1. Introduction

Soft soils are widely distributed all over the world and are found in coastal areas and round rivers and lakes. For example, there are deep soft soils in North America, Northern Europe and Southeast Asia [

1,

2,

3]. Soft soil has the engineering properties of low shear strength, high compressibility and low permeability, and its compressibility is the key parameter determining the deformation law of a foundation. Soil compressibility is reflected in two aspects: as the excess pore water pressure dissipates, the effective stress increases, and the compressive deformation is the primary consolidation deformation of the soil. After the excess pore water pressure is completely dissipated and the effective stress becomes basically stable, the bound water film on the surface of the soil particles creep and the rearrangement of the soil structure leads to the secondary compression deformation of the soil [

4].

Many secondary safety problems and engineering hazards are caused by secondary compression deformation. The Italian Leaning Tower of Pisa is caused by excessive uneven settlement due to secondary compression deformation of its foundation. Built in 1904, the Mexico City’s Art Palace is located on 25-m-thick soft soil. The ultrahigh compressibility of this soft soil is rare, with natural moisture content between 150% and 600%, and the highest void ratio is 12. Since its establishment, its settlement has been as much as 4 m [

1]. Therefore, the study of secondary compression deformation is very important in engineering construction. With the improvement in the requirements for postconstruction settlement of soft soil foundations in actual engineering, the role of secondary compression and its influencing factors have attracted wide attention.

As a multiphase medium, soft soil’s properties are closely related to the soil composition and structural characteristics. Currently, research on the secondary compression deformation law of soil is mainly focused on the influence of pore moisture content, load, loading history and loading time on secondary compression [

5,

6,

7,

8,

9,

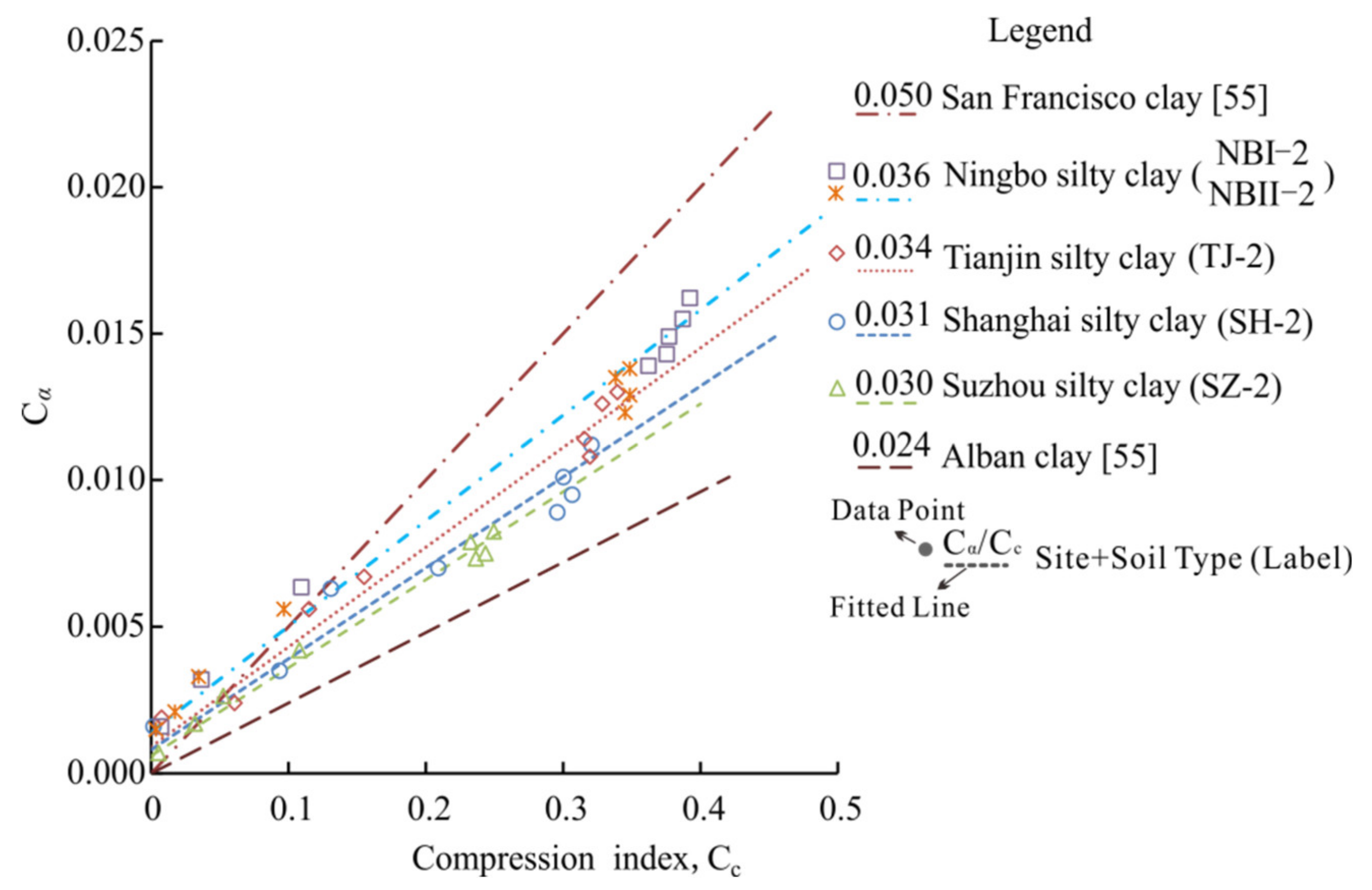

10]. There have been some studies on the effects of different soil compositions on the secondary compression characteristics. Mesri summarized the relationship between the secondary compression coefficient C

α and the compression index C

c of 22 geotechnical materials [

11,

12,

13]. The primary minerals are often the main components of the silt fraction, mainly including quartz and feldspar, which are resistant to weathering. The secondary minerals are mainly composed of clay minerals, including illite, kaolinite, chlorite, and illite–smectite mixed layers. The illite–smectite mixed layers and illite are relatively hydrophilic, and the bound water content is high, which has a great influence on the creep properties of soft soil. The mineral composition and content have important influences on the physical and mechanical properties [

14,

15,

16]. To study the influence of mineral composition and content on the one-dimensional compressibility of soft soil, soil samples mixed with some secondary minerals and silt have been examined, such as in research on the compressibility of different proportions of kaolin, illite and silty sand mixtures, as well as on the influence of several mineral component content on the compression characteristics; furthermore, the compressibility of kaolin and montmorillonite were compared [

17,

18,

19]. However, most research is based on the compressibility of remolded soil. The understanding of the influence of the composition of undisturbed soil on the secondary compression characteristics is not sufficiently comprehensive.

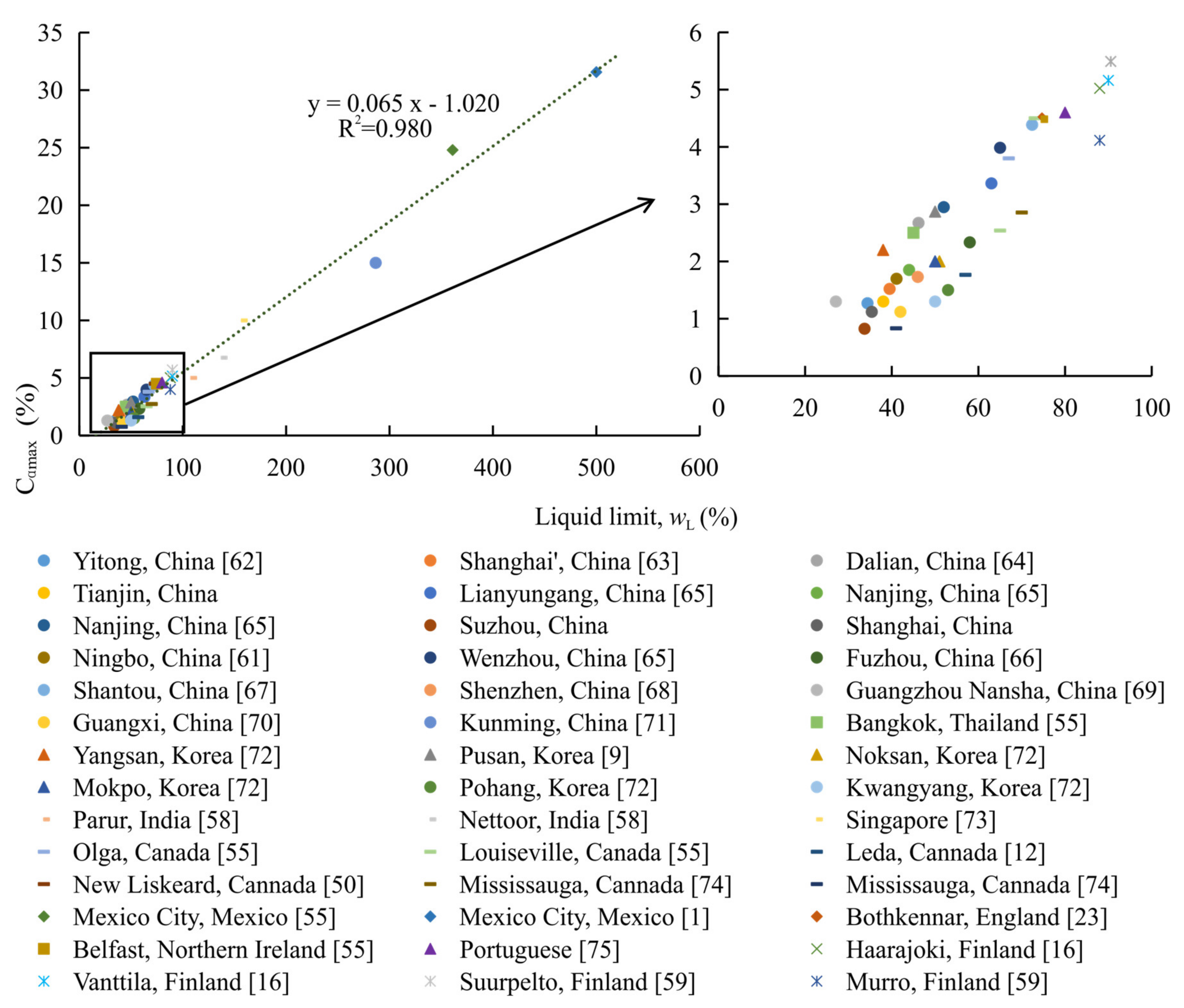

The prediction method for the secondary compression coefficient C

α proposed by Mesri is the most famous for the empirical relationship between ratio of the C

α and the compression index C

c [

11,

12,

13]. The slope of the curve in the secondary compression stage of the one-dimensional compression curve is C

α, and this secondary compression coefficient can be determined according to the compression index C

c of the soil [

13]. In 1967, Bjerrum proposed the isochronous

e–lg

p curve, which is used to calculate the secondary compression deformation of remolded soil [

20]. These studies, based on remolded soils, suggest that the secondary compression coefficient of the soil does not change with time. Regarding the relationship between the secondary compression coefficient C

α and pressure, Bjerrum and Newland believed that it is independent of consolidation pressure [

20,

21]. Horn and Lambe considered that the secondary compression coefficient is independent of the incremental ratio of the load but depends on the final consolidation pressure [

22].

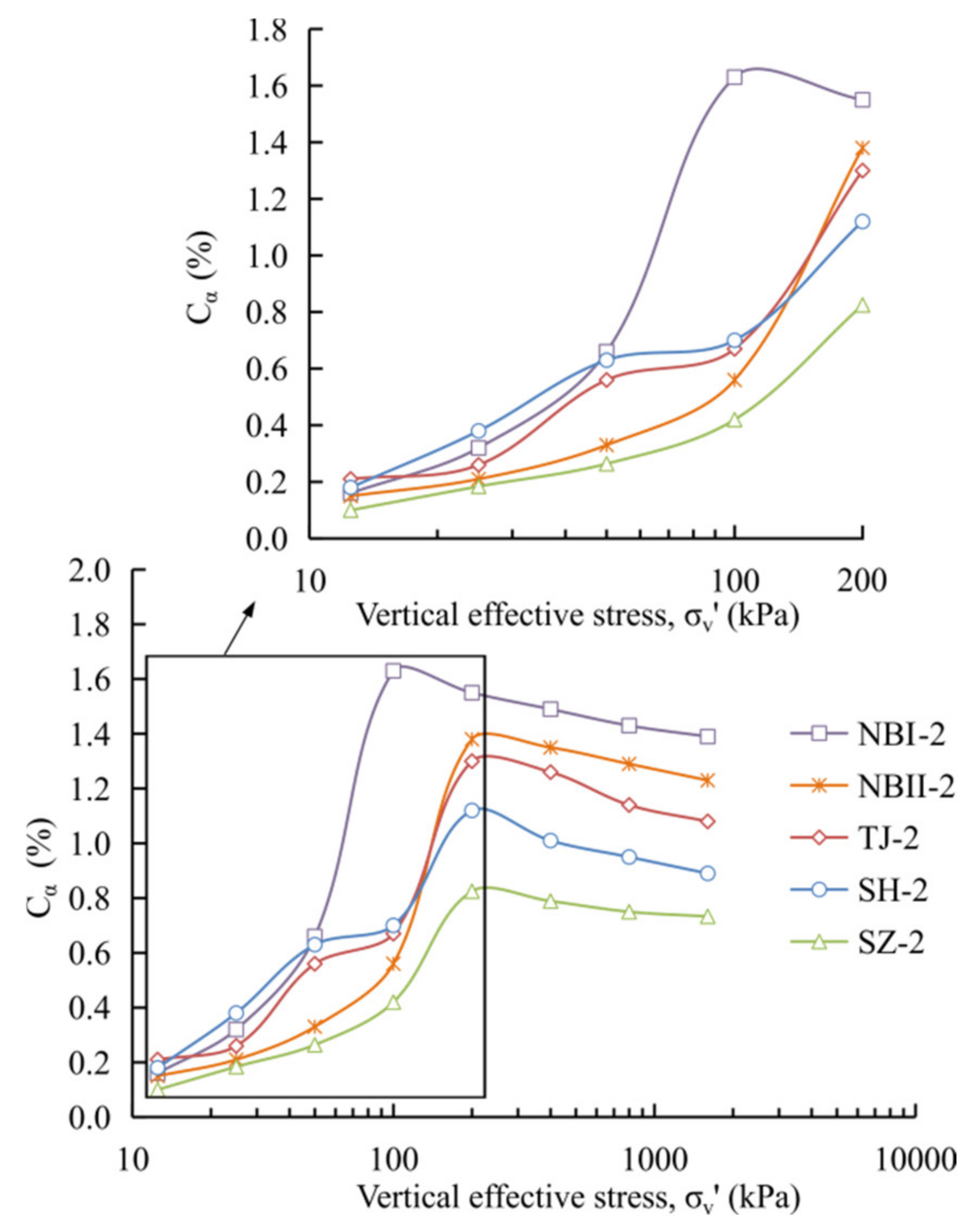

Another view is that the secondary compression coefficient C

α is related to pressure. It was found through experiments that as the pressure increases, the value of C

α increases from small to large and then decreases [

23]. For example, it was found by studying Hangzhou undisturbed clay that when the pressure was less than a certain value, the secondary compression coefficient increased with the pressure, and when the pressure was greater than this certain value, the secondary compression coefficient did not change with the pressure, but this certain value was not well defined [

24]. According to the research of Lei et al., on undisturbed marine soft soil in Tianjin, the secondary compression coefficient C

α is related to pressure, and they pointed out that the boundary point of the pressure is the pre-consolidation pressure [

25]. The secondary compression is related to the pressure when the soil is in the over-consolidated state and it is independent of the pressure during normal consolidation [

26].

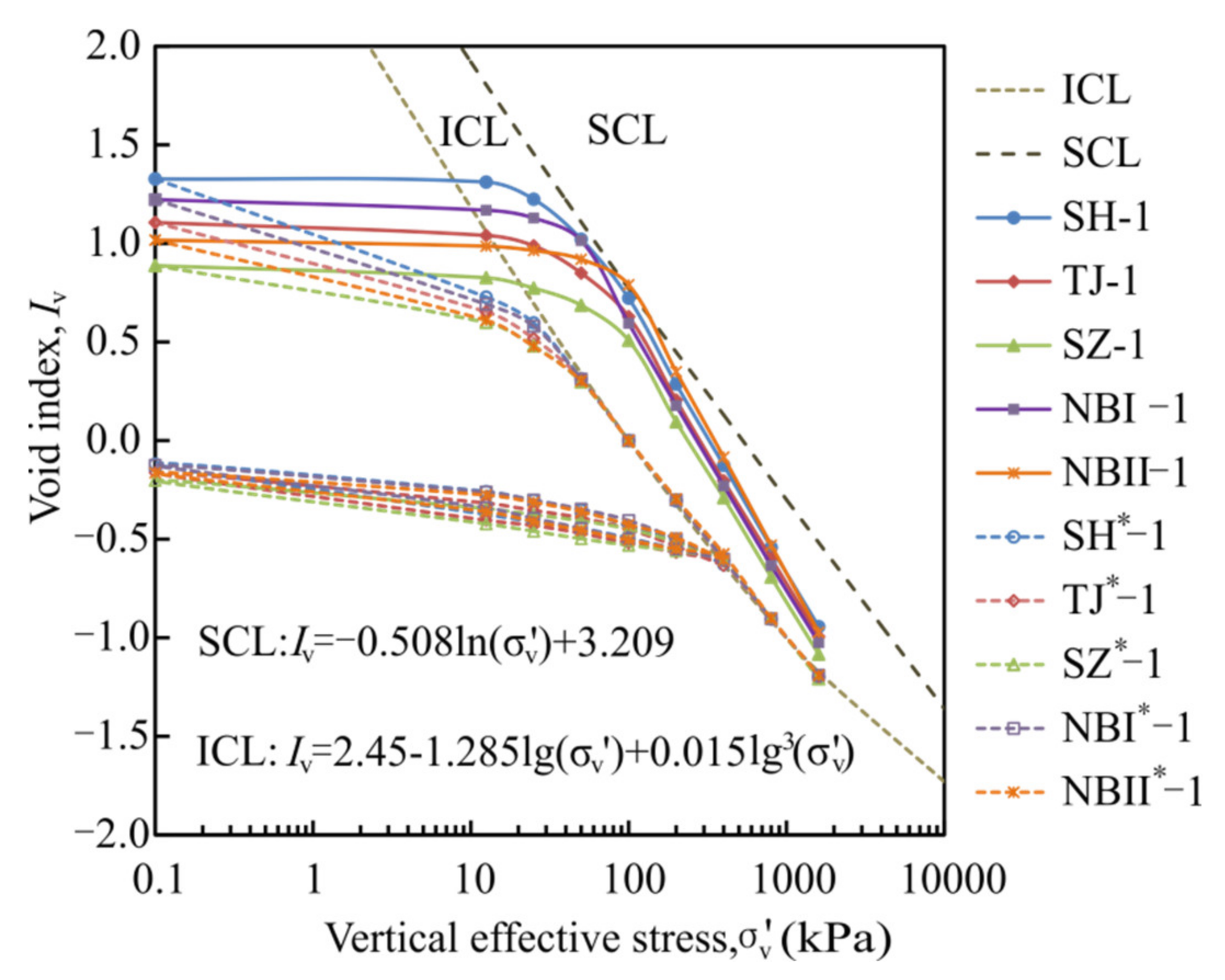

The above viewpoints and conclusions are reasonable and applicable under specific conditions, with more extensive research on secondary compression, the viewpoint that Cα varies with the consolidation pressure has been widely accepted, but there is no uniform and powerful conclusion on the load boundary points of Cα related to the pressure. The effect of soil structure on secondary compression and the relationship between structure and pressure are still worth studying.

Naturally deposited soft soils are affected by the structure during and after the deposition process. It has been well documented that such deposits behave differently under disturbed or remolded conditions [

27,

28,

29,

30]. This behavior difference results from structural resistance. The influence of the soil structure mainly refers to cementation, thixotropy, hardening, time effect eluviation and the rate of sedimentation [

31,

32]. Hattab et al. thought that the presence of soil structure could lead to an overestimation of the pre-consolidation pressure [

33]. It was emphasized that the soil structure is the core of the development of geotechnical engineering in the 21st century [

34]. For normal consolidated soil, the maximum load experienced historically is the self-weight stress, and so the yield stress of normal consolidated soil is near the pre-consolidation pressure. However, it was found that for some natural sedimentary soft soils, the yield stress is significantly greater than the self-weight stress, showing over-consolidation characteristics [

35]. This is due to the effect of soil structure on mechanical properties. The soils with this performance are called structural soft soils [

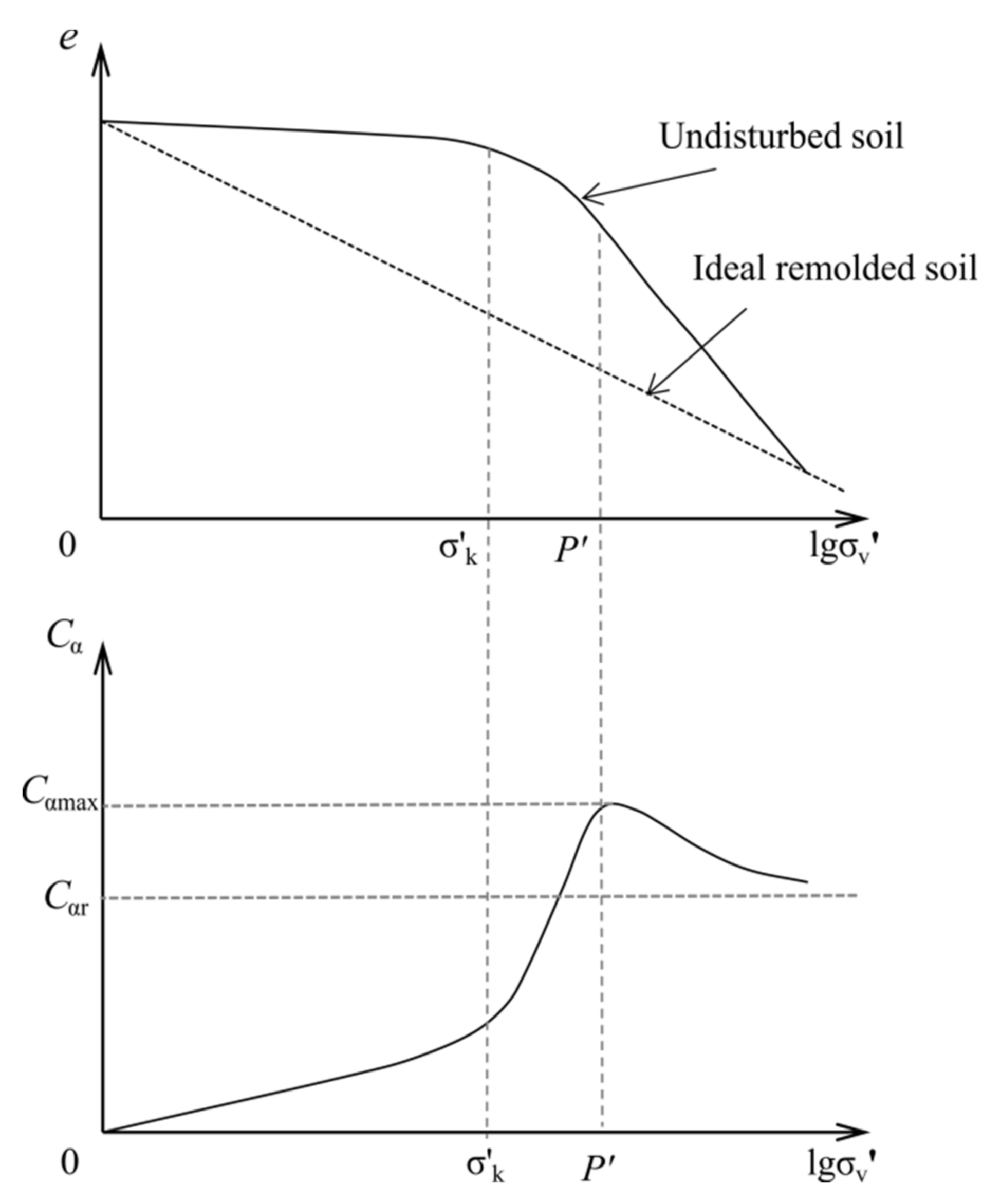

36]. The pre-consolidation pressure obtained by the Casagrande method is called the “structure yield stress” of the structural soil. The “over-consolidation ratio” is the “structure stress ratio” [

37].

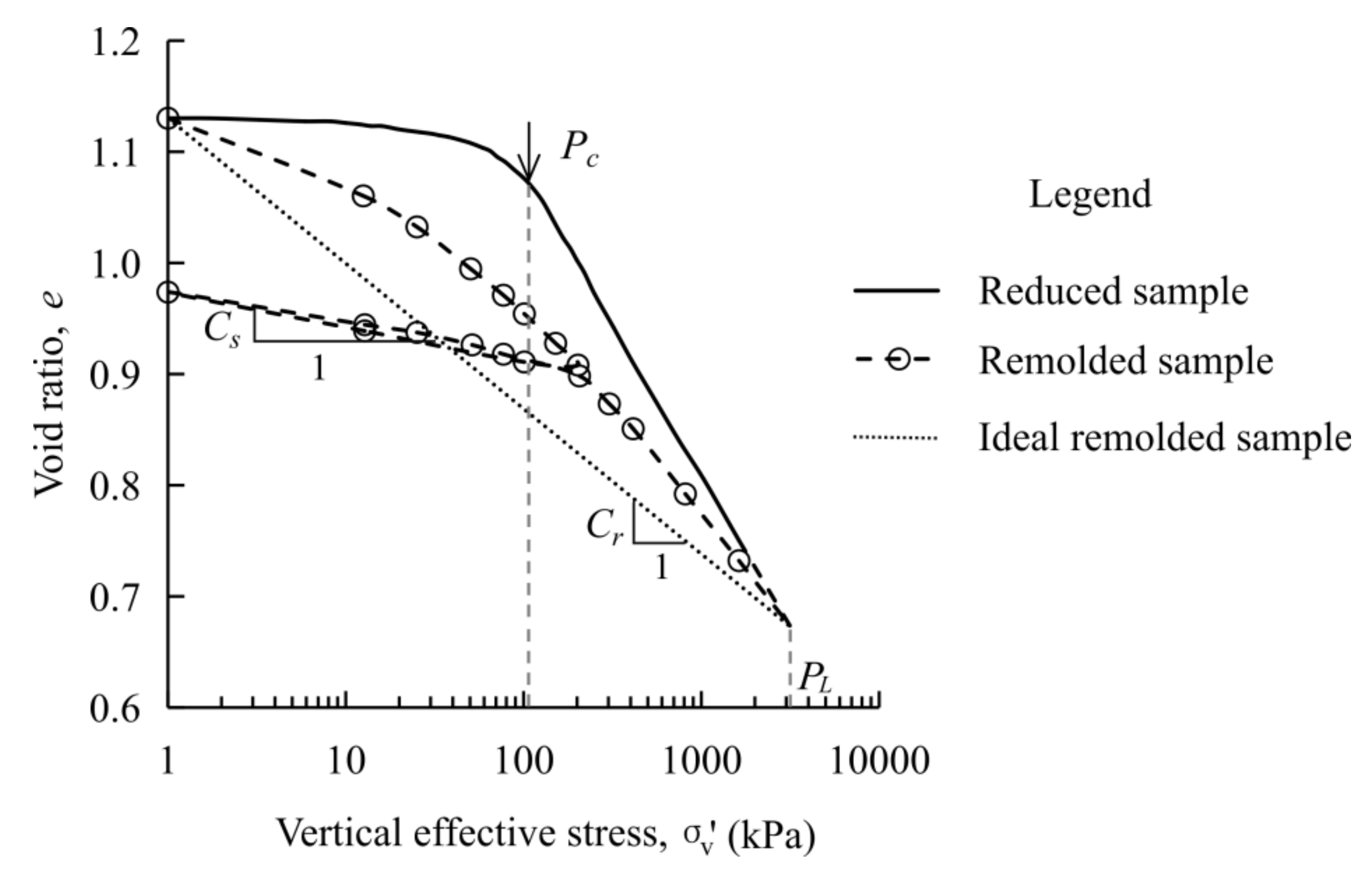

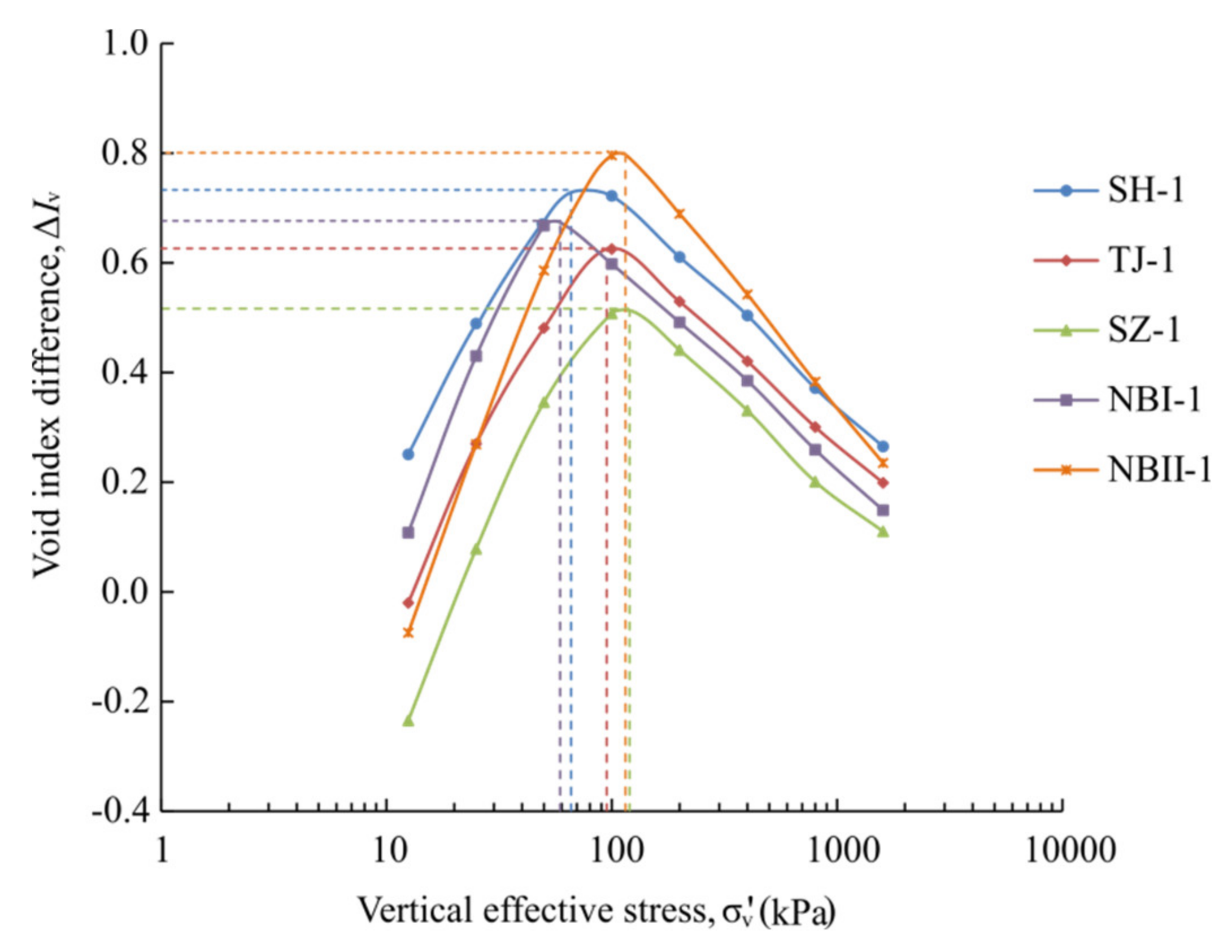

Yang et al. described the compression behavior of structural soils based on comparisons in a series of experiments on undisturbed and remolded soils [

38]. The mechanical properties of naturally deposited structural soils are often different from those of remolded soil; the soil structure almost disappears when the pressure exceeds a certain value, the properties of the soils are similar to those of remolded soils at this time, and C

α is similar to that of remolded soil, but the change in C

α is worth discussing when the pressure is less than this value and the relationship between this value and the soil sample is not explained [

39,

40]. Mesri noted that structural failure of natural soft soil mainly occurred in the pressure range of 0.7 to 2.0 σ’

k, which means that the soil structure was almost completely destroyed when the pressure was 2.0 σ’

k [

41]. However, the change in C

α is worth discussing when the soil structure is not completely yielded.

The C

α of structural soft soil is closely related to the stress level and time [

11,

12]. Marine sedimentary structural soil is different from the normal over-consolidated soil; the soil structure resists the external load and hinders secondary compression [

42,

43,

44]. A secondary compression deformation calculation model considering the effects of the soil structure was established [

45].

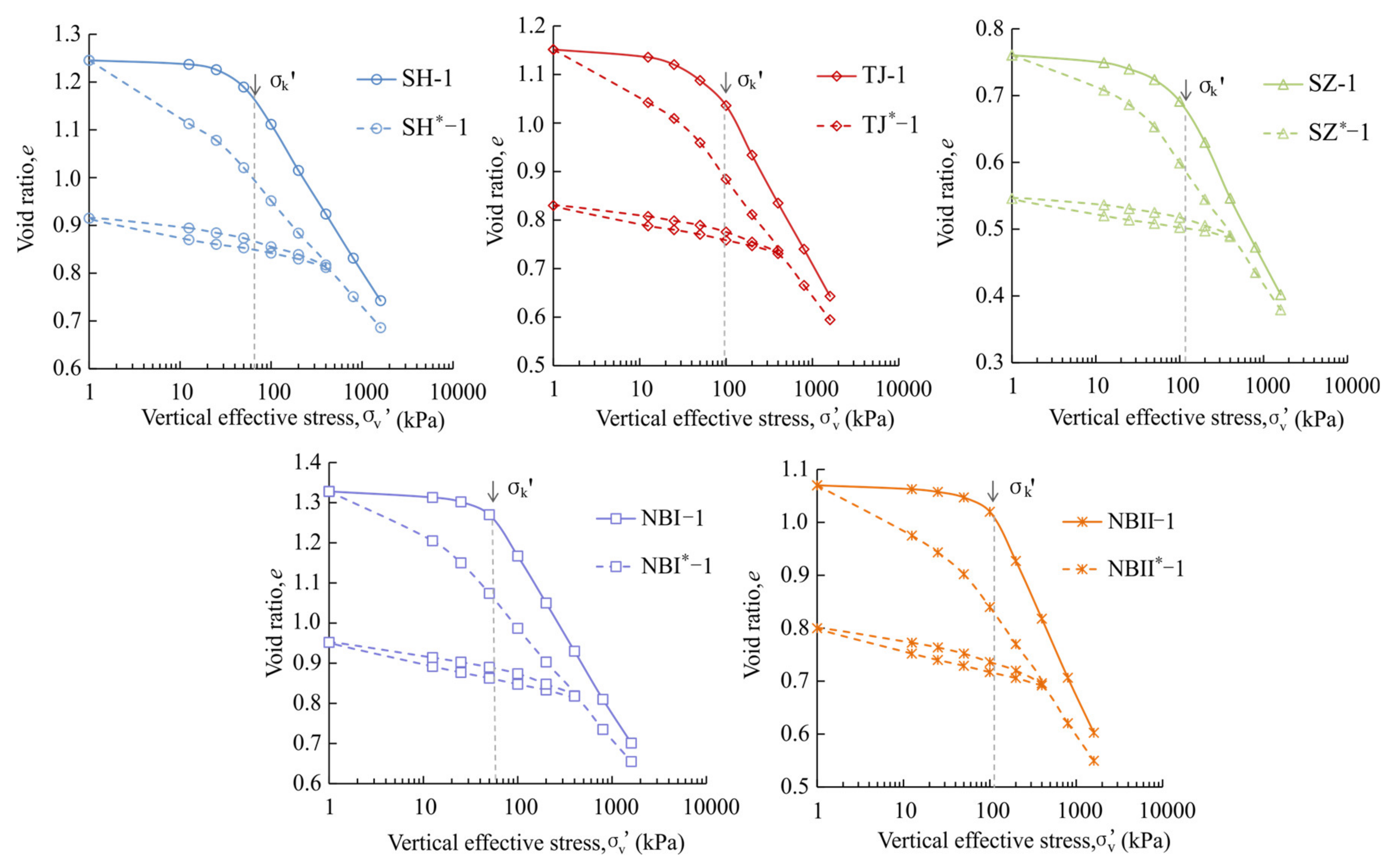

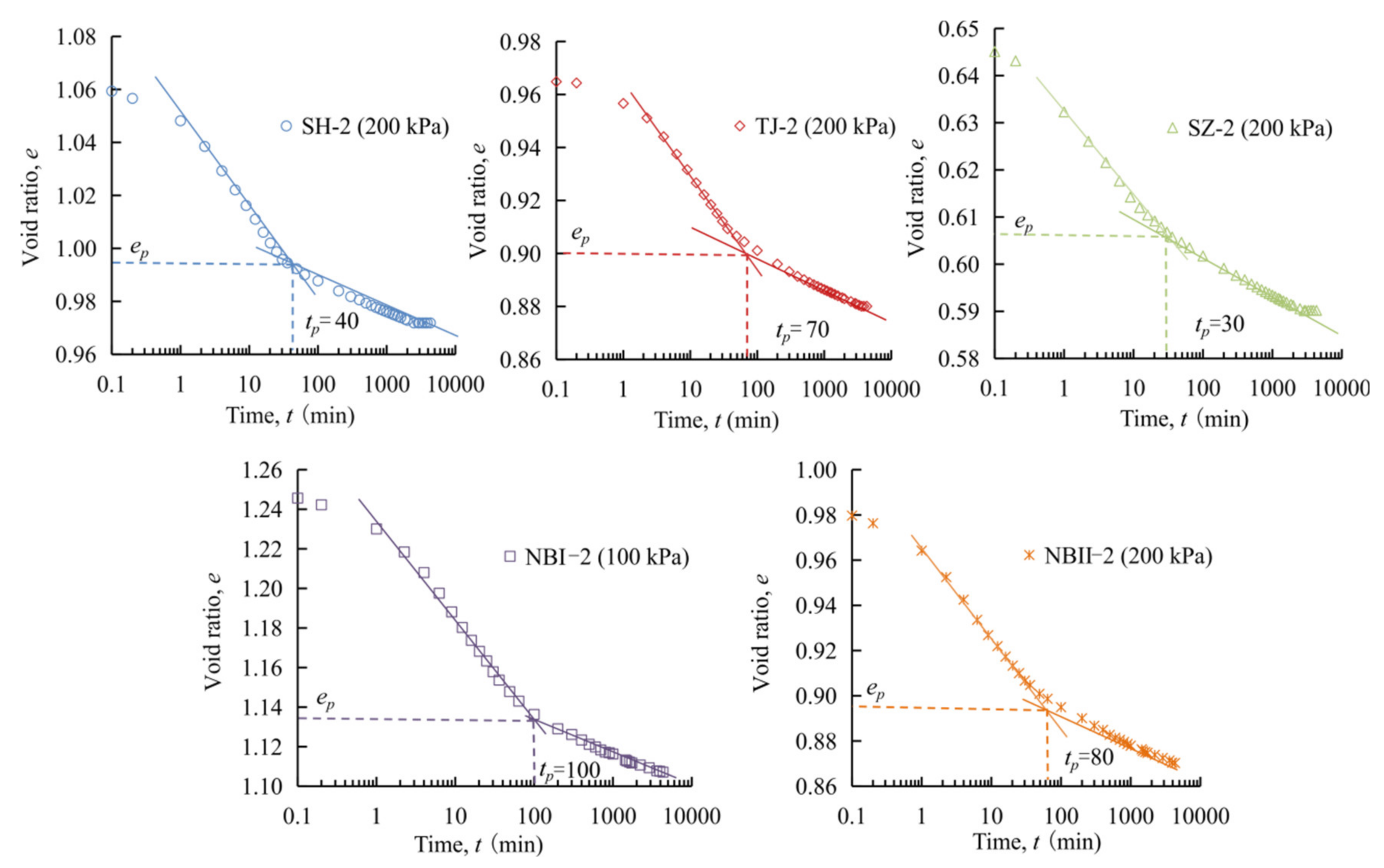

In the present study, natural sedimentary soft soils from Shanghai, Tianjin Suzhou and Ningbo were selected and one-dimensional compression and creep tests were carried out on undisturbed and remolded samples. The undisturbed samples were well obtained from thin-wall tube samples, meeting the test requirements, and based on their initial void ratio and the initial moisture content, the remolded samples were prepared by using sieved dry soil and distilled water to disrupt the structure of the soil (such as the influence of cementation, thixotropy, hardening, time effect and eluviation). The influence of soil composition, especially its structure, on the compressibility and secondary compression characteristics of naturally deposited soft soil was explored.

The objectives of present study were to investigate the one-dimensional compressibility, especially secondary compression behavior, and the soil structure effects of four clays obtained from Shanghai, Tianjin, Suzhou and Ningbo in China and compare the measured results with those of other natural soft soils worldwide. These four cities are relatively developed and densely populated, and the study of long-term foundation deformations is very important there. The soft soils in the four sites were selected from different sedimentary environments and depths, giving them different structural strength and yield stress. The different sorting degrees during the deposition process made the grain composition of the soft soils at these four sites different. The influence of structure and water–physical properties, such as liquid limit, on the secondary compressibility of soft soils was studied. The specific properties are described below.

2. Soft Soils and Methods

2.1. Geological Setting and Sampling

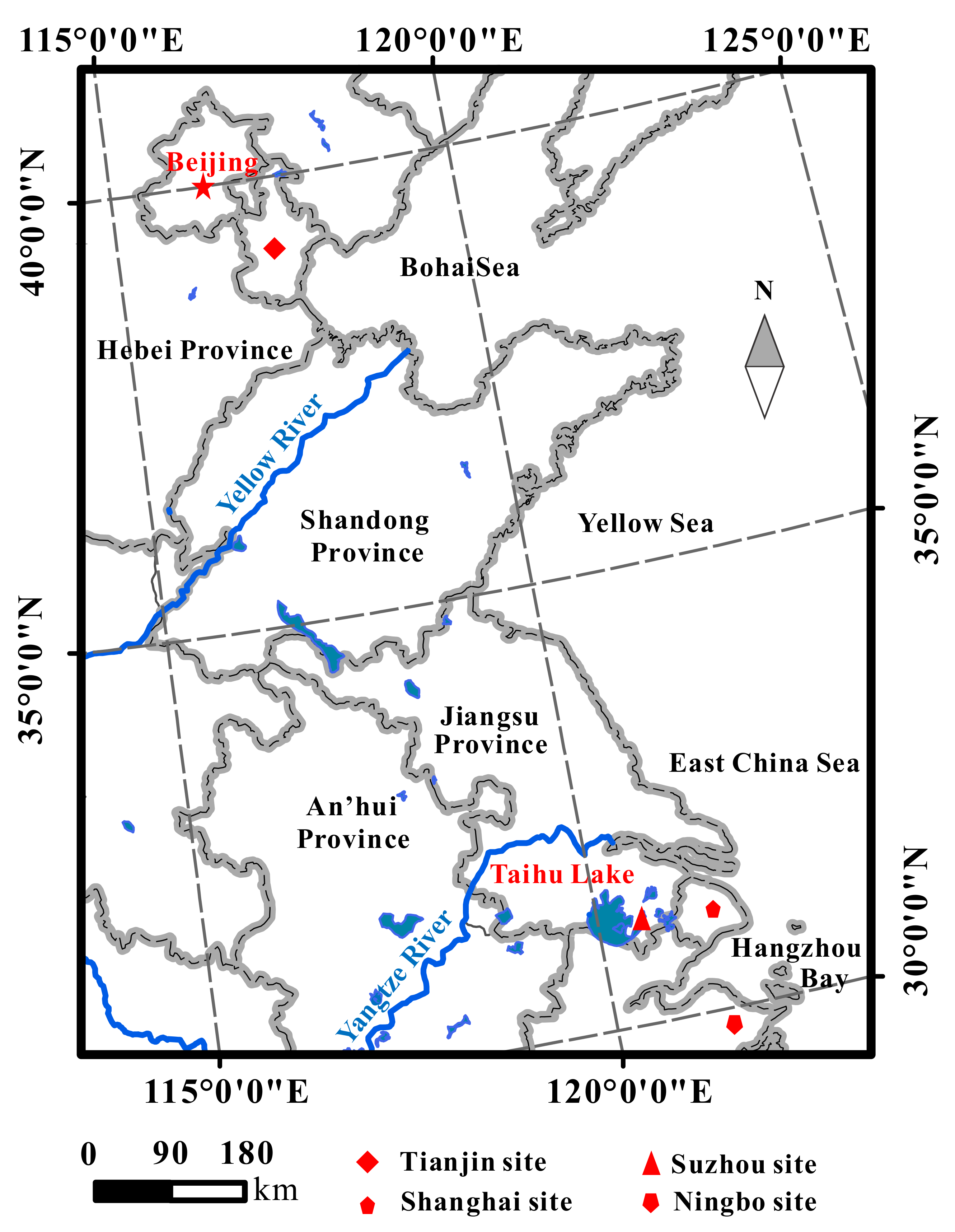

The investigation in the present study was carried out on undisturbed samples retrieved from areas of Tianjin, Shanghai, Suzhou and Ningbo, as shown in

Figure 1.

Table 1,

Table 2,

Table 3 and

Table 4 give the general geological conditions and sedimentary history of the four natural soft soils.

Shanghai is situated on the Yangtze River delta in eastern China, and the geology mainly consists of alluvial and marine sediments formed during the Quaternary period over the past 3 million years. The soft soil has low permeability, high sensitivity and remarkable creep properties. The Shanghai (SH) soft soil sample is from a gray muddy silty clay layer.

Most of Tianjin is a plain landform, and the southeast is bordered by Bohai Bay. The geological genesis of Tianjin (TJ) soil can be attributed to the Quaternary Holocene coastal sediment, which has the characteristics of a low bearing capacity, high compressibility and low permeability. The sample, consisting of gray silty clay, was taken from the Tianjin Airport Economic Zone.

Suzhou is located in the Taihu Lake Basin, close to the East China Sea. The soft soil is mainly composed of fluvial or limnetic sediments, with silty clay as the main part of the layer. It has the characteristics of low bearing capacity, high compressibility and a wide distribution of limnetic sediments. In present study, Suzhou (SZ) soft soil, from a gray yellow silty clay layer, was taken from the Suzhou Science and Technology City.

Ningbo is a plain landform bordering the East China Sea. The geological genesis of Ningbo soil can be attributed to the marine sediment of the middle or late Holocene, which has the characteristics of high water content, high void ratio and poor permeability. The Ningbo (NB) soft soil sample was taken from a gray yellow muddy silty clay layer.

The undisturbed samples were obtained by thin-wall samplers from the gray muddy silty clay layer, gray silty clay layer, gray yellow silty clay layer and gray yellow muddy silty clay of the SH, TJ, SZ and NB sites, respectively, in rotary wash borings, and each soil type was sampled at least 0.5 m thick. All the samples were immediately sealed on site to prevent the loss of water, packed into a sturdy wooden box, and transported to the laboratory. All care was taken to avoid disturbing the soil during sampling and transporting. According to laboratory tests, the disturbance index

ID of the four samples was within the scope of mild disturbance (0.15–0.30) [

41]. The soft soils from the four sampling sites belong to grade I (

ID ≤ 0.3), and soil of grade I can be used for all projects according to GB 50021-2001 [

46].

2.2. Properties of the Soft Soils

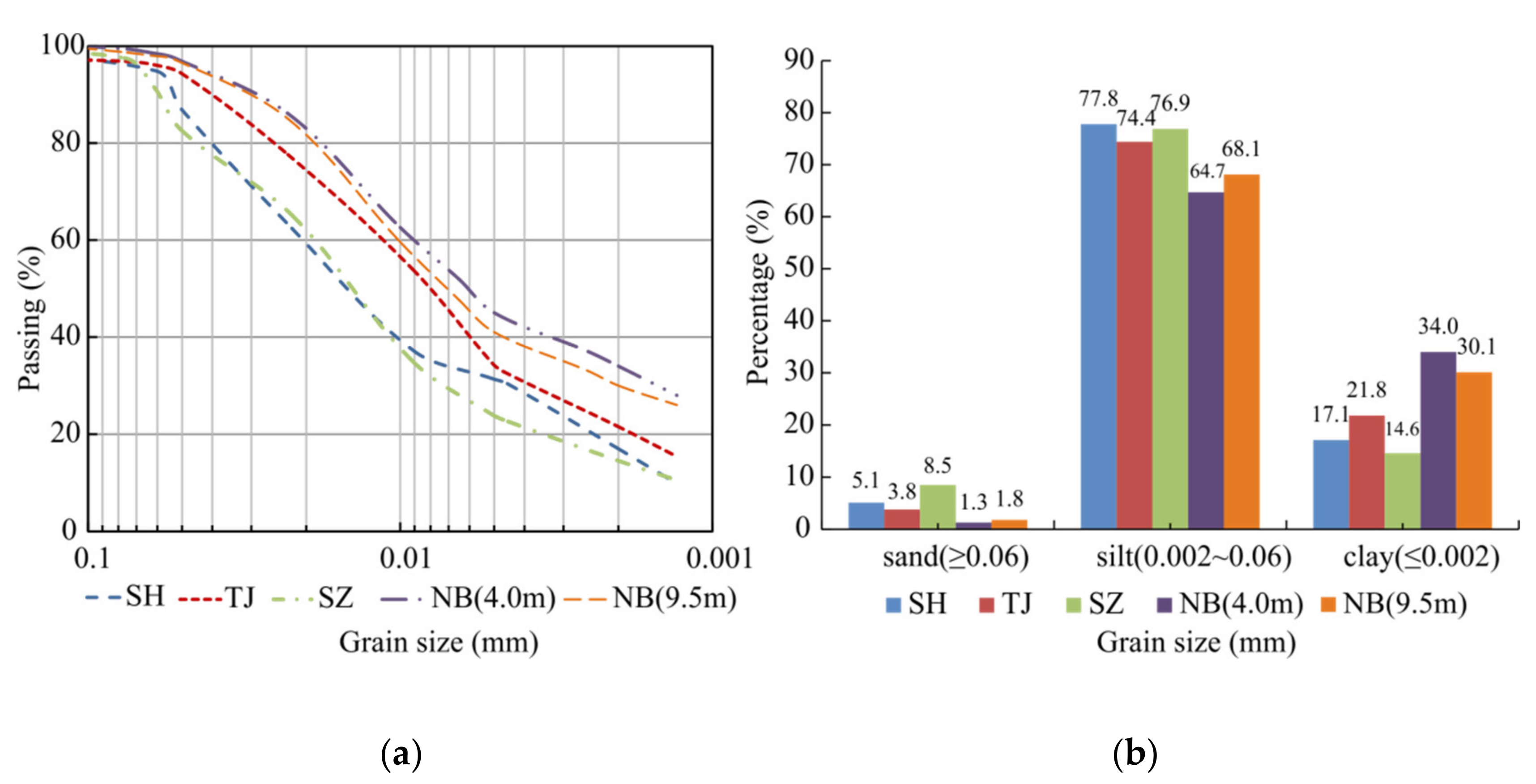

Figure 2a shows the grain size distribution curves of the SH, TJ, SZ and NB soft soils.

Figure 2b shows the percentage of fractions in the four sites. The clay fraction content (<0.002 mm) of the NB is the highest, exceeding 30.0%, while those of TJ, SH and SZ are 21.8%, 17.1% and 14.6%, respectively.

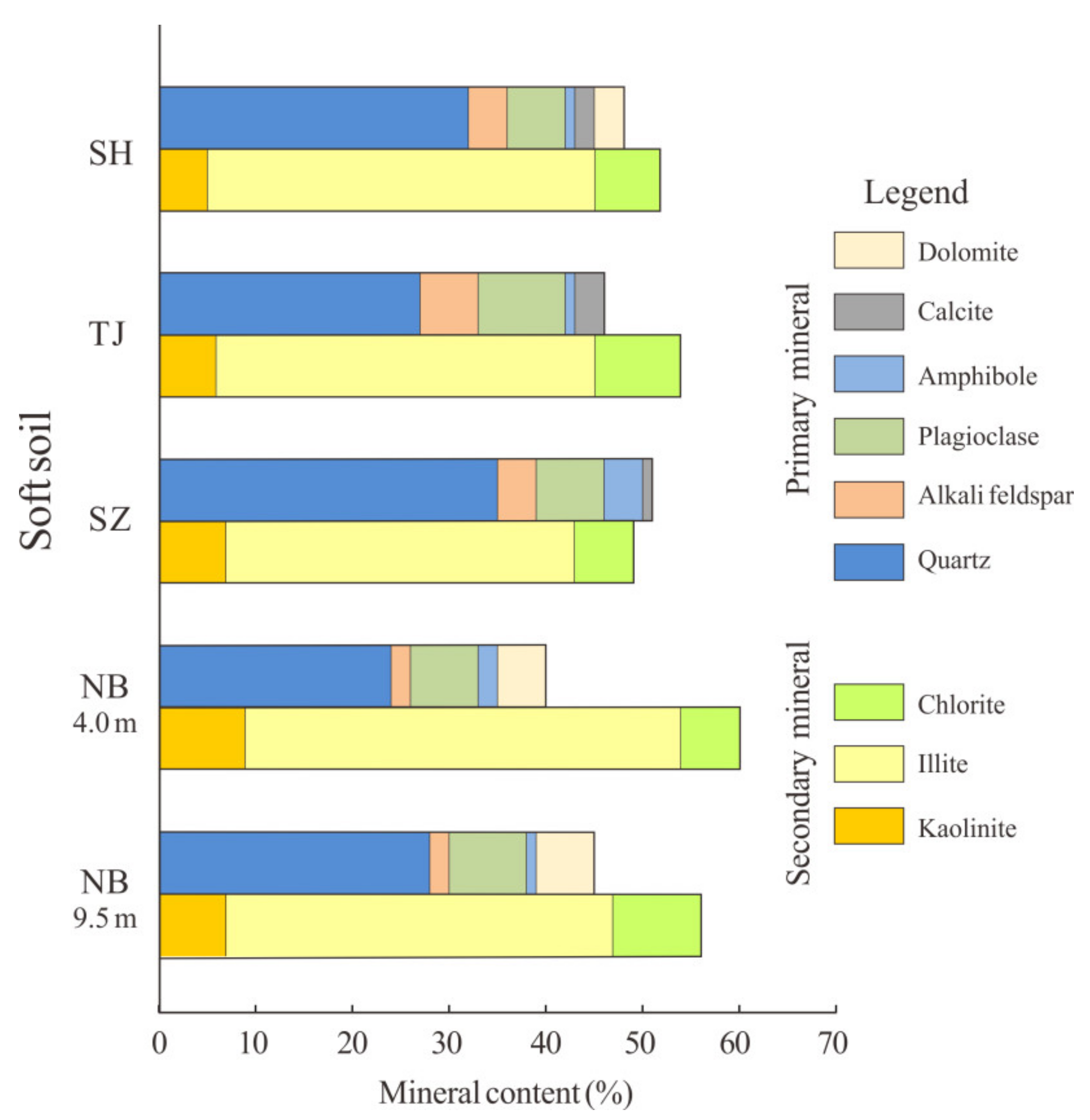

The mineral content according to the results of the X-ray diffraction (XRD) analysis is shown in

Figure 3. In general, the types of minerals in the soft soils in the four sites are similar. The primary mineral is quartz, which reflects the higher content of silt and fine sand fraction in the grain composition of the samples. The secondary minerals are mainly illite, kaolinite and chlorite. The secondary mineral content of the TJ, SH and SZ is 54%, 52% and 49%, respectively. The secondary mineral content of NB is higher than that of the other three sites; at a depth of 4.0 m it is up to 60%, and at a depth of 9.5 m is 56%, indicating that the weathering degree of the NB is the highest in four sites.

The physical properties of the SH, TJ, SZ and NB samples tested in the laboratory are presented in

Table 5, and there are two samples at different depths in NB site. All of the soft soils are saturated. We measured the liquid limit (

wL) by the fall cone method and obtained the different fall cone depths by configuring soil samples with different moisture contents. The

wL of the soil sample was determined by using the water contents and the fall cone depths in logarithmic coordinates, and parallel samples were adopted to ensure the accuracy of the results. The liquid limits (

wL) of the NB samples are 39.2% and 42.7%, which are higher than the other three soils. The plasticity indexes (PI) of the NB samples are 18.3% and 21.1%, which are higher than the other three natural soils. The natural moisture content of the NB, TJ and SH samples is higher than their

wL, while that of the SZ sample is close to its

wL, and the

w0/

wL of SZ is 0.93.

Table 5 shows that the NB sample from 4.0 to 4.5 m has the largest initial void ratio.

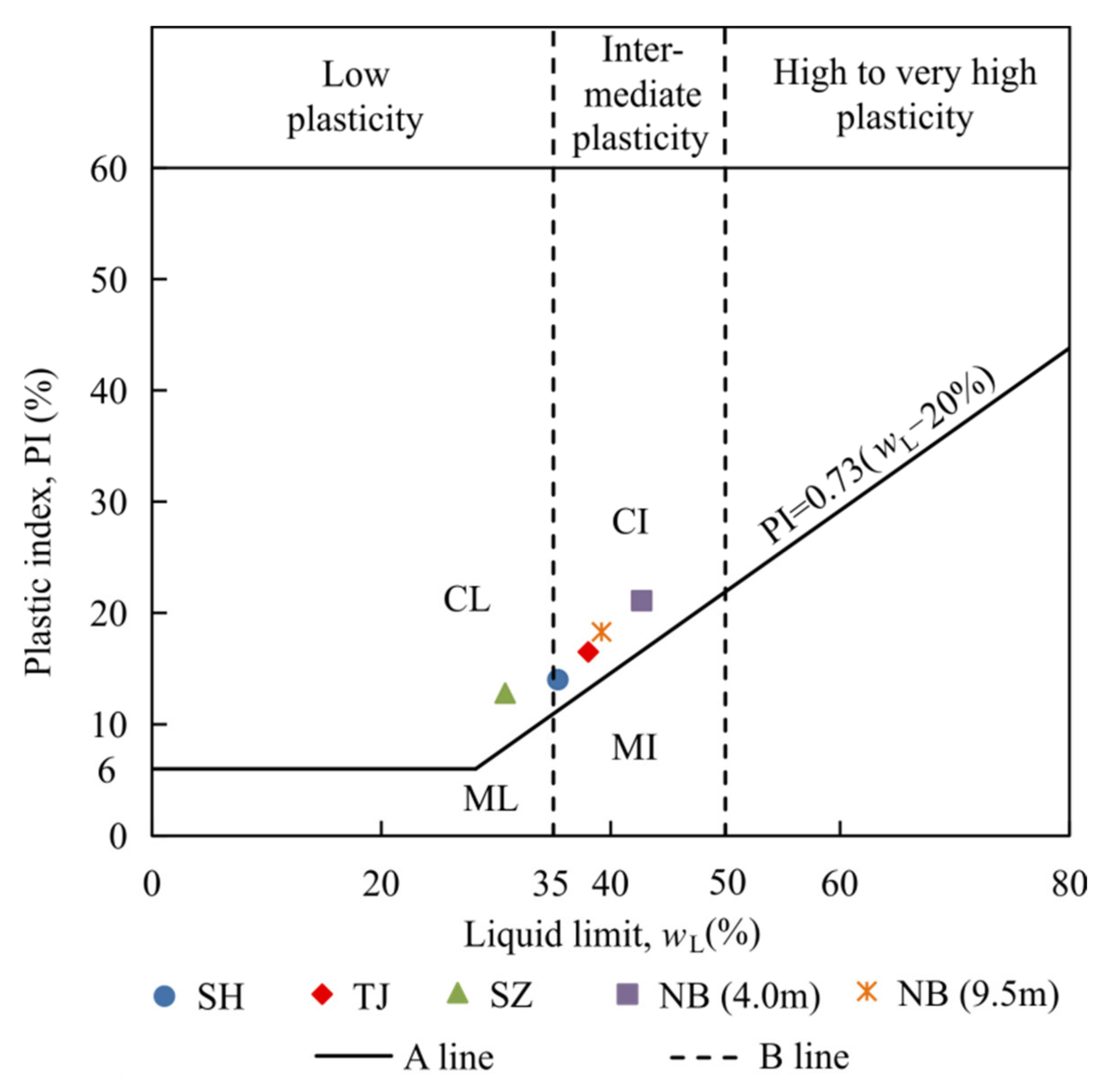

Figure 4 shows the plasticity chart for the four soil samples on the basis of the Atterberg limits. All data are above the A-line, which is a boundary between clay and silt. According to BS 5930, the five natural soils are categorized as clays with low to intermediate plasticity [

47].

2.3. Methods

Five natural soil samples were selected from different sedimentary environments or depths; the depths of the soil samples were approximately 5, 7 and 10 m from the sites of SH, TJ and SZ, respectively, and 4 and 9 m from NB. The effects on the secondary compressibility of soft soil were explored by using different clay contents, water contents and depths.

To determine the influence of soil structure on compressibility, a one-dimensional compression test was carried out on the undisturbed and remolded soil samples from the four sites. The remolded samples were prepared according to the void ratios and initial moisture contents of the undisturbed samples. To obtain the secondary compression characteristics, a one-dimensional consolidation creep test was performed on the undisturbed samples. We used a wire saw to cut off part of the soil on the surface from the thin-wall tube samples. To reduce the lateral friction between the stainless ring and the soil specimen, the inner side of the stainless ring was coated with silicone grease, then the stainless ring placed flat on the soil and gently pressed down; then we used a wire saw to cut off the soil outside the stainless ring, then continued to press down gently, repeating the operation until the stainless ring was filled with soil to obtain the undisturbed sample. We collected the cut soil, dried it to a constant weight at 105 °C, then crushed it and passed it through the sieve 10 (2 mm); depending on the initial void ratio and initial moisture content of the undisturbed sample, the required dry soil and distilled water were properly mixed by using a geotechnical blade, then the wet soil was sealed. After placing the wet soil aside for 24 h, we filled the stainless ring with a geotechnical blade according to the calculated mass of the wet soil to obtain the remolded sample. Great care was taken to control the speed during sample preparation to prevent water loss. All the tests were carried out in a temperature-controlled room (23 ± 1 °C) to minimize the effect of temperature on the consolidation tests.

The conventional consolidation instrument was used to test the undisturbed and remolded soil samples for the four sites under the condition of two-side drainage, and the samples were always in a saturated state. The diameter and height of the specimens were 61.8 and 20 mm, respectively. The consolidation rings containing the samples were placed in the consolidation cell with filter paper and porous stone on both ends of the samples.

Using a step-loading method and a load increment ratio of 1, a total of fifteen soil samples were tested in two series. Series 1, including five undisturbed samples and five corresponding remolded samples, underwent one-dimensional compression tests. Series 2, including five undisturbed samples, underwent one-dimensional consolidation creep tests. Details of the tests are summarized in

Table 6. The estimated in situ vertical stresses “σ

v’” were shown in

Table 6. The smallest σ

v’ of undisturbed soil was about 50 kPa, which is relatively small. In order to better reflect the compression process, reduce the load variation of the prior stage and better determine the structure yield stress of soil sample, we chose a small initial stress to be 12.5 kPa. We used a step-loading method and a load increment ratio of 1, for a total of 8 loading stages for all undisturbed soil samples. In one-dimensional compression test, all the remolded soil samples were unloaded and reloaded after 400 kPa and each stage of load was maintained for 24 h. At present, there is no definitive deformation standard for creep test; it is generally considered that the creep has reached stability when the deformation is less than 0.01 mm within 10,000 s [

48,

49]. According to the test situation of one-dimensional consolidation creep tests, and to avoid losing moisture during the long test time, we determined the deformation standard as follows: when the deformation of a sample was less than 0.01 mm within one day (which is longer than 10,000 s), the next stage load was applied, and the sample was loaded for three days at each stress level to meet this deformation standard, so the time of duration of load is three days for each stage in one-dimensional consolidation creep tests, which is consistent with Quigley’s deformation standard [

50].