Bio-Based Adhesives for Wooden Boatbuilding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- -

- Epoxy resin:

- •

- Bisphenol A Diglycidyl ether;

- •

- Epoxide derivatives mw < 700.

- -

- Curing agent:

- •

- Alkyl ether polyamine;

- •

- M-Xylene diamine;

- •

- Isophorone diamine.

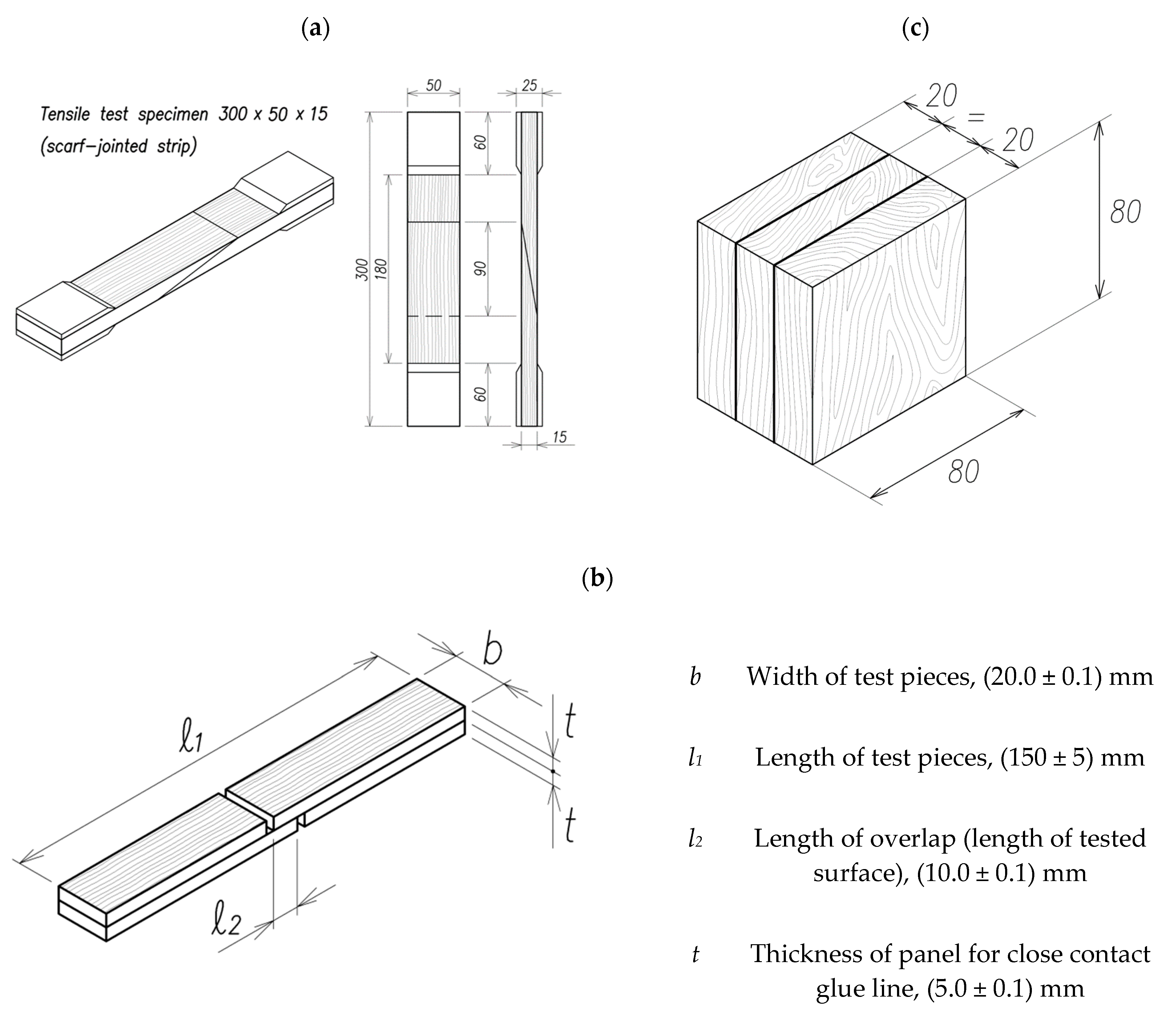

2.2. Methods

- •

- UNI EN 408: “Structural timber and glued laminated timber–Determination of some physical and mechanical properties” [29], used for tensile tests on scarf-jointed strips;

- •

- UNI EN 302-1: “Adhesives for load-bearing timber structures Part 1–Determination of longitudinal tensile shear strength” [30], used for tensile-shear tests on lap-jointed strips;

- •

- ASTM D905-03: “Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading” [31], used to set up the ad hoc compressive loading tests.

3. Results and Discussion

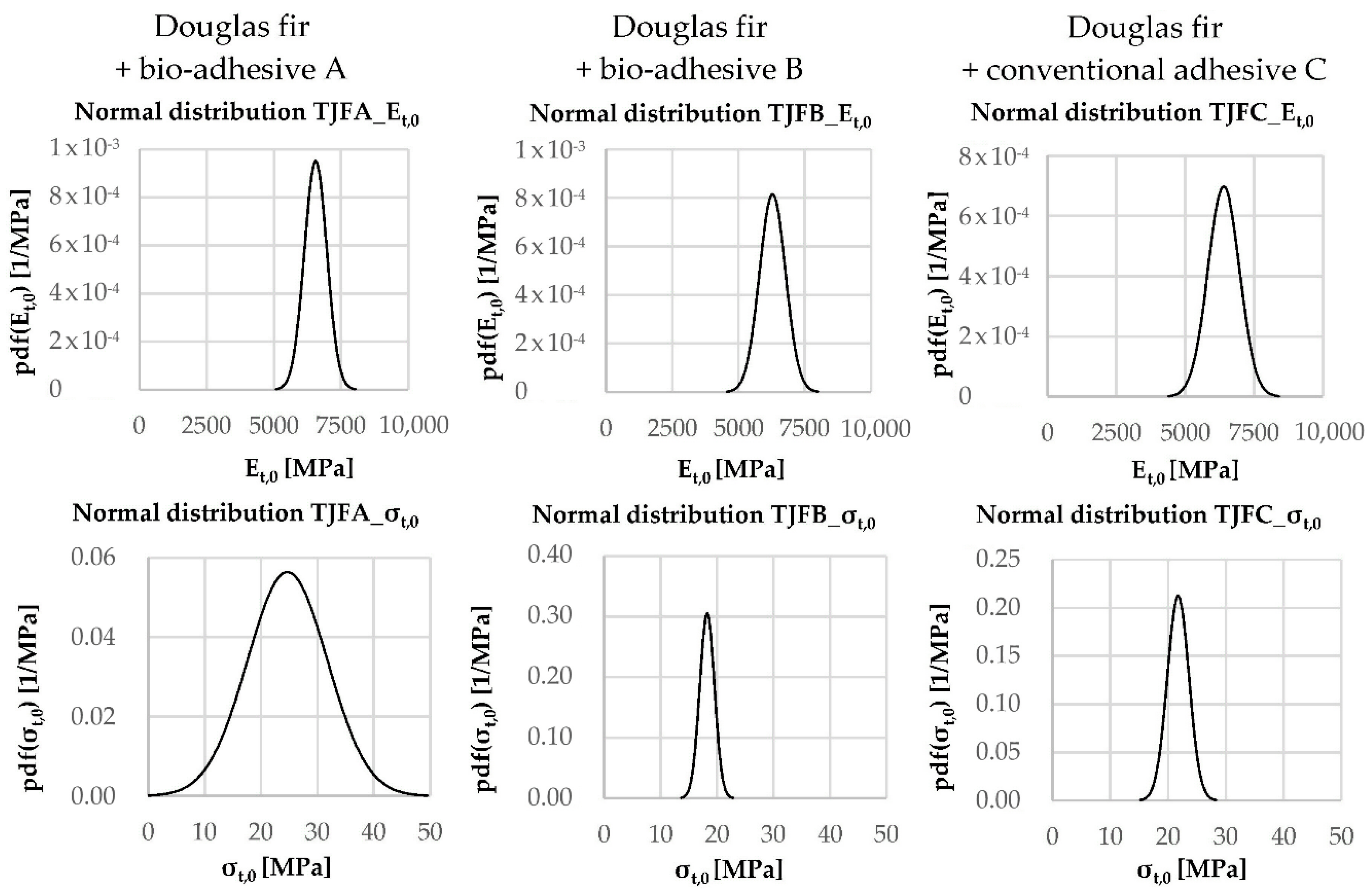

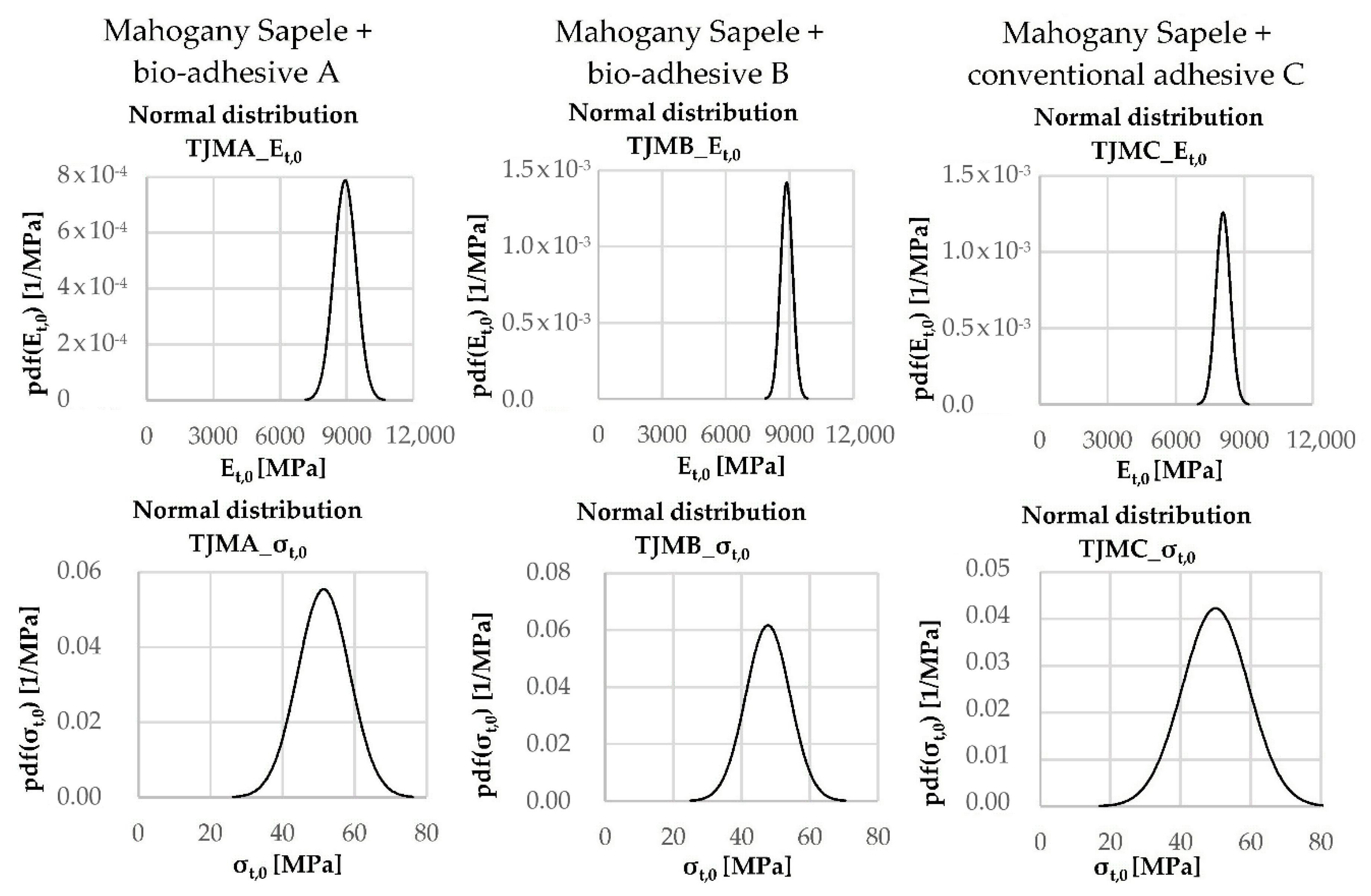

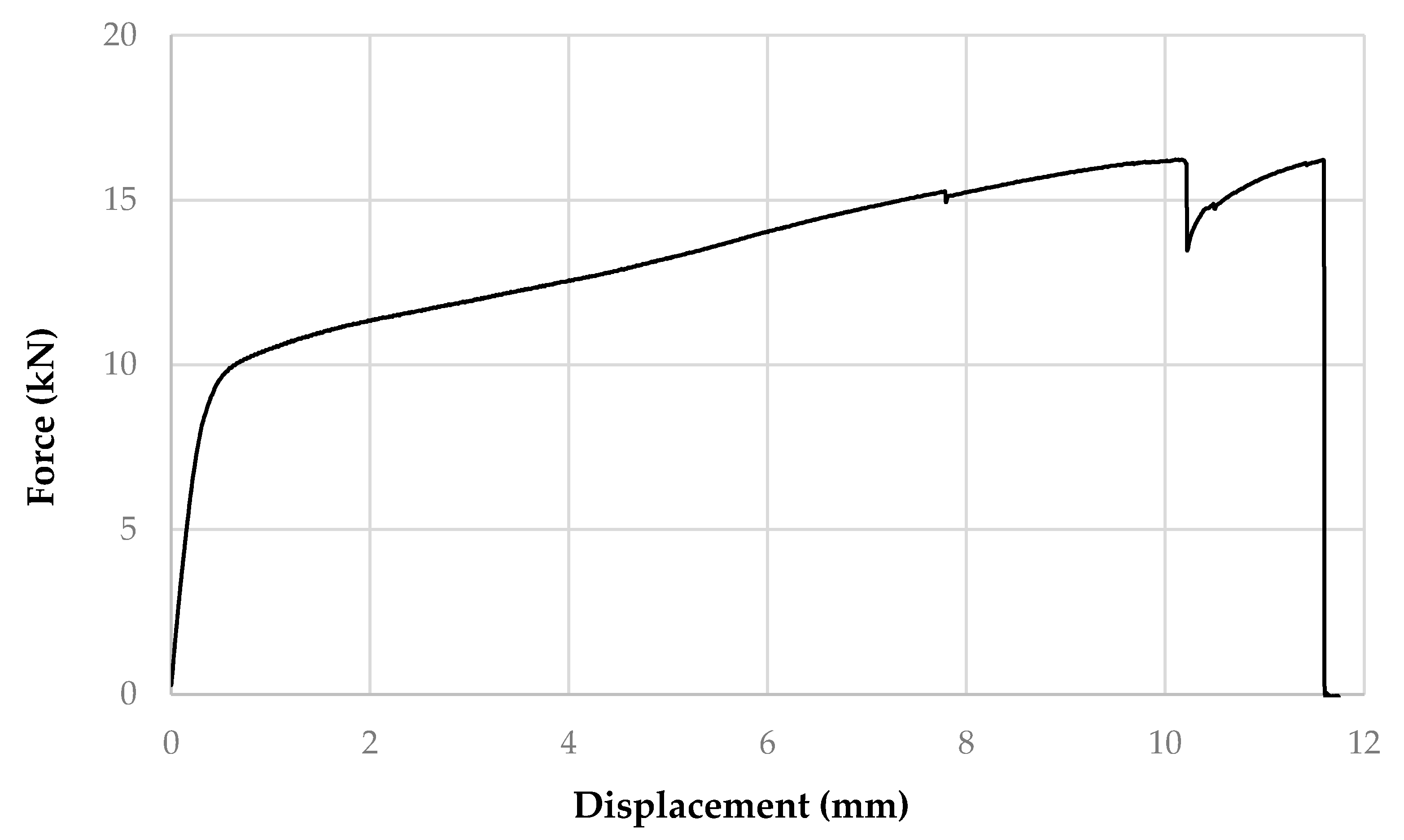

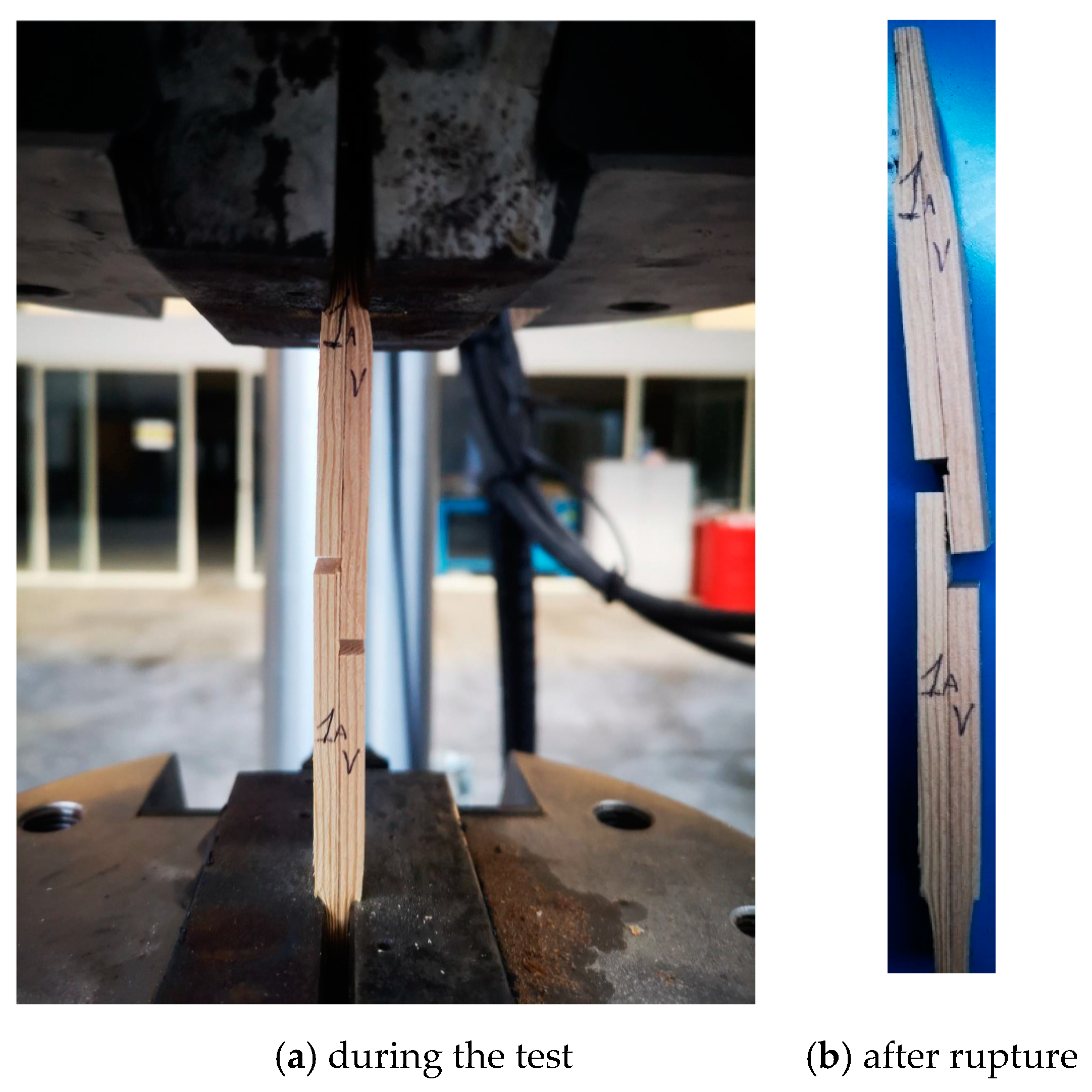

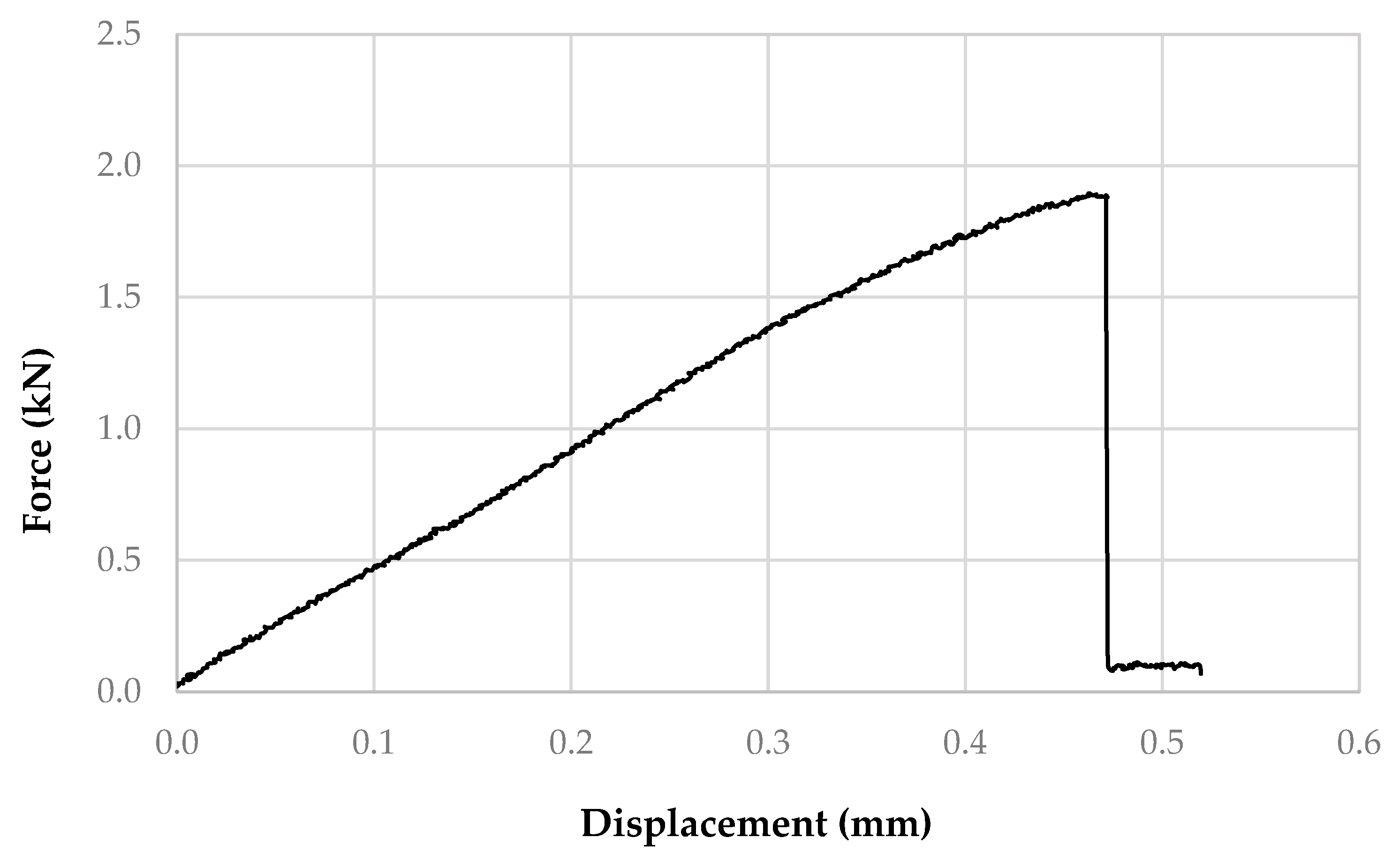

3.1. Tensile Properties of Scarf-Jointed Strips

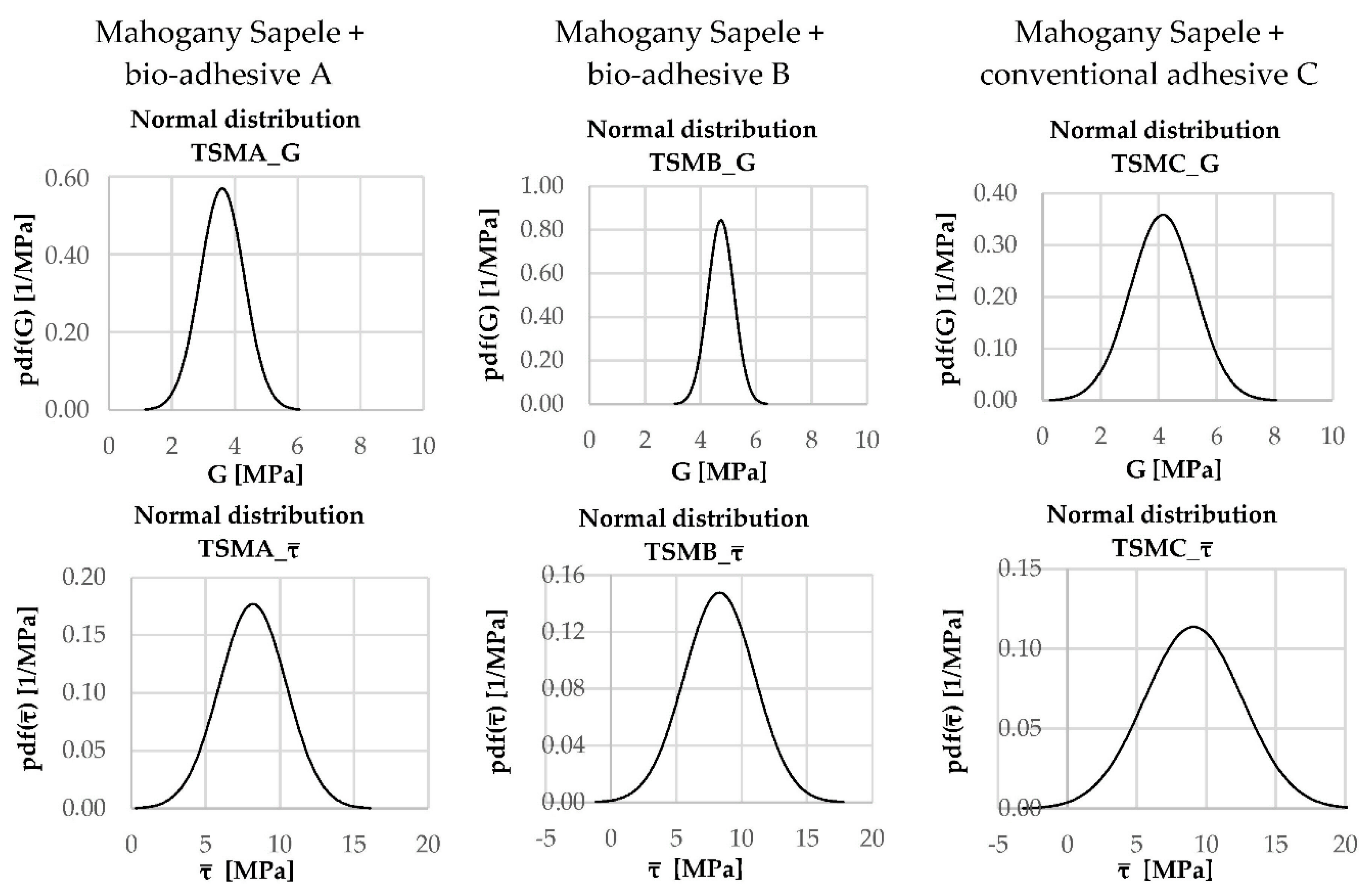

3.2. Shear Properties of Lap Joints by Tensile Loading

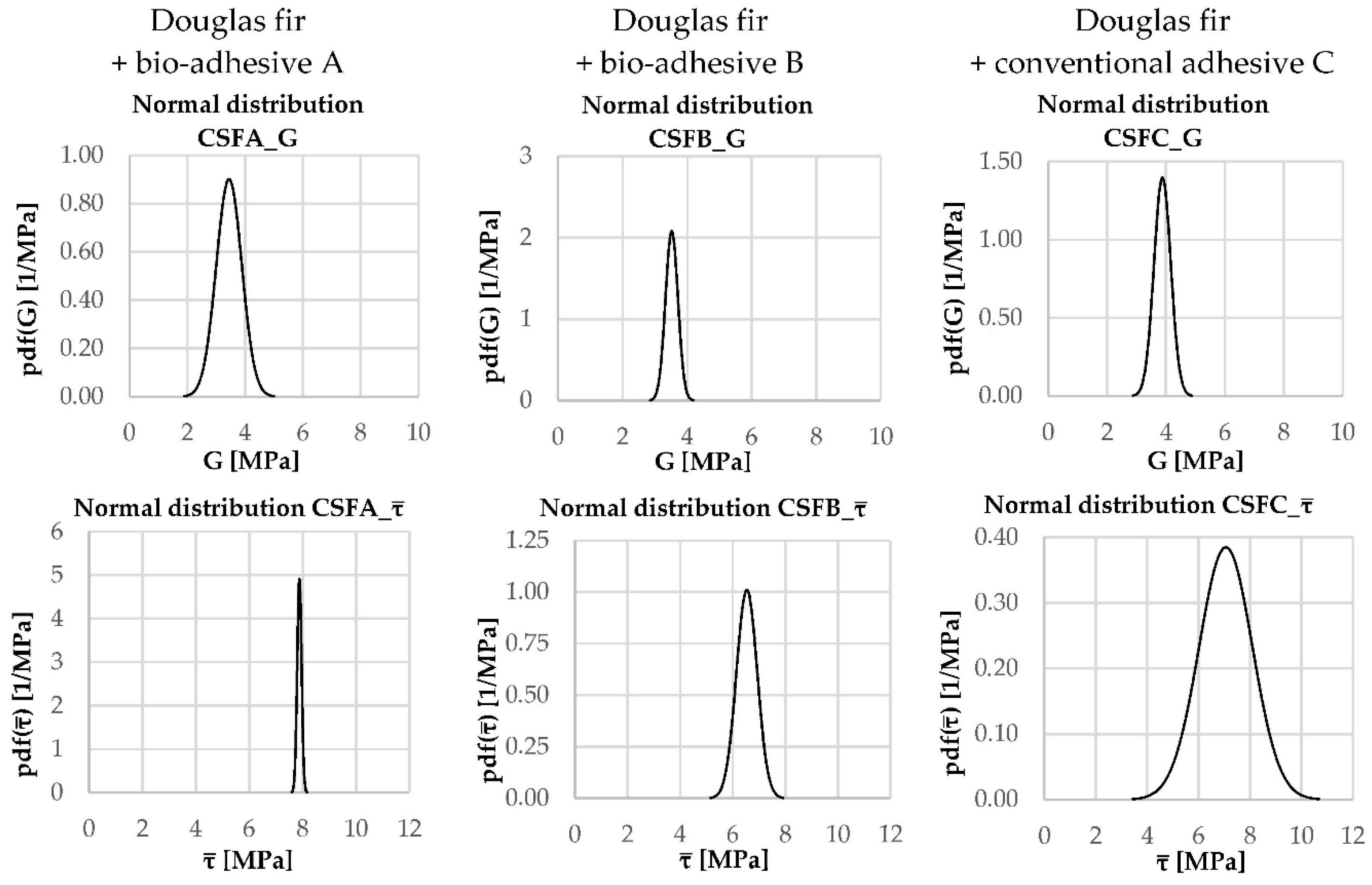

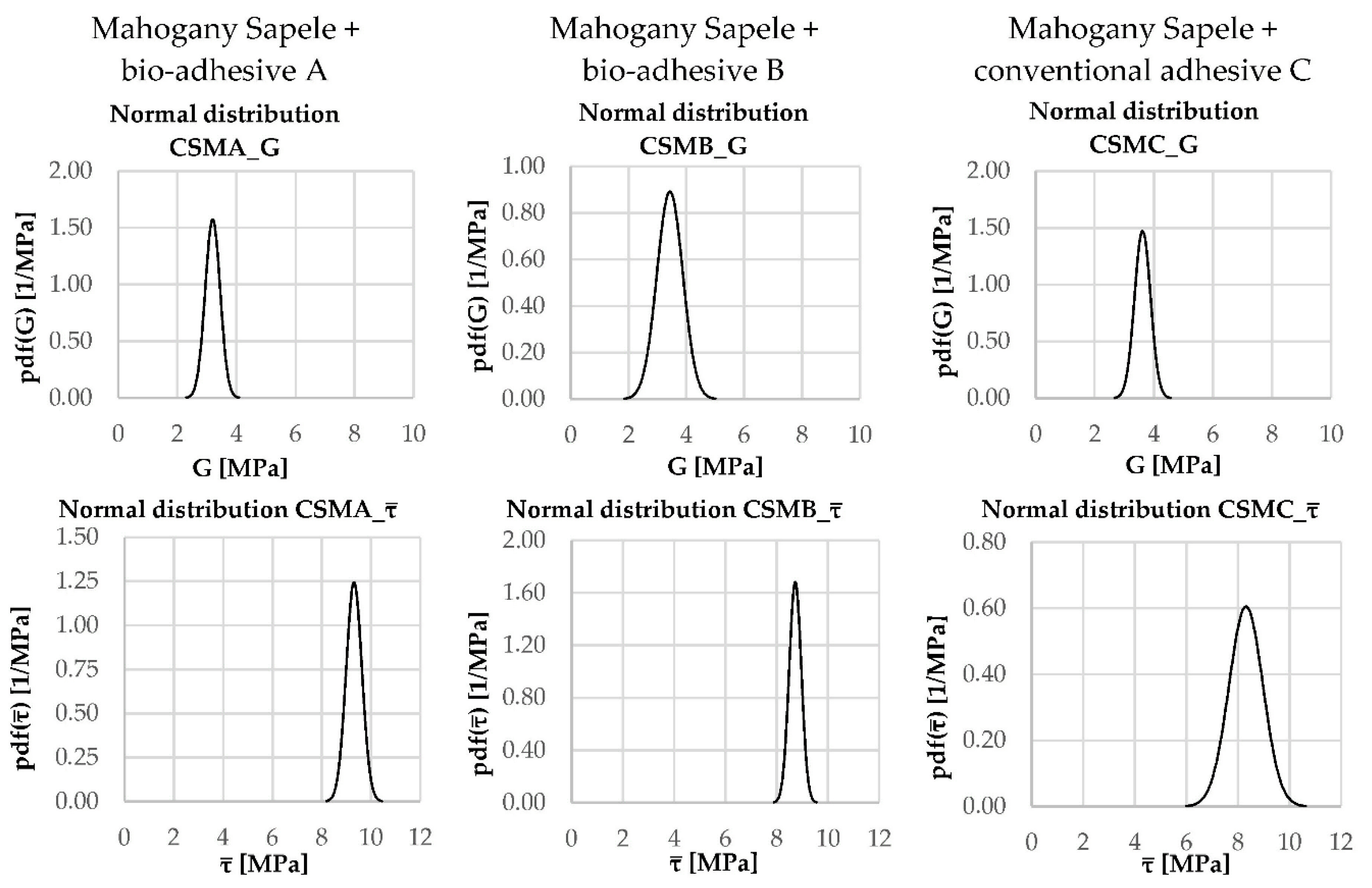

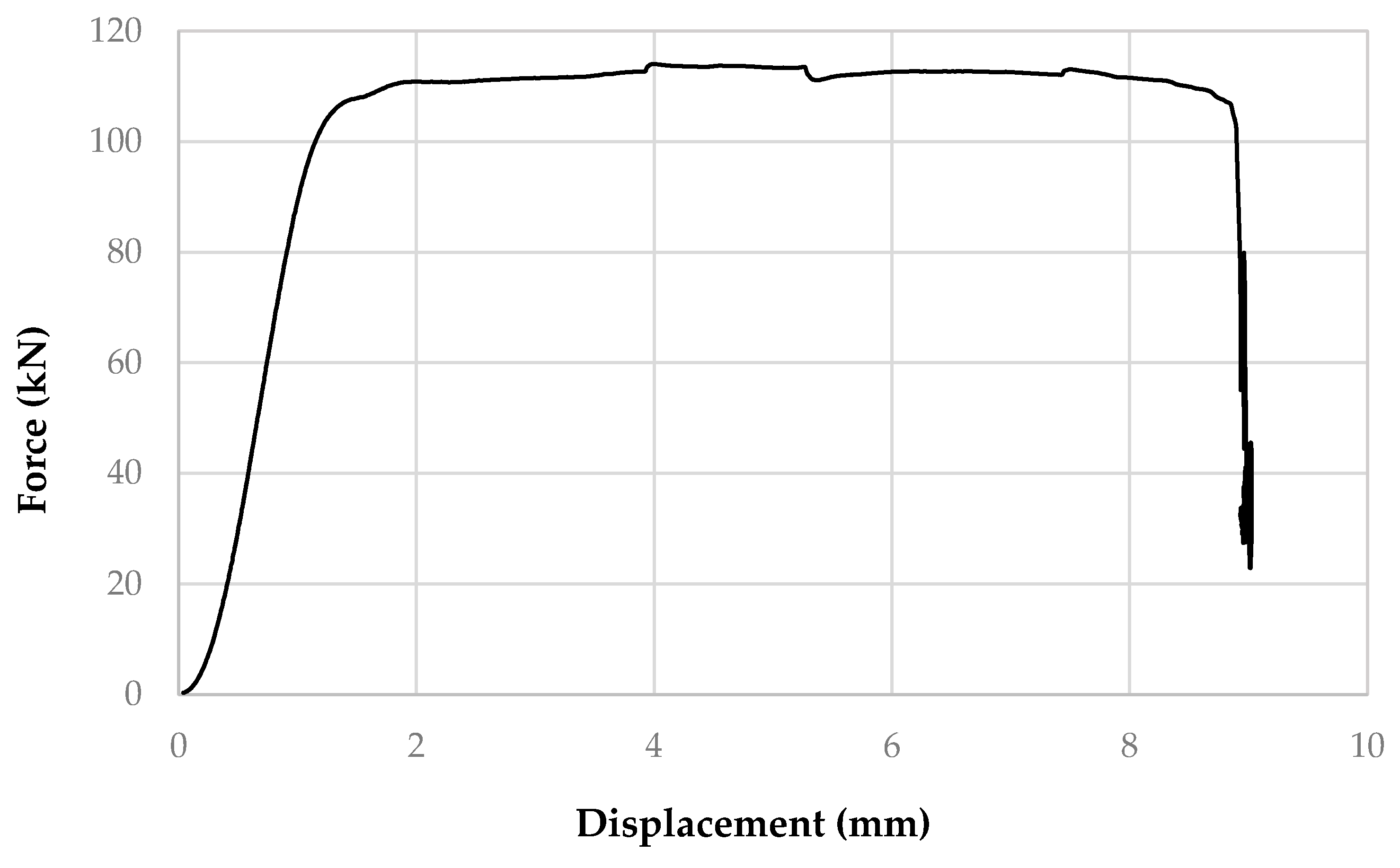

3.3. Shear Properties of Adhesives by Compression Loading

4. Conclusions

- •

- The obtained values of the modulus of elasticity in tension were nearly equal for all the investigated joints.

- •

- The bio-adhesive B was the best alternative to the conventional adhesive for both Douglas fir and Mahogany Sapele.

- •

- The three adhesives gave similar results with no significant differences.

- •

- The bio-adhesive B was the best alternative to the conventional adhesive for both Douglas fir and Mahogany Sapele.

- •

- The bio-adhesive A was the best in terms of shear stress and the worst in terms of shear modulus for Douglas fir, while the bio-adhesive B was the best compromise as it gave a higher shear stress and a slightly lower shear modulus with respect to the conventional adhesive.

- •

- The bio-adhesive A was the best compromise for Mahogany Sapele as it presented the highest shear stress and a slightly lower shear modulus with respect to the conventional adhesive.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Glass transition temperature [°C] | |

| Mean value | |

| RMS | Root mean square |

| Characteristic value (5-percentile) | |

| Tensile strength parallel to grain [MPa] | |

| Maximum load reached during the test [N] | |

| Area of the cross section of the specimen [mm2] | |

| Modulus of elasticity in tension parallel to grain [MPa] | |

| Reference length [mm] | |

| Load increase on the straight part of the force-displacement curve [MPa] | |

| Displacement increase corresponding to the range [mm] | |

| Coefficient of determination | |

| Mean shear stress [MPa] | |

| G | Shear modulus [MPa] |

| A | Bonded surface area [mm2] |

| γ | Shear strain |

| c | Mean adhesive layer thickness [mm] |

Appendix A

References

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine application of fiber reinforced composites: A review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Weitzenböck, J. Adhesives in Marine Engineering, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Corigliano, P.; Ragni, M.; Castagnetti, D.; Crupi, V.; Dragoni, E.; Guglielmino, E.; Ragni, M.; Castagnetti, D.; Crupi, V.; Dragoni, E.; et al. Measuring the static shear strength of anaerobic adhesives in finite thickness under high pressure. J. Adhes. 2019, 1–18. [Google Scholar] [CrossRef]

- Grabovac, I. Bonded composite solution to ship reinforcement. Compos. Part A Appl. Sci. Manuf. 2003, 34, 847–854. [Google Scholar] [CrossRef]

- Sapronov, O.; Maruschak, P.; Sotsenko, V.; Buketova, N.; Da Gloria De Deus, A.B.; Sapronova, A.; Prentkovskis, O. Development and use of new polymer adhesives for the restoration of marine equipment units. J. Mar. Sci. Eng. 2020, 8, 527. [Google Scholar] [CrossRef]

- Kolat, K.; Neşer, G.; Özes, Ç. The effect of sea water exposure on the interfacial fracture of some sandwich systems in marine use. Compos. Struct. 2007, 78, 11–17. [Google Scholar] [CrossRef]

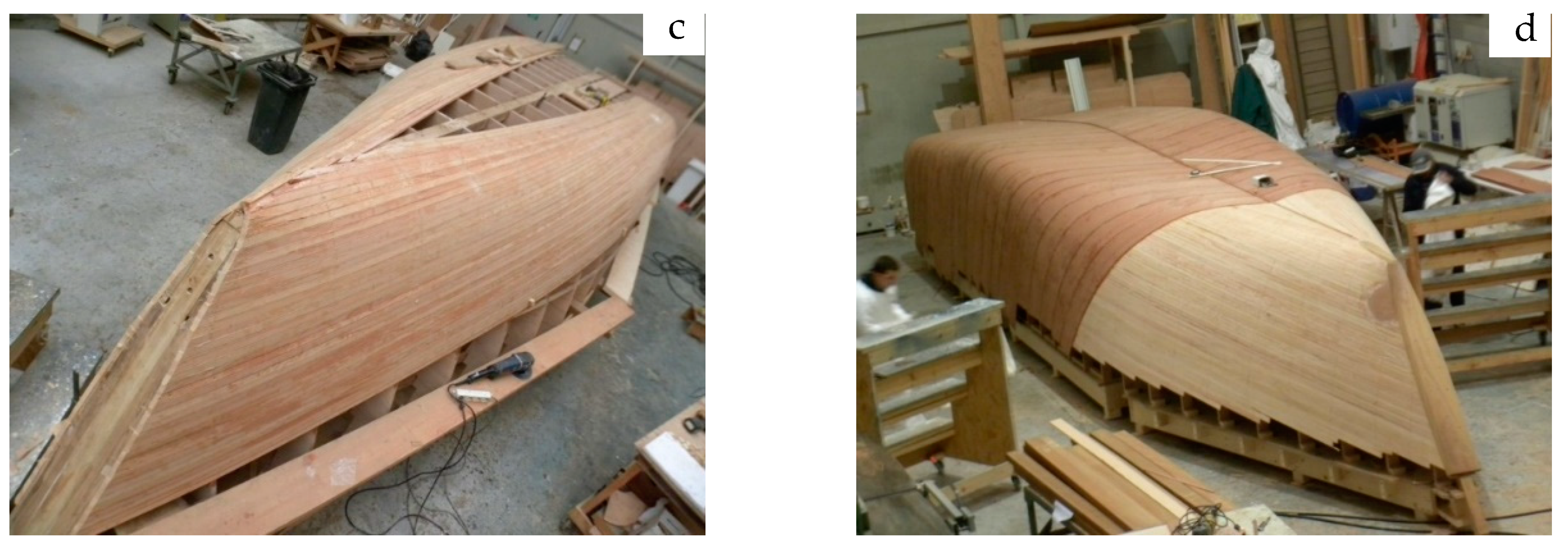

- Nasso, C.; la Monaca, U.; Marinò, A.; Bertagna, S.; Bucci, V. The strip planking: An eco-friendly solution for the end-of-life of ships. In Proceedings of the NAV International Conference on Ship and Shipping Research, Trieste, Italy, 20–22 June 2018; IOS Press: Amsterdam, The Netherlands, 2018. [Google Scholar]

- López, F.A.; Martín, M.I.; Alguacil, F.J.; Rincón, J.M.; Centeno, T.A.; Romero, M. Thermolysis of fibreglass polyester composite and reutilisation of the glass fibre residue to obtain a glass-ceramic material. J. Anal. Appl. Pyrolys. 2012, 93, 104–112. [Google Scholar] [CrossRef]

- Nahil, M.A.; Williams, P.T. Recycling of carbon fibre reinforced polymeric waste for the production of activated carbon fibres. J. Anal. Appl. Pyrolys. 2011, 91, 67–75. [Google Scholar] [CrossRef]

- Palmer, J.; Savage, L.; Ghita, O.R.; Evans, K.E. Sheet moulding compound (SMC) from carbon fibre recyclate. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1232–1237. [Google Scholar] [CrossRef]

- Pannkoke, K.; Oethe, M.; Busse, J. Efficient prepreg-recycling at low temperatures. Asian Text. J. 2000, 9, 70–74. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials-current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef]

- Bose, S.; Vijith, V. Wooden Boat Building For Sustainable Development. Int. J. Innov. Res. Dev. 2012, 1, 345–360. [Google Scholar]

- Önal, M.; Neşer, G. End-of-life alternatives of glass reinforced polyester boat hulls compared by LCA. Adv. Compos. Lett. 2018, 27, 134–141. [Google Scholar] [CrossRef]

- Nasso, C.; La Monaca, U.; Bertagna, S.; Braidotti, L.; Mauro, F.; Trincas, G.; Marinó, A.; Bucci, V. Integrated design of an eco-friendly wooden passenger craft for inland navigation. Int. Shipbuild. Prog. 2019, 66, 35–55. [Google Scholar] [CrossRef]

- Castegnaro, S.; Gomiero, C.; Battisti, C.; Poli, M.; Basile, M.; Barucco, P.; Pizzarello, U.; Quaresimin, M.; Lazzaretto, A. A bio-composite racing sailboat: Materials selection, design, manufacturing and sailing. Ocean Eng. 2017, 133, 142–150. [Google Scholar] [CrossRef]

- Praharsi, Y.; Jami’in, M.A.; Suhardjito, G.; Wee, H.M. Modeling a traditional fishing boat building in East Java, Indonesia. Ocean Eng. 2019, 189, 106234. [Google Scholar] [CrossRef]

- Lopez-Anido, R.; Michael, A.P.; Sandford, T.C. Experimental characterization of FRP composite-wood pile structural response by bending tests. Mar. Struct. 2003, 16, 257–274. [Google Scholar] [CrossRef]

- Bucci, V.; Corigliano, P.; Crupi, V.; Epasto, G.; Guglielmino, E.; Marinò, A. Experimental investigation on Iroko wood used in shipbuilding. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Epasto, G.; Guglielmino, E.; Maugeri, N.; Marinò, A. Experimental and theoretical analyses of Iroko wood laminates. Compos. Part B Eng. 2017, 112. [Google Scholar] [CrossRef]

- Yang, T.H.; Wang, S.Y.; Lin, C.J.; Tsai, M.J. Evaluation of the mechanical properties of Douglas-fir and Japanese cedar lumber and its structural glulam by nondestructive techniques. Constr. Build. Mater. 2008, 22, 487–493. [Google Scholar] [CrossRef]

- Winandy, J.; Morrell, J. Relationship between incipient decay, strength, and chemical composition of Douglas-fir heartwood. Wood Fiber Sci. 1993, 25, 278–288. [Google Scholar]

- Susainathan, J.; Eyma, F.; De Luycker, E.; Cantarel, A.; Castanie, B. Experimental investigation of impact behavior of wood-based sandwich structures. Compos. Part A Appl. Sci. Manuf. 2018, 109, 10–19. [Google Scholar] [CrossRef]

- Demircioğlu, T.K.; Balıkoğlu, F.; İnal, O.; Arslan, N.; Ataş, A. Experimental investigation on low-velocity impact response of wood skinned sandwich composites with different core configurations. Mater. Today Commun. 2018, 17, 31–39. [Google Scholar] [CrossRef]

- Nicolson, I. Cold-Molded and Strip-Planked Wood Boatbuilding; Adlard Coles Nautical: London, UK, 1991; ISBN 9780540071470. [Google Scholar]

- Germanischer Lloyd, Rules for Classification and Construction. Ship Technology; DNV GL SE: Hamburg, Germany, 2011. [Google Scholar]

- UNI EN 350:2016-Durability of Wood and Wood-Based Products-Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials; CEN: Brussels, Belgium, 2016.

- DIN EN 408-Structural Timber and Glued Laminated Timber. Determination of Some Physical and Mechanical Properties; CEN: Brussels, Belgium, 2004. [Google Scholar]

- UNI EN 302-1-Adhesives for Load-Bearing Timber Structures-Test Methods-Part 1: Determination of Longitudinal Tensile Shear Strength; SIST EN: Stockholm, Sweden, 2013.

- ASTM International D905-03: Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading; ASTM International: West Conshohocken, PA, USA, 2003.

| Property | Douglas Fir | Mahogany Sapele |

|---|---|---|

| Origin | North West of America | Ivory Coast, Congo, Nigeria, Ghana |

| Grain | Straight | Slightly interlocked |

| Log diameter [cm] | From 50 to 80 | From 70 to 120 |

| Specific gravity * | 0.54 ± 0.04 | 0.69 ± 0.04 |

| Fibre saturation point [%] | 27 | 29 |

| Crushing strength [MPa] | 50 ± 6 | 62 ± 7 |

| Static bending strength * [MPa] | 91 ± 6 | 102 ± 11 |

| Modulus of elasticity * [MPa] | 16,800 ± 1550 | 13,960 ± 2403 |

| Treatability (according to Standard EN 350:2016 [28]) | Class 4: not permeable | Class 3: poorly permeable |

| Conventional Epoxy Adhesive | Bio-Based Adhesives | ||

|---|---|---|---|

| C | A | B | |

| Pot life [min] | - | - | - |

| at 20 °C | 37 | - | - |

| at 25 °C | - | 18 | 58 |

| Viscosity (of the mixes) [mPa s] | - | - | - |

| at 20 °C | 800 | - | - |

| at 25 °C | - | 1300 | 1100 |

| at 40 °C | 240 | 600 | 377 |

| Ultimate Tg [°C] | 62 | 75 | 73 |

| Tensile strength [MPa] | 64 | 64 | 52 |

| Tensile modulus [MPa] | 2850 | 2886 | 2599 |

| Tensile elongation at Fmax/at break [%] | 3.6/6.9 | 4.51/6.27 | 4.3/11.3 |

| Flexural strength [MPa] | 102 | (117) * | 73 |

| Flexural modulus [MPa] | 3070 | (2921) * | 2104 |

| Natural-origin content [% wt] | - | 34.8 | 45.4 |

| Test Code | Wood Code | Adhesive Code |

|---|---|---|

| CS Compression Shear | F Douglas Fir | A Bio-based epoxy resin A |

| TS Tensile Shear | M Mahogany Sapele | B Bio-based epoxy resin B |

| TJ Tensile Scarf-Joint | - | C Conventional epoxy resin |

[MPa] | [MPa] | ||

|---|---|---|---|

| (TJFA): Douglas fir–bio-adhesive A | 6556 | 24.68 | |

| RMS | 419 | 7.072 | |

| 5866 | 13.04 | ||

| (TJFB): Douglas fir–bio-adhesive B | 6279 | 18.25 | |

| RMS | 490 | 1.306 | |

| 5473 | 16.10 | ||

| (TJFC): Douglas fir–conventional adhesive C | 6392 | 21.74 | |

| RMS | 572 | 1.877 | |

| 5451 | 18.65 |

[MPa] | [MPa] | ||

|---|---|---|---|

| (TJMA): Mahogany Sapele–bio-adhive A | 8926 | 50.90 | |

| RMS | 506 | 7.196 | |

| 8093 | 39.07 | ||

| (TJMB): Mahogany Sapele–bio-adhesive B | 8853 | 48.31 | |

| RMS | 281 | 6.375 | |

| 8391 | 37.82 | ||

| (TJMC): Mahogany Sapele–conventional adhesive C | 8071 | 49.99 | |

| RMS | 317 | 9.437 | |

| 7550 | 34.46 |

| G [MPa] | [MPa] | ||

|---|---|---|---|

| (TSFA): Douglas fir–bio-adhesive A | 4.930 | 4.854 | |

| RMS | 0.853 | 0.674 | |

| 3.526 | 3.744 | ||

| (TSFB): Douglas fir–bio-adhesive B | 3.760 | 8.465 | |

| RMS | 0.493 | 1.394 | |

| 2.949 | 6.171 | ||

| (TSFC): Douglas fir–conventional adhesive C | 4.531 | 7.916 | |

| RMS | 0.987 | 0.795 | |

| 2.907 | 6.609 |

| G [MPa] | [MPa] | ||

|---|---|---|---|

| (TSMA): Mahogany Sapele–bio-adhesive A | 3.598 | 8.180 | |

| RMS | 0.701 | 2.254 | |

| 2.446 | 4.472 | ||

| (TSMB): Mahogany Sapele–bio-adhesive B | 4.734 | 8.309 | |

| RMS | 0.473 | 2.702 | |

| 3.957 | 3.865 | ||

| (TSMC): Mahogany Sapele–conventional adhesive C | 4.143 | 9.078 | |

| RMS | 1.111 | 3.506 | |

| 2.314 | 3.311 |

| G [MPa] | [MPa] | ||

|---|---|---|---|

| (CSFA): Douglas fir–bio-adhesive A | 3.442 | 7.875 | |

| RMS | 0.442 | 0.081 | |

| 2.715 | 7.741 | ||

| (CSFB): Douglas fir–bio-adhesive B | 3.522 | 6.536 | |

| RMS | 0.192 | 0.395 | |

| 3.206 | 5.887 | ||

| (CSFC): Douglas fir–conventional adhesive C | 3.880 | 7.409 | |

| RMS | 0.285 | 0.306 | |

| 3.411 | 5.352 |

| G [MPa] | [MPa] | ||

|---|---|---|---|

| (CSMA): Mahogany Sapele–bio-adhesive A | 3.196 | 9.308 | |

| RMS | 0.254 | 0.321 | |

| 2.778 | 8.780 | ||

| (CSMB): Mahogany Sapele–bio-adhesive B | 3.431 | 8.724 | |

| RMS | 0.447 | 0.237 | |

| 2.695 | 8.334 | ||

| (CSMC): Mahogany Sapele–conventional adhesive C | 3.618 | 8.373 | |

| RMS | 0.271 | 0.686 | |

| 3.172 | 7.245 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corigliano, P.; Crupi, V.; Bertagna, S.; Marinò, A. Bio-Based Adhesives for Wooden Boatbuilding. J. Mar. Sci. Eng. 2021, 9, 28. https://doi.org/10.3390/jmse9010028

Corigliano P, Crupi V, Bertagna S, Marinò A. Bio-Based Adhesives for Wooden Boatbuilding. Journal of Marine Science and Engineering. 2021; 9(1):28. https://doi.org/10.3390/jmse9010028

Chicago/Turabian StyleCorigliano, Pasqualino, Vincenzo Crupi, Serena Bertagna, and Alberto Marinò. 2021. "Bio-Based Adhesives for Wooden Boatbuilding" Journal of Marine Science and Engineering 9, no. 1: 28. https://doi.org/10.3390/jmse9010028

APA StyleCorigliano, P., Crupi, V., Bertagna, S., & Marinò, A. (2021). Bio-Based Adhesives for Wooden Boatbuilding. Journal of Marine Science and Engineering, 9(1), 28. https://doi.org/10.3390/jmse9010028