Simplified Method for Defining 2-Dimensional Design Failure Curve of Marine Silty Sand under Dynamic Loading

Abstract

1. Introduction

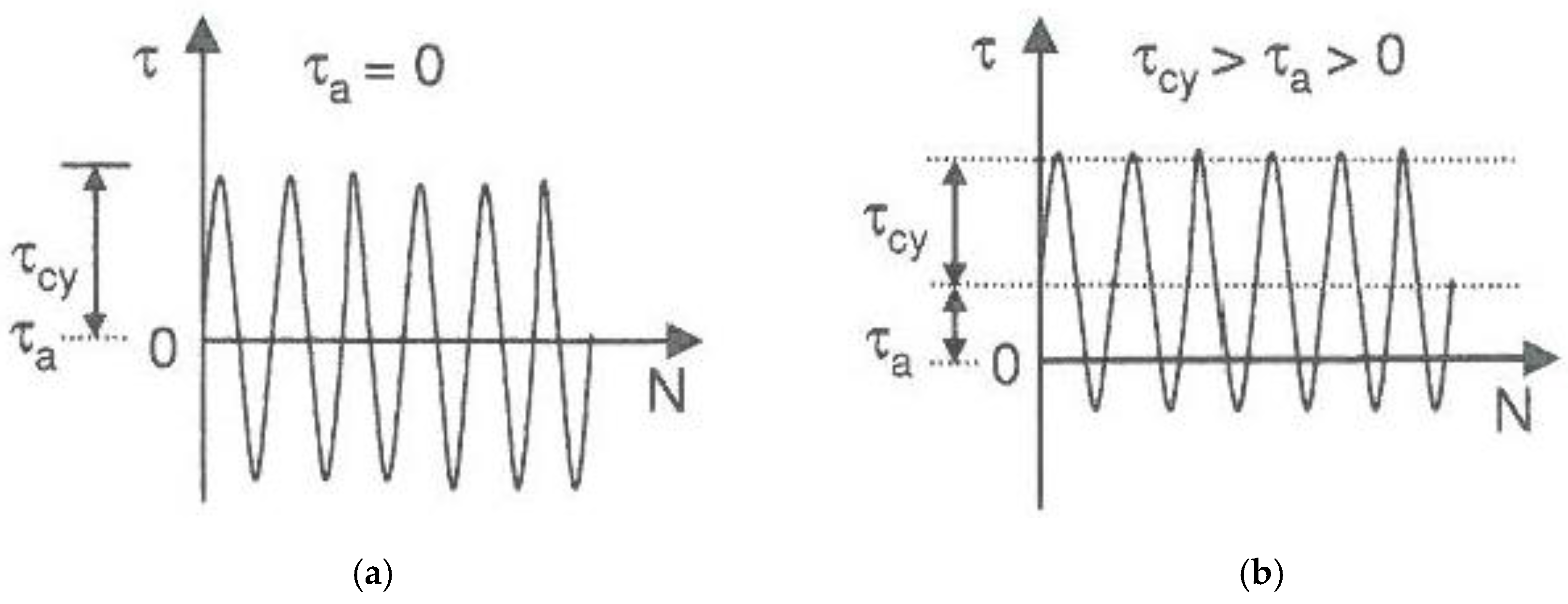

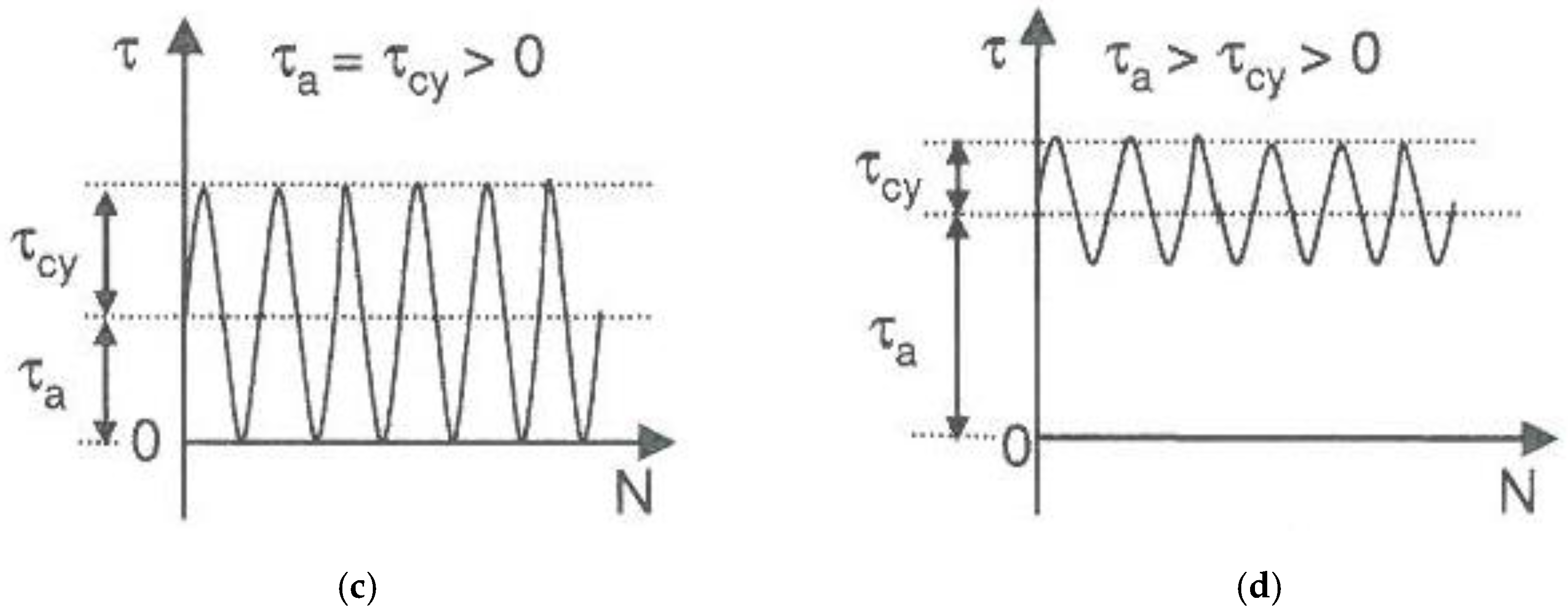

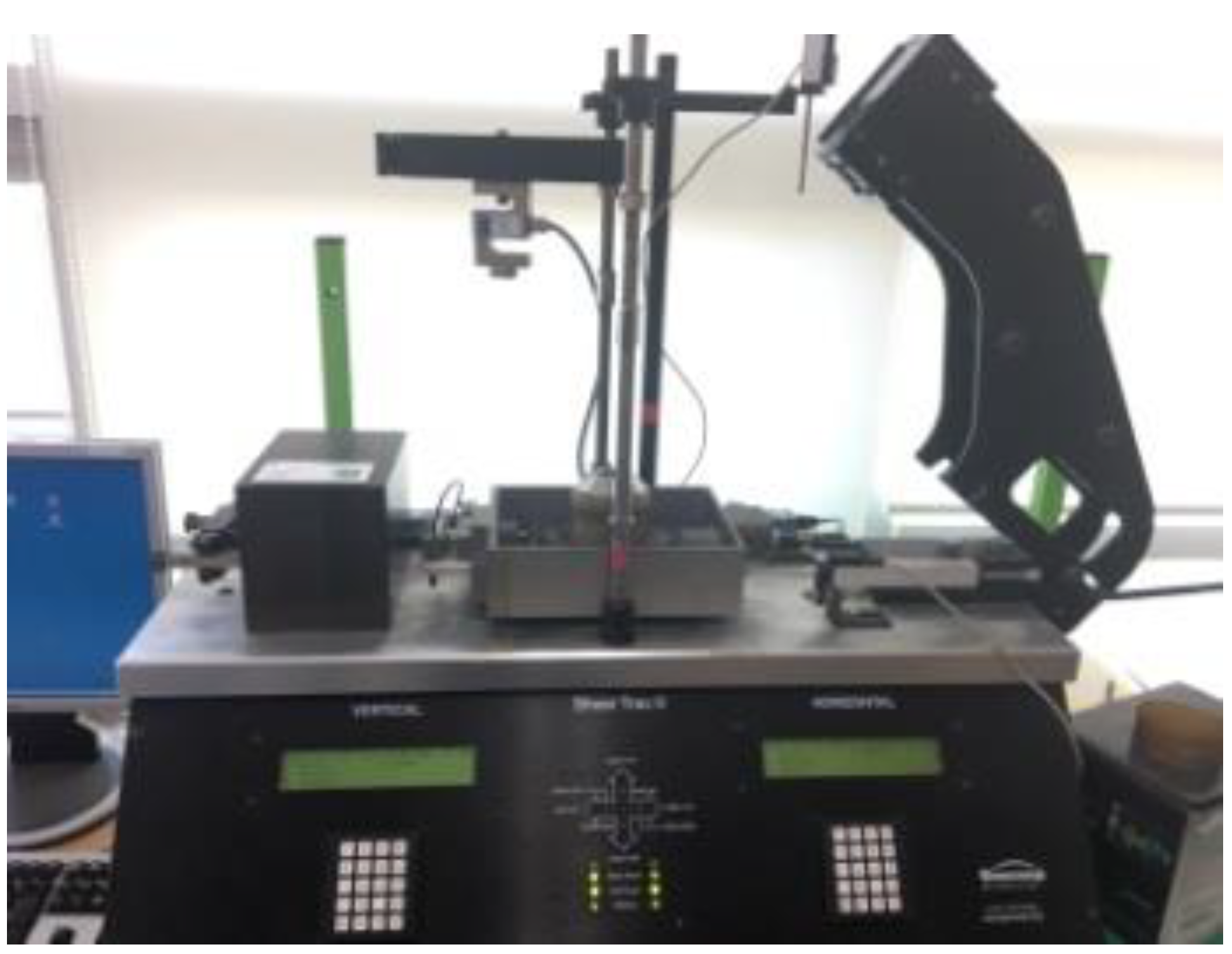

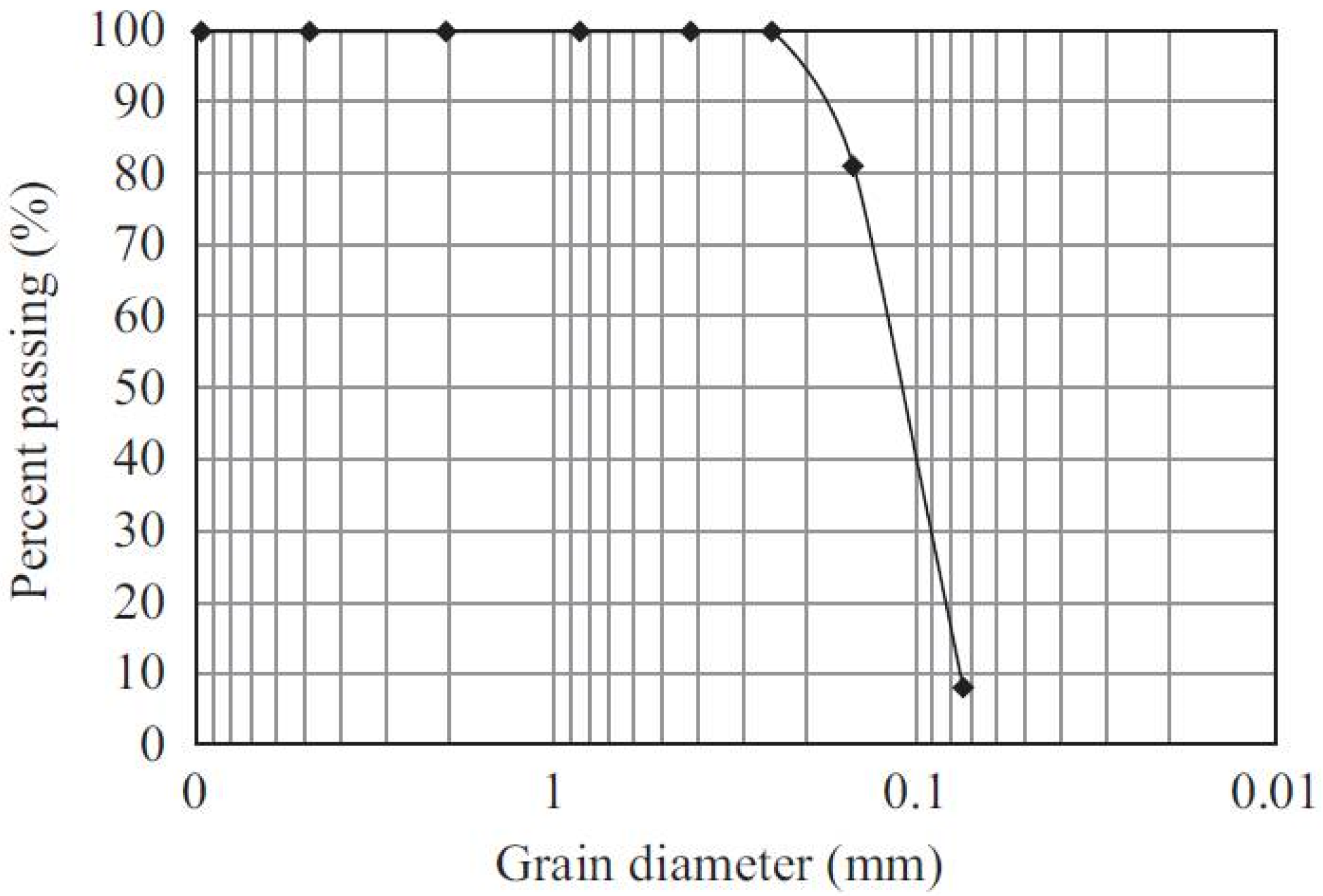

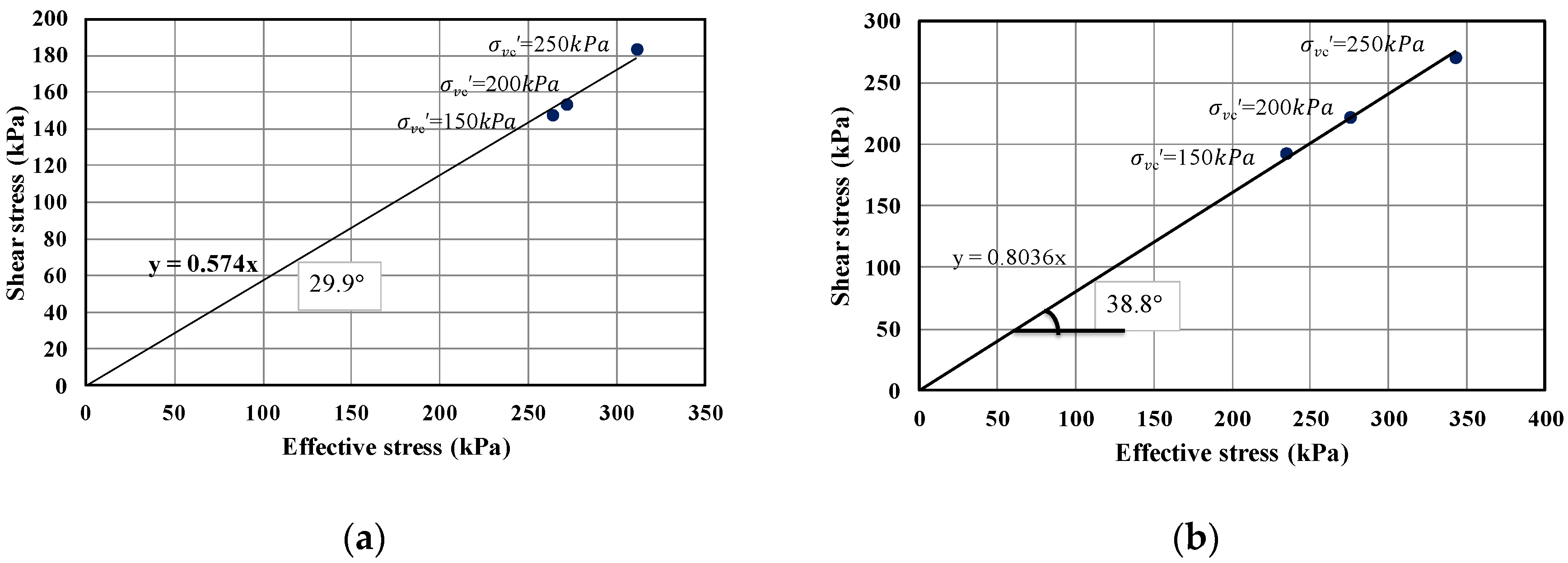

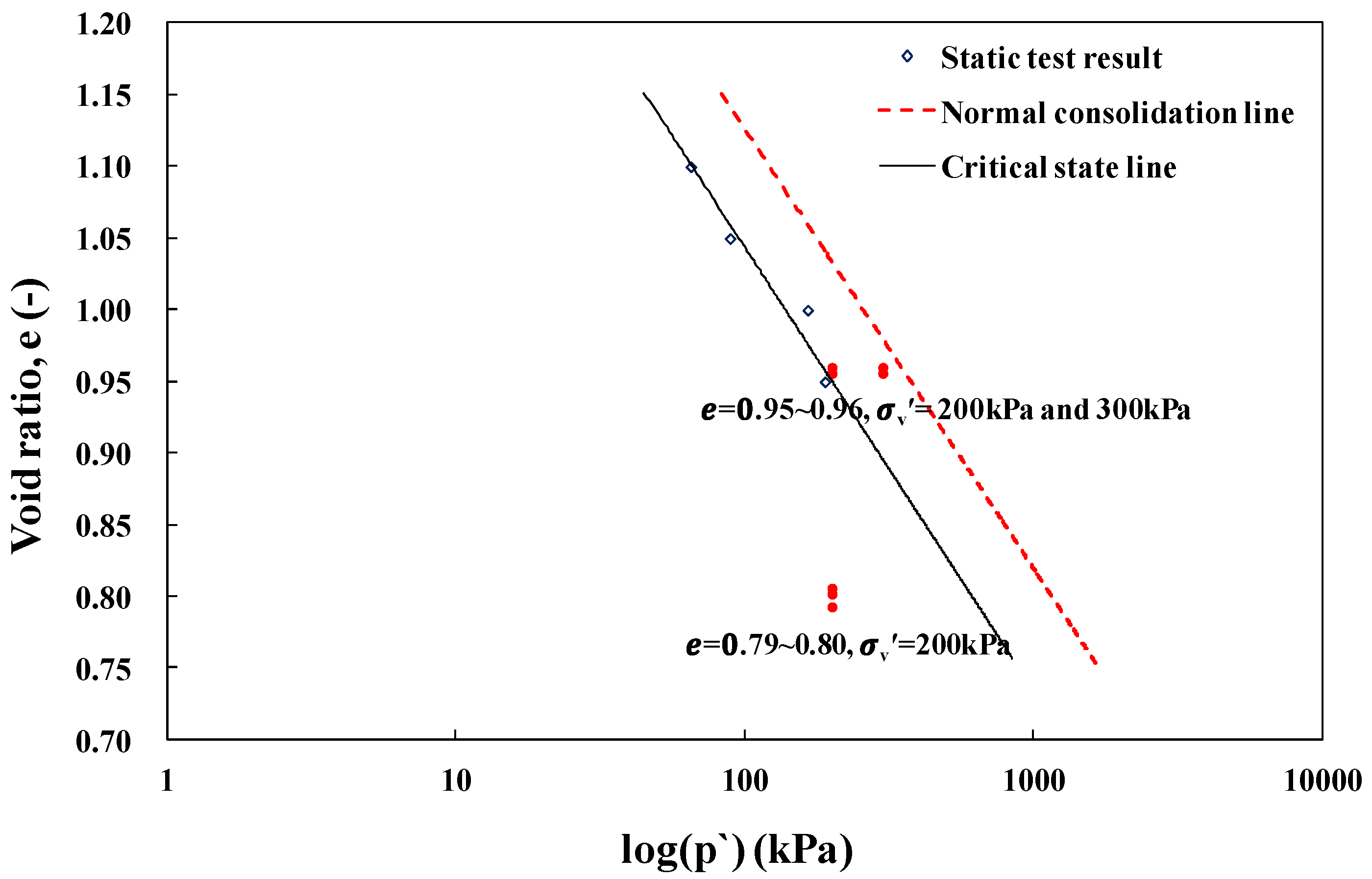

2. Test Apparatus and Program

3. Design Failure Curve

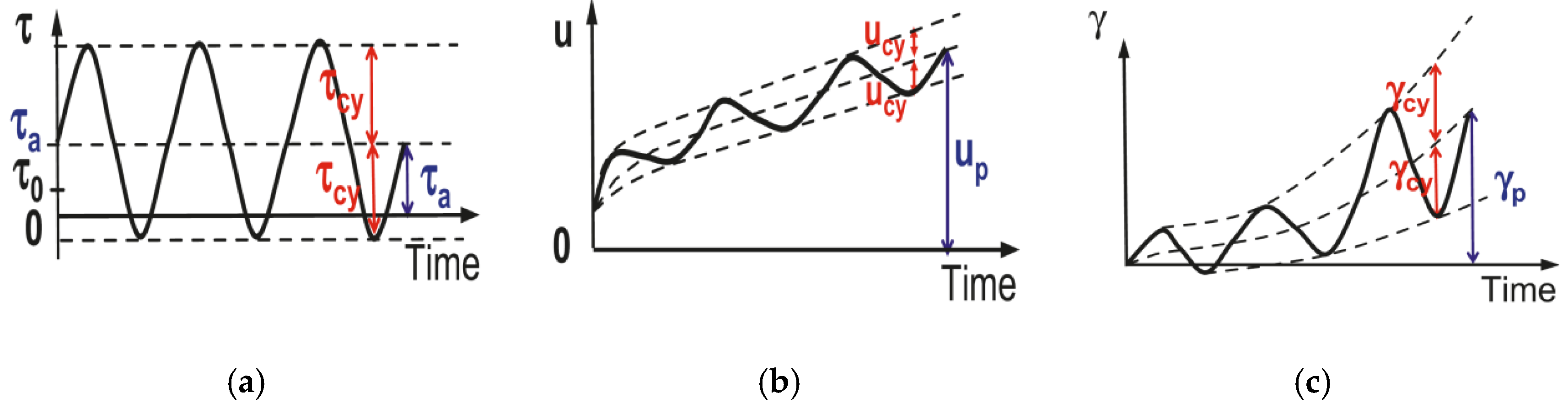

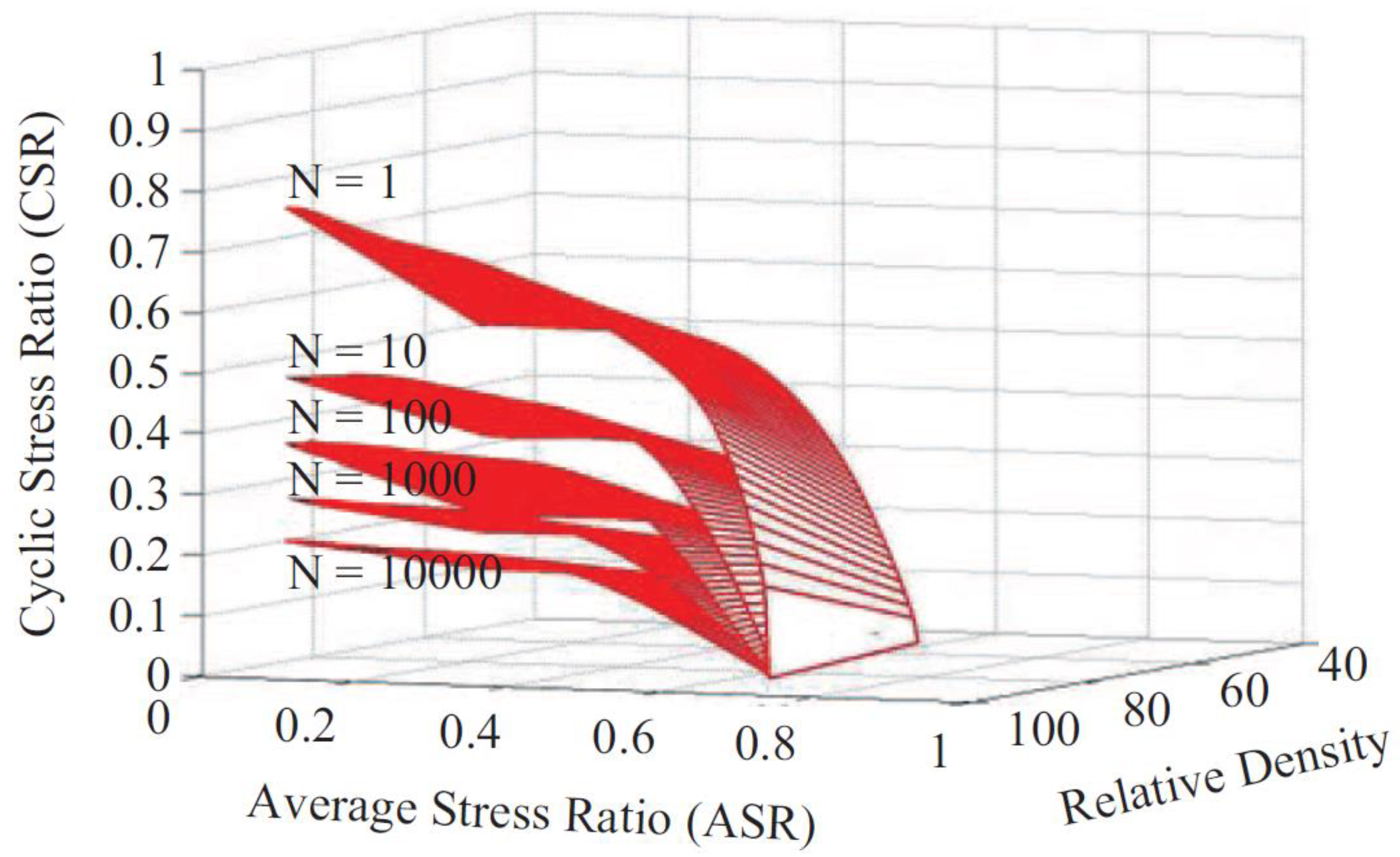

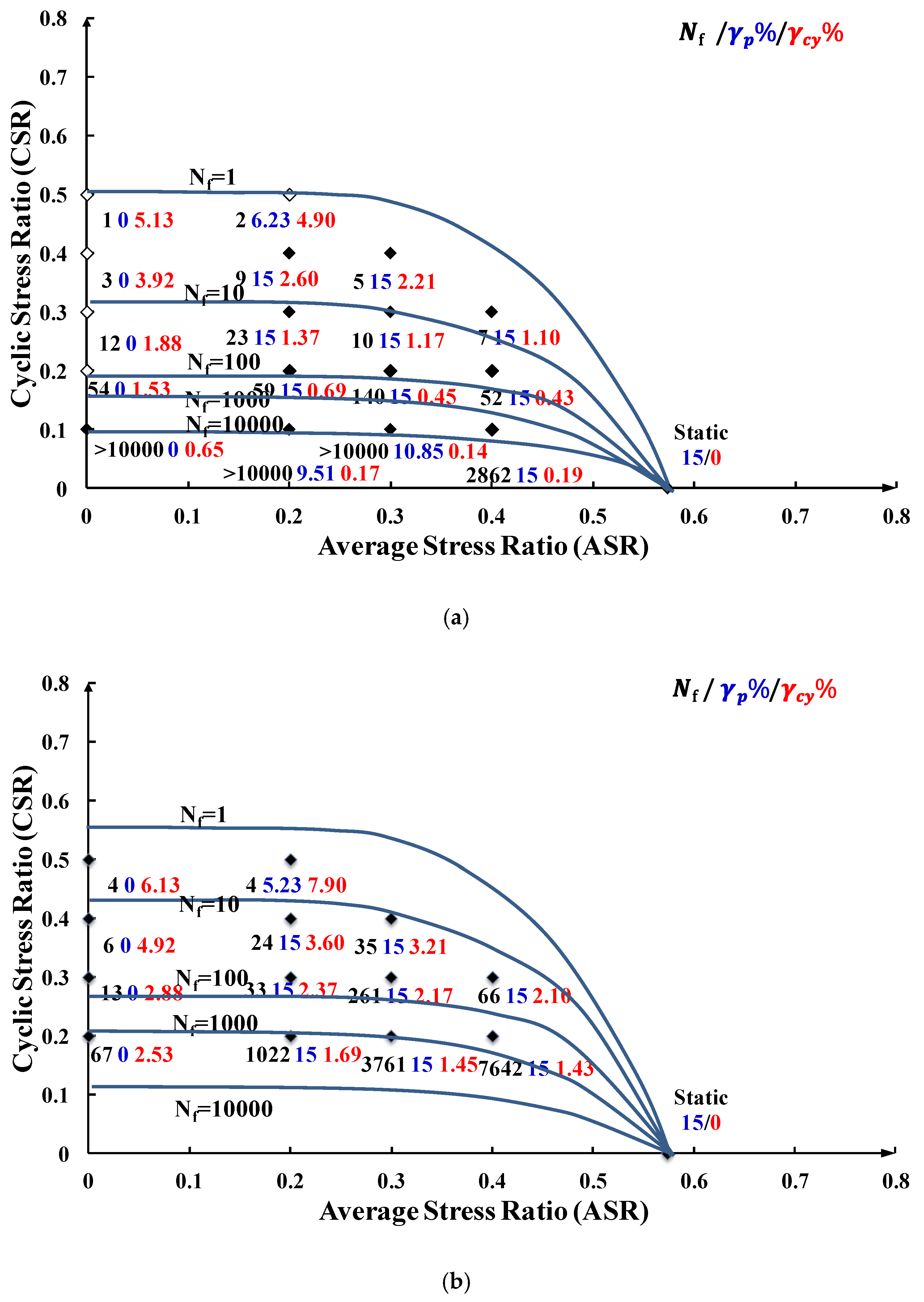

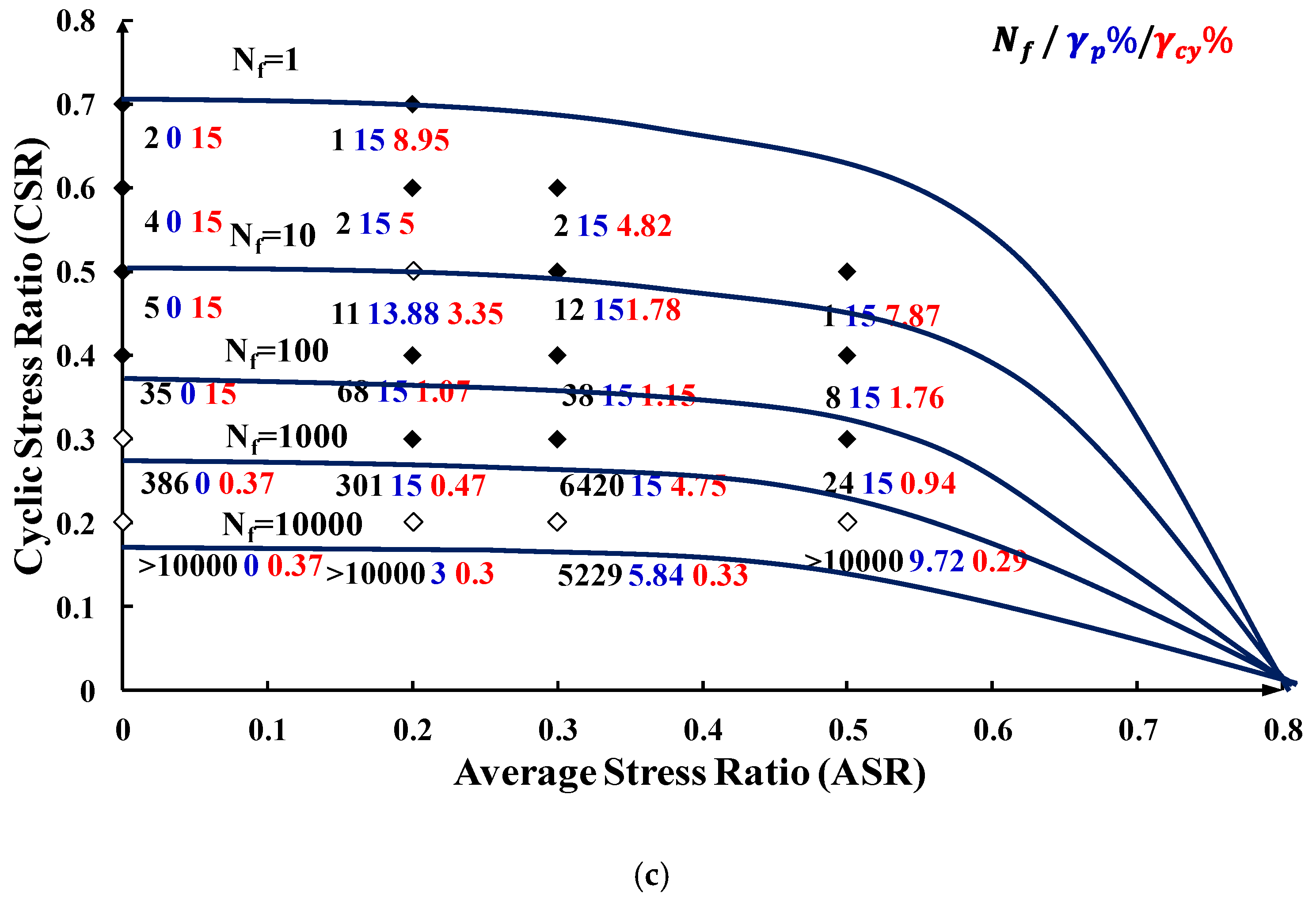

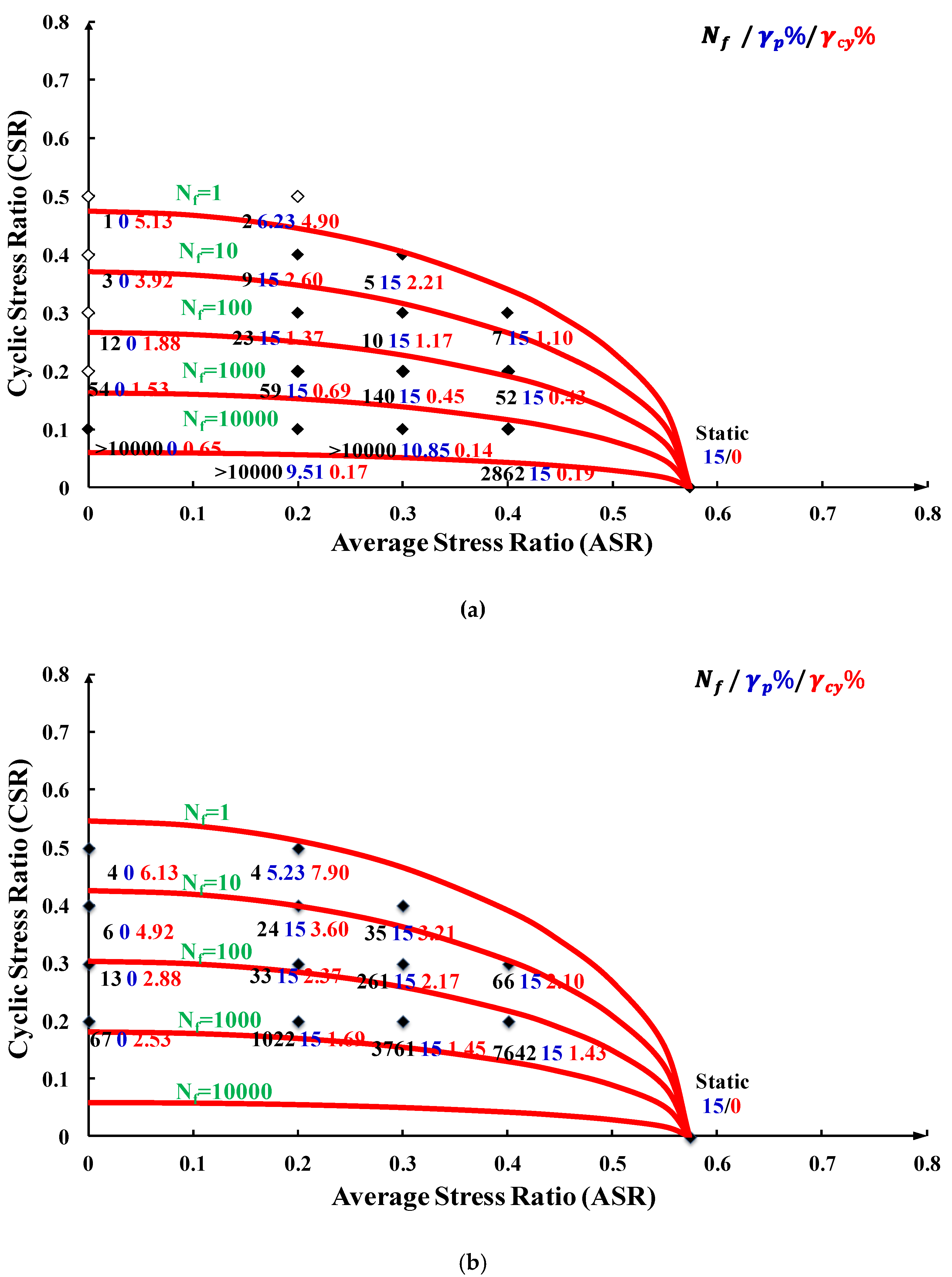

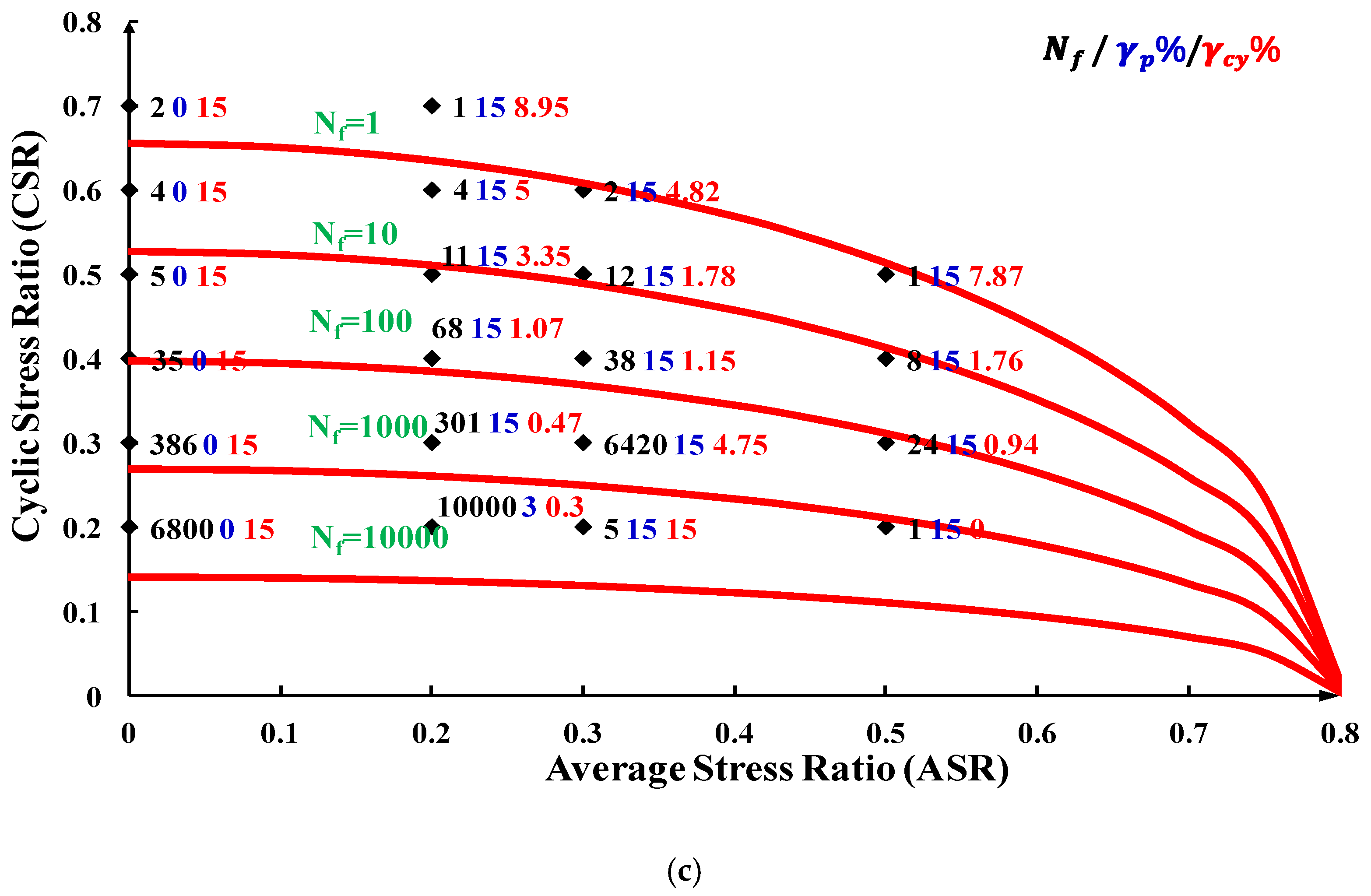

3.1. Design Graph

3.2. Design Graph Result

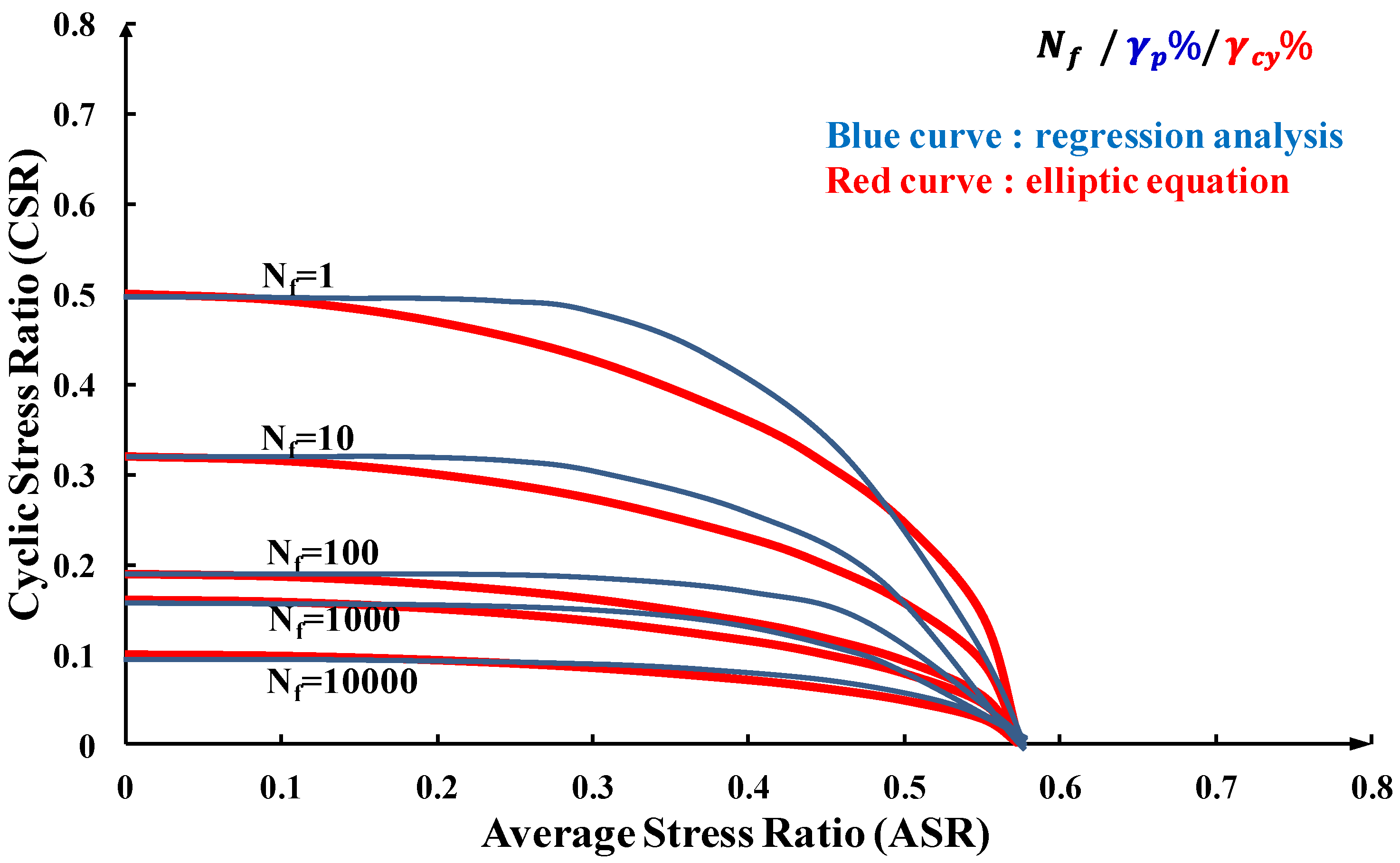

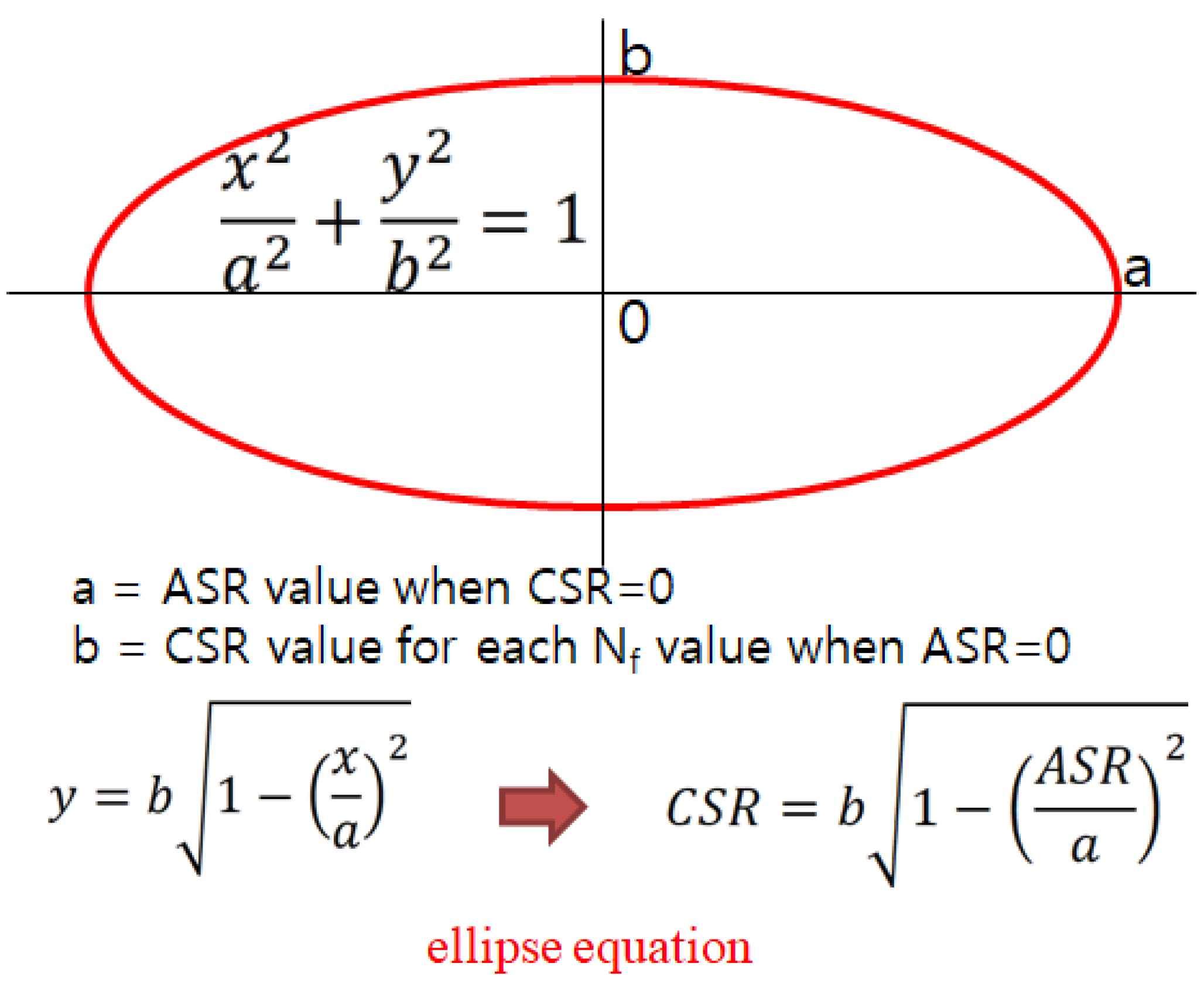

3.3. Proposed Drawing Technique of Design Failure Curve Model

- Conduct the static test. Obtain the ASR value when CSR = 0.

- Conduct the cyclic test to obtain the CSR value when ASR = 0 or 0.1.

- Plot the trend line between CSR and Nf when ASR = 0 or 0.1, obtained from step 2.

- Using the trend line in step 3, calculate the CSR value for each Nf value when ASR = 0 (Nf = 1, 10, 100, 1000, 10,000).

- Create the graph by applying the elliptic equation parameters ‘a’ (ASR value when CSR = 0) and ‘b’ (CSR value for each Nf value when ASR = 0).

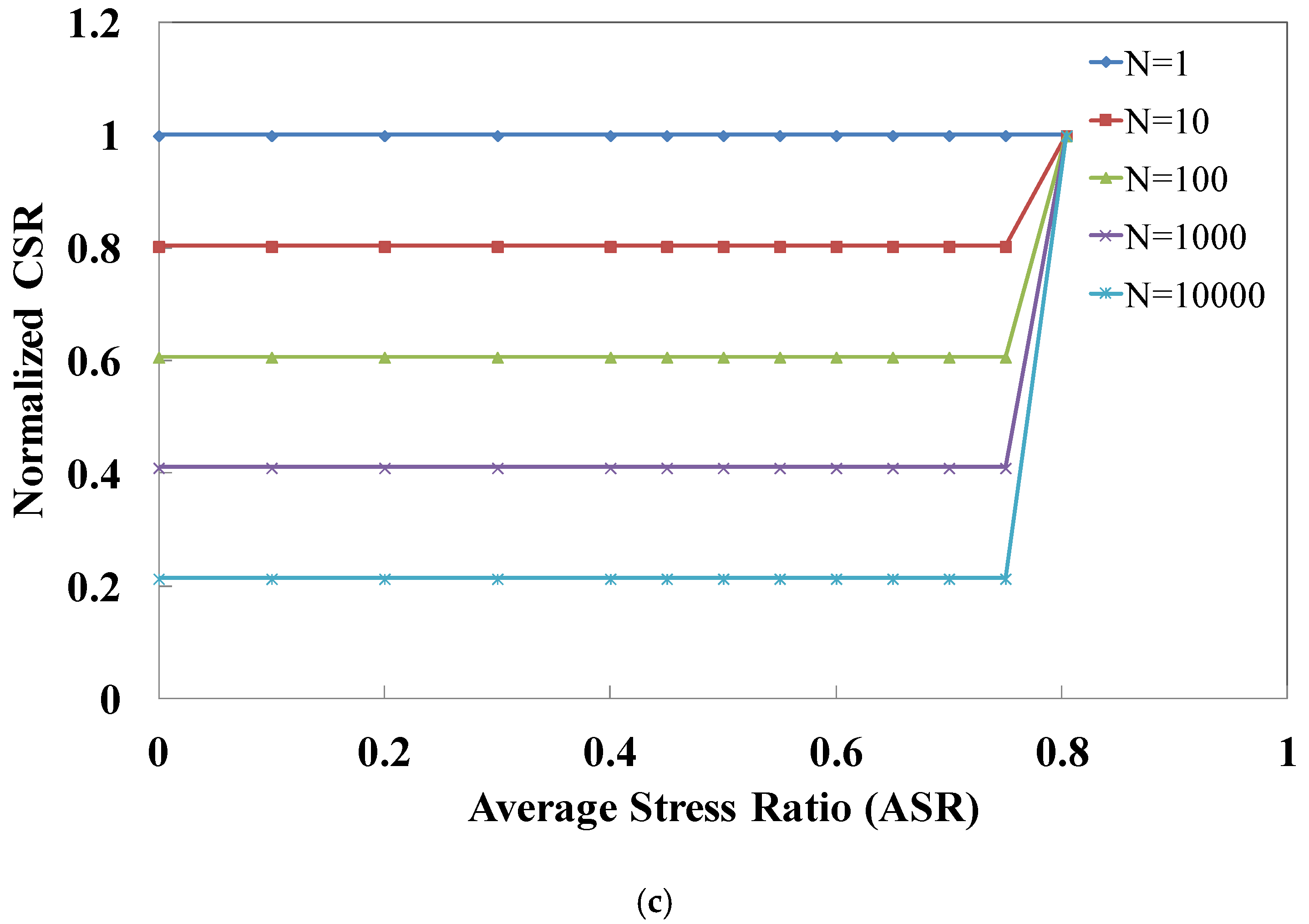

3.4. Normalized CSR

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Randolph, M.; Gourvenec, S. Offshore Geotechnical Engineering; Spon Press/Taylor & Francis Group: New York, NY, USA, 2011. [Google Scholar]

- Newlin, J.A. Suction Anchor Piles for the Na Kita FDS Mooring System, Part 1: Site Characterization and Design. In Deepwater Mooring Systems: Ceoncepts, Design, Analysis, and Materials; ASCE: Houston, TX, USA, 2003; pp. 28–54. [Google Scholar] [CrossRef]

- United Nations. Kyoto Protocol to the United Nations Framework Convention on Climate Change. 1998. Available online: https://unfccc.int/resource/docs/convkp/kpeng.pdf (accessed on 24 December 2019).

- Lee, K.; Seed, H.B. Dynamic strength of anisotropically consolidated sand. J. Soil Mech. Found. Div. 1967, 93, 169–190. [Google Scholar]

- Finn, W.D.L.; Vaid, Y.P. Liquefaction Potential from Drained Constant Volume Cyclic Simple Shear Test. In Proceedings of the 6th World Conference on Earthquake Engineering, New Delhi, India, 10–14 January 1977. [Google Scholar]

- Finn, W.D.L.; Vaid, Y.P.; Bhatia, S.K. Constant Volume Simple Shear Testing. In Proceedings of the 2nd International Conference on Microzonation for Safer Construction Research and Application, San Francisco, CA, USA, 26 November–1 December 1978; Volume 26, pp. 839–851. [Google Scholar]

- Stokoe, K.H.; Hwang, S.K.; Lee, J.N.K. Effects of Various Parameters on the Stiffness and Damping of Soils at Small to Medium Strains. In Prefailure Deformation of Geomaterials; Shibuya, S., Mitachi, T., Miura, S., Eds.; A.A. Balkema: Rotterdam, The Netherlands, 1994; Volume 2, pp. 785–816. [Google Scholar]

- Stokoe, K.H.; Darendeli, M.B.; Andrus, R.D.; Brown, L.T. Dynamic Soil Properties: Laboratory, Field and Correlation Studies. In Proceedings of the 2nd International Conference on Earthquake Geotechnical Engineering, Lisbon, Portugal, 21–25 June 1999; Volume 3, pp. 811–845. [Google Scholar]

- Lanzo, G.; Pagliaroli, A.; Tommasi, P.; Chiocci, F.L. Simple shear testing of sensitive, very soft offshore clay for wide strain range. Can. Geotech. J. 2009, 46, 1277–1288. [Google Scholar] [CrossRef]

- Andersen, K.H. Bearing capacity under cyclic loading—Offshore, along the coast, and on land. The 21st Bjerrum Lecture presented in Oslo, 23 November 2007. Can. Geotech. J. 2009, 46, 513–553. [Google Scholar] [CrossRef]

- Shajarati, A.; Srensen, K.W.; Nielsen, S.K.; Ibsen, L.B. Manual for Cyclic Triaxial Test; DCE Technical Memorandum No. 14; Aalborg University: Aalborg, Denmark, 2012. [Google Scholar]

- Kim, A.R.; Chang, I.; Cho, G.C.; Shim, S.H. Strength and dynamic properties of cement-mixed Korean marine clays. KSCE J. Civ. Eng. 2018, 22, 1150–1161. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, X.; Xiong, B.; Zhang, D. Experimental Study on Dynamic Characteristics of Marine Soft Clay in North China. J. Coast. Res. 2018, 474–478. [Google Scholar] [CrossRef]

- Nian, T.K.; Jiao, H.B.; Fan, N.; Guo, X.S. Microstructure analysis on the dynamic behavior of marine clay in the south China sea. Mar. Georesources Geotech. 2019, 1–14. [Google Scholar] [CrossRef]

- Banerjee, S.; Balaji, P. Effect of anisotropy on cyclic properties of Chennai marine clay. Int. J. Geosynth. Ground Eng. 2018, 4, 27. [Google Scholar] [CrossRef]

- Andersen, K.H. Properties of soft clay under static and cyclic loading. In Proceedings of the International Conference on Engineering Problems of Regional Soils, Beijing, China, 11–15 August 1988; Chinese Institution of Soil Mechanics, Ed.; Foundation Engineering International Academic Publishers: Beijing, China, 1988; pp. 7–26, (Also published in Publikasjon—Norges Geotekniske Institutt, Volume 176, pp. 1–20.). [Google Scholar] [CrossRef]

- Andersen, K.H.; Berre, T. Behaviour of a dense sand under monotonic and cyclic loading. In Proceedings of the 12th ECSMGE, Geotechnical Engineering for Transportation Infrastructure, Amsterdam, The Netherlands, 7–10 June 1999; A.A. Balkema: Rotterdam, The Netherlands, 1999; Volume 2, pp. 667–676. [Google Scholar]

- Andersen, K.H. Cyclic Clay Data for Foundation Design of Structures Subjected to Wave Loading. In Proceedings of the International Conference on Cyclic Behaviour of Soils and Liquefaction Phenomena, Bochum, Germany, 31 March–2 April 2004; Triantafyllidis, T., Ed.; CRC Press/Taylor & Francis Group: London, UK, 2004; pp. 371–387. [Google Scholar] [CrossRef]

- Ryu, T.G.; Kim, J.M. Stress-dependent failure criteria for marine silty sand subject to cyclic loading. J. Korean Geotech. Soc. 2015, 31, 15–23. (In Korean) [Google Scholar] [CrossRef][Green Version]

- Ko, M.J.; Son, S.W.; Kim, J.M. Relative density and stress-dependent failure criteria of marine silty sand subject to cyclic loading. J. Korean Geotech. Soc. 2017, 33, 79–91. (In Korean) [Google Scholar]

- Son, S.W.; Ko, M.J.; Kim, J.M. Cyclic shear behavior characteristics of marine silty sand. J. Mar. Sci. Technol. 2017, 25, 784–790. [Google Scholar] [CrossRef]

- Bjerrum, L.; Landva, A. Direct simple shear rests on a Norwegian quick clay. Geotechnique 1966, 16, 1–20. [Google Scholar] [CrossRef]

- Peacock, W.H.; Seed, H.B. Sand Liquefaction under Cyclic Loading Simple Shear Conditions. J. Soil Mech. Found. Div. 1968, 94, 689–708. [Google Scholar]

- De Alba, P.; Seed, H.B.; Chan, C.K. Sand Liquefaction in Large-Scale Simple Shear Tests. J. Geotech. Eng. Div. 1976, 102, 909–927. [Google Scholar] [CrossRef]

- Dyvik, R.; Berre, T.; Lacasse, S.; Raadim, B. Comparison of truly undrained and constant volume direct simple shear tests. Geotechnique 1987, 37, 3–10. [Google Scholar] [CrossRef]

- ASTM D 6528-17. Standard Test Method for Consolidated Undrained Direct Simple Shear Testing of Fine Grain Soils; ASTM International: West Conshohocken, PA, USA, 2017.

- Nielsen, S.D.; Shajarati, A.; Sorenson, K.W.; Ibsen, L.B. Behaviour of Dense Frederikshavn Sand during Cyclic Loading; DCE Technical Memorandum; Department of Civil Engineering, Aalborg University: Aalborg, Denmark, 2012; pp. 1–9. [Google Scholar]

- Korea Electric Power Corporation (KEPCO). Test Bed for 2.5GW Offshore Wind Farm at Yellow Sea Preliminary Design Basis Report; Korea Electric Power Corporation (KEPCO): Seoul, Korea, 2012. (In Korean) [Google Scholar]

- Ryu, T.G. Long-Term Dynamic Behavior Study of Marine Silty Sand for Offshore Structure Foundation Design. Master’s Thesis, Pusan National University, Busan, Korea, 2016. [Google Scholar]

| Max. Voids Ratio (-) | Min. Voids Ratio (-) | Uniformity Coefficient (-) | Coefficient of Curvature (-) | Unified Soil Classification System (USCS) | Specific Gravity (-) |

|---|---|---|---|---|---|

| 0.74 | 1.18 | 1.80 | 0.15 | SP-SM | 2.62 |

| Test ID | Cyclic Stress Ratio (CSR) (τcy/σvc`) | Average Stress Ratio (ASR) (τa/σvc`) |

|---|---|---|

| CDSS_1 | 0.1 | 0 |

| CDSS_2 | 0.1 | 0.2 |

| CDSS_3 | 0.1 | 0.3 |

| CDSS_4 | 0.1 | 0.4 |

| CDSS_5 | 0.2 | 0 |

| CDSS_6 | 0.2 | 0.2 |

| CDSS_7 | 0.2 | 0.3 |

| CDSS_8 | 0.2 | 0.4 |

| CDSS_9 | 0.3 | 0 |

| CDSS_10 | 0.3 | 0.2 |

| CDSS_11 | 0.3 | 0.3 |

| CDSS_12 | 0.3 | 0.4 |

| CDSS_13 | 0.4 | 0 |

| CDSS_14 | 0.4 | 0.2 |

| CDSS_15 | 0.4 | 0.3 |

| CDSS_16 | 0.5 | 0 |

| CDSS_17 | 0.5 | 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, S.-W.; Yoon, J.-C.; Kim, J.-M. Simplified Method for Defining 2-Dimensional Design Failure Curve of Marine Silty Sand under Dynamic Loading. J. Mar. Sci. Eng. 2020, 8, 51. https://doi.org/10.3390/jmse8010051

Son S-W, Yoon J-C, Kim J-M. Simplified Method for Defining 2-Dimensional Design Failure Curve of Marine Silty Sand under Dynamic Loading. Journal of Marine Science and Engineering. 2020; 8(1):51. https://doi.org/10.3390/jmse8010051

Chicago/Turabian StyleSon, Su-Won, Jong-Chan Yoon, and Jin-Man Kim. 2020. "Simplified Method for Defining 2-Dimensional Design Failure Curve of Marine Silty Sand under Dynamic Loading" Journal of Marine Science and Engineering 8, no. 1: 51. https://doi.org/10.3390/jmse8010051

APA StyleSon, S.-W., Yoon, J.-C., & Kim, J.-M. (2020). Simplified Method for Defining 2-Dimensional Design Failure Curve of Marine Silty Sand under Dynamic Loading. Journal of Marine Science and Engineering, 8(1), 51. https://doi.org/10.3390/jmse8010051