Microplastics in Combined Sewer Overflows: An Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

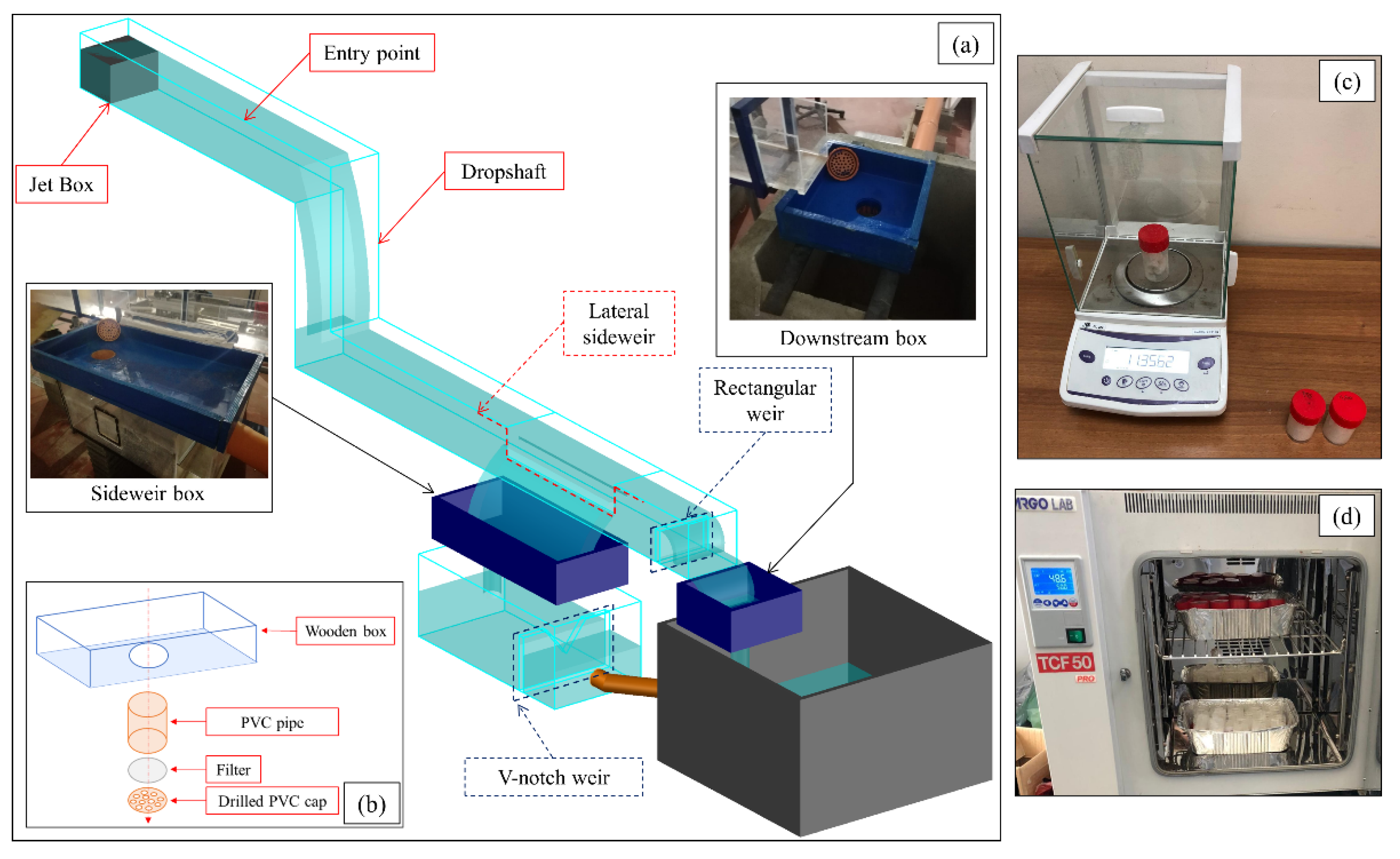

2.1. Experimental Setup

2.2. Measurement Methodology

- First, 3 g of nylon fibers were collected inside transparent plastic samplers and weighed (Wtot) with a laboratory balance (XS Balance model BL224, with weight range 0.1 mg–220 g, repeatability 0.1 mg, Figure 1c). In addition, for each sample of nylon fibers, two filters were weighed, one for the side weir box and the other for the downstream box;

- The fibers were then mixed in a plastic graduated cup containing 350 mL of water, in order to separate them and allow them to follow the water flow without affecting each other;

- The water–fiber mix was introduced at a distance of 5B upstream of the dropshaft (“entry point” in Figure 1a). The presence of the dropshaft allowed a better dispersion of the fibers in the water flow. Then, the fibers followed the water flow and were collected by means of the two filters after the outflows;

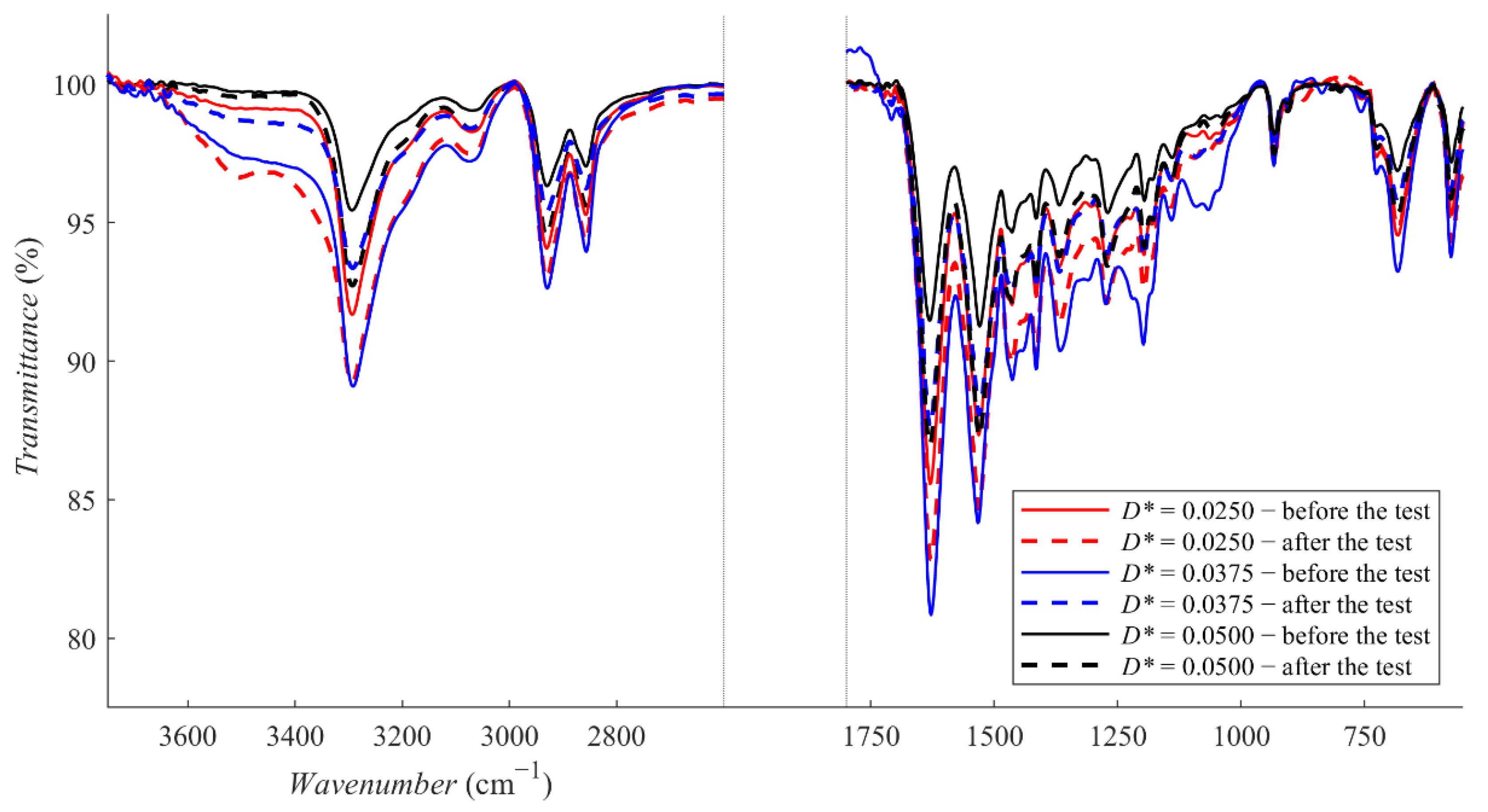

- The wet filters containing the fibers were placed in the plastic samplers and dried for 72 h at 50 °C in a laboratory oven (Argo Lab model TCF 50 Pro, with temperature range 10–300 °C and temperature uniformity in the space at 150 °C ± 2%, Figure 1d);

- The dried samples were then weighed allowing an evaluation of the weights of the fibers discharged from the side weir Wsideweir and of the fibers that followed the flow downstream.

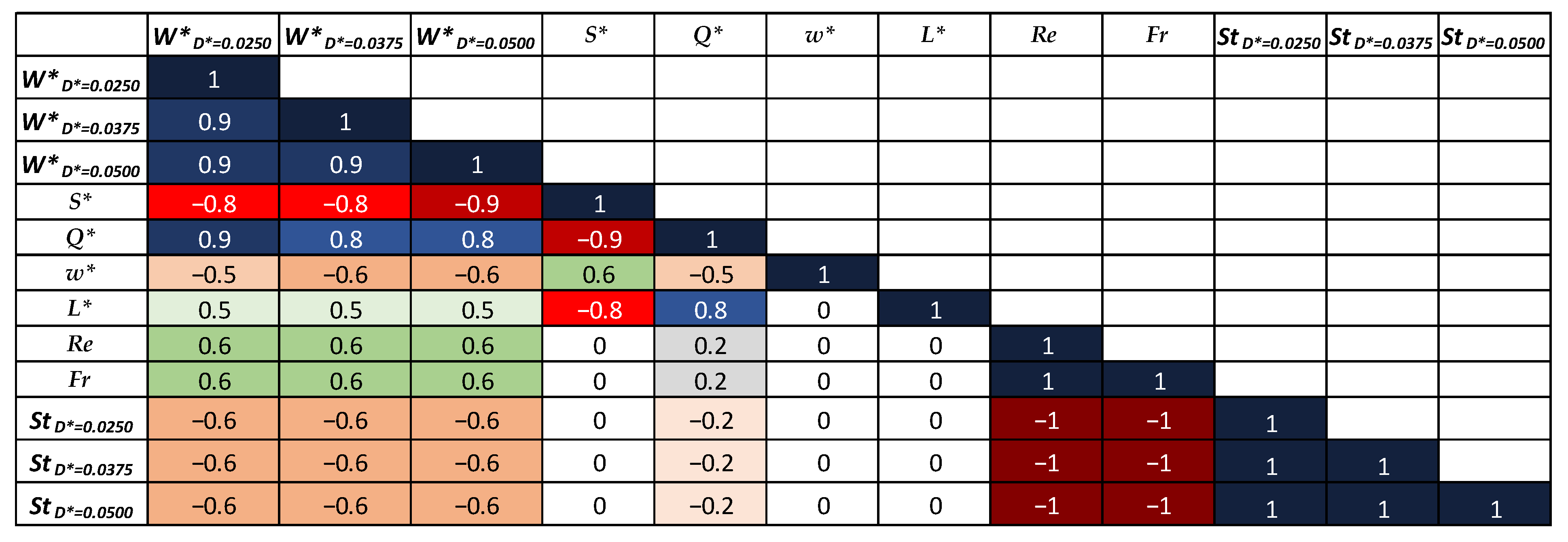

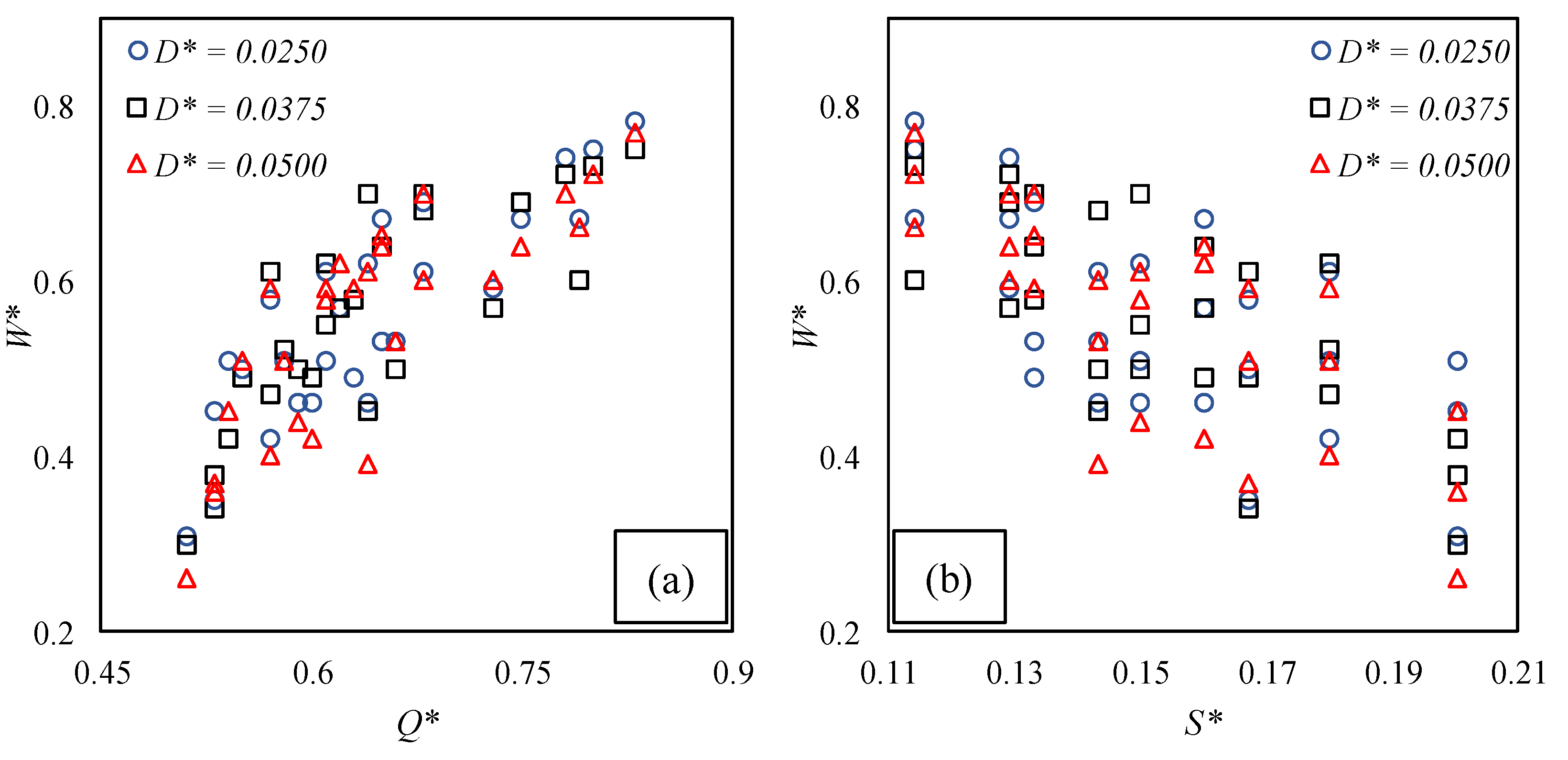

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Kamal, M.R.; Huang, B. Natural and artificial weathering of polymers. In Handbook of Polymer Degradation; Hamid, S.H., Ami, M.B., Maadhan, A.G., Eds.; Marcel Dekker: New York, NY, USA, 1992; pp. 127–168. [Google Scholar]

- Ali Shah, A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological degradation of plastics: A comprehensive review. Biotechnol. Adv. 2007, 26, 246–265. [Google Scholar] [CrossRef]

- Eubeler, J.P.; Zok, S.; Bernhard, M.; Knepper, T.P. Environmental biodegradation of synthetic polymers I. Test methodologies and procedures. TrAC Trends Anal. Chem. 2009, 28, 1057–1072. [Google Scholar] [CrossRef]

- Klein, S.; Dimzon, I.K.; Eubeler, J.; Knepper, T.P. Analysis, Occurrence, and Degradation of Microplastics in the Aqueous Environment. In Freshwater Microplastics; Wagner, M., Lambert, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 51–67. [Google Scholar]

- Kooi, M.; Besseling, E.; Kroeze, C.; van Wezel, A.P.; Koelmans, A.A. Modeling the Fate and Transport of Plastic Debris in Freshwaters: Review and Guidance. In Freshwater Microplastics; Wagner, M., Lambert, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 125–152. [Google Scholar]

- Koelmans, A.A.; Besseling, E.; Shim, W.J. Nanoplastics in the aquatic environment. Critical review. In Marine anthropogenic Litter; Bergmann, M., Gutow, L., Klages, M., Eds.; Springer: Berlin, Germany, 2015; pp. 325–340. [Google Scholar]

- Mattsson, K.; Hansson, L.A.; Cedervall, T. Nano-plastics in the aquatic environment. Environ. Sci. Process. Impacts 2015, 17, 1712–1721. [Google Scholar] [CrossRef] [PubMed]

- Arthur, C.; Baker, J.; Bamford, H. Proceedings of the International Research Workshop on the Occurrence, Effects and Fate of Microplastic Marine Debris; NOAA Technical Memorandum: Tacoma, WA, USA, 2008; Volume NOAA Technical Memorandum NOS-OR&R-30; p. 528. [Google Scholar]

- Hidalgo-Ruz, V.; Gutow, L.; Thompson, R.C.; Thiel, M. Microplastics in the marine environment: A review of the methods used for identification and quantification. Environ. Sci. Technol. 2012, 46, 3060–3075. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, W.; Bender, C.; Porcher, J.M. Wild gudgeons (Gobio gobio) from French rivers are contaminated by microplastics: Preliminary study and first evidence. Environ. Res. 2014, 128, 98–100. [Google Scholar] [CrossRef] [PubMed]

- Faure, F.; Demars, C.; and Wieser, O.; Kunz, M.; de Alencastro, L.F. Plastic pollution in Swiss surface waters: Nature and concentrations, interaction with pollutants. Environ. Chem. 2015, 12, 582–591. [Google Scholar] [CrossRef]

- Kooi, M.; Koelmans, A.A. Simplifying Microplastic via Continuous Probability Distributions for Size, Shape, and Density. Environ. Sci. Technol. Lett. 2019, 6, 551–557. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.; Zhang, K.; Xiong, X. Microplastic Pollution in Inland Waters Focusing on Asia. In Freshwater Microplastics; Wagner, M., Lambert, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 85–99. [Google Scholar]

- Dikareva, N.; Simon, K.S. Microplastic pollution in streams spanning an urbanization gradient. Environ. Pollut. 2019, 250, 292–299. [Google Scholar] [CrossRef] [PubMed]

- Unice, K.M.; Weeber, M.P.; Abramson, M.M.; Reid, R.C.D.; van Gils, J.A.G.; Markus, A.A.; Vethaak, A.D.; Panko, J.M. Characterizing export of land-based microplastics to the estuary—Part I: Application of integrated geospatial microplastic transport models to assess tire and road wear particles in the Seine watershed. Sci. Total Environ. 2019, 646, 1639–1649. [Google Scholar] [CrossRef]

- Kawecki, D.; Nowack, B. A proxy-based approach to predict spatially resolved emissions of macro- and microplastic to the environment. Sci. Total Environ. 2020, 748, 141137. [Google Scholar] [CrossRef]

- EPA. Report to Congress: Combined Sewer Overflows to the Lake Michigan Basin EPA-833-R-07-007. Available online: https://www.epa.gov/sites/default/files/2015-10/documents/cso_reporttocongress_lakemichigan.pdf (accessed on 9 December 2007).

- Eriksen, M.; Mason, S.; Wilson, S.; Box, C.; Zellers, A.; Edwards, W.; Farley, H.; Amato, S. Microplastic pollution in the surface waters of the Laurentian Great Lakes. Mar. Pollut. Bull. 2013, 77, 177–182. [Google Scholar] [CrossRef] [PubMed]

- Dris, R.; Gasperi, J.; Tassin, B. Sources and Fate of Microplastics in Urban Areas: A Focus on Paris Megacity. In Freshwater Microplastics; Wagner, M., Lambert, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 69–83. [Google Scholar]

- Polanco, H.; Hayes, S.; Roble, C.; Krupitsky, M.; Branco, B. The presence and significance of microplastics in surface water in the Lower Hudson River Estuary 2016–2019: A research note. Mar. Pollut. Bull. 2020, 161, 111702. [Google Scholar] [CrossRef] [PubMed]

- Rowley, K.H.; Cucknell, A.C.; Smith, B.D.; Clark, P.F.; Morritt, D. London’s river of plastic: High levels of microplastics in the Thames water column. Sci. Total Environ. 2020, 740, 140018. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Jia, Q.; Zhao, X.; Li, L.; Nie, Y.; Liu, H.; Ye, J. The occurrence of microplastics in water bodies in urban agglomerations: Impacts of drainage system overflow in wet weather, catchment land-uses, and environmental management practices. Water Res. 2020, 183. [Google Scholar] [CrossRef] [PubMed]

- Wagner, S.; Klöckner, P.; Stier, B.; Römer, M.; Seiwert, B.; Reemtsma, T.; Schmidt, C. Relationship between Discharge and River Plastic Concentrations in a Rural and an Urban Catchment. Environ. Sci. Technol. 2019, 53, 10082–10091. [Google Scholar] [CrossRef] [PubMed]

- Baresel, C.; Olshammar, M. On the Importance of Sanitary Sewer Overflow on the Total Discharge of Microplastics from Sewage Water. J. Environ. Prot. 2019, 10, 1105–1118. [Google Scholar] [CrossRef] [Green Version]

- Schernewski, G.; Radtke, H.; Hauk, R.; Baresel, C.; Olshammar, M.; Oberbeckmann, S. Urban Microplastics Emissions: Effectiveness of Retention Measures and Consequences for the Baltic Sea. Front. Mar. Sci. 2021, 8, 594415. [Google Scholar] [CrossRef]

- Osinski, R.D.; Enders, K.; Gräwe, U.; Klingbeil, K.; Radtke, H. Model uncertainties of a storm and their influence on microplastics/sediment transport in the Baltic Sea. Ocean. Sci. 2020, 16, 1491–1507. [Google Scholar] [CrossRef]

- Osinski, R.D.; Radtke, H. Ensemble hindcasting of wind and wave conditions with WRF and Wavewatch III R driven by ERA5. Ocean. Sci. 2020, 16, 355–371. [Google Scholar] [CrossRef] [Green Version]

- Schernewski, G.; Radtke, H.; Robbe, E.; Haseler, M.; Hauk, R.; Meyer, L.; Piehl, S.; Riedel, J.; Labrenz, M. Emission, Transport, and Deposition of visible Plastics in an Estuary and the Baltic Sea—a Monitoring and Modeling Approach. Environ. Manage. 2021, 68, 860–881. [Google Scholar] [CrossRef]

- Bollmann, U.E.; Simon, M.; Vollertsen, J.; Bester, K. Assessment of input of organic micropollutants and microplastics into the Baltic Sea by urban waters. Mar. Pollut. Bull. 2019, 148, 149–155. [Google Scholar] [CrossRef]

- Schmidt, C.; Kumar, R.; Yang, S.; Büttner, O. Microplastic particle emission from wastewater treatment plant effluents into river networks in Germany: Loads, spatial patterns of concentrations and potential toxicity. Sci. Total Environ. 2020, 737, 139544. [Google Scholar] [CrossRef] [PubMed]

- Castro-Orgaz, O.; Hager, W.H. Subcritical side-weir flow at high lateral discharge. J. Hydraul. Eng. 2012, 138, 777–787. [Google Scholar] [CrossRef] [Green Version]

- Granata, F.; de Marinis, G.; Gargano, R.; Tricarico, C. Novel approach for side weirs in supercritical flow. J. Irrig. Drain. Eng. 2013, 139, 672–679. [Google Scholar] [CrossRef]

- Azamathulla, H.M.; Haghiabi, A.H.; Parsaie, A. Prediction of side weir discharge coefficient by support vector machine technique. Water Supply 2016, 16, 1002–1016. [Google Scholar] [CrossRef] [Green Version]

- Granata, F.; de Marinis, G. Machine learning methods for wastewater hydraulics. Flow. Meas. Instrum. 2017, 57, 1–9. [Google Scholar] [CrossRef]

- Ghaderi, A.; Dasineh, M.; Abbasi, S.; Abraham, J. Investigation of trapezoidal sharp-crested side weir discharge coefficients under subcritical flow regimes using CFD. Appl. Water Sci. 2020, 10, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Saffar, S.; Babarsad, M.S.; Shooshtari, M.M.; Hosein Poormohammadi, M.; Riazi, R. Prediction of the discharge of side weir in the converge channels using artificial neural networks. Flow Meas. Instrum. 2021, 78, 101889. [Google Scholar] [CrossRef]

- Di Nunno, F.; Alves, F.P.; de Marinis, G.; Di Felice, F.; Gargano, R.; Granata, F.; Miozzi, M. Two-Phase PIV-LIF Measurements in a Submerged Bubbly Water Jet. J. Hydraul. Eng. 2019, 145, 04019030. [Google Scholar] [CrossRef]

- Bijankhan, M.; Ferro, V. Dimensional analysis and stage-discharge relationship for weirs: A review. J. Agric. Eng. 2017, 48, 1–11. [Google Scholar] [CrossRef]

- Granata, F.; Gargano, R.; Santopietro, S. A flow field characterization in a circular channel along a side weir. Flow. Meas. Instrum. 2016, 52, 92–100. [Google Scholar] [CrossRef]

- Granata, F.; Di Nunno, F.; Gargano, R.; de Marinis, G. Equivalent Discharge Coefficient of Side Weirs in Circular Channel-A Lazy Machine Learning Approach. Water 2019, 11, 2406. [Google Scholar] [CrossRef] [Green Version]

- Cheval, N.; Gindy, N.; Flowkes, C.; Fahmi, A. Polyamide 66 microspheres metallised with in situ synthesised gold nanoparticles for a catalytic application. Nanoscale Res. Lett. 2012, 7, 182. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mahmoudi-Rad, M.; Najafzadeh, M. Air Entrainment Mechanism in the Vortex Structure: Experimental Study. J. Irrig. Drain. Eng. 2021, 147, 04021007. [Google Scholar] [CrossRef]

- Amiri-Ardakani, Y.; Najafzadeh, M. Pipe Break Rate Assessment While Considering Physical and Operational Factors: A Methodology based on Global Positioning System and Data-Driven Techniques. Water Resour. Manage. 2021, 35, 3703–3720. [Google Scholar] [CrossRef]

- Moore, D.S.; Notz, W.I.; Flinger, M.A. The Basic Practice of Statistics, 8th ed.; W.H. Freeman and Company: New York, NY, USA, 2018; p. 654. [Google Scholar]

| S* | Q* | W*D* = 0.0250± σD* = 0.0250 | W*D* = 0.0375± σD* = 0.0375 | W*D* = 0.0500± σD* = 0.0500 |

|---|---|---|---|---|

| 0.114 | 0.79 | 0.67 ± 0.01 | 0.60 ± 0.01 | 0.66 ± 0.01 |

| 0.8 | 0.75 ± 0.02 | 0.73 ± 0.01 | 0.72 ± 0.02 | |

| 0.83 | 0.78 ± 0.03 | 0.75 ± 0.02 | 0.77 ± 0.03 | |

| 0.129 | 0.73 | 0.59 ± 0.01 | 0.57 ± 0.01 | 0.60 ± 0.02 |

| 0.75 | 0.67 ± 0.03 | 0.69 ± 0.02 | 0.64 ± 0.04 | |

| 0.78 | 0.74 ± 0.05 | 0.72 ± 0.04 | 0.70 ± 0.06 | |

| 0.133 | 0.63 | 0.49 ± 0.02 | 0.58 ± 0.01 | 0.59 ± 0.02 |

| 0.65 | 0.53 ± 0.05 | 0.64 ± 0.01 | 0.65 ± 0.02 | |

| 0.68 | 0.69 ± 0.07 | 0.70 ± 0.02 | 0.70 ± 0.03 | |

| 0.143 | 0.64 | 0.46 ± 0.04 | 0.45 ± 0.03 | 0.39 ± 0.01 |

| 0.66 | 0.53 ± 0.05 | 0.50 ± 0.04 | 0.53 ± 0.04 | |

| 0.68 | 0.61 ± 0.06 | 0.68 ± 0.06 | 0.60 ± 0.05 | |

| 0.150 | 0.59 | 0.46 ± 0.01 | 0.50 ± 0.03 | 0.44 ± 0.03 |

| 0.61 | 0.51 ± 0.03 | 0.55 ± 0.02 | 0.58 ± 0.08 | |

| 0.64 | 0.62 ± 0.05 | 0.70 ± 0.08 | 0.61 ± 0.10 | |

| 0.160 | 0.6 | 0.46 ± 0.02 | 0.49 ± 0.03 | 0.42 ± 0.02 |

| 0.62 | 0.57 ± 0.04 | 0.57 ± 0.05 | 0.62 ± 0.05 | |

| 0.65 | 0.67 ± 0.06 | 0.64 ± 0.10 | 0.64 ± 0.07 | |

| 0.167 | 0.53 | 0.35 ± 0.04 | 0.34 ± 0.04 | 0.37 ± 0.02 |

| 0.55 | 0.50 ± 0.05 | 0.49 ± 0.07 | 0.51 ± 0.03 | |

| 0.57 | 0.58 ± 0.08 | 0.61 ± 0.11 | 0.59 ± 0.06 | |

| 0.180 | 0.57 | 0.42 ± 0.05 | 0.47 ± 0.08 | 0.40 ± 0.08 |

| 0.58 | 0.51 ± 0.10 | 0.52 ± 0.07 | 0.51 ± 0.11 | |

| 0.61 | 0.61 ± 0.05 | 0.62 ± 0.11 | 0.59 ± 0.12 | |

| 0.200 | 0.51 | 0.31 ± 0.06 | 0.30 ± 0.05 | 0.26 ± 0.08 |

| 0.53 | 0.45 ± 0.10 | 0.38 ± 0.08 | 0.36 ± 0.06 | |

| 0.54 | 0.51 ± 0.07 | 0.42 ± 0.11 | 0.45 ± 0.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Nunno, F.; Granata, F.; Parrino, F.; Gargano, R.; de Marinis, G. Microplastics in Combined Sewer Overflows: An Experimental Study. J. Mar. Sci. Eng. 2021, 9, 1415. https://doi.org/10.3390/jmse9121415

Di Nunno F, Granata F, Parrino F, Gargano R, de Marinis G. Microplastics in Combined Sewer Overflows: An Experimental Study. Journal of Marine Science and Engineering. 2021; 9(12):1415. https://doi.org/10.3390/jmse9121415

Chicago/Turabian StyleDi Nunno, Fabio, Francesco Granata, Francesco Parrino, Rudy Gargano, and Giovanni de Marinis. 2021. "Microplastics in Combined Sewer Overflows: An Experimental Study" Journal of Marine Science and Engineering 9, no. 12: 1415. https://doi.org/10.3390/jmse9121415

APA StyleDi Nunno, F., Granata, F., Parrino, F., Gargano, R., & de Marinis, G. (2021). Microplastics in Combined Sewer Overflows: An Experimental Study. Journal of Marine Science and Engineering, 9(12), 1415. https://doi.org/10.3390/jmse9121415