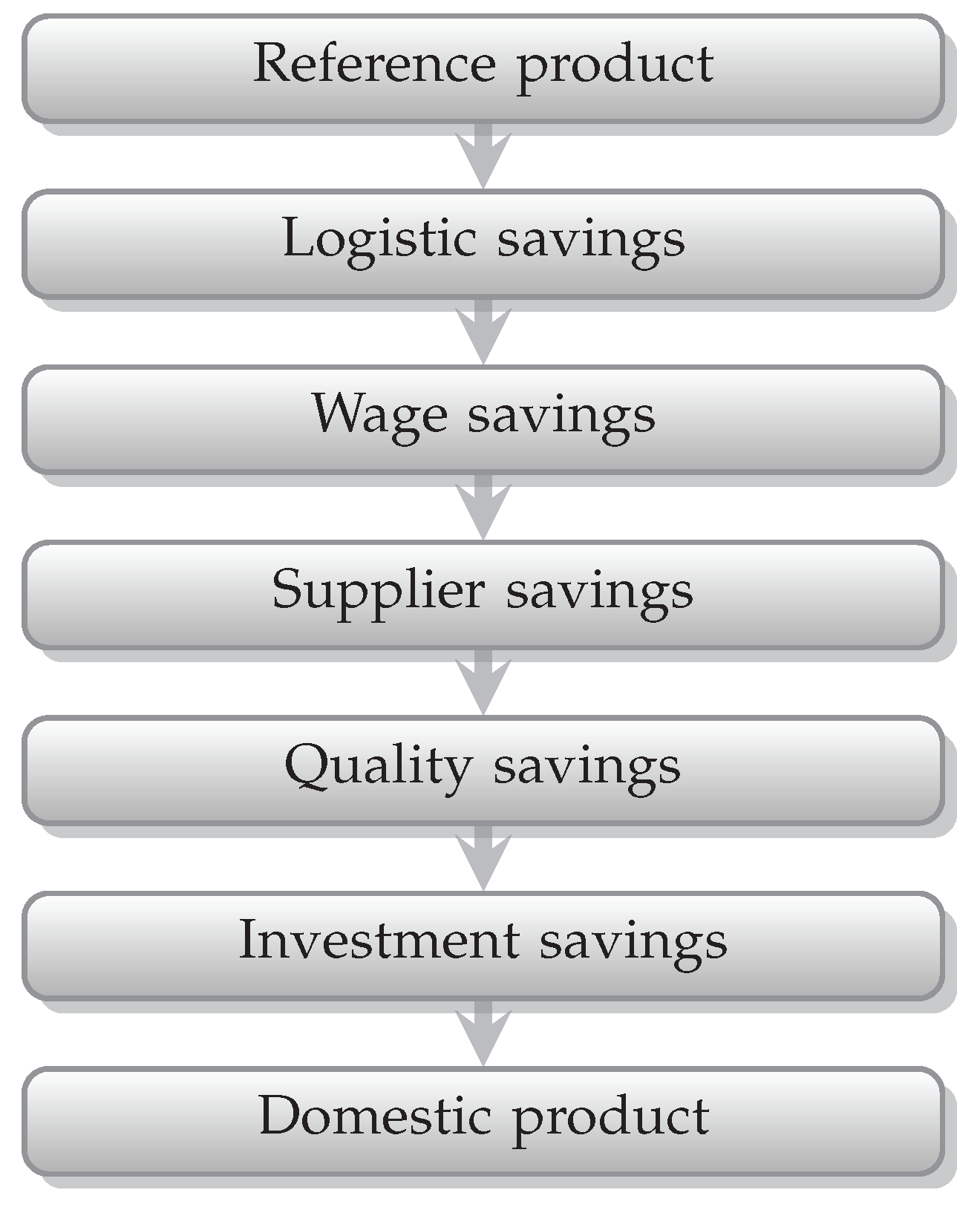

2.1. Benefits for Companies

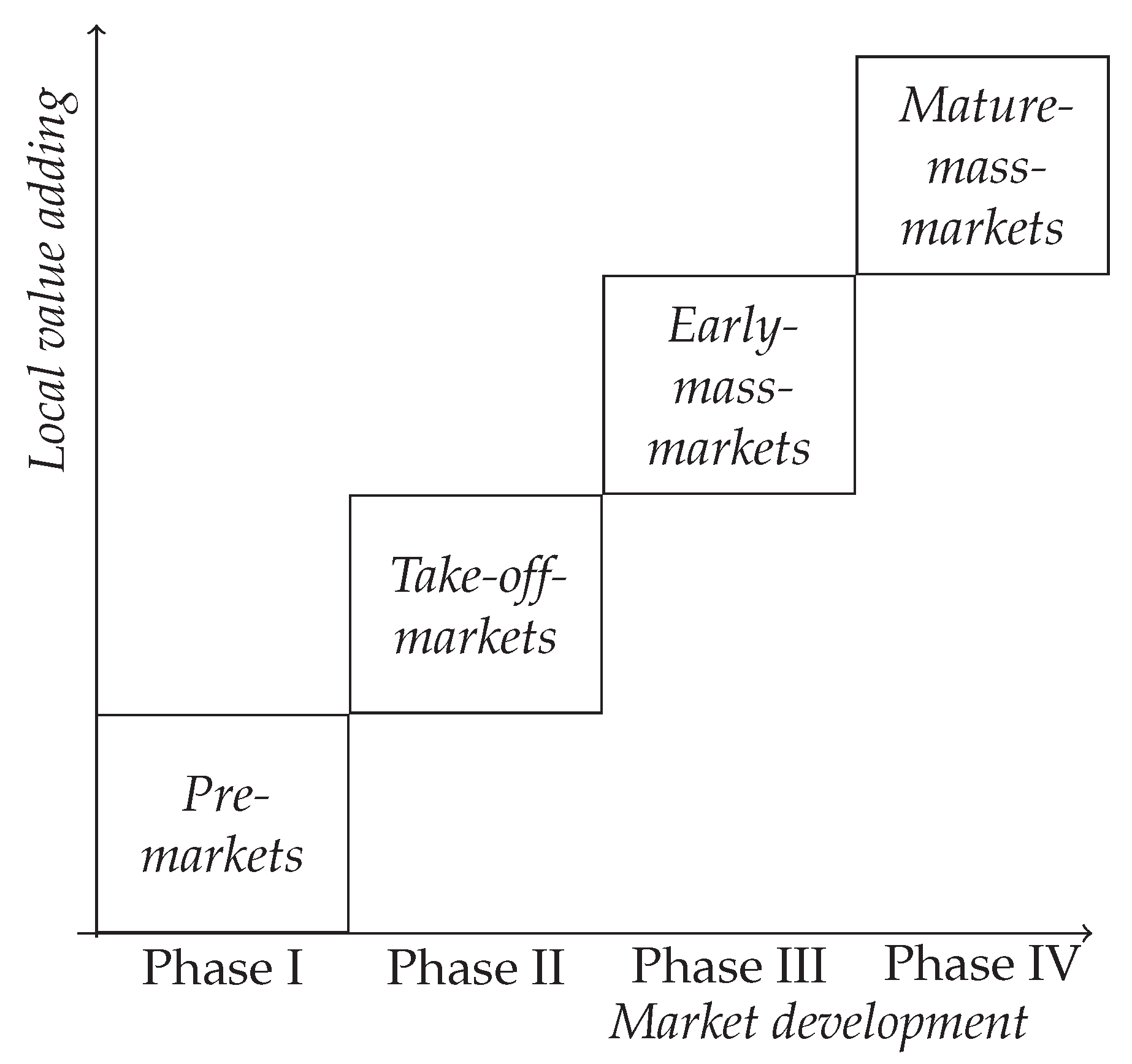

2.2. Strategies in Least Developed Countries

3. Proceeding of this paper

3.1. General framework

3.2. Literature Review

4. Production Challenges in Least Developed Countries

4.1. Organizational Challenges

4.2. Technological Challenges

4.3. Product Challenges

4.4. Employee Challenges

4.5. Society & Political Challenges

4.6. Sales & Procurement Challenges

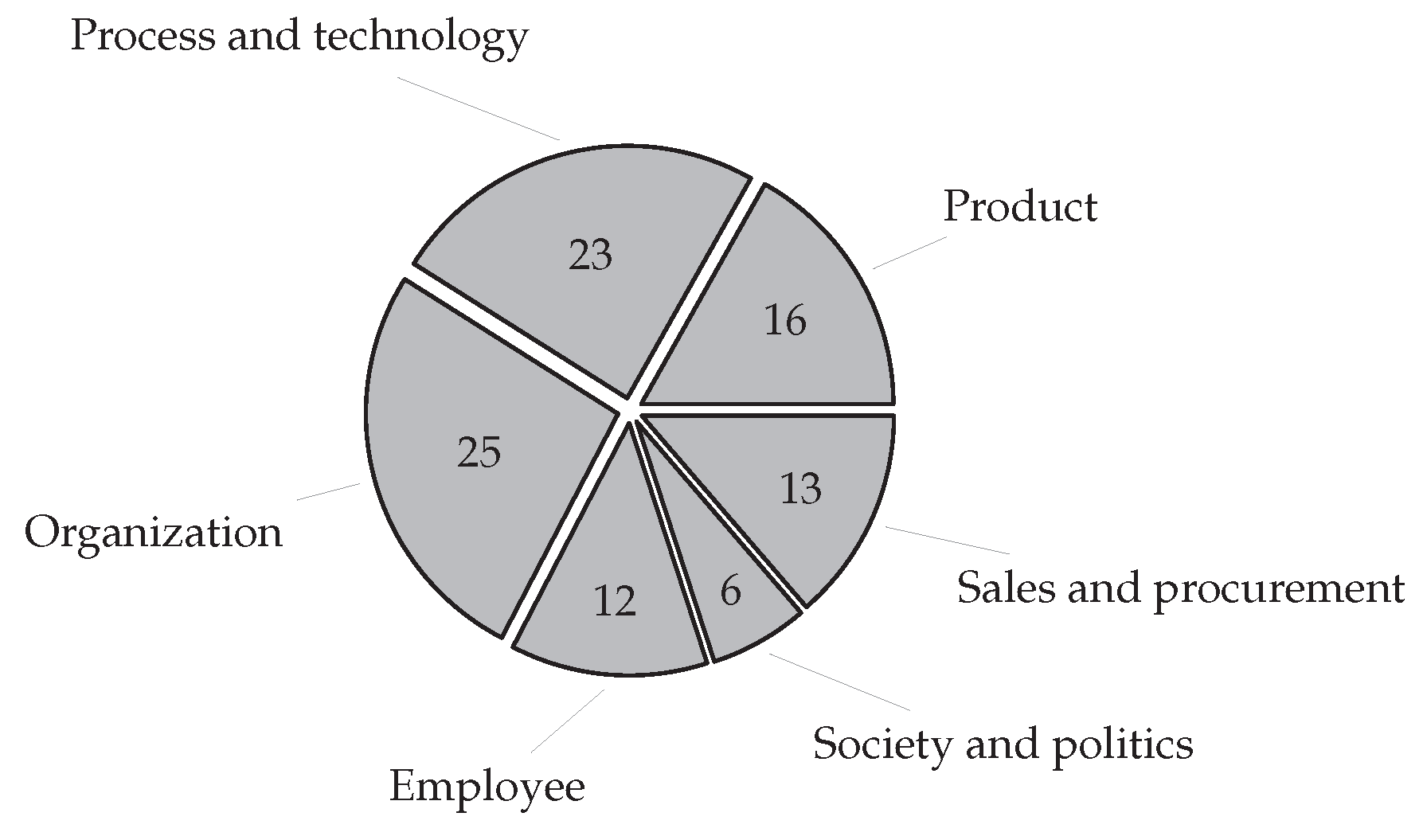

4.7. Conclusion of the Literature Research

5. Case Studies

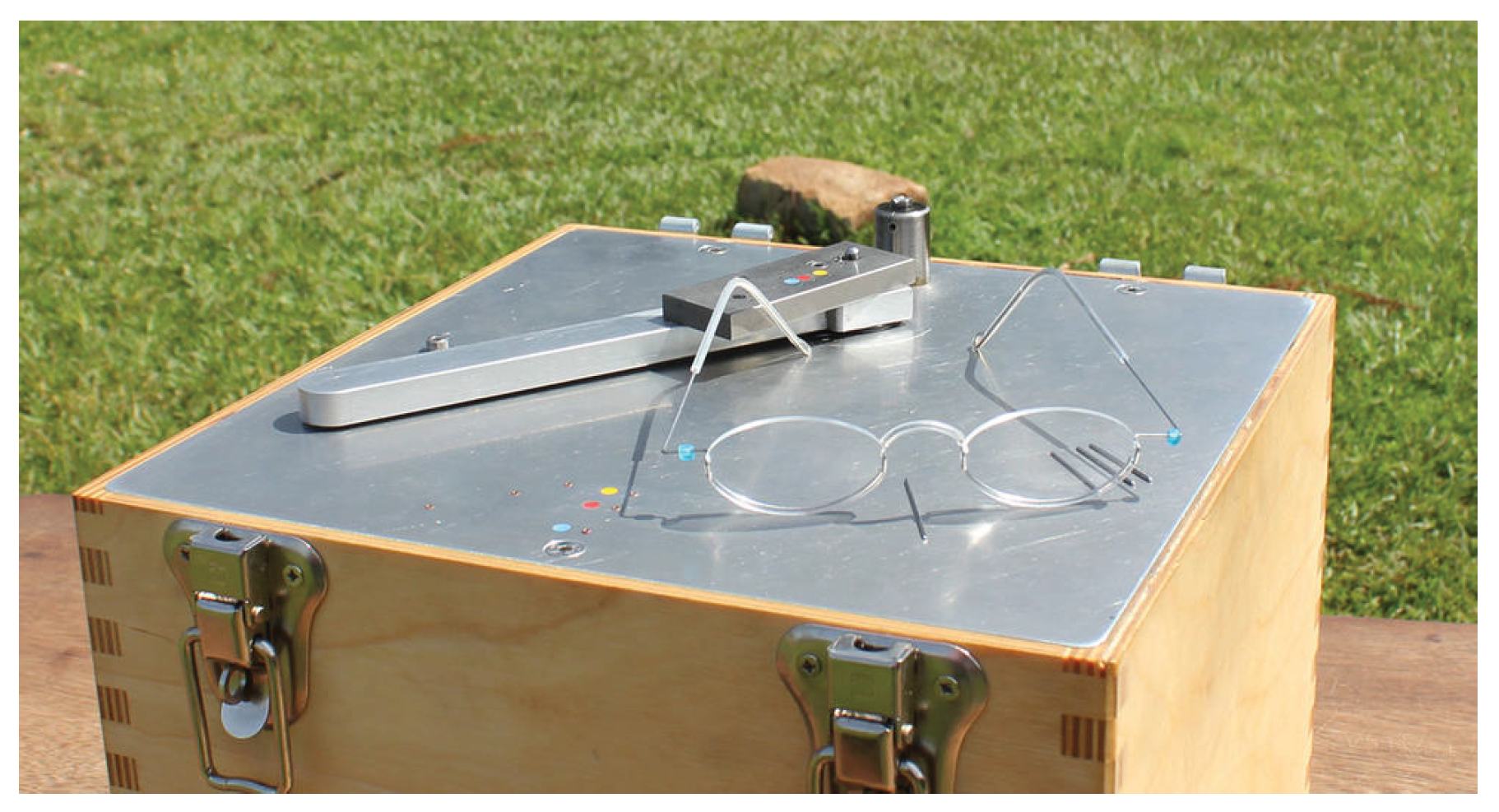

5.1. “OneDollarGlasses”

5.2. Overcoming the “OneDollarGlasses”-Challenges

5.3. Wallys

5.4. Overcoming the “Wallys”-Challenges

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GDP | Gross Domestic Product |

| MNC | Multi National Corporation |

| R&D | Research and Development |

Appendix A

| Cluster | Category | Challenge | ∑ | Source |

|---|---|---|---|---|

| Organization | Corporate | Corporate culture | 2 | [13,17] |

| Psychological fear | 1 | [26] | ||

| Local corporate management | 1 | [27] | ||

| Local competency | 11 | [28,29,30,31,32,33,34,35,36,37,77] | ||

| Local partnerships | 2 | [38,39] | ||

| Set up duration | 1 | [40] | ||

| Distance to main plant | 3 | [29,31,41] | ||

| Complexity of decentralization | 1 | [42] | ||

| Communication between subsidies and parents | 1 | [43] | ||

| Local labor standards | 1 | [44] | ||

| Aftersales processes | 1 | [45] | ||

| Investment | Investment climate | 8 | [29,36,42,45,46,47,48,66] | |

| FDI and longterm effects | 2 | [13,49] | ||

| Local financing | 3 | [47,50,108] | ||

| Appropriate profits | 3 | [31,51,77] | ||

| Strategy | Local competitors | 8 | [6,11,32,44,45,52,53,54] | |

| Time of market entry | 2 | [5,26] | ||

| Time-to-Market | 2 | [6,55] | ||

| Uncertainty of demand | 5 | [31,36,47,54,56] | ||

| Small margins | 2 | [38,57] | ||

| Market segment | 1 | [16] | ||

| Cannibalism effect in the home market | 1 | [53] | ||

| Intellectual property rights | 3 | [5,33,54] | ||

| Spin-offs | 8 | [16,31,58,59,60,61,62,109] | ||

| Economic incentives to adapt products and technology | 2 | [7,29] | ||

| Technology | Process | Adequate and low in expedience | 8 | [13,29,54,63,64,65,66,83] |

| Flexible in speed, product mix and quantities | 5 | [6,52,55,67,110] | ||

| Low in complexity | 2 | [5,38] | ||

| Low in effort | 1 | [6] | ||

| Robust | 1 | [68] | ||

| Avoid tests | 1 | [69] | ||

| Fast to ramp up | 1 | [70] | ||

| Standardized in process and measurement | 8 | [8,30,34,41,60,64,71,72] | ||

| Output depends on the worker‘s skill level | 3 | [46,54,111] | ||

| Output depends on technological capabilities | 4 | [46,65,67,73] | ||

| Appropriate to local requirements and assembly intensive | 9 | [5,27,29,47,54,57,64,65,90] | ||

| Local information system | 4 | [30,36,38,64] | ||

| Energy saving | 1 | [74] | ||

| Local manufacturing norms and waste reduction | 12 | [6,32,47,49,64,66,68,70,82,89,110,112] | ||

| Work safety | 1 | [64] | ||

| Productivity | Productivity and performance | 11 | [5,27,35,47,66,71,75,76,77,82,113] | |

| High scrap rates | 1 | [67] | ||

| Lack of capacity utilization | 1 | [77] | ||

| Constant development and improvement | 2 | [13,70] | ||

| Investment | Low initial investment | 8 | [8,9,29,39,75,78,90,114] | |

| Economic efficiency for small-scales | 3 | [8,54,71] | ||

| Environment | Robust against environmental influences | 4 | [27,29,63,79] | |

| Sustainability in technology selection | 1 | [74] | ||

| Product | Components | Appropriate in costs, function and quality | 27 | [7,16,27,29,30,31,32,36,39,42,45,47,50,52,53,54,57,61,78,80,81,82,83,84,85,91,115] |

| Reduction of components | 1 | [86] | ||

| Standardization of components | 6 | [8,16,29,64,72,87] | ||

| Reduction of resources (financial, material, time) | 9 | [26,27,29,30,38,47,49,51,114] | ||

| Involvement of local population | 2 | [38,79] | ||

| Local testing | 2 | [79,80] | ||

| Consideration of life cycle | 1 | [79] | ||

| Plan for reuse | 1 | [88] | ||

| Maintenance and spare parts availability | 9 | [27,29,50,58,64,73,89,90,114] | ||

| Constant quality improvement | 1 | [6] | ||

| Quality assurance | 8 | [3,5,6,29,50,58,67,71] | ||

| Costs | Competitive value | 1 | [91] | |

| Low material costs | 2 | [38,92] | ||

| Low break-even points | 7 | [8,10,27,29,38,57,93] | ||

| Economics of scale and scope | 5 | [7,27,32,38,54] | ||

| Employee | Qualification | Lack of skilled employees | 27 | [5,26,27,30,31,33,34,35,37,39,41,47,50,54,56,58,61,62,64,65,67,73,94,97,114,116] |

| Lack of implicit product knowledge | 1 | [7] | ||

| Different education level in different DCs | 1 | [46] | ||

| Attraction of top talents and managers | 2 | [30,77] | ||

| Fluctuation of trained employees | 2 | [95,96] | ||

| Lack of learning experience | 1 | [43] | ||

| Offering worker trainings | 4 | [36,62,83,97] | ||

| Focus on long term relationship with employees | 5 | [31,38,50,96,97] | ||

| Integration of local culture and language | 11 | [26,29,34,36,39,41,50,56,64,76,109] | ||

| Income equality, combat human rights violations, inequality and poverty | 8 | [26,27,38,50,78,79,96,109] | ||

| Know-how | Know-how-transfer | 18 | [20,32,33,34,35,37,43,49,54,58,61,62,73,76,80,83,87,117] | |

| Know-how transmitter | 7 | [5,40,41,58,71,98,5] | ||

| Age of technology | 2 | [41,98] | ||

| Codifiability | 2 | [97,98] | ||

| Society & Politics | Politics | Local requirements (e.g., safety, security, recycling) | 19 | [3,6,16,28,32,36,38,39,42,45,50,54,56,58,62,75,80,82,108] |

| Import taxes, trade barriers, local content, financial restrictions | 18 | [3,5,6,7,8,11,13,14,27,29,58,66,67,71,73,78,82,90] | ||

| Social commitment | 8 | [6,31,38,42,66,78,79,89] | ||

| Lack of political support | 1 | [48] | ||

| Corruption, abuse, theft | 7 | [36,47,48,49,54,56,109] | ||

| Instability and high inflation rates | 1 | [67] | ||

| Sales & Procurements | Supplier | Requirement of local suppliers | 5 | [13,27,28,50,64] |

| Quality issues | 1 | [48] | ||

| Unreliable delivery times, high communication costs, inflexibility and lack of innovation culture | 21 | [7,29,32,33,34,38,39,47,52,55,57,58,62,71,73,80,84,90,99,110,113] | ||

| Supplier training | 2 | [33,100] | ||

| Collaborative partnership | 4 | [13,34,76,100] | ||

| Integration of suppliers into network | 1 | [91] | ||

| Product | Usage of modules | 1 | [7] | |

| Standardized suppliers | 4 | [33,48,80,100] | ||

| Technology | Technological capabilities of supplier | 2 | [7,73] | |

| Infrastructure | Logistic/Distribution costs | 10 | [29,30,31,32,39,48,52,53,57,75] | |

| Underdeveloped business ecosystem | 1 | [53] | ||

| Building clusters | 5 | [33,71,96,101,102] | ||

| Lack of reliable infrastructure | 5 | [5,6,50,89,92] |

References

- Pyke, F.; Lund-Thomsen, P. Social upgrading in developing country industrial clusters: A reflection on the literature. Compet. Chang. 2016, 20, 53–68. [Google Scholar] [CrossRef] [Green Version]

- Bacchetta, M.; Beverelli, C.; Hancock, J.; Koulen, M.; Kummritz, V.; Monteiro, J.A.; Piermartini, R.; Rubinova, S.; Teh, R. Trade, Technology and Jobs; World Trade Report; WTO Publications: Geneva, Switzerland, 2017; Volume 2017. [Google Scholar]

- Saranga, H.; George, R.; Beine, J.; Arnold, U. Resource configurations, product development capability, and competitive advantage: An empirical analysis of their evolution. J. Bus. Res. 2018, 85, 32–50. [Google Scholar] [CrossRef]

- Sampath, P.G. Industrial development for Africa: Trade, technology and the role of the state. Afr. J. Sci. Technol. Innov. Dev. 2014, 6, 439–453. [Google Scholar] [CrossRef] [Green Version]

- Abele, E.; Meyer, T.; Näher, U.; Strube, G.; Sykes, R. (Eds.) Global Production: A Handbook for Strategy and Implementation; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Dombrowski, U.; Schmidt, S.; Wrehde, J. Herausforderungen in der Automobilproduktion. ZWF Z. Wirtsch. Fabr. 2006, 101, 254–259. [Google Scholar] [CrossRef]

- Gastrow, M. A review of trends in the global automotive manufacturing industry and implications for developing countries. Afr. J. Bus. Manag. 2012, 6. [Google Scholar] [CrossRef]

- Herrigel, G. Globalization and the German industrial production model. J. Labour Mark. Res. 2015, 48, 133–149. [Google Scholar] [CrossRef] [Green Version]

- Kampker, A.; Förstmann, R.; Ordung, M.; Haunreiter, A. Prototypen im agilen Entwicklungsmanagement. ATZ-Automob. Z. 2016, 118, 72–77. [Google Scholar] [CrossRef]

- Göpfert, I.; Braun, D.; Schulz, M. Automobillogistik: Stand und Zukunftstrends; Stand und Zukunftstrends; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017. [Google Scholar] [CrossRef]

- Dombrowski, U.; Vollrath, H. Optimierung von CKD-Prozessen. ZWF Z. Wirtsch. Fabr. 2008, 103, 48–52. [Google Scholar] [CrossRef]

- Rauch, E.; Dallinger, M.; Dallasega, P.; Matt, D.T. Sustainability in Manufacturing through Distributed Manufacturing Systems (DMS). In Proceedings of the 10th CIRP Conference on Intelligent Computation in Manufacturing Engineering—CIRP ICME’16, Naples, Italy, 6–10 April 2015; Volume 29, pp. 544–549. [Google Scholar] [CrossRef]

- Ivarsson, I.; Alvstam, C.G. Technology transfer from TNCs to local suppliers in developing countries: A study of AB Volvo’s truck and bus plants in Brazil, China, India, and Mexico. World Dev. 2005, 33, 1325–1344. [Google Scholar] [CrossRef]

- Kobayashi, H. Perspectives on Sustainable Product Design Methodology Focused on Local Communities. In Sustainability Through Innovation in Product Life Cycle Design; Matsumoto, M., Masui, K., Fukushige, S., Kondoh, S., Eds.; Springer: Singapore, 2017; pp. 79–92. [Google Scholar] [CrossRef]

- Radjou, N.; Prabhu, J.C.; Ahuja, S. Jugaad Innovation: Think Frugal, be Flexible, Generate Breakthrough Growth, 1st ed.; Jossey-Bass: San Francisco, CA, USA, 2012. [Google Scholar]

- Brandt, L.; Thun, E. Constructing a Ladder for Growth: Policy, Markets, and Industrial Upgrading in China. World Dev. 2016, 80, 78–95. [Google Scholar] [CrossRef]

- Browa, H. The Causes, Conditions and Patterns of Appropriate Technology: “An Attempt of Explanation and Description by means of System-Analytical Macro-Approach”. IFAC Proc. Vol. 1983, 16, 11–20. [Google Scholar] [CrossRef]

- United Nations Conference on Trade and Developement. Country Profiles; UNCTAD: Geneva, Switzerland, 2018. [Google Scholar]

- Leontiade, J. Planning strategy for world markets. Long Range Plan. 1970, 3, 40–45. [Google Scholar] [CrossRef]

- Putranto, K.; Stewart, D.; Moore, G.; Diatmoko, R. Implementing a technology strategy in developing countries. Technol. Forecast. Soc. Chang. 2003, 70, 163–176. [Google Scholar] [CrossRef]

- Xie, W. Technological learning in China’s colour TV (CTV) industry. Technovation 2004, 24, 499–512. [Google Scholar] [CrossRef]

- Karabag, S.F.; Tuncay-Celikel, A.; Berggren, C. The Limits of R&D Internationalization and the Importance of Local Initiatives: Turkey as a Critical Case. World Dev. 2011, 39, 1347–1357. [Google Scholar] [CrossRef]

- Kreikebaum, H. Strategische Unternehmensplanung, 6th ed.; W. Kohlhammer: Stuttgart, Germany, 1997. [Google Scholar]

- Okoli, C.; Schabram, K. A Guide to Conducting a Systematic Literature Review of Information Systems Research. SSRN Electron. J. 2010, 10. [Google Scholar] [CrossRef] [Green Version]

- Pawellek, G. Ganzheitliche Fabrikplanung; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Adams, K.; Nayak, B.S.; Koukpaki, S. Critical perspectives on “manufactured” risks arising from Eurocentric business practices in Africa. Crit. Perspect. Int. Bus. 2018, 14, 210–229. [Google Scholar] [CrossRef]

- Stewart, F. Technology and employment in LDCs. World Dev. 1974, 2, 17–46. [Google Scholar] [CrossRef]

- Athreye, S.; Tuncay-Celikel, A.; Ujjual, V. Internationalisation of R&D into Emerging Markets: Fiat’s R&D in Brazil, Turkey and India. Long Range Plan. 2014, 47, 100–114. [Google Scholar] [CrossRef] [Green Version]

- Teitel, S. On the concept of appropriate technology for less industrialized countries. Technol. Forecast. Soc. Chang. 1978, 11, 349–369. [Google Scholar] [CrossRef]

- Uddin, M.K. The role of diffusion of innovations for incremental development in small enterprises. Technovation 2006, 26, 274–284. [Google Scholar] [CrossRef]

- Webb, J.W.; Kistruck, G.M.; Ireland, R.D.; Ketchen, J.D.J. The Entrepreneurship Process in Base of the Pyramid Markets: The Case of Multinational Enterprise/Nongovernment Organization Alliances. Entrep. Theory Pract. 2010, 34, 555–581. [Google Scholar] [CrossRef]

- Brandt, L.; Thun, E. The Fight for the Middle: Upgrading, Competition, and Industrial Development in China. World Dev. 2010, 38, 1555–1574. [Google Scholar] [CrossRef] [Green Version]

- Altenburg, T.; Meyer-Stamer, J. How to Promote Clusters: Policy Experiences from Latin America. World Dev. 1999, 27, 1693–1713. [Google Scholar] [CrossRef]

- Simona, G.L.; Axèle, G. Knowledge Transfer from TNCs and Upgrading of Domestic Firms: The Polish Automotive Sector. World Dev. 2012, 40, 796–807. [Google Scholar] [CrossRef]

- Tidd, J.; Brocklehurst, M. Routes to Technological Learning and Development. Technol. Forecast. Soc. Chang. 1999, 62, 239–257. [Google Scholar] [CrossRef]

- Chowdhury, M.S. Overcoming entrepreneurship development constraints: The case of Bangladesh. J. Enterp. Commun. People Places Glob. Econ. 2007, 1, 240–251. [Google Scholar] [CrossRef]

- Agarwal, N.; Brem, A. Frugal and reverse innovation—Literature overview and case study insights from a German MNC in India and China. In Proceedings of the 2012 18th International ICE Conference on Engineering, Technology and Innovation (ICE 2012), Munich, Germany, 18–20 June 2012; Thoben, K.D., Katzy, B., Eds.; IEEE: Piscataway, NJ, USA, 2012; pp. 1–11. [Google Scholar] [CrossRef]

- Rosca, E.; Arnold, M.; Bendul, J.C. Business models for sustainable innovation—An empirical analysis of frugal products and services. J. Clean. Prod. 2017, 162, S133–S145. [Google Scholar] [CrossRef]

- Smith, A.; Fressoli, M.; Thomas, H. Grassroots innovation movements: challenges and contributions. J. Clean. Prod. 2014, 63, 114–124. [Google Scholar] [CrossRef]

- Falb, R. Global Footprint Design–Die Spielregeln der Internationalen Wertschöpfung Beherrschen: Studie und Empfehlung; Laboratorium für Werkzeugmaschinen und Betriebslehre der RWTH Aachen und Roland Berger Strategy Consultants: Aachen, Germany, 2006. [Google Scholar]

- Teece, D.J. Technology Transfer by Multinational Firms: The Resource Cost of Transferring Technological Know-How. Econ. J. 1977, 87, 242. [Google Scholar] [CrossRef]

- Rauch, E.; Dallasega, P.; Matt, D.T. Sustainable production in emerging markets through Distributed Manufacturing Systems (DMS). J. Clean. Prod. 2016, 135, 127–138. [Google Scholar] [CrossRef]

- Park, B.I. What changes the rules of the game in wholly owned subsidiaries? Determinants of knowledge acquisition from parent firms. Int. Bus. Rev. 2012, 21, 547–557. [Google Scholar] [CrossRef]

- Lund-Thomsen, P.; Nadvi, K.; Chan, A.; Khara, N.; Xue, H. Labour in Global Value Chains: Work Conditions in Football Manufacturing in China, India and Pakistan. Dev. Chang. 2012, 43, 1211–1237. [Google Scholar] [CrossRef]

- Grosse, R. Competitive advantages and multinational enterprises in Latin America. J. Bus. Res. 1992, 25, 27–42. [Google Scholar] [CrossRef]

- Baptist, S.; Teal, F. Technology and Productivity in African Manufacturing Firms. World Dev. 2014, 64, 713–725. [Google Scholar] [CrossRef]

- London, T.; Anupindi, R.; Sheth, S. Creating mutual value: Lessons learned from ventures serving base of the pyramid producers. J. Bus. Res. 2010, 63, 582–594. [Google Scholar] [CrossRef]

- Jia, F.; Zuluaga-Cardona, L.; Bailey, A.; Rueda, X. Sustainable supply chain management in developing countries: An analysis of the literature. J. Clean. Prod. 2018, 189, 263–278. [Google Scholar] [CrossRef]

- Hossain, M. Frugal innovation: A review and research agenda. J. Clean. Prod. 2018, 182, 926–936. [Google Scholar] [CrossRef]

- Ancarani, F.; Frels, J.K.; Miller, J.; Saibene, C.; Barberio, M. Winning in Rural Emerging Markets: General Electric’s Research Study on MNCs. Calif. Manag. Rev. 2014, 56, 31–52. [Google Scholar] [CrossRef] [Green Version]

- Howell, R.; van Beers, C.; Doorn, N. Value capture and value creation: The role of information technology in business models for frugal innovations in Africa. Technol. Forecast. Soc. Chang. 2018, 131, 227–239. [Google Scholar] [CrossRef]

- Chang, S.J.; Park, S.H. Winning Strategies in China: Competitive Dynamics Between MNCs and Local Firms. Long Range Plan. 2012, 45, 1–15. [Google Scholar] [CrossRef]

- Karamchandani, A.; Kubzansky, M.; Lalwani, N. The Globe: Is the Bottom of the Pyramid Really for You? Harvad Bus. Rev. 2011, 89, 107–111. [Google Scholar]

- Helleiner, G.K. The role of multinational corporations in the less developed countries’ trade in technology. World Dev. 1975, 3, 161–189. [Google Scholar] [CrossRef]

- Nassimbeni, G. Local manufacturing systems and global economy: Are they compatible? The case of the Italian eyewear district. J. Oper. Manag. 2003, 21, 151–171. [Google Scholar] [CrossRef]

- Adanu, K. Institutional change and economic development: A conceptual analysis of the African case. Int. J. Soc. Econ. 2017, 44, 547–559. [Google Scholar] [CrossRef]

- Ray, S.; Kanta Ray, P. Product innovation for the people’s car in an emerging economy. Technovation 2011, 31, 216–227. [Google Scholar] [CrossRef]

- O’Connor, D.C. The computer industry in the third world: Policy options and constraints. World Dev. 1985, 13, 311–332. [Google Scholar] [CrossRef]

- Hopkins, V. Analysis of international patent protection and global public health. J. Public Int. Aff. 2006, 17, 83. [Google Scholar]

- Tyagi, A.; Chopra, S. Standard essential patents (SEP’s)—Issues & Challenges in developing economies. J. Intellect. Prop. Rights 2017, 22, 121–135. [Google Scholar]

- Phuluwa, H.S.; Trimble, J.A. Technology Transfer in Press Tool Industry: Effectiveness and Efficiency in the South African Context. In Proceedings of the 2016 25th International Association for Management of Technology Conference (IAMOT 2016), Orlando, FL, USA, 8–11 June 2016; pp. 807–817. [Google Scholar]

- Chen, M. Technological transfer to China: Major rules and issues. Int. J. Technol. Manag. 1995, 10, 747–756. [Google Scholar]

- Grant, E.B.; Gregory, M.J. Adapting manufacturing processes for international transfer. Int. J. Oper. Prod. Manag. 1997, 17, 994–1005. [Google Scholar] [CrossRef]

- Gorrie, A.; Pons, D.; Maples, D.; Docherty, P. Principles of Product Design in Developing Countries. Appl. Syst. Innov. 2018, 1, 11. [Google Scholar] [CrossRef] [Green Version]

- Filho, E.R. Brazilian design for sustainability: in search of a local approach. J. Clean. Prod. 2015, 107, 467–474. [Google Scholar] [CrossRef]

- Johnson, O. Promoting green industrial development through local content requirements: India’s National Solar Mission. Clim. Policy 2016, 16, 178–195. [Google Scholar] [CrossRef]

- Alcorta, L. The diffusion of advanced automation in developing countries: Factors and adoption process. Technovation 1999, 19, 163–175. [Google Scholar] [CrossRef]

- Dombrowski, U.; Weckenborg, S.; Rennemann, T. CKD auf Basis von Produktionsprinzipien. Integr. Prozesse Kontin. Verbessern Ind. Manag. 2010, 4, 36–40. [Google Scholar]

- Bohn, R. The economics of yield-driven processes. J. Oper. Manag. 1999, 18, 41–59. [Google Scholar] [CrossRef] [Green Version]

- Terwiesch, C.; Xu, Y. The Copy-Exactly Ramp-Up Strategy: Trading-Off Learning With Process Change. IEEE Trans. Eng. Manag. 2004, 51, 70–84. [Google Scholar] [CrossRef]

- Damoense, M.Y.; Simon, A. An analysis of the impact of the first phase of South Africa’s motor industry development programme (midp), 1995–2000. Dev. S. Afr. 2004, 21, 251–269. [Google Scholar] [CrossRef]

- AIAG Automotive Industry Action Group. Quality 2020: Automotive Industry’s View on the Current State of Quality and a Strategic Path Forward; AIAG Automotive Industry Action Group: Southfield, MI, USA, 2016. [Google Scholar]

- Brannon, J.T.; James, D.D.; Lucker, G. Generating and sustaining backward linkages between maquiladoras and local suppliers in Northern Mexico. World Dev. 1994, 22, 1933–1945. [Google Scholar] [CrossRef]

- Oguntoye, O.; Evans, S. Framing Manufacturing Development in Africa and the Influence of Industrial Sustainability. Procedia Manuf. 2017, 8, 75–80. [Google Scholar] [CrossRef]

- Soderbom, M. Constraints and Opportunities in Kenyan Manufacturing: Report on the Kenyan Manufacturing Enterprise Survey 2000; Department of Economics, University of Oxford: Oxford, UK, 2011. [Google Scholar]

- Hyder, A.S. Differences between developed and developing country joint ventures—A reality or a myth? Int. Bus. Rev. 1999, 8, 441–461. [Google Scholar] [CrossRef]

- Burange, L. Competitiveness of Firms in Indian Automobile Industry; Working Paper, WP No. UDE (CAS)23/(8)/1/2008; Department of Economics, University of Mumbai: Mumbai, India, 2008. [Google Scholar]

- Dane, A. The Potential of Electric Vehicles to Contribute to South Africa’s Greenhouse Gas Emissions Targets and Other Developmental Objectives: How Appropriate Is the Investment in Electric Vehicles as a NAMA? Energy Research Center, University of Capetown: Cape Town, South Africa, 2013. [Google Scholar]

- Mattson, C.A.; Wood, A.E. Nine Principles for Design for the Developing World as Derived from the Engineering Literature. J. Mech. Des. 2014, 136, 121403. [Google Scholar] [CrossRef] [Green Version]

- Bångens, L.; Araujo, L. The structures and processes of learning. A case study. J. Bus. Res. 2002, 55, 571–581. [Google Scholar] [CrossRef]

- Sharif, M. Measurement of technology for national development. Technol. Forecast. Soc. Chang. 1986, 29, 119–172. [Google Scholar] [CrossRef]

- Ansal, H.K. Technical change and industrial policy: The case of truck manufacturing in Turkey. World Dev. 1990, 18, 1513–1528. [Google Scholar] [CrossRef]

- Williams, L.D.A. Three Models of Development: Community Ophthalmology NGOs and the Appropriate Technology Movement. Perspect. Glob. Dev. Technol. 2013, 12, 449–475. [Google Scholar] [CrossRef] [Green Version]

- Barnes, J.; Kaplinsky, R. Globalization and the Death of the Local Firm? The Automobile Components Sector in South Africa. Reg. Stud. 2000, 34, 797–812. [Google Scholar] [CrossRef]

- Lall, S. The international automotive industry and the developing world. World Dev. 1980, 8, 789–812. [Google Scholar] [CrossRef]

- Boothroyd, G. Design for assembly—The key to design for manufacture. Int. J. Adv. Manuf. Technol. 1987, 2, 3–11. [Google Scholar] [CrossRef]

- Xie, W.; Wu, G. Differences between learning processes in small tigers and large dragons. Res. Policy 2003, 32, 1463–1479. [Google Scholar] [CrossRef]

- Amelia, L.; Wahab, D.A.; Che Haron, C.H.; Muhamad, N.; Azhari, C.H. Initiating automotive component reuse in Malaysia. J. Clean. Prod. 2009, 17, 1572–1579. [Google Scholar] [CrossRef]

- Whitehead, T.; Evans, M.A.; Bingham, G.A. Design Tool for Enhanced New Product Development in Low Income Economies; Loughborough University: Loughborough, UK, 2016; pp. 2398–3132. [Google Scholar]

- Bendul, J.C.; Rosca, E.; Pivovarova, D. Sustainable supply chain models for base of the pyramid. J. Clean. Prod. 2017, 162, S107–S120. [Google Scholar] [CrossRef]

- Thomas, R.J.; Wind, Y. Symbiotic Innovation: Getting the Most Out of Collaboration. In Evolution of Innovation Management: Trends in an International Context; Brem, A., Viardot, É., Eds.; Palgrave Macmillan UK: London, UK, 2013; pp. 1–31. [Google Scholar] [CrossRef]

- Becker, D. Global Automotive Executive: KPMG’ 18th Consecutive; KPMG International Cooperative: Amstelveen, The Netherlands, 2017. [Google Scholar]

- Kampker, A.; Deutskens, C.; Deutschmann, K.; Maue, A.; Haunreiter, A. Increasing Ramp-up Performance By Implementing the Gamification Approach. Procedia CIRP 2014, 20, 74–80. [Google Scholar] [CrossRef] [Green Version]

- Vernon, R. International Investment and International Trade in the Product Cycle. Q. J. Econ. 1966, 80, 190. [Google Scholar] [CrossRef]

- King, K.J. Kenya’s informal machine-makers: A study of small-scale industry in Kenya’s emergent artisan society. World Dev. 1974, 2, 9–28. [Google Scholar] [CrossRef]

- Bair, J.; Gereffi, G. Local Clusters in Global Chains: The Causes and Consequences of Export Dynamism in Torreon’s Blue Jeans Industry. World Dev. 2001, 29, 1885–1903. [Google Scholar] [CrossRef]

- Gereffi, G.; Fernandez-Stark, K. Global Value Chain Analysis: A Primer, 2nd ed.; Duke University, Global Value Chains (GVC) Center: Durham, NC, USA, 2016. [Google Scholar]

- Kogut, B.; Zander, U. Knowledge of the Firm and the Evolutionary Theory of the Multinational Corporation. J. Int. Bus. Stud. 1993, 24, 625–645. [Google Scholar] [CrossRef] [Green Version]

- Jackson, G.A. Winning in Emerging Markets: A Roadmap for Strategy and Execution, by Tarun Khanna and Krishna G. Palepu. J. Bus. Bus. Mark. 2012, 19, 174–180. [Google Scholar] [CrossRef]

- Gold, S.; Hahn, R.; Seuring, S. Sustainable supply chain management in “Base of the Pyramid” food projects—A path to triple bottom line approaches for multinationals? Int. Bus. Rev. 2013, 22, 784–799. [Google Scholar] [CrossRef]

- Lema, R.; Quadros, R.; Schmitz, H. Reorganising global value chains and building innovation capabilities in Brazil and India. Res. Policy 2015, 44, 1376–1386. [Google Scholar] [CrossRef] [Green Version]

- Humphrey, J.; Schmitz, H. The Triple C approach to local industrial policy. World Dev. 1996, 24, 1859–1877. [Google Scholar] [CrossRef]

- Brönner, M.; Wolff, S.; Jovanovic, J.; Keuthen, K.; Lienkamp, M. Production Strategy Development: Simulation of Dependencies Using Recurrent Fuzzy Systems. Systems 2020, 8, 1. [Google Scholar] [CrossRef] [Green Version]

- Yin, R.K. Case Study Research: Design and Methods, 2nd ed.; Applied Social Research Methods Series; Sage Publ: Thousand Oaks, CA, USA, 2001; Volume 5. [Google Scholar]

- Flyvbjerg, B. Five Misunderstandings About Case-Study Research. Qual. Inq. 2006, 12, 219–245. [Google Scholar] [CrossRef] [Green Version]

- Ehie, I.; Muogboh, O. Analysis of manufacturing strategy in developing countries: A sample survey of Nigerian manufacturers. J. Manuf. Technol. Manag. 2016, 27, 234–260. [Google Scholar] [CrossRef]

- Brönner, M.; Baumgartner, V.; Lienkamp, M. Requirements Engineering for Production Transfer to Developing Countries. In Advances in Manufacturing II; Hamrol, A., Grabowska, M., Maletic, D., Woll, R., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2019; Volume 3, pp. 1–15. [Google Scholar] [CrossRef]

- PWC. Africa’s Next Automotive Hub; PWC: Lagos, Nigeria, 2014. [Google Scholar]

- Mair, J.; Martí, I.; Ventresca, M.J. Building Inclusive Markets in Rural Bangladesh: How Intermediaries Work Institutional Voids. Acad. Manag. J. 2012, 55, 819–850. [Google Scholar] [CrossRef] [Green Version]

- Avittathur, B.; Swamidass, P. Matching plant flexibility and supplier flexibility: Lessons from small suppliers of U.S. manufacturing plants in India. J. Oper. Manag. 2007, 25, 717–735. [Google Scholar] [CrossRef]

- Lall, S.; Mohammad, S. Technological effort and disembodied technology exports: An econometric analysis of inter-industry variations in India. World Dev. 1983, 11, 527–535. [Google Scholar] [CrossRef]

- Forbes, N.; Wield, D. Managing R&D in technology-followers. Res. Policy 2000, 29, 1095–1109. [Google Scholar] [CrossRef] [Green Version]

- Jordaan, J.A. FDI, Local Sourcing, and Supportive Linkages with Domestic Suppliers: The Case of Monterrey, Mexico. World Dev. 2011, 39, 620–632. [Google Scholar] [CrossRef]

- Cramer, C. Can Africa Industrialize by Processing Primary Commodities? The Case of Mozambican Cashew Nuts. World Dev. 1999, 27, 1247–1266. [Google Scholar] [CrossRef]

- Kumar, N. Intellectual property protection, market orientation and location of overseas R&D activities by multinational enterprises. World Dev. 1996, 24, 673–688. [Google Scholar] [CrossRef]

- Perez, C. Microelectronics, long waves and world structural change: New perspectives for developing countries. World Dev. 1985, 13, 441–463. [Google Scholar] [CrossRef]

- Guan, J.C.; Mok, C.K.; Yam, R.C.; Chin, K.S.; Pun, K.F. Technology transfer and innovation performance: Evidence from Chinese firms. Technol. Forecast. Soc. Chang. 2006, 73, 666–678. [Google Scholar] [CrossRef]

| Region | India | China | Africa | Mexico | Brazil | Latin America | Turkey | Bangladesh |

| Findings | 14 | 11 | 8 | 4 | 4 | 4 | 3 | 3 |

| Region | South Africa | Malaysia | Kenya | South Korea | Nepal | Caribbean | Mozambique | |

| Findings | 3 | 2 | 1 | 1 | 1 | 1 | 1 |

| Challenges | Solution |

|---|---|

| Product challenges | |

| Reduction of complexity | Standardized frame and lenses |

| Reduction of components and resources | Only essential components |

| Standardization | Low internal product variety |

| Employee challenges | |

| Lack of qualified workers | Customized training concept, open source manual |

| Combat poverty | |

| Know-how protection | Controlled material supply |

| Technological challenges | |

| Low process complexity | Customization during assembly, portable equipment |

| Low investments | No automation |

| Quality standards | Templates for quality assurance |

| Sales and procurement challenges | |

| Standardized suppliers | Central purchasing to enable economies of scale |

| Quality assurance | Central quality assurance |

| Lack of Infrastructure | On-site assembly and direct sales |

| Challenges | Solution |

|---|---|

| Product challenges | |

| Reduction of complexity | Straight windshields, fiberglass bodywork |

| Reduction of components and resources | Continuous improvement |

| Lack of local requirements | Homologation in Europe |

| Standardization | Standard components like the drivetrain |

| Employee challenges | |

| Lack of qualified workers | Intensive inhouse training, manual work tasks |

| High fluctuation of qualified employees | Company culture, intensive inhouse training |

| Technological challenges | |

| Low process complexity | Concentration on assembly |

| Low investments | No automation |

| Manual work tasks | Components especially designed for manual assembly |

| Sales and procurement challenges | |

| Local suppliers | Building and maintaining a local supplier base |

| Collaborative relationship | Early integration of suppliers |

| Unreliability of suppliers | Supplier quality management |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brönner, M.; Salah, S.; Lienkamp, M. Production Challenges in Least Developed Countries. Challenges 2020, 11, 1. https://doi.org/10.3390/challe11010001

Brönner M, Salah S, Lienkamp M. Production Challenges in Least Developed Countries. Challenges. 2020; 11(1):1. https://doi.org/10.3390/challe11010001

Chicago/Turabian StyleBrönner, Matthias, Skander Salah, and Markus Lienkamp. 2020. "Production Challenges in Least Developed Countries" Challenges 11, no. 1: 1. https://doi.org/10.3390/challe11010001

APA StyleBrönner, M., Salah, S., & Lienkamp, M. (2020). Production Challenges in Least Developed Countries. Challenges, 11(1), 1. https://doi.org/10.3390/challe11010001