On the Use of the Hybrid Causal Logic Methodology in Ship Collision Risk Assessment

Abstract

1. Introduction

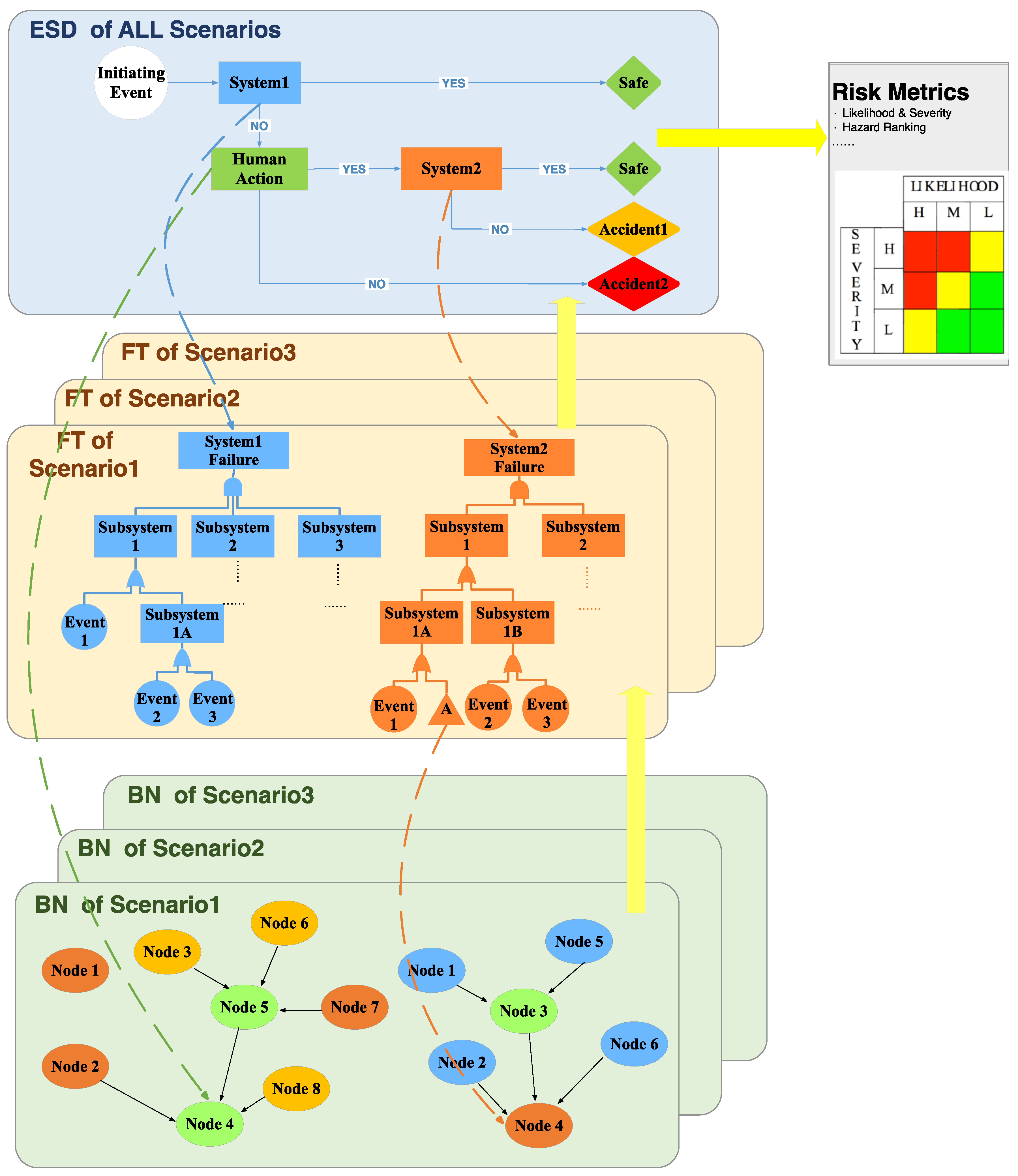

2. Overview of the HCL Methodology

2.1. HCL Modeling Concept and Algorithm Overview

2.2. HCL-Based Risk Management Metrics

2.3. Methodological Framework

- (1)

- Define the risk influencing factors (RIF) and causal relationships of all the possible accident event sequences and form the ESD with the relevant intermediate events.

- (2)

- Model the events related to hardware failures by performing system decompositions using FTs.

- (3)

- Model the events that are influenced by human factors or other factors at a more detailed level by using BNs.

- (4)

- Assign relevant event probabilities in the ESDs and FTs, and the Conditional Probability Tables (CPTs) in the BNs.

- (5)

- Calculate the risk results.

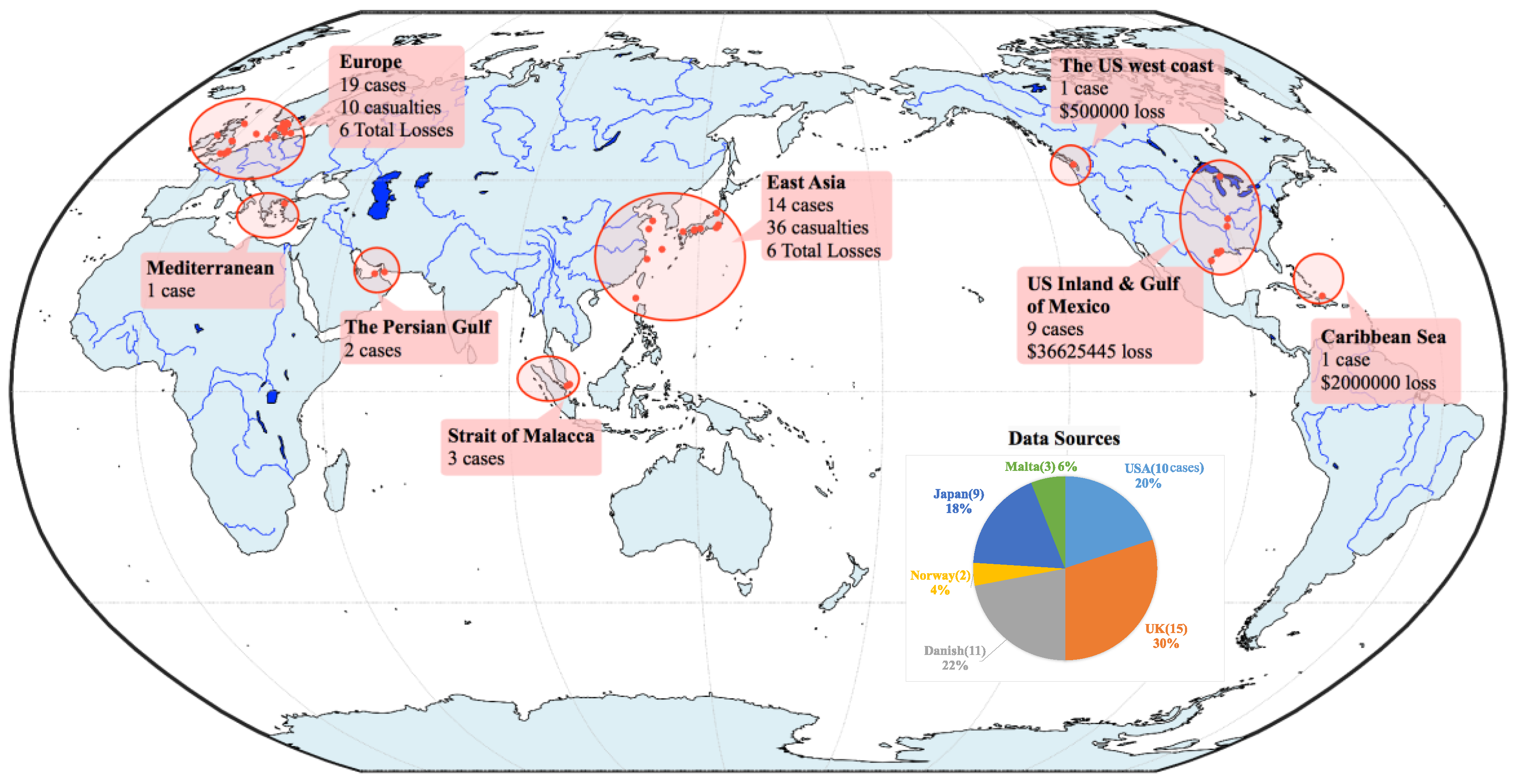

3. Information Sources and Modeling Procedure

3.1. Accident Reports

3.2. Modeling Approach

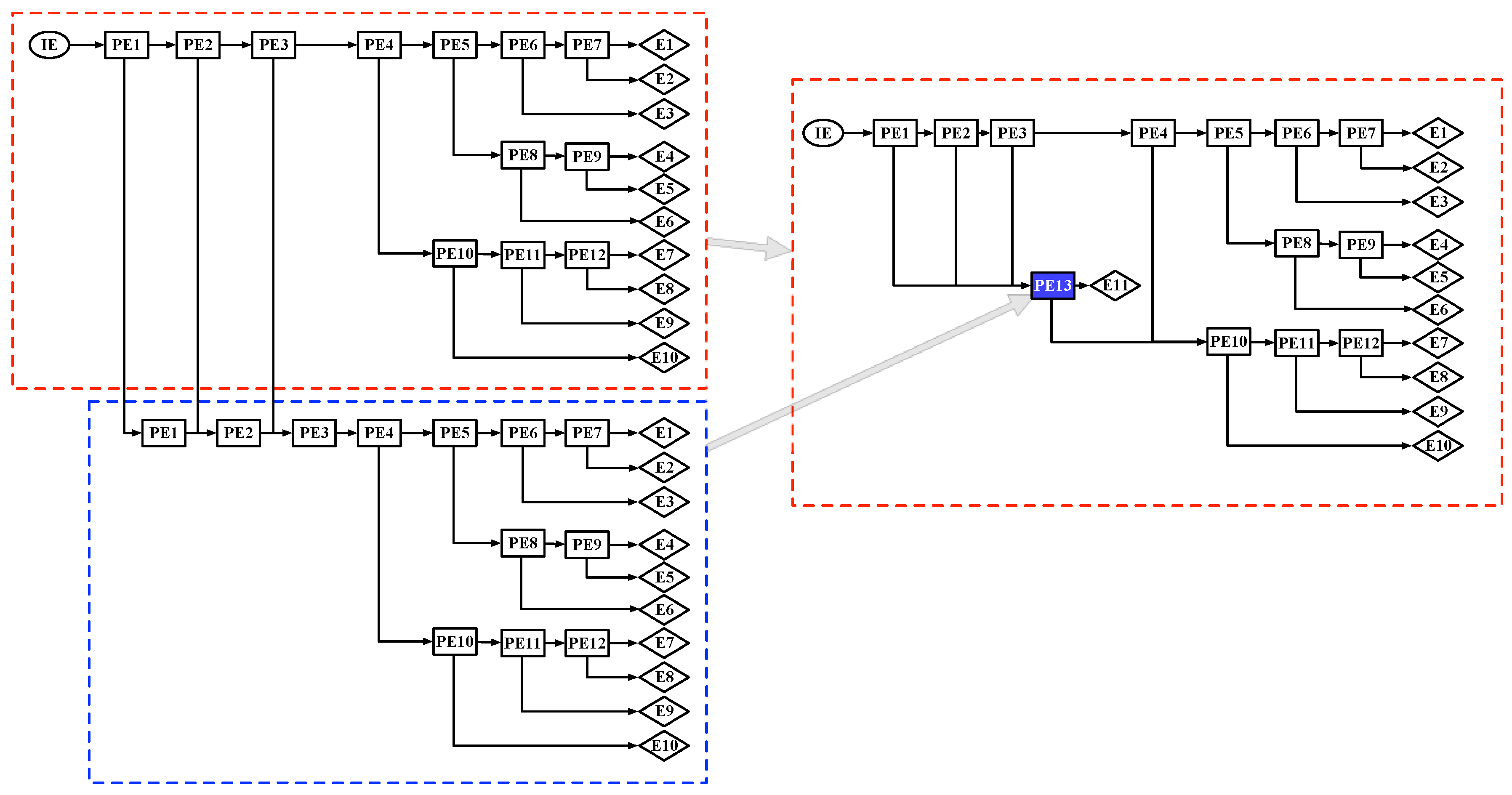

4. HCL Model for Ship Collision Risk Analyses of the Conventional Scenario

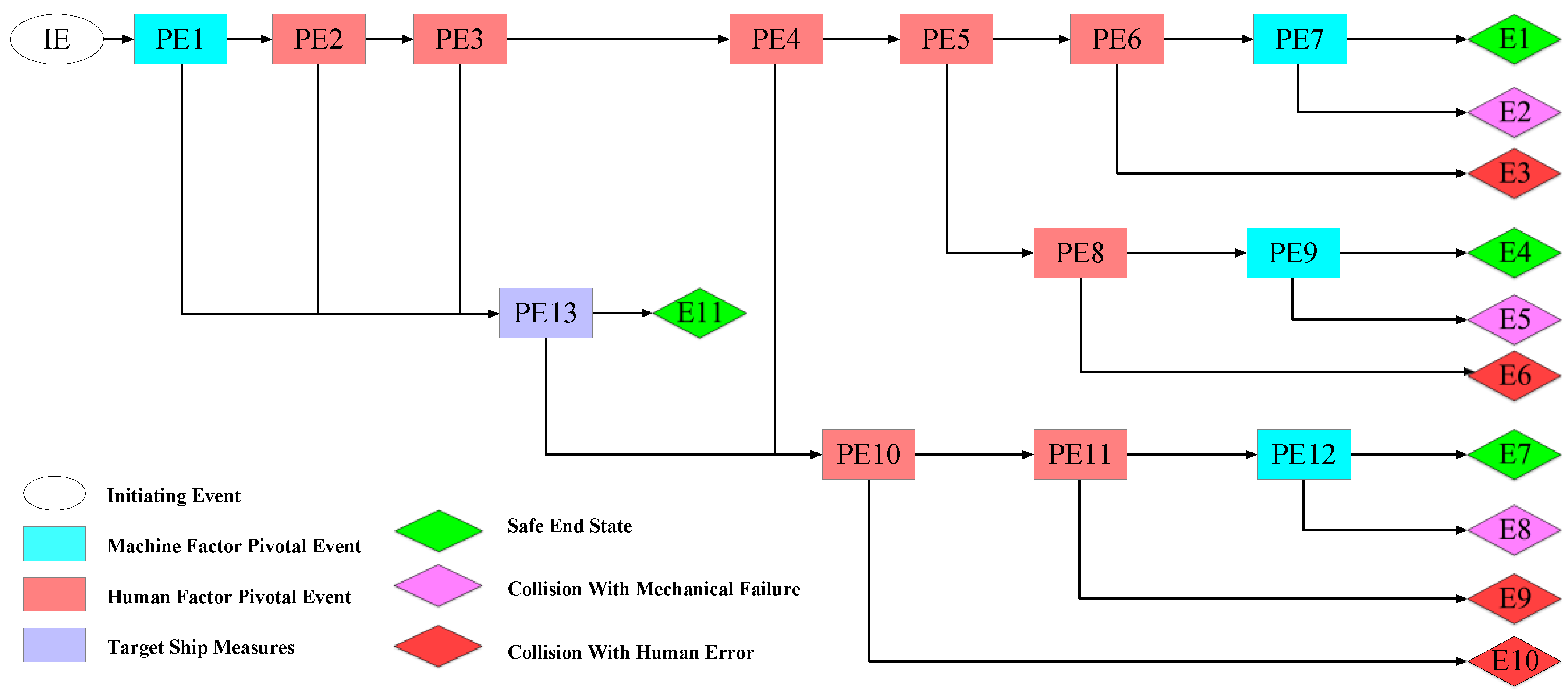

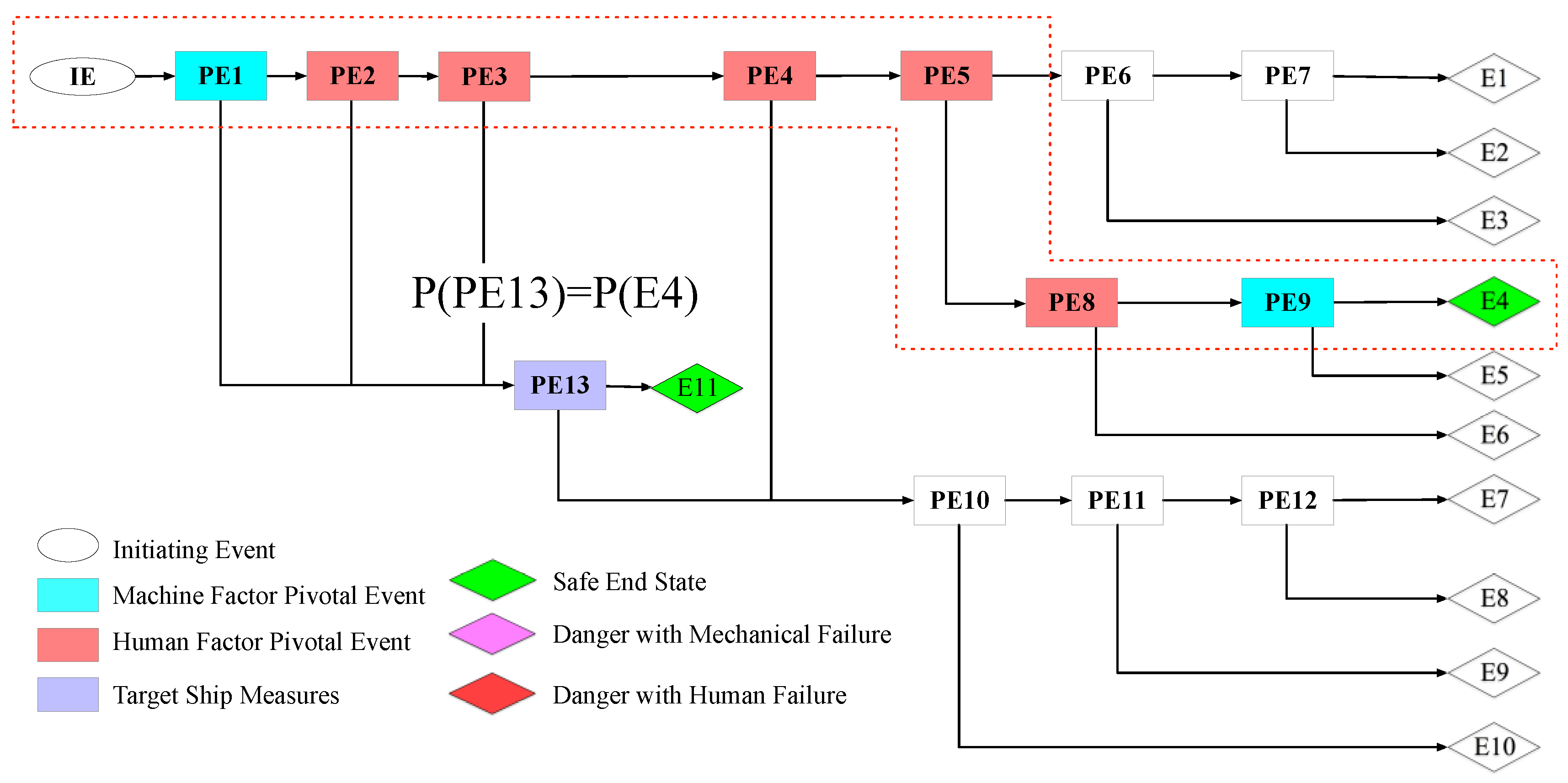

4.1. ESD Constructions of Ship Collision Scenario

- (1)

- The scenarios with successful communication with TS: This will lead to a collaborative effort between both sides for avoiding a collision (PE 4\5\6\7, End 1\2\3);

- (2)

- The scenarios with failed communication with TS: This will lead to a unilateral effort of collision avoidance (PE 4\8\9, End 4\5\6);

- (3)

- The scenarios under emergency conditions: Since it is under emergency conditions, both ships do not have time to communicate with each other and only take recovery measures based on their assessment alone (PE 10\11\12, End 7\8\9\10).

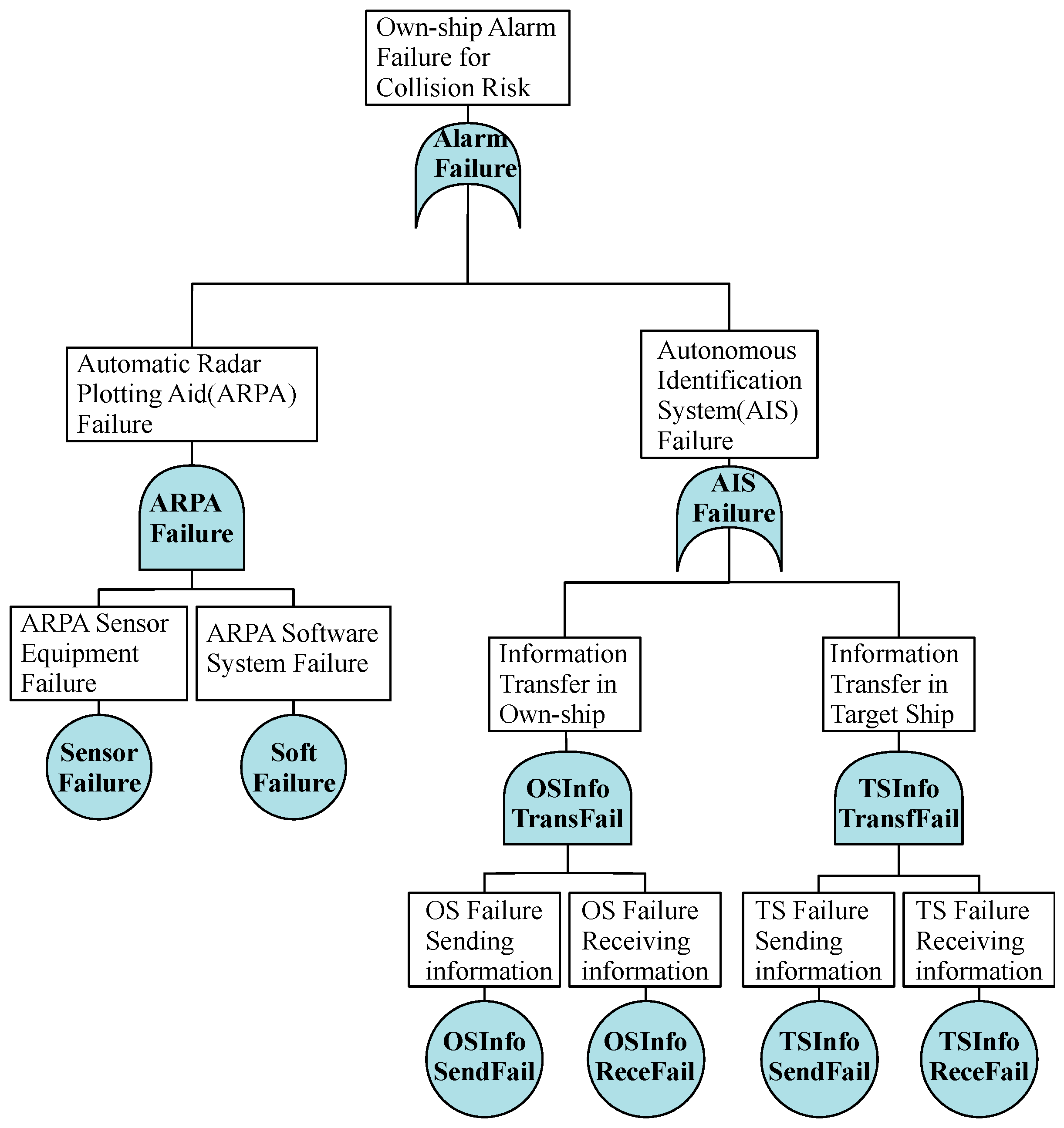

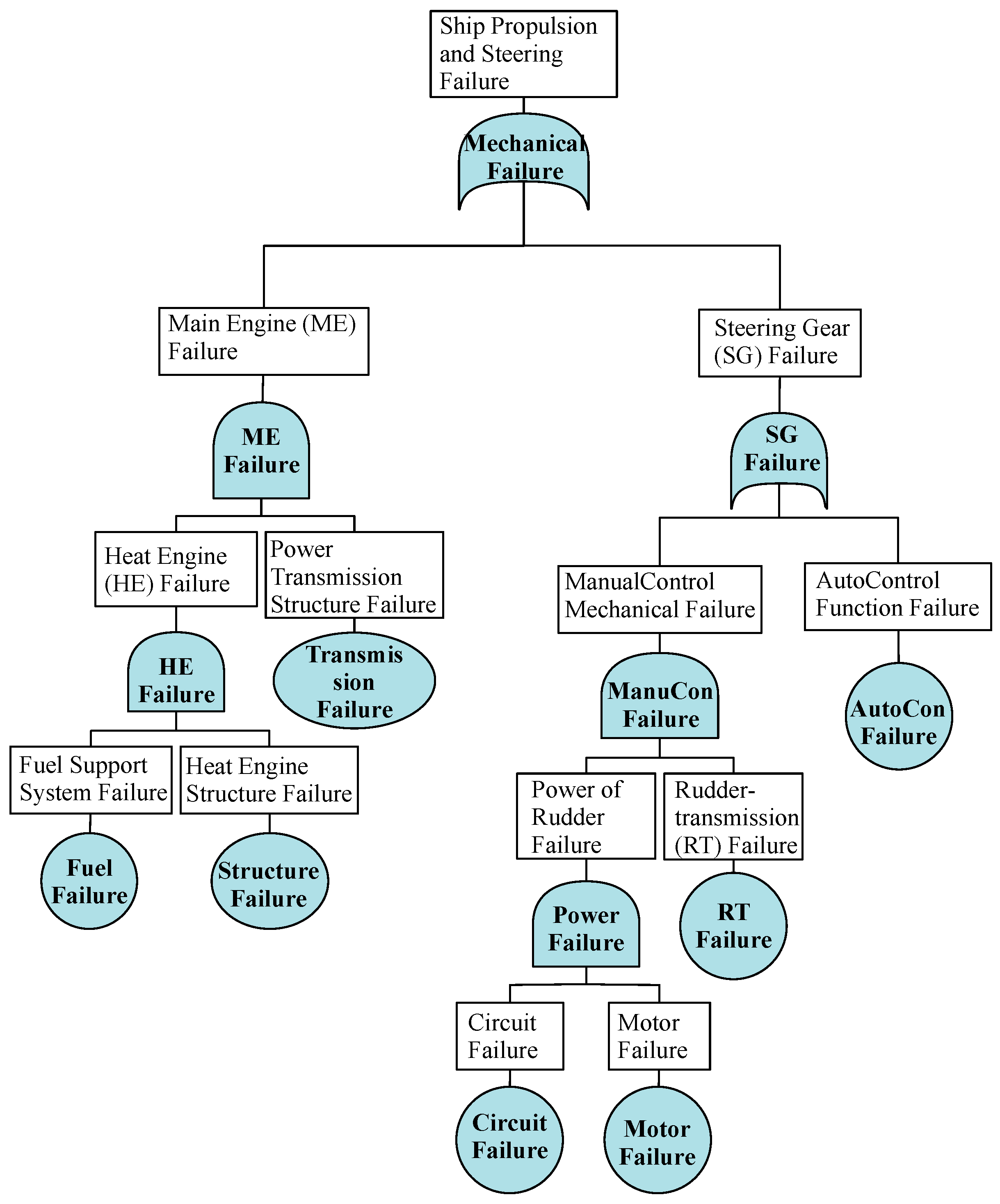

4.2. FTs Modeling of the Conventional Scenario

4.3. BNs Modeling of the Conventional Scenario

4.4. Model Assignment of the HCL Model

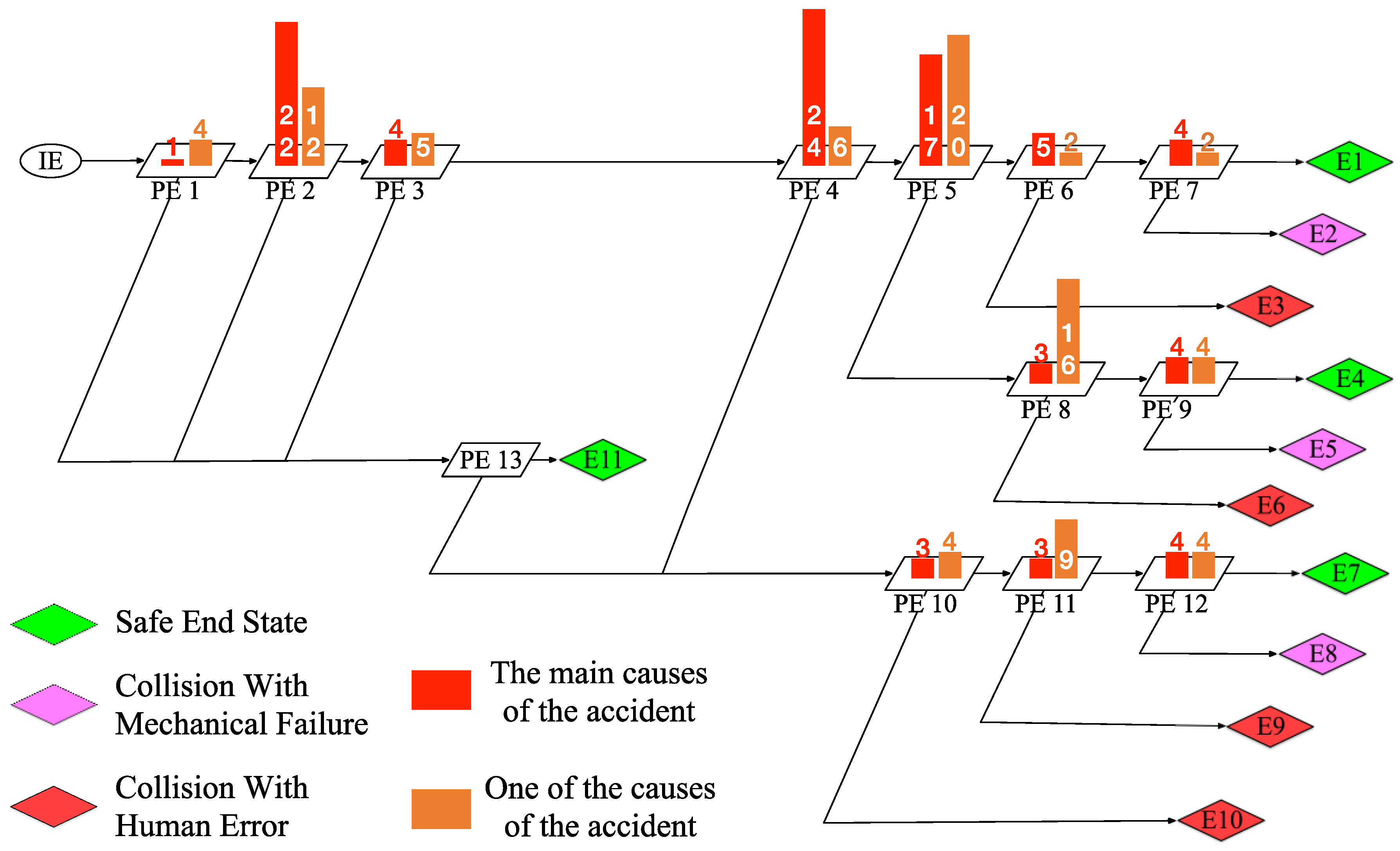

5. Results of Risk Analysis of Ship Collision Accident Scenarios

- (1)

- All the results are based on the probability of Initial Event (IE). The value is preset as Pr(IE) = 1 in Table 3 to show the probability of safe and collision in an easier way. This result shows that, given the probability of a dangerous encounter situation, the probability of safety is 0.3926 and the probability of a collision accident is 0.6073. Among it, the probability of accidents due to human error accounts for 94.27% of the total accident probability, and the probability of accidents due to mechanical failure is 5.73%.

- (2)

- The value of Pr(IE) comes from experts’ opinion, which means that in daily navigation, about Pr(IE) of the conflicts may lead to more urgent situations. In academically accepted data [41,42,43], the causation probability of different types of collision accidents is different, for instance, the causation probability of overtaking and head-on are 4.90 × 10−5, while the probability of crossing is 1.30 × 10−4.

- (3)

- The collision accidents due to human factors are accounted for 94.27% of the total in the ship collision scenario. Considering that the industry consensus is that 75–96% of marine accidents are human factor related [44,45], this result is reasonable. Compared with other situations, mechanical failure is more unlikely. Therefore, the improvement of ship collision safety by enhancing human reliability will be more effective than the improvement of mechanical system reliability.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. List of Accidents Analyzed (in Chronological Order)

| Case No. | Ship1, Type (Main Responsible) | Ship2, Type | Location | Date | Injuries | Property Damage (US $) | Source of Data | |

| Longitude and Latitude Data | Detail | |||||||

| 1. | FU SHAN HAI, Bulk carrier | GDYNIA, Container | 55°21.0′ N 014°44.6′ E | North of Bornholm in the Baltic Sea | 2003/5/31, 12:18 | None | FU SHAN HAI sank | Danish Division for Investigation of Maritime Accidents |

| 2. | BERGITTA, Tanker | MSC EYRA, Tanker | 55°11.55′ N 011°05.00′ E | Southwest of Agersoe Flak | 2004/24/10, 22:18 | None | 2,000,000 | The Danish Maritime Accident Investigation Board |

| 3. | ATLANTIC, bulk carrier | ARNGAST, general cargo vessel | 54°43.2′ N 010°46.9′ E | DW route east of Langeland, Denmark | 2005/8/4 | None | Danish Division for Investigation of Maritime Accidents | |

| 4. | BLUE BIRD, General cargo | HAGLAND BONA, General cargo | 56°30′28 N 10°13′77 E. | Randers Fjord, Denmark | 2008/12/1 | None | Danish Division for Investigation of Maritime Accidents | |

| 5. | GOTLAND CAROLINA, Products Tanker | CONTI HARMONY, Container Vessel | 25°25.3′ N 057°21.7′ E | Gulf of Oman | 2008/19/04, 09:26 | None | 2,000,000 | The Danish Maritime Accident Investigation Board |

| 6. | Eagle Otome, oil tankship | Dixie Vengeance, towboat | 29°51.6′ N 93°56.4′ W | Sabine-Neches Canal, Port of Port Arthur, Texas | 2010/1/23, 09:35 | None | 1,926,000 | National Transportation Safety Board (USA) |

| 7. | NINANITU, Fishing vessel | AFRICAN ZEBRA, Bulk carrier | 56°26.33′ N 11°32.5′ E | Kattegat, Route T | 2010/6/7, 18:41 | One fisherman injured | 2,000,000 | The Danish Maritime Accident Investigation Board |

| 8. | FRANK W, cargo | LILLY, trawler | 57 43′6 N 010 51′9 E | 2011/06/26, 07:38 | None | Lilly total loss | Danish Division for Investigation of Maritime Accidents | |

| 9. | Elka Apollon, Chemical tankship | MSC Nederland, Containership | 29°36′44.0″ N 94°57′ 02.7″ W | near the intersection of the Houston and Bayport Ship Channels and Five Mile Cut | 2011/10/29, 09:05 | None | 2,800,000 | National Transportation Safety Board (USA) |

| 10. | ACX Hibiscus, Container ship | Hyundai Discovery, Container ship | 01°30.855 N 104°33.475 E | 8nm ENE of the start of the Eastern Singapore Strait Traf c Separation Scheme | 2011/11/12, 07:56 | None | 2,000,000 | Marine Accident Investigation Branch, United Kingdom |

| 11. | Alexander Tvardovskiy, Multi-purpose dry cargo | UKD Bluefin, Trailing suction hopper dredger and Wilson Hawk, General cargo | 53°37′55.1″ N 0°11′06.7″ W | Immingham | 2012/01/08, 13:37 | None | 2,000,000 | Marine Accident Investigation Branch, United Kingdom |

| 12. | TIAN FU (TIANJIN), Container ship | SENTAIMARU, Chemical tanker | 34°27′09″ N 133°45′23″ E | In Mizushima Port, Kurashiki City, Okayama Prefecture | 2012/03/07, 07:15 | None | 2,000,000 | Japan Transport Safety Board |

| 13. | MV SPRING BOK, cargo vessel | MV GAS ARCTIC, liquid petroleum gas (LPG) tanker | 50°49.1′ N 00°58.8′ E | 6nm south of Dungeness, UK | 2012/03/24, 10:14 | None | 2,000,000 (12,500 L of diesel oil leakage, 5500 L of lubricating oil leakage) | Marine Accident Investigation Branch, United Kingdom |

| 14. | SPRING GLORY, Bulk carrier | JOSEPHINE MÆRSK, Container ship | 1°25.3′ N 104°29.01′ E | Strait of Singapore, eastern approaches, about 7 nm NE of Horsburgh Lighthouse | 2012/05/06, 22:34 | None | 2,000,000 | The Danish Maritime Accident Investigation Board |

| 15. | FR8 Pride, oil tanker | Rowan EXL I, mobile offshore drilling unit (MODU) | 27°49.1′ N 097°00.5′ W | Aransas Pass - Port Aransas/Corpus Christi, Texas | 2012/05/02, 07:18 | None | 17,000,000 | National Transportation Safety Board (USA) |

| 16. | KOTA DUTA, Container ship | TANYA KARPINSKAYA, Cargo ship | 37°58.5′ N 139°13.9′ E | Vicinity of 180° true, 4900 m from Port of Niigata Higashi Ku | 2012/07/02, 16:22 | None | TANYA KARPINSKAYA foundered | Japan Transport Safety Board |

| 17. | Stena Feronia, RoPax | Union Moon, General cargo vessel | 54°55′ N 5°54′ W | Belfast Lough | 2012/07/03, 18:58 | None | 2,000,000 | Marine Accident Investigation Branch, United Kingdom |

| 18. | Seagate, Geared bulk carrier | Timor Stream, Refrigerated-cargo ship with containers on deck | 20°18.4 N 071°38.9 W | 24 nautical miles north of the Dominican Republic | 2012/10/03, 05:40 | None | 2,000,000 | Marine Accident Investigation Branch, United Kingdom |

| 19. | CMA CGM Florida, Container vessel | Chou Shan, Bulk carrier | 30°14′23.0″ N 125°50′07.4″ E | 140 miles east of Shanghai, East China Sea | 2013/03/19, 00:33 | None | 2,000,000 | Marine Accident Investigation Branch, United Kingdom |

| 20. | TYUMEN-2, Cargo ship | OOCL FINLAND, Container ship | 54°8.5′ N 009°20.65′ E | Kiel Canal (NOK), km 32.2 | 2013/04/14, 07:00 | 2 people killed and 3 injured | Marine Accident Investigation Branch, United Kingdom | |

| 21. | American Dynasty, US fishing vessel | Winnipeg, Canadian Navy frigate | 48°25.9′ N 123°25.8′ W | Esquimalt, British Columbia, Canada | 2013/4/23, 0817 | 6 (minor injuries) | 500,000 | National Transportation Safety Board (USA) |

| 22. | Cosco Hong Kong, Container Ship | Zhe Ling Yu Yun 135, Fish Transportation | 28°10′7 N 122°14′5 E | 126° Xia Yu Light 22 nm | 2013/06/03, 02:18 | 11 dead | Fish Vessel lost | Marine Accident Investigation Branch, United Kingdom |

| 23. | JIA HUI, Cargo ship | EIFUKU MARU No.18, Cargo ship | 34°47.46′ N 139°15.53′ E | Approximately 265° true and 5.6 nautical miles from Izu Oshima Lighthouse off the west of Izu Oshima Island, Oshima-machi, Tokyo | 2013/09/27, 01:22 | EIFUKU MARU No.18 capsized and all 6 crew members were killed dead, and JIA HUI had damage on the bow but no one was injured or killed dead. | Japan Transport Safety Board | |

| 24. | PUTERI NILAM SATU, LNG tanker | SAKURA HARMONY, LPG tanker | 35°26.0′ N 139°46.2′ E | Off the East of Yokohama District of Keihin Port | 2013/10/01, 12:19 | None | 2,000,000 | Japan Transport Safety Board |

| 25. | Ever Smart, container ship | Alexandra 1, oil tanker | 25°03′02.4″ N 55°01′32.5″ E | Jebel Ali, United Arab Emirates | 2013/11/02, 19:42 | None | 2,000,000 | Marine Accident Investigation Branch, United Kingdom |

| 26. | Paula C, General cargo | Darya Gayatri, Bulk carrier | 51°22.8586 N 1°18′42.2″ E | south-west lane of the Dover Strait Traffic Separation | 2013/11/12, 00:27 | None | 2,000,000 | Marine Accident Investigation Branch, United Kingdom |

| 27. | Mesabi Miner, a self-unloading bulk carrier | Hollyhock, US Coast Guard cutter | 45°51′ N 085°15′ W | Straits of Mackinac, Michigan | 2014/01/05 | None | 494,145 | National Transportation Safety Board (USA) |

| 28. | Summer Wind, bulk carrier | Miss Susan tow | 29°21′18.3″ N 94°47′58.1″ W | Houston Ship Channel, Lower Galveston Bay, Texas. | 2014/03/22, 12:35 | None | 1,378,000 | National Transportation Safety Board (USA) |

| 29. | BEAGLE III, Cargo ship | PEGASUS PRIME, Container ship | 35°05.7′ N 139°43.2′ E | South-east offshore Tsurugizaki, Miura City, Kanagawa Prefecture, Around 143° true, 3.5M from Tsurugisaki Lighthouse | 2014/08/03, 03:10 | Seven crews of BEAGLE III died, two are missing, and the ship sank due to a damage hole in side shell plating of the central port-side. A crew of PEGASUS PRIME was injured and the ship bow buckled. | Japan Transport Safety Board | |

| 30. | RIG, General cargo | INGE MARIE, Fishing vessel–stern trawler | 57°26.81′ N 011°27.17′ E | Kattegat, Sweden | 2014/10/07, 06:07 | 1 death (crew on INGER MARIE) | 2,000,000 | The Danish Maritime Accident Investigation Board |

| 31. | KRASLAVA, Chemical/products tanker | ATLANTIC LADY, Refrigerated cargo ship | 55°32.0′ N 12 °42.5′ E | The Sound, southern part, Denmark | 2014/11/1, 13:19 | None | The Danish Maritime Accident Investigation Board | |

| 32. | Star Kvarven, Mixed cargo/bulk/container | Lulanyu 61809, Stern trawler | 34°34.7′ N 122° 04.3′ E | The Yellow Sea | 2014/11/27, 22:20 | Lulanyu 61809, fishing vessel sank and entire crew of 8 died | Accident Investigation Board Norway (AIBN) | |

| 33. | NECKAR HIGHWAY, Vehicle carrier | ORION, AS 28, Fishing vessel, gillnetter | 57°36.804′ N 009°50.871′ E | North Sea, 4 nm northwest of Hirtshals | 2015/01/07, 23:27 | None | ORION total loss | The Danish Maritime Accident Investigation Board |

| 34. | Chembulk Houston, tanker | Monte Alegre, container ship | 29°26.2′ N 94°50.2′ W | Houston Ship Channel, Galveston Bay, Houston, Texas.USA | 2015/3/5 | None | 1,727,300 | National Transportation Safety Board (USA) |

| 35. | Conti Peridot, Bulk carrier | Carla Maersk, Chemical tanker | 29°40′38.5″ N 94°58′44.9″ W | Houston Ship Channel near Morgan’s Point, Texas. USA | 2015/03/09, 12:30 | None | 8,200,000 | National Transportation Safety Board (USA) |

| 36. | Tongala, Vehicle carrier | Bo Spring, General cargo | 19° 51.20′ N 119° 56.5′ E | off the coast of the Philippines | 2015/05/07, 15:35 | None | 2,000,000 | Marine Safety Investigation Unit, Malta |

| 37. | SULPHUR GARLAND, Chemical Tanker | WAKOMARU NO. 2, Oil Tanker | 33°58.9′ N 130°52.9′ E | East off Mutureshima Island, Shimonoseki City, Yamaguchi Prefecture | 2015/07/10, 03:26 | None | 2,000,000 | Japan Transport Safety Board |

| 38. | Daroja, general cargo ship | Erin Wood, oil bunker barge | 57°32′34.1″ N 1°36′01.2″ W | 4 nautical miles south-east of Peterhead, Scotland | 2015/08/29, 16:58 | None | Marine Accident Investigation Branch, United Kingdom | |

| 39. | Dewey R tow, Towing vessel | P. B. Shah tow, Towing vessel | 36°46′05.2″ N 89°06′59.5″ W | Lower Mississippi River, near Columbus, Kentucky. USA | 2015/09/02, 19:59 | None | 1,100,000 | National Transportation Safety Board (USA) |

| 40. | Clipper Quito, VLGC LPG/Ethylene | Lurongyu 71108, Blue fishing vessel–Stern trawler | 36° 17.6′ N 122° 53.7′ E | The Yellow Sea | 2015/10/21, 20:00 | Lurongyu 71108, fishing vessel sank and 1 crew died | Accident Investigation Board Norway (AIBN) | |

| 41. | City of Rotterdam, pure car carrier | Primula Seaways, the ro-ro freight ferry | 53°35.1 N 000°02.6 E | River Humber, UK | 2015/12/03, 20:40 | None | Marine Accident Investigation Branch, United Kingdom | |

| 42. | William E Strait, Towing vessel | Margaret Ann tow, Towing vessel | 35°07′17.8″ N 90°09′50.1″ W | Lower Mississippi River (LMR), mile marker 727.4 | 2015/12/14, 11:22 | None | 2,000,000 | National Transportation Safety Board (USA) |

| 43. | Petunia Seaways | Peggotty | 53°37′45.8″ N 0°08′24.0″ W | River Humber, out Immingham | 2016/05/19, 04:50 | None | Peggotty total loss | Marine Accident Investigation Branch, United Kingdom |

| 44. | Container Ship ESTELLE MAERSK | Container Ship JJ SKY | 34°38.7′ N 135°16.0′ E | Kobe Chuo Passage, Kobe Section, Hanshin Port | 2016/07/06, 07:08 | None | 2,000,000 | Japan Transport Safety Board |

| 45. | EASTERN PHOENIX, Chemical Tanker | KEIHIN MARU No. 8, Oil Tanker | 35°28.2′ N 139°47.3′ E | Off to the Southeast of Higashi-Ogishima Island, Kawasaki City, Kanagawa Prefecture; | 2016/07/08, 09:27 | None | 2,000,000 | Japan Transport Safety Board |

| 46. | Saga Sky, General cargo | Stema Barge II, Barge | 51°05′51.1″ N 1°18′42.2″ E | English Channel, off the Kent Coast | 2016/11/20, 08:50 | None | Marine Accident Investigation Branch, United Kingdom | |

| 47. | Sider Capri, General Cargo | Grande Anversa, Vehicle Carrier | 40°01.45′ N 026°11.37′ E | Çanakkale Strait’s Traffic Separation Scheme | 2016/11/27, 19:06 | None | 2,000,000 | Marine Safety Investigation Unit, Malta |

| 48. | Gortynia, Bulk carrier | DZ Qingdao, Bulk carrier | 1°11.67′ N 103°51.64′ E | Singapore Strait | 2017/05/17, 00:30 | None | 2,000,000 | Marine Safety Investigation Unit, Malta |

| 49. | Vertrouwen, Commercial Fshing vessel | James 2, recreational motor cruiser | 50°49.33′ N 000°12.56′ W | Near Shoreham | 2017/06/08, 00:26 | 3 death | James 2 total loss | Marine Accident Investigation Branch, United Kingdom |

| 50. | ASIAN BEAUTY, Cargo ship | ZEUS, Liquefied gas bulk carrier | 34°15.3′ N 133°38.3′ E | Around 328o true bearing and 1.4 nautical miles from the Takuma port Sudaichimonji breakwater east lighthouse | 2017/07/08, 06:08 | None | 2,000,000 | Japan Transport Safety Board |

References

- Inoue, K.; Kawase, M. Innovative probabilistic prediction of accident occurrence. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2007, 1, 19–22. [Google Scholar]

- Montewka, J.; Goerlandt, F.; Kujala, P. On a systematic perspective on risk for formal safety assessment (FSA). Reliab. Eng. Syst. Saf. 2014, 127, 77–85. [Google Scholar] [CrossRef]

- Yang, W.; Shanshan, F.; Bing, W.; Jinhui, H.; Xiaoyang, W. Towards optimal recovery scheduling for dynamic resilience of networked infrastructure. J. Syst. Eng. Electron. 2018, 29, 995–1008. [Google Scholar] [CrossRef]

- Wu, B.; Yip, T.L.; Yan, X.; Guedes Soares, C. Fuzzy logic based approach for ship-bridge collision alert system. Ocean Eng. 2019, 187, 106152. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, D.; Yao, H.; Zhang, K. A probabilistic model of human error assessment for autonomous cargo ships focusing on human–autonomy collaboration. Saf. Sci. 2020, 130, 104838. [Google Scholar] [CrossRef]

- Zhang, W.; Floris, G.; Jakub, M.; Pentti, K. A method for detecting possible near miss ship collisions from AIS data. Ocean Eng. 2015, 107, 60–69. [Google Scholar] [CrossRef]

- Wu, B.; Cheng, T.; Yip, T.L.; Wang, Y. Fuzzy logic based dynamic decision-making system for intelligent navigation strategy within inland traffic separation schemes. Ocean Eng. 2020, 197, 106909. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, D.; Yan, X.; Haugen, S.; Soares, C.G.; Guedes Soares, C. A distributed anti-collision decision support formulation in multi-ship encounter situations under COLREGs. Ocean Eng. 2015, 105, 336–348. [Google Scholar] [CrossRef]

- Perera, L.P.; Carvalho, J.P.; Guedes Soares, C. Fuzzy logic based decision making system for collision avoidance of ocean navigation under critical collision conditions. J. Mar. Sci. Technol. 2011, 16, 84–99. [Google Scholar] [CrossRef]

- Perera, L.P.; Carvalho, J.P.; Guedes Soares, C.; Fang, Z.; Yu, H.; Ke, R.; Shaw, S.; Peng, G.; Chen, L.; Huang, Y.; et al. Intelligent ocean navigation and fuzzy-Bayesian decision/action formulation. IEEE J. Ocean. Eng. 2012, 37, 204–219. [Google Scholar] [CrossRef]

- Goerlandt, F.; Ståhlberg, K.; Kujala, P. Influence of impact scenario models on collision risk analysis. Ocean Eng. 2012, 47, 74–87. [Google Scholar] [CrossRef]

- Du, L.; Goerlandt, F.; Valdez Banda, O.A.; Huang, Y.; Wen, Y.; Kujala, P. Improving stand-on ship’s situational awareness by estimating the intention of the give-way ship. Ocean Eng. 2020, 201, 107110. [Google Scholar] [CrossRef]

- Wang, T.; Wu, Q.; Zhang, J.; Wu, B.; Wang, Y. Autonomous decision-making scheme for multi-ship collision avoidance with iterative observation and inference. Ocean Eng. 2020, 197, 106873. [Google Scholar] [CrossRef]

- Bakdi, A.; Glad, I.K.; Vanem, E.; Engelhardtsen, Ø. AIS-based multiple vessel collision and grounding risk identification based on adaptive safety domain. J. Mar. Sci. Eng. 2020, 8, 5. [Google Scholar] [CrossRef]

- Wang, T.; Yan, X.P.; Wang, Y.; Wu, Q. Ship Domain Model for Multi-ship Collision Avoidance Decision-making with COLREGs Based on Artificial Potential Field. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2017, 11, 85–92. [Google Scholar] [CrossRef]

- Zhang, L.; Meng, Q. Probabilistic ship domain with applications to ship collision risk assessment. Ocean Eng. 2019, 186, 106130. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, L.; van Gelder, P.H.A.J.M. Generalized velocity obstacle algorithm for preventing ship collisions at sea. Ocean Eng. 2019, 173, 142–156. [Google Scholar] [CrossRef]

- Goerlandt, F.; Montewka, J. A framework for risk analysis of maritime transportation systems: A case study for oil spill from tankers in a ship-ship collision. Saf. Sci. 2015, 76, 42–66. [Google Scholar] [CrossRef]

- Fan, S.; BlancoDavis, E.; Yang, Z.; Zhang, J.; Yan, X. Incorporation of human factors into maritime accident analysis using a data-driven Bayesian network. Reliab. Eng. Syst. Saf. 2020, 203, 107070. [Google Scholar] [CrossRef]

- Wang, C. Hybrid Causal Logic Methodology for Risk Assessment. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2007. [Google Scholar]

- Groen, F.J.; Mosleh, A. An algorithm for the quantification of hybrid causal logic models. In Proceedings of the 8th International Conference on Probabilistic Safety Assessment and Management, PSAM 2006, New Orleans, LA, USA, 14–18 May 2006; pp. 924–930. [Google Scholar]

- Ren, D.; Zheng, W.; Wu, D. Hybrid causal methodology in quantitative risk assessment for the on-board ATP of high speed railway. In Proceedings of the 2014 17th IEEE International Conference on Intelligent Transportation Systems, ITSC 2014, Qingdao, China, 8–11 October 2014; pp. 1577–1582. [Google Scholar]

- Røed, W.; Mosleh, A.; Vinnem, J.E.; Aven, T. On the use of the hybrid causal logic method in offshore risk analysis. Reliab. Eng. Syst. Saf. 2009, 94, 445–455. [Google Scholar] [CrossRef]

- Wang, Y.F.; Xie, M.; Habibullah, M.S.; Ng, K.M. Quantitative risk assessment through hybrid causal logic approach. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2011, 225, 323–332. [Google Scholar] [CrossRef]

- Diaconeasa, M.A. Integration of Qualitative and Quantitative Hybrid Causal Logic into a Simulation-Based Platform for Probabilistic Risk Assessment of Nuclear Power Plants. Ph.D. Thesis, University of California, Los Angeles, CA, USA, 2017. [Google Scholar]

- Quantitative risk assessment system (QRAS). Reliab. Eng. Syst. Saf. 2006, 91, 292–304. [CrossRef]

- Mosleh, A.; Dias, A.; Eghbali, G.; Fazen, K. An Integrated Framework for Identification, Classification, and Assessment of Aviation Systems Hazards. In Probabilistic Safety Assessment and Management; Springer: London, UK, 2004; pp. 2384–2390. [Google Scholar]

- Cheok, M.C.; Parry, G.W.; Sherry, R.R. Use of importance measures in risk-informed regulatory applications. Reliab. Eng. Syst. Saf. 1998, 60, 213–226. [Google Scholar] [CrossRef]

- Meng, F.C. Relationships of Fussell-Vesely and Birnbaum Importance to Structural Importance in Coherent Systems. Reliab. Eng. Syst. Saf. 2000, 67, 55–60. [Google Scholar] [CrossRef]

- Board, S. Marine Accident. Available online: https://www.ntsb.gov/investigations/AccidentReports/Pages/marine.aspx (accessed on 29 July 2019).

- Mærsk, S. The Danish Maritime Accident Investigation Board. Available online: www.dmaib.com (accessed on 11 February 2019).

- MAIB Marine Accident Investigation Branch—About Us. Available online: http://www.maib.gov.uk/about_us/index.cfm (accessed on 11 February 2019).

- Marine Accident and Incident Reports (Japan). Available online: http://www.mlit.go.jp/jtsb/marrep.html (accessed on 11 February 2019).

- Marine Published Reports (Norway). Available online: https://www.aibn.no/Sjofart/Published-reports (accessed on 11 February 2019).

- Marine Safety Investigations(Malta). Available online: https://mtip.gov.mt/en/msiu/Pages/2017.aspx (accessed on 11 February 2019).

- Groth, K.; Wang, C.; Mosleh, A. Hybrid causal methodology and software platform for probabilistic risk assessment and safety monitoring of socio-technical systems. Reliab. Eng. Syst. Saf. 2010, 95, 1276–1285. [Google Scholar] [CrossRef]

- Goerlandt, F.; Montewka, J.; Kuzmin, V.; Kujala, P. A risk-informed ship collision alert system: Framework and application. Saf. Sci. 2015, 77, 182–204. [Google Scholar] [CrossRef]

- Hänninen, M.; Kujala, P. Influences of variables on ship collision probability in a Bayesian belief network model. Reliab. Eng. Syst. Saf. 2012, 102, 27–40. [Google Scholar] [CrossRef]

- Dhanak, M.R.; Xiros, N.I. Springer Handbook of Ocean Engineering; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9783319166490. [Google Scholar]

- Brocken, E.M. Improving the Reliability of Ship Machinery: A Step towards Unmanned Shipping. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2016. [Google Scholar]

- Otto, S.; Pedersen, P.T.; Samuelides, M.; Sames, P.C. Elements of risk analysis for collision and grounding of a RoRo passenger ferry. Mar. Struct. 2002, 15, 461–474. [Google Scholar] [CrossRef]

- Pedersen, P.T. Collision risk for fixed offshore structures close to high-density shipping lanes. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2002, 216, 29–44. [Google Scholar] [CrossRef]

- Kujala, P.; Hänninen, M.; Arola, T.; Ylitalo, J. Analysis of the marine traffic safety in the Gulf of Finland. Reliab. Eng. Syst. Saf. 2009, 94, 1349–1357. [Google Scholar] [CrossRef]

- Zhang, D.; Yan, X.P.; Yang, Z.L.; Wall, A.; Wang, J. Incorporation of formal safety assessment and Bayesian network in navigational risk estimation of the Yangtze River. Reliab. Eng. Syst. Saf. 2013, 118, 93–105. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, X.P.; Zhang, D.; Haugen, S. Ship Trajectory Control Optimization in Anti-collision Maneuvering. TransNav, Int. J. Mar. Navig. Saf. Sea Transp. 2013, 7, 89–93. [Google Scholar] [CrossRef]

- Weng, J.; Meng, Q.; Qu, X. Vessel Collision Frequency Estimation in the Singapore Strait. J. Navig. 2012, 65, 207–221. [Google Scholar] [CrossRef]

- Zhang, L.; Meng, Q.; Fang Fwa, T. Big AIS data based spatial-temporal analyses of ship traffic in Singapore port waters. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 287–304. [Google Scholar] [CrossRef]

- Montewka, J.; Goerlandt, F.; Kujala, P. Determination of collision criteria and causation factors appropriate to a model for estimating the probability of maritime accidents. Ocean Eng. 2012, 40, 50–61. [Google Scholar] [CrossRef]

| Node NO. | Node Name | Description |

|---|---|---|

| Initial Event (IE) | Initiating Event: CPA alarm | Closest point of approach less than minimum safe distance (e.g., 100 m) |

| Pivotal Event 1 (PE1) | OS Collision Alarm | Own-Ship Alarm Signal for Possible Collision |

| PE2 | Officer on Watch (OW) Identifies Collision | Officer on Watch Identifies Possible Collision |

| PE3 | OS Crew Confirmation | OS Crew Confirm Possible Collision |

| PE4 | OS Response Strategy Decision | Crew decides response strategy |

| PE5 | OS Effective Communication with TS | OS Effective Communication with TS |

| PE6 | OS Crew Response Action with Successful TS Communication | OS Crew Response Action with Successful TS Communication |

| PE7 | OS Propulsion and Steering | |

| PE8 | OS Crew Response Action with Failed TS Communication | OS Crew Response Action with Failed TS Communication |

| PE9 | OS Propulsion and Steering with Failed TS Communication | OS Propulsion and Steering with Failed TS Communication |

| PE10 | OS Response Strategy Decision for Emergency | Crew decides response strategy for Emergency |

| PE11 | OS Crew Response Action for Emergency | OS Crew Response Action for Emergency |

| PE12 | OS Propulsion and Steering for Emergency | OS Propulsion and Steering for Emergency |

| PE13 | TS Measures | Target Ship Measures |

| End 1 (E1) | End State 1 | Successful Avoidance |

| E2 | End State 2 | Ship Mechanical Failure |

| E3 | End State 3 | Crew Response Action Failure |

| E4 | End State 4 | Successful Avoidance with Failure TS Communication |

| E5 | End State 5 | Ship Mechanical Failure with Failed TS Communication |

| E6 | End State 6 | Crew Response Action Failure with Failed TS Communication |

| E7 | End State 7 | Successful Avoidance for Emergency |

| E8 | End State 8 | Crew Response Action Failure for Emergency |

| E9 | End State 9 | Crew Response Action Failure for Emergency |

| E10 | End State 10 | Crew Response Decision Failure |

| E11 | End State 11 | OS and TS all failure for collision |

| Node Name | Description | Level Name |

|---|---|---|

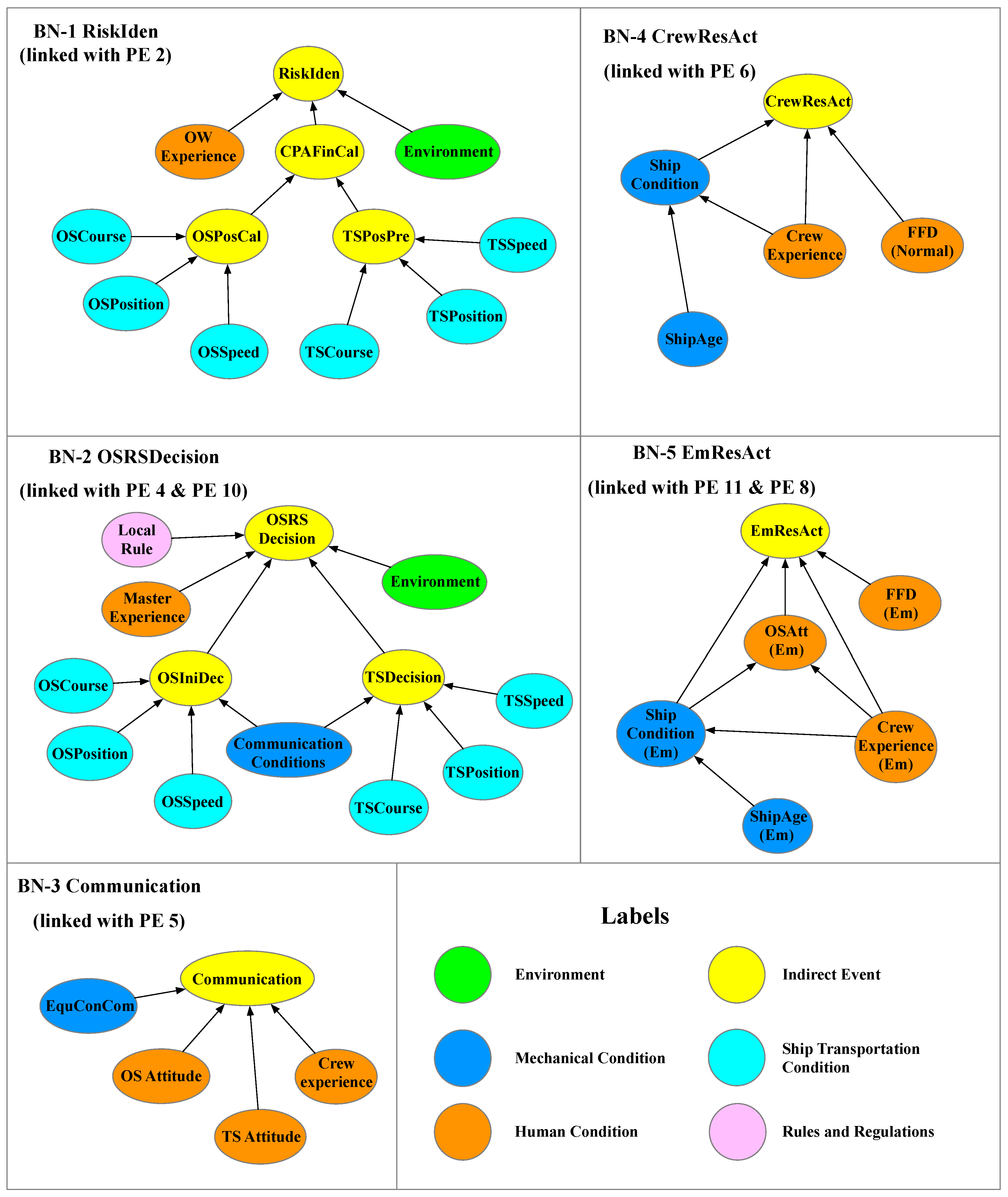

| BN-1 RiskIden was linked with PE 2 (OW Identifies Collision) | ||

| RiskIden | OW Indentifies Possible Collision | Not Sure\Sure |

| OW Experience | Intership\1~5 year\>5 year | |

| Environment | Advantage\Disadvantage | |

| CPAFinCal | CPA Final Calculation | Effective\NonEffect |

| OSPosCal | Own-ship Position Calculation | Effective\NonEffect |

| TSPosPre | Target Ship Position Prediction | Effective\NonEffect |

| OSCourse | OS current course angle | Advantage\Disadvantage |

| OSPosition | Advantage\Disadvantage | |

| OSSpeed | Advantage\Disadvantage | |

| TSCourse | TS current course angle | Advantage\Disadvantage |

| TSPosition | Advantage\Disadvantage | |

| TSSpeed | Advantage\Disadvantage | |

| BN-2 OSRSDecision was linked with PE 4 (OS Response Strategy Decision), share BN structure with PE 10 (OS Response Strategy Decision for Emergency) | ||

| OSIniDec | OSInitialDecision | Effective\NonEffect |

| OSRSDecision | OS Response Strategy Decision | Effective\NonEffect |

| TSDecision | Effective\NonEffect | |

| environment | Advantage\Disadvantage | |

| experience | Intership\1~5 year\>5 year | |

| local rule | Obey\Not obey | |

| OS course | OS current course angle | Advantage\Disadvantage |

| OS position | Advantage\Disadvantage | |

| OS speed | Advantage\Disadvantage | |

| TS course | TS current course angle | Advantage\Disadvantage |

| TS position | Advantage\Disadvantage | |

| TS speed | Advantage\Disadvantage | |

| Communicate | Information Communication | Effective\NonEffect |

| BN-3 Communication was linked with PE 5 (OS Effective Communication with TS) | ||

| Communication | Effective Communication between two ships | Effective\Failure |

| Crew experience | Crew experience for both ship | Intership\1~5 year\>5 year |

| EquConCom | Equipment Condition for communication | Work\Fail |

| OS Attitude | Attitude of OS crews | Positive\Negative |

| TS Attitude | Attitude of TS crews | Positive\Negative |

| BN-4 CrewResAct was linked with PE 6 (OS Crew Response Action) | ||

| CrewResAct | Crew Response Action | Effective\NonEffect |

| FFD(Normal) | Fitness for Duty (FFD), Level 0 means don’t fit current operation | Level 0\Level 1\Level 2 |

| Ship Condition | Bad\Good | |

| Crew Experience | Intership\1~5 year\>5 year | |

| ShipAge | 0~3 year\3~10 year\>10 year | |

| BN-5 EmResAct was linked with PE 11 (OS Crew Response Action for Emergency), share BN structure with PE 8 (OS Crew Response Action with Failed TS Communication). | ||

| EmResAct | OS Crew Response Action for emergency | Effective\NonEffect |

| FFD(Em) | Fitness for Duty in emergency, Level 0 means don’t fit current operation | Level 0\Level 1\Level 2 |

| OSAtt(Em) | OS Attitude for Emergency | Positive\Negative |

| ShipCon(Em) | Ship Condition in Emergency | Bad\Good |

| EmExperence | Crew Experience for Emergency | Intership\1~5 year\>5 year |

| ShipAge(Em) | Ship Age | 0~3 year\3~10 year\>10 year |

| End State | End State Type | Probability |

|---|---|---|

| E1 | Safe | 0.1236 |

| E2 | Collision due to Mechanical Failure | 0.0051 |

| E3 | Collision due to Human Error | 0.0700 |

| E4 | Safe | 0.0713 |

| E5 | Collision due to Mechanical Failure | 0.0066 |

| E6 | Collision due to Human Error | 0.0305 |

| E7 | Safe | 0.1611 |

| E8 | Collision due to Mechanical Failure | 0.0230 |

| E9 | Collision due to Human Error | 0.1277 |

| E10 | Collision due to Human Error | 0.3444 |

| E11 | Safe | 0.0366 |

| Total | Safe | 0.3926 |

| Collision | 0.6073 | |

| (1) Collision due to Mechanical Failure | 0.0348 (5.73% of Collision) | |

| (2) Collision due to Human Error | 0.5725 (94.27% of Collision) |

| Collision Type | Causation Probability 1 | Number of Conflicts (1/Month) | Number of Conflicts (1/Year = 12 × 1/Month) | Estimated Collision Frequency (1/Year) 2 |

|---|---|---|---|---|

| Overtaking | 4.90 × 10−5 | 1014 | 12,168 | 0.36 |

| Head-on | 4.90 × 10−5 | 441 | 5292 | 0.16 |

| Crossing | 1.30 × 10−4 | 620 | 7440 | 0.59 |

| Total | 2075 | 24,900 | 1.11 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Wu, Q.; A. Diaconeasa, M.; Yan, X.; Mosleh, A. On the Use of the Hybrid Causal Logic Methodology in Ship Collision Risk Assessment. J. Mar. Sci. Eng. 2020, 8, 485. https://doi.org/10.3390/jmse8070485

Wang T, Wu Q, A. Diaconeasa M, Yan X, Mosleh A. On the Use of the Hybrid Causal Logic Methodology in Ship Collision Risk Assessment. Journal of Marine Science and Engineering. 2020; 8(7):485. https://doi.org/10.3390/jmse8070485

Chicago/Turabian StyleWang, Tengfei, Qing Wu, Mihai A. Diaconeasa, Xinping Yan, and Ali Mosleh. 2020. "On the Use of the Hybrid Causal Logic Methodology in Ship Collision Risk Assessment" Journal of Marine Science and Engineering 8, no. 7: 485. https://doi.org/10.3390/jmse8070485

APA StyleWang, T., Wu, Q., A. Diaconeasa, M., Yan, X., & Mosleh, A. (2020). On the Use of the Hybrid Causal Logic Methodology in Ship Collision Risk Assessment. Journal of Marine Science and Engineering, 8(7), 485. https://doi.org/10.3390/jmse8070485