Abstract

The increase of greenhouse gases (GHG) generated by the burning of fossil fuels has been recognized as one of the main causes of climate change (CC). Different countries of the world have developed new policies on national energy security directed to the use of renewable energies mainly, ocean energy being one of them. The implementation of ocean energy is increasing worldwide. However, the use of these technologies is not exempt from the generation of potential environmental impacts throughout their life cycle. In this context, life cycle assessment (LCA) is a holistic approach used to evaluate the environmental impacts of a product or system throughout its entire life cycle. LCA studies need to be conducted to foster the development of ocean energy technologies (OET) in sustainable management. In this paper, a systematic review was conducted and 18 LCA studies of OET were analyzed. Most of the LCA studies are focused on wave and tidal energy. CC is the most relevant impact category evaluated, which is generated mostly by raw material extraction, manufacturing stage and shipping operations. Finally, the critical stages of the systems evaluated were identified, together with, the opportunity areas to promote an environmental management for ocean energy developers.

1. Introduction

Nowadays, energy production is mainly based in fossil fuels accounting for an 81.1% of total power generation, contributing 33,481 million tons of carbon dioxide (CO2) emissions in 2015 [1]. Nevertheless, fossil fuel reserves are limited, and their use contributes significantly to climate change (CC) due to the emission of greenhouse gases (GHG) [2]. The Intergovernmental Panel on Climate Change (IPCC) states that fossil fuel greenhouse gas emission is the major cause of global warming concern [3]. One of the greatest challenges of this century is to find an alternative energy source to fossil fuels; it should be low cost, ecologically friendly, socially acceptable and highly available for current demand [4]. Therefore, it is important to establish priorities to accelerate cost reduction and market uptake of key low-carbon technologies to improve the environmental impact of energy generation in the world [5]. This type of technology has been directed to the use of renewable energies to minimize potential environmental threat [6,7]. This kind of energy is reliable, usable and environmentally friendly for power generation in a sustainable and decentralized way to provide the electricity supply at medium and small scale [7]. Overall, it is estimated that renewable energy accounted for 26% of the world’s energy generation in 2018 [8].

Among the main renewable energies that have presented growth in their research and development is ocean energy [9]. The world’s oceans and seas are an abundant source of diverse forms of renewable energy and comprise a group of low carbon technologies that could play a significant role in the transition of the power sector in the world, contributing to energy security of the countries located close to the sea as well as to the GHG emissions reduction [10]. One of the main advantages of ocean energy compared to other renewable energy sources is its abundance and wide availability [7]. The ocean energy system covers all forms of oceanic renewable resources and can be divided into six types of different origin and characteristics: Waves and tidal energy, marine currents, thermal and saline gradient, and offshore wind [7,11,12]. According with Liu et al. [13], it is estimated that global resources of energy from the ocean are over 30,000 TWh/year, theoretically. However, different surveys have been carried out to evaluate their feasibility and efficiency of these energy technologies, as well as economic, social and environmental issues [7]. Currently, the European Commission has invested in ocean energy research, 45% of the funds being directed to technology development wave energy, 23% to technology development tidal energy, 17% to environmental research and the remaining 15% for other aspects [14,15]. Europe maintains a leadership position in the research and development (R & D) of the ocean energy sector [10]. On the other hand, USA during the last decade has been supporting the ocean energy sector with R & D funding. In Latin America, Chile has very high levels for implementation and deployment with adequate financing strategies; it could be a future leader in regards to the ocean energy system [16].

The development and application of ocean energy systems are limited, and the knowledge about environmental impacts generated by these technologies are too [9]. Nevertheless, the use of these systems is not exempt from the environmental impact’s generation throughout their life cycle, including the stages of construction and decommissioning [17].

Direct and indirect environmental impacts due to materials and energy required over its useful life as well as alteration of biodiversity, noise, habitat change and biological pollution can be generated [18,19]. However, limited knowledge contributes to the uncertainty about the potential impacts and their probable magnitude. Based on the latter, life cycle assessment (LCA) is a methodology designed to account for the environmental impacts of a technology over their whole life cycle. In this way, LCA becomes a tool that helps to identify the most critical stages of the life cycle of a system to obtain environmental improvements, in addition, to compare the environmental impacts of systems or technologies that have an equivalent function or performance, allowing decision-makers to select the systems with lower environmental impact [20,21].

In this context, this paper aims to compile and discuss the state of the art LCA practices on ocean energy technologies (OET). The bibliographic review involves the following goals: To gather the relevant studies of LCA on ocean energy; to recognize the different ocean energy types with most advanced scientific and technological progress; to identify the main life cycle stages of OET with the greatest environmental impact; to identify life cycle environmental impacts per type of energy conversion technology and to evaluate improvement opportunities to reduce the potential environmental effects of ocean energy systems. The paper is structured as follows: Section 2 briefly describes some of the main ocean energy technologies. Section 3 provides a detailed review methodology in the present review. Section 4 presents the overview of LCA on OET, including life cycle inventory, life cycle impact assessment, life cycle carbon emissions, carbon and energy payback. Section 5 comprise a general discussion of ocean energy LCAs. The study ends with conclusions (Section 6).

2. Description of the Main Ocean Energy Technologies

The world’s oceans and seas are an abundant source of various forms of renewable energy. Compared with the other renewable energy sources, the potential for harnessing energy from the ocean is diverse. Wave, tidal, thermal and gradient salinity energies have been the most research and development technologies worldwide [22,23].

2.1. Wave Energy Technology

This is the energy produced by the movement of the waves which is generated by the action of the wind on the sea surface. This type of energy has the advantage of being available throughout the ocean at very low cost and has high energy spatial concentration compared to other renewable energies [7]. There are several wave energy converters (WEC) and these can be classified according to several criteria, among them: Location, devices sizes and orientation, energy capture, energy use, and installation site [15]. Many countries operate WEC devices, including oscillating buoys, floating ducks, snakes, flaps, and enclosed chambers [24]. A fundamental component in these devices is the power takeoff (PTO) system; the mechanism which converts the wave energy into electricity [25]. The power generation capacities of WEC may vary from 10 to 150 kW [15].

2.2. Tidal Energy Technology

This is potential energy associated with the periodic rise and fall of the water level (high tide and low tide). The tides are periodic fluctuations in the level of the oceans, due to the gravitational and centrifugal forces between the earth, moon and sun. One of the key advantages of tidal power is its predictability [26,27]. Commonly, the tidal energy technologies function by the movement of tides via a bladed propeller mounted on a hub, with a rotor connecting it to a gearbox, which turns a generator in order to produce electricity [28]. Tidal energy converters (TEC) have been classified in their technical concepts and operation of devices. Based on the device type, including: A horizontal axis with a parallel and perpendicular axis, vertical axis and oscillating hydrofoil, as well as others.

2.3. Thermal Gradient Ocean

This is a system that makes use of the temperature difference in the ocean [29]. This energy allows the conversion of the temperature gradient between the surface and the ocean deeps into useful energy. To achieve acceptable performance, it is necessary to have a minimum gradient of 20 °C, which is reached at a depth of 1000 m, using the solar heat stored in warm surface waters to drive hydraulic or vapor turbines [30]. One of the main disadvantages of these systems is their high installation costs. There are mainly three types of technologies for the thermal gradient ocean system, commonly known as ocean thermal energy conversion (OTEC): Close cycle, open cycle and hybrid cycle [15]. The benefits derived from thermal gradient ocean facilities include the potable water production and the use of cold water for aquaculture, refrigeration and air conditioning of seawater [31].

2.4. Salinity Gradient Ocean

This is the energy generated from the mixing water of different salinities, commonly; fresh water and salt water. The process is based in the osmotic principle; it occurs due to the contact of fresh water and saline water via a semipermeable membrane, which is permeable to water but not to salt [32]. The greater the difference in salinity between the two bodies of water and the smaller the distance at which these differences occur, the greater is the salinity gradient. While greater is the difference in salinity between both water flows and less is the distance that occurs with these differences, the greater is the salinity gradient. The membranes of these systems are still in the research and development phase; its efficiency is important since it requires selective membranes, and low electrical accumulation [33]. Two salinity gradient ocean (SGO) technologies have been developed at the pilot scale: Reverse electrodialysis (RED) and pressure retarded osmosis (PRO) [34]. The first generates a voltage by differences of positive and negative charges, similar to a battery. In the PRO, the membrane generates a current that can move a turbine.

3. Methodology

LCA Methodology

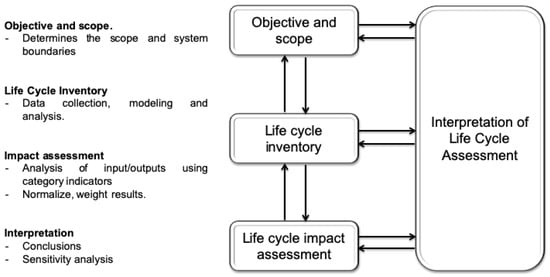

Life cycle assessment (LCA) analyses quantitatively account for all the energy, materials, emissions and waste products associated with everything from the extraction of raw materials to disposal at the end of the use of technology [20,35]. An LCA allows a decision-maker to study an entire system, in addition, to compare the environmental impacts of systems or technologies that have an equivalent function or performance [20,21]. The LCA process is regulated by the International Standards Organization (ISO) 14,000 series: ISO 14040: 2006 (Environmental Management-Life Cycle Assessment-Principles and Framework) and ISO 14044: 2006 (Environmental Management-Life Cycle Assessment-Requirements and Guidelines). The LCA methodology is an iterative process that consists of four stages (all of them interrelated): Objective and scope; life cycle inventory; life cycle impact evaluation and interpretation of results (Figure 1). The LCA method for the assessment of energy systems could be a useful and universally applicable tool for the monitoring and assessment of proposed energy systems as it can indicate areas that have a significant impact on the environment [5].

Figure 1.

Life cycle assessment (LCA) structure. Adapted from ISO 140403.2. Review Methodology.

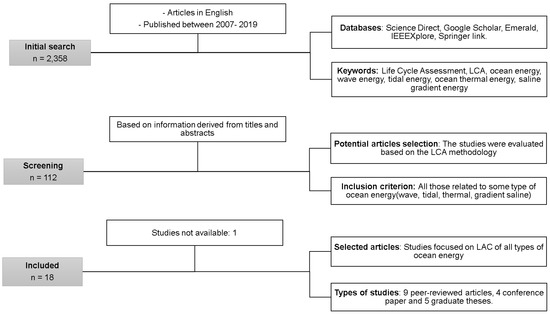

To achieve the objective of this review, a systematic analysis was undertaken to identify and assess all LCA studies of ocean energy systems reported in literature from 2007 to 2019. The methodology for this literature search is shown in Figure 2, and includes the three-step practical screening conducted. This review was based on the standardized technique for assessing and reporting reviews of LCA by Zumsteg et al. [36]. First, two inclusion criteria were applied: Articles must be in English and must have been published between 2007–2019 (since during the last decade there has been reflected a major attention to the environmental impact assessment generated by these new technologies). The relevant literature was searched in different search engines of major publishers (Science Direct, Springer link, Emerald, IEEEXplore). The search engine Google Scholar was used to include studies that were not published in journals. Searches were started with various keywords in an iterative process, such as: Life cycle assessment and its synonyms (LCA and life cycle analysis), ocean energy, wave energy, tidal energy, thermal energy and saline gradient. In the initial search, 2358 studies were identified considering the diverse keywords for our systematic review. A second screening was based on information derived from titles and abstracts, in this stage 112 relevant studies were identified. In the final count, potential articles selection was focused on the LCA methodology and inclusion criterion (all types of ocean energy). Lastly, the literature review involved 18 potential LCA studies of ocean energy; nine scientific papers published in international peer-reviewed journals, five post-graduate theses (four master and one bachelor’s degree) and four papers presented at conference congress. The studies considered in the present review allowed for obtaining a global environmental assessment of the ocean energy generation systems in the different stages of their life cycle that could be used to guide the research and development of these systems.

Figure 2.

Systematic methodology review.

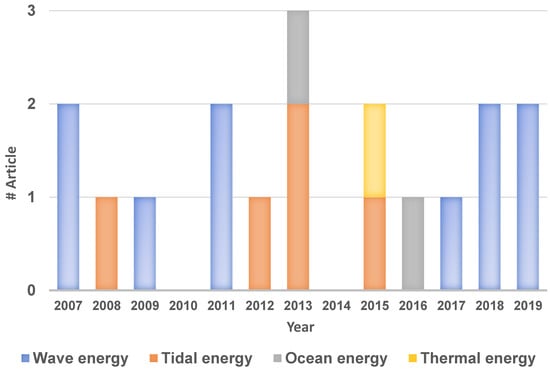

In this review, the results are presented by a type of technology used for ocean energy generation, which includes: Wave, tidal and thermal energy. Although the energy generation by saline gradient was also considered in the bibliographic review, there is no information available regarding to LCA studies on this technology (Figure 3).

Figure 3.

Number of published studies about LCA of ocean energies from 2007 until 2019.

4. Results and Discussion

4.1. LCA on Ocean Energy Technologies

In the last two decades, LCA methodology has been widely applied to evaluate the environmental impacts of energy generation systems [37,38,39,40,41,42,43,44], as well as individual technologies [45,46,47,48]. So far, only a few LCA have been performed on ocean energy systems with a focus on full-scale prototypes and good environmental performance relative to conventional power plants [12,14,49,50]. Furthermore, most of the papers involve the application of new ocean energy technologies focused on embodied energy and carbon emissions, and only some of them give a complete environmental evaluation. To date, tidal and wave energy are the most developed kinds of ocean energy and have been identified as the technologies with the highest potential to offer a significant contribution to countries with ocean resource in the medium to long term [12,13,14].

It is important to highlight that 11 of the 18 studies analyzed concentrate only on carbon emissions and embodied energy [26,29,49,50,51,52,53,54,55,56,57] and the rest give a more detailed evaluation including other environmental impact categories [9,12,58,59,60,61,62]. In general, scientific papers and surveys provided information about LCA of ocean energy studies, considering different operating criteria, geographical area, and costs, among others. The environmental impact categories, the impact assessment method, and the functional unit (FU) considered for each LCA study analyzed have been included in Table 1. The functional unit of all projects is 1 kWh of electricity delivered, similar to what has been established as FU in other LCA studies on power generation systems in order to be consistent throughout the study so that the results can be comparable and provide useful information for the energy sector [12,29,63]. On the other hand, the life time depends on the type of technology, generally the wave energy systems have a low life time compared to OTEC technology due to the type of infrastructure (equipment, power connections, structural components) of each device, as well as, the operating and maintenance conditions. The LCA studies include all life cycle stages (assembly, installation, operation and maintenance, final disposition) and in some cases, also involve the mooring and foundation stages, and the cable connection to the grid.

Table 1.

LCA studies of ocean energy technologies.

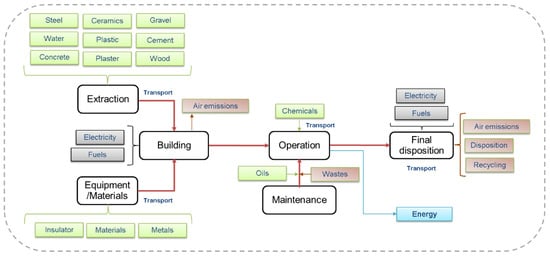

4.2. Life Cycle Inventory for Ocean Energy Technologies

Life cycle inventory (LCI) involves collecting input and output data for all unit processes of WEC devices. LCI includes two aspects of data collection; primary data and secondary data [68]. Primary data are directly related to the plant’s life cycle and they are collected from the design report for the plant and staff of the plant. Secondary data are the life cycle burdens of the former inputs, such as equipment manufacturing, transportation, and electricity generation. These data are regularly collected from international database platforms or previous LCA studies [29,69]. The LCI database allows an in-depth review of the state-of-the-art of ocean energy technologies, paying attention to the different technology components, such as foundations, moorings and storage systems (Figure 4). The European Commission’s Joint Research Centre (JRC) developed a detailed database with technical information on global ocean energy devices that have been tested or deployed in real-water conditions [14]. The Table 2 shows the LCI with the main characteristics of the ocean energy systems evaluated in the LCA studies.

Figure 4.

Overall schemes of life cycle inventory (LCI) of the energy ocean system.

Table 2.

Characteristics of the ocean energy devices evaluated in the LCA studies.

4.3. Life Cycle Assessment of Ocean Energy Technologies

As mentioned above, most LCA studies focus on carbon life cycle assessment, only a few of them perform a global evaluation integrating other impact categories. Besides, all of these are focused on wave energy (seven of 18 published articles). Until now, there have been no studies in the literature that present a comprehensive evaluation of LCA regarding other types of ocean energy (tidal, thermal and gradient salinity). Even though the results from this comprehensive review show the available information about the life cycle environmental assessment of ocean power systems, it is important to mention that the data and information are diverse, mainly due to structural components, size (nominal capacity), design device and type of technology. Although seven articles with evaluation of different impact categories are reported, only three of them show net values of the impact categories evaluated (with different units) [59,60,62]. The remaining five do not present results that can contribute to the making of comparisons between devices, and only show environmental impacts generated by a kind of material or device mass, in percentage or even by units of equivalent persons [9,12,58,61]. Hence, comparisons of environmental impacts between devices is limited.

Life Cycle Impact Assessment of Wave Energy Technologies

As it is well known, wave energy represents a strategic option for renewable energy systems in the foreseeable future [61]. Overall, all the authors agree that most of the environmental impacts obtained by this type of system (point absorbers WEC, wave dragon, Pelamis WEC; buoy-rope-drum (BRD) WEC) are presented in the manufacturing stage of the device [9,12,58,59,60]. These environmental impacts are caused mainly by structural components (turbine propellers, buoy structure, turbines), energy consumption, mooring foundations and the materials used to manufacture the devices, among which are: Stainless steel, tin, steel parts, concrete, and cast iron. These impacts can represent between 40% and 90% of the total impacts obtained during their life cycle [9,12,59]. The categories that have a greater impact, include: Climate change, resource depletion, aquatic eutrophication, human toxicity water, ecotoxicity water, hazardous waste, ozone depletion, terrestrial acidification, freshwater eutrophication, photochemical oxidant formation, particulate matter formation, agricultural land occupation, urban land occupation, natural land transformation, water depletion, metal depletion, and fossil depletion [9,12,60]. Particularly, the steelmaking processes have a significant impact in freshwater eutrophication, freshwater and marine ecotoxicity [62]. In addition, power takeoff (PTO) components play a significant role in three impact categories: Ionizing radiation, freshwater eutrophication and terrestrial ecotoxicity [9,12]. In this case, freshwater eutrophication impacts are generated by materials manufacturing used for cables in the electrical connection, such as: Polycarbonate, copper and stainless steel (mooring and foundations stages). The ionizing radiation impacts come from production of electronics (assembly stage) and terrestrial ecotoxicity due to permanent magnet [12]. Additionally, the shipping operations related with operation and maintenance also contributing significantly in some categories, such as: Ozone depletion, terrestrial eutrophication and acidification, photochemical oxidant formation, and natural land transformation [60,62].

Furthermore, the environmental impacts generated by assembly, installation, operation and maintenance are not significant. The total contribution from these stages, ranges from one to over forty percent [9,12,59,62]. It is important to mention that within the analyzed LCA studies, two devices that operate in real-sea environments are considered, with similar findings [58,62]. However, Moan [72] mentions in his study on life cycle structural management of offshore structures, such as offshore gas and oil structures, that a design reassessment is required during the operation stage considering operational restrictions, repair and maintenance inspections due to possible changes of the offshore structure function, updated knowledge about environmental loads or damages, as well as, expected life time. In addition, several authors have remarked on the importance of contemplating the impacts generated during the service life of these devices in the ocean [58,62,73]. Moan [73] reports that operational experiences show that several safety measures are required to control the risks associated with different environmental hazards in offshore structures. Until now, few LCA studies that consider devices deployed under real operating conditions establish that during the operation stage, more ecological research is required to determine the potential environmental impact on marine life, and this information will allow improvements in environmental monitoring standards and best practices for OET design [58,62,74]. Among the potential impacts that have been reported during the operation stage are scour, physical benthic habitat disturbance, operational noise, water flow patterns, pollution of antifoulants, sediment mobilization, collision and other risk for marine animal and birds [74,75]. Regarding the last stage, the disposal of the components structure presents an impact on the categories of marine eutrophication, natural land transformation, freshwater, and marine ecotoxicity, and these impacts are generated mainly by waste treatment and management [9,62]. The life cycle impact assessments show that the most important avoided impacts are acidification, bulk waste, human toxicity, soil and global warming mainly associated with the electricity production from WEC devices due to fossil fuel consumption and, hence, GHG emissions and other chemical compounds [58].

In this sense, the search for alternative efficient and environmentally sustainable structure materials for the device manufacture is an improvement opportunity to reduce the environmental performance of these technologies [49]. The device developers should focus on reducing the amount of steel in the new structural designs used in the manufacturing process [59,62]. Besides, efficient shipping operations for installation, maintenance and decommissioning should be considered, utilizing more fuel-efficient transportation methods or reducing the frequency of maintenance operations [62]. Another aspect to consider is the potential to recycle structure materials. This could be a significant environmental improvement, avoiding the environmental impacts of waste management and also the impacts that are associated with raw material extraction [60]. These actions could reduce the overall life cycle environmental impacts of WEC technologies [9,60].

In addition, the assessment of different scenarios to increase environmental improvement in these systems is essential, evaluating of critical factors such as: Increased efficiency or durability (capacity factor and lifetime), other mooring structures (using mooring lines), and reduced offshore distance (do not use longer cable connection) [12]. For instance, Soerensen et al. [58] in a sensitivity analysis evaluated various parameters (the lifetime of different components, the power production achieved, wave height, maintenance) obtaining as a result that when the lifetime of WEC (Wave Dragon) increased, the global electricity production increment and more resource consumptions and environmental impacts were avoided. Parker et al. [49] evaluated two alternative materials as a partial replacement of the steel structure, particularly; concrete and glass-reinforced plastic (GRP); in this case, the climate change category was reduced using these alternate materials. Uihlein [12] conducted a sensitivity analysis with different steel types for structural components manufacture; the results showed that the significant environmental impacts would be much lower. Zhai et al. [9] performed a sensitivity analysis varying the capacity factor (defined as the actual electricity production divided by the maximum possible electricity output of a power plant, over a period of time [76]) values (20–50%), the results showed that climate change category decrease with the increase of capacity factor. Further, Thomson et al. [62] reported that an increase in design life and shortening offshore distance could reduce global environmental impacts significantly.

4.4. Life Cycle Carbon Emissions Assessment

As mentioned earlier, most of the papers concentrate only on carbon emissions and embodied energy (11 of 18 published articles) (Table 1) [49,50,51,54,56]. The articles focused on these topics are in line with the current global situation regarding increased energy demand, the use of renewable energy sources, and climate change. In this context, ocean energy represents a promising worldwide transition to a low-carbon electricity system [49,57]. This section involves a thorough life cycle carbon emission assessment of the all different devices evaluated, considering the technologies of each system.

The general results show that the manufacture of materials used in the structure (particularly, steel manufacturing, in most cases), mooring and foundations, and the shipping operations have the greatest impact on total CO2 emissions (between 40–95% of the total emissions) [12,26,49,50,60]. Walker and Howell [51] evaluated an Oyster WEC device; the assessment included CO2 emissions from materials, manufacture, transport, installation, operation, maintenance and decommissioning (including recycling). According to the results, the manufacture materials stages represent the more than 95% of the total emissions. Douglas et al. [50] reported a life cycle carbon emission of Seagen turbines; the results showed that the most significant stage was the materials extraction and manufacturing stage, accounting for 86% of total emissions. Elmehag and Torosian [53] presented that foundation and structural components account for 86% of the total emissions of a Deep Green tidal device. In this case, the manufacturing stage is the one that contributes most to environmental impact. Walker et al. [55] evaluated four tidal devices (two three blade horizontal axes, a multi-blade turbine and an Archimedes screw device): The results obtained are similar to previous authors. The materials and manufacture stage present the greatest impacts in terms of CO2 emissions for the four devices. Another similar instance is reported by Aalberts [29] evaluating OTEC technology. The results show that the raw materials extraction stage is the one that presents a greater contribution of CO2 emissions, in particular, the platform structure is the biggest contributor in the climate change category (more than 50% of total emissions), and this is mainly due to the large amount of steel that is required. Gastelum [56] evaluated the total environmental impact in terms of climate change of a new model of point absorber WEC; the evaluation was done by the three modules: Buoy, generator and mooring system. The results of the whole system show that the polyurethane buoy manufacturing process contributes to 60% of total CO2 emissions, which is attributed mainly to the materials used to manufacture the buoy (steel rolling) and the shipping operations. Another similar study was conducted by Patrizi et al. [57] evaluating an OBREC WEC device; the results shows that 82% of the total CO2 emissions is due to the use of materials for the components construction (including structural elements, ramp, foundations and cables for the connection to the grid). Notably, 51% of the emissions are due to the electrical connection, and to the terrestrial cable (copper and iron major components). These findings are similar to what was reported by Parker et al. [49], Thomson et al. [60] and Uihlein [12].

In this context, environmental improvements can be reached by increased structural materials efficiency and the use of alternative installation methods to increase steel recovery in the dismantling stage. The LCA studies report that the recycling process in the final disposal stage has a significant reduction in CO2 emissions [50,55]. For instance, Elmehag and Torosian [53] evaluated alternate materials for the different components of the deep green tidal device. The results showed that it is possible to reduce emissions by 30 to 50% depending on the evaluated structure. Walker et al. [55] performed a sensitivity analysis in order to understand the effect of total CO2 emissions variation if the amount of structural materials (steel and cement) would be adjusted (±5%) due to its significant contribution to overall values. The results showed that the variation from original values led to a change of between 2.5% and 3.5% lower in CO2 emissions of the functional unit, a significant percentage to be considered. Aalberts [29] evaluated diverse scenarios, one of them was to assume that 90% of primary materials (steel and titanium) will be recycled. This option reduces CO2 emissions by 25%. Another proposed scenario was to increase the production scale (10 MW to 100 MW); the overall results of this method show a 57% reduction in CO2 emissions, and the contribution of the platform structure together with the mooring was much smaller than with 10 MW OTEC.

In the same way as the other impact categories, the other life cycle stages (assembly, installation, operation and end of life) have almost a negligible impact on global warming [12]. This is supported by other LCA evaluations regarding ocean energy technologies [12,49,62] demonstrating that most of their climate change impact are related to materials of structural components such as the installation, operation and maintenance stages of devices [57]. With the exception of Kelly et al. [52], when they performed the carbon emissions assessment of the tidal Severn barrage. In this study, the operation stage was identified as the stage with the greatest contribution. This is mainly due to the fact that for this type of device whilst during the operation stage there are direct and auxiliary energy processes, such as: Flood pumping and an auxiliary power plant for running the plant.

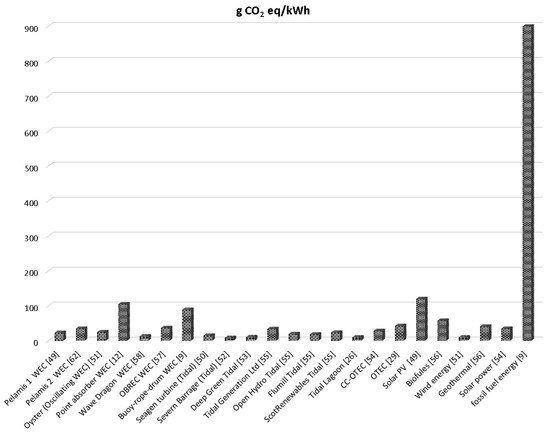

Table 3 shows a compilation of the CO2 emissions of the different devices evaluated. The difference of values between devices evaluated may well be due to the specific features and properties considered, such as: Structural components, manufacturing materials, PTO systems, etc. [62].

Table 3.

Emission of gases in term of g CO2 eq/kWh by ocean energy devices.

Comparison with Other Generation Energy Technologies

Diverse studies compare carbon emissions with other types of energy generation in order to benchmark the environmental performance of ocean energy devices. Most of these comparisons present favorable results for ocean energy in terms of CO2 emissions. Figure 5 shows the comparison of the devices evaluated in the present review according to other conventional electrical generation technologies; the comparison includes wave, tidal and thermal energy converters.

Figure 5.

CO2 emissions of ocean energy technologies (OET) compared with other generation energy systems.

4.5. Carbon and Energy Payback Period

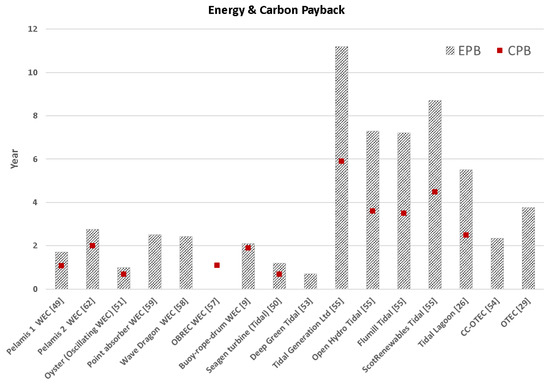

An important environmental criterion for evaluating the scope of acceptability of ocean energies is the energy payback period (EPB) which indicates the time period for renewable energy technology to produce the amount of energy that was used for manufacturing, maintenance, operation and the energy produced during the useful life of the system [9,53,54,59]. The EPB is obtained by dividing the total lifetime energy input by annual energy production [49]. EPBvalues depend mainly of annual energy production, device life, and type materials required of the manufacture stage. Additionally, another significant environmental indicator for renewable sources is carbon payback (CPB). CPB is the time period in which the CO2 emissions are retrieved from renewable ocean devices. The CPB is calculated as by dividing the total embodied carbon by the annual carbon avoided by the use of the ocean energy technologies [9,49]. Figure 6 shows the comparison of energy and carbon paybacks for the different ocean energy technologies evaluated, including: Wave, tidal and thermal energy systems. At a global scale, the WEC devices have relatively less EPB and CPB than tidal converters. Additionally, the CPB of WEC is expected to be shorter than tidal energy.

Figure 6.

Energy payback period (EPB) and carbon payback (CPB) of ocean energy technologies.

5. Overall Discussion

Overall, the results of this analysis have shown that there is still considerable divergence in design and dimensions options for ocean energy devices which further complicates a correct comparison in terms of environmental impacts between technologies [14]. There are considerable uncertainties due to the lack of available data such as: Specific technological parameters, alternative structural components and materials as well as assumptions made in each study [9]. The environmental impacts are very much depending on size of installation and the location selected. As the uncertainty assessments of LCA results are generally extended based on assumptions and estimates, it must be noted that full statistical uncertainty is generally beyond the reach of LCAs, even for parameter uncertainty. This especially true for complex assessment targets applicable to renewable energy, and special wave ocean energy. As an example, if the age of the data is associated with an uncertainty value and the geographical representativeness with another, neither these percentage values, nor the resulting uncertainty when combining those, can be said to represent the statistical variations in results due to these factors, but the resulting value instead represents a systematically calculated quality index for the data set. Thus, uncertainty values are generally seen as quality indexes which do not predict the overall variation in results. Further, as the estimates and assumptions behind them are often based on subjective judgments, such quality indexes cannot be directly compared between studies. The renewable energy industry is today mainly focused on the life cycle inventory phase and the evaluation impact assessment phase is mainly focused on climate change impact, as this is the main focus of most stakeholders. However, other categories related to, e.g., biodiversity and marine impacts should be addressed and need to receive more attention. Parameter, scenario and model uncertainty should be evaluated both for the life cycle inventory and the life cycle impact assessment phases. For climate change, there is broad scientific agreement related to assessment methodology. Nevertheless, for other impact categories, there is less scientific consensus, and when it comes to uncertainty, toxicity impacts can be caused by multiples substances emitted and the effects of each of them and the combinations effects is often less well-known. For example, climate change effects [77,78] are related to around 80–90% of GHG, and in any other impact category, the number of substances/flows is between one and 40. Consequently, uncertainties are higher for toxicity as of the amounts of substances cannot be studied and modeled specifically, or in great detail [79].

Though, all studies agree that the main environmental impacts of ocean energy devices from an LCA perspective are due to raw material extraction and the manufacturing stage, while installation, maintenance and operation do not show significant impacts [12]. Furthermore, as observed in Section 4.4, the OET provides a satisfactory outlook in environmental terms associated with other energy generation technologies, especially in global warming [12]. In an integrated vision, with the aim of reducing the environmental impacts of these systems, a probable alternative is that the devices can be installed in arrays or ocean energy farms in the future. This action will significantly reduce the environmental impacts produced by structural components and materials [9]. Additionally, the development and research of OET should focus on alternate materials for device manufacturing, better mooring and foundations systems, improvements in shipping operations during construction and installation of ocean energy devices (reducing the distance of shipping operations, as well as the search for more efficient fuels), and increasing the efficiency and reliability of the new device [10,12,14,59].

Another critical factor to consider is that all ocean energy devices installed at offshore locations are connected to land through power cables that emit electromagnetic fields. The magnitude of these fields vary with cable dimension and grid design [19]. All studies performed are addressed to the amount of energy generation without considering the fluctuations in storage or grid integration. In this sense, some of the main research areas in OET are electricity storage and grid integration, a comprehensive LCA, and technical and economic evaluation which are required for approval purposes [10,14,15]. In addition, another issue to be noted that we have detected in our research group is the sustainable development of coatings through LCA studies where different potential components for corrosion and biofouling protection can be evaluated. Quantification of both the environmental impacts and environmental benefits for coatings for the corrosion and biofouling protection of ocean renewable energy infrastructure can promote a better understanding of the consequences related to its use. Marine biofouling is the undesirable accumulation of plants, microorganisms, algae, plants and invertebrates on marine surfaces immersed in sea water [80,81]. It may affect marine biodiversity of the ecosystem, hydrodynamics of water flows and conflict with the efficiency of marine energy devices [82,83]. Effects on aquatic organisms can range from temporary water quality degradation (decline in dissolved oxygen content) to biotoxicity and bioaccumulation of previously buried pollutants such as heavy metals [84]. Therefore, it is important to investigate in detail the adverse effects caused by this environmental phenomenon and how it affects device performance. Antifouling coatings are one of many additives usually incorporated into a marine protective coating system as the foundation of marine energy devices. An optimal antifouling coating should be environmentally acceptable, anticorrosive, stable, durable, resistant to erosion, long life and economically viable [82,85]. Various types of antifouling coatings have been developed to control corrosion and biofouling protection of marine renewable devices [85]. Polymeric and ceramic coatings offer a promising method of protecting the foundation on the seabed by concentrating antifouling compounds around surfaces with much less environmental impact than traditional coatings and they are easy to apply at affordable cost [85,86,87,88,89].

Although, investments in ocean energy systems have increased considerably over the last decade and have a lower risk profile than conventional energy sources, these energies still involve considerable technological, economic, social and environmental regulatory risks, depending on the technology type and region for the deployment of devices [7,90,91]. In this context, it is of great importance to consider extensive research and understanding of the environmental implications of OET before its real-scale application [14]. While it is true that the degree of success in extracting these types of energies depends on the long-term availability of the energy source and the adequacy of the regions chosen for the implementation of OET [92], it is crucial to evaluate these technologies from an environmental perspective, and include this data among other important factors, such as the cost of investing, geographic area, and social aspect to its overall assessment [56,92]. Therefore, the technological development in the ocean energy sector should be evaluated from a sustainable holistic approach, considering the possible social, economic and environmental impacts associated with the entire life cycle of devices used. Finally, it is worth noting that future environmental studies should also focus on general issues related to marine environments such as: Artificial reef effects, biofouling, bird migration, environmental changes and hydrodynamics effects, water quality changes and possible pollution, areas that have not been deeply studied and that could cause cumulative impacts and compromise the life of marine and coastal ecosystems [14,92]. In this regard, Felix et al. [92] mentions that mitigation strategy designed to avoid ecosystem alteration due to the use of OET is a priority in future projects.

6. Conclusions

Ocean energy currently represents a high potential for global power generation. During the last two decades, research and technical development of ocean energy systems has been growing and hence also the study of the possible environmental impacts and benefits related to this renewable technology. In this sense, the application of LCA methodology has provided a better knowledge in environmental terms of ocean energy systems. In this literature review paper, available information was compiled and classified based on the type of energy conversion technology used for ocean energy generation (wave, tidal and ocean thermal). The results of this review show that most of the LCA studies are focused on the life cycle carbon emissions assessment (11 of 18 published articles), as well as a comparison to other conventional and renewable energy systems. Hitherto, tidal and wave energy are currently the most advanced systems in science, development and technology. So far, good quality studies are lacking, especially for ocean thermal energy and salinity gradient technologies. Overall, the analyses show that the main environmental impacts of ocean energy devices are due to raw material extraction of structural components, manufacturing devices, energy consumption and mooring foundations. In this way, some alternatives to mitigate these impacts are as follows: Energy farm design, alternate structural materials and components, improvements in shipping operations, and increases in the efficiency and reliability of new devices. These relevant findings could help technology developers and decision and policy-makers design appropriate strategies to maximize a positive and sustainability environmental contribution. Lastly, the integration of economic and social aspects should be considered in the scope of future LCA studies in order to evaluate the implementation of new sustainable OET, including whole ocean energy arrays or ocean energy farms, as well as considering the marine environmental impacts.

Author Contributions

M.G.P. contributed with the review, writing and editing data analysis, results assessment and discussion. A.P.-R. worked in data integration and analysis, writing review and visualization. L.P.G. gave the conceptualization and main ideas, manuscript revision, supervision and funding acquisition.

Funding

This research was funded by Fondo CONACYT-SENER/Sustentabilidad Energética through the Centro Mexicano de Inovación en Energías del Océano (CEMIE-Océano), grant number 249795.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- European Union. EU Energy in Figures, Statistical Pocketbook. 2018. Available online: https://publications.europa.eu/en/publication-detail/-/publication/99fc30eb-c06d-11e8-9893-01aa75ed71a1/language-en/format-PDF/source-77059768 (accessed on 7 September 2019).

- Coxtinica, A. La Generación de Energía Eléctrica Por Fuentes Renovables y su Uso en México. Bachelor’s Thesis, Electric Engineering, Faculty of Engineering, National Autonomous University of Mexico, Mexico, Mexico, 2015. [Google Scholar]

- IPCC (Intergovernmental Panel on Climate Change). Climate Chage 2007, Synthesis Report, Summary for Policymakers. Available online: https://www.ipcc.ch/site/assets/uploads/2018/02/ar4_syr_spm.pdf (accessed on 15 August 2019).

- Owusu, P.A.; Asumadu-Sarkodie, S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016, 3, 1–14. [Google Scholar] [CrossRef]

- Lelek, L.; Kulczycka, J.; Lewandowska, A.; Zarebska, J. Life cycle assessment of energy generation in Poland. Int. J. Life Cycle Assess. 2016, 21, 1–14. [Google Scholar] [CrossRef]

- Hadian, S.; Madani, K. A system of systems approach to energy sustainability assessment: Are all renewables really green? Ecol. Indic. 2015, 52, 194–206. [Google Scholar] [CrossRef]

- Hussain, A.; Arif, S.M.; Aslam, M. Emerging renewable and sustainable energy technologies: State of the art. Renew. Sustain. Energy Rev. 2017, 71, 12–28. [Google Scholar] [CrossRef]

- REN 21 (Renewable Energy Policy Network for the 21st Century). Renewable Global Status Report 2019. Available online: https://www.ren21.net/wp-content/uploads/2019/05/gsr_2019_full_report_en.pdf (accessed on 7 September 2019).

- Zhai, Q.; Zhu, L.; Lu, S. Life cycle assessment of a buoy-rope-drum wave energy converter. Energies 2018, 11, 2432. [Google Scholar] [CrossRef]

- Sgobbi, A.; Simões, S.G.; Magagna, D.; Nijs, W. Assessing the impacts of technology improvements on the deployment of marine energy in Europe with an energy system perspective. Renew. Energy 2016, 89, 515–525. [Google Scholar] [CrossRef]

- Garzón, C. Evaluación de Alternativas de Generación de Electricidad Desde el Punto de Vista de su Impacto Ambiental, Para Sectores no Conectados a Redes Elétricas. Bachelor’s Thesis, Electric Engineering. Instituto Superior Politécnico José Antonio Echeverría, La Habana Cuba, Cuba, 2010. [Google Scholar]

- Uihlein, A. Life cycle assessment of ocean energy technologies. Int. J. Life Cycle Assess. 2016, 21, 1425–1437. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; He, F.; Wang, H. Comparison study of tidal stream and wave energy technology development between China and some Western Countries. Renew. Sustain. Energy Rev. 2017, 76, 701–716. [Google Scholar] [CrossRef]

- Magagna, D.; Uihlein, A. Ocean energy development in Europe: Current status and future perspectives. Int. J. Mar. Energy 2015, 11, 84–104. [Google Scholar] [CrossRef]

- Khan, N.; Kalair, A.; Abas, N.; Haider, A. Review of ocean tidal, wave and thermal energy technologies. Renew. Sustain. Energy Rev. 2017, 72, 590–604. [Google Scholar] [CrossRef]

- De Andres, A.; MacGillivray, A.; Roberts, O.; Guanche, R.; Jeffrey, H. Beyond LCOE: A study of ocean energy technology development and deployment attractiveness. Sustain. Energy Technol. Assess. 2017, 19, 1–16. [Google Scholar] [CrossRef]

- Gibon, T.; Arvesen, A.; Hertwich, E.G. Life cycle assessment demonstrates environmental co-bene fi ts and trade-offs of low-carbon electricity supply options. Renew. Sustain. Energy Rev. 2017, 76, 1283–1290. [Google Scholar] [CrossRef]

- Pelc, R.; Fujita, R.M. Renewable energy from the ocean. Mar. Policy 2002, 26, 471–479. [Google Scholar] [CrossRef]

- Hammar, L.; Gullström, M.; Dahlgren, T.G.; Asplund, M.E.; Goncalves, I.B.; Molander, S. Introducing ocean energy industries to a busy marine environment. Renew. Sustain. Energy Rev. 2017, 74, 178–185. [Google Scholar] [CrossRef]

- ISO 14040 (International Standard). Environmental Management—Life Cycle Assessment—Principles and Framework, 2nd ed.; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Padilla-Rivera, A. Metodología Para Evaluar el Desempeño de la Infraestructura Hídrica en el Contexto de la Sustentabilidad Urbana. Ph.D. Thesis, Institute of Engineering, National Autonomous University of Mexico, Mexico City, Mexico, 2015. [Google Scholar]

- Falcão, A.F. Wave energy utilization: A review of the technologies. Renew. Sustain. Energy Rev. 2010, 14, 899–918. [Google Scholar] [CrossRef]

- Esteban, M.; Leary, D. Current developments and future prospects of offshore wind and ocean energy. Appl. Energy 2010, 90, 128–136. [Google Scholar] [CrossRef]

- Borthwick, A.G.L. Marine Renewable Energy Seascape. Engineering 2016, 2, 69–78. [Google Scholar] [CrossRef]

- Kim, D.Y.; Kim, Y.T. Preliminary design and performance analysis of a radial inflow turbine for ocean thermal energy conversion. Renew. Energy 2017, 106, 255–263. [Google Scholar] [CrossRef]

- Simon, P. Assessment of Embodied Energy and Carbon Emissions of the Swansea Bay Tidal Lagoon from a Life Cycle Perpective. Master’s Thesis, Department of Ecotechnology and Sustainable Building Engineering, Mid Sweden University, Östersund, Switzerland, 2015. [Google Scholar]

- Sangiuliano, S.J. Turning of the tides: Assessing the international implementation of tidal current turbines. Renew. Sustain. Energy Rev. 2017, 80, 971–989. [Google Scholar] [CrossRef]

- Rourke, F.O.; Boyle, F.; Reynolds, A. Tidal energy update 2009. Appl. Energy 2010, 87, 398–409. [Google Scholar] [CrossRef]

- Aalbers, R.R.D. Life Cycle Assessment of Ocean Thermal Energy Conversion. Master’s Thesis, Sustainable Energy and Technology, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Devis-Morales, A.; Montoya-Sánchez, R.A.; Osorio, A.F.; Otero-Díaz, L.J. Ocean thermal energy resources in Colombia. Renew. Energy 2014, 66, 759–769. [Google Scholar] [CrossRef]

- Garduño, E.P.; García, A.; Rodríguez, Y.; Bárcenas, J.F.; Alatorre, M.A.; Cerezo, E.; Tobal, J.G.; Romero, V.M.; Silva, R. Conversión de Energía Térmica Océanica (OTEC), Estado del Arte. Colección Energías Renovables del Océano. Research Project: CEMIE-Océano. Universidad Autónoma de Campeche, México, 2017. Available online: https://cemieoceano.mx/downloads/libros/CEMIEOceano_Gradiente_Termico.pdf (accessed on 15 August 2019).

- Helfer, F.; Lemckert, C.; Anissimov, Y.G. Osmotic power with Pressure Retarded Osmosis: Theory, performance and trends—A review. J. Membr. Sci. 2014, 453, 337–358. [Google Scholar] [CrossRef]

- Alvarez-Silva, O.A.; Osorio, A.F.; Winter, C. Practical global salinity gradient energy potential. Renew. Sustain. Energy Rev. 2016, 60, 1387–1395. [Google Scholar] [CrossRef]

- Seyfried, C.; Palko, H.; Dubbs, L. Potential local environmental impacts of salinity gradient energy: A review. Renew. Sustain. Energy Rev. 2019, 102, 111–120. [Google Scholar] [CrossRef]

- Güereca, L.P.; Gassó, S.; Baldasano, J.M.; Jiménez-Guerrero, P. Life cycle assessment of two biowaste management systems for Barcelona, Spain. Resour. Conserv. Recycl. 2006, 49, 32–48. [Google Scholar] [CrossRef]

- Zumsteg, J.M.; Cooper, J.S.; Noon, M.S. Systematic Review Checklist: A Standardized Technique for Assessing and Reporting Reviews of Life Cycle Assessment Data. J. Ind. Ecol. 2012, 16, S12–S21. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Gujba, H.; Azapagic, A. Life cycle assessment of electricity generation in Mexico. Energy 2011, 36, 1488–1499. [Google Scholar] [CrossRef]

- Varun; Bhat, I.K.; Prakash, R. LCA of renewable energy for electricity generation systems—A review. Renew. Sustain. Energy Rev. 2009, 13, 1067–1073. [Google Scholar] [CrossRef]

- Raadal, H.L.; Gagnon, L.; Modahl, I.S.; Hanssen, O.J. Life cycle greenhouse gas (GHG) emissions from the generation of wind and hydro power. Renew. Sustain. Energy Rev. 2011, 15, 3417–3422. [Google Scholar] [CrossRef]

- Dolan, S.L.; Heath, G.A. Life Cycle Greenhouse Gas Emissions of Utility-Scale Wind Power: Systematic Review and Harmonization. J. Ind. Ecol. 2012, 16, S136–S154. [Google Scholar] [CrossRef]

- Whitaker, M.; Heath, G.A.; O’Donoughue, P.; Vorum, M. Life Cycle Greenhouse Gas Emissions of Coal-Fired Electricity Generation. J. Ind. Ecol. 2012, 16, S53–S72. [Google Scholar] [CrossRef]

- Turconi, R.; Boldrin, A.; Astrup, T. Life cycle assessment (LCA) of electricity generation technologies: Overview, comparability and limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef]

- Arvesen, A.; Nes, R.N.; Huertas-Hernando, D.; Hertwich, E.G. Life cycle assessment of an offshore grid interconnecting wind farms and customers across the North Sea. Int. J. Life Cycle Assess. 2014, 19, 826–837. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, X.; Yuan, Z. Life-cycle assessment of multi-crystalline photovoltaic (PV) systems in China. J. Clean. Prod. 2015, 86, 180–190. [Google Scholar] [CrossRef]

- Lean, S.R. CO2 emissions, electricity consumption and output in ASEAN. Appl. Energy 2010, 87, 1858–1864. [Google Scholar] [CrossRef]

- Atkins, M.J.; Morrison, A.S.; Walmsley, M.R.W. Carbon Emissions Pinch Analysis (CEPA) for emissions reduction in the New Zealand electricity sector. Appl. Energy 2010, 87, 982–987. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Hermansen, J.E.; Mogensen, L. Environmental consequences of different beef production systems in the EU. J. Clean. Prod. 2010, 18, 756–766. [Google Scholar] [CrossRef]

- Tonini, D.; Astrup, T. LCA of biomass-based energy systems: A case study for Denmark. Appl. Energy 2012, 99, 234–246. [Google Scholar] [CrossRef]

- Parker, R.P.M.; Harrison, G.P.; Chick, J.P. Energy and carbon audit of an offshore wave energy converter. Proc. Inst. Mech. Eng. Part A J. Power Energy USA 2007, 221, 1119–1130. [Google Scholar] [CrossRef]

- Douglas, C.A.; Harrison, G.P.; Chick, J.P. Life cycle assessment of the Seagen marine current turbine. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. USA 2008, 222, 1–12. [Google Scholar] [CrossRef]

- Walker, S.; Howell, R. Life Cycle Comparison of a Wave and Tidal Energy Device. Ph.D Thesis, E-Futures Doctoral Training Centre, University of Sheffield, Sheffield, UK, 2011. [Google Scholar]

- Kelly, K.A.; McManus, M.C.; Hammond, G.P. An energy and carbon life cycle assessment of tidal power case study: The proposed Cardiff-Weston severn barrage scheme. Energy 2012, 44, 692–701. [Google Scholar] [CrossRef]

- Elmehag, E.; Torosian, R. Life Cycle Assessment of an Ocean Energy Power Plant: Evaluation and Analysis of the Energy Payback Time with Comparison Between Sweden and Tanzania. Bachelor’s Thesis, School of Technology and Science, University of Skövde, Skövde, Sweden, 2013. [Google Scholar]

- Banerjee, S.; Duckers, L.; Blanchard, R.E. An overview on green house gas emission characteristics and energy evaluation of ocean energy systems from life cycle assessment and energy accounting studies. J. Appl. Nat. Sci. 2013, 5, 535–540. [Google Scholar] [CrossRef]

- Walker, S.; Howell, R.; Hodgson, P.; Griffin, A. Tidal energy machines: A comparative life cycle assessment study. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. USA 2015, 229, 124–140. [Google Scholar] [CrossRef]

- Gastelum, L. Life Cycle Assessment of a Wave Energy Converter. Bachelor’s Thesis, Mechanical Engineering, School of Arquitecture and the Built Environment, KTH Royal Institute of Technology, Stockholm, Sweden, 2017. [Google Scholar]

- Patrizi, N.; Pulselli, R.M.; Neri, E.; Niccolucci, V.; Vicinanza, D.; Contestabile, P.; Bastianoni, S. Life cycle environmental impact assessment of an overtopping wave energy converter embedded in breakwater systems. Front. Energy Res. 2019, 7, 1–10. [Google Scholar] [CrossRef]

- Sørensen, H.C.; Naef, S.; Anderberg, S.; Hauschild, M.Z. Life cycle assessment of the wave energy converter: Wave Dragon. In Proceedings of the International Conference on Ocean Energy, Bremerhaven, Germany, 23–24 October 2006. [Google Scholar]

- Dahlsten, H. Life Cycle Assessment of Electricity from Wave Power. Master’s Thesis, Department of Energy and Technology, Faculty of Natural Resources and Agricultural Sciences, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2009. [Google Scholar]

- Thomson, R.C.; Harrison, G.P.; Chick, J.P. Full life cycle assessment of a wave energy converter. In Proceedings of the IET Conference on Renewable Power Generation (RPG 2011), Edinburgh, UK, 6–8 September 2011. [Google Scholar]

- Curto, D.; Neugebauer, S.; Viola, A.; Traverso, M.; Franzitta, V.; Trapanese, M. First Life cycle impact considerations of two wave energy converters. In Proceedings of the 2018 Ocean-MTS/IEEE Kobe Techno-Oceans (OTO), Kobe, Japan, 28–31 May 2018. [Google Scholar]

- Thomson, R.C.; Chick, J.P.; Harrison, G.P. An LCA of the Pelamis wave energy converter. Int. J. Life Cycle Assess. 2019, 24, 51–63. [Google Scholar] [CrossRef]

- Douziech, M.; Hellweg, S.; Verones, F. Are wave and tidal energy plants new green technologies? Environ. Sci. Technol. 2016, 50, 7870–7878. [Google Scholar] [CrossRef]

- Hauschild, M.; Potting, J. Spatial Differentiation in Life Cycle Impact Assessment—The EDIP2003 Methodology; Environment. News No. 80. Copenhagen (Denmark); Danish Ministry of the Environment: Geneva, Switzerland, 2005. [Google Scholar]

- International EPD Cooperation. Product Category Rules for Preparing an EPD for Electricity, Steam and Hot and Cold Water Generation and Distribution; Product Category Rules; The International EPD System: Stockholm, Sweden, 2007. [Google Scholar]

- Wenzel, L.; Hauschild, H.; Alting, M. Methodology, Tools and Case Studies in Product Development; Environ. Assessments Product. No. 1; Chapman & Hall: London, UK, 1997. [Google Scholar]

- Hauschild, M.Z.; Goedkoop, M.; Guinée, J.; Heijungs, R.; Huijbregts, M.; Jolliet, O.; Margni, R.; Schryver, A.D.; Humbert, S.; Laurent, A.; et al. Identifying best existing practice for characterization modeling in life cycle impact assessment. Int. J. Life Cycle Assess. 2013, 18, 683–697. [Google Scholar] [CrossRef]

- Cao, L.; Diana, J.S.; Keoleian, G.A.; Lai, Q. Life cycle assessment of Chinese shrimp farming systems targeted for export and domestic sales. Environ. Sci. Technol. 2011, 45, 6531–6538. [Google Scholar] [CrossRef]

- Pang, M.; Zhang, L.; Wang, C.; Liu, G. Environmental life cycle assessment of a small hydropower plant in China. Int. J. Life Cycle Assess. 2015, 20, 796–806. [Google Scholar] [CrossRef]

- Kofoed, J.P.; Friggard, P.; Friis-Madsen, E.; Sorensen, H.C. Prototype testing of the wave energy converter wave dragon. Renew Energy 2006, 31, 181–189. [Google Scholar] [CrossRef]

- Green, H.J.; Guenther, P.R. Carbon Di-oxide release from OTEC cycles. In Proceedings of the International Conference on Ocean Energy Recovery, Report -SERI/TP-253-3594, Honolulu, HI, USA, 28–30 November 1989. [Google Scholar]

- Moan, T. Life cycle structural integrity management of offshore structures. Struct. Infrastruct. Eng. 2018, 14, 911–927. [Google Scholar] [CrossRef]

- Moan, T. Life-cycle assessment of marine civil engineering structures. Struct. Infrastruct. Eng. 2011, 7, 11–32. [Google Scholar] [CrossRef]

- Bonar, P.A.; Bryden, I.G.; Borthwick, A.G. Social and ecological impacts of marine energy development. Renew. Sustain. Energy Rev. 2015, 47, 486–495. [Google Scholar] [CrossRef]

- DETI (Department of Enterprise, Trade and Investment). Ireland Offshore Renewable Energy Strategic Action Plan 2012–2020; Report by UK Department of Enterprise Trade and Investment; DETI: Ankara, Turkey, 2012. Available online: https://tethys.pnnl.gov/sites/default/files/publications/Ireland_Offshore_Renewable_Energy_Strategic_Action_Plan.pdf (accessed on 07 September 2019).

- Simon, P.N.; Reza, H. Chapter 5—Wave Energy. Fundamentals of Ocean Renewable Energy. In E-Business Solutions; Academic Press: New York, NY, USA, 2018; pp. 107–140. [Google Scholar]

- IES (Institute of Environmental Sciences). CML-IA Characterization Factors Database; Leiden University: Leiden, The Netherlands, 2016; Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 16 September 2019).

- Goedkoop, M.J.; Heijungs, R.; Huijbregts, M.; De Scheryver, A.; Stujins, J.; Van Zelm, R. Recipe 2008, A life cycle impact assessment method which comprises harmonized category indicators at the midpoint and the endpoint level. First edition Report I:Characterization. 6 January 2009. Available online: https://www.rivm.nl/en/life-cycle-assessment-lca/recipe (accessed on 16 September 2019).

- Rosenbaum, R.K. Quantification of uncertainty and spatial variability of characterization factors in the new global LCIA method IMPACT World+. In Abstract Book, SETAC 6th World Congress/SETAC Europe 22nd Annual Meeting; Society of Environmental Toxicology and Chemistry: Berlin, Germany, 20–24 May 2012; pp. 107–108. [Google Scholar]

- Yebra, D.M.; Kiil, S.; Dam-Johansen, K. Antifouling technology—Past, present and future steps towards efficient and environmentally friendly antifouling coatings. Prog. Org. Coat. 2004, 50, 75–104. [Google Scholar] [CrossRef]

- Carteau, D.; Vallée-Réhel, K.; Linossier, I.; Quiniou, F.; Davy, R.; Compére, C.; Delbury, M.; Faÿ, F. Development of environmentally friendly antifouling paints using biodegradable polymer and lower toxic substances. Prog. Org. Coat. 2014, 77, 485–493. [Google Scholar] [CrossRef]

- Chambers, L.; Stokes, K.; Walsh, F.; Wood, R. Modern approaches to marine antifouling coatings. Surf. Coat. Technol. 2006, 201, 3642–3652. [Google Scholar] [CrossRef]

- Dafforn, K.; Lewis, J.; Johnston, E. Antifouling strategies: History and regulation, ecological impacts and mitigation. Mar. Poll. Bull. 2011, 62, 453–465. [Google Scholar] [CrossRef]

- US DOF (United State Department of Energy). Report to Congress on the Potential Environmental Effects of Marine and Hydrokinetic Energy Technologies; US DOF: Washington, DC, USA, 2009; pp. 11–46.

- Yang, W.; Neoh, K.; Kang, E.; Lay-Ming, S.; Rittschof, D. Polymer brush coatings for combating marine biofouling. Prog. Polym. Sci. 2014, 39, 1017–1042. [Google Scholar] [CrossRef]

- Drew, B.; Plummer, A.; Sahinkaya, M. A review of wave energy converter technology. Proc. IMechE Part A J. Power Energy 2009, 3, 887–902. [Google Scholar] [CrossRef]

- Gittens, J.E.; Smith, T.J.; Suleiman, R.; Akid, R. Current and emerging environmentally-friendly systems for fouling control in the marine environment. Biotechnol. Adv. 2013, 31, 1738–1753. [Google Scholar] [CrossRef]

- Chen, S.; Ma, C.; Zhang, G. Biodegradable polymer as controlled release system of organic antifoulant to prevent marine biofouling. Prog. Org. Coat. 2017, 104, 58–63. [Google Scholar] [CrossRef]

- Mardare, L.; Benea, L. Development of anticorrosive polymer nanocomposite coating for corrosion protection in marine environment. IOP Conf. Ser. Mater. Sci. Eng. 2017, 209, 012056. [Google Scholar] [CrossRef]

- Ioannou, A.; Angus, A.; Brennan, F. Risk-based methods for sustainable energy system planning: A review. Renew. Sustain. Energy Rev. 2017, 74, 602–615. [Google Scholar] [CrossRef]

- Zeng, S.; Liu, Y.; Liu, C.; Nan, X. A review of renewable energy investment in the BRICS countries: History, models, problems and solutions. Renew. Sustain. Energy Rev. 2017, 74, 860–872. [Google Scholar] [CrossRef]

- Felix, A.; Hernández-Fontes, J.V.; Lithgow, D.; Mendoza, E.; Posada, G.; Ring, M.; Silva, R. Wave Energy in Tropical Regions: Deployment Challenges, Environmental and Social Perspectives. J. Mar. Sci. Eng. 2019, 7, 219. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).