1. Introduction

Pipeline Integrity Management is one of the most extensively carried out programs across the world that focuses on safety and environmental hazards associated with liquid and natural gas pipelines. In the United States, the transmission pipeline infrastructure is estimated to have more than 100,000 km of pipeline crossings in rivers, streams, lakes or flood plains. Accidents at river crossings account for less than one percent of the total number of pipeline accidents. However the environmental consequence of a release of hydrocarbons into water can be severe. The impact of these spills on the environment have been analysed in terms of cost, rate of contamination of soil, average volume of release, annual ratio of water type contamination, and effects on fish, birds and terrestrial wildlife between 2010 and 2017 based on the information from the Pipeline and Hazardous Material Safety Administration (PHMSA) database by Chiara Belvederesi, Megan S. Thompson and Petr E. Komers [

1]. Among the many different failure modes of pipeline in river crossings, the predominant ones have been caused by Vortex Induced Vibration (VIV) loading due to the exposure of unsupported free spanning pipelines over flowing water, as documented in Reference [

2]. Their study focused on developing a flood monitoring program to quantify threshold flood levels that would result in exposure and failure of pipeline water crossings. The flood monitoring program is in turn aimed at establishing an action plan based on the assessment of the flood scenario to reduce the consequences of a pipeline watercourse crossing failure.

Free-span management of pipelines transporting liquid and natural gas starts from the early project phases including pre-engineering survey, design and construction, and continues throughout the whole operating life. The design phase is the core of free span integrity management. Hence determination of Maximum Allowable Free Span Length (MAFSL) or Critical Span Length (CSL) plays a crucial role in the design of pipelines and in trouble shooting existing pipelines in river crossings. In addition, an accurate measure of scour depth potentially identifies a feasible Depth of Cover (DoC) for the pipelines to be buried during the initial laying phase. Over many years, various research papers, design codes and industry publications have come up with different analysis and methods to determine critical span length for pipelines. The combined analysis method prescribes various static and dynamic analysis methods, addressing different loading conditions on the pipe span which are listed below as follows [

3]:

- (1)

Static Analysis of free spans induced by low depressions.

- (2)

Static Analysis of free spans using simple beam relations based on ASME B31.8 codes.

- (3)

Static Analysis of free spans induced by elevated obstructions.

- (4)

General Dynamic VIV Analysis.

- (5)

Analysis of Cross-flow VIV based on DNV Guidelines.

The output from all of these methods are compared and the most conservative or minimum value is chosen as the critical span length. There is no single approach that entirely captures the physics of the problem. Hence, difficulties exist in the mathematical modelling of scenario considering all physical and environmental parameters associated with pipelines using the traditional deterministic approach. Artificial Neural Networks play a key role in mathematical modelling of such a system. A part of this research in this paper was presented in author Adithyaa Karthikeyan’s thesis for his Master’s degree.

2. Background

Prediction of fatigue life-cycles of onshore pipelines that become exposed at river crossings due to riverbed erosion were modelled using DNV GL’s FATFREE software based on S-N curves approach [

4]. Studies have been carried out to assess and model VIV loading for free spanning pipelines for estimating MAFSL for both offshore and onshore water crossing pipelines [

5,

6]. Rhett Dotson and Lawrence Matta discussed the analytical assessments for MAFSL by ensuring that total longitudinal stresses fall below the elastic code limits. They also carried out finite element assessment based on elastic and elastic-plastic modelling of pipelines for three different scenarios posed by operators [

7]. The influence of soil characteristics on pipeline supports in free span was analysed in determining the natural frequency of pipeline vibrations [

8]. Recommendations and guidelines have been prescribed by DNV [

9] to evaluate the dynamic response of a free spanning pipeline based on pipe-soil interactions [

10]. Determining the combination of loads that act on the pipeline is crucial for modelling and analysis of MAFSL. Variation in factors such as line geometry or end restraints can greatly affect the nature of results. These results are based on deterministic approach.

The oil and gas industry has vast amounts of data captured by instruments and generated by simulations. We are in a period ideally positioned to combine traditional methodologies with computational intelligence characterized by data driven models. With the availability of real time geometrical survey data, the implementation of Artificial Neural Networks (ANN) to model nonlinear functions with several variables is increasingly finding its advantages in the industry. Performance of Multivariate Adaptive Regression Splines (MARS) was compared with multilayer perceptron neural network model in the prediction of scour depth beneath pipelines based on data available in literature written by Haghiabi [

11]. The MARS model was found to have high precision for modelling scour depth and gave clear information regarding internal processes carried out in the model development due to its linear nature. However the model had less accuracy in prediction when compared to the neural network model. In relation to the above article, Barati (2009) developed new models for scour depth estimation using regression optimization based on power functions [

12]. Numerical modeling using CFD techniques were carried out for flow and local scour around pipelines in steady currents and results were compared to published laboratory measurements [

13]. Failure prediction of underground pipeline in non-uniform soil settlement was modelled using artificial neural networks with axial stress as the output vector and buried depth, wall thickness, pipe diameter, precipitation level, soil modulus of elasticity, and soil density as six input vectors [

14].

2.1. Influence of Internal Fluid Pressure on Critical Span Length

A number of authors have suggested that critical span length can be influenced by internal fluid pressure. Olav Fyriliev and Leif Collberg explained how both buoyancy (external pressure) and weight of internal fluid (internal pressure) have an indirect effect on the effective axial force which is mathematically modelled into a differential equation using hoop stress and poisson effect [

15]. This on the contrary defers from the results showed by Galgoul et al. (2004) where internal pressure will increase the natural frequency [

16]. Though DNV-RP-F105 provides some guidance on the critical buckling load and natural frequency of vibration of pipeline based on internal and external pressure, the non-linear effects due to gradual pipeline deflection are not exactly modelled and expressions based on linear beam theory shall not be valid for all cases.

2.2. Influence of Soil Stiffness on Critical Span Length

In order to understand the effects of soil characteristics on the natural frequency of vibration, literature studies were carried out by simulating pipe-soil interactions using vertical and horizontal springs that would prevent pipe oscillations in the cross-flow and in-line directions respectively [

8]. The results showed that dense sand with pinned-pinned boundary condition had maximum influence on the natural frequency of vibration and soft clay soil with fixed-fixed end condition had minimal influence on the natural frequency. A pinned boundary condition allows the structural member to rotate, but not to translate in any direction, whereas in fixed support both translation and rotational degrees of freedom are constrained.

In the United States, pipeline operators are required to abide by regulations put forth by the federal Pipeline and Hazardous Materials Safety Administration (PHMSA). With a large number of historical data available from PHMSA database, the United States Geographical Survey (USGS) and the National Oceanic and Atmospheric Administration (NOAA), we have set up an ANN model to predict critical span length and scour depth and understand the non-linear variation of 12 input factors such as river flow rate, river depth, reduced velocity due to inline and crossflow oscillations, lateral and vertical dynamic soil stiffness coefficients, pipeline outer diameter, wall thickness, yield strength, age and incident fluid pressure.

3. Materials and Methods

3.1. Data Preparation

The factors that govern scour depth and critical span length of river crossing pipelines are multi-fold in nature. The exact relationships between them have not been identified completely and hence we resort to ANN to develop a robust prediction model. The selection of relevant parameters is based on engineering judgement and experience about the vibration behaviour of the pipelines. This section highlights the process of gathering data for features from various data sources available online.

3.1.1. PHMSA Database

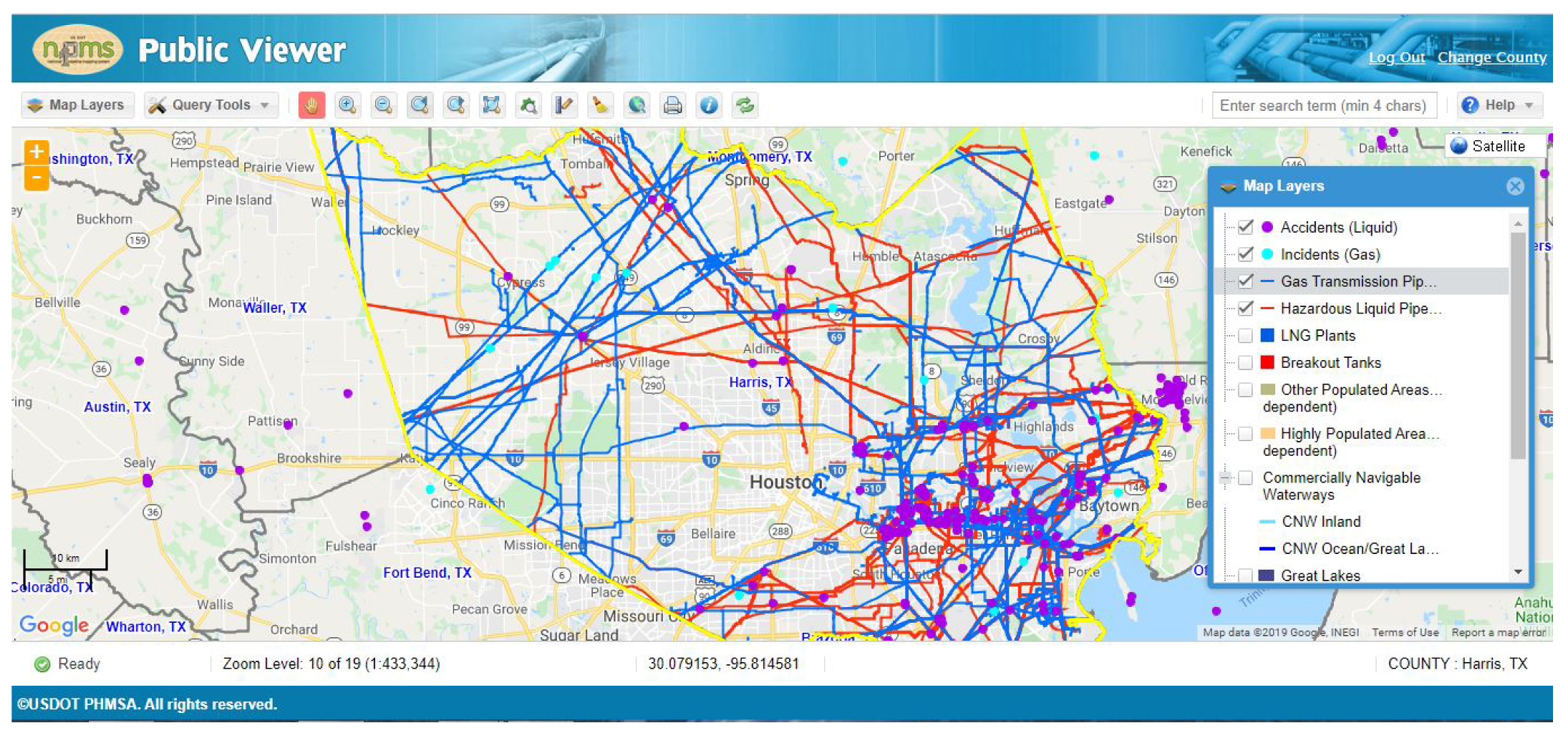

Pipeline and Hazardous Material Safety Administration of the U.S. Department of Transportation (DOT) has been responsible for collecting oil and gas pipeline related data and incident reports in the United States from the early 1970’s, and have made them publicly accessible online. The National Pipeline Mapping System (NPMS) Public Map Viewer, a web based mapping application that serves public with displaying and querying data including attributes related to gas transmission and hazardous liquid pipelines, functions under the jurisdiction of PHMSA.

Figure 1 indicates the map of Harris county in Texas as seen via NPMS Public Map Viewer. The blue lines represent the Gas Transmission Pipelines and the red lines represent Hazardous Liquid Pipelines. The violet and the green dots in the map indicate accidents that occurred at those locations in Hazardous Liquid pipelines and Gas Transmission pipelines respectively. The user can obtain the latitude and longitude coordinates of every point by manoeuvring over the map.

This study considers all onshore river crossing gas transmission and hazardous liquid pipelines in the U.S., regulated by PHMSA subject to failure by VIV loading during floods from 1986. Factors including pipeline outer diameter (OD), wall thickness (WT), yield strength (SMYS), pipe material, internal fluid pressure (P), and age of pipe from its installation year are all captured from the corresponding incident reports in the PHMSA database. Apart from these factors, the latitude, longitude and time of all pipeline failures are stored separately in order to reference other databases to capture the associated river and soil properties of the incidents.

3.1.2. USGS and NOAA

The United States Geological Survey (USGS) and the National Oceanic and Atmospheric Administration (NOAA) monitor real time discharge rates and water levels/stages for various rivers and streams by setting up a network of stream gages and stations across the United States. The Advanced Hydrological Prediction Service under the NOAA provide river hydrograph mappings that indicate the peak discharge rate during floods at various times in history. For each incident, based on the latitude and longitude from the PHMSA database, we capture river depth, discharge rate (Q) and in turn river velocity at four different times including the peak velocity occurrence during the flood event.

3.1.3. Estimation of Reduced Velocity for Inline and Cross-Flow Oscillations

Interactions between pipeline and external fluid flow (in this case, river water) in a direction perpendicular to the axis of the pipeline reduces the flow around the pipe and in turn induces oscillations due to the formation of vortices. This unsteady phenomenon occurs at specific flow velocities governed by the length and shape of the exposed pipeline and is an important source of fatigue damage for both onshore and offshore free spanning pipelines. The onset of vortex shedding-induced oscillations for both in-line and cross-flow motions is determined by reduced velocity

and is defined as,

where

is the natural frequency of vibration of pipe,

V is the actual velocity of river water and

D is the outer diameter of the pipe.

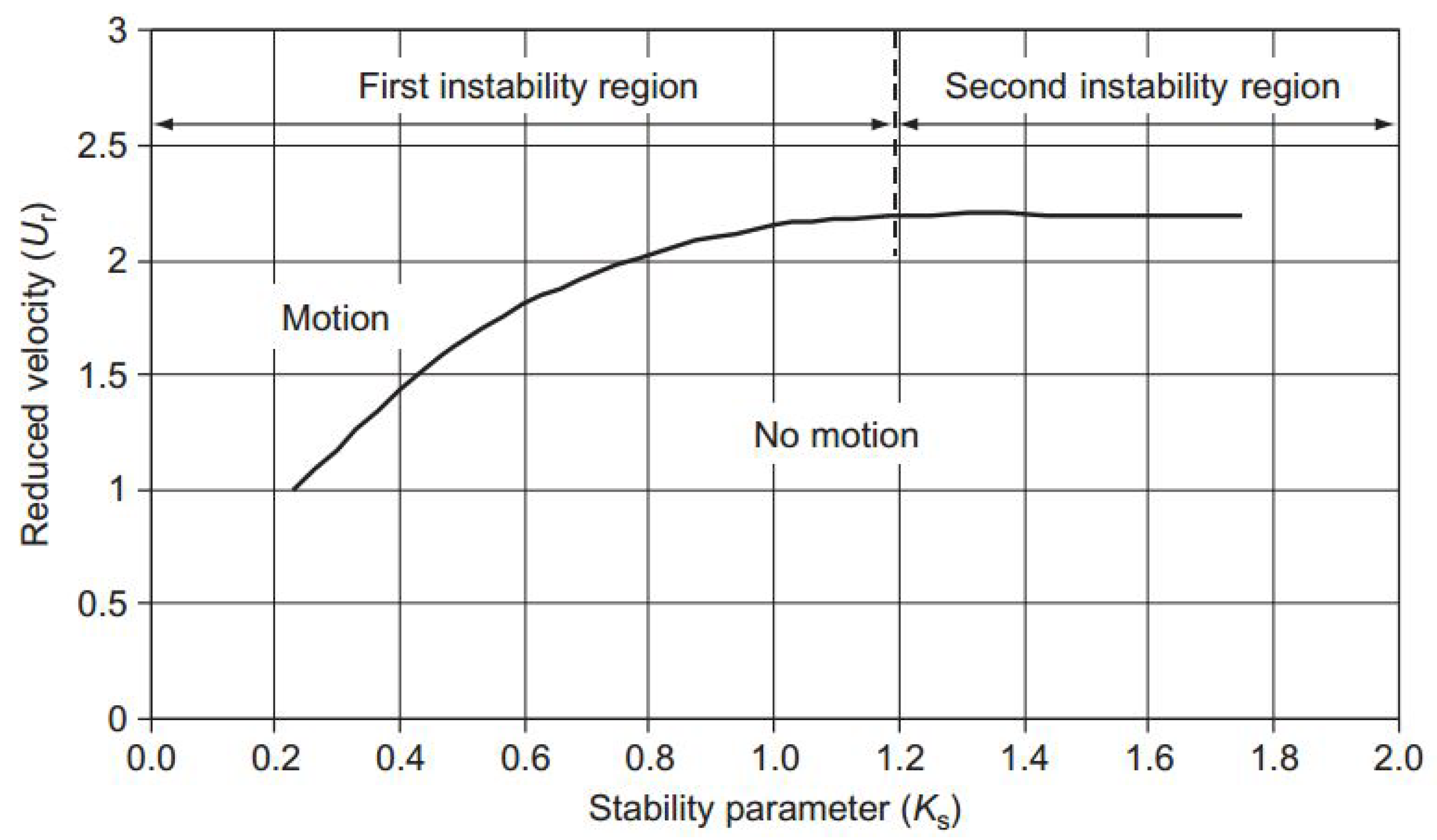

When river velocity is low, symmetric vortices are shed and the pipe begins to oscillate in-line with the flow when vortex shedding frequency equals to about one-third the natural frequency of the pipe span. The in-line response of a pipeline span in current dominated conditions is associated with either alternating or symmetric vortex shedding. The onset of in-line VIV can be analyzed from the plot between reduced velocity (

) and stability parameter (

) as shown as

Figure 2. The dimensionless stability parameter plays a significant role in assessing in-line vortex induced motion and is defined as,

where

is the effective mass and equals the sum of mass of pipe, its contents and added mass,

is the logarithmic decrease of structural damping and equals 0.125 for steel,

is the density of fluid around the pipe and

D is the pipe outer diameter [

17].

In-line VIV occurs in two distinct instability regions. The amplitude of in-line VIV increases with reduced velocity in the first region and the amplitude almost remains constant in the second instability region. Reduced velocity typically varies between 1 and 2.2 in the first instability region and varies between 2.2 and 4.5 in the second instability region.

The mathematical function representing the relation between reduced velocity and stability parameter in the first and second instability region is given by the following equation, from Chapter 11, Handbook of Offshore Engineering [

18].

At higher velocities, the Reynolds number increases and the flow becomes asymmetric resulting in motion transverse to the flow due to the development of lift forces on either side of the pipe. Cross-flow VIV typically occurs at reduced velocities between 3 and 5. The exact transition from in-line second stability region to the onset of cross-flow vibrations is difficult to determine. The onset of cross-flow VIV can be estimated from the plot between reduced velocity (

) and Reynolds number (

) as shown in

Figure 3, Offshore Pipelines (Second edition, Chapter 5) [

17].

Excitations in the cross-flow direction are far more dangerous than in-line when the vortex shedding frequency roughly equals the natural frequency of vibration of pipe span due to higher amplitudes of response and fatigue damage. The mathematical function representing the relation between the two parameters is given by the below equation from Chapter 11, Handbook of Offshore Engineering [

18].

where

,

,

,

and

.

3.1.4. Data for Dynamic Lateral and Vertical Soil Stiffness Values

Modelling of pipe-soil interactions is essential for evaluating the static equilibrium configuration and dynamic response of a free spanning pipeline. The lateral (horizontal) dynamic stiffness

is defined as the dynamic horizontal force between pipe and soil per unit length of pipe. The vertical dynamic stiffness

is defined as the dynamic vertical force between pipe and soil per unit length of pipe. The two parameters

and

for non-stratified and homogeneous soil are determined based on the DNV Recommended Practice for Free Spanning Pipelines [

9] as follows,

where

and

are coefficients selected based on

Table 1,

is the Poisson’s ratio and equals 0.5 for undrained conditions,

/

represents the specific mass ratio between pipe mass and displaced water and

D is the pipe outer diameter in meters. Density of steel equals 7861 kg/m

. Density of fluid inside the pipeline is taken as 870 kg/m

for light crude oil and 0.8 kg/m

for natural gas. The above stiffness parameters

and

play a crucial role in modelling pipe-soil interactions to determine the natural frequency of vibration of the pipe. The soil type is identified by the value of its friction angle, which is a characteristic parameter of the soil. Typical friction angles and stiffness values for different types of sand are given in

Table 1.

The Natural Resources Conservation Service (NRCS) under the United States Department of Agriculture provides soil maps and data surveyed throughout the United States as a web based application to the public. Based on the river, the latitude and longitude of the pipeline incident, contents of sand on the pipeline shoulders are identified to determine its friction angle and in turn the coefficient values. Using this method, lateral and vertical dynamic soil stiffness values are determined at all pipeline incidents.

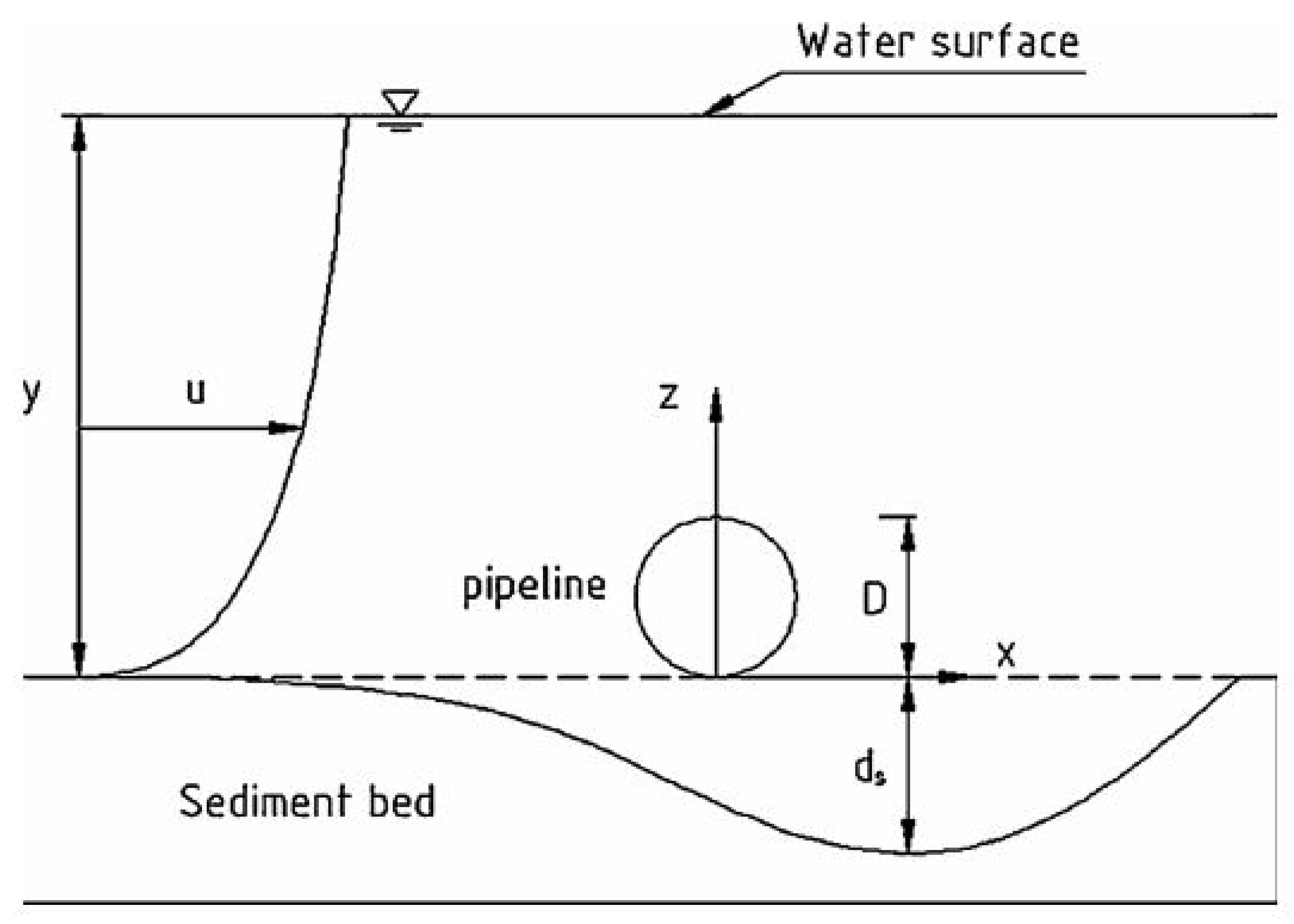

3.1.5. River Bed Scour

Scouring action of river bed refers to the removal of top sediment layer and occurs when hydraulic shear stress on the stream bed exceeds the capability of bed material to resist motion. Scouring is a common type of erosion that exposes a buried pipeline at its approach to a crossing and could potentially impact the integrity of the pipeline due to hydrodynamic loading, fatigue caused by vortex shedding, and impact loads. Major hazards at river crossings that may expose a pipeline due to natural or environmental changes are listed in

Table 2 [

19]. Flow properties such as river depth, velocity and water density, river bed and soil characteristics namely dynamic lateral and vertical stiffness of soil, longitudinal slope of the river bed, size of sediment particles, initial gap between pipeline and undisturbed bed (

e), and pipeline geometry including diameter and wall thickness influence localized scour below pipelines as indicated in

Figure 4 1. Many studies have been conducted to understand the correlation between scour depth below pipelines and non-dimensional numbers based on flow properties such as Froude number (

F), Reynolds number (

) and Shields parameter (

) [

21].

Here we restrict our study on exposed pipelines due to the onset of scour in riverbeds that experience vortex induced vibrations due to the flowing water. Moncada and Aguirre-Pe (1999) presented the following relationship for estimating localized scour depth under pipelines [

22],

where

is the scour depth,

F =

is the Froude number,

V is the velocity of river,

y is the water depth,

g is gravitational acceleration and

D is the pipeline outer diameter. They have concluded that parameters such as river bed slope and

ratio have very minimal effect on scour depth and have been neglected in our prediction model.

3.2. Artificial Neural Network Model

Forty five incidents were captured from the PHMSA database pertaining to failure of gas transmission and hazardous liquid pipelines as a result of VIV loading due to floods in the last 35 years. For each of the forty five incident cases, river velocity, discharge rate and river stage were captured at four different times resulting in a total of 180 analyzed data sets.

Table 3 indicates the 12 input features and its correlation with the 3 output parameters used in modelling the neural network. Scour depth parameters were evaluated for the entire dataset using the Froude Number approach as prescribed by Moncada and Aguirre-Pe [

22]. First general formulations of DNV on calculations of critical span lengths due to inline and cross flow oscillations were carried out for all cases. The critical span length calculations for all incidents were validated based on the approach prescribed by Minerals Management Service under United States Department of the Interior [

3].

Feature scaling was performed to selective attributes such as yield strength, internal fluid pressure, discharge rate and dynamic lateral and vertical soil stiffness values to ensure all input attributes had values in a similar range. Feature scaling involves dividing the input values of one or more attributes by the maximum value of that particular attribute, resulting in a new range between 0 and 1. The error decreases rapidly after every iteration and the model converges quickly when the input features are re-scaled. Feature scaling prevents weight matrices from oscillating inefficiently when the variables are uneven and have large ranges. Unlike normalization, feature scaling does not alter the distribution of the data and only re-scales the data to the desired range.

3.2.1. Correlation Matrix

Correlation coefficients were calculated between the input and output variables as shown in

Table 3. Correlation is a statistical measure that indicates the strength and direction of a relationship between a pair of variables. Correlation coefficient between variables

X and

Y where each pair of data is denoted by (

) is calculated using the following relation:

Here, n represents the total number of ordered pairs in the dataset, , indicate the mean of variables, and , represent the standard deviation of the variables X and Y. The correlation coefficient (r) varies between and 1, and is a numerical measure of the degree of association between the variables. Positive coefficients indicate a direct relation between the variables and negative correlations represent an inverse relationship.

3.2.2. Assumptions

The model formulation during this study needed certain key assumptions to be made to predict critical span length and scour depth which are listed as follows:

The pipelines are situated perpendicular to the flow, where maximum hydrodynamic loads and vortex induced vibrations would be expected.

The pipeline under study is on the river bed and hence scouring will expose the pipeline and induce VIV, when flooding occurs.

The soil on the pipe shoulder is assumed to be non-stratified and homogeneous in all the cases for calculating lateral and vertical dynamic soil stiffness as there are no standard prescriptions for computing stiffness values for heterogeneous soils.

The free span end fixity constant is 1.57 for pinned-pinned ends and 3.54 for fixed-fixed ends. In this study, we have considered the value to be 2.52 for all cases because in reality, pipes are neither completely pinned nor clamped on the ends.

The cross sectional area of the river is taken as the product of width and depth, and the river water is assumed to flow at mean velocity when it comes in contact with the pipe neglecting the variation of velocity with depth.

4. Results

4.1. Best Fit Neural Network Architecture

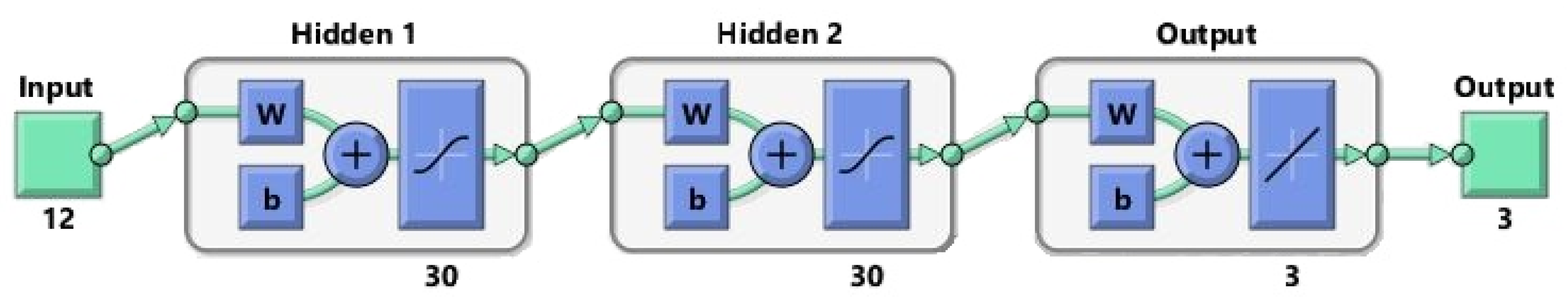

Our input and output data can be represented as 180 × 12 and 180 × 3 matrices. The dataset was split into 3 categories named Training, Validation and Testing in the ratio 15:2:3 determined by trial and error through interactive tests. The schematic diagram of the Neural Network architecture designed by using Deep Learning Toolbox in Matlab is depicted in

Figure 5. The architecture comprised of a backpropagation network [

23] with 2 hidden layers having 30 neurons each and the input layer having 12 neurons corresponding to the 12 features. Architectures with 3 hidden layers were found to overfit the model with low training set errors and high testing set errors. Similarly architectures with a single hidden layer were found to underfit the model with high training set errors. The number of hidden layers, neurons, transfer functions and training algorithm were determined in an iterative manner based on the model performance.

The hyperbolic tangent sigmoid (

tansig) activation function which is the mathematical equivalent of

tanh function was used in both the hidden layers. The symmetric nature of the

tansig function enables faster learning of the model when compared to other activation functions. For the output neuron(s), the most appropriate activation function for a feedforward neural network is a linear transfer function (purelin), as it reduces the loss in accuracy of the model when hyperbolic tangent sigmoid transfer function is applied to normalized data in the hidden layers. The network was trained iteratively using the Levenberg-Marquardt (LM) algorithm [

24].

4.2. Performance Evaluation

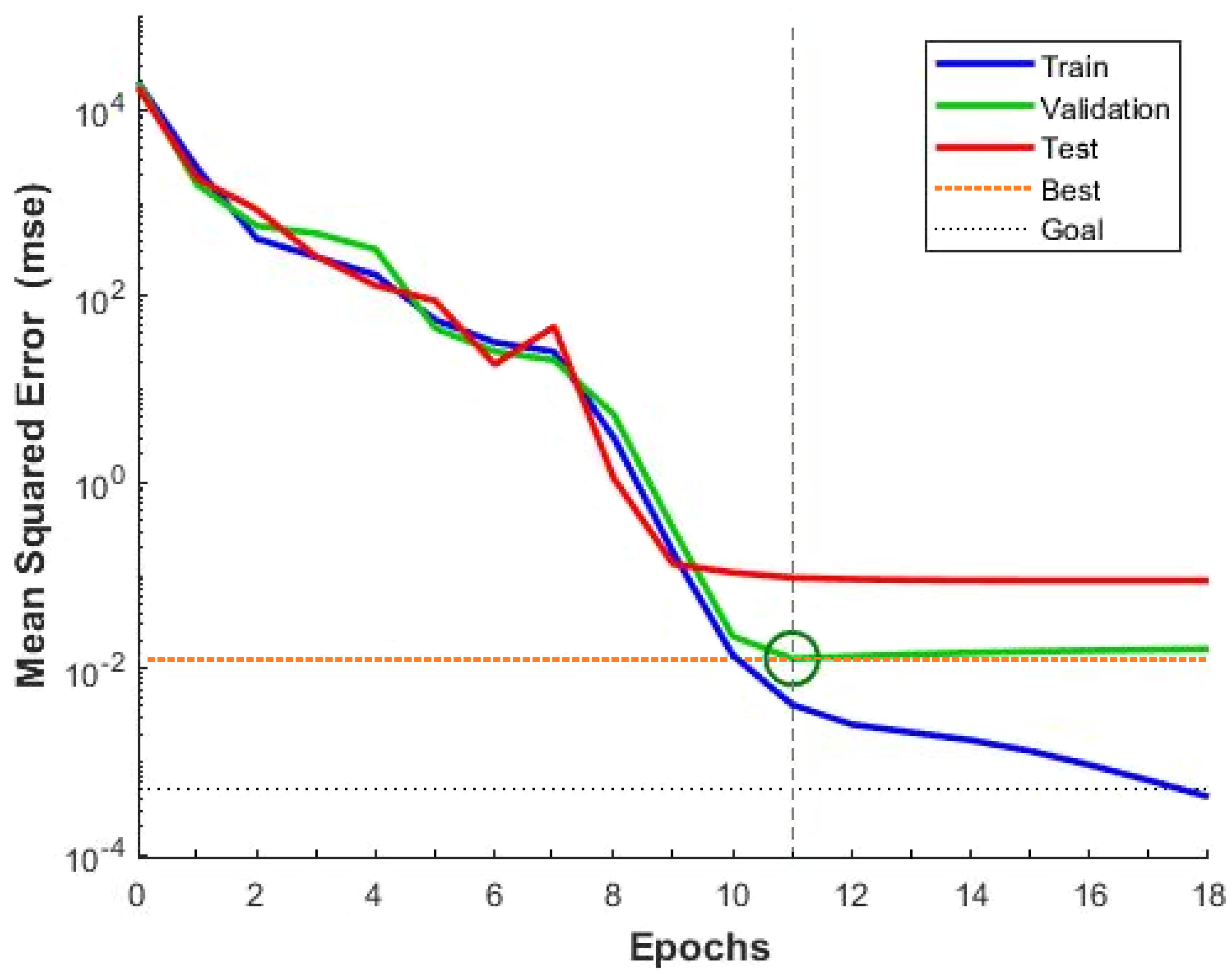

Mean Squared Error (MSE) is chosen as the model performance evaluation function to analyze the speed and accuracy of the learning network. The MSE for Training, Validation and Testing datasets after each iteration (epochs) is shown in

Figure 6. The y axis is logarithmically scaled to clearly interpret the variations in MSE as it goes below 10

. The MSE for training dataset decreases continuously with the increase in number of iterations and reaches the target of 10

after 18th iteration. The MSE for validation dataset decreases for 11 iterations, and gradually increases thereafter. The iteration where least MSE is observed for the validation dataset is selected as the best model. Models from 12th iteration onwards are considered to overfit the training data. The results of the mean squared error for training, validation and testing data set are given in

Table 4.

4.3. Error Histogram

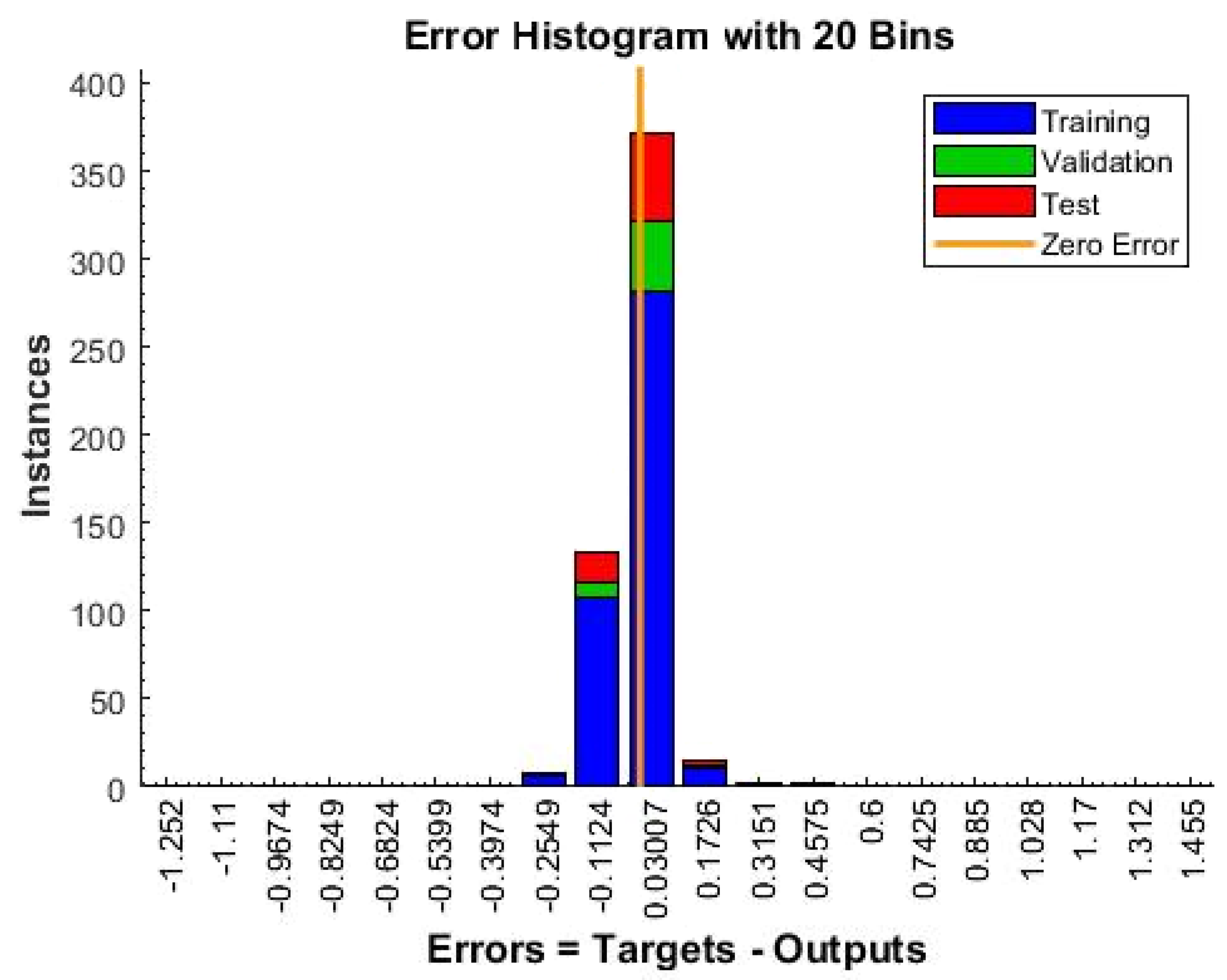

The errors between the target values and predicted values for our dataset after training our feedforward neural network can be visualized from

Figure 7. The histogram categorizes the 540 error values into 20 bins with orange line indicating zero error. Percentage error distribution for training, validation and testing data is given in

Table 5 and

Table 6. We see that 92% of predicted outputs in the validation dataset and 94% of predicted outputs in the testing dataset have less than 1% error when compared to theoretical results. The errors of the remaining outputs are also less than 4%.

4.4. Training State and Regression Plots

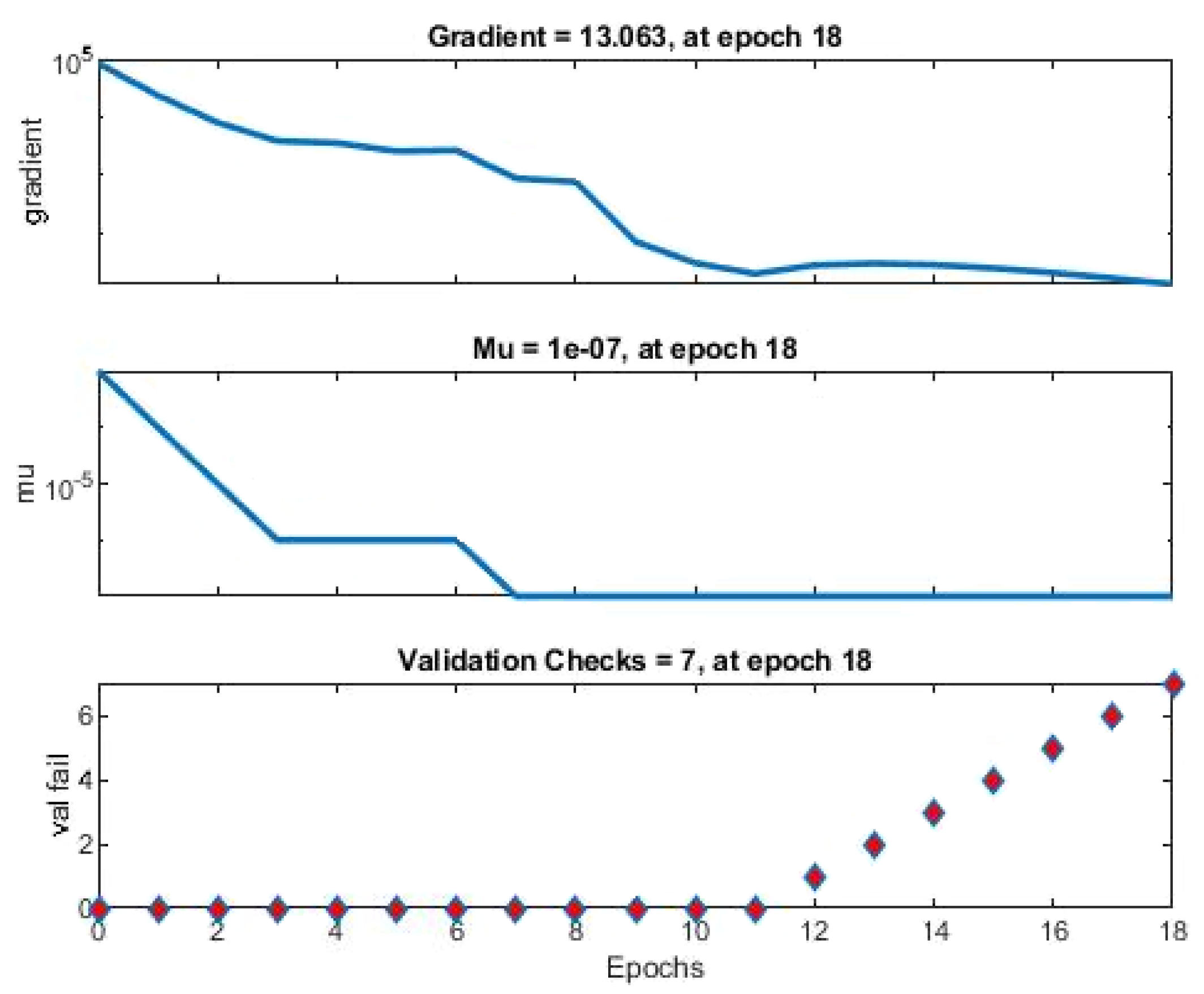

Training state plots indicate how the control parameters vary with iterations. From the various plots in

Figure 8, we can observe the gradient value to decrease gradually indicating that the error function is reaching its minimum.

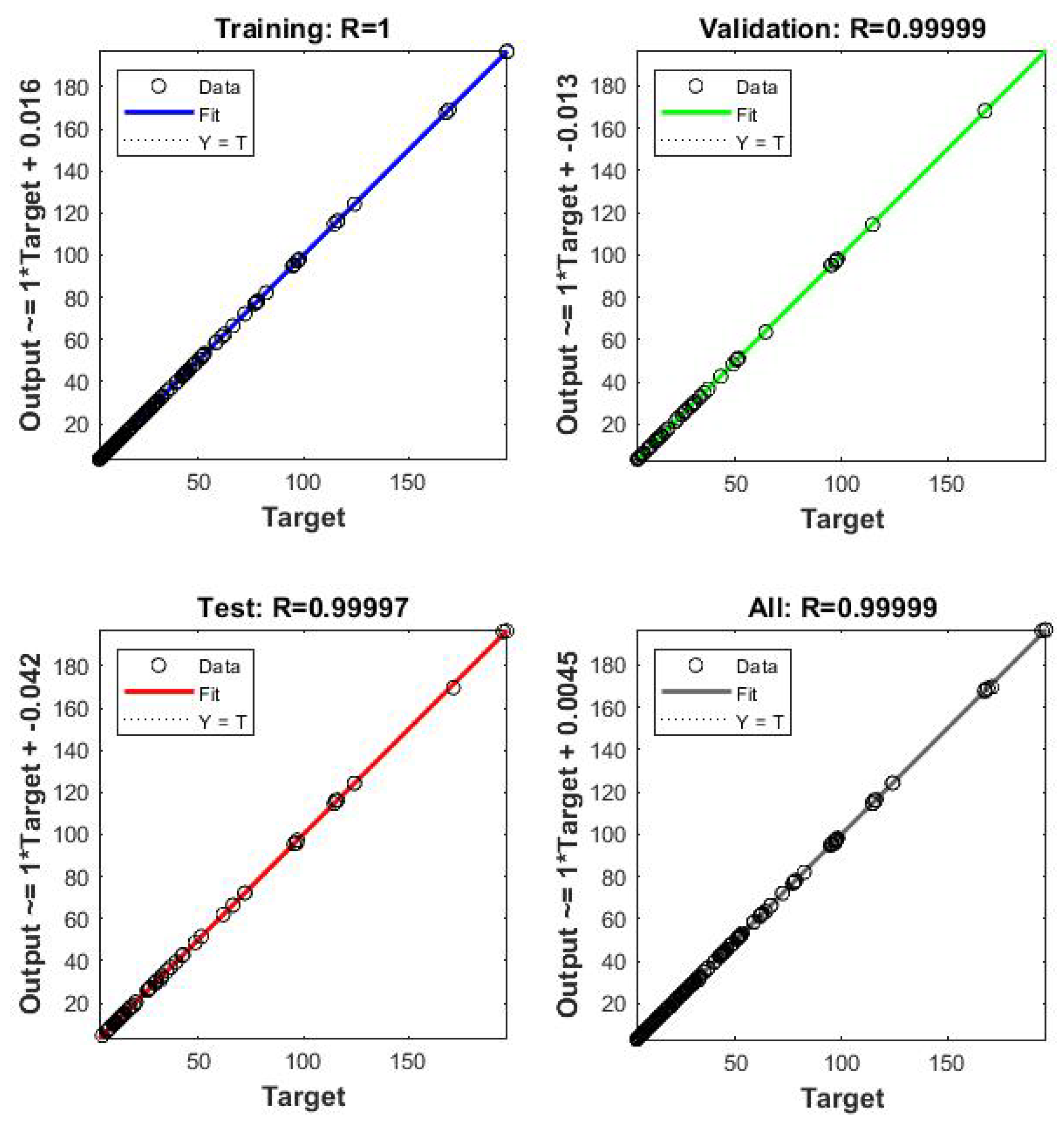

Mu is referred to as the Momentum parameter which is included in weight update function to avoid the problem of local minima. It is approximately equal to the inverse of the Hessian matrix. And finally, from the third plot between Validation checks and iteration, we can see that the validation dataset MSE increases continuously after the 11th iteration, an indication that the minimum MSE has been achieved. Regression plots, as shown in

Figure 9 indicate the relationship between actual values and the predicted values for the chosen set of data points.

5. Discussion

5.1. Quantifying Relative Importance of Input Parameters

ANN is a powerful statistical technique that captures the relationship between variables that cannot be easily described by a simple mathematical model. The Connection Weight Approach provides an excellent methodology for quantifying the importance of input variables in a neural network [

25]. This method calculates the product of raw input-hidden-output connection weights between each input neuron and output neuron and sums the products across all hidden neurons. The final weights are then used to rank the relative importance of input features for each output variable.

In order to better understand the interactions between variables, the strength and direction of each connection weight within the network must be examined directly.

Table 7 provides a summary of overall connection weights of the input parameters corresponding to each output. A weight decides how much influence the input will have on the output. Weights near zero imply changing this input will not significantly affect the output. Negative weights mean increasing this input will decrease the output. The relative importance of an input variable in estimating an output variable is computed as a percentage of magnitude of its overall connection weight with respect to the summation of absolute values of overall connection weights of all input variables.

Table 8 shows the relative order of input features used in ANN to estimate scour depth. Moncada and Aguirre-Pe used river velocity, water depth and pipeline outer diameter in their derivation of empirical relationship to estimate scour depth [

22]. Here, we see that factors such as internal fluid pressure, yield strength, pipe wall thickness, dynamic vertical and lateral soil stiffness are also statistically significant in terms of weights and play a crucial role in the prediction process.

Table 9 shows the relative order of input features used to estimate critical span length due to in-line as well as cross-flow motion. We can observe that factors such as reduced velocities based on Reynolds number and stability parameter, discharge rate, pipe wall thickness and internal fluid pressure have high relative importance in both cases. Dynamic vertical and lateral soil stiffness values also have significant statistical contribution in terms of weights for critical span length due to cross-flow motion.

5.2. Pipeline Vulnerability Assessment Using the ANN Model

A screening level evaluation of vulnerability of pipelines at water crossings is performed by comparing MAFSL and the maximum exposure length of the watercourse based on its geomorphic properties. The vulnerability can be characterized using Free Span Ratio (FSR), which is defined as the ratio of MAFSL to the maximum exposure length [

27]. For the purpose of calculation, a convenient assumption made is to use the bankfull width (

L) of the water crossing in place of the maximum exposure length, as it is relatively easier to measure either using aerial imagery or laser rangefinder.

Moody and Troutman developed power law relationships between river bankfull width (

w), depth (

d) and discharge (

Q) based on data from a number of studies of world rivers that were used to characterize the two dimensional structure of channel networks [

28]. The proposed relationships were:

If FSR is less than 1.0, the maximum exposure length or bankfull width of the river is more than the MAFSL, and hence the water crossing pipeline is said to be more vulnerable to VIV if it becomes exposed. On the contrary, if FSR exceeds 1.0, the pipeline is unlikely to fail due to VIV even if it becomes fully exposed as MAFSL is greater than the entire bankfull width of the river.

Three values of the exponent namely 0.48, 0.5 and 0.52 are chosen to calculate bankfull width and Free Span Ratio (FSR) for the entire data set. The calculated FSR values were found to be greater than 1 only for 4 out of the 180 cases when using all three values for the exponent value of discharge rate. In all the remaining cases, FSR was less than 1 validating the potential threat of flood induced VIV resulting in pipeline failures. This method of evaluating bankfull width and FSR can be considered as a preliminary screening tool to assess the situation. The vulnerability estimate could be refined by replacing the bankfull width with a more accurate or realistic value for the maximum exposure length.

6. Conclusions

Artificial Neural Network has helped develop a robust nonlinear model to predict critical span length and scour depth of river crossing pipelines prone to failure due to VIV based on data available from PHMSA. In the ANN model developed using backpropagation algorithm, 12 parameters were identified including but not limited to exposure flow rate, reduced velocity, river depth, lateral and dynamic soil stiffness coefficients on the pipe shoulder, age of pipe installed, internal fluid pressure, pipeline geometry and material properties. The overall influence of every input variable on the prediction model was analysed in terms of its connection weights and their relative importance was ranked for each output. It is seen that factors such as internal fluid pressure, dynamic lateral and vertical soil stiffness and age of pipeline have a significant contribution in terms of weights in the ANN model. Best validation performance was observed at 11th iteration, with a mean squared error value of 0.0129. Performance of training dataset reached its target mean squared error value of 0.001 after the 18th iteration. More than 80% of the predicted values in the validation and testing dataset had less than 0.5% error. Free span ratio was calculated for all the cases and pipeline failure vulnerability was estimated as the inverse of Free Span Ratio. About 97.8% of the cases were found to be vulnerable to VIV failure which validates the model data. The performance of the model was satisfactory, and hence alternate machine learning techniques were not considered.

This work can be further extended by collecting datasets for a particular pipeline or a specific river having large number of water crossing pipelines, leading to the development of prediction models for each pipeline and river. This way, all the unique environmental factors associated with each river and pipeline can be successfully captured. Emerging wireless solutions and sensor technologies enable unprecedented asset visibility and help understand pipeline behaviours under different conditions including structural loads, deflection, weather changes, soil characteristics, moisture and pH levels. This real time data from IoT based sensors play an important role to develop reliable prediction models and optimize the effective service life of a pipeline.

Author Contributions

Conceptualization, A.K. and S.M.; Data curation, A.K. and S.M.; Formal analysis, A.K. and S.M.; Investigation, A.K., S.M. and R.L.; Methodology, A.K., S.M. and B.H.; Project administration, S.M. and B.H.; Resources, S.M.; Software, A.K.; Supervision, B.H., G.P. and R.L.; Validation, S.M., B.H. and G.P.; Visualization, A.K.; Writing—original draft, A.K.; Writing—review & editing, S.M., B.H., G.P. and R.L. All authors have read and agreed to the published version of the manuscript.

Funding

The open access publishing fees for this article have been covered by the Texas A&M University Open Access to Knowledge Fund (OAKFund), supported by the University Libraries.

Acknowledgments

We would like to thank Timothy Jacobs and Julie Ingram for their valuable insights and guidance during the course of this research.

Conflicts of Interest

The authors declare no conflict of interest. There was no role played by funders in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| ANN | Artificial Neural Networks |

| CFD | Computational Fluid Dynamics |

| CSL | Critical Span Length, (also) Maximum Allowable Free Span Length |

| DNV | Det Norske Veritas |

| FSR | Free Span Ratio |

| IoT | Internet of Things |

| LM | Levenberg-Marqaurdt Training algorithm |

| MAFSL | Maximum Allowable Free Span Length, (also) Critical Span Length |

| MARS | Multivariate Adaptive Regression Splines |

| MSE | Mean Square Error |

| NOAA | National Oceanic and Atmospheric Administration |

| NPMS | National Pipeline Mapping System |

| PHMSA | Pipeline and Hazardous Materials Safety Administration |

| VIV | Vortex Induced Vibrations |

| USGS | United States Geological Survey |

References

- Belvederesi, C.; Thompson, M.; Komers, P. Statistical Analysis of Environmental Consequences of Hazardous Liquid Pipeline Accidents. Heliyon 2018, 4, e00901. [Google Scholar] [CrossRef] [PubMed]

- Ferris, G.; Newton, S.; Ho, M.; Eichhorn, G.; Bear, D. Flood Monitoring for Buried Pipeline Watercourse Crossing. In Proceedings of the Rio Pipeline Conference & Exposition, Rio de Janiro, Brazil, 24–25 September 2015. [Google Scholar]

- Analysis and Assessment of Unsupported Subsea Pipeline Spans; United States Department of the Interior, Minerals Management Service: Washington, DC, USA, 1997; pp. 1–42.

- Heggen, H.O.; Fletcher, R.; Ferris, G.; Ho, M. Fatigue of Pipelines Subjected to Vortex-Induced Vibrations at River Crossings. In Proceedings of the Rio Oil & Gas Expo and Conference, Rio de Janeiro, Brazil, 15–18 September 2014. [Google Scholar]

- Xu, J.; Li, G.; Horrillo, J.; Rongmin, Y.; Cao, L. Calculation of Maximum Allowable Free Span Length and Safety Assessment of the DF1-1 Submarine Pipeline. J. Ocean. Univ. China 2010, 9, 1–10. [Google Scholar] [CrossRef]

- Koushan, K. Vortex Induced Vibrations of Free Span Pipelines. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2009. [Google Scholar]

- Matta, L.; Dotson, R. Key considerations in the assessment of pipeline spans. In Proceedings of the Pipeline Pigging Integrity Management Conference, Houston, TX, USA, 9–12 February 2015. [Google Scholar]

- Yaghoobi, M.; Mazaheri, S.; Jabbari, E. Determining Natural Frequency of Free Spanning Offshore Pipelines by Considering the Seabed Soil Characteristics. J. Persian Gulf 2012, 3, 25–34. [Google Scholar]

- DNV Recommended Practice DNV-RP-F105—Free Spanning Pipelines. February 2006. Available online: https://www.academia.edu/34034147/ (accessed on 26 October 2020).

- Fyrileiv, O.; MÃrk, K.; Ronold, K. Free Span Design according to the DNV-RP-F105 for Free Spanning Pipelines. In Proceedings of the Offshore Pipeline Technology Conference, Amsterdam, The Netherlands, 1 January 2002. [Google Scholar]

- Haghiabi, A.H. Prediction of River Pipeline Scour Depth using Multivariate Adaptive Regression Splines. J. Pipeline Syst. Eng. Pract. 2016, 8, 04016015. [Google Scholar] [CrossRef]

- Barati, R. Discussion of Prediction of River Pipeline Scour Depth using Multivariate Adaptive Regression Splines by Amir Hamzeh Haghiabi. J. Pipeline Syst. Eng. Pract. 2019, 10, 07019001. [Google Scholar] [CrossRef]

- Yan, X.; Mohammadian, A.; Rennie, C.D. Numerical Modeling of Flow and Local Scour around Pipeline in Steady Currents using moving mesh with masked elements. J. Hydraul. Eng. 2020, 146, 06020005. [Google Scholar] [CrossRef]

- Ychen, Y.H.; Li, J.N.; Kai, L.; Zhu, Q.J.; Liu, Y.L. Failure Prediction of Underground Pipeline Based on Artificial Neural Network. Destech Trans. Comput. Sci. Eng. 2017. [Google Scholar] [CrossRef][Green Version]

- Fyrileiv, O.; Collberg, L. Influence of Pressure in Pipeline Design—Effective Axial Force. In Proceedings of the 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005. [Google Scholar]

- Nelson, G.; Andre, M.; Cláudia, C. A Discussion on How Internal Pressure is Treated in Offshore Pipeline Design. In Proceedings of the IPC 2004, International Pipeline Conference, Calgary, AB, Canada, 4–8 October 2004. [Google Scholar] [CrossRef]

- Guo, B.; Song, S.; Ghalambor, A.; Lin, T.R. Chapter 5–Pipeline Span. In Offshore Pipelines, 2nd, ed.; Gulf Professional Publishing: Houston, TX, USA, 2014; pp. 53–63. [Google Scholar]

- Nogueira, A.C.; Mckeehan, D.S. Chapter 11–Design and Construction of Offshore Pipelines. In Handbook of Offshore Engineering; Chakrabarti, S.K., Ed.; Elsevier: London, UK, 2005; pp. 891–937. [Google Scholar]

- Sawatsky, L.F.; Bender, M.J.; Long, D. Pipeline Exposure at River Crossings: Causes and Cures. In Proceedings of the International Pipeline Conference, Calgary, AB, Canada, 7–11 June 1998; American Society of Mechanical Engineers: New York, NY, USA, 1998; Volume 1, pp. 159–163. [Google Scholar]

- Azamathulla, M.H.; Ghani, A.A. Genetic programming to predict river pipeline scour. J. Pipeline Syst. Eng. Pract. 2010, 1, 127–132. [Google Scholar] [CrossRef]

- Chiew, Y.M. Prediction of maximum scour depth at submarine pipelines. J. Hydraul. Eng. 1991, 117, 452–466. [Google Scholar] [CrossRef]

- Moncada-M, A.; Aguirre-Pe, J. Scour below pipeline in river crossings. J. Hydraul. Eng. 1999, 125, 953–958. [Google Scholar] [CrossRef]

- Skorpil, V.; Stastny, J. Neural Networks and Back Propagation Algorithm. In Proceedings of the ELECTRONICS’ 2006, Sozopol, Bulgaria, 20–22 September 2006. [Google Scholar]

- Gavin, H.P. The Levenberg-Marquardt Algorithm for Nonlinear Least Squares Curve-Fitting Problems; Department of Civil and Environmental Engineering, Duke University: Durham, NC, USA, 2019. [Google Scholar]

- Olden, J.D.; Joy, M.K.; Death, R.G. An accurate comparison of methods for quantifying variable importance in artificial neural networks using simulated data. Ecol. Model. 2004, 178, 389–397. [Google Scholar] [CrossRef]

- Olden, J.; Jackson, D. Illuminating the “black box”: A randomization approach for under-standing variable contributions in artificial neural networks. Ecol. Model. 2002, 154, 135–150. [Google Scholar] [CrossRef]

- Dooley, C.; Prestie, Z.; Ferris, G.; Fitch, M.; Zhang, H. Approaches for evaluating the vulnerability of pipelines at water crossings. In Proceedings of the Biennial International Pipeline Conference, IPC, Calgary, AB, Canada, 29 September–3 October 2014; Volume 2. [Google Scholar]

- Moody, J.A.; Troutman, B.M. Characterization of the spatial variability of channel morphology. Earth Surf. Process. Landf. 2002, 27, 1251–1266. [Google Scholar] [CrossRef]

| 1. | Figure 4 was reprinted from Reference [ 20]. With permission from ASCE. |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).