Prediction of Loss of Position during Dynamic Positioning Drilling Operations Using Binary Logistic Regression Modeling

Abstract

1. Introduction

- to analyze the variables included in the incident reports and extract data for regression modeling;

- to construct models, using binary logistic regression, predicting the probability of a LoP; and

- to explore whether or not human factors were considered to have contributed to the LoP.

2. Materials and Methods

2.1. Database

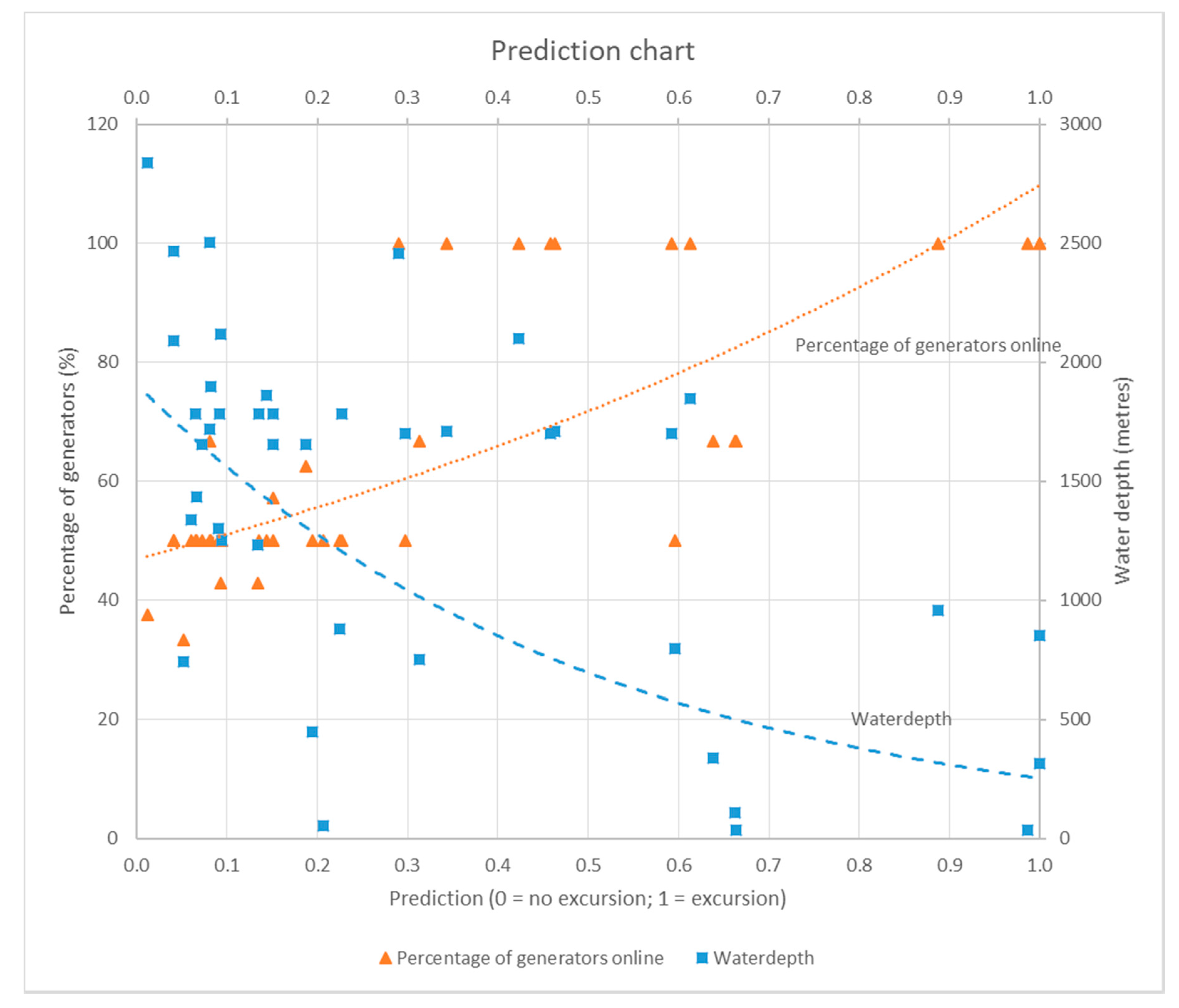

- Water depth (in meters): indicates the water depth at which the drilling operations took place;

- Percentage of thrusters: the number of thrusters online divided by the total number of thrusters, both online and stand-by;

- Percentage of generators: the number of generators online divided by the total number of generators, both online and stand-by;

- DGNSS: the number of Differential Global Navigation Satellite Systems (DGNSS) systems selected in the DP system;

- HPR systems: the number of hydroacoustic position reference (HPR) systems selected in the DP system;

- Taut wires: the number of taut wires in use during the operations;

- Inertia systems: the number of inertia systems in use during the drilling operations;

- Gyros: the number of gyros in use during the drilling operations;

- MRUs: the number of motion reference units (MRUs) in use during the drilling operations;

- Wind sensors: the number of wind sensors in use during the drilling operations;

- Wind force: the force in knots of the wind blowing when the incident occurred;

- Current speed: the speed of the current in knots when the incident occurred;

- Wave height: the height of the waves in meters;

- Visibility: the visibility when the incident happened, categorized as “poor” when the visibility was less than 2 nautical miles, “moderate”, between 2 and 5 nautical miles, and “good”, above 5 nautical miles [44], coded as 1, 2, and 3, respectively;

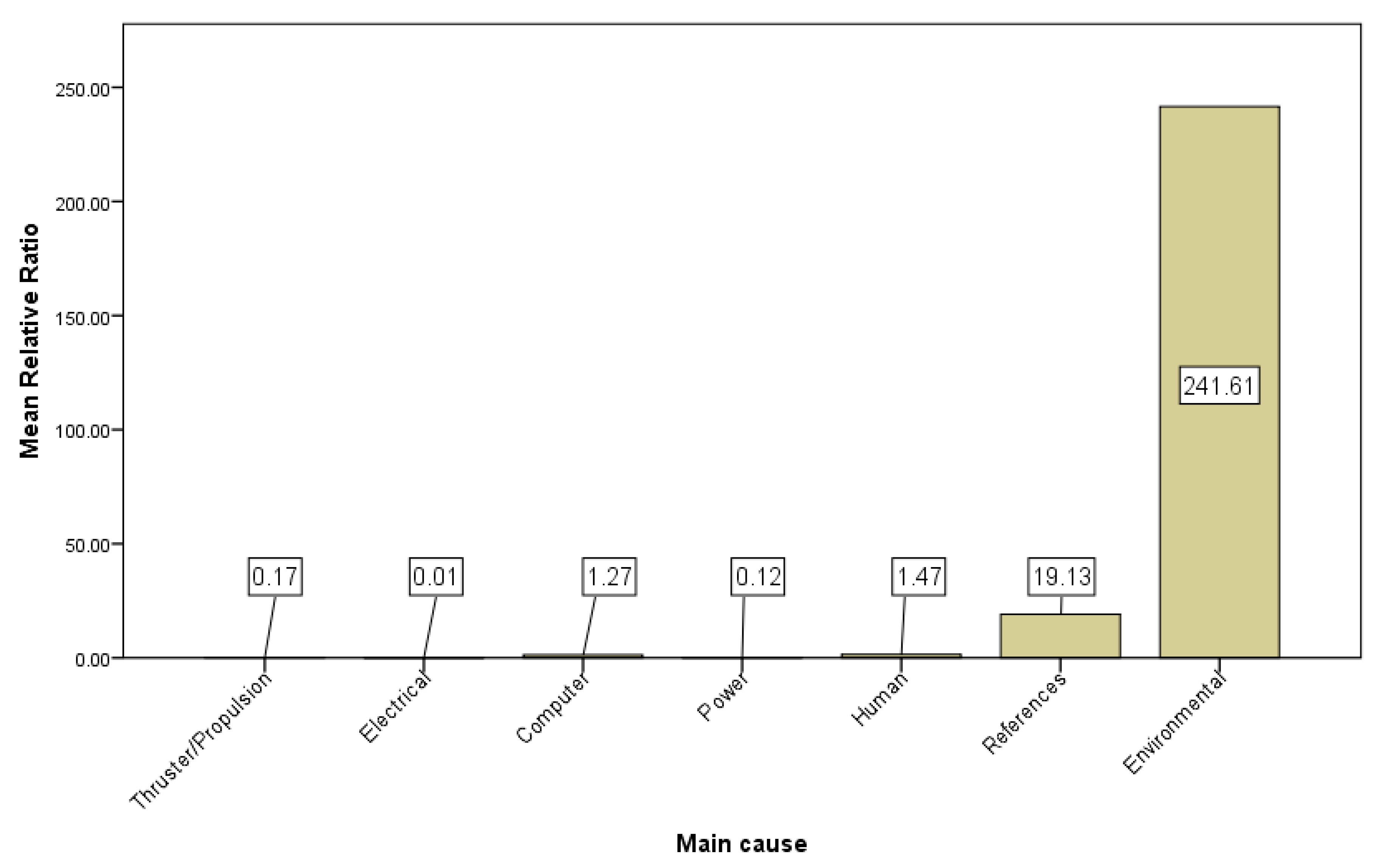

- Main cause: the leading cause, as given by the IMCA, based on the following categories: Computer, Electrical, Environmental, External, Human error, Power, References, Sensors, and Thruster;

- Secondary cause: the secondary cause, if present, as given by the IMCA, with the same categories as the main cause;

- Excursion: whether or not a LoP occurred (coded as 1 or 0 respectively).

- Human cause: whether or not the main and/or secondary causes are due to human factors (coded as 1 if so, and 0 otherwise).

2.2. Binary Logistic Regression Model

3. Results

3.1. Descriptive Statistics

3.2. Binary Logistic Regression Model

4. Discussion

Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Percentage of Thrusters | Percentage of Generators | DGNSS | HPR | Taut Wire | Inertia System | Gyros | MRU | Wind Sensors | Wind Force | Current Speed | Wave Height | Visibility | Human Cause | Excursion | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Water depth | −0.15 | −0.10 | 0.02 | 0.14 | −0.37 | −0.25 | 0.05 | 0.03 | −0.14 | −0.26 | 0.19 | −0.09 | 0.27 | −0.05 | −0.35 |

| Percentage of thrusters | - | 0.23 | −0.22 | −0.05 | 0.16 | 0.11 | 0.00 | −0.16 | −0.03 | 0.07 | 0.14 | 0.00 | −0.09 | −0.63 | 0.25 |

| Percentage of generators | - | - | −0.32 | 0.12 | 0.15 | 0.21 | 0.00 | −0.25 | −0.51 | 0.11 | 0.28 | −0.13 | −0.14 | −0.11 | 0.47 |

| DGNSS | - | - | - | 0.10 | −0.13 | −0.09 | 0.00 | 0.13 | 0.10 | −0.19 | −0.19 | −0.22 | −0.03 | 0.03 | −0.25 |

| HPR | - | - | - | - | −0.18 | 0.02 | 0.10 | 0.26 | 0.01 | −0.31 | 0.17 | −0.17 | −0.11 | −0.22 | −0.27 |

| Taut wire | - | - | - | - | - | 0.70 | 0.00 | −0.16 | −0.04 | 0.17 | −0.14 | 0.09 | −0.11 | 0.02 | 0.30 |

| Inertia system | - | - | - | - | - | - | 0.00 | 0.07 | 0.06 | 0.26 | −0.02 | 0.18 | −0.29 | −0.12 | 0.09 |

| Gyros | - | - | - | - | - | - | - | 0.37 | 0.33 | −0.08 | −0.01 | −0.08 | 0.07 | 0.00 | −0.24 |

| MRU | - | - | - | - | - | - | - | - | 0.48 | −0.12 | −0.03 | 0.02 | 0.16 | 0.17 | −0.48 |

| Wind sensors | - | - | - | - | - | - | - | - | - | 0.03 | −0.20 | 0.08 | −0.04 | −0.06 | −0.38 |

| Wind force | - | - | - | - | - | - | - | - | - | - | −0.02 | 0.41 | −0.12 | 0.07 | 0.41 |

| Current speed | - | - | - | - | - | - | - | - | - | - | - | 0.00 | −0.06 | −0.22 | 0.11 |

| Wave Height | - | - | - | - | - | - | - | - | - | - | - | - | 0.00 | 0.02 | 0.35 |

| Human cause | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.23 | −0.24 |

References

- Nie, Z.; Chang, Y.; Liu, X.; Chen, G. A DBN-GO approach for success probability prediction of drilling riser emergency disconnect in deepwater. Ocean. Eng. 2019, 180, 49–59. [Google Scholar] [CrossRef]

- United States Department of the Interior. Mineral Management Service. “Accident Investigation Report”. Available online: https://www.bsee.gov/sites/bsee.gov/files/incident-statisticssummaries-fatalities/inspection-and-enforcement/060320-pdf.pdf (accessed on 15 December 2020).

- Mac Sheoin, T.; Zavestoski, S. Chapter four: Corporate catastrophes from UC bhopal to BP deepwater horizon: Continuities in causation. corporate negligence. and crisis management. In Black Beaches and Bayous; Eargle, L.A., Esmail, A., Eds.; University Press of America: Lanham, MD, USA, 2012; pp. 53–94. [Google Scholar]

- Mauro, F.; Prpić-Oršić, J. Determination of a DP operability index for an offshore vessel in early design stage. Ocean. Eng. 2020, 195, 106764. [Google Scholar] [CrossRef]

- Chen, H.; Moan, T.; Verhoeven, H. Safety of dynamic positioning operations on mobile offshore drilling units. Reliab. Eng. Syst. Saf. 2008, 93, 1072–1090. [Google Scholar] [CrossRef]

- Verhoeven, H.; Chen, H.; Moan, T. Safety of dynamic positioning operation on mobile offshore drilling units. In Proceedings of the MTS Dynamic Positioning Conference, Houston, TX, USA, 17–18 October 2006. [Google Scholar]

- Chae, C. A Study on Human Error of DP Vessels LOP Incidents. J. Korean Soc. Mar. Environ. 2015, 21, 515–523. [Google Scholar] [CrossRef]

- Chae, C. A Study on FSA Application for Human Errors of Dynamic Positioning Vessels Incidents. J. Navig. Port. Res. 2017, 41, 259–268. [Google Scholar] [CrossRef]

- Dong, Y.; Vinnem, J.E.; Utne, I.B. Improving safety of DP operations: Learning from accidents and incidents during offshore loading operations. Eur. J. Decis. Process. 2017, 5, 5–40. [Google Scholar] [CrossRef]

- Øvergård, K.I.; Sorensen, L.J.; Nazir, S.; Martinsen, T.J. Critical incidents during dynamic positioning: Operators’ situation awareness and decision-making in maritime operations. Theor. Issues Ergon. Sci. 2015, 16, 366–387. [Google Scholar] [CrossRef]

- Mao, L.; Zeng, S.; Liu, Q. Dynamic mechanical behavior analysis of deep water drilling riser under hard hang-off evacuation conditions. Ocean Eng. 2019, 183, 318–331. [Google Scholar] [CrossRef]

- Bray, D. DP Operations. Part 2—What is DP used for? Seaways 2018, 9, 13–16. [Google Scholar]

- Marine Technology Society. DP Operations Guidance—Part 2—Appendix 1–MODUs; Marine Tecnology Society: Washington, DC, USA, 2012. [Google Scholar]

- Bray, D. DP Operations. Part 1—Basic Principles and Systems. Seaways 2018, 8, 22–25. [Google Scholar]

- Weingarth, L. Refining the DP watch circle. In Proceedings of the MTS Dynamic Positioning Conference, Houston, TX, USA, 17–18 October 2006. [Google Scholar]

- Bhalla, K.; Cao, Y. Watch circle assessment of drilling risers during a drift-off and drive-off event of a dynamically positioned vessel. In Proceedings of the MTS Dynamic Positioning Conference, Houston, TX, USA, 15–16 November 2005. [Google Scholar]

- Quigley, C.; Williams, D. A Revised Methodology for the Calculation of Modu Watch Circles. In Proceedings of the ASME 2015 34th International Conference on Ocean Offshore and Arctic Engineering, St. John’s, NL, Canada, 31 May–5 June 2015; The American Society of Mechanical Engineers, 2015; p. V05AT04A008. [Google Scholar] [CrossRef]

- Adamson, A.; Abrahamsen, B. WSOG—History and future. A summary of the development & worldwide use of well-specific operating guidelines. In Proceedings of the MTS Dynamic Positioning Conference, Houston, TX, USA, 17–18 October 2006. [Google Scholar]

- Teixeira, F.J.R.; Oshiro, A.T.; Tannuri, E.A. Drifting Time of a Standard Drillship. In Proceedings of the ASME 2014 33rd International Conference on Ocean Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; The American Society of Mechanical Engineers, 2014. Volume 1B: Offshore Technology. p. V01BT01A029. [Google Scholar] [CrossRef]

- Kristiansen, S. Part III. Risk Analysis. In Maritime Transportation; Safety Management and Risk Analysis; Elsevier Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Khan, F.I.; Abbasi, S.A. Techniques and methodologies for risk analysis in chemical process industries. J. Loss Prev. Process Ind. 1998, 11, 261–277. [Google Scholar] [CrossRef]

- Ancione, G.; Bragatto, P.; Milazzo, M.F. A Bayesian network-based approach for the assessment and management of ageing in major hazard establishments. J. Loss Prev. Process Ind. 2020, 64, 104080. [Google Scholar] [CrossRef]

- Mkrtchyan, L.; Podofillini, L.; Dang, V.N. Bayesian belief networks for human reliability analysis: A review of applications and gaps. Reliab. Eng. Syst. Saf. 2015, 139, 1–16. [Google Scholar] [CrossRef]

- Bier, V.M.; Mosleh, A. The analysis of accident precursors and near misses: Implications for risk assessment and risk management. Reliab. Eng. Syst. Saf. 1990, 27, 91–101. [Google Scholar] [CrossRef]

- Bier, V.M.; Yi, V.M. The performance of precursor-based estimators for rare event frequencies. Reliab. Eng. Syst. Saf. 1995, 50, 241–251. [Google Scholar] [CrossRef]

- Khakzad, N.; Khakzad, S.; Khan, F. Probabilistic risk assessment of major accidents: Application to offshore blowouts in the Gulf of Mexico. Nat. Hazards 2014, 74, 1759–1771. [Google Scholar] [CrossRef]

- Yang, M.; Khan, F.; Lye, L.; Amyotte, P. Risk assessment of rare events. Process Saf. Environ. Prot. 2015, 98, 102–108. [Google Scholar] [CrossRef]

- Arnaldo Valdés, R.M.; Liang Cheng, S.Z.Y.; Gómez Comendador, V.F.; Sáez Nieto, F.J. Application of Bayesian Networks and Information Theory to Estimate the Occurrence of Mid-Air Collisions Based on Accident Precursors. Entropy 2018, 20, 969. [Google Scholar] [CrossRef]

- Rebello, S.; Yu, H.; Ma, L. An integrated approach for real-time hazard mitigation in complex industrial processes. Reliab. Eng. Syst. Saf. 2019, 188, 297–309. [Google Scholar] [CrossRef]

- Shengli, L.; Yongtu, L. Exploring the temporal structure of time series data for hazardous liquid pipeline incidents based on complex network theory. Int. J. Crit. Infrastruct. Prot. 2019, 26, 100308. [Google Scholar] [CrossRef]

- Agarwal, S.; Kachroo, P.; Regentova, E. A hybrid model using logistic regression and wavelet transformation to detect traffic incidents. IATSS Res. 2016, 40, 56–63. [Google Scholar] [CrossRef]

- Li, R.; Pereira, F.C.; Ben-Akiva, M.E. Competing risks mixture model for traffic incident duration prediction. Accid. Anal. Prev. 2015, 75, 192–201. [Google Scholar] [CrossRef]

- McFadden, K.L. Predicting pilot-error incidents of US airline pilots using logistic regression. Appl. Ergon. 1997, 28, 209–212. [Google Scholar] [CrossRef]

- Erjavac, A.J.; Iammartino, R.; Fossaceca, J.M. Evaluation of preconditions affecting symptomatic human error in general aviation and air carrier aviation accidents. Reliab. Eng. Syst. Saf. 2018, 178, 156–163. [Google Scholar] [CrossRef]

- Hogenboom, S.; Rokseth, B.; Vinnem, J.E.; Utne, I.B. Human reliability and the impact of control function allocation in the design of dynamic positioning systems. Reliab. Eng. Syst. Saf. 2020, 194, 106340. [Google Scholar] [CrossRef]

- Weng, J.; Yang, D.; Chai, T.; Fu, S. Investigation of occurrence likelihood of human errors in shipping operations. Ocean Eng. 2019, 182, 28–37. [Google Scholar] [CrossRef]

- Boullosa-Falces, D.; Larrabe-Barrena, J.L.; Lopez-Arraiza, A.; Menendez, J.; Gomez-Solaetxe, M.A. Monitoring of fuel oil process of marine diesel engine. Appl. Therm. Eng. 2017, 127, 517–526. [Google Scholar] [CrossRef]

- International Marine Contractors Association (IMCA). Dynamic Positioning Station Keeping Incidents—Incidents Reported for 2011; IMCA: London, UK, 2015; Available online: https://www.imca-int.com/store/digital-publications/marine/ (accessed on 27 June 2017).

- International Marine Contractors Association (IMCA). Dynamic Positioning Station Keeping Incidents—Incidents Reported for 2012; IMCA: London, UK, 2015. [Google Scholar]

- International Marine Contractors Association (IMCA). Dynamic Positioning Station Keeping Incidents—Incidents Reported for 2013; IMCA: London, UK, 2015. [Google Scholar]

- International Marine Contractors Association (IMCA). Dynamic Positioning Station Keeping Incidents—Incidents Reported for 2014; IMCA: London, UK, 2016. [Google Scholar]

- International Marine Contractors Association (IMCA). Dynamic Positioning Station Keeping Review—Incidents and Events Reported for 2015; IMCA: London, UK, 2016. [Google Scholar]

- International Marine Contractors Association (IMCA). Dynamic Positioning Station Keeping Review—Incidents and Events Reported for 2016; IMCA: London, UK, 2017. [Google Scholar]

- Marine Forecasts Glossary. Available online: https://www.metoffice.gov.uk/weather/guides/coast-and-sea/glossary (accessed on 10 December 2020).

- Menard, S. Applied Logistic Regression Analysis, 2nd ed.; Sage Publications Inc.: Thousand Oaks, CA, USA, 2002. [Google Scholar]

- Martín-Martín, Q.; Cabero-Morán, M.T.; de Paz-Santana, Y.R. Capítulo 9. Regresión Logística. In Tratamiento Estadístico de Datos Con SPSS; Ediciones Paraninfo: Madrid, Spain, 2008; pp. 259–292. [Google Scholar]

- Halsey, L.G. The reign of the p-value is over: What alternative analyses could we employ to fill the power vacuum? Biol. Lett. 2019, 15, 20190174. [Google Scholar] [CrossRef]

- Kmetz, J.L. Correcting Corrupt Research: Recommendations for the Profession to Stop Misuse of p-Values. Am. Stat. 2019, 73, 36–45. [Google Scholar] [CrossRef]

- Lewis, N.D.C. Operational Risk with Excel and VBA: Applied Statistical Methods for Risk Management; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Steyerberg, E.W.; Vickers, A.J.; Cook, N.R.; Gerds, T.; Gonen, M.; Obuchowski, N.; Pencina, M.J.; Kattan, M.W. Assessing the Performance of Prediction Models: A Framework for Traditional and Novel Measures. Epidemiology 2010, 21, 128–138. [Google Scholar] [CrossRef]

- Øvergård, K.I. Human Error: Causality and the Confusion of Normative and Descriptive Accounts of Human Performance. In Creating Sustainable Work Environments; Fostervold, K.I., Johnsen, S.Å.K., Rydstedt, L., Watten, R.G., Eds.; Norwegian Society for Ergonomics and Human Factors: Lillehammer, Norway, 2015; pp. C5-6–C5-10. [Google Scholar]

| Variables | Mean | Standard Error | Median | Standard Deviation | Minimum | Maximum |

|---|---|---|---|---|---|---|

| Water depth | 1409.24 | 112.06 | 1678.00 | 726.26 | 37.00 | 2838.00 |

| Percentage of thrusters | 92.55 | 2.34 | 100.00 | 15.17 | 50.00 | 100.00 |

| Percentage of generators | 64.51 | 3.47 | 50.00 | 22.52 | 33.33 | 100.00 |

| DGNSS | 2.33 | 0.12 | 2.00 | 0.79 | 1.00 | 4.00 |

| HPR systems | 1.40 | 0.10 | 1.50 | 0.67 | 0.00 | 2.00 |

| Taut wires | 0.12 | 0.06 | 0.00 | 0.40 | 0.00 | 2.00 |

| Inertia systems | 0.05 | 0.03 | 0.00 | 0.22 | 0.00 | 1.00 |

| Gyros | 3.00 | 0.03 | 3.00 | 0.22 | 2.00 | 4.00 |

| MRUs | 2.90 | 0.05 | 3.00 | 0.30 | 2.00 | 3.00 |

| Wind sensors | 2.83 | 0.10 | 3.00 | 0.66 | 1.00 | 4.00 |

| Wind Force | 16.01 | 1.88 | 12.50 | 12.15 | 1.00 | 55.00 |

| Current Speed | 1.90 | 0.23 | 1.40 | 1.47 | 0.30 | 6.00 |

| Wave Height | 1.88 | 0.30 | 1.35 | 1.93 | 0.10 | 9.50 |

| Visibility | 2.62 | 0.96 | 3.00 | 0.62 | 1.00 | 3.00 |

| Causal Factor | n | B | Wald | p-Value | Odds Ratio (OR) | 95% CI for OR | |

|---|---|---|---|---|---|---|---|

| Lower | Upper | ||||||

| Water depth | 42 | −0.001 | 4.645 | 0.031 | 0.999 | 0.998 | 1.000 |

| Percentage of thrusters | 42 | 0.054 | 2.002 | 0.157 | 1.055 | 0.980 | 1.136 |

| Percentage of generators | 42 | 0.047 | 8.057 | 0.005 | 1.048 | 1.015 | 1.082 |

| DGNSS | 42 | - | 0.756 | 0.860 | - | - | - |

| DGNSS(1) | 42 | 0.318 | 0.061 | 0.804 | 1.375 | 0.111 | 17.093 |

| DGNSS(2) | 42 | −20.510 | 0.000 | 0.999 | 0.000 | 0.000 | - |

| DGNSS(3) | 42 | −0.693 | 0.175 | 0.676 | 0.500 | 0.019 | 12.898 |

| HPR | 42 | - | 0.000 | 1.000 | - | - | - |

| HPR(1) | 42 | −22.382 | 0.000 | 0.999 | 0.000 | 0.000 | - |

| HPR(2) | 42 | −22.366 | 0.000 | 0.999 | 0.000 | 0.000 | - |

| Taut wire | 42 | - | 0.000 | 1.000 | - | - | - |

| Taut wire(1) | 42 | 22.233 | 0.000 | 0.999 | Abn.1 | 0.000 | - |

| Taut wire(2) | 42 | −20.173 | 0.000 | 1.000 | 0.000 | 0.000 | - |

| Inertia system(1) | 42 | 0.847 | 0.339 | 0.561 | 2.333 | 0.135 | 40.464 |

| Gyros | 42 | - | 0.000 | 1.000 | - | - | - |

| Gyros(1) | 42 | −22.050 | 0.000 | 1.000 | 0.000 | 0.000 | - |

| Gyros(2) | 42 | −42.406 | 0.000 | 0.999 | 0.000 | 0.000 | - |

| MRU(1) | 42 | −22.373 | 0.000 | 0.999 | 0.000 | 0.000 | - |

| Wind sensors | 42 | - | 5.389 | 0.145 | - | - | - |

| Wind sensors(1) | 42 | −20.797 | 0.000 | 1.000 | 0.000 | 0.000 | - |

| Wind sensors(2) | 42 | −22.638 | 0.000 | 1.000 | 0.000 | 0.000 | - |

| Wind sensors(3) | 42 | −22.589 | 0.000 | 1.000 | 0.000 | 0.000 | - |

| Wind force | 42 | 0.078 | 5.084 | 0.024 | 1.081 | 1.010 | 1.156 |

| Current speed | 42 | 0.162 | 0.522 | 0.470 | 1.176 | 0.757 | 1.826 |

| Wave Height | 42 | 0.437 | 3.043 | 0.081 | 1.549 | 0.947 | 2.532 |

| Visibility | 42 | - | 2.491 | 0.288 | - | - | - |

| Visibility(1) | 42 | −1.099 | 0.630 | 0.427 | 0.333 | 0.022 | 5.027 |

| Visibility(2) | 42 | −1.838 | 2.002 | 0.157 | 0.159 | 0.012 | 2.031 |

| Human cause (1) | 42 | 0.140 | 0.030 | 0.862 | 1.150 | 0.239 | 5.540 |

| Variables in the Equation | B | S.E. | Wald | df | Sig. | OR | 95% CI for OR | |

|---|---|---|---|---|---|---|---|---|

| Lower | Upper | |||||||

| Water depth | −0.001 | 0.001 | 1.884 | 1 | 0.170 | 0.999 | 0.998 | 1.000 |

| Percentage of generators | 0.058 | 0.023 | 6.411 | 1 | 0.011 | 1.060 | 1.013 | 1.109 |

| Wind force | 0.050 | 0.051 | 0.959 | 1 | 0.327 | 1.051 | 0.951 | 1.162 |

| Wave Height | 0.461 | 0.496 | 0.866 | 1 | 0.352 | 1.586 | 0.600 | 4.189 |

| Constant | −4.936 | 2.311 | 4.564 | 1 | 0.033 | 0.007 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchez-Varela, Z.; Boullosa-Falces, D.; Larrabe Barrena, J.L.; Gomez-Solaeche, M.A. Prediction of Loss of Position during Dynamic Positioning Drilling Operations Using Binary Logistic Regression Modeling. J. Mar. Sci. Eng. 2021, 9, 139. https://doi.org/10.3390/jmse9020139

Sanchez-Varela Z, Boullosa-Falces D, Larrabe Barrena JL, Gomez-Solaeche MA. Prediction of Loss of Position during Dynamic Positioning Drilling Operations Using Binary Logistic Regression Modeling. Journal of Marine Science and Engineering. 2021; 9(2):139. https://doi.org/10.3390/jmse9020139

Chicago/Turabian StyleSanchez-Varela, Zaloa, David Boullosa-Falces, Juan Luis Larrabe Barrena, and Miguel A. Gomez-Solaeche. 2021. "Prediction of Loss of Position during Dynamic Positioning Drilling Operations Using Binary Logistic Regression Modeling" Journal of Marine Science and Engineering 9, no. 2: 139. https://doi.org/10.3390/jmse9020139

APA StyleSanchez-Varela, Z., Boullosa-Falces, D., Larrabe Barrena, J. L., & Gomez-Solaeche, M. A. (2021). Prediction of Loss of Position during Dynamic Positioning Drilling Operations Using Binary Logistic Regression Modeling. Journal of Marine Science and Engineering, 9(2), 139. https://doi.org/10.3390/jmse9020139