Heave Compensation Dynamics for Offshore Drilling Operation

Abstract

:1. Introduction

2. Related Works

2.1. Multibody Dynamics Kernels

2.2. Dynamic Response Analysis of a Heave Compensation System

3. Heave Compensation System Equipment

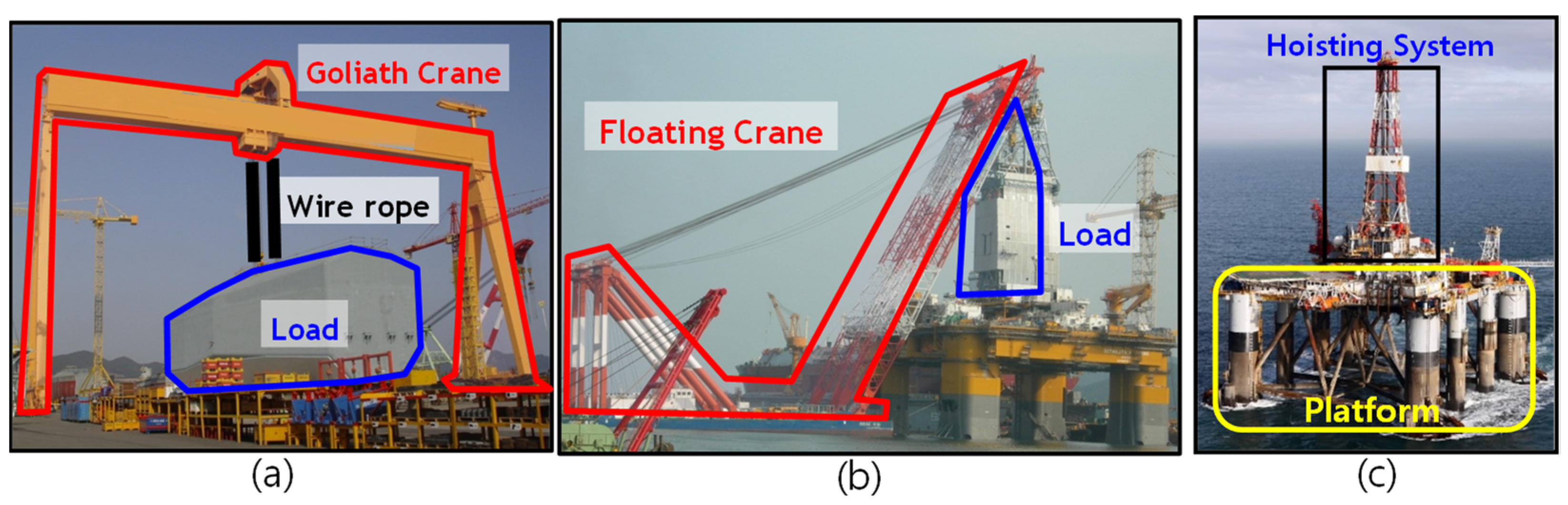

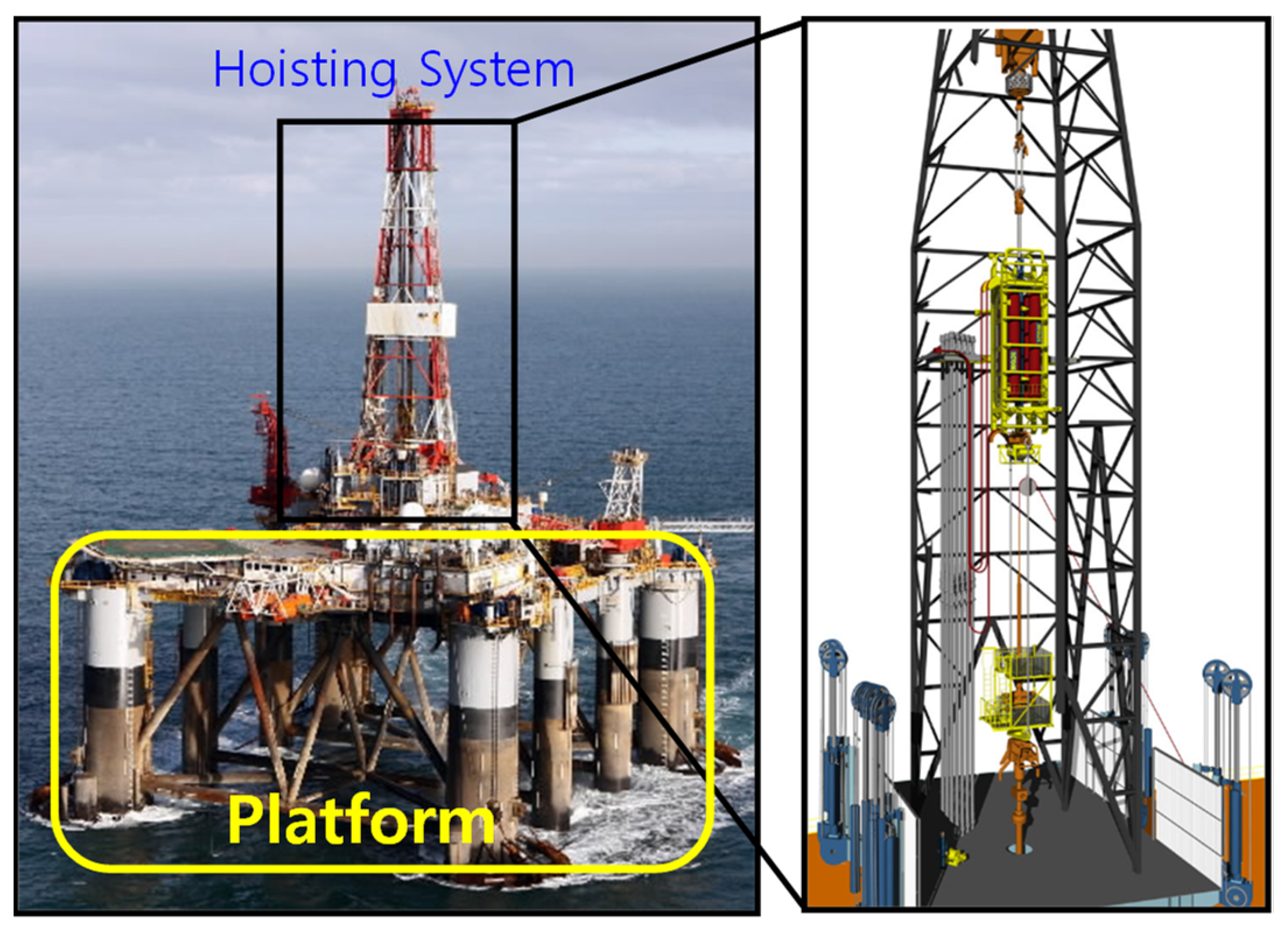

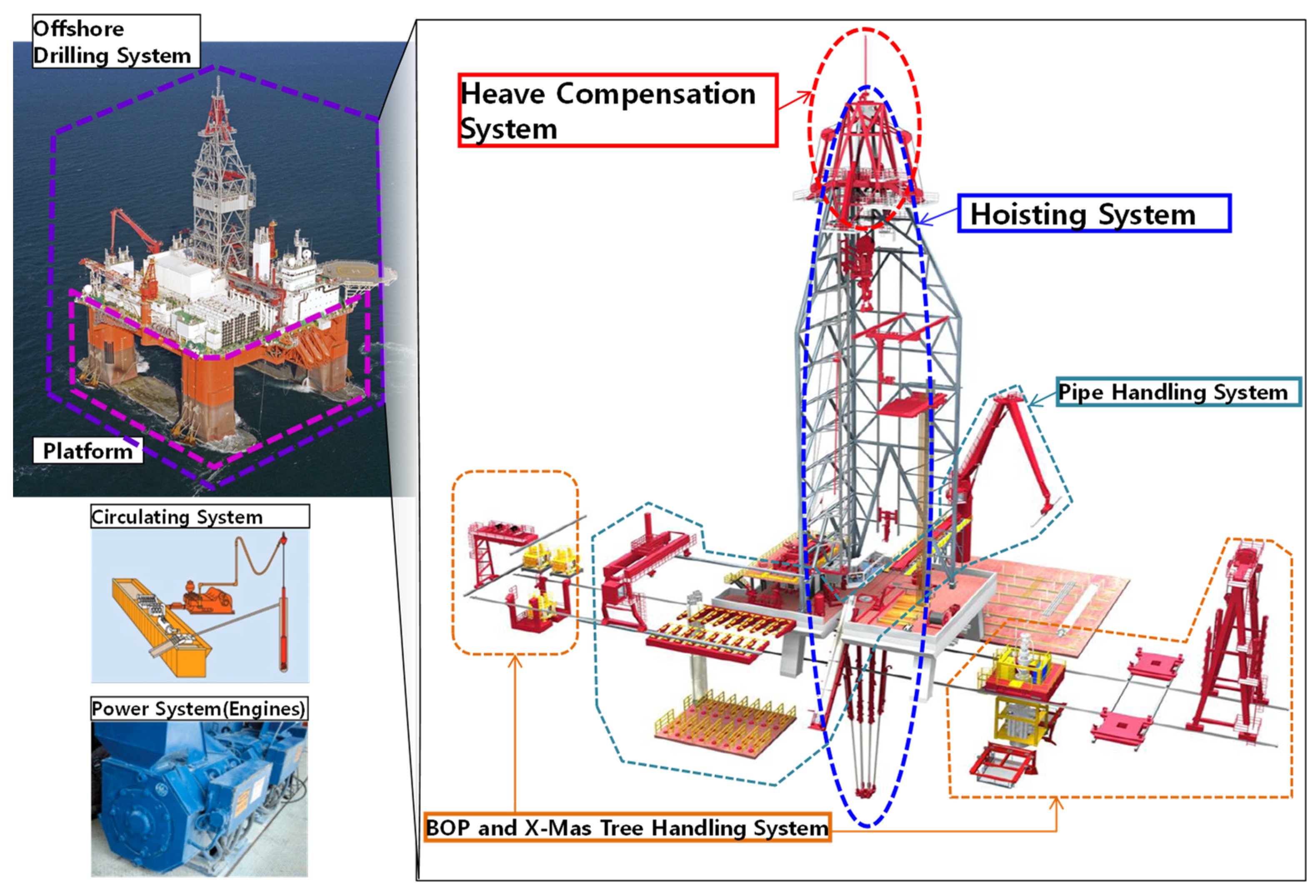

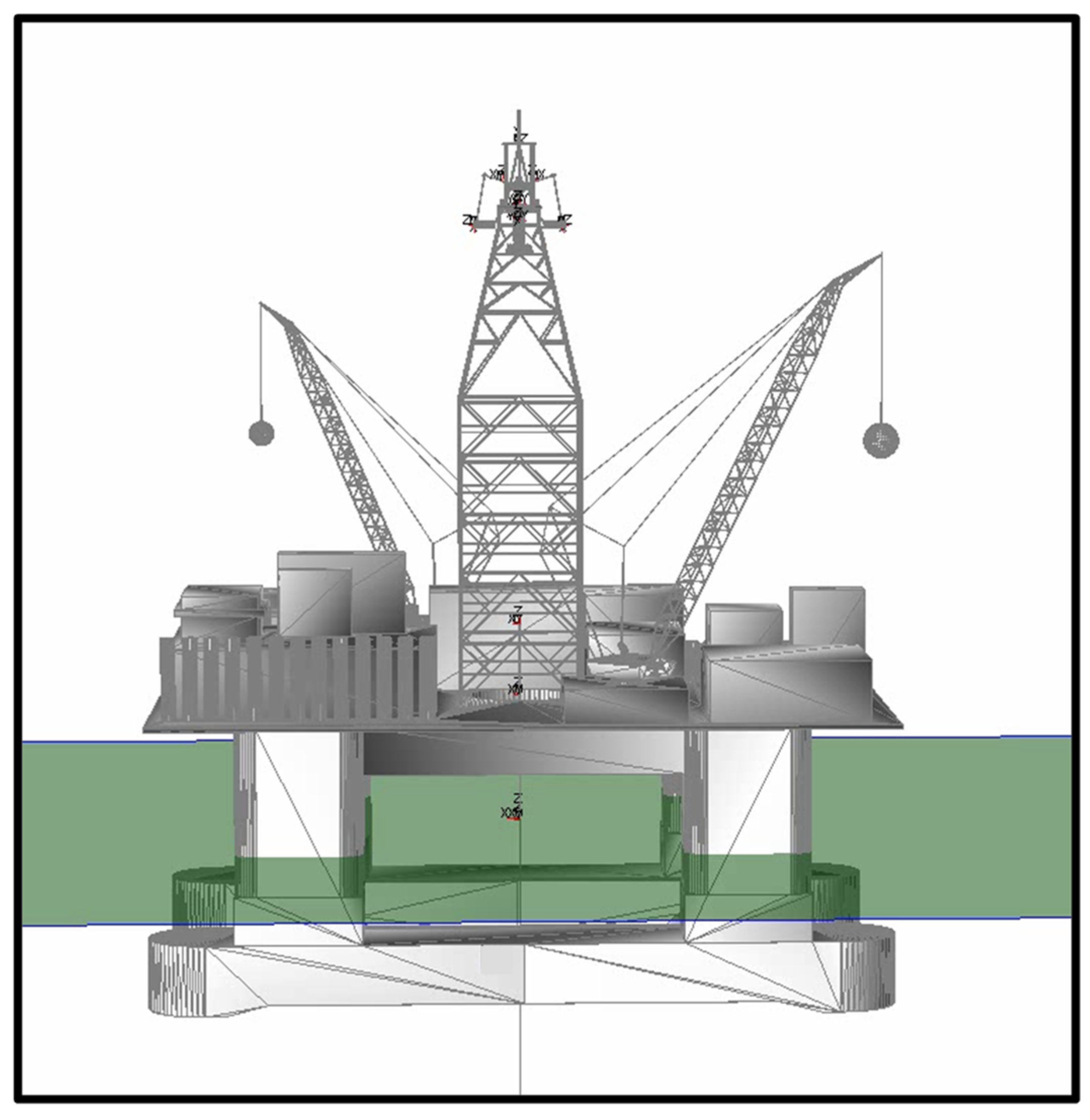

3.1. Configuration of an Offshore Drilling System

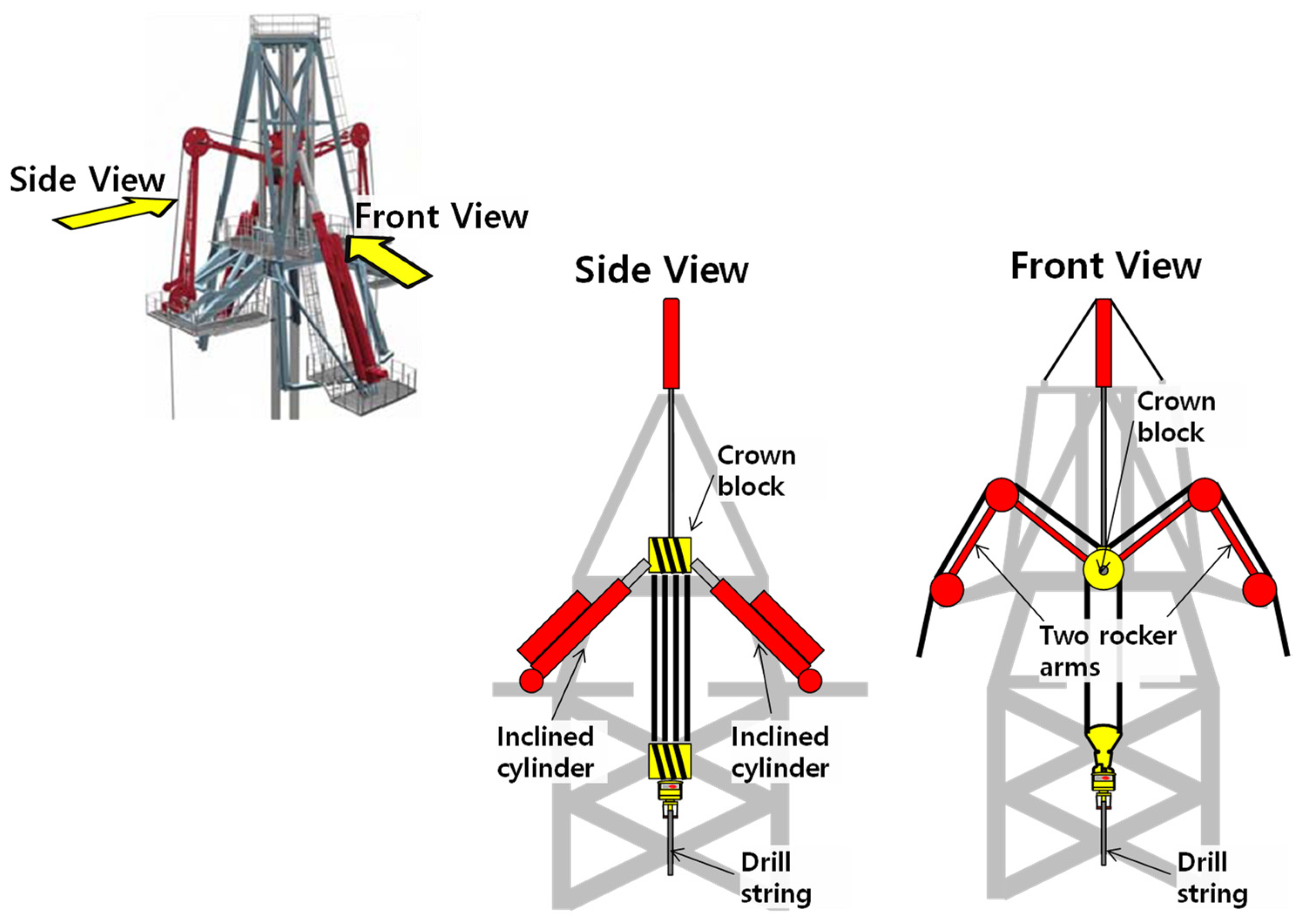

3.2. Components of a Heave Compensation System

4. Multibody Dynamics Based on Recursive Formulation

4.1. Forward and Inverse Dynamics

- -

- Forward dynamics: The calculation of the acceleration response of a given rigid-body system to a given applied force;

- -

- Inverse dynamics: The calculation of the force that must be applied to a given rigid-body system to produce a given acceleration response.

4.2. Verification of the Dynamics Kernel

5. Construction of Mathematical Model

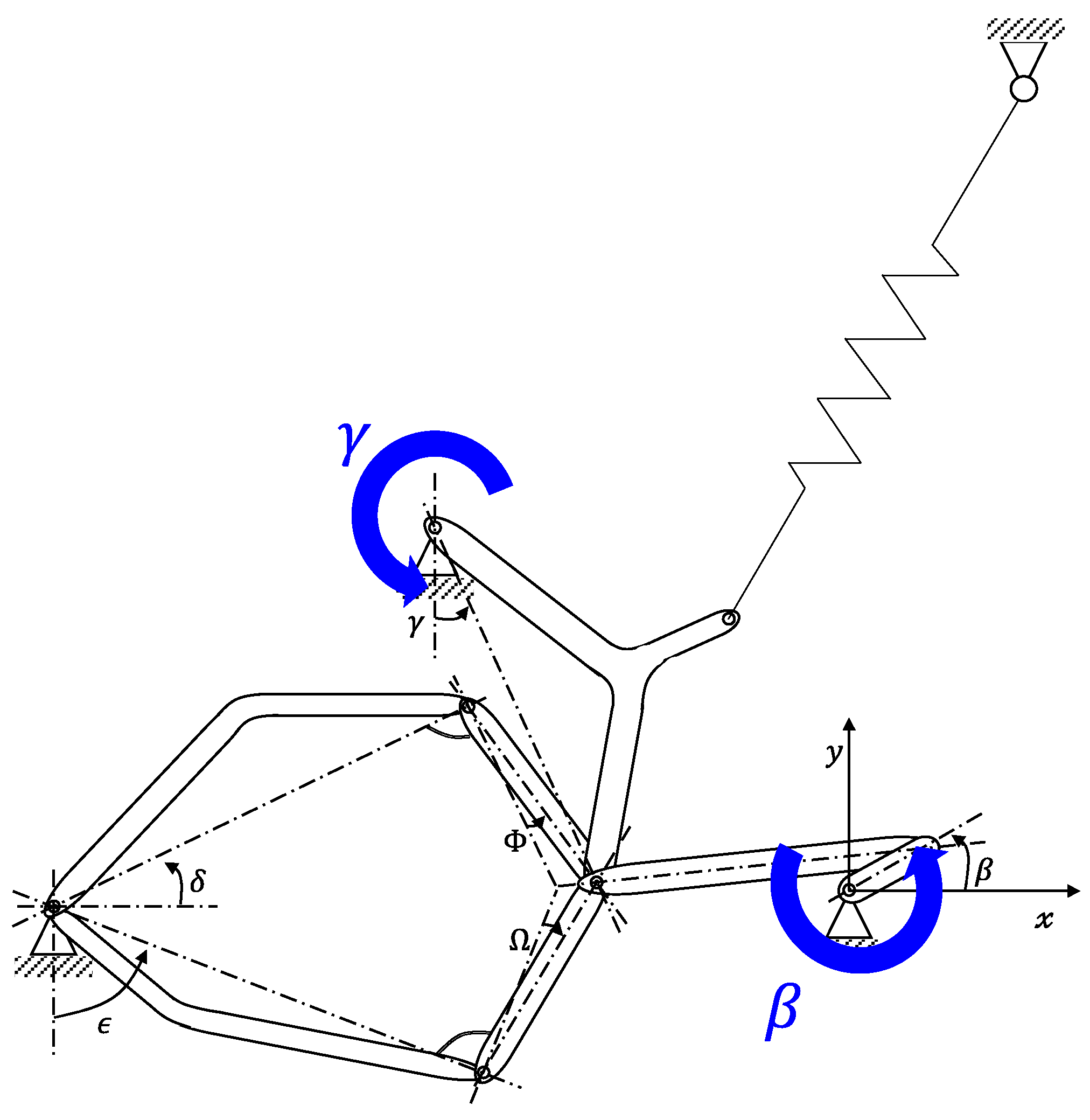

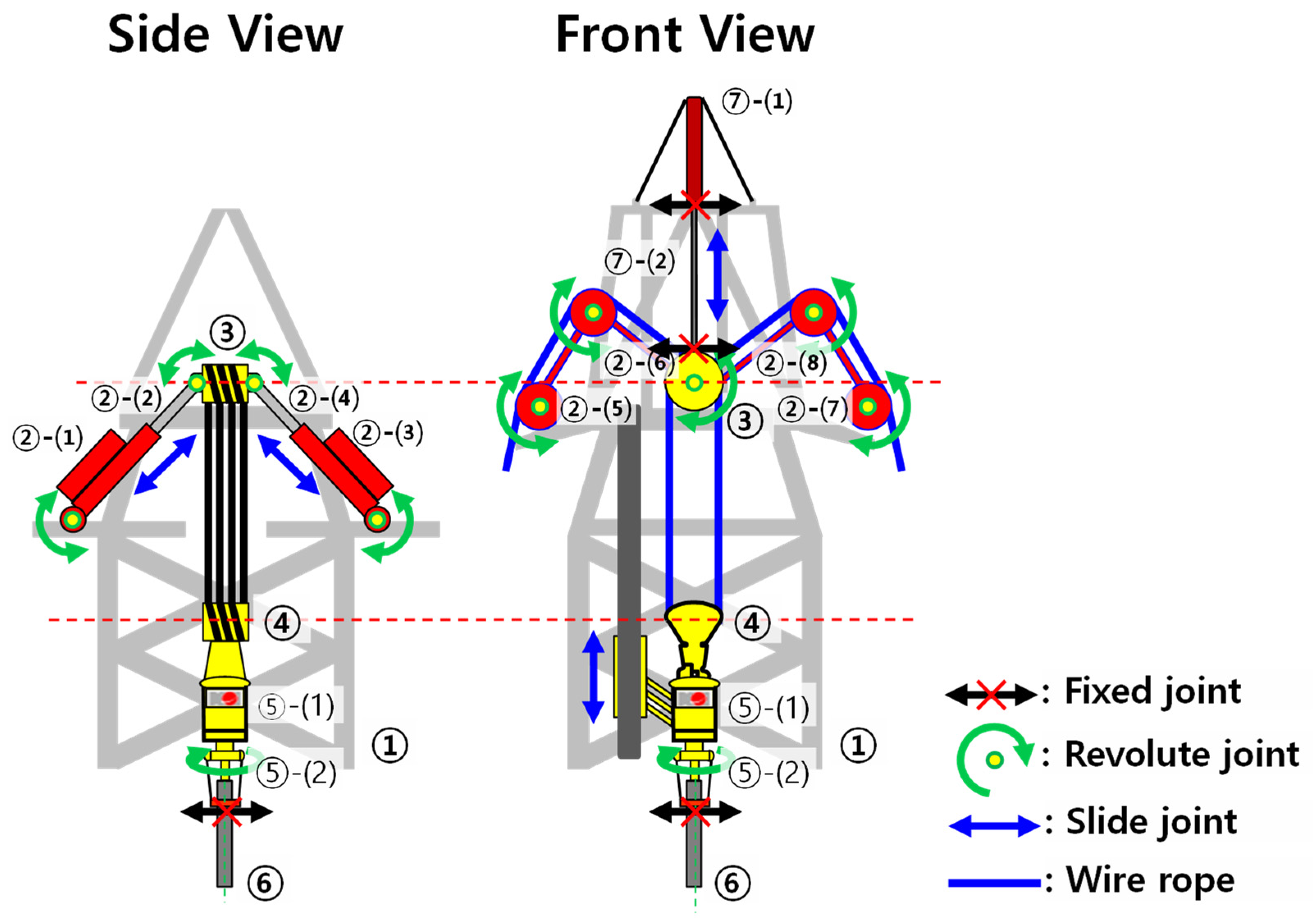

5.1. Mechanical Configuration of the Hoisting and Compensation System

- -

- Fixed joint: A joint that can fix one body to another; this joint has a zero degree of freedom;

- -

- Revolute joint: A joint that can rotate around one axis; this joint has one degree of freedom;

- -

- Slide joint: A joint that can translate along one axis; this joint has one degree of freedom.

5.2. Pneumatic and Hydraulic Control of the Heave Compensator

5.3. Construction of Equations of Motion for the Heave Compensation System

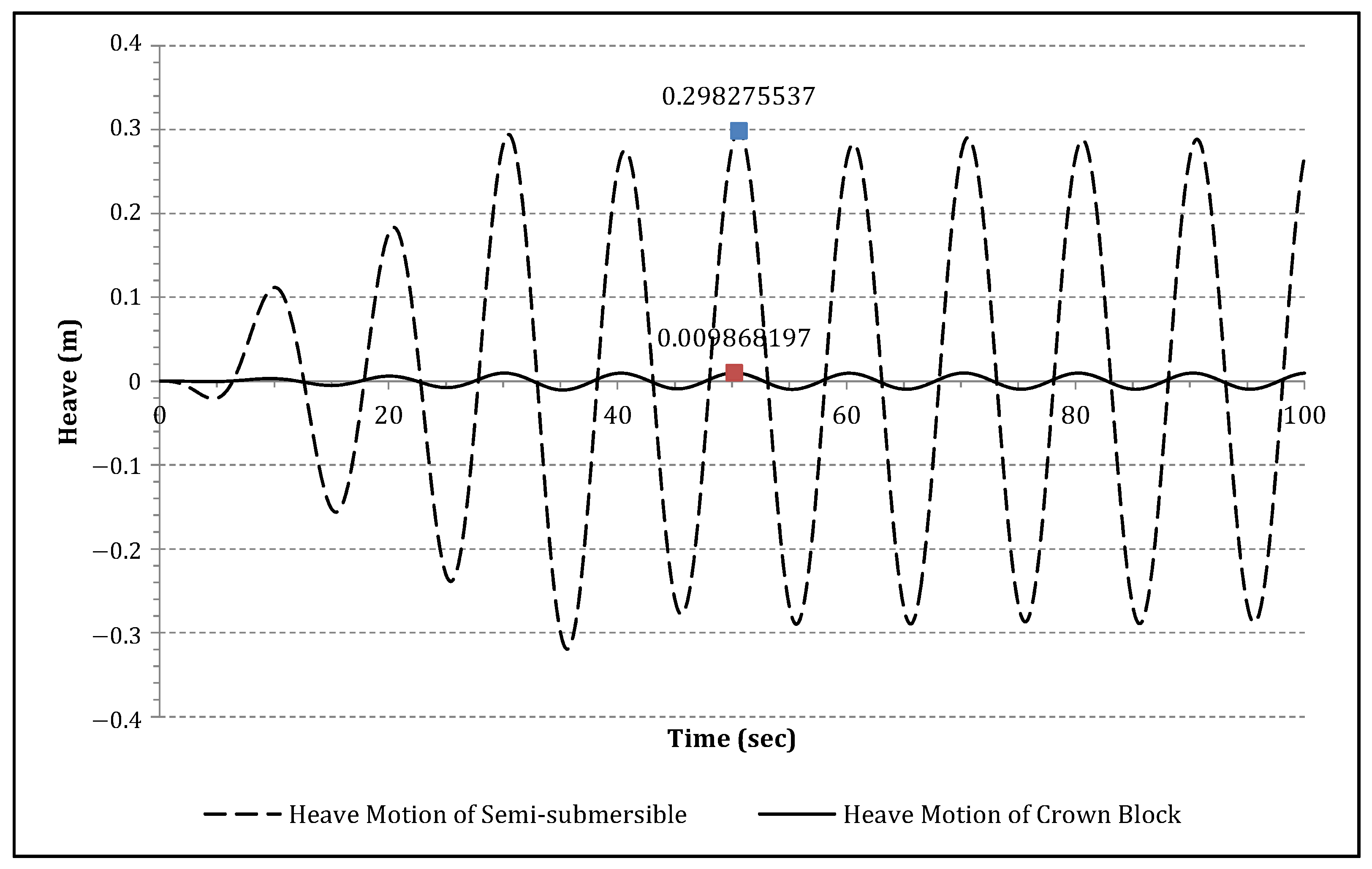

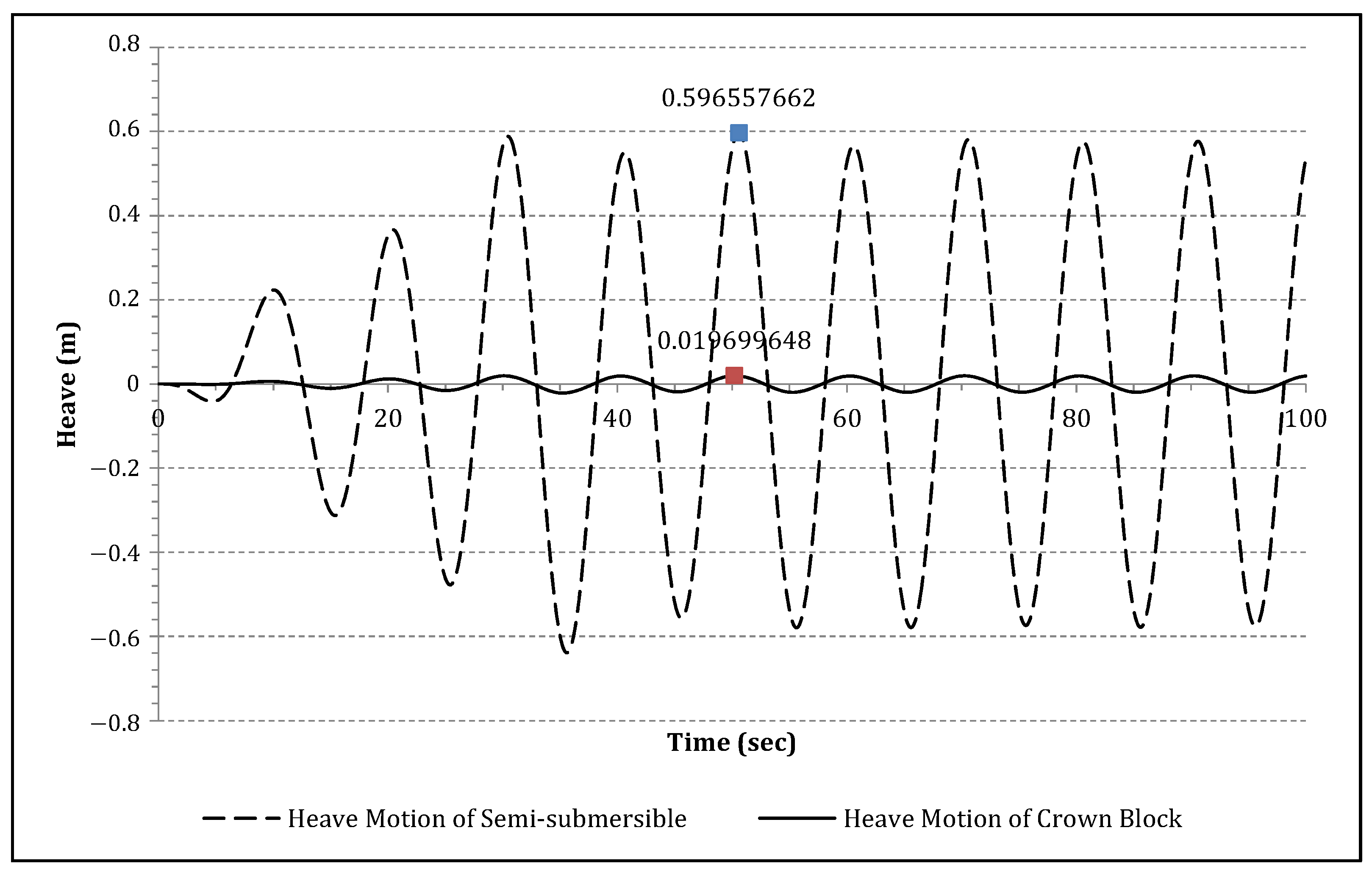

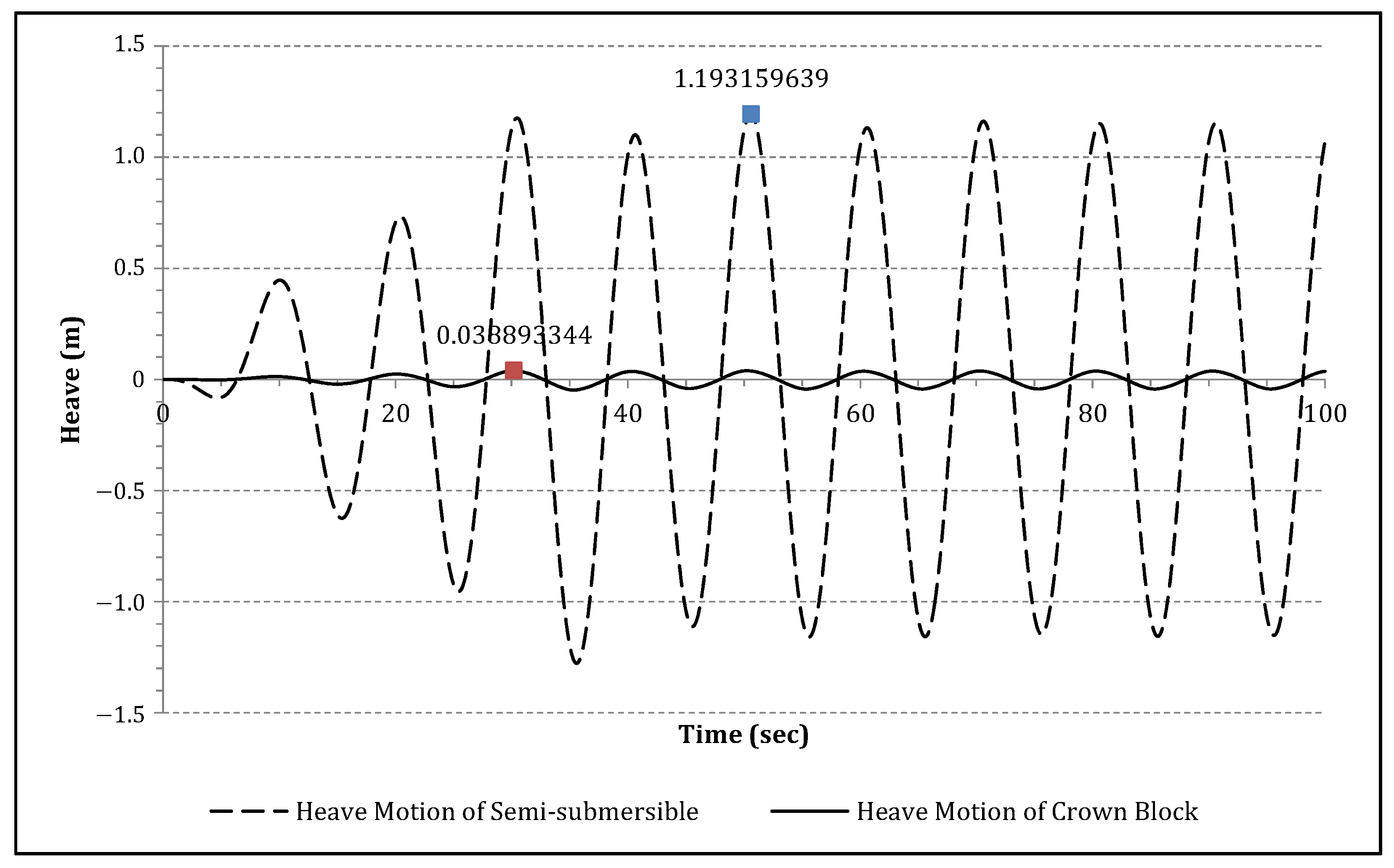

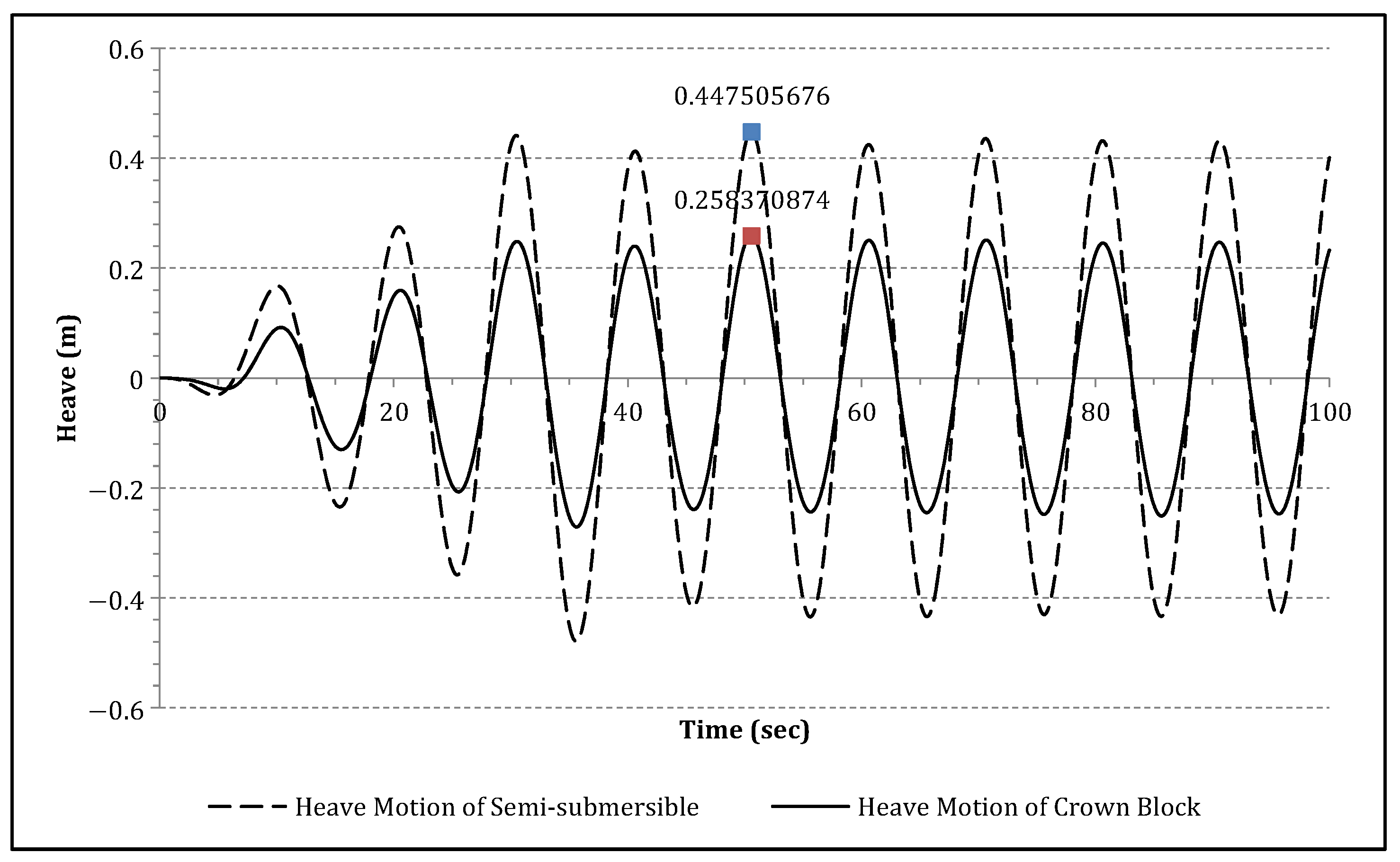

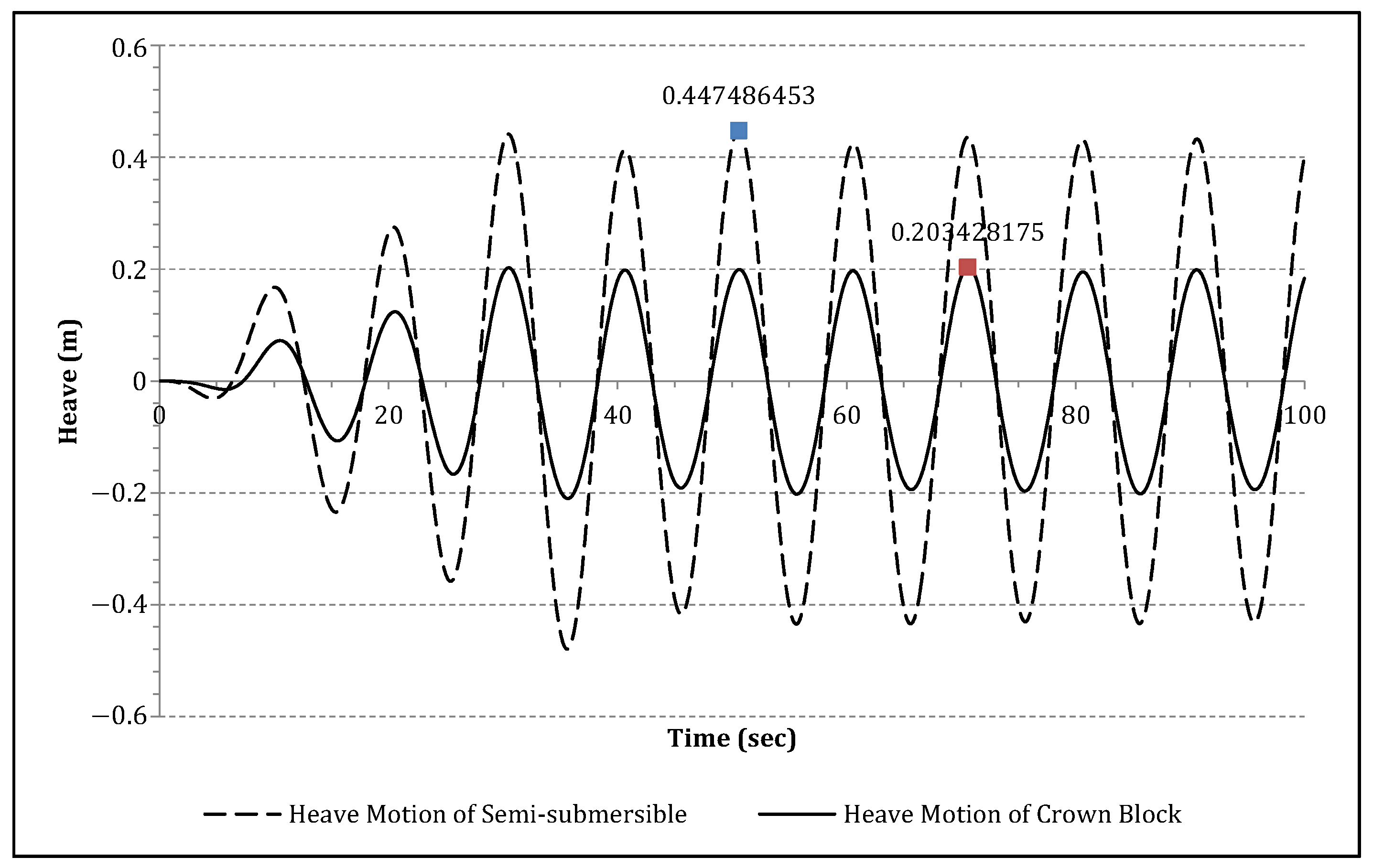

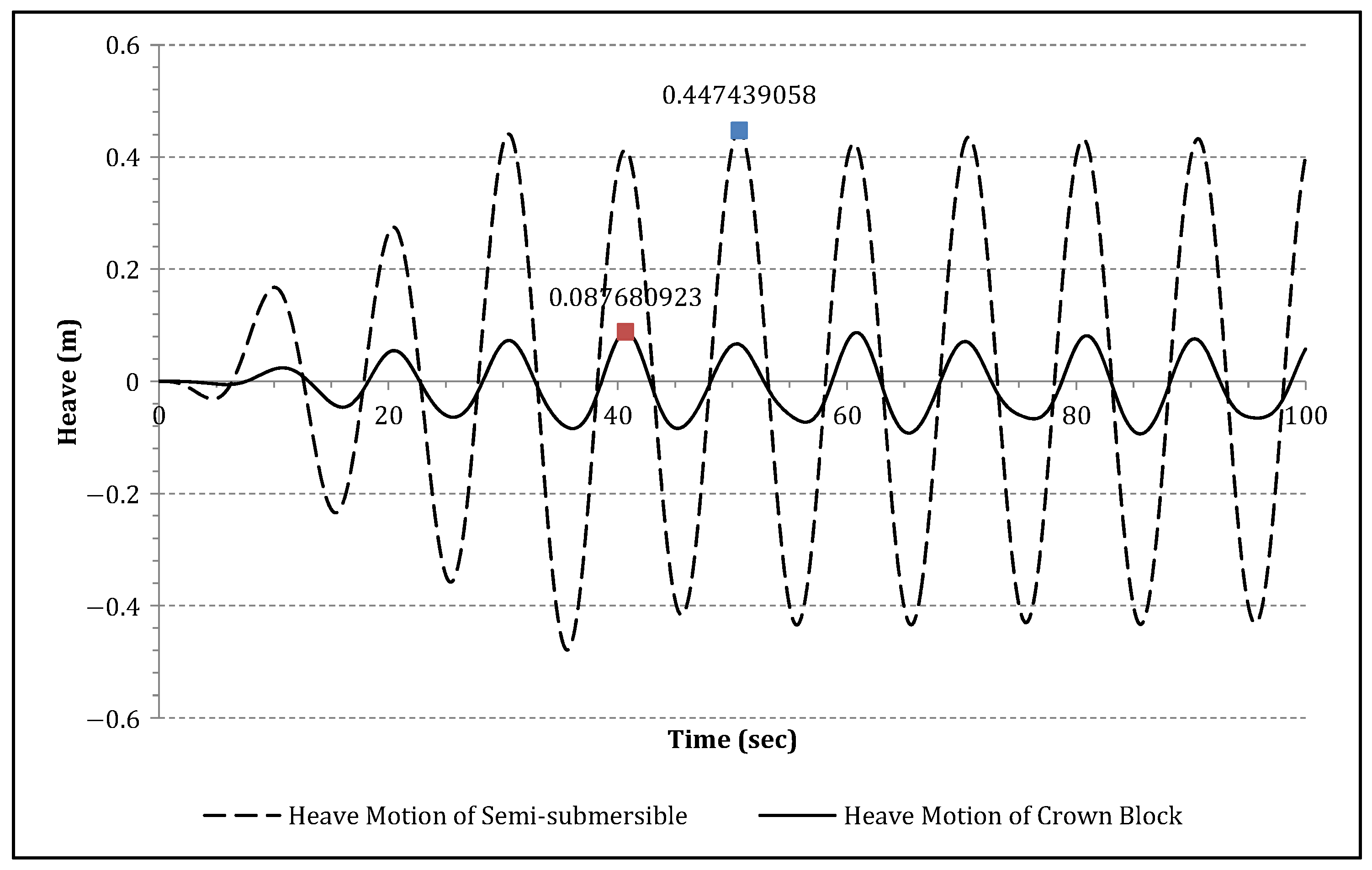

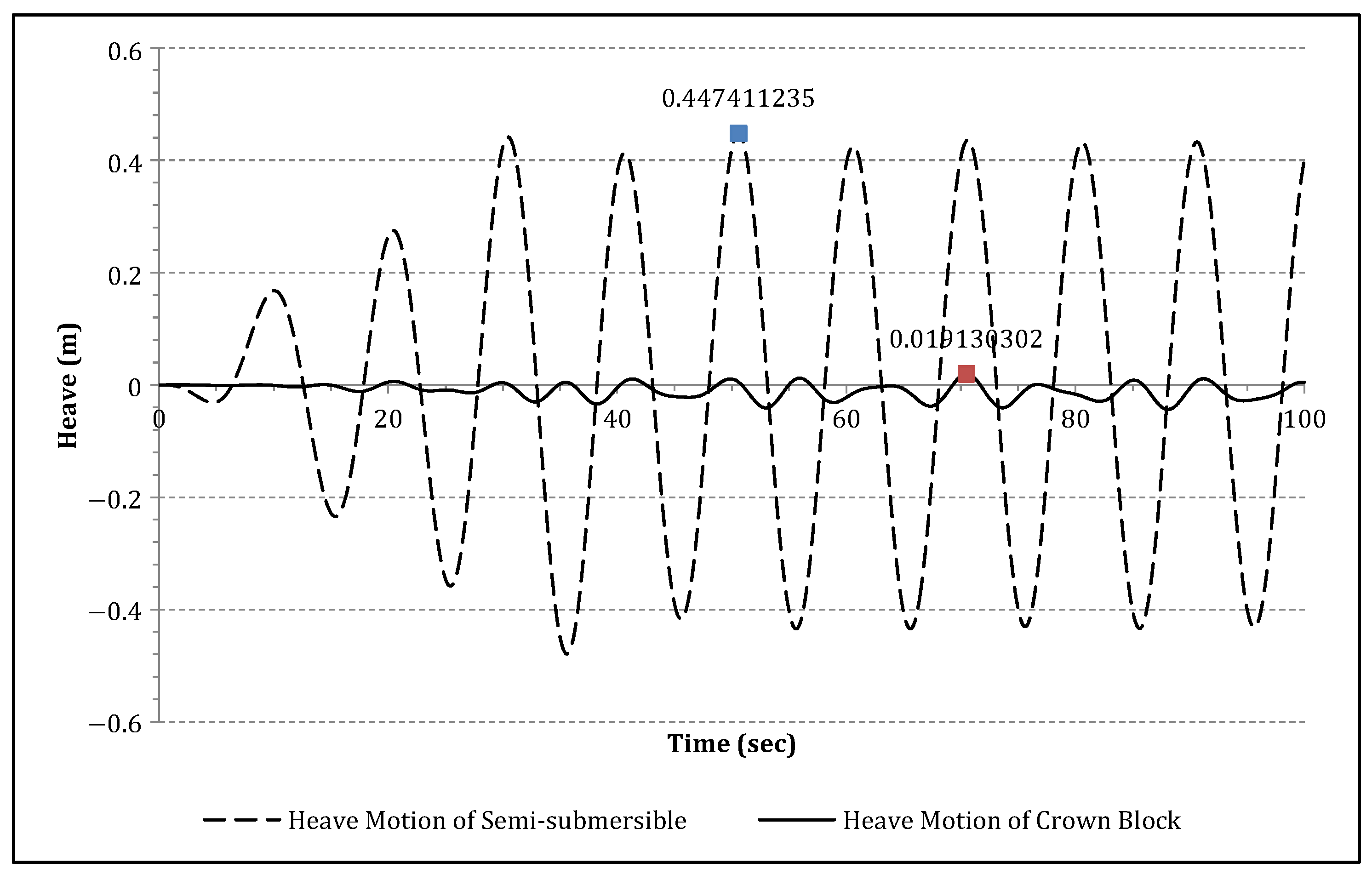

6. Dynamic Analysis of the Heave Compensation System

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Orlandea, N.; Chace, M.; Calahan, D.A. A sparsity-oriented approach to the dynamic analysis and design of mechanical systems-part1&2. J. Eng. Ind. Trans. ASME 1977, 99, 773–779. [Google Scholar]

- Schiehlen, W. Multibody Systems Handbook; Springer: Berlin/Heidelberg, Germany, 1990; pp. 361–402. [Google Scholar]

- Smith, R. Open Dynamics Engine v0.5 User Guide. 2006, pp. 15–20. Available online: http://ode.org/ode-latest-userguide.pdf (accessed on 10 August 2021).

- FunctionBay, Inc. RecurDyn V7R5 Release Notes. 2011. Available online: https://pdfslide.net/documents/recurdyn-v7r5-release-notes-v-v-recurdyncatia-read-write-v-v-all-data-number.html (accessed on 10 August 2021).

- Do, K.; Pan, J. Nonlinear control of an active heave compensation system. Ocean. Eng. 2008, 35, 558–571. [Google Scholar] [CrossRef] [Green Version]

- Beutlich, T.; Lien, R. Multidisciplinary simulation of active heave compensators for offshore module handling systems. In Proceedings of the MULTIBODY Dynamics 2009: ECCOMAS Thematic Conference, Warsaw, Poland, 29 June–2 July 2009. [Google Scholar]

- Albers, P. Motion Control in Offshore and Dredging; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Hatleskog, J.; Dunnign, M. Peer-reviewed technical communication—Passive compensator load variation for deep-water drilling. J. Ocean. Eng. 2007, 32, 3. [Google Scholar] [CrossRef]

- Lumeng, H.; Yanting, Z.; Lei, Z.; Meiying, L. Semi-active drilling drawworks heave compensation system. Pet. Explor. Dev. 2013, 40, 5. [Google Scholar]

- Bommer, P. A Primer of Oilwell Drilling; The University of Texas at Austin: Austin, UT, USA, 2008. [Google Scholar]

- Featherstone, R. Rigid Body Dynamics; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Luh, J. On-line computational scheme for mechanical manipulators. J. Dyn. Syst. Meas. Control 1980, 102, 69–76. [Google Scholar] [CrossRef]

- Graber, K.; Pollard, E.; Jonasson, B.; Schulte, E. Overview of ocean drilling program engineering tools and hardware. Tech. Notes 2002, 31. Available online: https://www.semanticscholar.org/paper/Overview-of-Ocean-Drilling-Program-Engineering-and-Graber-Pollard/701cf277855b5af0e5717159e6060e3b05ffdb33 (accessed on 1 August 2021). [CrossRef]

- McNary, J.; Person, A.; Ozudogru, Y. A 7500-ton-capacity, shipboard, completely gimbaled and heave-compensated platform. J. Pet. Technol. 1977, 29, 439–448. [Google Scholar] [CrossRef]

- Daewoo Shipbuilding & Marine Engineering (DSME) Co. Ltd. Dynamic Response Analysis and Control of Hoisting System for Drilling Rig in Ocean Environment based on Multibody Dynamics; Technical Research Report; Central Research Institute: Kasauli, India, 2012. [Google Scholar]

- Jonggeun, C.; Schubert, J.; Juvkam-wold, H. Analyses and procedures for kick detection in subsea mudlift drilling. SPE Drill. Complet. 2007, 22, 296–303. [Google Scholar]

- Jo, A.; Ku, N.; Park, K.; Lee, K. Mathematical modeling and dynamic behavior analysis of drill string compensator for off-shore drilling operation. In Proceedings of the Society of Naval Architecture of Korea Fall Conference, Changwon, Korea, 20–25 October 2011. [Google Scholar]

| This Study | ADAMS | RecurDyn | |

|---|---|---|---|

| Multibody formulation | Recursive formulation | Augmented formulation | Recursive formulation |

| Various joints | O | O | O |

| Flexible body | X | O | O |

| Hydrostatic force | Δ | Δ | Δ |

| Linearized hydrodynamic force | Δ | Δ | Δ |

| This Research | Albers [7] | Hatleskog [8] | Do [5] | Lumeng [9] | Beutlich [6] | |||

|---|---|---|---|---|---|---|---|---|

| Object | DSC for offshore drilling rig | DSC for offshore drilling rig | DSC for offshore drilling rig | AHC for offshore drilling rig | DSC for offshore drilling rig | DSC for offshore drilling rig | ||

| Equation of motion | Multibody | Mass spring–damper system | Mass spring–damper system | Mass spring–damper system | Lumped mass method | Multibody | ||

| External force | External force exerted on platform (*: forced oscillation) | Hydrostatic force, hydrodynamic force | X * | X * | X * | O (Physical test bed) | X * | |

| DSC control force | Spring | O | O | O | O | O | O | |

| Implementation of the spring mechanism | Pneumatic | Constant coefficient | Pneumatic | Active control | Pneumatic | Pneumatic | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.; Ku, N. Heave Compensation Dynamics for Offshore Drilling Operation. J. Mar. Sci. Eng. 2021, 9, 965. https://doi.org/10.3390/jmse9090965

Kim D, Ku N. Heave Compensation Dynamics for Offshore Drilling Operation. Journal of Marine Science and Engineering. 2021; 9(9):965. https://doi.org/10.3390/jmse9090965

Chicago/Turabian StyleKim, Dave, and Namkug Ku. 2021. "Heave Compensation Dynamics for Offshore Drilling Operation" Journal of Marine Science and Engineering 9, no. 9: 965. https://doi.org/10.3390/jmse9090965

APA StyleKim, D., & Ku, N. (2021). Heave Compensation Dynamics for Offshore Drilling Operation. Journal of Marine Science and Engineering, 9(9), 965. https://doi.org/10.3390/jmse9090965