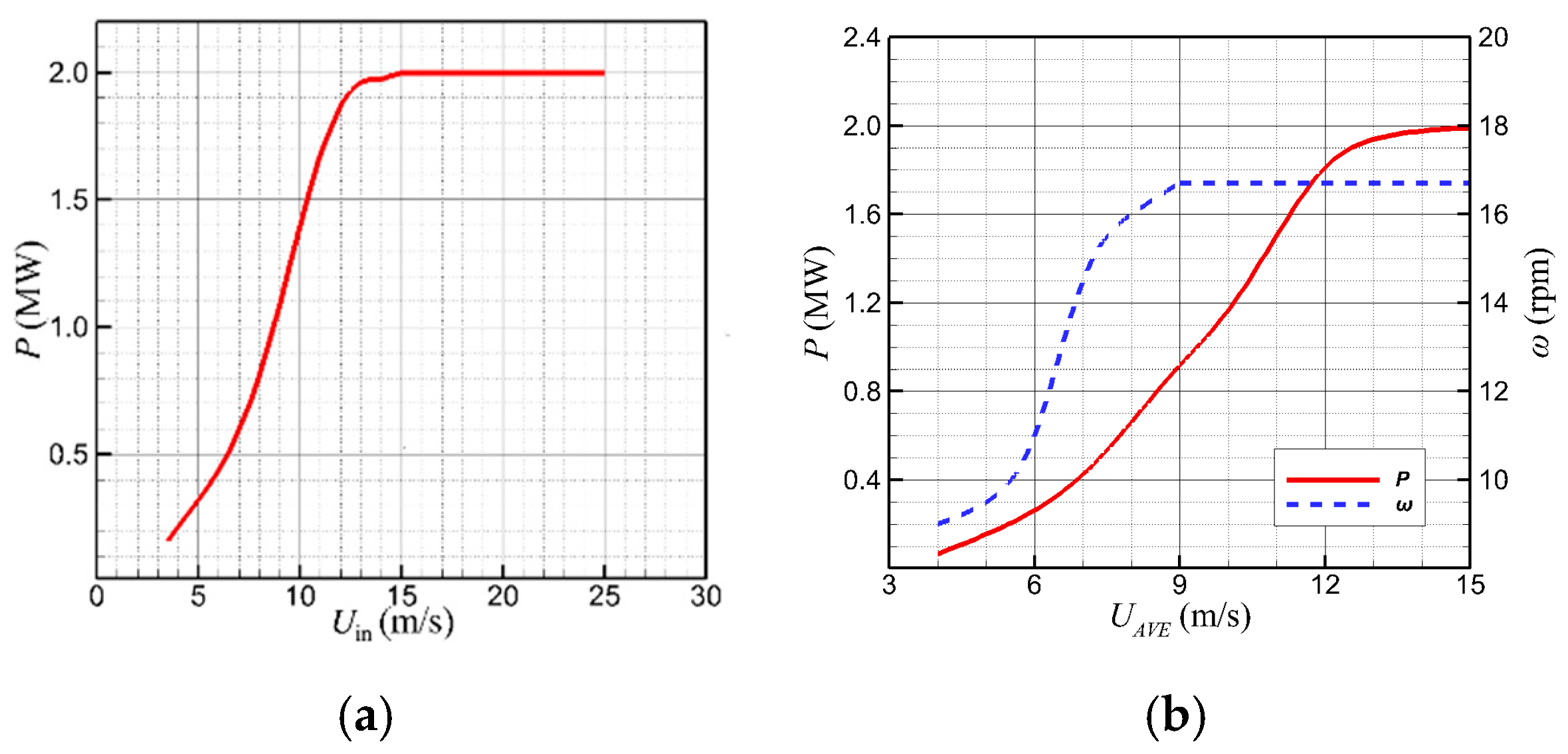

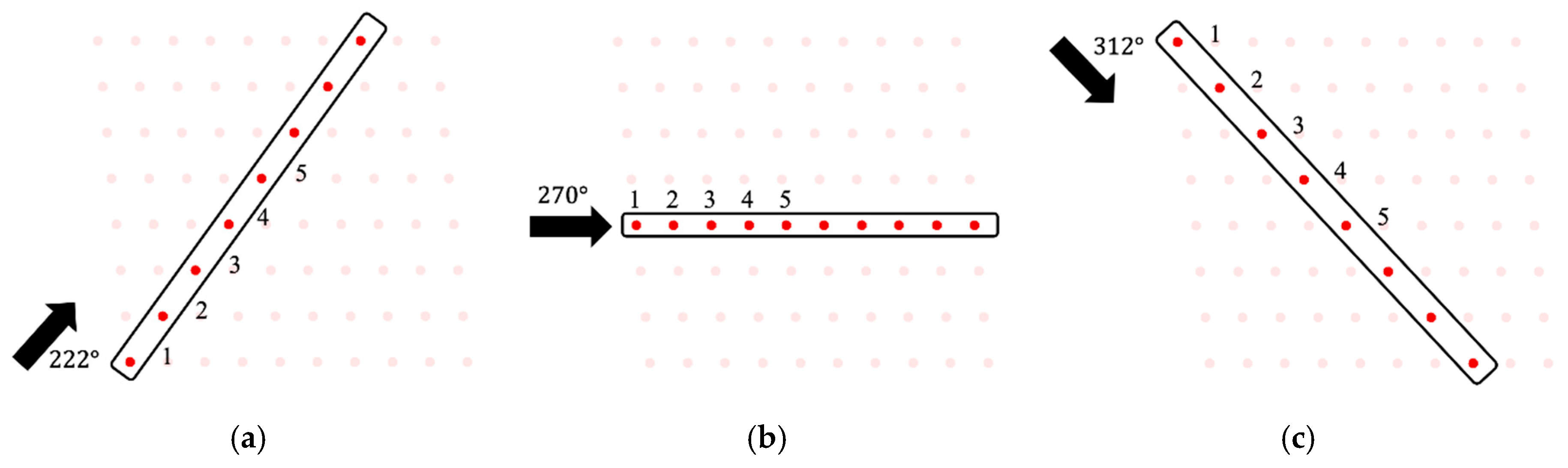

This study first predicts the power output of Horns Rev wind farm for a wind speed of 8 m/s with three distinct wind directions. The wind turbine layout of Horns Rev wind farm is shown in

Figure 7a, where the red solid dots represent the locations of the installed Vestas V80 wind turbines. Three specific wind directions (

,

, and

) corresponding to a tower spacing (

d) of 9.3

, 7

, and 10.4

are selected as the validation cases.

Figure 7b illustrates the typical grid arrangement for the Horns Rev wind farm, where

is the longitudinal size of the wind farm,

the lateral size of the wind farm,

and

. The numerical mesh was particularly clustered in the region where the rotor of a wind turbine is located. Two different domain sizes, i.e., a full model and a reduced one, are additionally compared to identify their computational advantages and drawbacks in the power prediction of wind farms. In the full model, a complete wind farm is simulated,

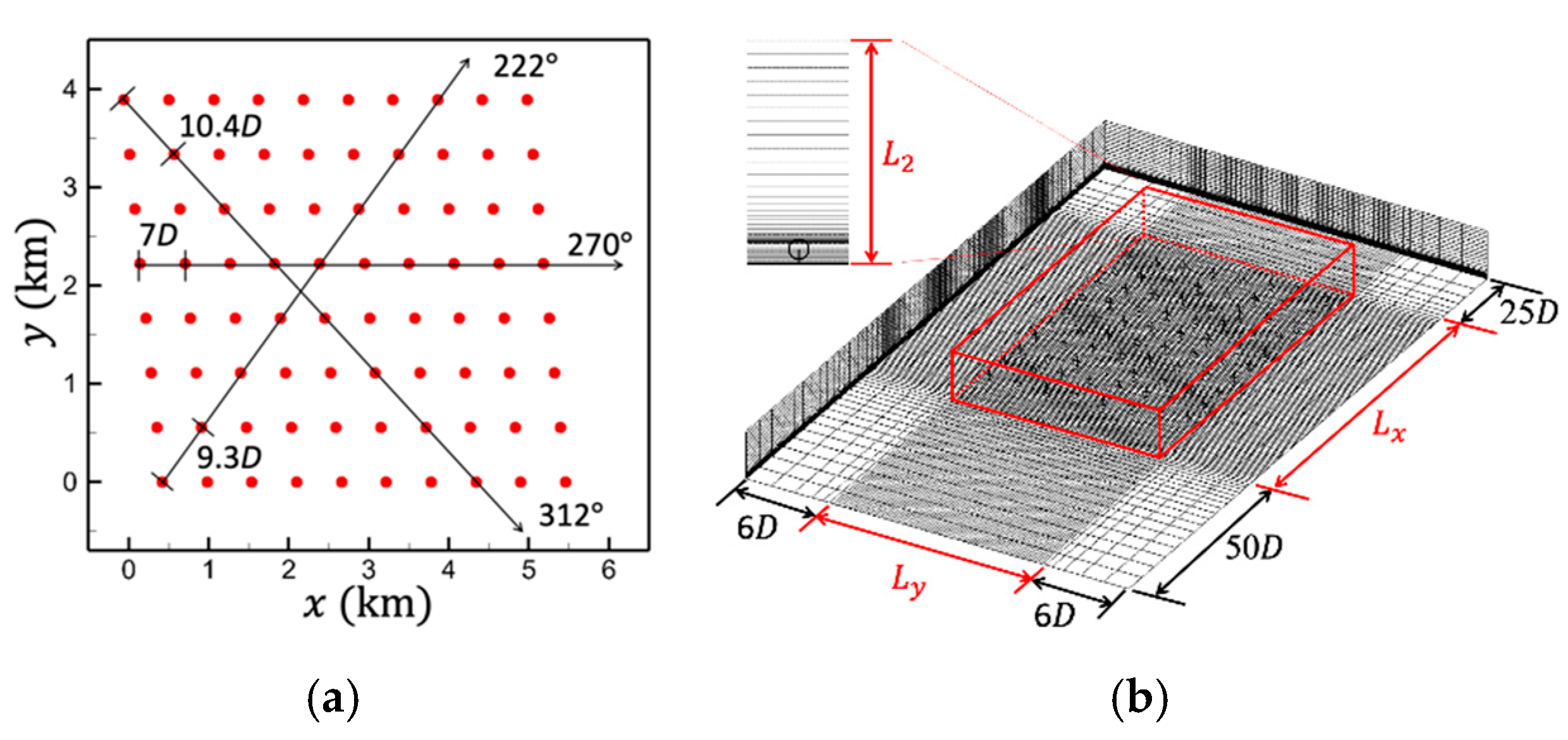

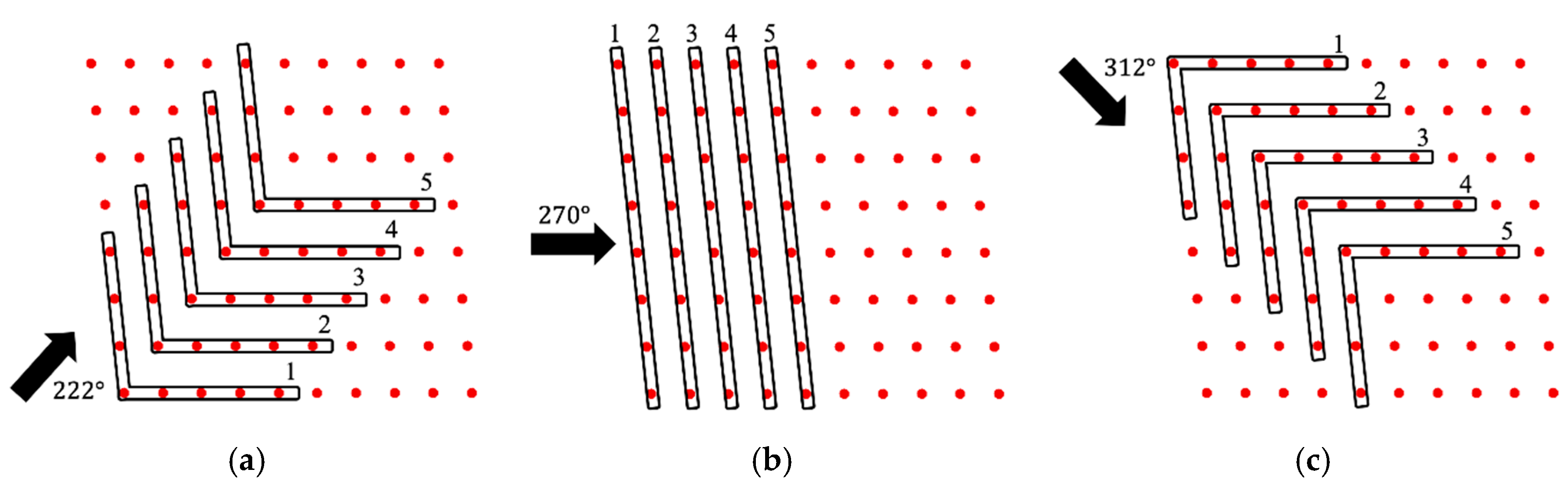

Figure 8, whereas the reduced model only considers a cascading wind turbine arrangement due to the tower location symmetry of the investigated wind turbine array,

Figure 9.

Table 3 and

Table 4 summarize the grid parameters to create a numerical mesh for the full and reduced domains, respectively. The first group of parameters, i.e.,

dx,

dy,

dz, represent the grid spacing of the rotor region in the

x,

y, and

z directions, respectively, where

is the first off-wall grid spacing for accommodating the adopted turbulence model. The second group of parameters, i.e.,

and

, denotes the grid numbers covering the rotor area in the spanwise and vertical directions, respectively.

Figure 10 displays the predicted axial velocity distribution at the hub height for various wind directions. The airflow obviously decelerates across wind turbines and the wake gradually recovers its velocity along the downstream direction. A slow wake recovery was found as airflow passes through multiple wind turbines. It is mainly due to a successive energy transfer from airflow to the wind turbine that results in less chance for airflow to receive energy from neighboring high velocity streams. The normalized power of a turbine row (

is defined as follows:

where

represents the power of the first wind turbine row and

the power of a wind turbine row defined in

Figure 8. The normalized power

for three wind directions is forecasted in

Figure 10, where the field measurement is labeled an average value alongside its upper and lower limits. For understanding the relative prediction accuracy of the proposed approach compared to other numerical approaches, a benchmark LES result [

25] was chosen in this study to serve as a comparison basis of the numerical predictions.

Figure 11 depicts the power forecast of the full model along with the LES prediction. In the case of

, the prediction of the full model favorably falls within the measurement limits. Despite a small overprediction of the average power output, the full model successfully delivered a sharp power drop in the second row, accompanied by a very mild power decrease along the downstream direction that truthfully describes the field performance of wind turbine rows. By contrast, the LES approach delivers a similar conclusion to the full model but it suggests an almost unchanged power tendency of the downstream rows where the average power is underpredicted especially for the second and third rows. For the wind farm simulation of

, the power forecast of the full model very well agreed with the measurement, except for a within-limits overprediction of the average power at the second row, whereas the LES prediction gives an obvious underprediction for all downstream wind turbine rows in addition to a deep power deficiency of the second row that is apparently inconsistent with the wind farm measurement. A large discrepancy between the measurement and the numerical result predicted by the full model, as well as the LES approach, was found in the power prediction of

. The field data indicates a clear power decline growing with the increase of the row number that is unable to be reproduced by both numerical approaches. One cause of this large disagreement on the power prediction might come to the unsatisfactory modeling of the turbulence development in the atmosphere boundary by both methods. As the tower spacing increases, the wake recovery is expected to become more pronounced. The nonlinear behavior of strong wake recovery at large tower spacing should be further investigated in future studies to obtain an accurate power prediction of wind turbine array, especially for the wind farms employing high-power wind turbines. Another reason for this substantial underprediction is the experimental data representing a period of measurement that records the wind turbine power under time-varying wind direction and speed rather than a fixed wind direction and speed in the ideal case considered in the numerical calculation. From this viewpoint, the case of

clearly exhibits a more stable wind condition than the case of

.

Figure 11 also compares the numerical results between the full and reduced models. Interestingly, the reduced model gives a very close result to the full model. This implies a significant reduction up to one order of magnitude in the computation cost can be easily achieved by utilizing the geographical symmetry without bring substantial modeling errors.