Optimization and Verification of the Spreading Performance of a Pneumatic Pond Feeder Using a Coupled CFD–DEM Approach

Abstract

1. Introduction

2. Materials and Methods

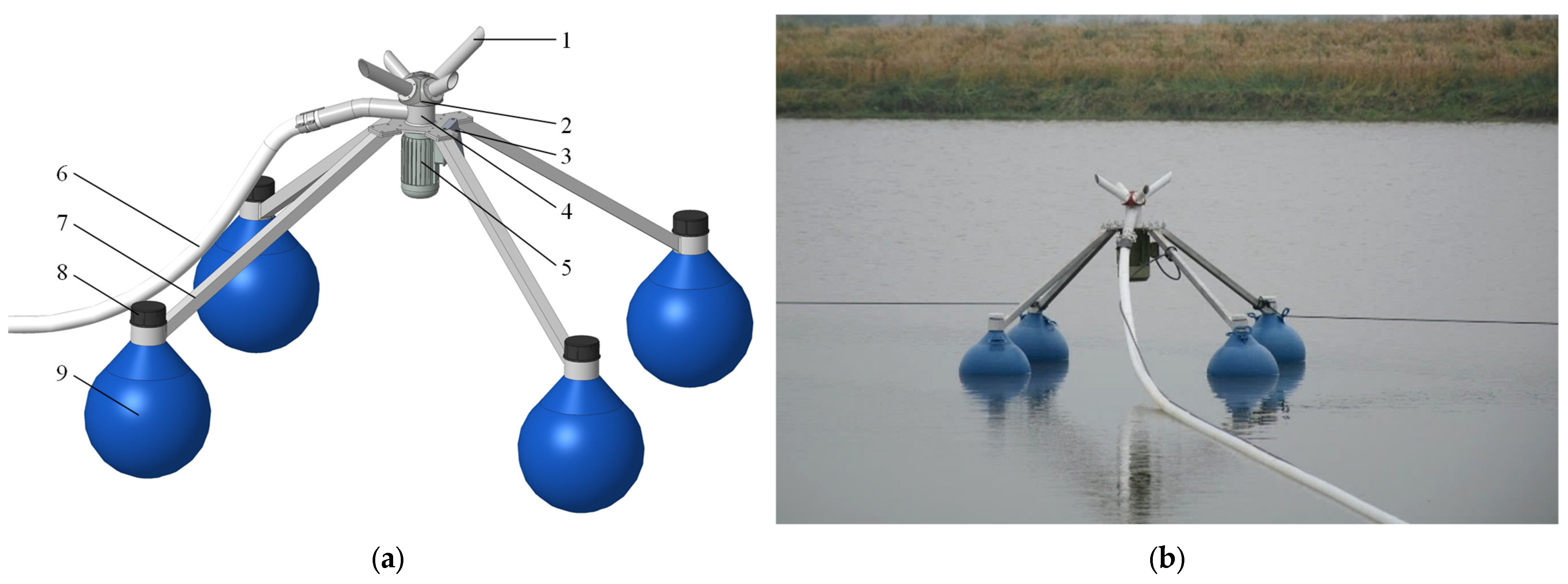

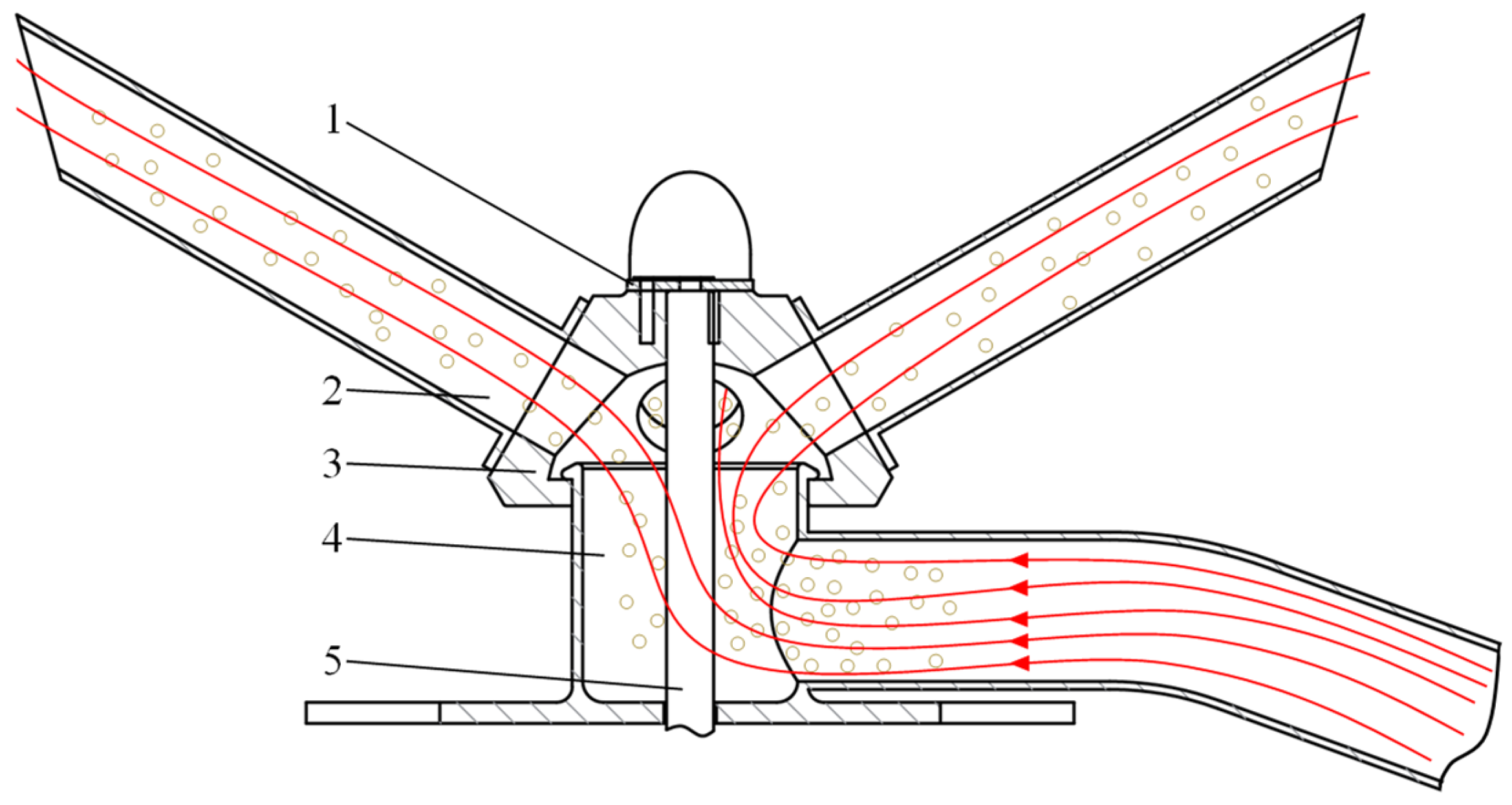

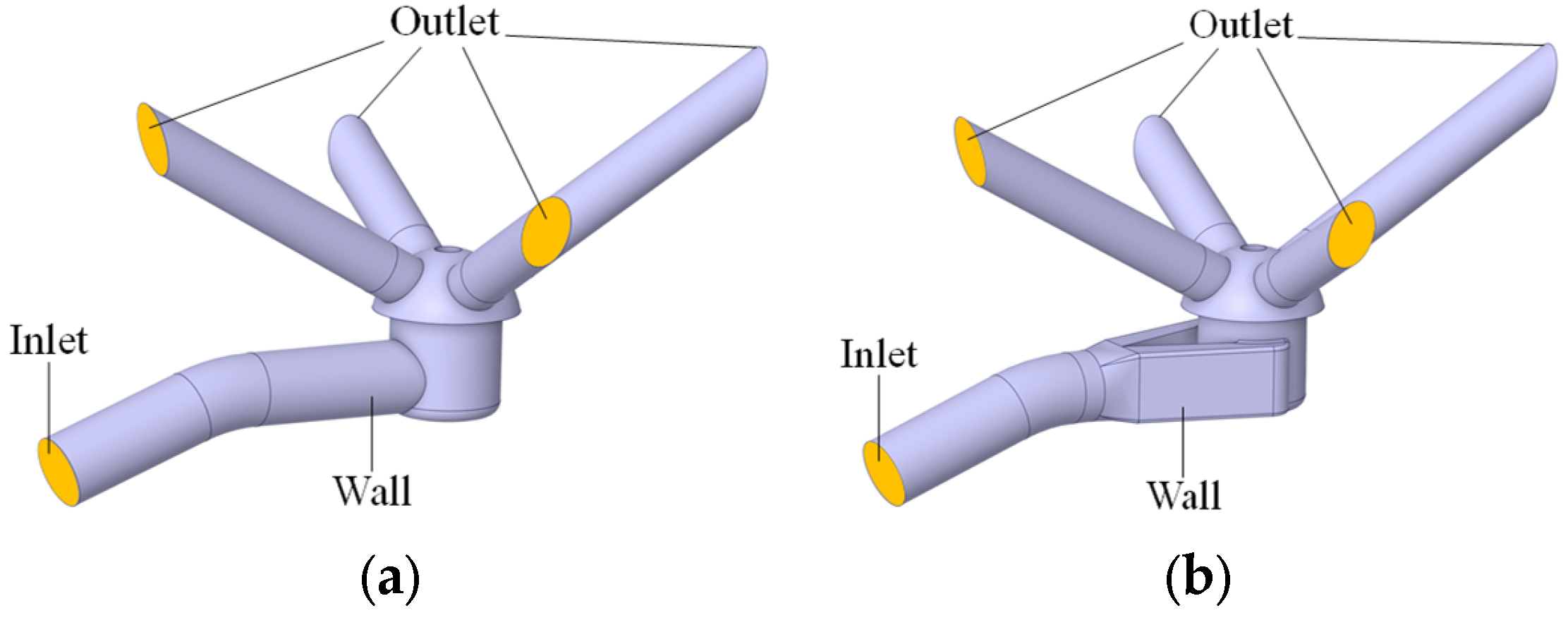

2.1. Structure and Working Principle of the Pneumatic Feeder

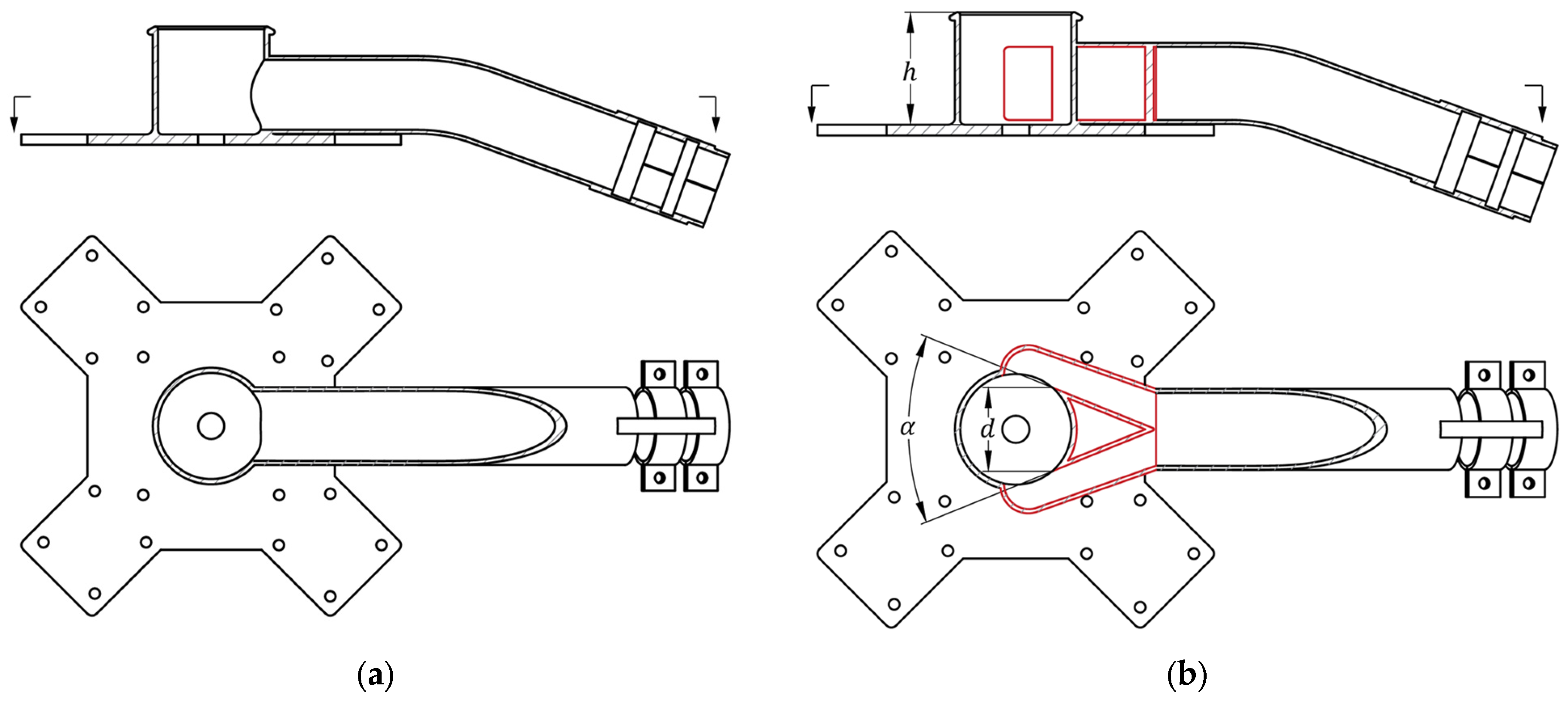

2.2. Feeder Structural Design Optimization of the Triangular Flow-Splitter Plate in the Feed Chamber

2.3. Analysis of Granular Material Kinetics

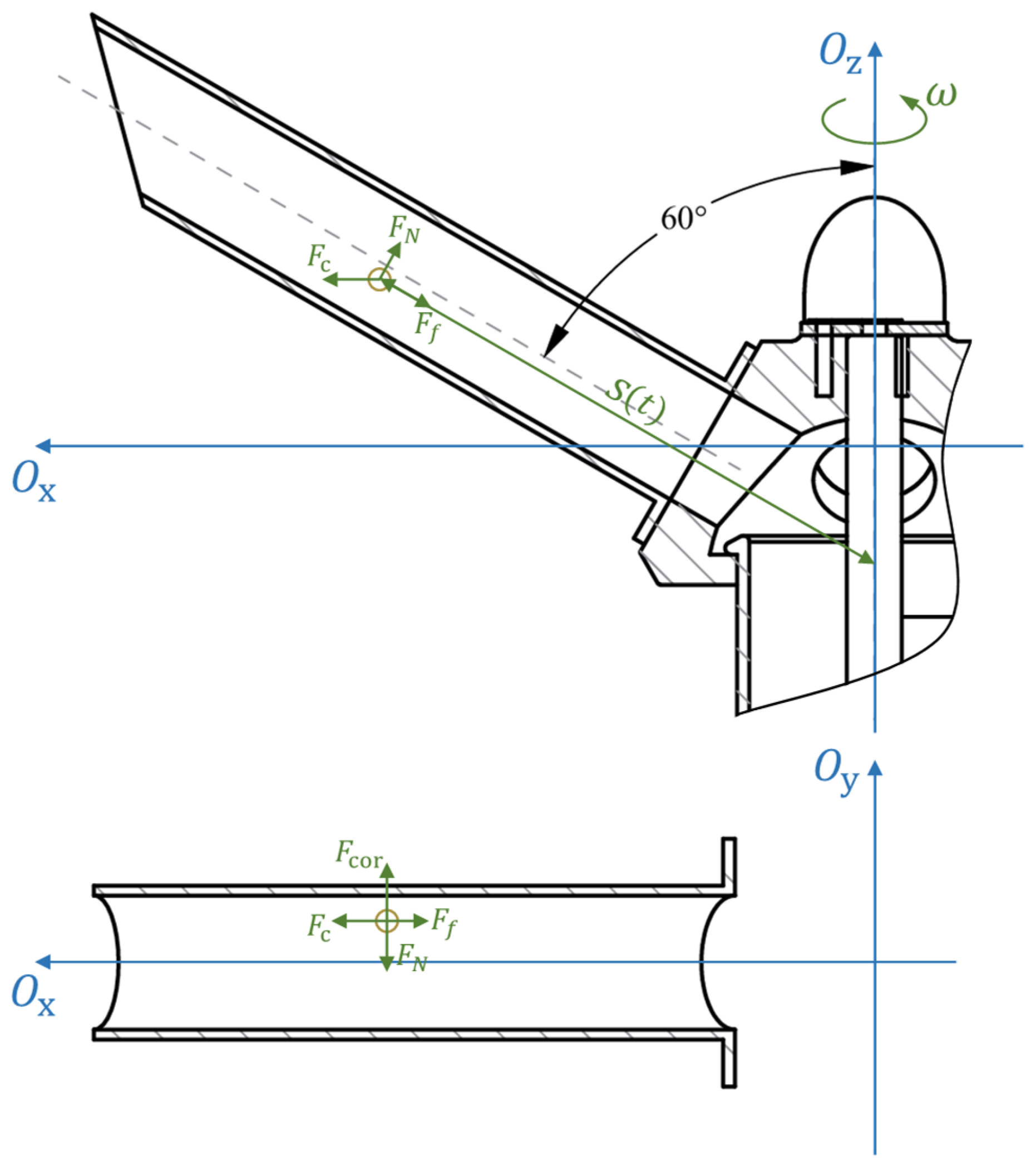

2.3.1. Motion Analysis in Discharge Tubes

2.3.2. Postejection Motion Analysis of Granular Materials

2.4. Simulation Experiment Design

2.4.1. Construction of a 3D Simulation Model

2.4.2. Physical Property Parameters of Granular Materials

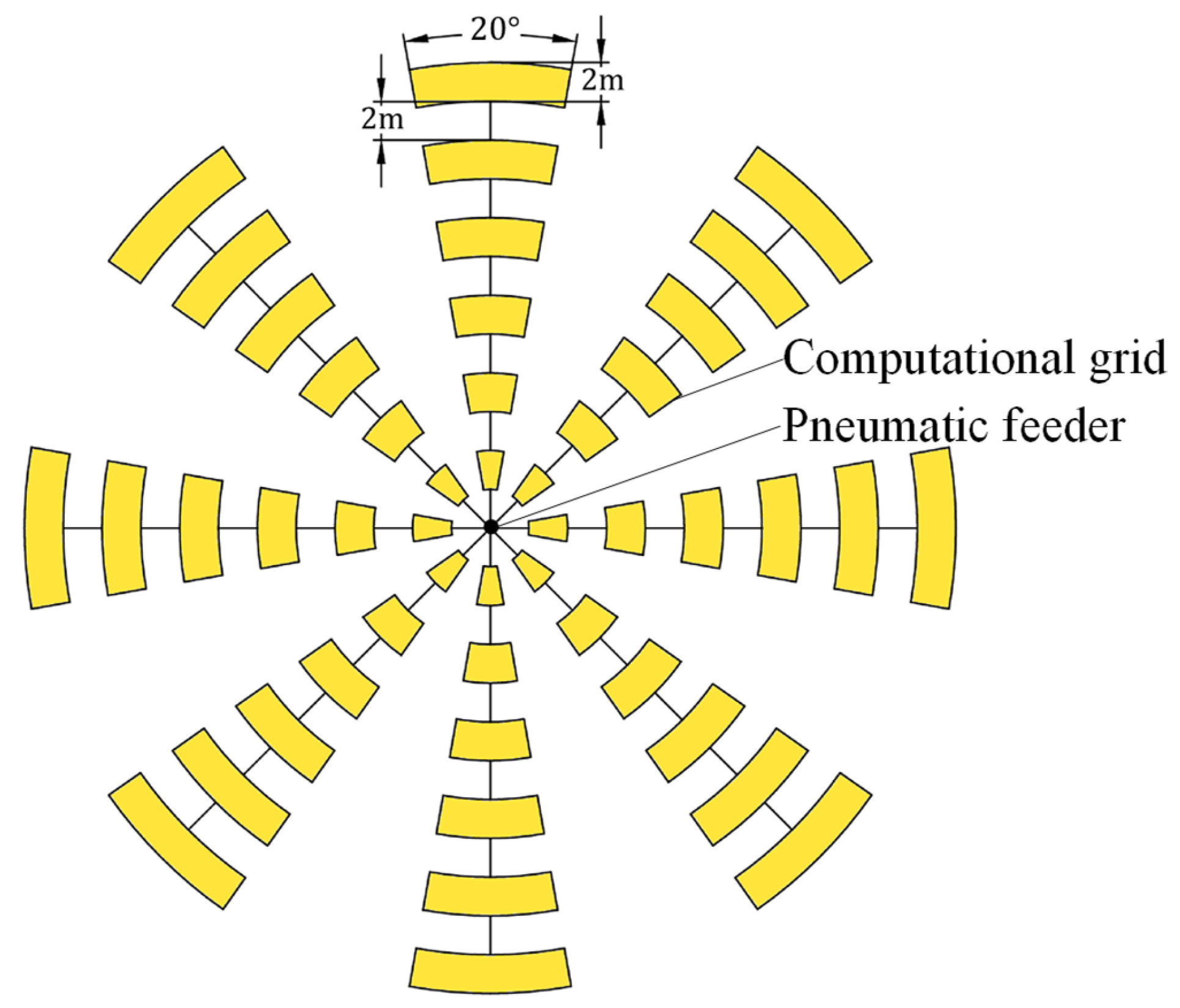

2.4.3. Uniformity Evaluation Metrics

3. Results and Analysis

3.1. Simulation Results and Analysis

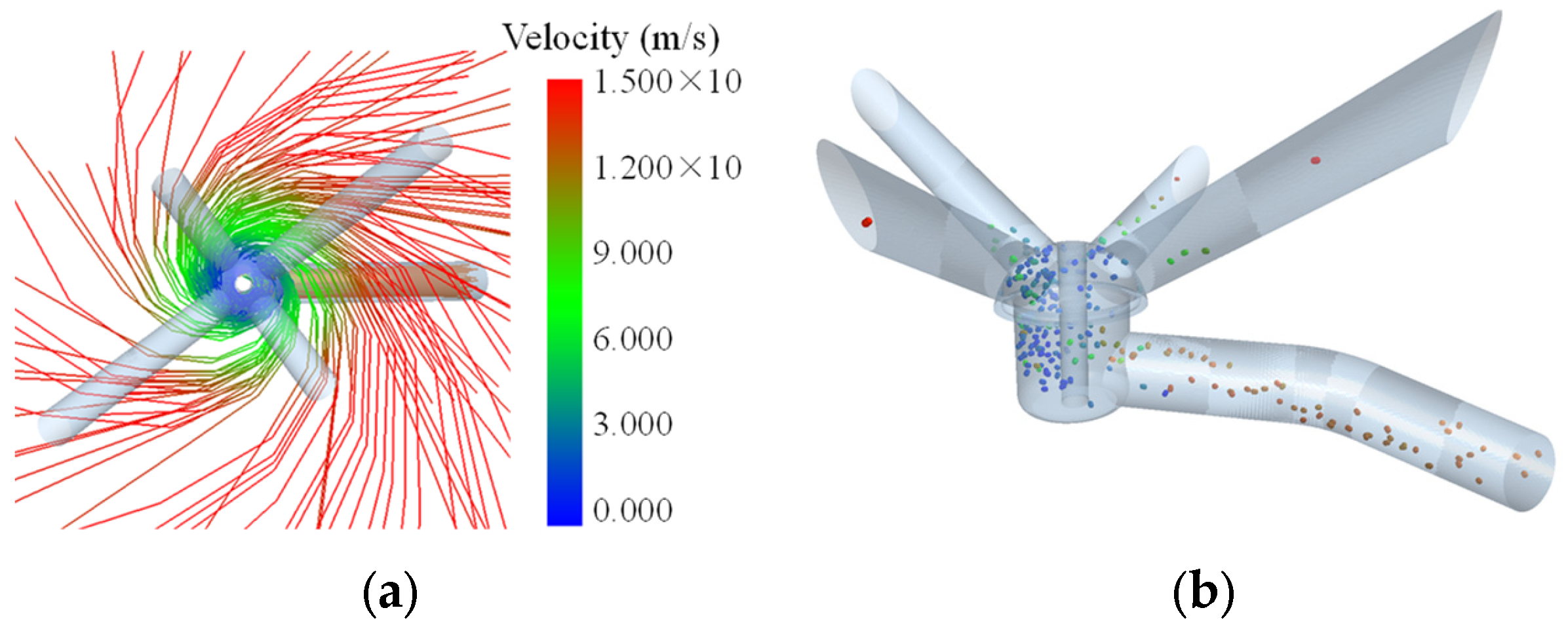

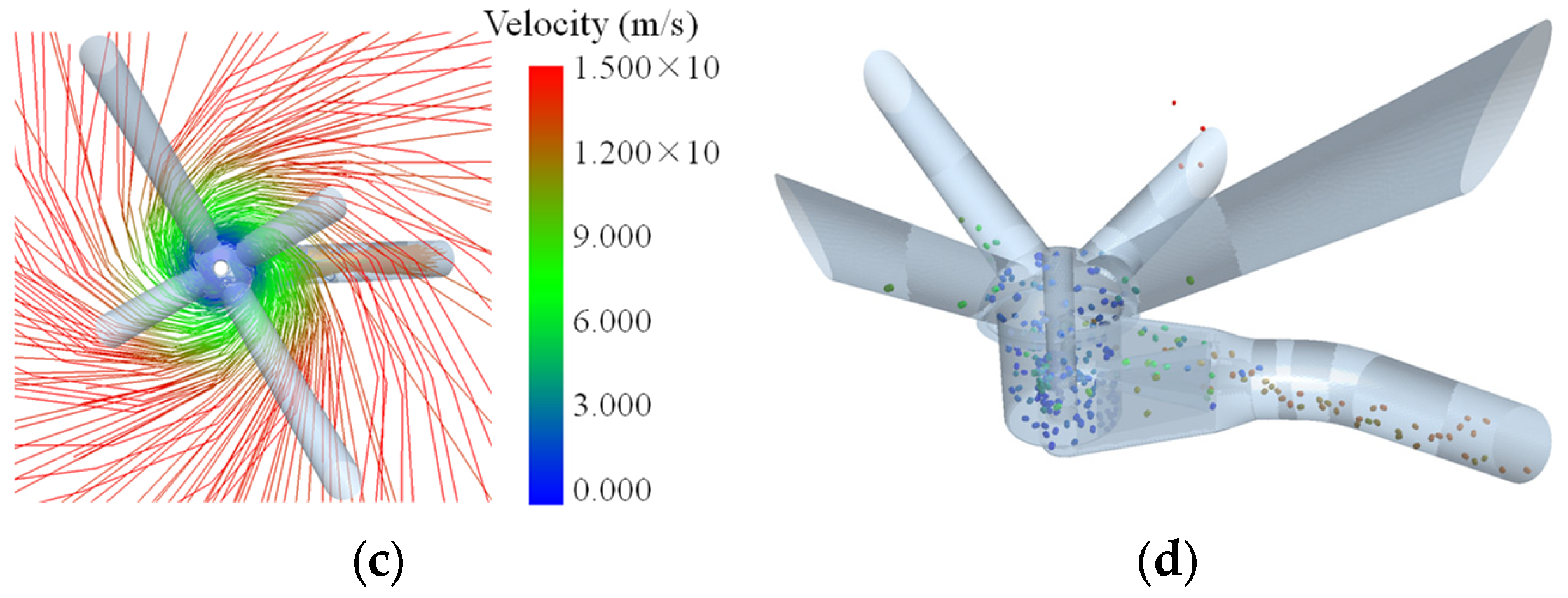

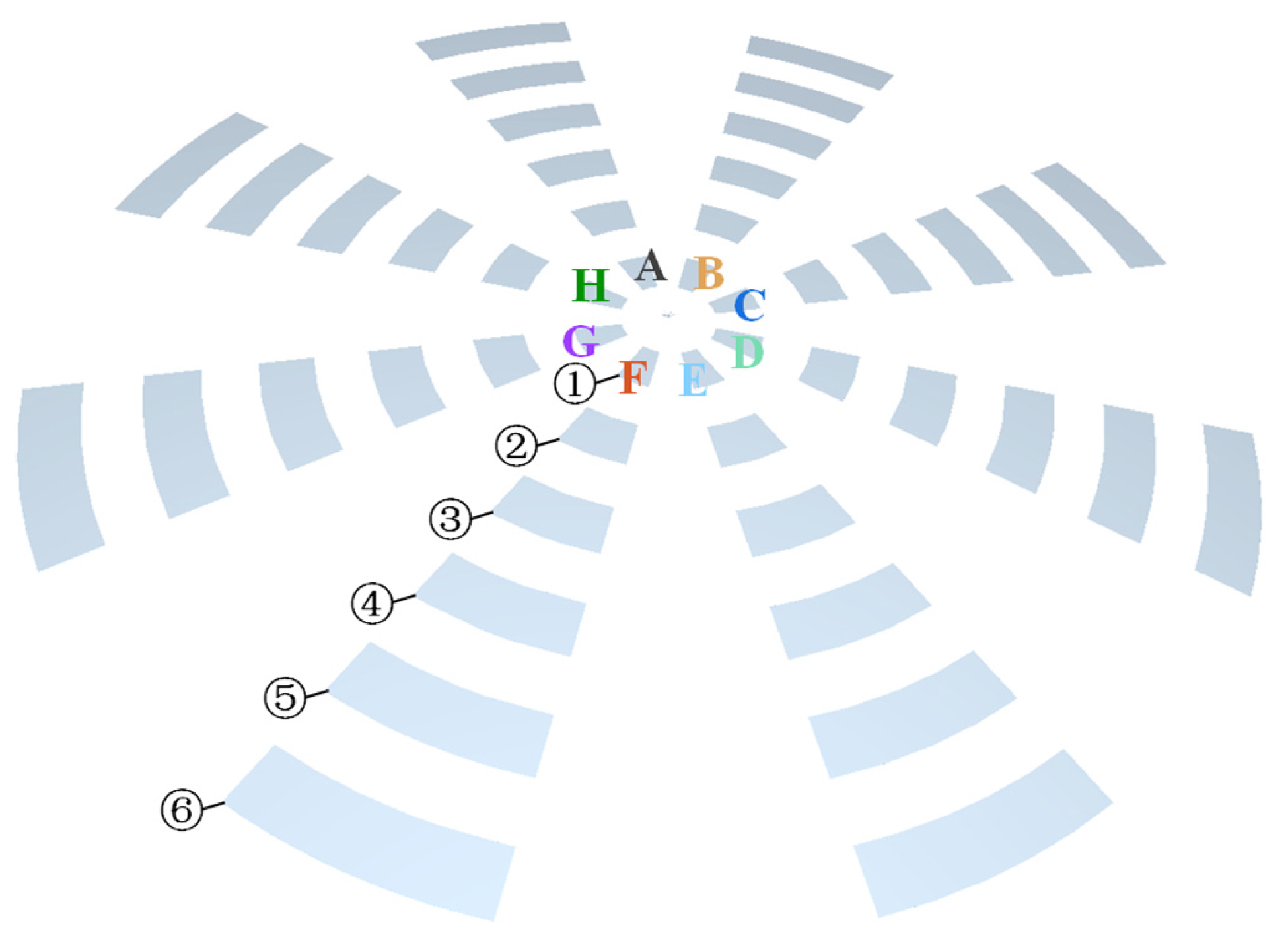

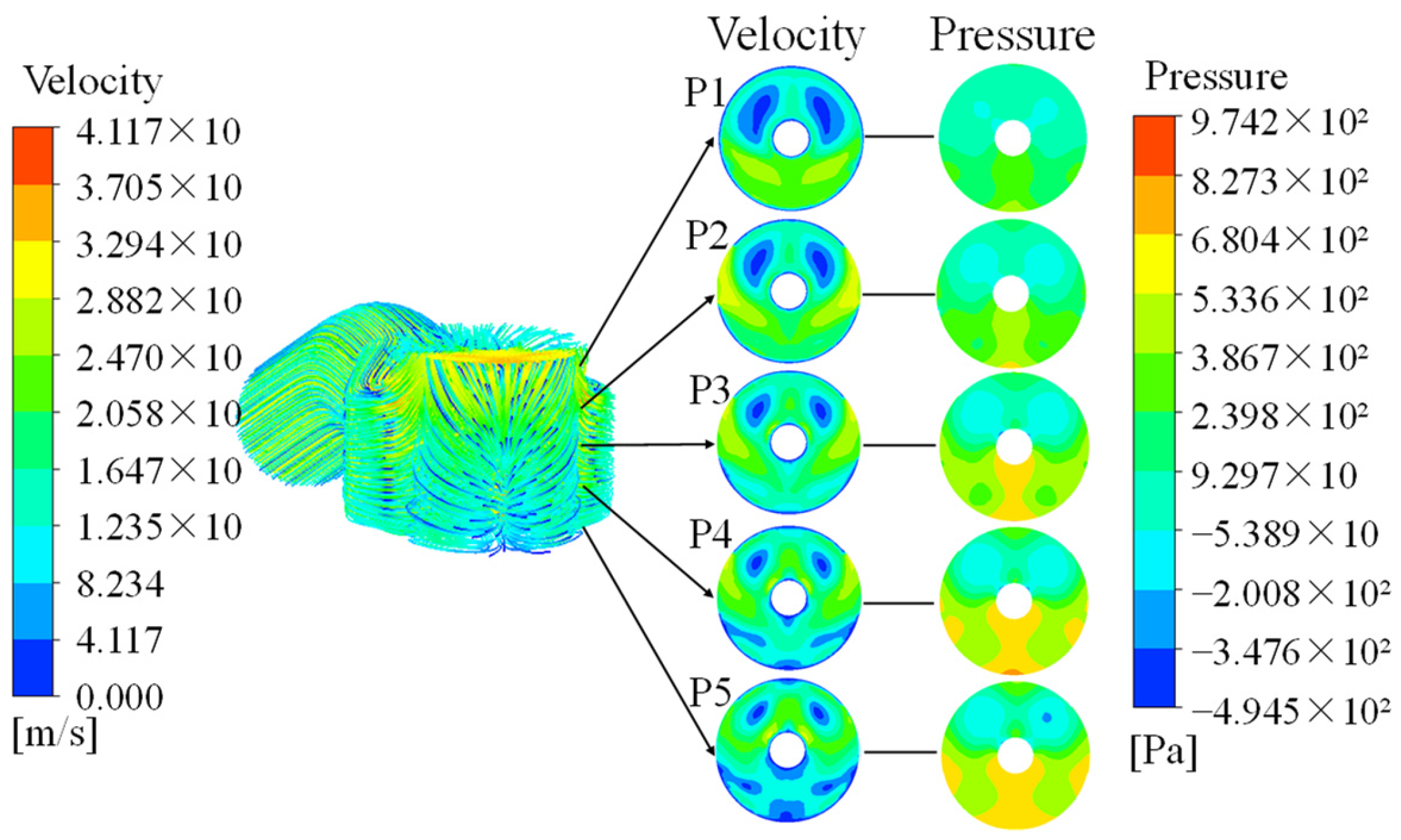

3.1.1. EDEM Particle Simulation Analysis

3.1.2. Analysis of Pellet Distribution Uniformity Results

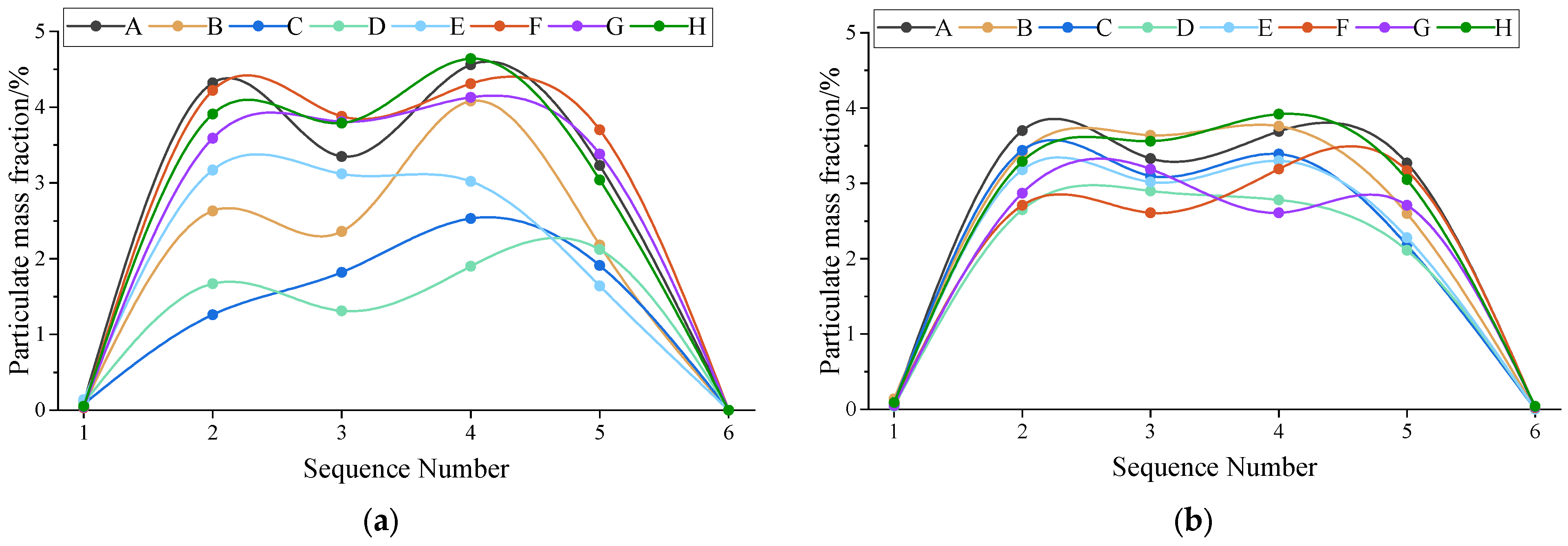

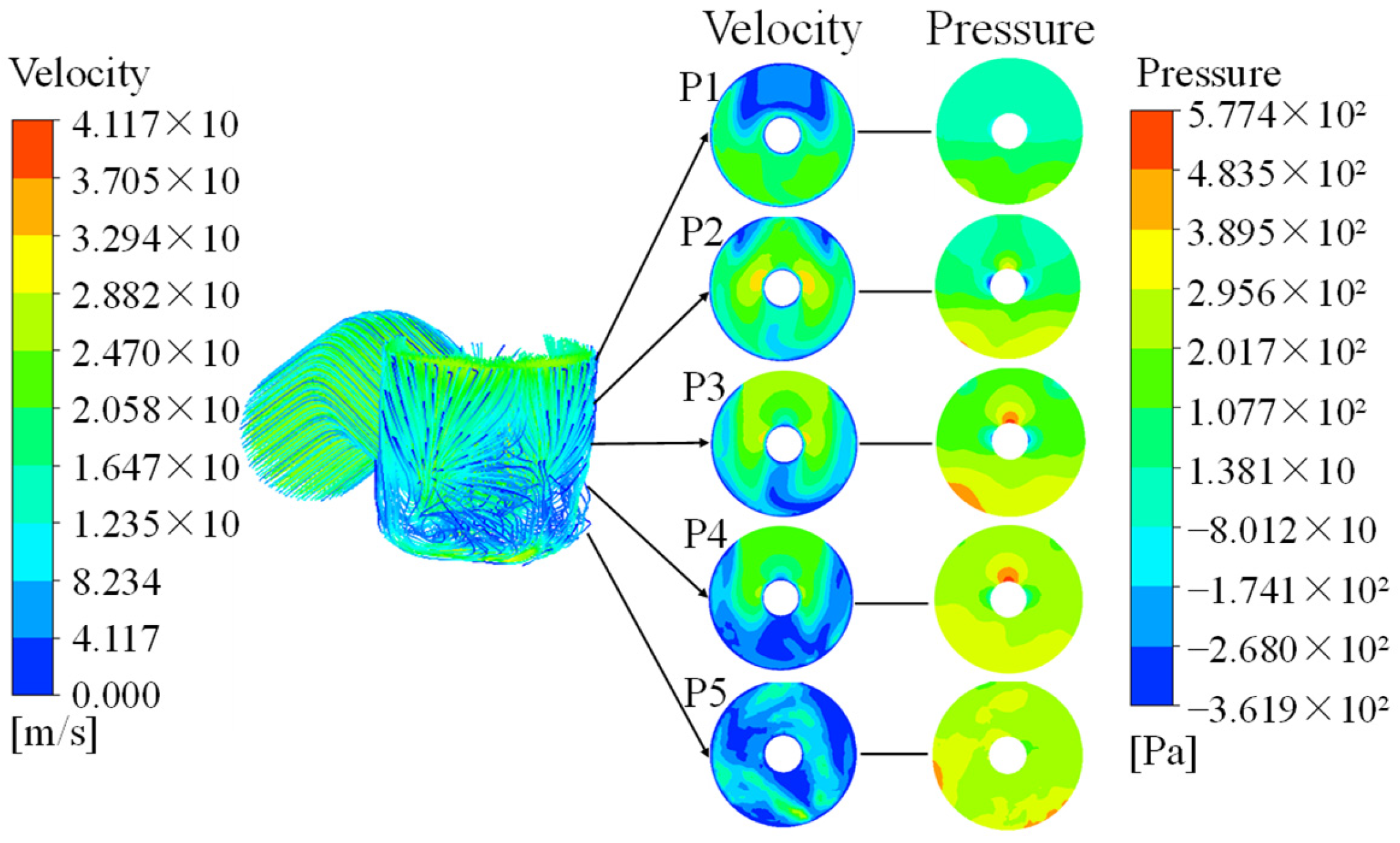

3.1.3. Contour Analysis of Fluid Domain Simulation

3.2. Orthogonal Regression-Based Central Composite Simulation Optimization

3.2.1. Analysis of Experimental Results

3.2.2. Response Surface Analysis

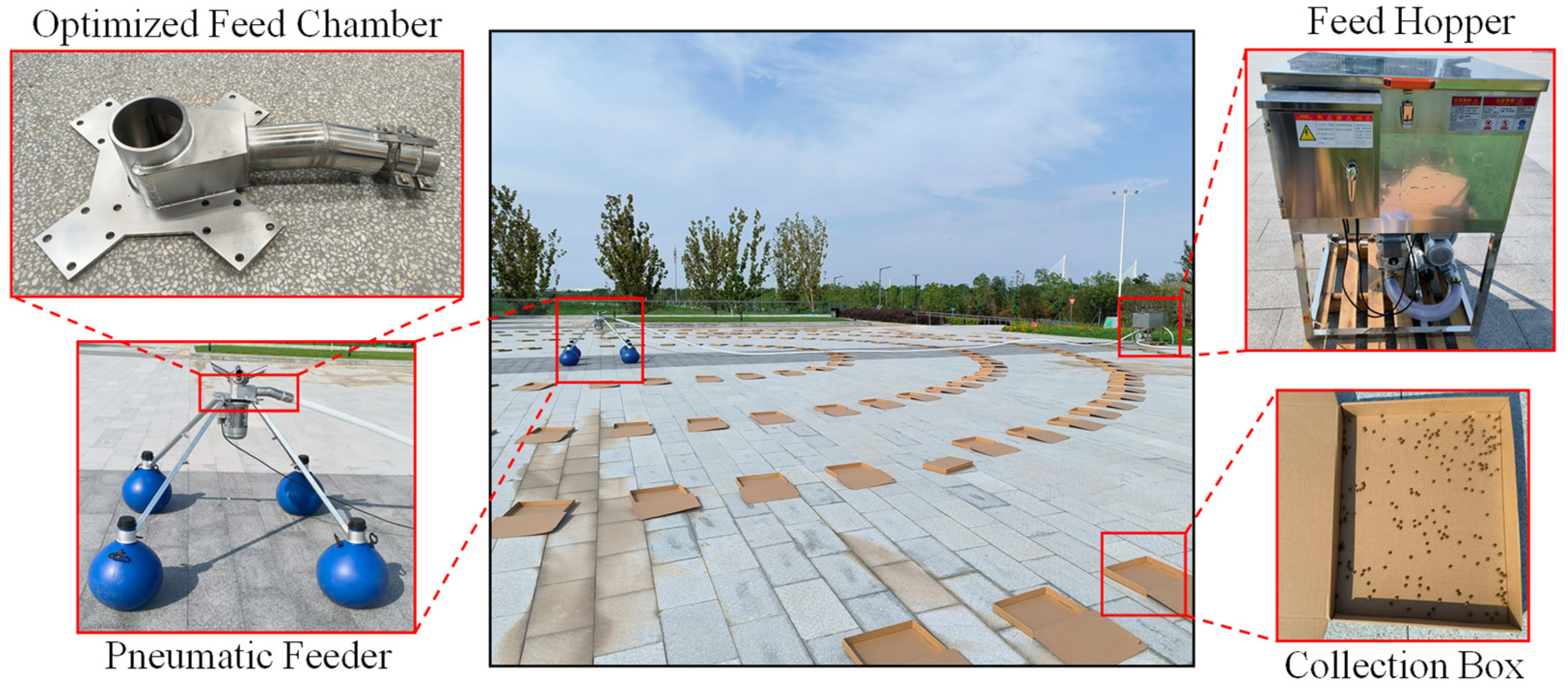

3.3. Experimental Verification

4. Conclusions

- (1)

- The triangular flow-splitter plate design splits and recombines the gas–solid mixed flow within the feed chamber, thereby improving the homogeneity of the flow field. The feeding process of the pneumatic feeder was simulated using the coupled EDEM–Fluent method. Comparative analysis of feeding performance before and after optimization established the efficacy of the structural improvements to the feed chamber.

- (2)

- This study employed a 32-grid computational model to evaluate pellet dispersion uniformity. The results show that the optimized feeder achieved a dispersion of 18.27%, representing a 22.19% improvement in performance over the conventional design. Subsequent central composite design with response surface analysis yielded a prediction for the optimal parameter combination, that is, chamber height = 82.26 mm, splitter width = 61.54 mm, and inlet angle = 44.06°, theoretically predicting a minimum of 15.81%.

- (3)

- Pellets were collected at the test site to validate the actual performance of the pneumatic feeder. The results indicate a of 17.02% under optimal parameter combinations, which is generally in good agreement with the simulation results. This finding verifies the reliability of the feeder simulation and demonstrates that the structural improvements to the feed chamber can significantly enhance the uniformity of pellet dispersion.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, T.X.; Fan, J.J.; Zhang, R.X.; Liu, J.L.; Bai, Z.C.; Sun, J.G. Research on the development situation of aquatic feeding equipment. J. Chin. Agric. Mech. 2024, 45, 45–50. [Google Scholar]

- Royall, R.Q.; Coble, K.F.; Stephens, K.R.; Tokach, M.D.; Woodworth, J.C.; DeRouchey, J.M.; Goodband, R.D.; Gebhardt, J.T.; Karl, J.; Corns, P.J.; et al. Effect of Lactation Feeder Design on Sow and Litter Performance, Feeder Cleaning Criteria, and Economic Return. Transl. Anim. Sci. 2024, 8, txae146. [Google Scholar] [CrossRef] [PubMed]

- Reis, J.; Novriadi, R.; Swanepoel, A.; Guo, J.P.; Rhodes, M.; Davis, D.A. Optimizing Feed Automation: Improving Timer-Feeders and on Demand Systems in Semi-Intensive Pond Culture of Shrimp Litopenaeus vannamei. Aquaculture 2020, 519, 734759. [Google Scholar] [CrossRef]

- Tang, R.; Shen, Y.; Xu, P.; Yang, J.P.; Liu, Y.B.; Liu, X.G. Design and application of the automatic precision feeding system of pond aquaculture. Trans. Chin. Soc. Agric. Eng. 2021, 37, 289–296. [Google Scholar]

- Cubillo, A.M.; Ferreira, J.G.; Robinson, S.M.C.; Pearce, C.M.; Corner, R.A.; Johansen, J. Role of Deposit Feeders in Integrated Multi-Trophic Aquaculture—A Model Analysis. Aquaculture 2016, 453, 54–66. [Google Scholar] [CrossRef]

- Gao, W.P.; Xie, Y.H.; Li, D.T.; Wang, J. Development and Experiment of Automatic Feeding Machine for Breeding Vessels Based on CFD-DEM Coupling. Siliao Gongye 2024, 45, 10–18. [Google Scholar]

- Ramezanzad, A.; Jaradat, K.; Abdelaziz, S. Coupled CFD-DEM Simulations: A Review of Applications and Modeling Limitations. In IFCEE 2024: Earth Retaining Systems, Ground Improvement, and Seepage Control; Moug, D.M., Ed.; Amer Soc Civil Engineers: New York, NY, USA, 2024; Volume 355, pp. 216–226. [Google Scholar]

- Lin, J.J.; Luo, K.; Wang, S.; Hu, C.S.; Fan, J.R. An Augmented Coarse-Grained CFD-DEM Approach for Simulation of Fluidized Beds. Adv. Powder Technol. 2020, 31, 4420–4427. [Google Scholar] [CrossRef]

- Ma, C.C.; Yi, S.J.; Tao, G.X.; Li, Y.F.; Wang, S.; Wang, G.Y.; Gao, F. Research on Receiving Seeds Performance of Belt-Type High-Speed Corn Seed Guiding Device Based on Discrete Element Method. Agriculture 2023, 13, 1085. [Google Scholar] [CrossRef]

- Zhao, S.Q.; DING, W.M.; Zhao, S.Q.; Gu, J.B.; Zhang, J.K. Performance Analysis and Optimization of Pneumatic Fishpond Feeder Based on EDEM—Fluent Coupling. Trans. Chin. Soc. Agric. Mach. 2019, 50, 130–139. [Google Scholar] [CrossRef]

- Yang, Q.L.; Li, Z.H.; Li, H.W.; He, J.; Wang, Q.J. Numerical Analysis of Particle Motion in Pneumatic Centralized Fertilizer Distribution Device Based on CFD DEM. Trans. Chin. Soc. Agric. Mach. 2019, 50, 81–89. [Google Scholar] [CrossRef]

- Wang, L.B.; Yang, H.Y.; Wang, Z.N.; Wang, Q.J.; Lu, C.Y.; Wang, C.; He, J. Calibration of DEM Polyhedron Model for Wheat Seed Based on Angle of Repose Test and Semi-Resolved CFD-DEM Coupling Simulation. Agriculture 2025, 15, 506. [Google Scholar] [CrossRef]

- Chen, X.X.; Hou, T.Y.; Liu, S.L.; Guo, Y.X.; Hu, J.P.; Xu, G.; Ma, G.; Liu, W. Design of a Micro-Plant Factory Using a Validated CFD Model. Agriculture 2024, 14, 2227. [Google Scholar] [CrossRef]

- Shi, G.T.; Yang, X.; Li, B.Y.; Chai, H.Q.; Qin, H. Research on Particle Motion Characteristics in a Spiral-Vane-Type Multiphase Pump Based on CFD-DEM. J. Mar. Sci. Eng. 2025, 13, 845. [Google Scholar] [CrossRef]

- Dong, W.C.; Zhang, X.Y.; Jiang, Z.; Hu, X.; Ge, Y.; Zhang, L.X. Study on Structure Design and Parameter Optimization of Diversion Rifled Feeder Based on CFD-DEM. Agriculture 2025, 15, 351. [Google Scholar] [CrossRef]

- Guo, J.; Roberts, A.W.; Jones, M.; Robinson, P. Bulk Solids Flow at the Hopper Feeder Interface with Special Plane Flow Configuration. Powder Technol. 2022, 403, 117372. [Google Scholar] [CrossRef]

- Hu, Y.; Huang, X.H.; Tao, Q.Y.; Yuan, T.P.; Wang, S.M.; Liu, H.Y. Simulation of automatic pneumatic conveying process of automatic feeding system based on computational fluid dynamics-discrete element method. South China Fish. Sci. 2019, 15, 113–119. [Google Scholar] [CrossRef]

- Hu, Y.H.; Chen, L.K.; Liu, Z.H.; Ma, H.Q.; Zhou, L.Y.; Zhao, Y.Z. CFD-DEM Modeling and Experimental Verification of Heat Transfer Behaviors of Cylindrical Biomass Particles with Super-Ellipsoid Model. Energies 2025, 18, 1504. [Google Scholar] [CrossRef]

- Razavi, F.; Komrakova, A.; Lange, C.F. CFD–DEM Simulation of Sand-Retention Mechanisms in Slurry Flow. Energies 2021, 14, 3797. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Ma, C.Y.; Zhao, C.; Zheng, Z.; Li, W.; Liu, R.; Li, X.; Wang, H. Diffusion Mechanism in Running-Water and CFD-DEM Numerical Simulation of Expandable Particulate Grouting Material. Materials 2025, 18, 1681. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, S.H.; Shang, F.; Ge, Z.W.; Guo, L.J. Numerical Simulation of Particle Jet in Supercritical Water Environment Based on an Improved Coarse-Grained CFD-DEM Method. Powder Technol. 2025, 456, 120833. [Google Scholar] [CrossRef]

- Bai, S.H.; Yuan, Y.W.; Niu, K.; Zhou, L.M.; Zhao, B.; Wei, L.G.; Liu, L.J.; Xiong, S.; Shi, Z.L.; Ma, Y.H.; et al. Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering. Agriculture 2022, 12, 870. [Google Scholar] [CrossRef]

- Peng, F.; Zhang, L.M.; Li, Z.Q.; Chen, J.M. Calibration and Verification of DEM Parameters of Wet-Sticky Feed Raw Materials. Sci. Rep. 2023, 13, 9246. [Google Scholar] [CrossRef]

- Huang, H.N.; Zhang, Y.; Wang, D.F.; Fu, Z.J.; Tian, H.; Shang, J.; Helal, M.; Lv, Z. Study the Flow Capacity of Cylindrical Pellets in Hopper with Unloading Paddle Using DEM. Agriculture 2024, 14, 523. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Z.; Zhang, N.; Zhao, H.Y.; Liu, L.; Huang, K.P.; Chen, X. Local Scour Mechanism of Offshore Wind Power Pile Foundation Based on CFD-DEM. J. Mar. Sci. Eng. 2022, 10, 1724. [Google Scholar] [CrossRef]

- Ma, Q.Y.; Shi, Y.H.; Xu, Z.F.; Ma, D.D.; Huang, K. Research on a Multivariate Non-Linear Regression Model of Dynamic Mechanical Properties for the Alkali-Activated Slag Mortar with Rubber Tire Crumb. Case Stud. Constr. Mater. 2022, 17, e01371. [Google Scholar] [CrossRef]

- Alzaatreh, A.; Aljarrah, M.; Almagambetova, A.; Zakiyeva, N. On the Regression Model for Generalized Normal Distributions. Entropy 2021, 23, 173. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.J.; Wang, M.X.; Wu, G.Z.; Wu, L.; Ouyang, J.F.; Song, Z.J. Optimization of the Structure of a Grain Particle Gas-Solid Mixer Based on a CFD-DEM Orthogonal Experiment. J. Mech. Sci. Technol. 2025, 39, 2089–2098. [Google Scholar] [CrossRef]

| Parameter | Pellet Feed | Feeding Device |

|---|---|---|

| Poisson’s ratio | 0.23 | 0.3 |

| Density/(kg·m−3) | 1200 | 7800 |

| Shear modulus/(MPa) | 9.74 | 70,000 |

| Coefficient of restitution (w/feeder) | 0.35 | 0.39 |

| Static friction coefficient (w/feeder) | 0.34 | 0.17 |

| Rolling friction coefficient (w/feeder) | 0.16 | 0.02 |

| Coding | Factors | ||

|---|---|---|---|

| /mm | /mm | /(°) | |

| −1.68179 | 70 | 50 | 35 |

| −1 | 74 | 54 | 38 |

| 0 | 80 | 60 | 42.5 |

| 1 | 86 | 66 | 47 |

| 1.68179 | 90 | 70 | 50 |

| Run | Factor | |||

|---|---|---|---|---|

| /mm | /mm | /(°) | ||

| 1 | 80 | 60 | 42.5 | 16.39 |

| 2 | 86 | 66 | 47 | 18.35 |

| 3 | 70 | 60 | 42.5 | 22.24 |

| 4 | 80 | 60 | 50 | 17.57 |

| 5 | 74 | 54 | 38 | 24.81 |

| 6 | 80 | 60 | 42.5 | 17.02 |

| 7 | 74 | 54 | 47 | 21.8 |

| 8 | 86 | 54 | 47 | 18.24 |

| 9 | 80 | 60 | 42.5 | 15.89 |

| 10 | 80 | 60 | 42.5 | 17.19 |

| 11 | 80 | 60 | 35 | 23.87 |

| 12 | 80 | 70 | 42.5 | 17.95 |

| 13 | 90 | 60 | 42.5 | 17.13 |

| 14 | 86 | 66 | 38 | 20.91 |

| 15 | 80 | 60 | 42.5 | 16.67 |

| 16 | 74 | 66 | 38 | 20.38 |

| 17 | 80 | 60 | 42.5 | 16.07 |

| 18 | 80 | 50 | 42.5 | 21.34 |

| 19 | 74 | 66 | 47 | 19.86 |

| 20 | 86 | 54 | 38 | 22.3 |

| Source | Sum of Squares | df | Mean Square | F | p |

|---|---|---|---|---|---|

| Model | 136.95 | 9 | 15.22 | 29.41 | <0.0001 |

| 17.81 | 1 | 17.81 | 34.41 | 0.0002 | |

| 13.15 | 1 | 13.15 | 25.41 | 0.0005 | |

| 31.66 | 1 | 31.66 | 61.19 | <0.0001 | |

| 3.18 | 1 | 3.18 | 6.14 | 0.0327 | |

| 1.23 | 1 | 1.23 | 2.38 | 0.1538 | |

| 2.04 | 1 | 2.04 | 3.94 | 0.0752 | |

| 22.14 | 1 | 22.14 | 42.79 | <0.0001 | |

| 21.64 | 1 | 21.64 | 41.82 | <0.0001 | |

| 37.14 | 1 | 37.14 | 71.78 | <0.0001 | |

| Residual | 5.17 | 10 | 0.5175 | ||

| Lack of Fit | 3.87 | 5 | 0.7733 | 2.96 | 0.1297 |

| Pure Error | 1.31 | 5 | 0.2617 | ||

| Cor Total | 142.13 | 19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Xu, W.; Li, D.; Zheng, H.; Li, H.; Wang, B.; Xiao, M. Optimization and Verification of the Spreading Performance of a Pneumatic Pond Feeder Using a Coupled CFD–DEM Approach. J. Mar. Sci. Eng. 2025, 13, 1731. https://doi.org/10.3390/jmse13091731

Zhu Y, Xu W, Li D, Zheng H, Li H, Wang B, Xiao M. Optimization and Verification of the Spreading Performance of a Pneumatic Pond Feeder Using a Coupled CFD–DEM Approach. Journal of Marine Science and Engineering. 2025; 13(9):1731. https://doi.org/10.3390/jmse13091731

Chicago/Turabian StyleZhu, Yejun, Weixiong Xu, Dongfang Li, He Zheng, Hongran Li, Bingqing Wang, and Maohua Xiao. 2025. "Optimization and Verification of the Spreading Performance of a Pneumatic Pond Feeder Using a Coupled CFD–DEM Approach" Journal of Marine Science and Engineering 13, no. 9: 1731. https://doi.org/10.3390/jmse13091731

APA StyleZhu, Y., Xu, W., Li, D., Zheng, H., Li, H., Wang, B., & Xiao, M. (2025). Optimization and Verification of the Spreading Performance of a Pneumatic Pond Feeder Using a Coupled CFD–DEM Approach. Journal of Marine Science and Engineering, 13(9), 1731. https://doi.org/10.3390/jmse13091731