Analysis of Removing Barnacles Attached on Rough Substrate with Cleaning Robot

Abstract

1. Introduction

2. Cleaning Robot

3. Barnacle Geometric Model and Cleaning Methods

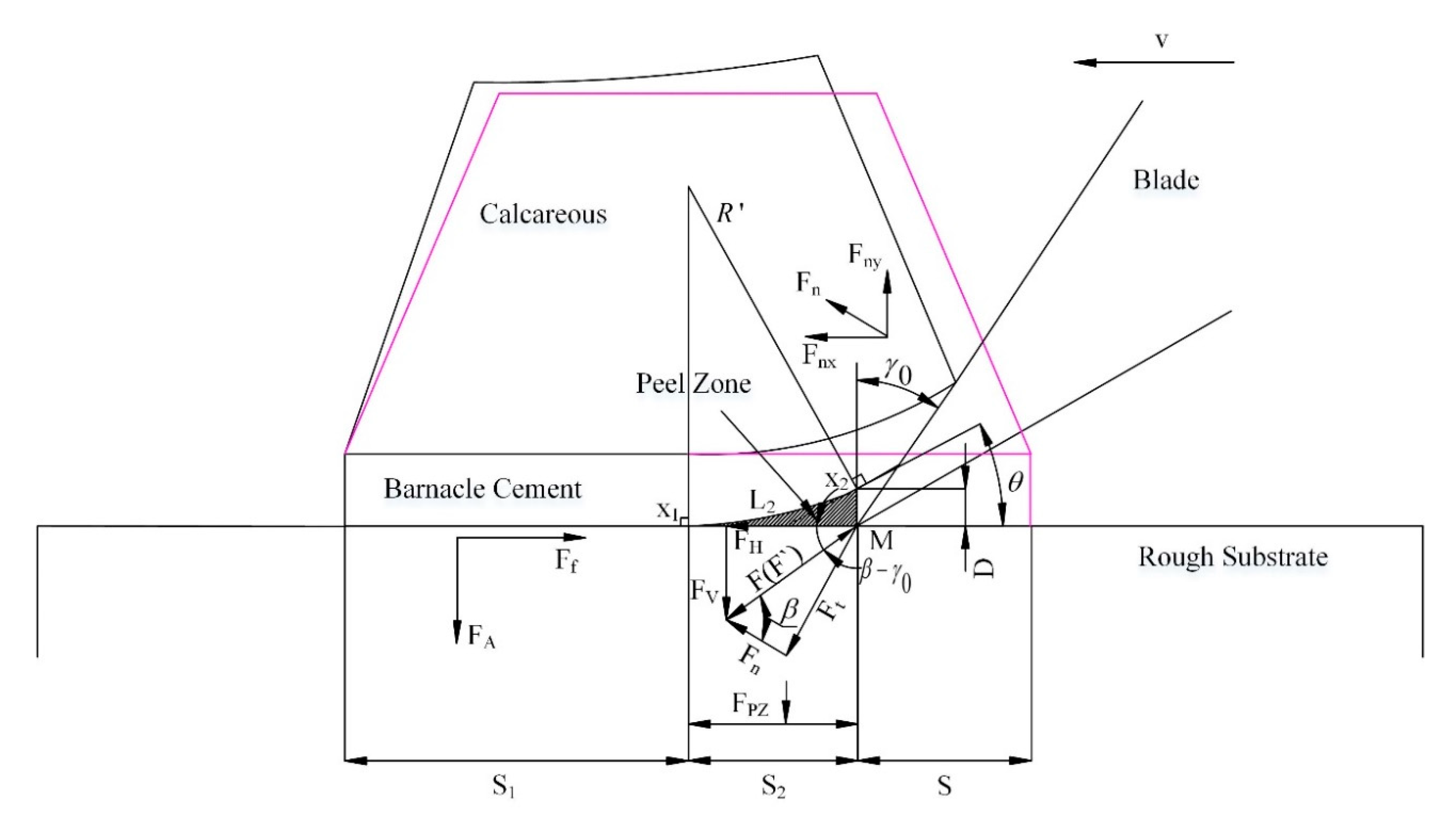

4. Force Modeling

4.1. Calculation of FPZ

4.2. Calculation of FA and Ff

4.3. Effect of Friction

5. Simulation and Results

6. Conclusions

- (1)

- Through the finite element simulation, the mathematical analysis model is verified, and the verification results show that the relative average error of the mathematical model is less than 15%. During the operation of barnacle scraping, the mechanical analysis process can be presented to estimate the horizontal cutting force in order to optimize the angle of the scraping blade for the cleaning robot design.

- (2)

- During the scraping process, the blade rake angle and substrate roughness have a big effect on the horizontal cutting force. The blade rake angle could be recommended to [30°, 60°]. It could be seen that the smaller the blade rake angle, the greater the horizontal cutting force needed to clean up the barnacles, Additionally, the rougher the substrate is, the greater the horizontal cutting force required. Finally, it is recommended that a 60° blade rake angle is more suitable for the cleaning robot design.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Symbol | Significance | Unit |

|---|---|---|

| d1 | The bottom diameter of the barnacle geometrical model | mm |

| d2 | The top diameter of the barnacle geometrical model | mm |

| h1 | The average height of one-year-old barnacle | mm |

| h2 | The height of cement layer | mm |

| F | Cutting force | N |

| Fn | Normal component force of F | N |

| Ft | Tangential friction force | N |

| Fnx | Horizontal component force of Fn | N |

| Fny | Vertical component force of F′ | N |

| F′ | Counterforce of F | N |

| FH | Horizontal component force of F′(rough) | N |

| F′H | Horizontal component force of F′(smooth) | N |

| FV | Vertical component force of F′ | N |

| γ0 | Fake angle of the blade | ° |

| β | The angle between F and Fn | ° |

| β-γ0 | The angle between F′ and FH | ° |

| FA | Adhesion force of barnacle | N |

| FPZ | Peeling force | N |

| Ff | Horizontal friction force of barnacle | N |

| AZ | The area of the adhesion zone | m2 |

| R′ | Radius of calcareous shell circular arc | m |

| L2 | Arc length | m |

| x1, x2 | Point on arc length | |

| θ | Peel angle | ° |

| B | Width of the Peel Zone | m |

| A | Hamaker constant | |

| D | Surface gap | |

| R | Barnacle diameter | m |

| P | Barnacle’s adhesion strength | N/m2 |

| S | Blade displacement | m |

| μ | Friction coefficient between substrate and cement |

References

- Wei, S.C.; Xu, B.S.; Liang, X.B.; Wang, Y.J.; Liu, Y. Research on Corrosion-Resistance of High Velocity Arc Spray Coatings on Surface of Steel Structure in Splash Zone Environment. Mater. Sci. Forum 2011, 675–677, 1291–1294. [Google Scholar] [CrossRef]

- Magin, C.M.; Cooper, S.P.; Brennan, A.B. Non-toxic antifouling strategies. Mater. Today 2010, 13, 36–44. [Google Scholar] [CrossRef]

- Telegdi, J.; Trif, L.; Románszki, L. Smart anti-biofouling composite coatings for naval applications. Smart Compos. Coat. Membr. 2016, 123–155. [Google Scholar] [CrossRef]

- Yebra, D.M.; Kiil, S.; Dam-Johansen, K. Antifouling technology—past, present and future steps towards efficient and environmentally friendly antifouling coatings. Prog. Org. Coat. 2004, 50, 75–104. [Google Scholar] [CrossRef]

- Gao, H.B.; Chen, Q.; Wang, J.; Liu, B.Y.; Wan, Z.X.; Hou, B.R. Anticorrosion Technology Application of Petrolatum Tape and Covering (PTC) on Offshore Wind Farm. China Coat. 2013, 28, 39–43. [Google Scholar]

- Gule, N.P.; Begum, N.M.; Klumperman, B. Advances in biofouling mitigation: A review. Crit. Rev. Environ. Sci. Technol. 2016, 46, 535–555. [Google Scholar] [CrossRef]

- Jia, R.; Li, Y.; Al-Mahamedh, H.; Gu, T. Enhanced Biocide Treatments with D-amino Acid Mixtures against a Biofilm Consortium from a Water Cooling Tower. Front. Microbiol. 2017, 8, 1538. [Google Scholar] [CrossRef]

- Rubio, D.; Casanueva, J.F.; Nebot, E. Assessment of the antifouling effect of five different treatment strategies on a seawater cooling system. Appl. Therm. Eng. 2015, 85, 124–134. [Google Scholar] [CrossRef]

- Neilson, B.J.; Wall, C.B.; Mancini, F.T.; Gewecke, C.A. Herbivore biocontrol and manual removal successfully reduce invasive macroalgae on coral reefs. PeerJ 2018, 6, 5332. [Google Scholar] [CrossRef]

- Albitar, H.; Dandan, K.; Ananiev, A.; Kalaykov, I. Underwater Robotics: Surface Cleaning Technics, Adhesion and Locomotion Systems. Int. J. Adv. Robot. Syst. 2016, 13, 7. [Google Scholar] [CrossRef]

- Eslamdoost, A.; Larsson, L.; Bensow, R. A pressure jump method for modeling waterjet/hull interaction. Ocean. Eng. 2014, 88, 120–130. [Google Scholar] [CrossRef]

- Narewski, M. Hismar-Underwater Hull Inspection And Cleaning System As A Tool For Ship Propulsion System Performance Increase. J. Pol. CIMAC 2009, 4, 227–232. [Google Scholar]

- Yamada, J.; Takiguchi, T.; Saito, A.; Odanaka, H.; Soyama, H.; Yamamoto, M. Removal of Oral Biofilm on an Implant Fixture by a Cavitating Jet. Implant Dent. 2017, 26, 904–910. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Khoo, B.C.; Teo, S.L.; Lee, H.P. The effect of cavitation bubbles on the removal of juvenile barnacles. Colloids Surf. B Biointerfaces 2013, 109, 219–227. [Google Scholar] [CrossRef]

- Legg, M.; Yuecel, M.K.; de Carellan, I.G.; Kappatos, V.; Selcuk, C.; Gan, T.H. Acoustic methods for biofouling control: A review. Ocean Eng. 2015, 103, 237–247. [Google Scholar] [CrossRef]

- Mazue, G.; Viennet, R.; Hihn, J.; Carpentier, L.; Albaina, I. Large-scale ultrasonic cleaning system: Design of a multi-transducer device for boat cleaning (20 kHz). Ultrason. Sonochem. 2010, 18, 895–900. [Google Scholar] [CrossRef] [PubMed]

- Patil, J.S.; Kimoto, H.; Kimoto, T.; Saino, T. Ultraviolet radiation (UV-C): A potential tool for the control of biofouling on marine optical instruments. Biofouling 2007, 23, 215–230. [Google Scholar] [CrossRef]

- Lopez-Galindo, C.; Casanueva, J.F.; Nebot, E. Efficacy of different antifouling treatments for seawater cooling systems. Biofouling 2010, 26, 923–930. [Google Scholar] [CrossRef]

- Murakawa, M.; Takeuchi, S. Quantitative adhesion strength measurement of diamond coatings. Thin Solid Films 1989, 181, 443–450. [Google Scholar] [CrossRef]

- Xie, Z.; Zhu, J. The effect of the vertical load on the scraping test. Thin Solid Films 1998, 315, 192–194. [Google Scholar] [CrossRef]

- Xie, Z.; Zhu, J.; Guo, W. The Scraping Test and Adhesion Measurements of Diamond and Nickel Electroless Coatings. Mater. Charact. 2000, 44, 347–352. [Google Scholar] [CrossRef]

- Daitoku, T.; Utaka, Y. An effect of scraper shapes on detachment of solid adhered to cooling surface for formation of clathrate hydrate slurry. Heat Transfer. Asian Res. 2007, 36, 489–500. [Google Scholar] [CrossRef]

- Matsumoto, K.; Akimoto, T.; Teraoka, Y. Study of scraping force of ice growing on cooling solid surface. Int. J. Refrig. 2010, 33, 419–427. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Utaka, Y.; Daitoku, T.; Ohkubo, H.; Yang, C. Scraping force characteristics of frost formed on vertical cooling surfaces having different structures and wettability. Int. J. Refrig. 2019, 101, 148–154. [Google Scholar] [CrossRef]

- Jadidi, P.; Zeinoddini, M.; Soltanpour, M.; Zandi, A.P.; Seif, M.S. Towards an understanding of marine fouling effects on VIV of circular cylinders: Aggregation effects. Ocean Eng. 2018, 147, 227–242. [Google Scholar] [CrossRef]

- Crisp, D.J.; Bourget, E. Growth in Barnacles. Adv. Mar. Biol. 1985, 22, 199–244. [Google Scholar]

- And, A.B.Y.; Walker, G. The Adhesion of the Barnacle, Balanus Balanoides, to Slate Surfaces. J. Mar. Biol. Assoc. UK 2009, 64, 147–156. [Google Scholar]

- Smith, D.A.M.; Callow, D.J.A. Biological Adhesives, 1st ed.; Springer: Berlin, Germany, 2006; pp. 145–152. [Google Scholar]

- Pesika, N.S.; Tian, Y.; Zhao, B.; Rosenberg, K.; Zeng, H.; McGuiggan, P.; Autumn, K.; Israelachvili, J.N. Peel-zone model of tape peeling based on the gecko adhesive system. J. Adhes. 2007, 83, 383–401. [Google Scholar] [CrossRef]

- Yu, T.; Noshir, P.; Hongbo, Z.; Kenny, R.; Boxin, Z.; Patricia, M.G.; Kellar, A.; Jacob, I. Adhesion and friction in gecko toe attachment and detachment. Proc. Natl. Acad. Sci. USA 2006, 103, 19320–19325. [Google Scholar]

- Merchant, M.E. Mechanics of the Metal Cutting Process. I. Orthogonal Cutting and a Type 2 Chip. J. Appl. Phys. 1945, 16, 267–275. [Google Scholar] [CrossRef]

- Merchant, M.E. Mechanics of the Metal Cutting Process. II. Plasticity Conditions in Orthogonal Cutting. J. Appl. Phys. 1945, 16, 318–324. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Wang, G.; Chen, K.; Jia, P.; Wang, L.; Wang, X.; Yun, F. Analysis of Removing Barnacles Attached on Rough Substrate with Cleaning Robot. J. Mar. Sci. Eng. 2020, 8, 569. https://doi.org/10.3390/jmse8080569

Li C, Wang G, Chen K, Jia P, Wang L, Wang X, Yun F. Analysis of Removing Barnacles Attached on Rough Substrate with Cleaning Robot. Journal of Marine Science and Engineering. 2020; 8(8):569. https://doi.org/10.3390/jmse8080569

Chicago/Turabian StyleLi, Chao, Gang Wang, Kaiyun Chen, Peng Jia, Liquan Wang, Xiangyu Wang, and Feihong Yun. 2020. "Analysis of Removing Barnacles Attached on Rough Substrate with Cleaning Robot" Journal of Marine Science and Engineering 8, no. 8: 569. https://doi.org/10.3390/jmse8080569

APA StyleLi, C., Wang, G., Chen, K., Jia, P., Wang, L., Wang, X., & Yun, F. (2020). Analysis of Removing Barnacles Attached on Rough Substrate with Cleaning Robot. Journal of Marine Science and Engineering, 8(8), 569. https://doi.org/10.3390/jmse8080569