An Approach for Predicting the Specific Fuel Consumption of Dual-Fuel Two-Stroke Marine Engines

Abstract

1. Introduction

2. Methodology

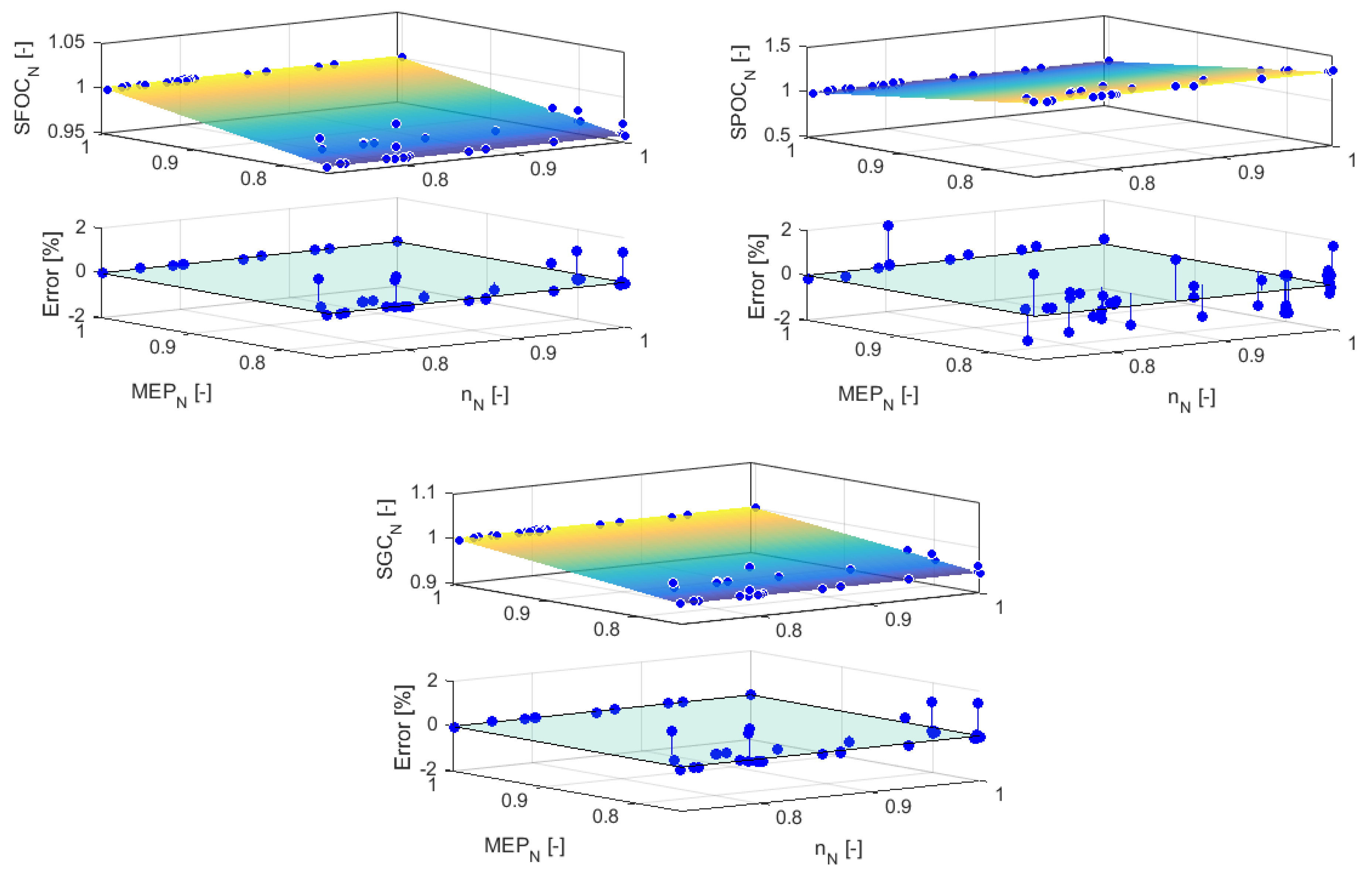

2.1. Specific Fuel Consumption at SMCR

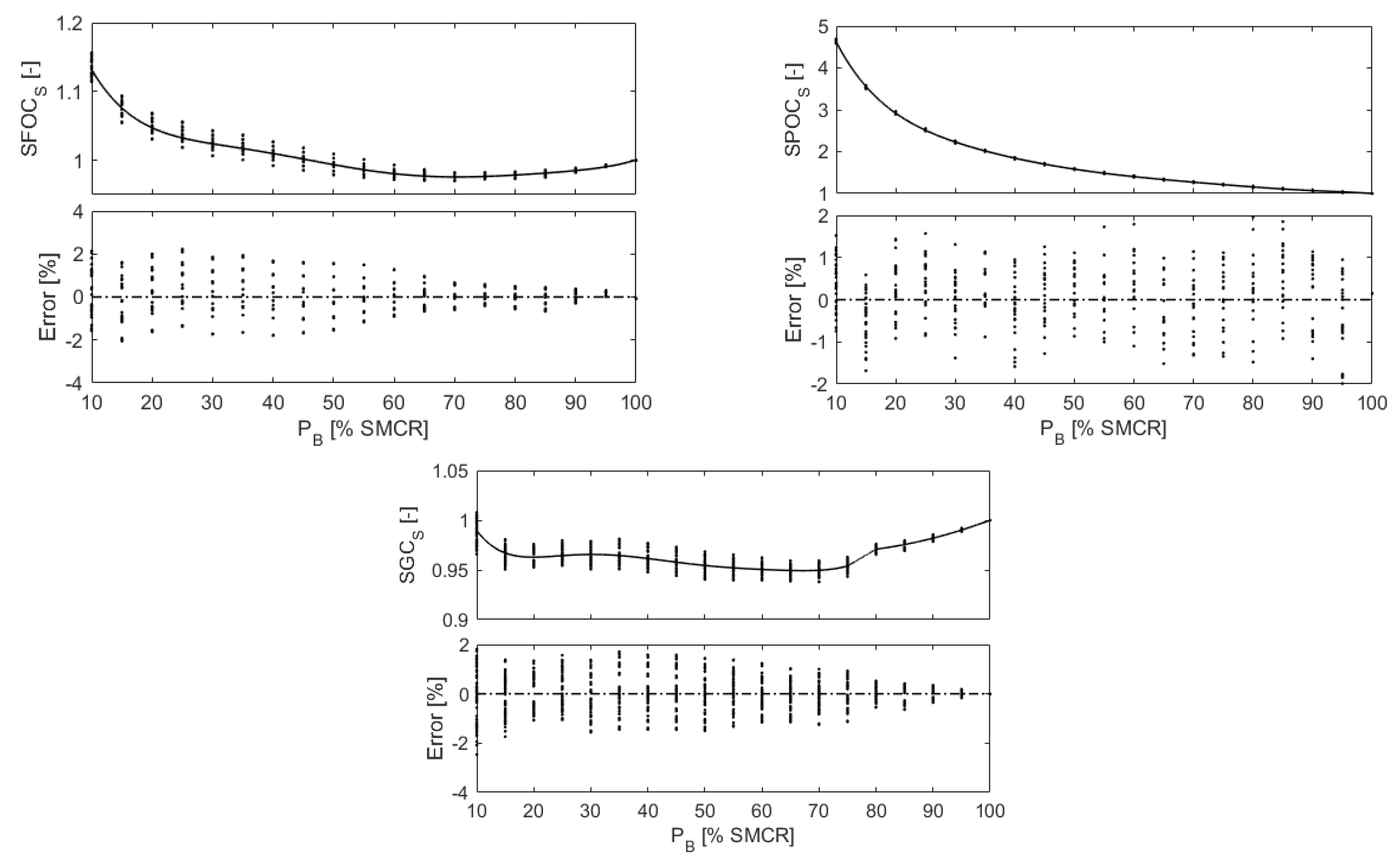

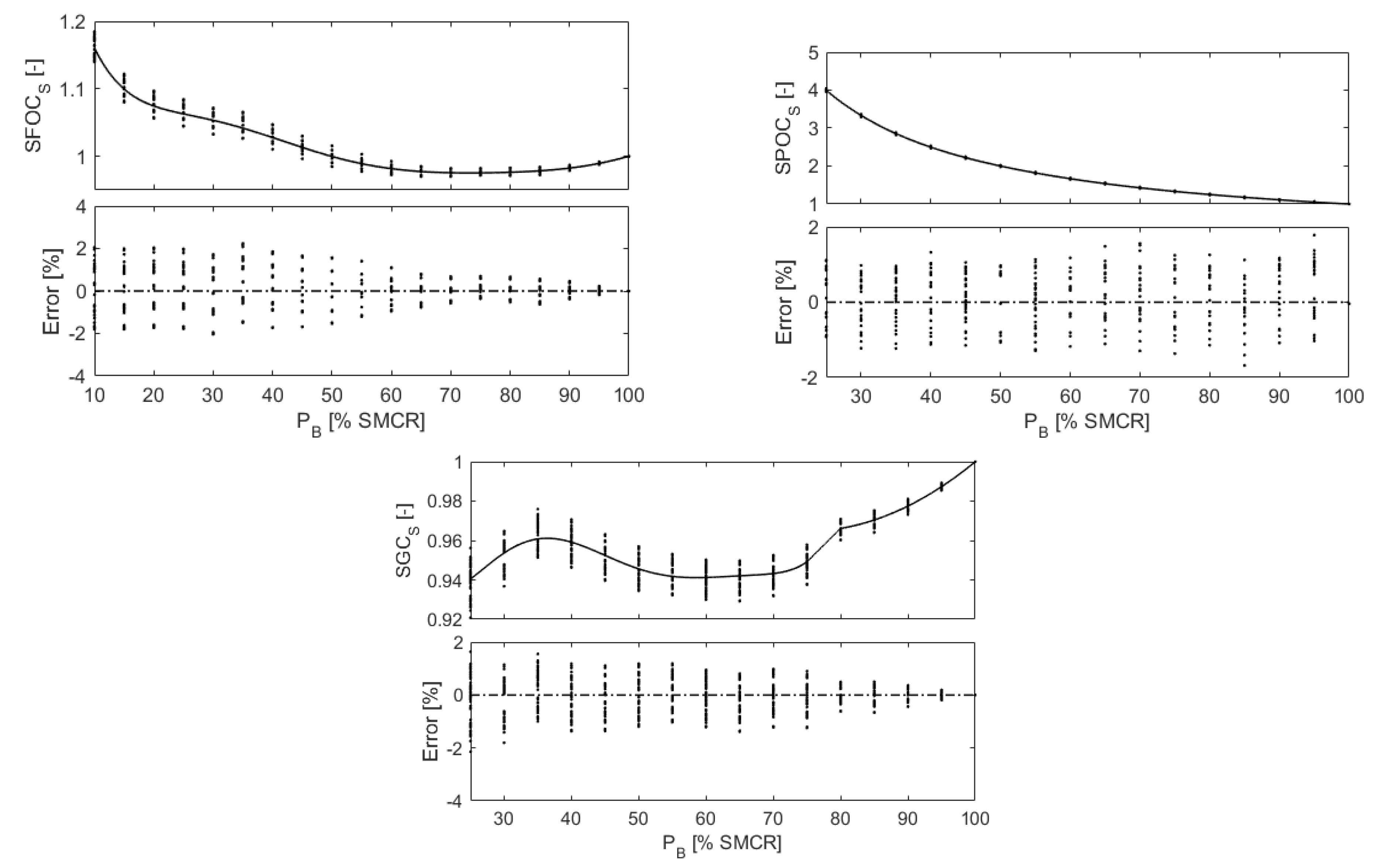

2.2. Specific Fuel Consumption at Part Load

3. Model

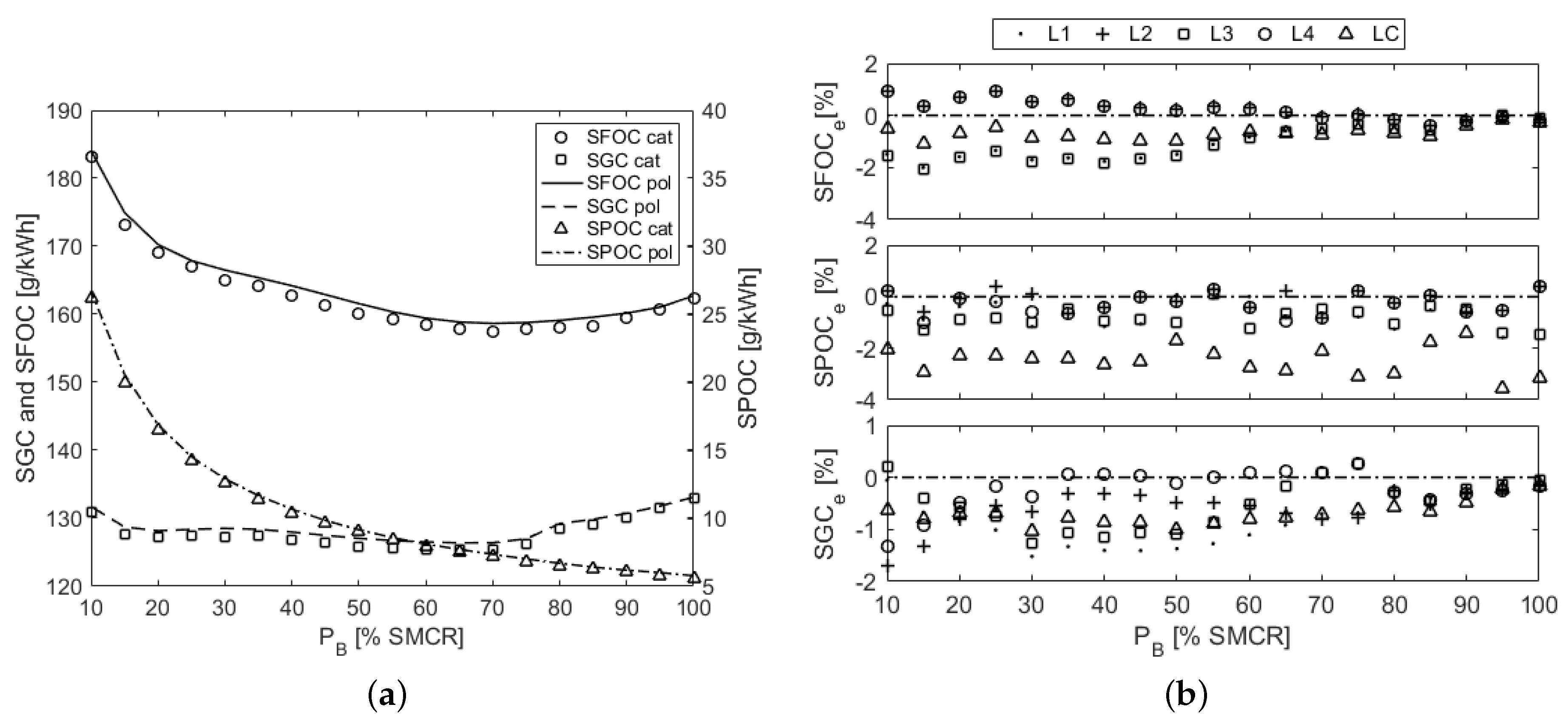

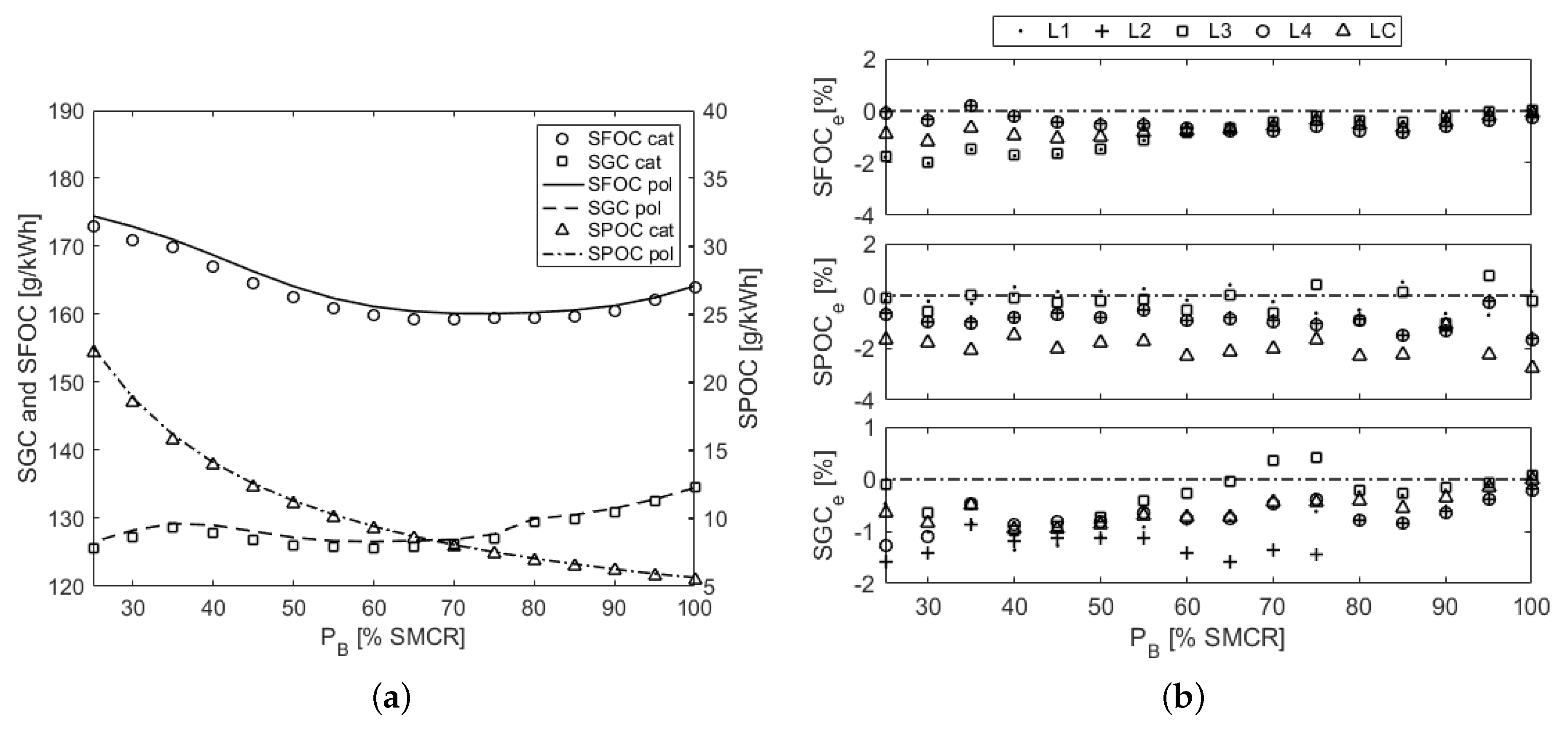

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 0-D | zero-dimensional |

| CFD | computational fluid dynamics |

| CPP | controllable pitch propeller |

| FPP | fixed pitch propeller |

| MEP | mean effective pressure |

| MVEM | mean value engine model |

| NMCR | nominal maximum continuous rating |

| SFC | specific fuel consumption (generic) |

| SFOC | specific fuel oil consumption |

| SGC | specific gas consumption |

| SMCR | specified maximum continuous rating |

| SPOC | specific pilot oil consumption |

| TFEM | transfer function engine model |

References

- Thomson, H.; Corbett, J.J.; Winebrake, J.J. Natural gas as a marine fuel. Energy Policy 2015, 87, 153–167. [Google Scholar] [CrossRef]

- IMO. Resolution MEPC.176(58): Amendments to the Annex of the Protocol of 1997 to Amend the International Convention for the Prevention of Pollution from Ships, 1973, as Modified by the Protocol of 1978 Relating Thereto. 2008. Available online: http://www.imo.org/en/KnowledgeCentre/IndexofIMOResolutions/Marine-Environment-Protection-Committee-%28MEPC%29/Documents/MEPC.176%2858%29.pdf (accessed on 3 October 2018).

- IMO. IMO Sets 2020 Date for Ships to Comply with Low Sulphur Fuel Oil Requirement. 2016. Available online: http://www.imo.org/en/MediaCentre/PressBriefings/Pages/MEPC-70-2020sulphur.aspx (accessed on 3 October 2018).

- DNV-GL. Sulphur Cap Ahead—Time to Take Action. Available online: https://www.dnvgl.com/article/sulphur-cap-ahead-time-to-take-action-94198 (accessed on 3 October 2018).

- Karim, G. Dual-Fuel Diesel Engines; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Caton, J.A. (Ed.) An Introduction to Thermodynamic Cycle Simulations for Internal Combustion Engines; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Schulten, P.J.M. The Interaction Between Diesel Engines, Ship and Propellers During Manoeuvring. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2005. [Google Scholar]

- Hountalas, D.T. Prediction of marine diesel engine performance under fault conditions. Appl. Therm. Eng. 2000, 20, 1753–1783. [Google Scholar] [CrossRef]

- Rakopoulos, C.; Dimaratos, A.; Giakoumis, E.; Rakopoulos, D. Evaluation of the effect of engine, load and turbocharger parameters on transient emissions of diesel engine. Energy Convers. Manag. 2009, 50, 2381–2393. [Google Scholar] [CrossRef]

- Scappin, F.; Stefansson, S.H.; Haglind, F.; Andreasen, A.; Larsen, U. Validation of a zero-dimensional model for prediction of NOx and engine performance for electronically controlled marine two-stroke diesel engines. Appl. Therm. Eng. 2012, 37, 344–352. [Google Scholar] [CrossRef]

- Cordtz, R.; Schramm, J.; Andreasen, A.; Eskildsen, S.S.; Mayer, S. Modeling the Distribution of Sulfur Compounds in a Large Two Stroke Diesel Engine. Energy Fuels 2013, 27, 1652–1660. [Google Scholar] [CrossRef]

- Raptotasios, S.I.; Sakellaridis, N.F.; Papagiannakis, R.G.; Hountalas, D.T. Application of a multi-zone combustion model to investigate the NOx reduction potential of two-stroke marine diesel engines using EGR. Appl. Energy 2015, 157, 814–823. [Google Scholar] [CrossRef]

- Payri, F.; Olmeda, P.; Martín, J.; García, A. A complete 0D thermodynamic predictive model for direct injection diesel engines. Appl. Energy 2011, 88, 4632–4641. [Google Scholar] [CrossRef]

- Cordtz, R.; Mayer, S.; Eskildsen, S.S.; Schramm, J. Modeling the condensation of sulfuric acid and water on the cylinder liner of a large two-stroke marine diesel engine. J. Mar. Sci. Technol. 2017, 23, 178–187. [Google Scholar] [CrossRef]

- Gugulothu, S.; Reddy, K. CFD simulation of in-cylinder flow on different piston bowl geometries in a DI diesel engine. J. Appl. Fluid Mech. 2016, 9, 1147–1155. [Google Scholar] [CrossRef]

- Pang, K.M.; Karvounis, N.; Walther, J.H.; Schramm, J. Numerical investigation of soot formation and oxidation processes under large two-stroke marine diesel engine-like conditions using integrated CFD-chemical kinetics. Appl. Energy 2016, 169, 874–887. [Google Scholar] [CrossRef]

- Sun, X.; Liang, X.; Shu, G.; Lin, J.; Wang, Y.; Wang, Y. Numerical investigation of two-stroke marine diesel engine emissions using exhaust gas recirculation at different injection time. Ocean Eng. 2017, 144, 90–97. [Google Scholar] [CrossRef]

- Benvenuto, G.; Carrera, G.; Rizzuto, E. Dynamic Simulation of Marine Propulsion Plants. In Proceedings of the International Conference on Ship and Marine Research, Rome, Italy, 5–7 October 1994. [Google Scholar]

- Kyrtatos, N.P.; Theodossopoulos, P.; Theotokatos, G.; Xiros, N. Simulation of the overall ship propulsion plant for performance prediction and control. In Proceedings of the Conference on Advanced Marine Machinery Systems with Low Pollution and High Efficiency, Newcastle upon Tyne, UK, 25–26 March 1999. [Google Scholar]

- Theotokatos, G.P. Ship Propulsion Plant Transient Response Investigation using a Mean Value Engine Model. Int. J. Energy 2008, 2, 66–74. [Google Scholar]

- Stapersma, D.; Vrijdag, A. Linearisation of a ship propulsion system model. Ocean Eng. 2017, 142, 441–457. [Google Scholar] [CrossRef]

- Michalski, J. A method for selection of parameters of ship propulsion system fitted with compromise screw propeller. Pol. Marit. Res. 2007, 14. [Google Scholar] [CrossRef]

- Aldous, L.; Smith, T. Speed Optimisation for Liquefied Natural Gas Carriers: A Techno-Economic Model. In Proceedings of the International Conference on Technologies, Operations, Logistics & Modelling for Low Carbon Shipping, Newcastle, UK, 11–12 September 2012. [Google Scholar]

- Talluri, L.; Nalianda, D.; Kyprianidis, K.; Nikolaidis, T.; Pilidis, P. Techno economic and environmental assessment of wind assisted marine propulsion systems. Ocean Eng. 2016, 121, 301–311. [Google Scholar] [CrossRef]

- Sakalis, G.N.; Frangopoulos, C.A. Intertemporal optimization of synthesis, design and operation of integrated energy systems of ships: General method and application on a system with Diesel main engines. Appl. Energy 2018, 226, 991–1008. [Google Scholar] [CrossRef]

- Trivyza, N.L.; Rentizelas, A.; Theotokatos, G. A novel multi-objective decision support method for ship energy systems synthesis to enhance sustainability. Energy Convers. Manag. 2018, 168, 128–149. [Google Scholar] [CrossRef]

- Shi, W.; Grimmelius, H.T.; Stapersma, D. Analysis of ship propulsion system behaviour and the impact on fuel consumption. Int. Shipbuild. Prog. 2010, 57, 35–64. [Google Scholar] [CrossRef]

- MAN Diesel & Turbo. Computerised Engine Application System-Engine Room Dimensioning (CEAS-ERD); MAN Diesel & Turbo: Munich, Germany, 2018. [Google Scholar]

- Woud, H.K.; Stapersma, D. Design of Propulsion and Electric Power Generation Systems; IMarEST: London, UK, 2013. [Google Scholar]

- Woodyard, D. Pounder’s Marine Diesel Engines and Gas Turbines; Elsevier BV: Oxford, UK, 2009. [Google Scholar]

| Engine | ||||||||

|---|---|---|---|---|---|---|---|---|

| kW/Cylinder | rpm | Cylinder | ||||||

| G95ME-C9.6 | 6870 | 5170 | 6440 | 4840 | 75 | 80 | 5 | 12 |

| G95ME-C10.5 | 6870 | 5170 | 6010 | 4520 | 70 | 80 | 5 | 12 |

| G95ME-C9.5 | 6870 | 5170 | 6010 | 4520 | 70 | 80 | 5 | 12 |

| G90ME-C10.5 | 6240 | 4670 | 5350 | 4010 | 72 | 84 | 5 | 12 |

| S90ME-C10.5 | 6100 | 4880 | 5230 | 4180 | 72 | 84 | 5 | 12 |

| G80ME-C9.5 | 4710 | 3550 | 3800 | 2860 | 58 | 72 | 6 | 9 |

| S80ME-C9.5 | 4510 | 3610 | 4160 | 3330 | 72 | 78 | 6 | 9 |

| G70ME-C10.5 | 3060 | 2540 | 2620 | 2180 | 66 | 77 | 5 | 6 |

| G70ME-C9.5 | 3640 | 2740 | 2720 | 2050 | 62 | 83 | 5 | 8 |

| S70ME-C10.5 | 3430 | 2580 | 2750 | 2070 | 73 | 91 | 5 | 8 |

| S70ME-C8.5 | 3270 | 2610 | 2620 | 2100 | 73 | 91 | 5 | 8 |

| S65ME-C8.5 | 2870 | 2290 | 2330 | 1860 | 77 | 95 | 5 | 8 |

| G60ME-C9.5 | 2680 | 2010 | 1990 | 1500 | 72 | 97 | 5 | 8 |

| S60ME-C10.5 | 2490 | 1880 | 2000 | 1500 | 84 | 105 | 5 | 8 |

| S60ME-C8.5 | 2380 | 1900 | 1900 | 1520 | 84 | 105 | 5 | 8 |

| G50ME-C9.6 | 1720 | 1290 | 1360 | 1020 | 79 | 100 | 5 | 9 |

| S50ME-C9.7 | 1780 | 1340 | 1290 | 970 | 85 | 117 | 5 | 9 |

| S50ME-C9.6 | 1780 | 1420 | 1350 | 1080 | 89 | 117 | 5 | 9 |

| S50ME-C8.5 | 1660 | 1330 | 1340 | 1070 | 102 | 127 | 5 | 9 |

| G45ME-C9.5 | 1390 | 1045 | 1090 | 820 | 87 | 111 | 5 | 8 |

| G40ME-C9.5 | 1100 | 825 | 870 | 655 | 99 | 125 | 5 | 8 |

| S40ME-C9.5 | 1135 | 910 | 865 | 690 | 111 | 146 | 5 | 9 |

| Coefficients | SFOC | SPOC | SGC |

|---|---|---|---|

| 0.8342 | 2.294 | 0.7870 | |

| −0.0009009 | −0.0006027 | −0.000691 | |

| 0.1665 | −1.296 | 0.2136 |

| Driving | Coefficients | SFOC | SPOC | SGC | ||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| * | 986.3 | 1484 | 959.6 | 962.4 | 982.0 | |

| * | −36.64 | −486.5 | −15.06 | 11.91 | 10.34 | |

| * | 25.25 | 256.4 | −0.4842 | 0 | 1.730 | |

| * | 20.94 | −134.4 | 12.56 | 0 | 0 | |

| FPP | * | −13.29 | −47.19 | −5.405 | 0 | 0 |

| * | −8.209 | 36.87 | −4.242 | 0 | 0 | |

| * | 5.533 | 49.79 | 2.848 | 0 | 0 | |

| * | 0 | −26.58 | 0 | 0 | 0 | |

| 55.00 | 55.00 | 42.50 | 77.50 | 90.00 | ||

| 27.39 | 27.39 | 20.16 | 3.536 | 7.079 | ||

| * | 989 | 1599 | 945.6 | 957.7 | 977.5 | |

| * | −49.71 | −596.8 | −17.73 | 11.95 | 11.99 | |

| * | 50.68 | 221.8 | 16.44 | 0 | 2.789 | |

| * | 4.908 | −62.2 | 9.05 | 0 | 0 | |

| CPP | * | −31.54 | 20.48 | −13.56 | 0 | 0 |

| * | 7.997 | −22.79 | −0.3384 | 0 | 0 | |

| * | 9.374 | 9.135 | 2.745 | 0 | 0 | |

| * | −3.594 | 0 | 0 | 0 | 0 | |

| 55.00 | 55.00 | 42.50 | 77.50 | 90.00 | ||

| 27.39 | 27.39 | 20.16 | 3.536 | 7.079 | ||

| Engine | SFOC | SPOC | SGC |

|---|---|---|---|

| G95ME-C9.6 | 165.0 | 4.9 | 135.9 |

| G95ME-C10.5 | 163.0 | 4.9 | 134.2 |

| G95ME-C9.5 | 166.0 | 5.0 | 136.7 |

| G90ME-C10.5 | 165.0 | 4.9 | 135.9 |

| S90ME-C10.5 | 166.0 | 5.0 | 136.7 |

| G80ME-C9.5 | 166.0 | 5.0 | 136.7 |

| S80ME-C9.5 | 166.0 | 5.0 | 136.7 |

| G70ME-C10.5 | 163.0 | 5.5 | 133.7 |

| G70ME-C9.5 | 167.0 | 5.0 | 137.5 |

| S70ME-C10.5 | 166.0 | 5.0 | 136.7 |

| S70ME-C8.5 | 169.0 | 5.0 | 139.2 |

| S65ME-C8.5 | 169.0 | 5.0 | 139.2 |

| G60ME-C9.5 | 167.0 | 5.0 | 137.5 |

| S60ME-C10.5 | 166.0 | 5.0 | 136.7 |

| S60ME-C8.5 | 169.0 | 5.0 | 139.2 |

| G50ME-C9.6 | 167.0 | 5.0 | 137.5 |

| S50ME-C9.7 | 165.0 | 4.9 | 135.9 |

| S50ME-C9.6 | 167.0 | 5.0 | 137.5 |

| S50ME-C8.5 | 170.0 | 5.1 | 140.0 |

| G45ME-C9.5 | 170.0 | 5.1 | 140.0 |

| G40ME-C9.5 | 174.0 | 5.2 | 143.3 |

| S40ME-C9.5 | 172.0 | 5.1 | 141.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, C.H.; Caprace, J.-D.; Belchior, C.R.P.; Martini, A. An Approach for Predicting the Specific Fuel Consumption of Dual-Fuel Two-Stroke Marine Engines. J. Mar. Sci. Eng. 2019, 7, 20. https://doi.org/10.3390/jmse7020020

Marques CH, Caprace J-D, Belchior CRP, Martini A. An Approach for Predicting the Specific Fuel Consumption of Dual-Fuel Two-Stroke Marine Engines. Journal of Marine Science and Engineering. 2019; 7(2):20. https://doi.org/10.3390/jmse7020020

Chicago/Turabian StyleMarques, Crístofer H., Jean-D. Caprace, Carlos R. P. Belchior, and Alberto Martini. 2019. "An Approach for Predicting the Specific Fuel Consumption of Dual-Fuel Two-Stroke Marine Engines" Journal of Marine Science and Engineering 7, no. 2: 20. https://doi.org/10.3390/jmse7020020

APA StyleMarques, C. H., Caprace, J.-D., Belchior, C. R. P., & Martini, A. (2019). An Approach for Predicting the Specific Fuel Consumption of Dual-Fuel Two-Stroke Marine Engines. Journal of Marine Science and Engineering, 7(2), 20. https://doi.org/10.3390/jmse7020020