Improving Health and Wealth by Introduction of an Affordable Bacterial Starter Culture for Probiotic Yoghurt Production in Uganda

Abstract

:1. Introduction

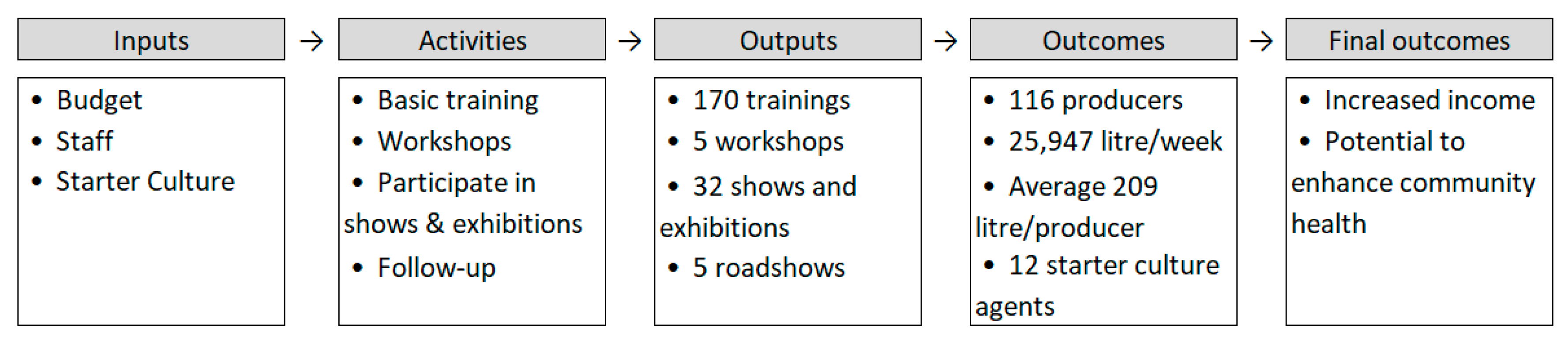

2. Results

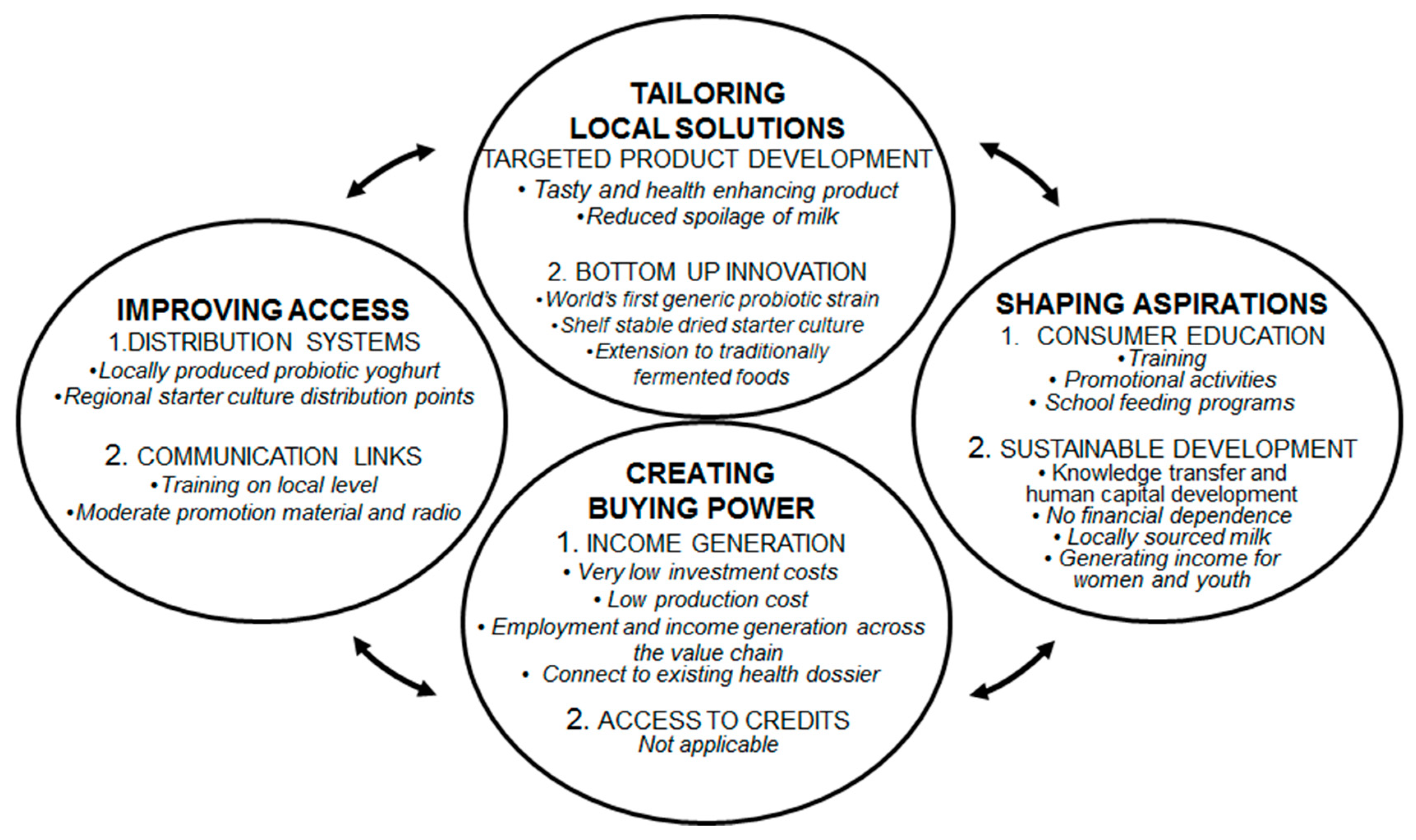

2.1. Start-Up and Development

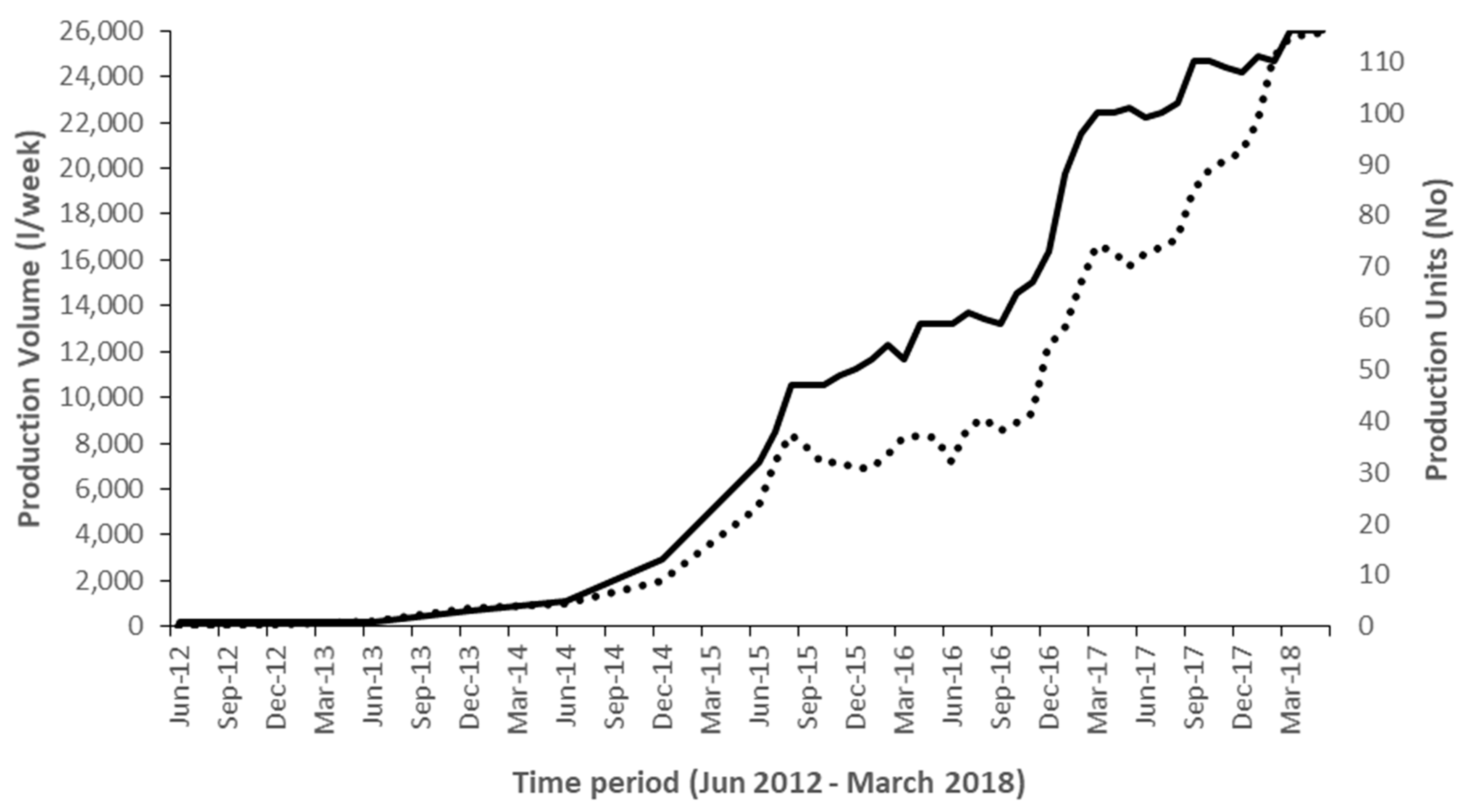

2.2. Production Volume as Performance Indicator

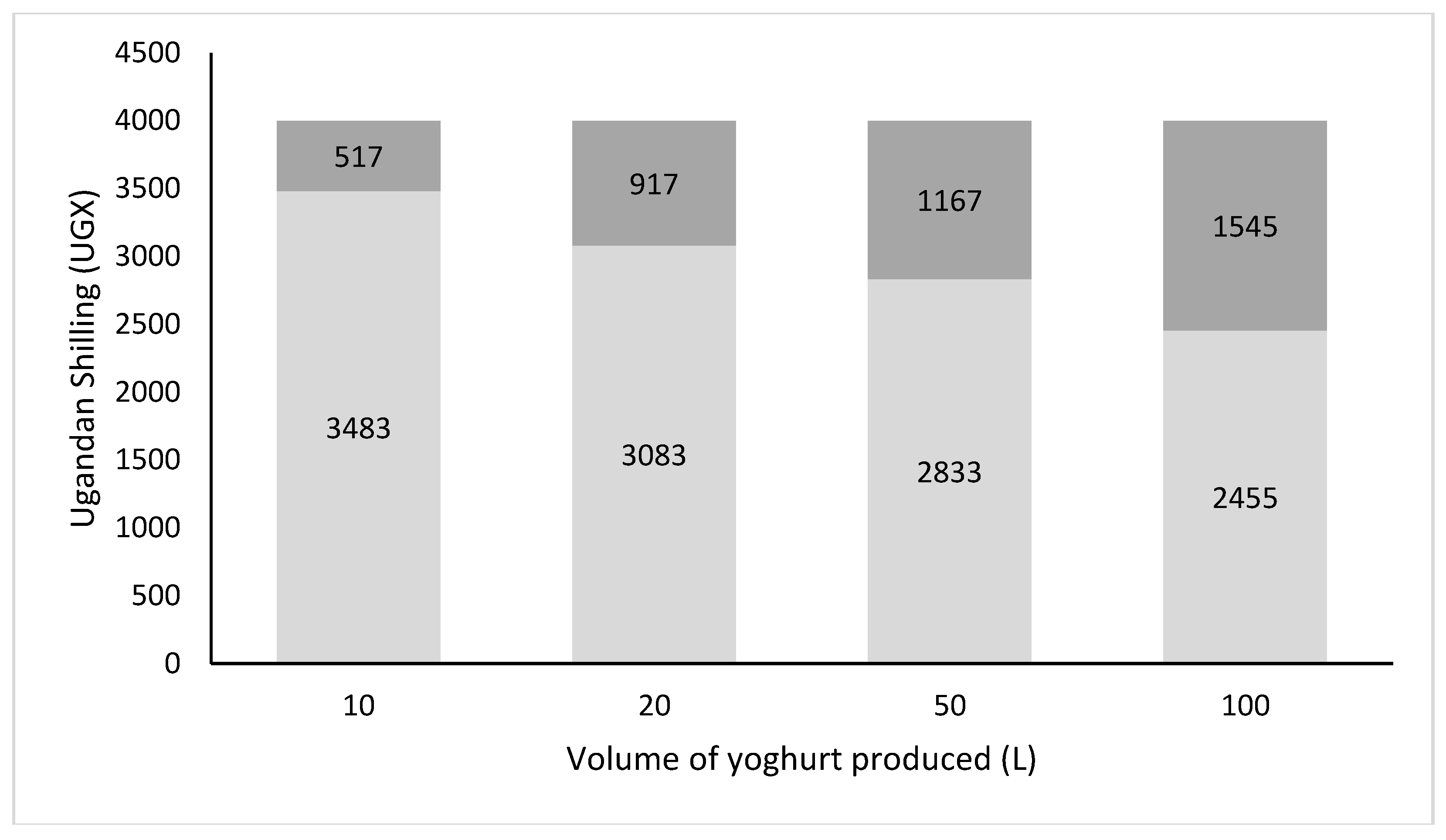

2.3. Sales and Income Generation

2.4. Reduction of Milk Losses

2.5. Potential Health Benefits

3. Discussion

3.1. Evaluation of Economic and Political Related Factors

3.2. Stimulating Demand

3.3. Regional Differences

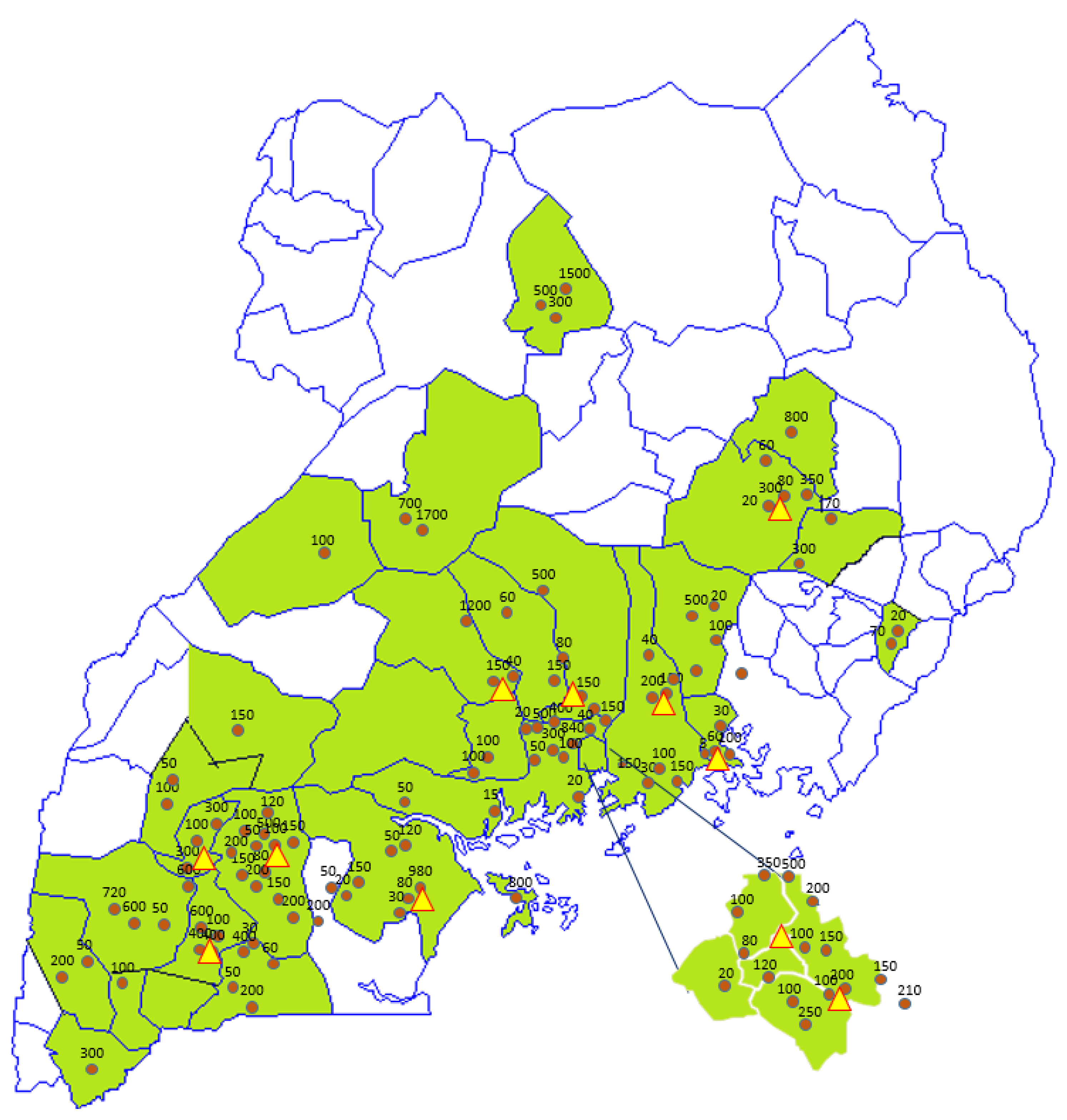

3.4. Health Benefits

3.5. Outlook

4. Methods

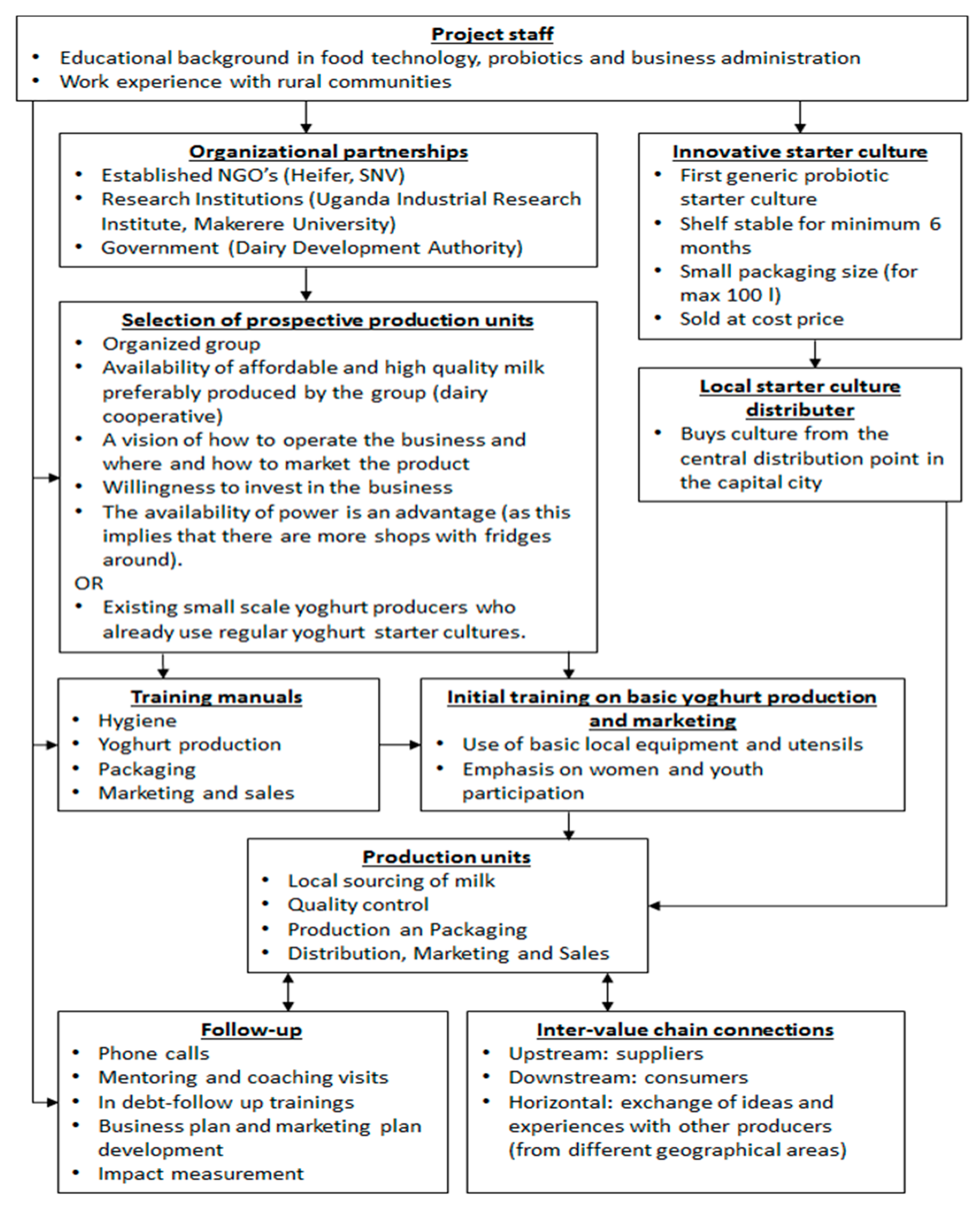

4.1. Intervention Set-Up

4.2. Production of Probiotic Yoghurt

4.3. Participating Dairy Companies and NGOs

4.4. Data Collection and Evaluation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bahiigwa, G.; Mdoe, N.; Ellis, F. Livelihoods research findings and agriculture-led growth. IDS Bull. 2005, 36, 115–120. [Google Scholar] [CrossRef]

- Lanjouw, J.O.; Lanjouw, P. The rural non-farm sector: Issues and evidence from developing countries. Agric. Econ. 2001, 26, 1–23. [Google Scholar] [CrossRef]

- Barrett, C.B.; Reardon, T.; Webb, P. Nonfarm income diversification and household livelihood strategies in rural Africa: Concepts, dynamics, and policy implications. Food Policy 2001, 26, 315–331. [Google Scholar] [CrossRef]

- Ajani, E.N.; Igbowke, E.M. Prospects of occupational diversification among rural women in sub-Saharan Africa: A review. J. Agric. Ext. Rural Dev. 2014, 6, 69–74. [Google Scholar]

- Uganda Bureau of Statistics (UBOS). Uganda National Household Survey 2012/13; UBOS: Kampala, Uganda, 2014.

- Livingstone, J.; Ruhindi, E. Economic Empowerment for pastoralist Women: A Comparative Look at Program Experience in Uganda, Somaliland and Sudan; Land Deals Politics Initiative: Sussex, UK, 2011. [Google Scholar]

- Balikowa, D. A Review of Uganda’s Dairy Industry, Dairy Development in Uganda; Dairy Development Authority: Kampala, Uganda, 2011.

- East Africa Dairy Development Project Uganda Dairy Market Study Report; Tig Marketing Consultant: Kampala, Uganda, 2015.

- McKenney, C. Growth Projections | The Atlas of Economic Complexity. Available online: http://atlas.cid.harvard.edu/rankings/growth-predictions/ (accessed on 2 September 2017).

- World Bank GDP per Capita (Current US$) | Data. Available online: https://data-worldbank-org.vu-nl.idm.oclc.org/indicator/NY.GDP.PCAP.CD (accessed on 9 September 2017).

- Lagarde, C.; Kampala, I.M.D. Becoming the Champion: Uganda’s Development Challenge. Available online: https://www-imf-org.vu-nl.idm.oclc.org/en/News/Articles/2017/01/27/ sp01272016-Becoming-the-Champion-Ugandas-Development-Challenge (accessed on 9 September 2017).

- UN FAO Uganda at a Glance | FAO in Uganda. Available online: http://www.fao.org/uganda/fao-in-uganda/uganda-at-a-glance/en/ (accessed on 7 August 2018).

- World Bank Uganda | Data. Available online: https://data.worldbank.org/country/uganda (accessed on 7 August 2018).

- Uganda Bureau of Statistics (UBOS); ICF. Key Indicators Report; UBOS; ICF: Kampala, Uganda; Rockville, MD, USA, 2017.

- World Health Organization GHO | By Category | Rate of Deaths by Country—Uganda. Available online: http://apps.who.int/gho/data/view.main.ghe2002015-UGA?lang=en (accessed on 17 April 2018).

- Westerik, N.; Kort, R.; Sybesma, W.; Reid, G. Lactobacillus rhamnosus probiotic food as a tool for empowerment across the value chain in Africa. Front. Microbiol. 2018, 9, 1501. [Google Scholar] [CrossRef]

- Franz, C.M.A.P.; Huch, M.; Mathara, J.M.; Abriouel, H.; Benomar, N.; Reid, G.; Galvez, A.; Holzapfel, W.H. African fermented foods and probiotics. Int. J. Food Microbiol. 2014, 190, 84–96. [Google Scholar] [CrossRef]

- Prahalad, C.K.; Hart, S.L. Strategies for the Bottom of the Pyramid: Creating Sustainable Development. Available online: http://pdf.wri.org/2001summit_hartarticle.pdf (accessed on 7 December 2018).

- Van Klinken, R. Uganda Poised to Become the Largest Dairy Exporter in Africa. Available online: http://www.busiweek.com/uganda-largest-dairy-exporter/ (accessed on 16 August 2018).

- Uganda Bureau of Statistics (UBOS). Uganda National Household Survey 2016/17; UBOS: Kampala, Uganda, 2018.

- Deininger, K.; Okidi, J. Rural households: Incomes, productivity, and nonfarm enterprises. In Uganda’s Recovery: The Role of Farms, Firms, and Government; The World Bank: Washington, DC, USA, 2001; pp. 123–175. [Google Scholar]

- FAO/WHO Working Group. Guidelines for the Evaluation of Probiotics in Food; FAO; WHO: London, UK, 2002. [Google Scholar]

- Okeke, I.N.; Aboderin, O.A.; Byarugaba, D.K.; Ojo, K.K.; Opintan, J.A. Growing problem of multidrug-resistant enteric pathogens in Africa. Emerg. Infect. Dis. 2007, 13, 1640–1646. [Google Scholar] [CrossRef]

- Fujita, K.; Kaku, M.; Yanagase, Y.; Ezaki, T.; Furuse, K.; Ozawa, A.; Saidi, S.M.; Sang, W.K.; Waiyaki, P.G. Physicochemical characteristics and flora of diarrhoeal and recovery faeces in children with acute gastroenteritis in Kenya. Ann. Trop. Paediatr. 1990, 10, 339–345. [Google Scholar] [CrossRef]

- Mshana, S.E.; Joloba, M.; Kakooza, A.; Kaddu-Mulindwa, D. Campylobacter spp among Children with acute diarrhea attending Mulago hospital in Kampala—Uganda. Afr. Health Sci. 2009, 9, 201–205. [Google Scholar]

- Burkholder, K.M.; Bhunia, A.K. Salmonella enterica serovar Typhimurium adhesion and cytotoxicity during epithelial cell stress is reduced by Lactobacillus rhamnosus GG. Gut Pathog. 2009, 1, 14. [Google Scholar] [CrossRef]

- Castillo, N.A.; de Moreno de LeBlanc, A.; Galdeano, C.M.; Perdigón, G. Probiotics: An alternative strategy for combating salmonellosis: Immune mechanisms involved. Food Res. Int. 2012, 45, 831–841. [Google Scholar] [CrossRef]

- Marianelli, C.; Cifani, N.; Pasquali, P. Evaluation of antimicrobial activity of probiotic bacteria against Salmonella enterica subsp. enterica serovar typhimurium 1344 in a common medium under different environmental conditions. Res. Microbiol. 2010, 161, 673–680. [Google Scholar] [CrossRef]

- Nomoto, K. Prevention of infections by probiotics. J. Biosci. Bioeng. 2005, 100, 583–592. [Google Scholar] [CrossRef]

- Xu, H.; Jeong, H.S.; Lee, H.Y.; Ahn, J. Assessment of cell surface properties and adhesion potential of selected probiotic strains. Lett. Appl. Microbiol. 2009, 49, 434–442. [Google Scholar] [CrossRef] [Green Version]

- Keersmaecker, S.C.J.D.; Verhoeven, T.L.A.; Desair, J.; Marchal, K.; Vanderleyden, J.; Nagy, I. Strong antimicrobial activity of Lactobacillus rhamnosus GG against Salmonella typhimurium is due to accumulation of lactic acid. FEMS Microbiol. Lett. 2006, 259, 89–96. [Google Scholar] [CrossRef]

- Hütt, P.; Shchepetova, J.; Lõivukene, K.; Kullisaar, T.; Mikelsaar, M. Antagonistic activity of probiotic lactobacilli and bifidobacteria against entero- and uropathogens. J. Appl. Microbiol. 2006, 100, 1324–1332. [Google Scholar] [CrossRef] [Green Version]

- Rinkinen, M.; Jalava, K.; Westermarck, E.; Salminen, S.; Ouwehand, A.C. Interaction between probiotic lactic acid bacteria and canine enteric pathogens: A risk factor for intestinal Enterococcus faecium colonization? Vet. Microbiol. 2003, 92, 111–119. [Google Scholar] [CrossRef]

- Kosek, M.; Bern, C.; Guerrant, R.L. The global burden of diarrhoeal disease, as estimated from studies published between 1992 and 2000. Bull. World Health Organ. 2003, 81, 197–204. [Google Scholar]

- Parashar, U.D.; Burton, A.; Lanata, C.; Boschi-Pinto, C.; Shibuya, K.; Steele, D.; Birmingham, M.; Glass, R.I. Global mortality associated with rotavirus disease among children in 2004. J. Infect. Dis. 2009, 200, S9–S15. [Google Scholar] [CrossRef]

- Szajewska, H.; Skórka, A.; Ruszczyński, M.; Gieruszczak-Białek, D. Meta-analysis: Lactobacillus GG for treating acute diarrhoea in children. Aliment. Pharmacol. Ther. 2007, 25, 871–881. [Google Scholar] [CrossRef]

- Guandalini, S. Probiotics for prevention and treatment of diarrhea. J. Clin. Gastroenterol. 2011, 45, S149–S153. [Google Scholar] [CrossRef]

- Guarino, A.; Guandalini, S.; Vecchio, A.L. Probiotics for prevention and treatment of diarrhea. J. Clin. Gastroenterol. 2015, 49, S37–S45. [Google Scholar] [CrossRef]

- Allen, S.J.; Martinez, E.G.; Gregorio, G.V.; Dans, L.F. Probiotics for treating acute infectious diarrhoea. Cochrane Database Syst. Rev. 2010, 11, CD003048. [Google Scholar] [CrossRef]

- De Roos, N.M.; Katan, M.B. Effects of probiotic bacteria on diarrhea, lipid metabolism, and carcinogenesis: A review of papers published between 1988 and 1998. Am. J. Clin. Nutr. 2000, 71, 405–411. [Google Scholar] [CrossRef]

- Larcombe, S.; Hutton, M.L.; Lyras, D. Involvement of bacteria other than Clostridium difficile in antibiotic-associated diarrhoea. Trends Microbiol. 2016, 24, 463–476. [Google Scholar] [CrossRef]

- Okeke, I.N.; Lamikanra, A.; Edelman, R. Socioeconomic and behavioral factors leading to acquired bacterial resistance to antibiotics in developing countries. Emerg. Infect. Dis. 1999, 5, 18–27. [Google Scholar] [CrossRef]

- Hawrelak, J.A.; Whitten, D.L.; Myers, S.P. Is Lactobacillus rhamnosus GG effective in preventing the onset of antibiotic-associated diarrhoea: A systematic review. Digestion 2005, 72, 51–56. [Google Scholar] [CrossRef]

- Kate, V.; Ananthakrishnan, N.; Tovey, F.I. Is Helicobacter pylori infection the primary cause of duodenal ulceration or a secondary factor? A Review of the Evidence. Gastroenterol. Res. Pract. 2013, 2013, e425840. [Google Scholar] [CrossRef]

- Tovey, F.I. Staple diets and duodenal ulcer prevalence. Int. Health 2009, 1, 124–132. [Google Scholar] [CrossRef]

- Newton, R.; Ziegler, J.L.; Casabonne, D.; Carpenter, L.; Gold, B.D.; Owens, M.; Beral, V.; Mbidde, E.; Parkin, D.M.; Wabinga, H.; et al. Helicobacter pylori and cancer among adults in Uganda. Infect. Agents Cancer 2006, 1, 5. [Google Scholar] [CrossRef]

- Westerik, N.; Reid, G.; Sybesma, W.; Kort, R. The probiotic Lactobacillus rhamnosus for alleviation of Helicobacter pylori-associated gastric pathology in East Africa. Front. Microbiol. 2018, 9, 1873. [Google Scholar] [CrossRef]

- Myllyluoma, E.; Kajander, K.; Mikkola, H.; Kyrönpalo, S.; Rasmussen, M.; Kankuri, E.; Sipponen, P.; Vapaatalo, H.; Korpela, R. Probiotic intervention decreases serum gastrin-17 in Helicobacter pylori infection. Dig. Liver Dis. 2007, 39, 516–523. [Google Scholar] [CrossRef]

- Hamilton-Miller, J.M.T. The role of probiotics in the treatment and prevention of Helicobacter pylori infection. Int. J. Antimicrob. Agents 2003, 22, 360–366. [Google Scholar] [CrossRef]

- Gotteland, M.; Cruchet, S.; Verbeke, S. Effect of Lactobacillus ingestion on the gastrointestinal mucosal barrier alterations induced by indometacin in humans. Aliment. Pharmacol. Ther. 2001, 15, 11–17. [Google Scholar] [CrossRef] [Green Version]

- Lam, E.K.Y.; Tai, E.K.K.; Koo, M.W.L.; Wong, H.P.S.; Wu, W.K.K.; Yu, L.; So, W.H.L.; Woo, P.C.Y.; Cho, C.H. Enhancement of gastric mucosal integrity by Lactobacillus rhamnosus GG. Life Sci. 2007, 80, 2128–2136. [Google Scholar] [CrossRef]

- Lam, E.K.Y.; Yu, L.; Wong, H.P.S.; Wu, W.K.K.; Shin, V.Y.; Tai, E.K.K.; So, W.H.L.; Woo, P.C.Y.; Cho, C.H. Probiotic Lactobacillus rhamnosus GG enhances gastric ulcer healing in rats. Eur. J. Pharmacol. 2007, 565, 171–179. [Google Scholar] [CrossRef]

- Kaaya, N.A.; Warren, H.L. A review of past and present research on aflatoxin in Uganda. Afr. J. Food Agric. Nutr. Dev. 2005, 5, 1–18. [Google Scholar]

- Paul Wacoo, A.; Wendiro, D.; Nanyonga, S.; Hawumba, J.; Sybesma, W.; Kort, R. Feasibility of a novel on-site detection method for aflatoxin in maize flour from markets and selected households in Kampala, Uganda. Toxins 2018, 10, 327. [Google Scholar] [CrossRef]

- Haskard, C.; Binnion, C.; Ahokas, J. Factors affecting the sequestration of aflatoxin by Lactobacillus rhamnosus strain GG. Chem. Biol. Interact. 2000, 128, 39–49. [Google Scholar] [CrossRef]

- Gratz, S.W.; Mykkanen, H.; El-Nezami, H.S. Probiotics and gut health: A special focus on liver diseases. World J. Gastroenterol. 2010, 16, 403–410. [Google Scholar] [CrossRef]

- Ahlberg, S.H.; Joutsjoki, V.; Korhonen, H.J. Potential of lactic acid bacteria in aflatoxin risk mitigation. Int. J. Food Microbiol. 2015, 207, 87–102. [Google Scholar] [CrossRef]

- Hernandez-Mendoza, A.; Guzman-de-Peña, D.; Garcia, H.S. Key role of teichoic acids on aflatoxin B1 binding by probiotic bacteria. J. Appl. Microbiol. 2009, 107, 395–403. [Google Scholar] [CrossRef]

- Mbonye, A.K. Risk factors for diarrhoea and upper respiratory tract infections among children in a rural area of Uganda. J. Health Popul. Nutr. 2004, 22, 52–58. [Google Scholar]

- O’Brien, K.L.; Wolfson, L.J.; Watt, J.P.; Henkle, E.; Deloria-Knoll, M.; McCall, N.; Lee, E.; Mulholland, K.; Levine, O.S.; Cherian, T. Burden of disease caused by Streptococcus pneumoniae in children younger than 5 years: Global estimates. Lancet 2009, 374, 893–902. [Google Scholar] [CrossRef]

- Kibuule, D.; Kagoya, H.R. Household management of acute respiratory infections in children under five years in Kampala Uganda. Afr. J. Pharm. Pharmacol. 2015, 9, 730–737. [Google Scholar] [CrossRef]

- Uganda Bureau of Statistics (UBOS). Uganda Demographic and Health Survey 2011; UBOS and ICF International: Kampala, Uganda, 2012.

- Kekkonen, R.A.; Vasankari, T.J.; Vuorimaa, T.; Haahtela, T.; Julkunen, I.; Korpela, R. The effect of probiotics on respiratory infections and gastrointestinal symptoms during training in marathon runners. Int. J. Sport Nutr. Exerc. Metab. 2007, 17, 352–363. [Google Scholar] [CrossRef]

- Hojsak, I.; Abdović, S.; Szajewska, H.; Milošević, M.; Krznarić, Ž.; Kolaček, S. Lactobacillus GG in the prevention of nosocomial gastrointestinal and respiratory tract infections. Pediatrics 2010, 125, e1171–e1177. [Google Scholar] [CrossRef]

- Hojsak, I.; Snovak, N.; Abdović, S.; Szajewska, H.; Mišak, Z.; Kolaček, S. Lactobacillus GG in the prevention of gastrointestinal and respiratory tract infections in children who attend day care centers: A randomized, double-blind, placebo-controlled trial. Clin. Nutr. 2010, 29, 312–316. [Google Scholar] [CrossRef]

- Kumpu, M.; Kekkonen, R.A.; Kautiainen, H.; Järvenpää, S.; Kristo, A.; Huovinen, P.; Pitkäranta, A.; Korpela, R.; Hatakka, K. Milk containing probiotic Lactobacillus rhamnosus GG and respiratory illness in children: A randomized, double-blind, placebo-controlled trial. Eur. J. Clin. Nutr. 2012, 66, 1020–1023. [Google Scholar] [CrossRef]

- Hatakka, K.; Savilahti, E.; Pönkä, A.; Meurman, J.H.; Poussa, T.; Näse, L.; Saxelin, M.; Korpela, R. Effect of long term consumption of probiotic milk on infections in children attending day care centres: Double blind, randomised trial. BMJ 2001, 322, 1327. [Google Scholar] [CrossRef]

- Popova, M.; Molimard, P.; Courau, S.; Crociani, J.; Dufour, C.; Vacon, F.; Carton, T. Beneficial effects of probiotics in upper respiratory tract infections and their mechanical actions to antagonize pathogens. J. Appl. Microbiol. 2012, 113, 1305–1318. [Google Scholar] [CrossRef]

- Vendt, N.; Grünberg, H.; Tuure, T.; Malminiemi, O.; Wuolijoki, E.; Tillmann, V.; Sepp, E.; Korpela, R. Growth during the first 6 months of life in infants using formula enriched with Lactobacillus rhamnosus GG: Double-blind, randomized trial. J. Hum. Nutr. Diet. 2006, 19, 51–58. [Google Scholar] [CrossRef]

- American Academy of Pediatrics. Probiotics Help Extremely Premature Infants Gain Weight. Available online: https://www.sciencedaily.com/releases/2010/05/100501013401.htm (accessed on 22 January 2017).

- Bortz, G.; Thomas, H. Biotechnologies for inclusive development: Scaling up, knowledge intensity and empowerment (the case of the probiotic yoghurt ‘Yogurito’ in Argentina). Innov. Dev. 2017, 7, 37–61. [Google Scholar] [CrossRef]

- Kort, R.; Sybesma, W. Probiotics for every body. Trends Biotechnol. 2012, 30, 613–615. [Google Scholar] [CrossRef]

- Kort, R.; Westerik, N.; Serrano, L.M.; Douillard, F.P.; Gottstein, W.; Mukisa, I.M.; Tuijn, C.J.; Basten, L.; Hafkamp, B.; Meijer, W.C.; et al. A novel consortium of Lactobacillus rhamnosus and Streptococcus thermophilus for increased access to functional fermented foods. Microb. Cell Factories 2015, 14, 195. [Google Scholar] [CrossRef]

- Westerik, N.; Wacoo, A.P.; Sybesma, W.; Kort, R. Novel production protocol for small-scale manufacture of probiotic fermented foods. JoVE J. Vis. Exp. 2016, e54365. [Google Scholar] [CrossRef]

- Reid, G.; Kort, R.; Alvarez, S.; Bourdet-Sicard, R.; Benoit, V.; Cunningham, M.; Saulnier, D.M.; van Hylckama Vlieg, J.E.T.; Verstraelen, H.; Sybesma, W. Expanding the reach of probiotics through social enterprises. Benef. Microbes 2018, 9, 707–715. [Google Scholar] [CrossRef]

- Liedholm, C.; McPherson, M.; Chuta, E. Small enterprise employment growth in rural Africa. Am. J. Agric. Econ. 1994, 76, 1177–1182. [Google Scholar] [CrossRef]

- Lenoir-Wijnkoop, I.; Nuijten, M.J.C.; Gutiérrez-Ibarluzea, I.; Hutton, J.; Poley, M.J.; Segal, L.; Bresson, J.L.; van Ganse, E.; Jones, P.; Moreno, L.; et al. Workshop Report: Concepts and methods in the economics of nutrition—Gateways to better economic evaluation of nutrition interventions. Br. J. Nutr. 2012, 108, 1714–1720. [Google Scholar] [CrossRef]

- Chilton, S.N.; Burton, J.P.; Reid, G. Inclusion of fermented foods in food guides around the world. Nutrients 2015, 7, 390–404. [Google Scholar] [CrossRef]

- Marco, M.L.; Heeney, D.; Binda, S.; Cifelli, C.J.; Cotter, P.D.; Foligne, B.; Gänzle, M.; Kort, R.; Pasin, G.; Pihlanto, A.; et al. Health benefits of fermented foods: Microbiota and beyond. Curr. Opin. Biotechnol. 2017, 44, 94–102. [Google Scholar] [CrossRef]

- Bandiera, O.; Burgess, R.; Gulesci, S.; Rasul, I.; Sulaiman, M. Can You Successfully Teach People How to Run Small Businesses? Available online: http://www.iig.ox.ac.uk/output/briefingpapers/pdfs/iig-briefingpaper-14-teaching-how-to-run-small-businesses.pdf (accessed on 2 January 2019).

- Hassan, R.; Birungi, P. Social capital and poverty in Uganda. Dev. S. Afr. 2011, 28, 19–37. [Google Scholar] [CrossRef] [Green Version]

- Butler, L.M.; Mazur, R.E. Principles and processes for enhancing sustainable rural livelihoods: Collaborative learning in Uganda. Int. J. Sustain. Dev. World Ecol. 2007, 14, 604–617. [Google Scholar] [CrossRef]

- Villena, J.; Salva, S.; Núñez, M.; Corzo, J.; Tolaba, R.; Faedda, J.; Font, G.; Alvarez, S. Probiotics for everyone! The novel immunobiotic Lactobacillus rhamnosus CRL1505 and the beginning of Social Probiotic Programs in Argentina. Int. J. Biotechnol. Wellness Ind. 2012, 1, 189–198. [Google Scholar]

- Di Stefano, E.; White, J.; Seney, S.; Hekmat, S.; McDowell, T.; Sumarah, M.; Reid, G. A novel millet-based probiotic fermented food for the developing world. Nutrients 2017, 9, 529. [Google Scholar] [CrossRef]

- Premand, P.; Rawlings, L.B.; Vermeersch, C. Impact Evaluation in Practice; The World Bank: Washington, DC, USA, 2010; pp. 1–266. [Google Scholar]

| Kampala | Central 1 a: Wakiso, Gomba, Mpigi, Bukomansimbi, Kalangala, Kalungu, Masaka, Lyantonde, Sembabule, | Central 2 a: Buikwe, Kayunga, Kiboga, Luwero, Mityana, Mubende, Mukono, Nakaseke, Nakasongola | Busoga a: Buyende, Iganga, Jinja, Kaliro, Kamuli, Luuka, Mayuge, | Teso a: Amuria, Bukedea, Ngora, Soroti, Serere | Ankole a: Bushenyi, Ibanda, Isingiro, Kiruhura, Mbarara, Ntungamo, Sheema | |

|---|---|---|---|---|---|---|

| Number of yoghurt production units | 15 | 23 | 20 | 8 | 8 | 28 |

| Average volume per producer (L/wk) | 171 | 233 | 179 | 115 | 275 | 253 |

| Average number of people per production unit | 3.4 | 9.8 | 3.9 | 2.6 | 5.9 | 6.5 |

| Gender distribution (%Female) | 33% | 75% | 51% | 38% | 34% | 66% |

| Age distribution (% <35 y) | 53% | 38% | 62% | 57% | 68% | 31% |

| Gender distribution in ownership (%Female) | 60% | 74% | 60% | 25% | 25% | 57% |

| Age distribution in ownership (% <35 y) | 13% | 22% | 30% | 0% | 38% | 25% |

| Average Production Volume | Cooperatives | Groups | Individuals | |

|---|---|---|---|---|

| Average production volume | 209 | 158 | 260 | 224 |

| Female-owned | 193 | 130 | 257 | 183 |

| Male-owned | 256 | 168 | 264 | 285 |

| Youth (<35 y)-owned | 270 | - | 377 | 232 |

| Adult (>35 y)-owned | 210 | 158 | 131 | 222 |

| Growing | Stable | Fluctuating | TOTAL | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Micro | 0–100 L/week | 3 | 3% | 18 | 16% | 15 | 14% | 36 | 32% |

| Small | 100–200 L/week | 13 | 12% | 14 | 13% | 5 | 5% | 32 | 29% |

| Medium | 200–500 L/week | 8 | 7% | 12 | 11% | 9 | 8% | 29 | 26% |

| Medium-Large | >500 L/week | 3 | 3% | 7 | 6% | 4 | 4% | 14 | 13% |

| TOTAL | 27 | 24% | 51 | 46% | 33 | 30% | 111 | 100% | |

| Stable | Fluctuating | Failed | |

|---|---|---|---|

| Being comfortable with their current volumes and market, not interested in looking for additional market | 61% | 33% | |

| Yoghurt production not being the main occupation or focus for the owner(s)/owner choosing to do something different | 24% | 45% | 13% |

| A specific problem, either in business or personal life (e.g., financial distress or sickness) negatively affected the business | 20% | 21% | 13% |

| The production unit is a group business and therefore there is little incentive for individual group members to progress, as they benefit less at personal level | 8% | 27% | |

| Constraints in milk supply | 6% | 36% | |

| Operating at very small scale (weekly production volumes below 50 L) for several months, before giving up, either due to the lack of motivation or effort, or due to an unfavorable business environment | 33% | ||

| Poor management of the business or governance issues in group or cooperative businesses | 25% | ||

| Business faced financial distress | 8% | ||

| Business owner choose to continue with regular non-probiotic yoghurt | 4% |

| Common Public Health Challenges in Sub-Saharan Africa | References | The Effect of L. rhamnosus GG on the Health Challenge | References |

|---|---|---|---|

| Numerous types of bacterial infections, e.g., Salmonella, E. coli, L. monocytogenes, Campylobacter jejuni, Shigella sonnei, and S. aureus have a high prevalence due to poor sanitation and challenging living environments. | [23,24,25] | Reduces infections by inhibiting adhesion of pathogens in intestine, accumulation of lactic acid, secretion of antimicrobial substances and modulation of the immune system | [26,27,28,29,30,31,32,33]. |

| 21% of the deaths of children < 5 years is caused by diarrhea, of which 29% is rotavirus-associated. | [34,35] | Stimulates gut health and reduces the incidence and severity of rotavirus-associated diarrhea. | [36,37,38,39,40] |

| Increasing (mis)use of antibiotics. Diarrhea is a reported side-effect of antibiotics use. | [23,41,42] | Alleviates the effect on antibiotics-induced diarrhea. | [29,43] |

| High incidence of ulcers in Uganda, which has been attributed to poor diet and high incidence of H. pylori colonialization of the stomach. | [44,45,46,47] | Arrests the development of ulcers and reduces the size and severity of existing ulcers via two mechanisms. Firstly, through the ability to reduce H. pylori colonialization. | [48,49]. |

| Secondly, through the ability to protect and restore stomach tissue (the mucosal layer). | [50,51,52] | ||

| Aflatoxins are found in alarmingly high levels in commonly consumed foods in Uganda, especially in ground nuts and maize. Aflatoxins are carcinogenic substances produced by molds in poorly stored food. | [53,54] | Binds Aflatoxin B1, thereby reducing its absorption in the intestine, and hence reducing aflatoxin associated pathogenicity. | [55,56,57,58] |

| Respiratory tract infections have an incidence of 18% among Ugandan children >5 years. Pneumonia due to S. pneumoniae infection occurs in 3% of all children >5 years in Africa. It is responsible for 23% of the deaths of children between 1–59 months in Uganda | [15,59,60,61,62] | Reduces different types of respiratory tract infections from different origins. Possibly through direct antimicrobial effects, improvement in mucosal barrier function and immune-modulating activity. | [63,64,65,66,67,68] |

| 29% of children >5 years in Uganda are stunted. | [14] | Improves feeding tolerance and nutrient absorption (increased proliferation of villus cells). | [69,70] |

| Body Part | Baseline | Midline | End Line |

|---|---|---|---|

| Face/head | 70 | 13 | 10 |

| Hand/arm | 14 | 6 | 2 |

| Leg | 1 | 0 | 0 |

| Neck | 16 | 3 | 3 |

| Coverage | |||

| Full | 23 | 13 | 2 |

| Half | 78 | 9 | 13 |

| Severity | |||

| Mild | 76 | 20 | 12 |

| Moderate | 20 | 1 | 3 |

| Severe | 5 | 1 | 0 |

| Total number of skin rashes | 101 | 22 | 15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Westerik, N.; Wacoo, A.P.; Anyimo, E.; Matovu, W.; Reid, G.; Kort, R.; Sybesma, W. Improving Health and Wealth by Introduction of an Affordable Bacterial Starter Culture for Probiotic Yoghurt Production in Uganda. Challenges 2019, 10, 2. https://doi.org/10.3390/challe10010002

Westerik N, Wacoo AP, Anyimo E, Matovu W, Reid G, Kort R, Sybesma W. Improving Health and Wealth by Introduction of an Affordable Bacterial Starter Culture for Probiotic Yoghurt Production in Uganda. Challenges. 2019; 10(1):2. https://doi.org/10.3390/challe10010002

Chicago/Turabian StyleWesterik, Nieke, Alex Paul Wacoo, Esther Anyimo, William Matovu, Gregor Reid, Remco Kort, and Wilbert Sybesma. 2019. "Improving Health and Wealth by Introduction of an Affordable Bacterial Starter Culture for Probiotic Yoghurt Production in Uganda" Challenges 10, no. 1: 2. https://doi.org/10.3390/challe10010002

APA StyleWesterik, N., Wacoo, A. P., Anyimo, E., Matovu, W., Reid, G., Kort, R., & Sybesma, W. (2019). Improving Health and Wealth by Introduction of an Affordable Bacterial Starter Culture for Probiotic Yoghurt Production in Uganda. Challenges, 10(1), 2. https://doi.org/10.3390/challe10010002