A Kinematic Collision Box Algorithm Applied for the Anti-Collision System of Offshore Drilling Vessels

Abstract

1. Introduction

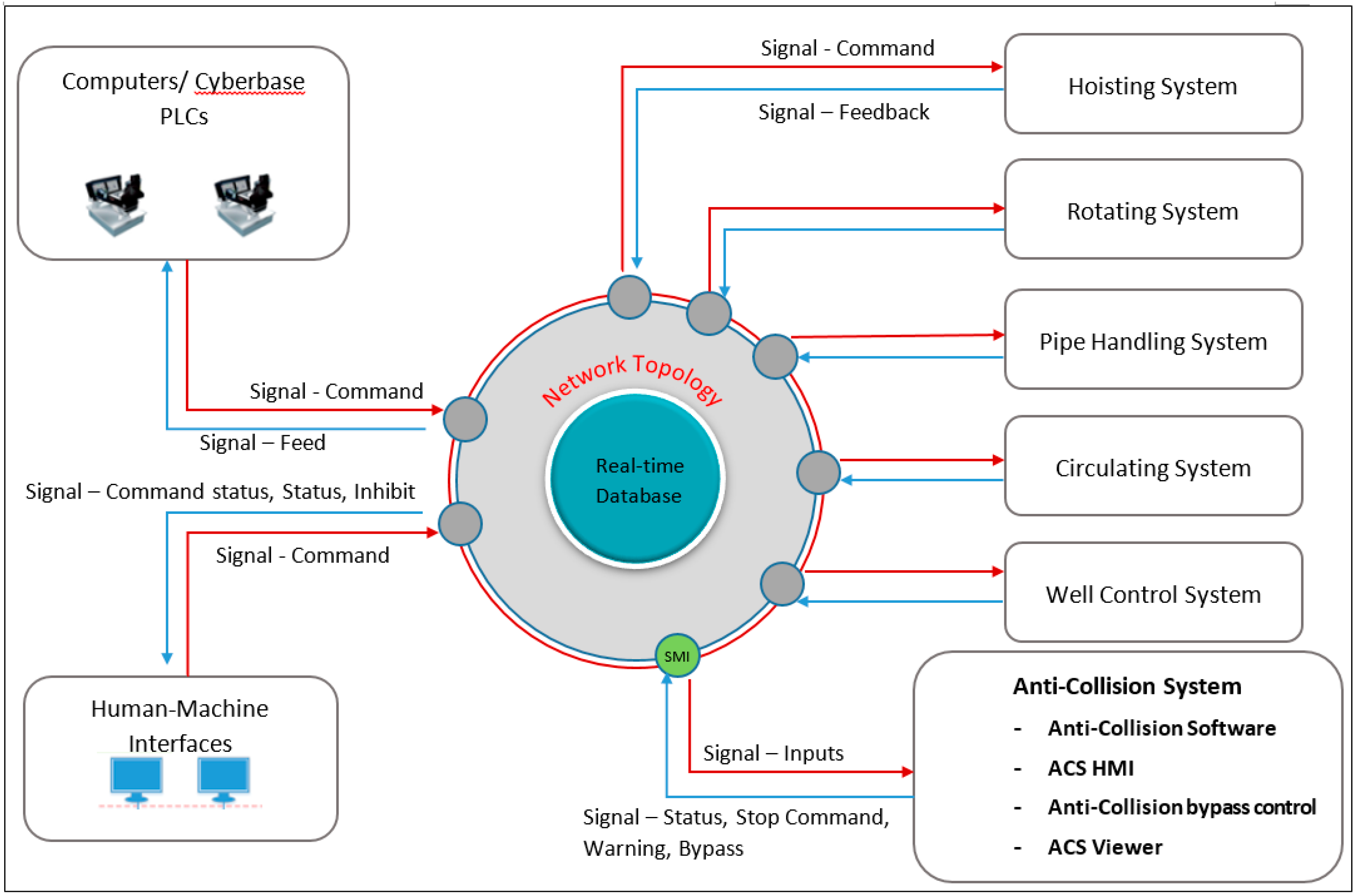

2. Overall Architecture of the ACS

2.1. Configuration of the ACS in an Integrated Drilling System

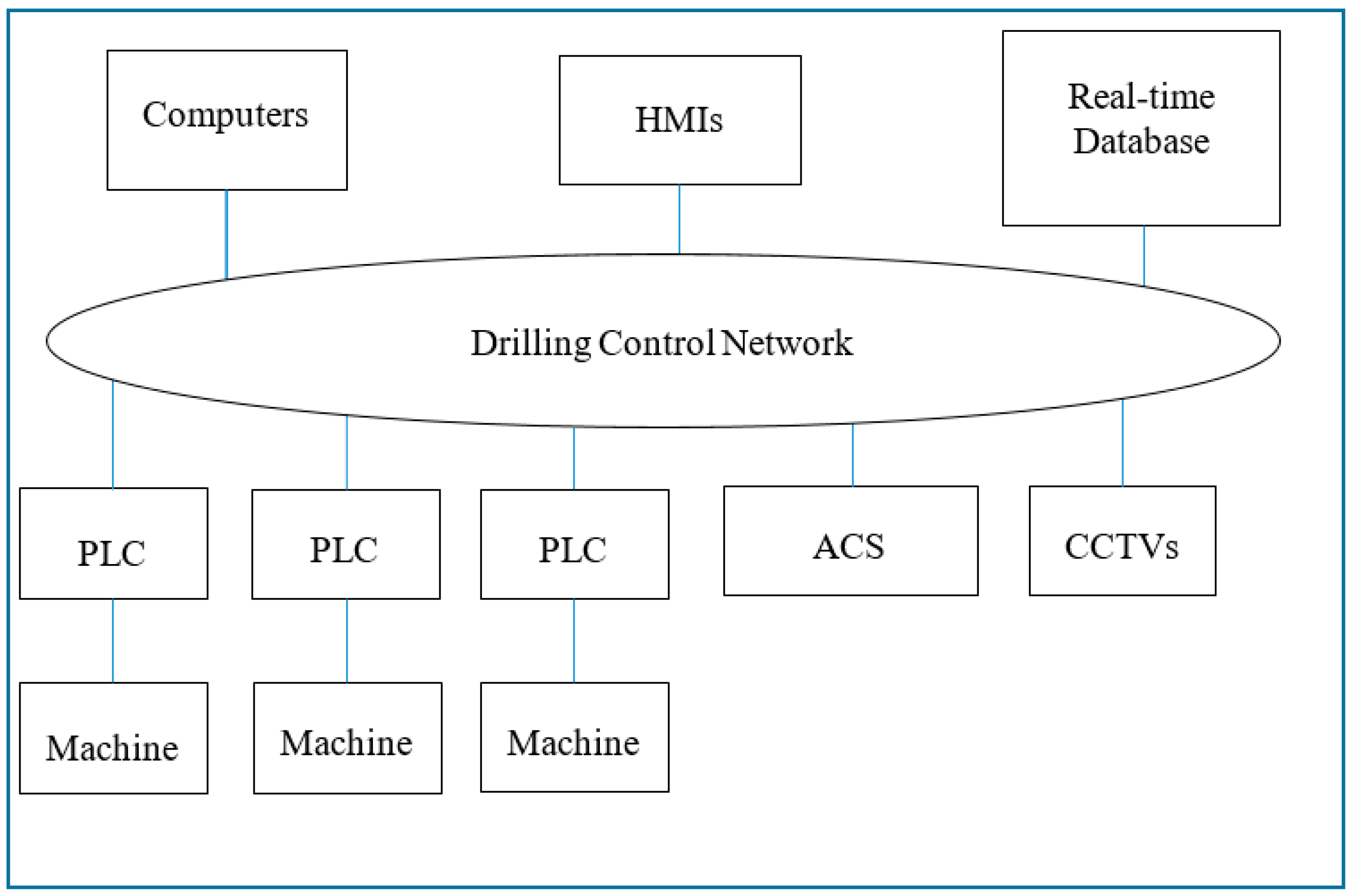

2.1.1. Integrated Drilling System

- Drilling Control Network (DCN)

- Programmable Logic Controllers (PLCs)

- Computers

- A real-time database

- Human–Machine Interfaces (HMIs)

- Auxiliary tools [8]

2.1.2. Components of ACS

- Anti-Collision Software: to determine stop positions and stop commands by using a collision detection algorithm.

- HMI: to represent the status of equipment, the ACS matrix, and messages.

- ACS Viewer: to provide 3D visualization of drilling floor and bounding boxes of equipment.

- Anti-Collision Bypass Control Module: override function switches.

2.1.3. Network Topology between ACS and DCN

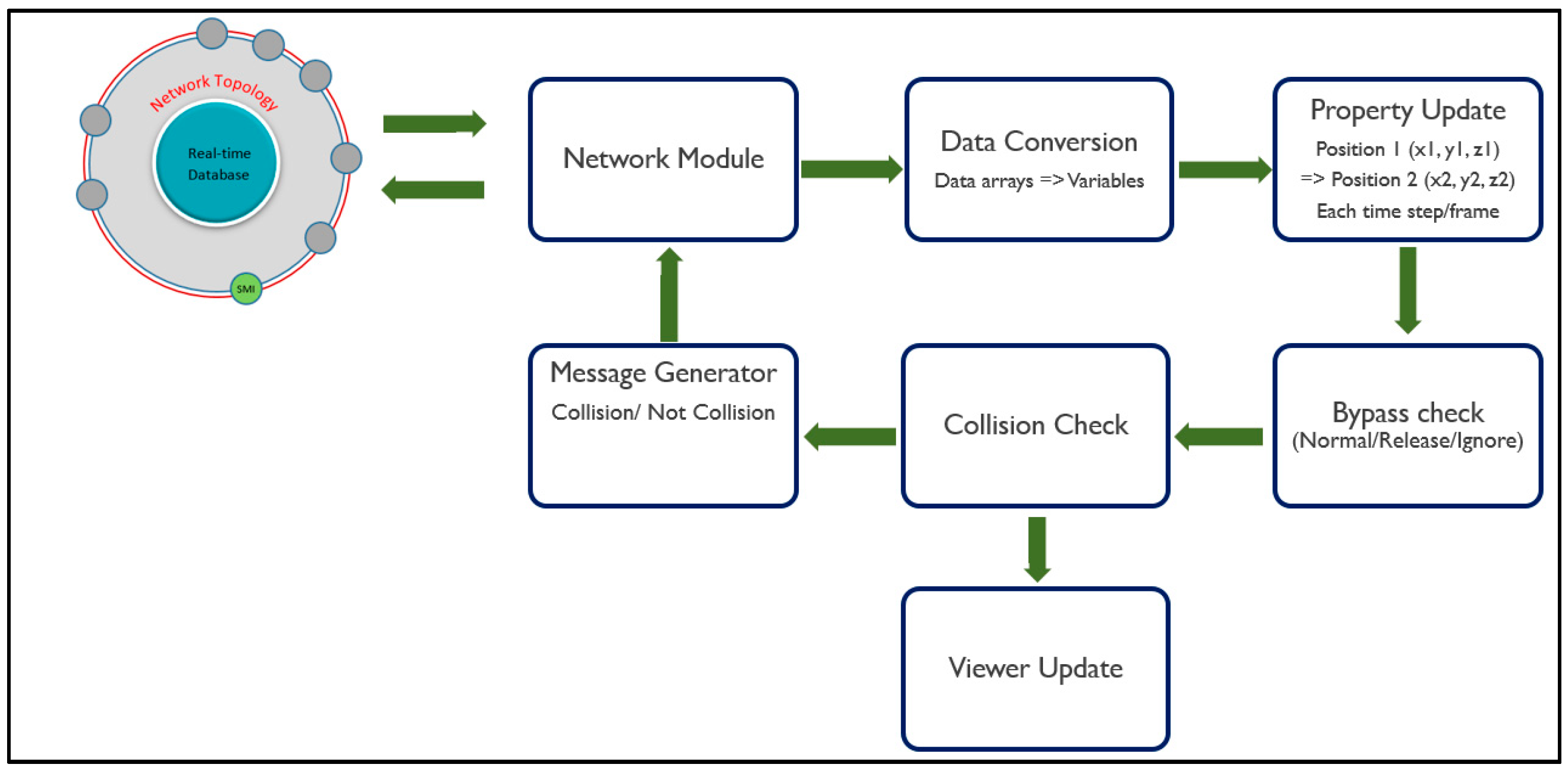

2.2. ACS Software

3. Collision Check Algorithm

3.1. Conventional Collision Box

3.1.1. Collision Detection

- They provide an inexpensive test for intersection.

- They fit tightly around the bounded object(s).

- They are inexpensive to compute.

- They can be easy transformed (e.g., rotated).

- They require little memory.

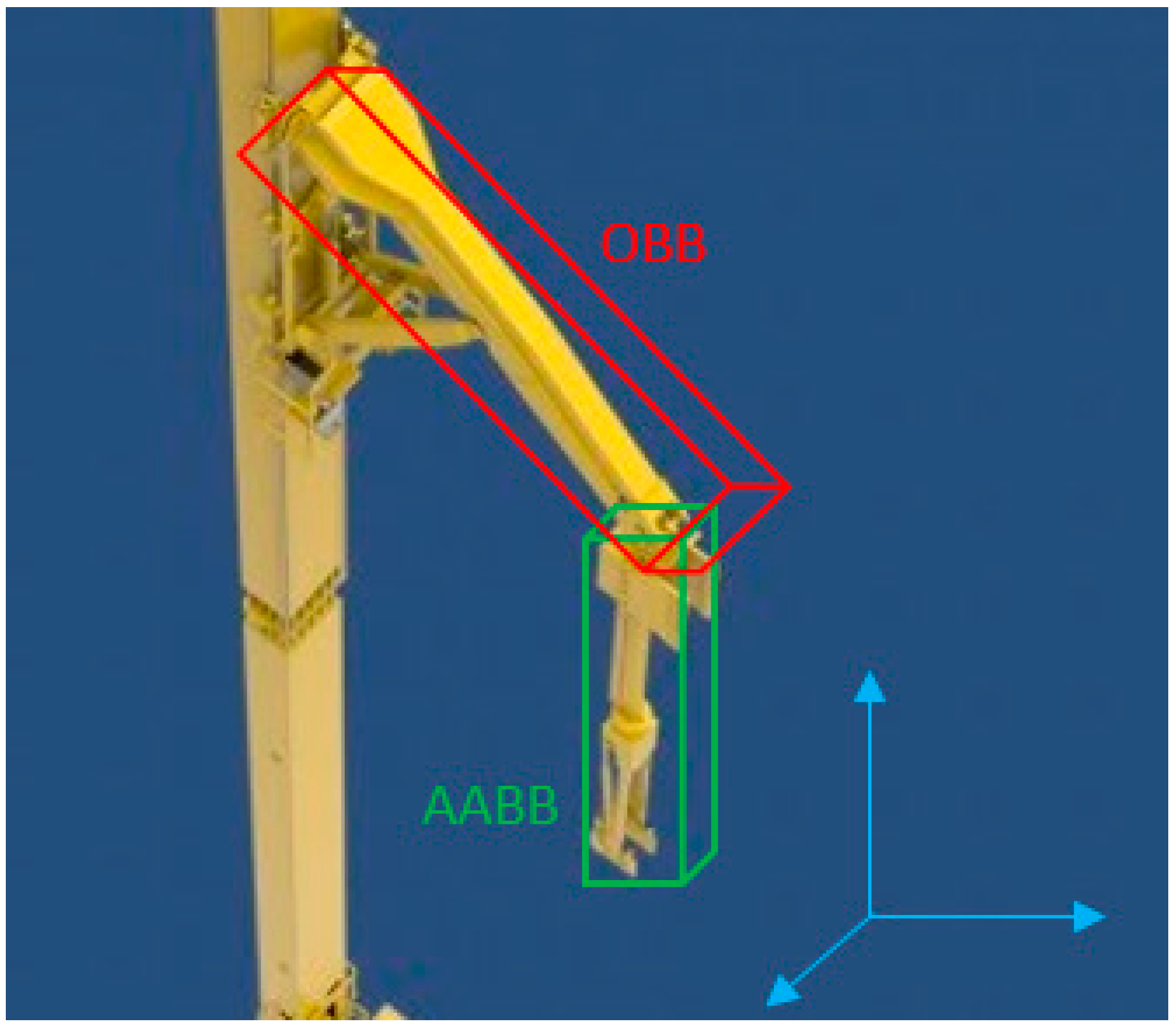

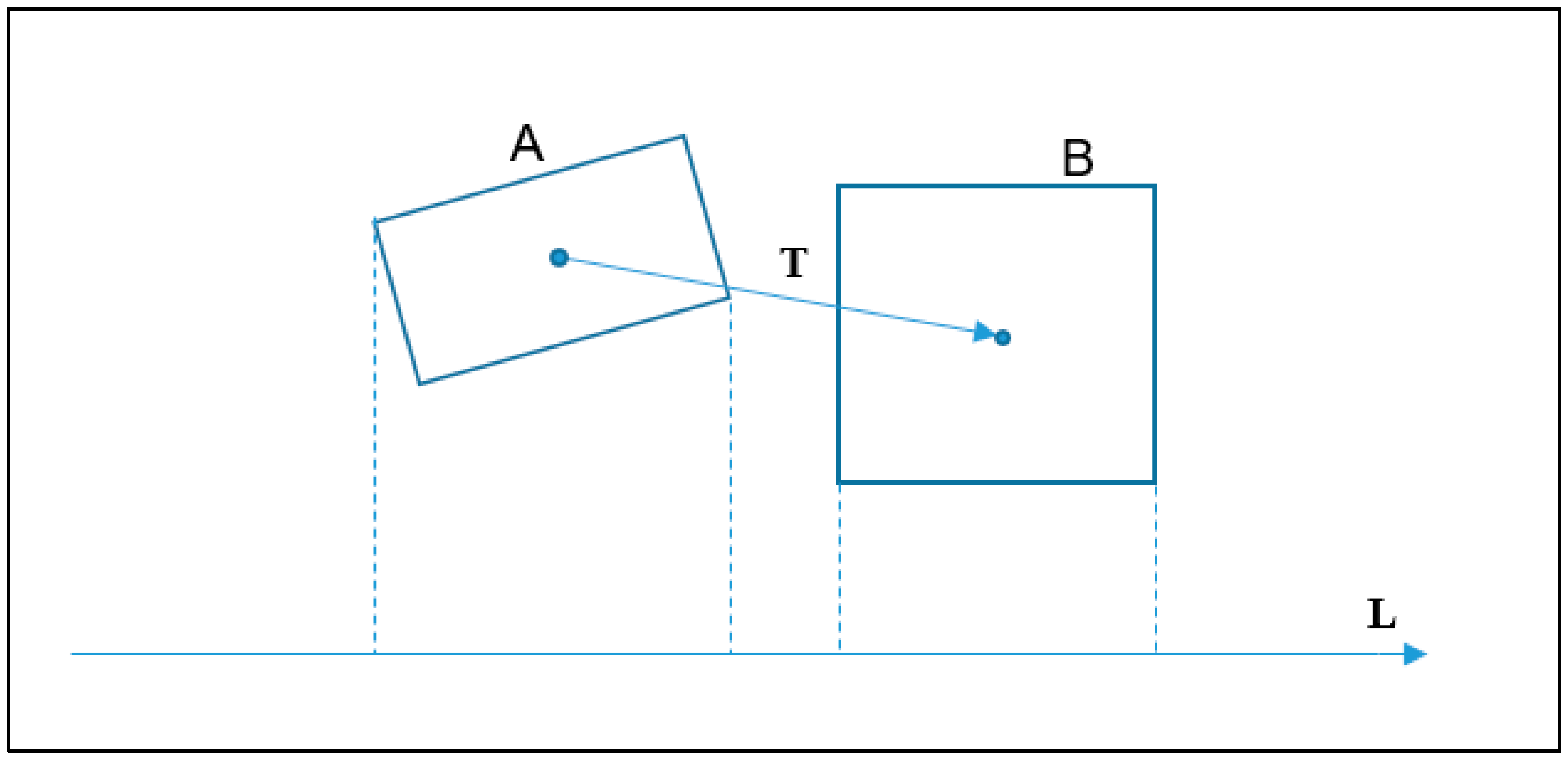

3.1.2. Axis-Aligned Bounding Box (AABB) and Oriented Bounding Box (OBB) Collision Detection

yminA < ymaxB and ymaxA > yminB

zminA < zmaxB and zmaxA > zminB

- A = coordinate position of the center of A

- A = unit vector representing the local x-axis of A

- A = unit vector representing the local y-axis of A

- A = unit vector representing the local z-axis of A

- A = half-width of A (corresponds with the local x-axis of A)

- A = half-length of A (corresponds with the local y-axis of A)

- A = half-height of A (corresponds with the local z-axis of A)

- B = coordinate position of the center of B

- B = unit vector representing the local x-axis of B

- B = unit vector representing the local y-axis of B

- B = unit vector representing the local z-axis of BWB = half-width of B (corresponds with the local x-axis of B)LB = half-length of B (corresponds with the local y-axis of B)HB = half-height of B (corresponds with the local z-axis of B)

- Variable

- = B − A: vector

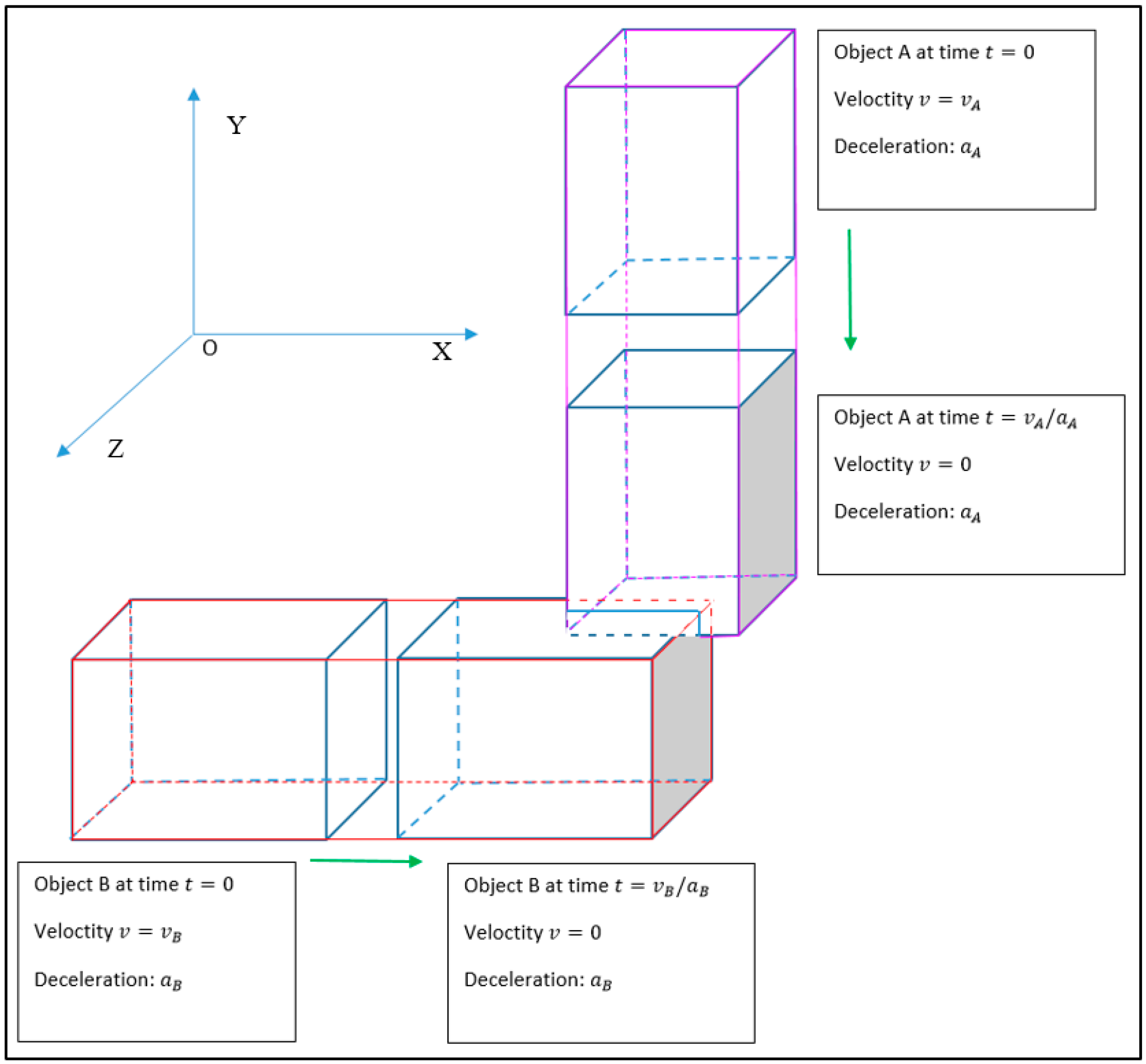

3.2. Kinematic Collision Box

3.2.1. Kinematic Collison Box Algorithm for Drilling Floor

3.2.2. Axis-Aligned Kinematic Collision Box

- A (A, A, A) = coordinate position of the center of A

- WA = half-width of A (corresponds with the local x-axis of A)

- LA = half-length of A (corresponds with the local y-axis of A)

- HA = half-height of A (corresponds with the local z-axis of A)

- C = A: Half-width of Axis-Aligned Kinematic Collision Box of A

- C = A: Half-length of Axis-Aligned Kinematic Collision Box of A

- C = A: Half-height of Axis-Aligned Kinematic Collision Box of A

3.2.3. Oriented Kinematic Collision Box

- A (A, A, A) = coordinate position of the center of A

- A = unit vector representing the local x-axis of A

- A = unit vector representing the local y-axis of A

- A = unit vector representing the local z-axis of A

- WA = half-width of A (corresponds with the local x-axis of A)

- LA = half-length of A (corresponds with the local y-axis of A)

- HA = half-height of A (corresponds with the local z-axis of A)

- A, A, A: Three Euler angles to determine the orientation of bounding box

- = A; ;

- = A; ;

- = A; ;

- C = A: Half-width of Oriented Kinematic Collision Box of A.

- = A: Half-length of Oriented Kinematic Collision Box of A.

- = A: Half-height of Oriented Kinematic Collision Box of A.

- : Linear velocity of A corresponds with three axes X, Y, and Z.

- : Minimum linear deceleration of A corresponds with three axes X, Y, and Z.

- : Angular velocity of A corresponds with three axes X, Y, and Z.

- : Angular deceleration of A corresponds with three axes X, Y, and Z.

4. Simulation

4.1. Drilling Floor Layout in the Simulation

- Draw-works/Top Drive

- Mainwell HydraTong (MW_HT)

- Auxiliary Well HydraTong (AW_HT)

- Main well HydraRacker (MW_HR)

- Auxiliary well HydraRacker (AW_HR)

- Catwalk System (CW)

- Main well

- Auxiliary well (Mouse Hole)

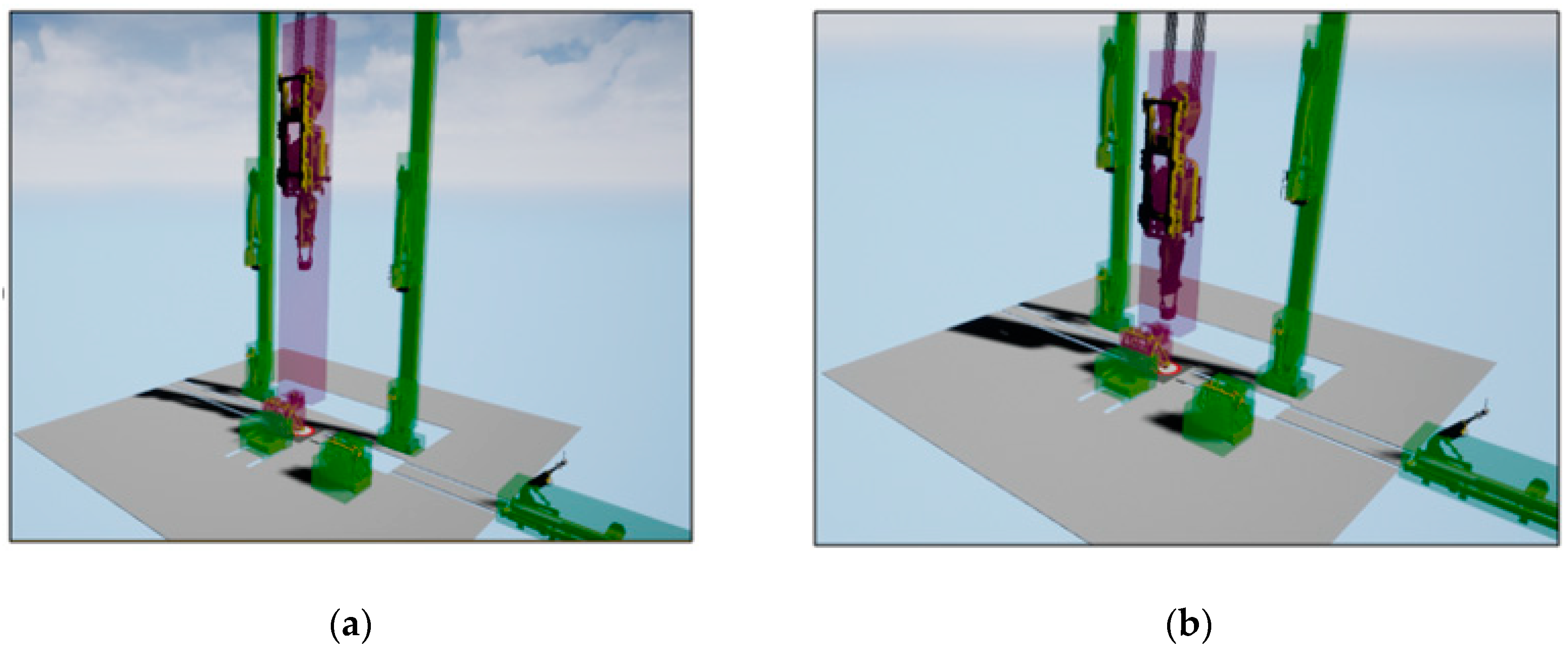

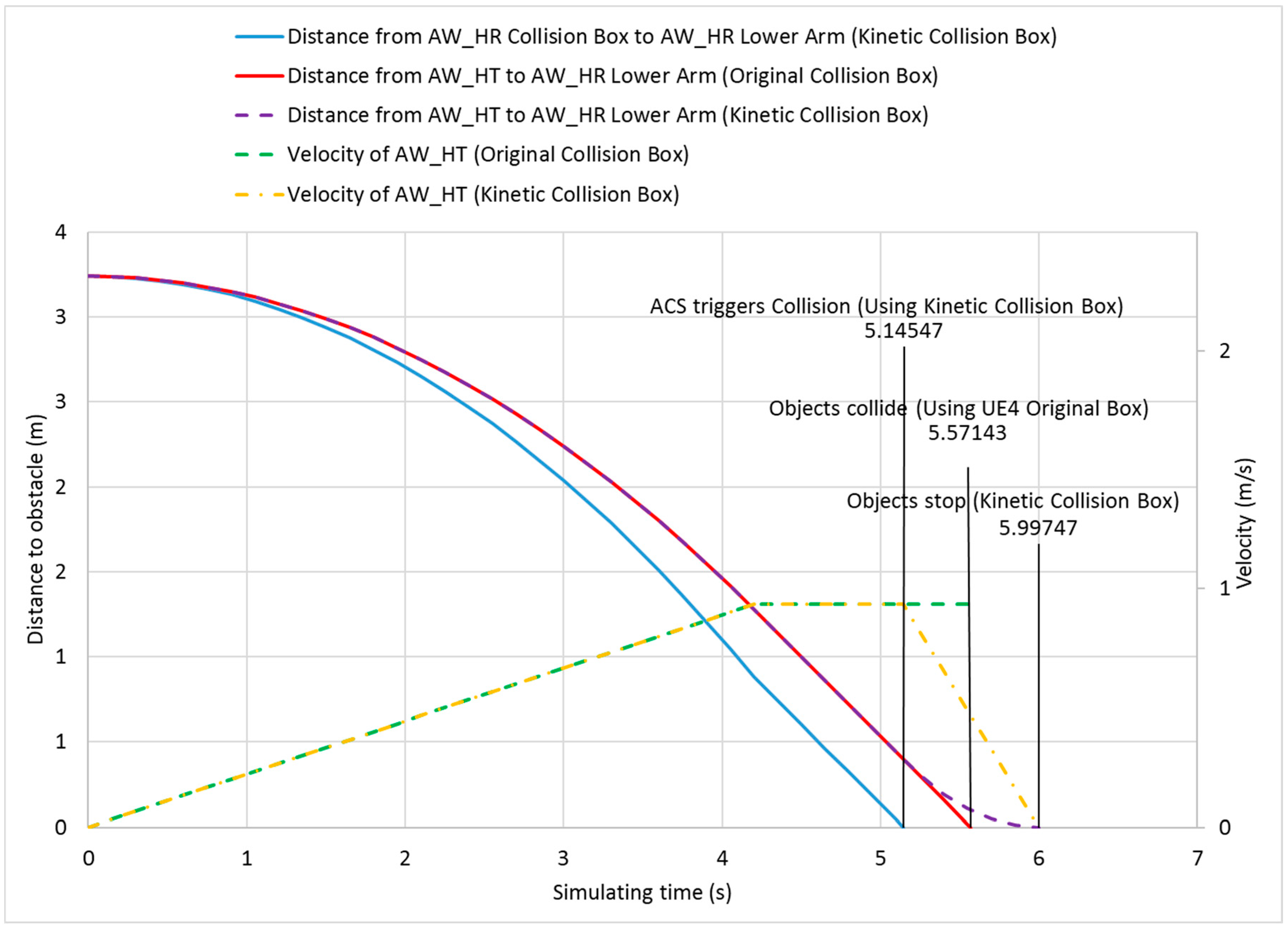

4.2. Simulation Scenarios

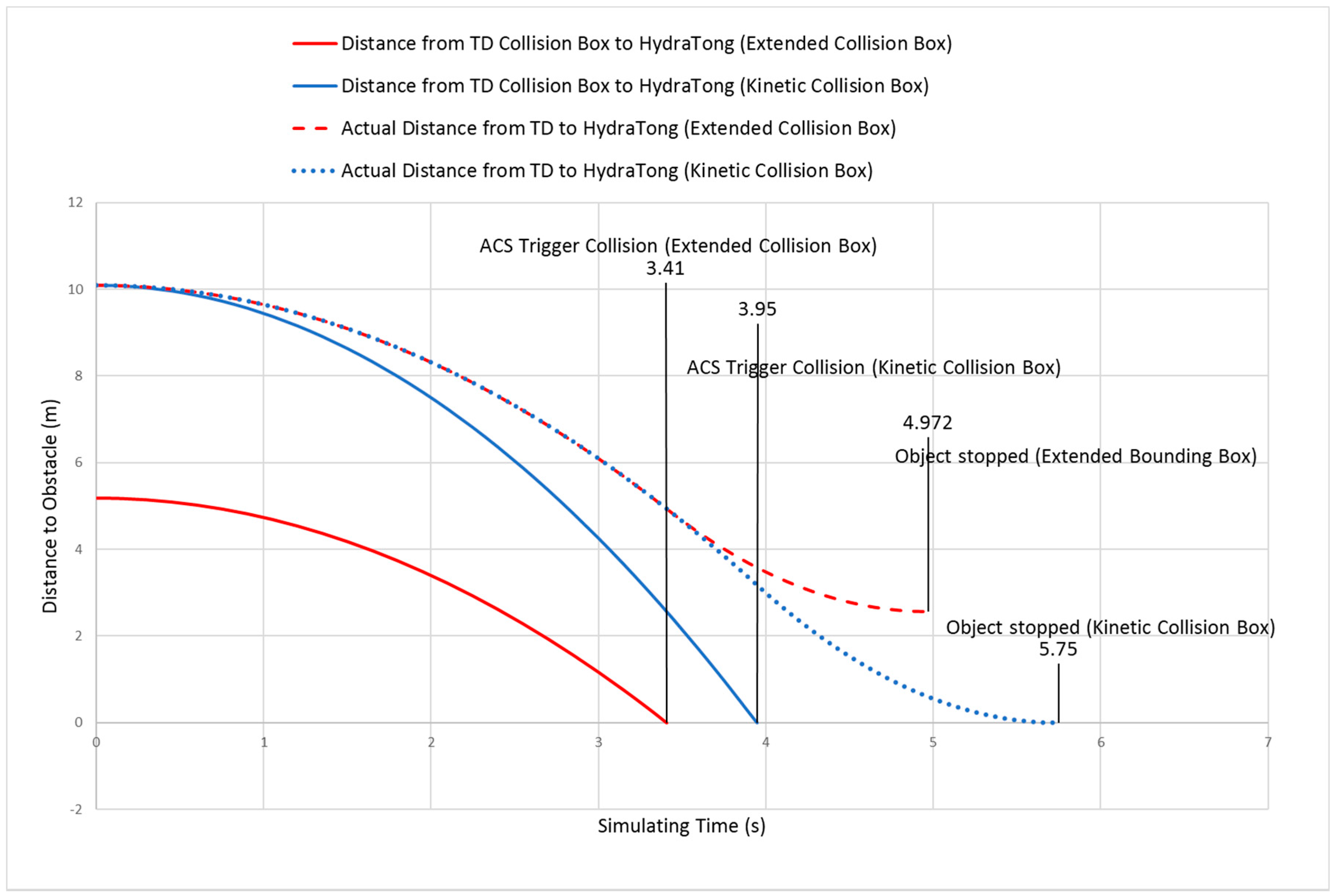

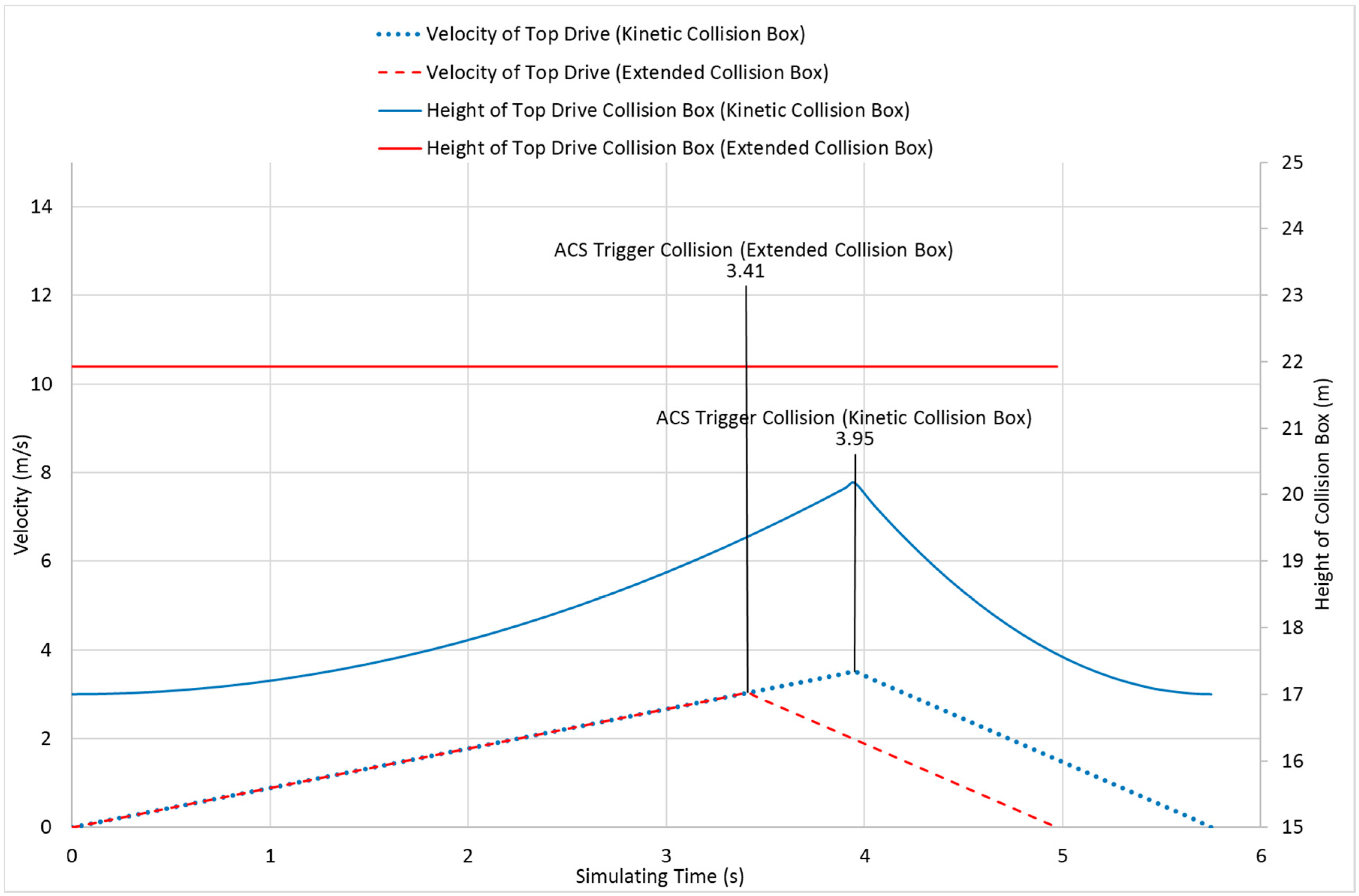

- Scenario 1:

- When tripping out occurs, the top drive is lowered while the HydraTong is still in the Main Well pipe disconnecting area.

- Scenario 2:

- In the process of performing a dual-task: Stand-building in the Auxiliary Well and normal drilling process in the Main Well, two HydraRacker Trolleys collide.

- Scenario 3:

- During Stand-building, Auxiliary Well HydraTong and HydraRacker Lower Arm interfere while making drill pipe connection.

- Using original collision box of Unreal Engine to cohere with ACS.

- Applying kinematic collision box algorithm to ACS.

4.3. Simulation Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thorogood, J.; Walt, A.; Florence, F.; Iversen, F. Drilling Automation: Technologies, Terminology, and Parallels with other Industries. SPE Drill. Complet. 2010, 25, 419–425. [Google Scholar] [CrossRef]

- Macpherson, J.; John, P.; Wardt, E.; Fred, F.; Clinton, D.C.; Mario, Z.; Moray, L.; Fionn, P.I. Drilling-System Automation: Current State, Initiatives, and Potential Impact. SPE Drill. Complet. 2013, 28, 296–308. [Google Scholar] [CrossRef]

- Sanjana, T.; Wahid, F.; Habib, M.M.; Rumel, A.A. Design of an Automatic Forward and Back Collision Avoidance System for Automobiles. Adv. Sci. Technol. Eng. Syst. J. 2018, 3, 205–212. [Google Scholar] [CrossRef][Green Version]

- Alberto, B.; Luca, B.; Marco, R.; Paolo, R.; Andrea, M.Z.; Anders, R. Integrating an anti-collision system based on laser Time-Of-Flight sensor in an industrial robot controller. IFAC Symp. Robot Control 2012, 10, 664–669. [Google Scholar]

- Liu, X.; Qin, F.; Niu, H. Design of Ship Anti-collision System Based on Microcontroller. Adv. Eng. Res. 2017, 122, 233–237. [Google Scholar]

- Poedjono, B.; Akinniranye, G.; Conran, G.; Spidle, K.; Antonio, T.S. A Comprehensive Approach to Well-Collision Avoidance. In Proceedings of the AADE National Technical Conference and Exhibition, Houston, TX, USA, 10–12 April 2007. [Google Scholar]

- Chen, L.; Kapoor, S.; Bhatia, R. Intelligent Systems for Science and Information. In Extended and Selected Results from the Science and Information Conference 2013; Springer: Berlin/Heidelberg, Germany, 2014; p. 314. [Google Scholar]

- Tonnesen, H.A.; Esso Norge, A.S.; Berg, B.; Stromsnes, O.; Kvalvaag, T. Integrated Drilling System. In Proceedings of the Petroleum Computer Conference, Houston, TX, USA, 11–14 June 1995. [Google Scholar]

- Haavik, T.K. Integrated Drilling Operation as Sociotechnical System. In New Tools, Old Tasks: Safety Implications of New Technologies and Work Processes for Integrated Operations in the Petroleum Industry; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Wang, H.; Ge, Y.; Shi, L. Technologies in deep and ultra-deep well drilling: Present status, challenges and future trend in the 13th Five-Year Plan period (2016–2020). Nat. Gas Ind. B 2017, 4, 319–326. [Google Scholar] [CrossRef]

- Whyte, J.A. Adding Human Factor to Rig Anti-Collision System: A New Technology Explored. Soc. Petroleum Eng. J. 2003. [Google Scholar]

- Epic Game Inc. Unreal Engine 4 Documentation. Available online: https://docs.unrealengine.com/en-US/index.html (accessed on 20 January 2019).

- Redon, S.; Kheddar, A.; Coquillart, S. Fast Continuous Collision Detection between Rigid Bodies. EuroGraphics 2002, 21, 279–287. [Google Scholar]

- O’Rourke, J.; Goodman, J.E. (Eds.) Handbook of Discrete and Computation Geometry; CRC-Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Govindaraju, N.K.; Lin, M.C.; Manocha, D. Fast and Reliable Collision Culling Using Graphics Processors. In Proceedings of the ACM Symp. Virtual Reality Software and Technology (VRST), Hong Kong, 10–12 November 2004. [Google Scholar]

- Szauer, G. Game Physics Cookbook; Packt Publishing Ltd.: Birmingham, UK, 2017. [Google Scholar]

- Bergen, G.V.D. Efficient Collision Detection of Complex Deformable Models using AABB Trees. J. Gr. Tools 1997, 2, 1–13. [Google Scholar] [CrossRef]

- Zhang, X.; Kim, J.Y. Interactive collision detection for deformable models using streaming AABBs. IEEE Trans. Vis. Comput. Gr. 2007, 13, 318–329. [Google Scholar] [CrossRef]

- Gottschalk, S. Collision Queries Using Oriented Bounding Boxes; The University of North Carolina: Chapel Hill, NC, USA, 2000. [Google Scholar]

- Gottschalk, S.; Lin, M.; Manocha, D. OBBTree: A Hierarchical Structure for Rapid Interference Detection. ACM Siggraph 1996. [Google Scholar]

- Liang, C.; Liu, X. The Research of Collision Detection Algorithm Based on Separating Axis Theorem. Int. J. Sci. 2015, 2, 110–114. [Google Scholar]

- Cronan, D.S. Exploration Methodology. In Handbook of Marine Mineral Deposits; Routledge: Abingdon, UK, 2017. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, D.T.; Jung, K.H.; Kwon, K.-Y.; Ku, N.; Lee, J. A Kinematic Collision Box Algorithm Applied for the Anti-Collision System of Offshore Drilling Vessels. J. Mar. Sci. Eng. 2020, 8, 420. https://doi.org/10.3390/jmse8060420

Nguyen DT, Jung KH, Kwon K-Y, Ku N, Lee J. A Kinematic Collision Box Algorithm Applied for the Anti-Collision System of Offshore Drilling Vessels. Journal of Marine Science and Engineering. 2020; 8(6):420. https://doi.org/10.3390/jmse8060420

Chicago/Turabian StyleNguyen, Duy Thanh, Kwang Hyo Jung, Ki-Youn Kwon, Namkug Ku, and Jaeyong Lee. 2020. "A Kinematic Collision Box Algorithm Applied for the Anti-Collision System of Offshore Drilling Vessels" Journal of Marine Science and Engineering 8, no. 6: 420. https://doi.org/10.3390/jmse8060420

APA StyleNguyen, D. T., Jung, K. H., Kwon, K.-Y., Ku, N., & Lee, J. (2020). A Kinematic Collision Box Algorithm Applied for the Anti-Collision System of Offshore Drilling Vessels. Journal of Marine Science and Engineering, 8(6), 420. https://doi.org/10.3390/jmse8060420