Twin Marine Hydrokinetic Cross-Flow Turbines in Counter Rotating Configurations: A Laboratory-Scaled Apparatus for Power Measurement

Abstract

1. Introduction

2. Apparatus and Methodology

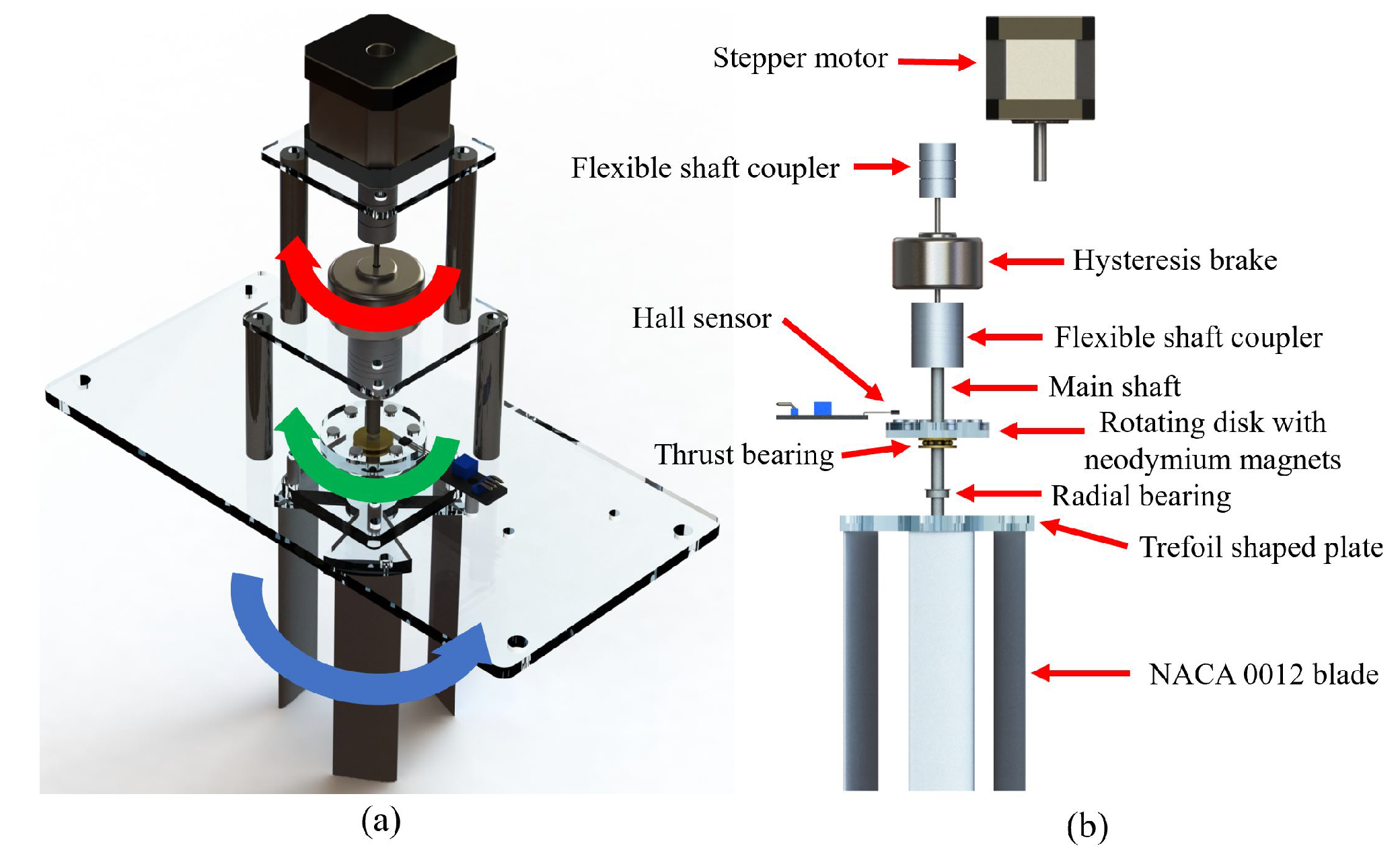

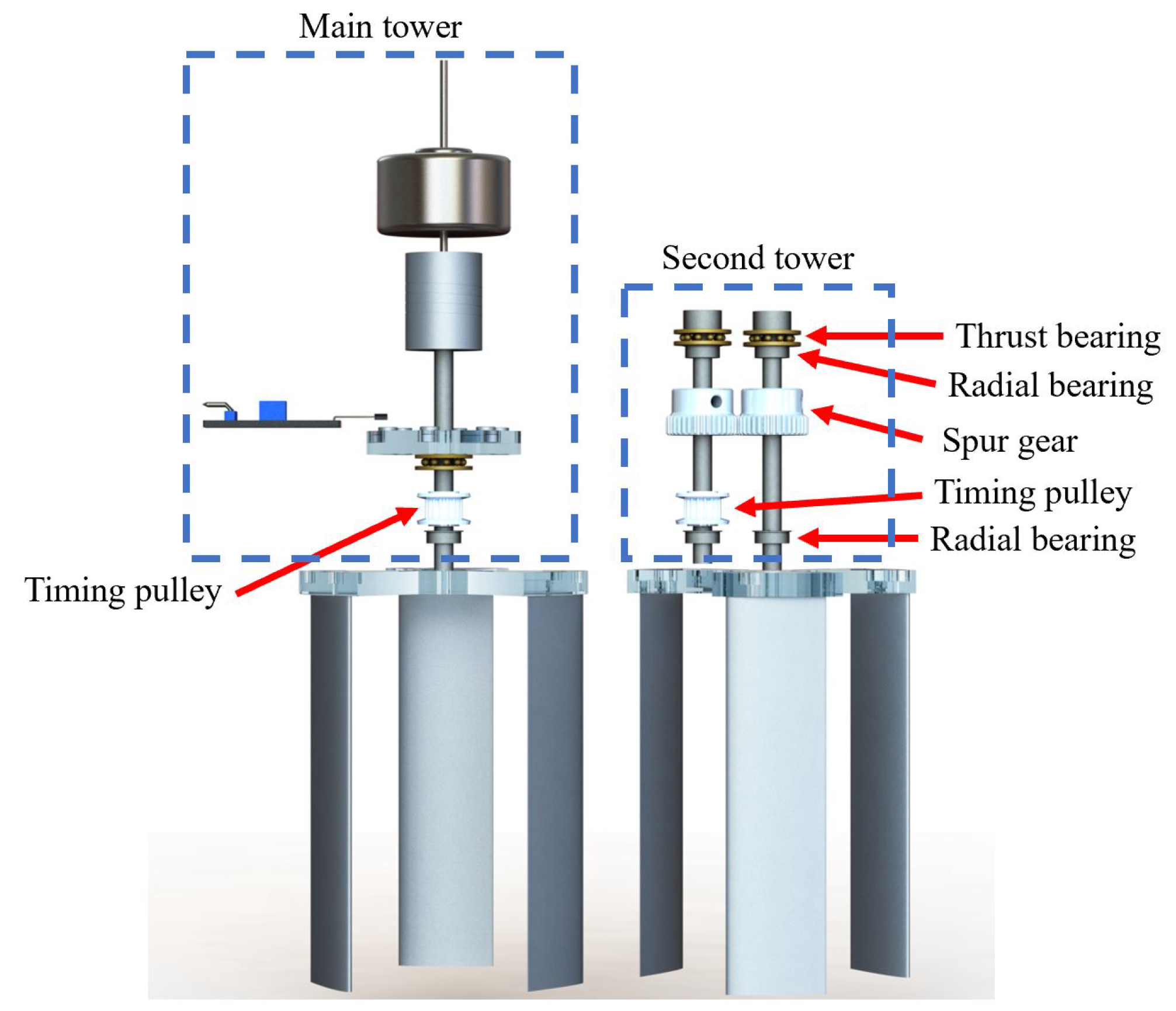

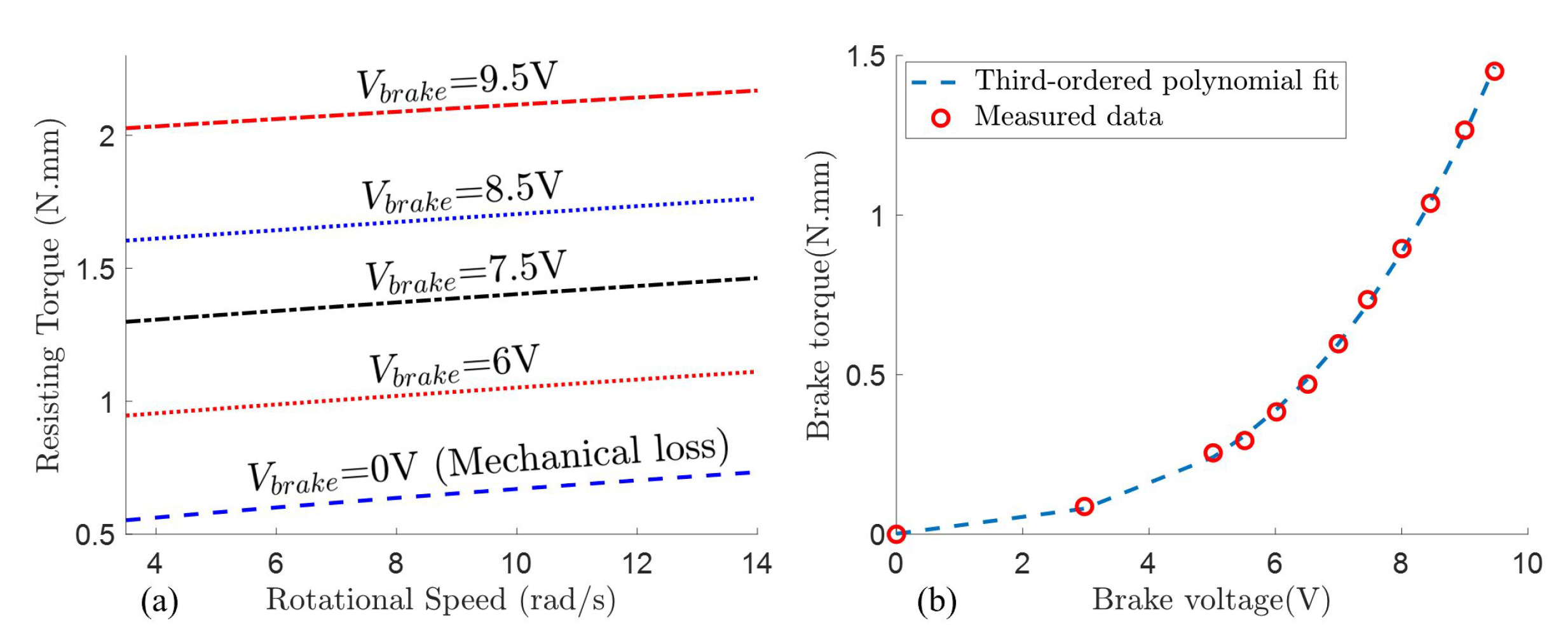

2.1. Mechanical Design and Electronics

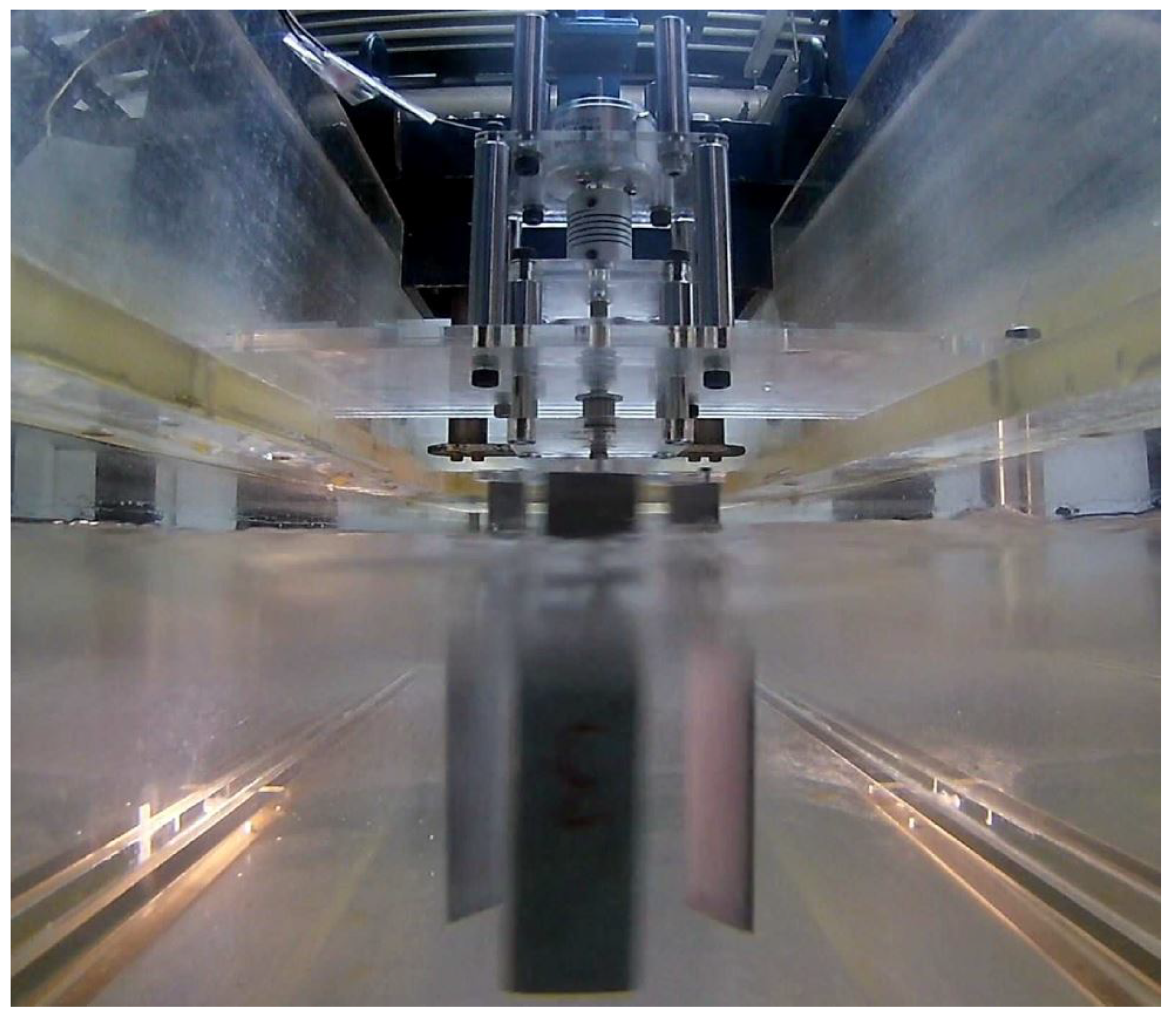

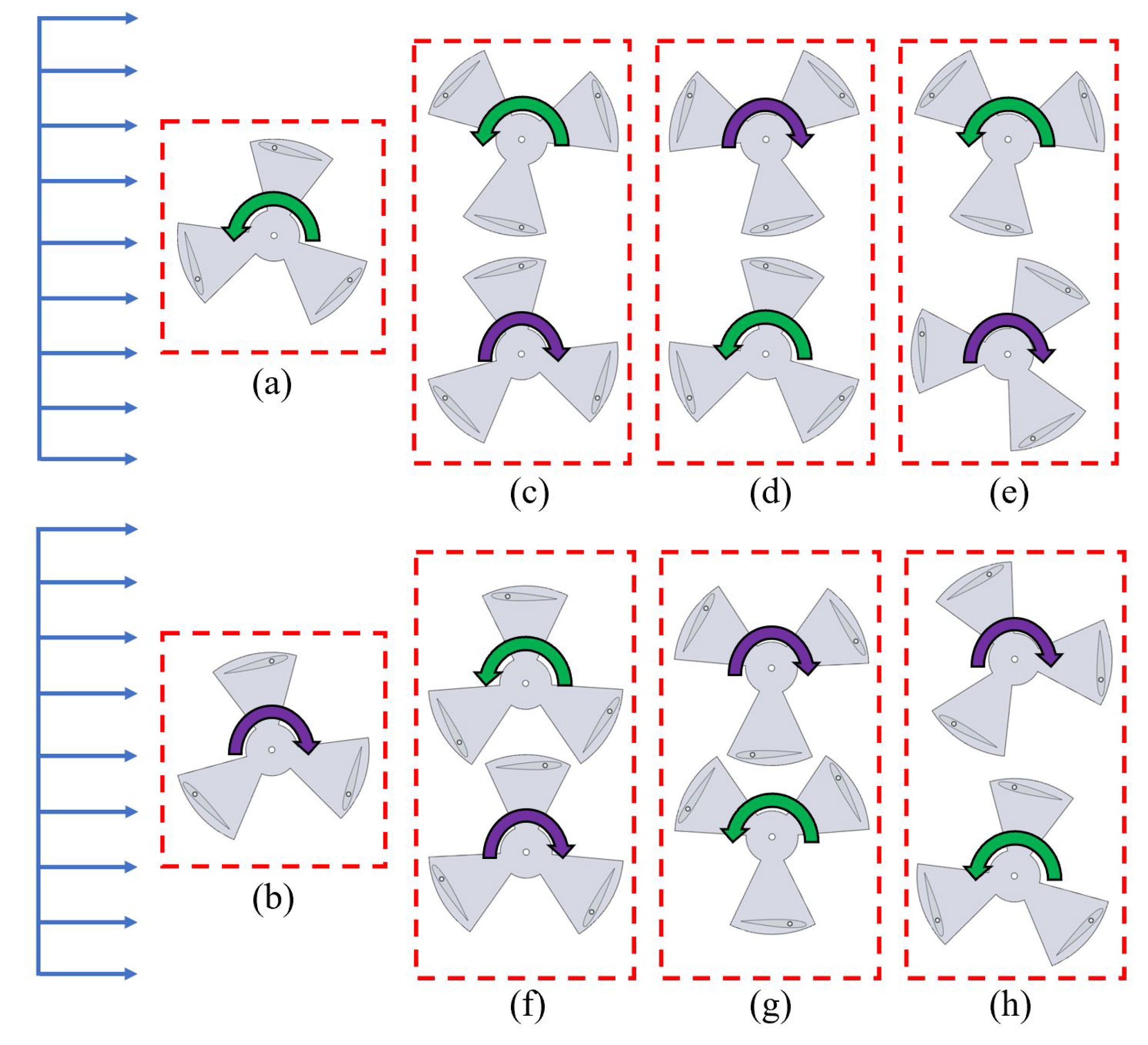

2.2. Experimental Procedure

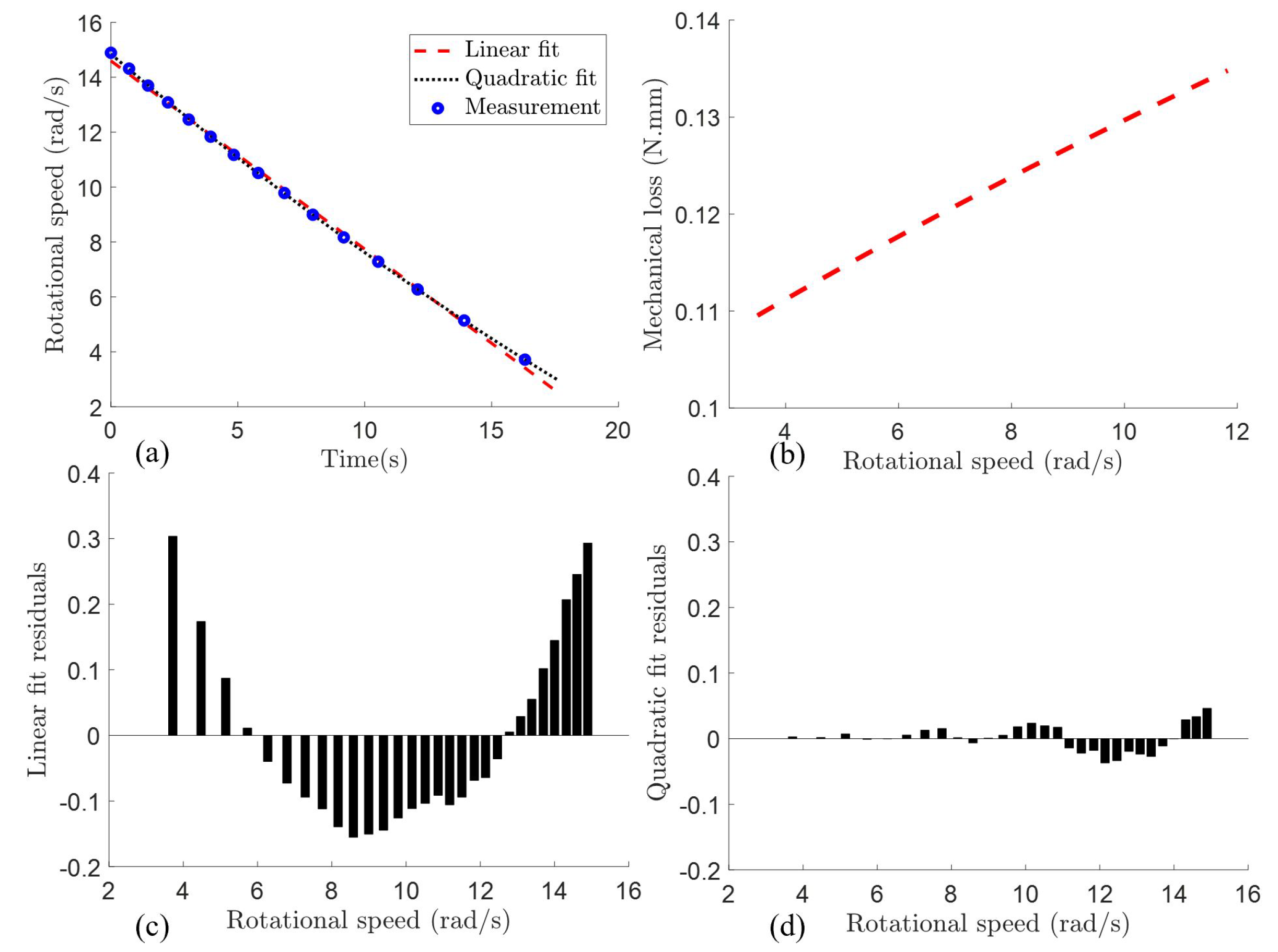

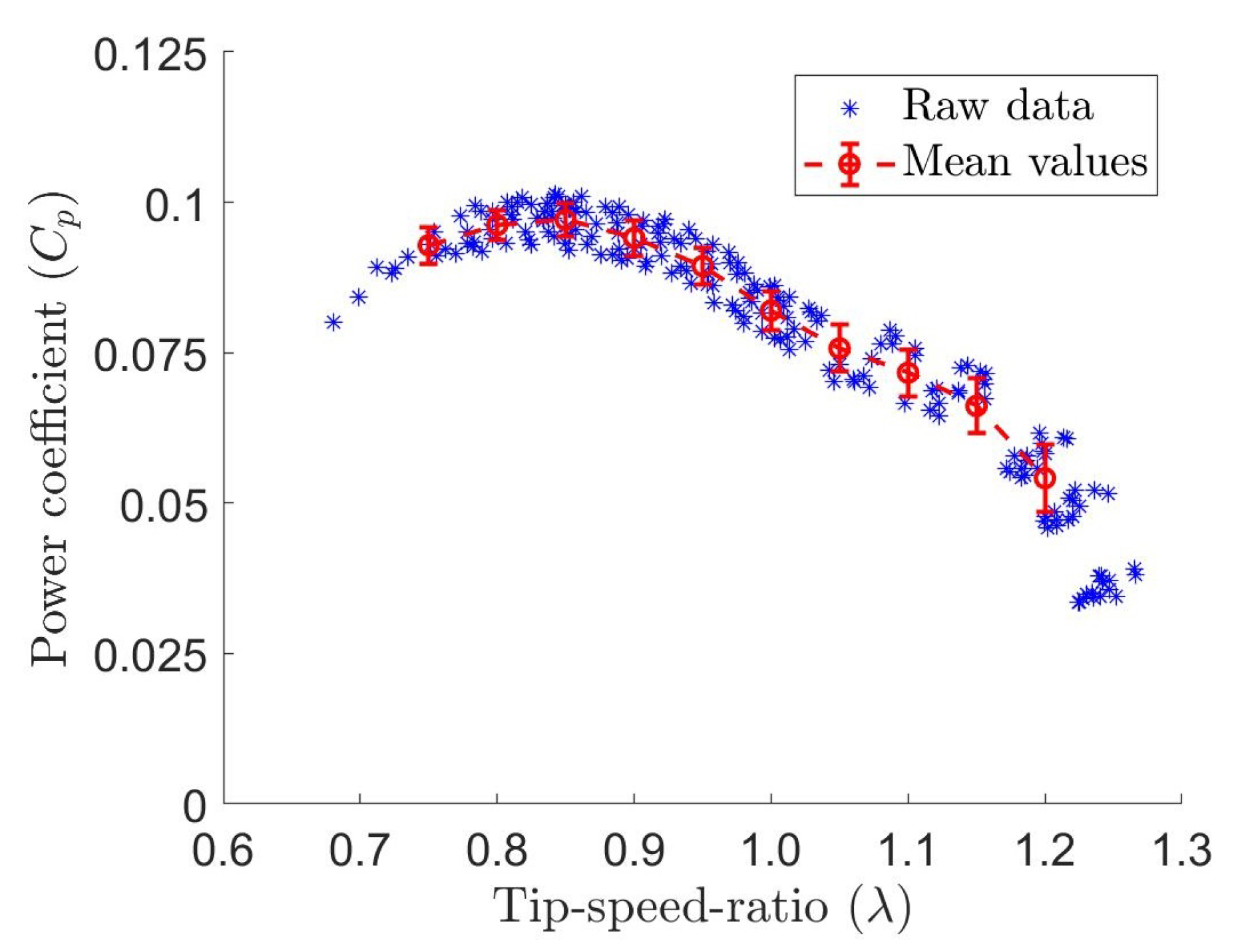

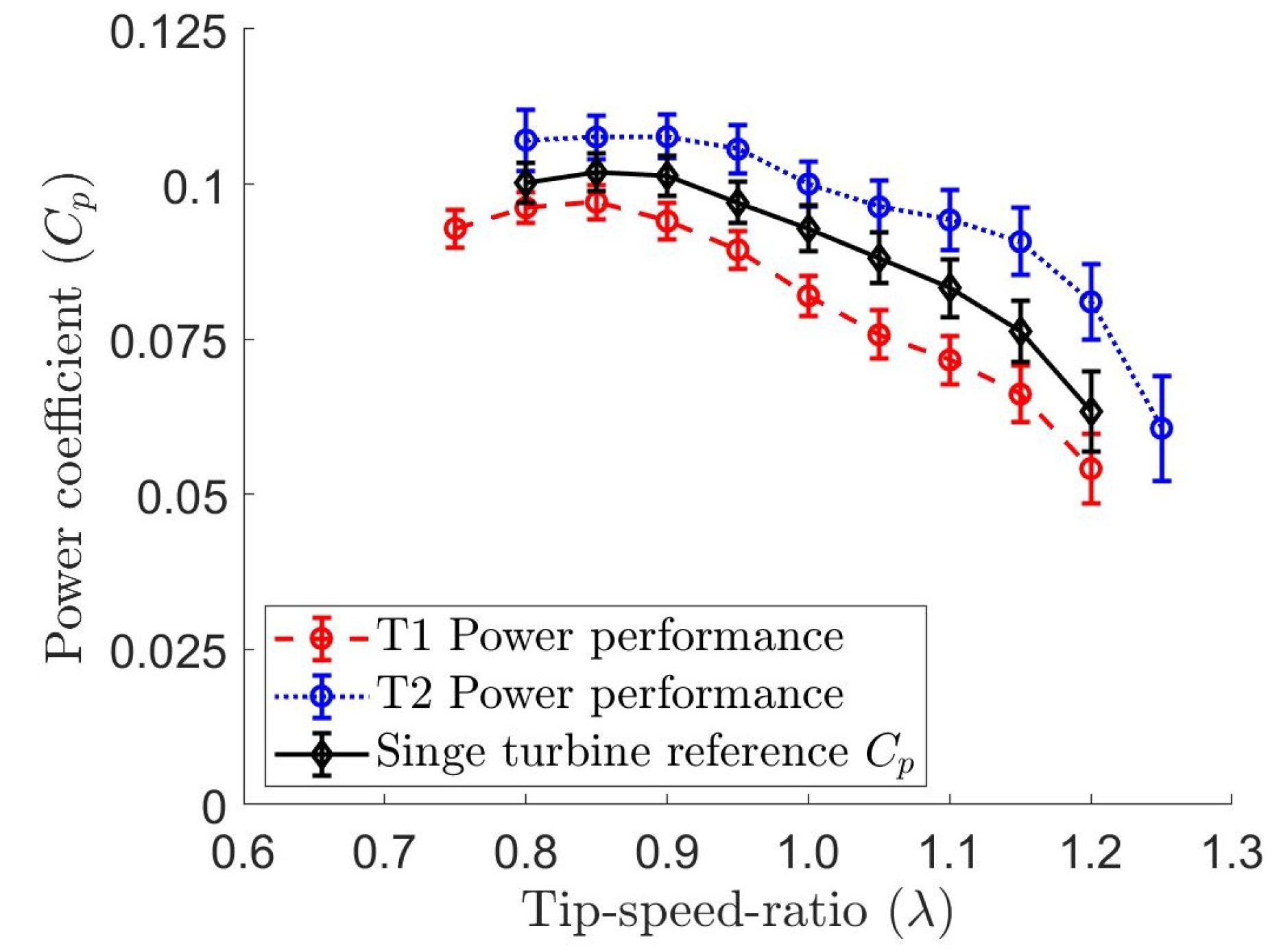

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| MHK | Marine hydrokinetic turbine |

| EDM | Electrical discharge machining |

| VAWT | Vertical axis wind turbine |

| LDV | Laser Doppler velocimetry |

Appendix A. Estimation of the Effect on the Measured Mechanical Loss Due to Water Drag on the Turbine

| Parameter | Value | Unit |

|---|---|---|

| Water density | 998 | |

| Drag coefficient | 1.4 | - |

| Freestream velocity | 0.3158 | m/s |

| Frontal area A | 20.32 | |

| Bearing nominal diameter | 5 | mm |

| Bearing frictional coefficient | 0.0015 | - |

Appendix B. Estimation of the Effect on the Measured Mechanical Loss Due Turbine Mass Distribution

References

- Narune, A.; Prasad, E. Renewable Energy Market by Type (Hydroelectric Power, Wind Power, Bioenergy, Solar Energy, and Geothermal Energy), and End Use (Residential, Commercial, Industrial, and Others): Global Opportunity Analysis and Industry Forecast, 2018–2025; Report EN 17140; Allied Market Research: Portland, OR, USA, 2019. [Google Scholar]

- Wu, J.; Huang, J.; Han, X.; Xie, Z.; Gao, X. Ecology: Three-Gorges dam experiment in habitat fragmentation? Science 2003, 300, 1239–1240. [Google Scholar] [CrossRef] [PubMed]

- Jackson, S.; Sleigh, A. Resettlement for China’s Three Gorges Dam: Socio-economic impact and institutional tensions. Communist Post Communist Stud. 2000, 33, 223–241. [Google Scholar] [CrossRef]

- Tilt, B.; Braun, Y.; He, D. Social impacts of large dam projects: A comparison of international case studies and implications for best practice. J. Environ. Manag. 2009, 90, S249–S257. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, R.; Wood, D. The design of high efficiency crossflow hydro turbines: A review and extension. Energies 2018, 11, 267. [Google Scholar] [CrossRef]

- Adhikari, R.; Wood, D. A new nozzle design methodology for high efficiency crossflow hydro turbines. Energy Sustain. Dev. 2017, 41, 139–148. [Google Scholar] [CrossRef]

- Joshi, C.; Seshadi, V.; Singh, S. Parametric study on performance of cross-flow turbine. J. Energy Eng. 1995, 121, 28–45. [Google Scholar] [CrossRef]

- Bachant, P.; Wosnik, M. Performance measurements of cylindrical- and spherical-helical cross-flow marine hydrokinetic turbines, with estimates of exergy efficiency. Renew. Energy 2014, 74, 318–325. [Google Scholar] [CrossRef]

- Bachant, P.; Wosnik, M.; Gunawan, B.; Neary, V. Experimental study of a reference model vertical-axis cross-flow turbine. PLoS ONE 2016, 11, e0163799. [Google Scholar] [CrossRef]

- Bachant, P.; Wosnik, M. Effects of Reynolds number on the energy conversion and near-wake dynamics of a high solidity vertical-axis cross-flow turbine. Energies 2016, 9, 73. [Google Scholar] [CrossRef]

- Strom, B.; Brunton, S.; Polagye, B. Intracycle angular velocity control of cross-flow turbines. Nat. Energy 2017, 2, 1–9. [Google Scholar] [CrossRef]

- Lust, E.; Flack, K.; Luznik, L. Survey of the near wake of an axial-flow hydrokinetic turbine in quiescent conditions. Renew. Energy 2018, 129, 92–101. [Google Scholar] [CrossRef]

- Lust, E.E. The Influence of Surface Gravity Waves on the Performance and Near-Wake of an Axial-Flow Marine Hydrokinetic Turbine. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2017. [Google Scholar]

- Sanchit, S.; Oumnia, E.F.; Shanti, B.; David, T.; Daphne, O.; Tim, O.; Allan, M.J. Validation of Tidal Stream Turbine Wake Predictions and Analysis of Wake Recovery Mechanism. J. Mar. Sci. Eng. 2019, 7, 362. [Google Scholar]

- Gaurier, B.; Carlier, C.; Germain, G.; Pinon, G.; Rivoalen, E. Three tidal turbines in interaction: An experimental study of turbulence intensity effects on wakes and turbine performance. Renew. Energy 2019, 1468, 1150–1164. [Google Scholar] [CrossRef]

- Scarlett, G.T.; Viola, I.M. Unsteady hydrodynamics of tidal turbine blades. Renew. Energy 2019, 146, 843–855. [Google Scholar] [CrossRef]

- Vinod, A.; Banerjee, A. Performance and near-wake characterization of a tidal current turbine in elevated levels of free stream turbulence. Appl. Energy 2019, 254, 113639. [Google Scholar] [CrossRef]

- Kim, S.J.; Singh, P.M.; Hyun, B.S.; Lee, Y.H.; Choi, Y.D. A study on the floating bridge type horizontal axis tidal current turbine for energy independent islands in Korea. Renew. Energy 2017, 112, 35–43. [Google Scholar] [CrossRef]

- Guo, X.; Gao, Z.; Li, X.; Yang, J.; Moan, T. Loading and Blade Deflection of a Tidal Turbine in Waves. J. Offshore Mech. Arct. Eng. 2019, 141, 041902. [Google Scholar] [CrossRef]

- Bachant, P.; Wosnik, M. Modeling the near-wake of a vertical-axis cross-flow turbine with 2-D and 3-D RANS. J. Renew. Sustain. Energy 2016, 8, 053311. [Google Scholar] [CrossRef]

- Mannion, B.; Leen, S.; Nash, S. A two and three-dimensional CFD investigation into performance prediction and wake characterisation of a vertical axis turbine. J. Renew. Sustain. Energy 2018, 10, 034503. [Google Scholar] [CrossRef]

- Doan, M.N.; Alayeto, I.H.; Kumazawa, K.; Obi, S. Computational fluid dynamic analysis of a marine hydrokinetic crossflow turbine in low Reynolds number flow. In Proceedings of the ASME-JSME-KSME 2019 8th Joint Fluids Engineering Conference, San Francisco, CA, USA, 28 July–1 August 2019; American Society of Mechanical Engineer: New York, NY, USA, 2019; Volume 2, p. V002T02A067. [Google Scholar]

- Alayeto, I.H.; Doan, M.N.; Kumazawa, K.; Obi, S. Wake characteristics comparison between isolated and pair configurations of marine hydrokinetic crossflow turbines at low Reynolds numbers. In Proceedings of the ASME-JSME-KSME 2019 8th Joint Fluids Engineering Conference, San Francisco, CA, USA, 28 July–1 August 2019; American Society of Mechanical Engineer: New York, NY, USA, 2019; Volume 1, p. V001T01A037. [Google Scholar]

- Mannion, B.; McCormack, V.; Leen, S.; Nash, S. A CFD investigation of a variable-pitch vertical axis hydrokinetic turbine with incorporated flow acceleration. J. Ocean Eng. Mar. Energy 2019, 5, 21–39. [Google Scholar] [CrossRef]

- Lande-Sudall, D.; Stallard, T.; Stansby, P. Co-located deployment of offshore wind turbines with tidal stream turbine arrays for improved cost of electricity generation. Renew. Sustain. Energy Rev. 2019, 104, 492–503. [Google Scholar] [CrossRef]

- Dabiri, J. Potential order-of-magnitude enhancement of wind farm power density via counter-rotating vertical-axis wind turbine arrays. J. Renew. Sustain. Energy 2011, 3, 043104. [Google Scholar] [CrossRef]

- Li, Y.; Calisal, S. Modeling of twin-turbine systems with vertical axis tidal current turbines: Part 1—Power Output. Ocean Eng. 2010, 37, 627–637. [Google Scholar] [CrossRef]

- Li, Y.; Calisal, S. Modeling of twin-turbine systems with vertical axis tidal current turbine: Part 2—Torque Fluctuation. Ocean Eng. 2011, 38, 550–558. [Google Scholar] [CrossRef]

- Brownstein, I.D.; Wei, N.J.; Dabiri, J.O. Aerodynamically Interacting Vertical-Axis Wind Turbines: Performance Enhancement and Three-Dimensional Flow. Energies 2019, 12, 2427. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, P.; Stoesser, T.; Wang, K.; Zhou, L. Experimental and numerical investigation of twin vertical axis wind turbines with a deflector. Energy Convers. Manag. 2020, 209, 112588. [Google Scholar] [CrossRef]

- Javaherchi, T.; Stelzenmuller, N.; Aliseda, A. Experimental and numerical analysis of the performance and wake of a scale–model horizontal axis marine hydrokinetic turbine. J. Renew. Sustain. Energy 2017, 9, 044504. [Google Scholar] [CrossRef]

- Markovic, U.V. Characterizing the Wake and the Performance of a Marine Hydrokinetic Turbine in a Tandem Array Configuration. Master’s Thesis, Bucknell University, Lewisburg, PA, USA, 2016. [Google Scholar]

- Mannion, B.; McCormack, V.; Kennedy, C.; Leen, S.; Nash, S. An experimental study of a flow-accelerating hydrokinetic device. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 1, 148–162. [Google Scholar] [CrossRef]

- Doan, M.N.; Alayeto, I.H.; Padricelli, C.; Obi, S.; Totsuka, Y. Experimental and computational fluid dynamic analysis of laboratory-scaled counter-rotating cross-flow turbines in marine environment. In Proceedings of the ASME 2018 5th Joint US-European Fluids Engineering Division Summer Meeting, Montreal, QC, Canada, 15–20 July 2018; American Society of Mechanical Engineer: New York, NY, USA, 2018; Volume 2, p. V002T14A003. [Google Scholar]

- Tsai, H.C.; Colonius, T. Coriolis Effect on Dynamic Stall in a Vertical Axis Wind Turbine. AIAA J. 2016, 54, 216–226. [Google Scholar] [CrossRef]

- Kunz, P. Aerodynamics and Design for Ultra-Low Reynolds Number Flight. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2003. [Google Scholar]

- White, F. Fluid Mechanics 8th Edition in SI Units, Table A1 738–739; McGraw-Hill Education (Asia): Singapore, 2016. [Google Scholar]

- Ross, H.; Polagye, B. An experimental assessment of analytical blockage corrections for turbines. Renew. Energy 2020, 152, 1328–1341. [Google Scholar] [CrossRef]

- Montgomerie, B. Drag Coefficient Distribution on a Wing at 90 Degrees to the Wind; Technical Report ECN-C-95-061; Netherlands Energy Research Foundation: Petten, The Netherlands, 1996. [Google Scholar]

- JTEKT. Frictional Coefficient (Reference). Retrieved from JTEKT Corporation Website. 2020. Available online: https://koyo.jtekt.co.jp/en/support/bearing-knowledge/8-4000.html (accessed on 2 November 2020).

Sample Availability: All results in numeric are available from the authors. |

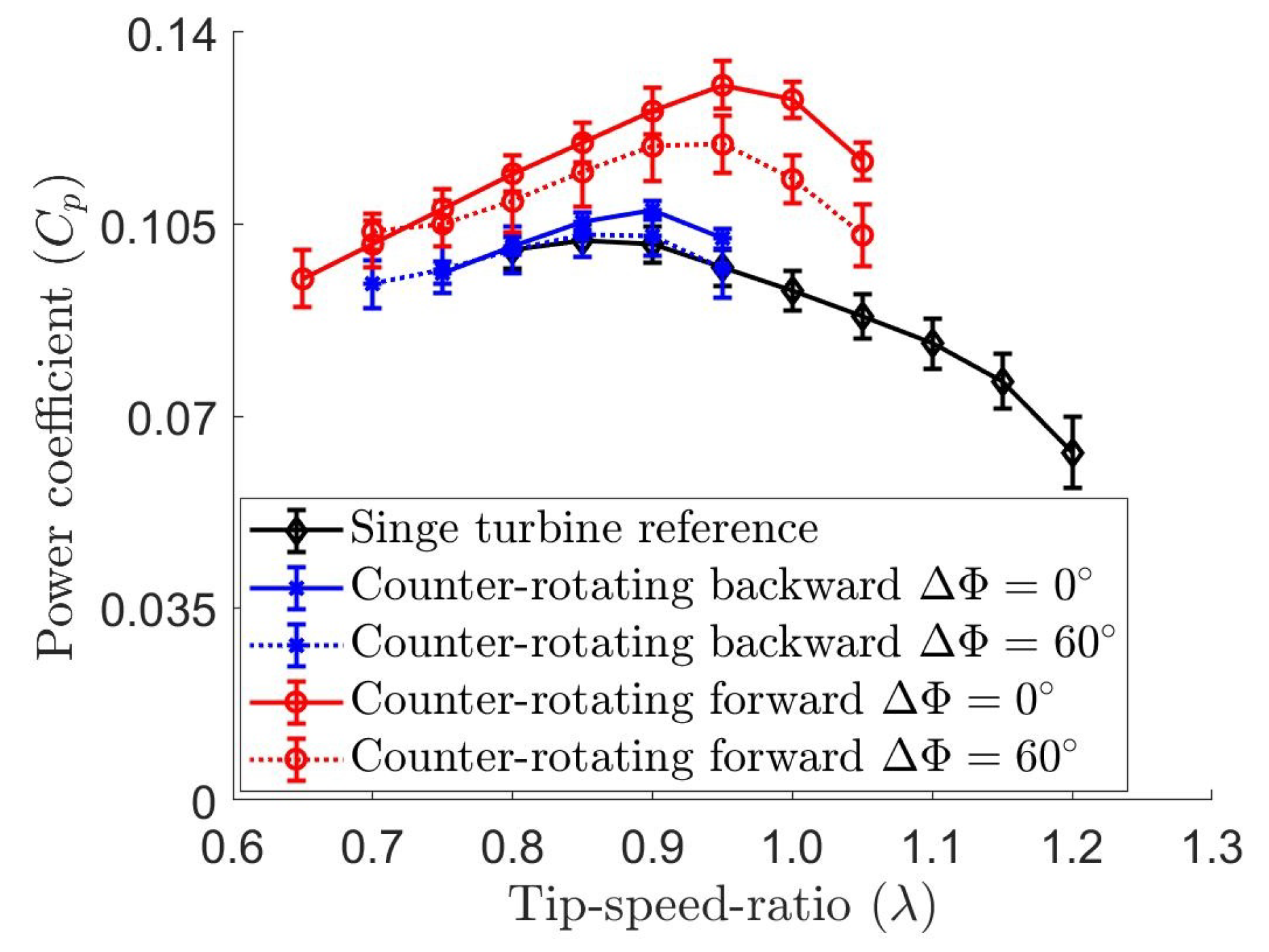

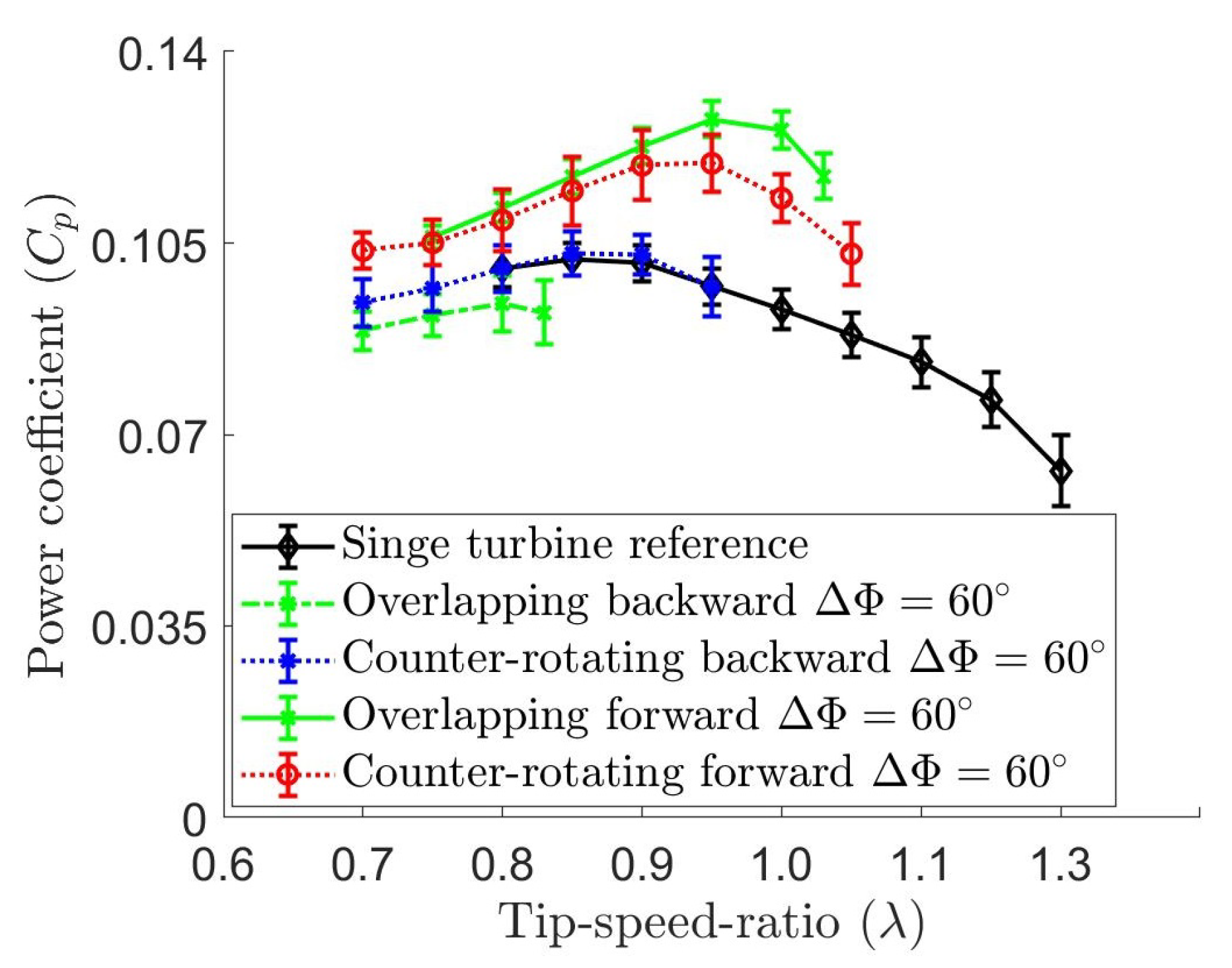

| Configuration | Maximum | Difference from | |

|---|---|---|---|

| Single turbine T1 | 0.097 | −4.76% | |

| Single turbine T2 | 0.108 | +5.61% | |

| Single turbine reference | 0.102 | N/A | |

| Counter-rotating backward | 0.107 | +5.41% | |

| Counter-rotating forward | 0.130 | +27.9% | |

| Counter-rotating backward | 0.103 | +1.05% | |

| Counter-rotating forward | 0.120 | +17.3% | |

| Overlapping backward | 0.094 | −7.87% | |

| Overlapping forward | 0.128 | +25.2% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doan, M.N.; Kai, Y.; Obi, S. Twin Marine Hydrokinetic Cross-Flow Turbines in Counter Rotating Configurations: A Laboratory-Scaled Apparatus for Power Measurement. J. Mar. Sci. Eng. 2020, 8, 918. https://doi.org/10.3390/jmse8110918

Doan MN, Kai Y, Obi S. Twin Marine Hydrokinetic Cross-Flow Turbines in Counter Rotating Configurations: A Laboratory-Scaled Apparatus for Power Measurement. Journal of Marine Science and Engineering. 2020; 8(11):918. https://doi.org/10.3390/jmse8110918

Chicago/Turabian StyleDoan, Minh N., Yuriko Kai, and Shinnosuke Obi. 2020. "Twin Marine Hydrokinetic Cross-Flow Turbines in Counter Rotating Configurations: A Laboratory-Scaled Apparatus for Power Measurement" Journal of Marine Science and Engineering 8, no. 11: 918. https://doi.org/10.3390/jmse8110918

APA StyleDoan, M. N., Kai, Y., & Obi, S. (2020). Twin Marine Hydrokinetic Cross-Flow Turbines in Counter Rotating Configurations: A Laboratory-Scaled Apparatus for Power Measurement. Journal of Marine Science and Engineering, 8(11), 918. https://doi.org/10.3390/jmse8110918