Numerical Study of the Negative Skin Friction (NSF) of Large-Diameter Rock-Socketed Monopiles for Offshore Wind Turbines Incorporating Lateral Loading Effects

Abstract

1. Introduction

2. Finite Element Model Development and Verification

2.1. Modelling Methodology

2.1.1. Soil and Monopile

2.1.2. Pile–Soil Interaction

2.1.3. Surcharge Load

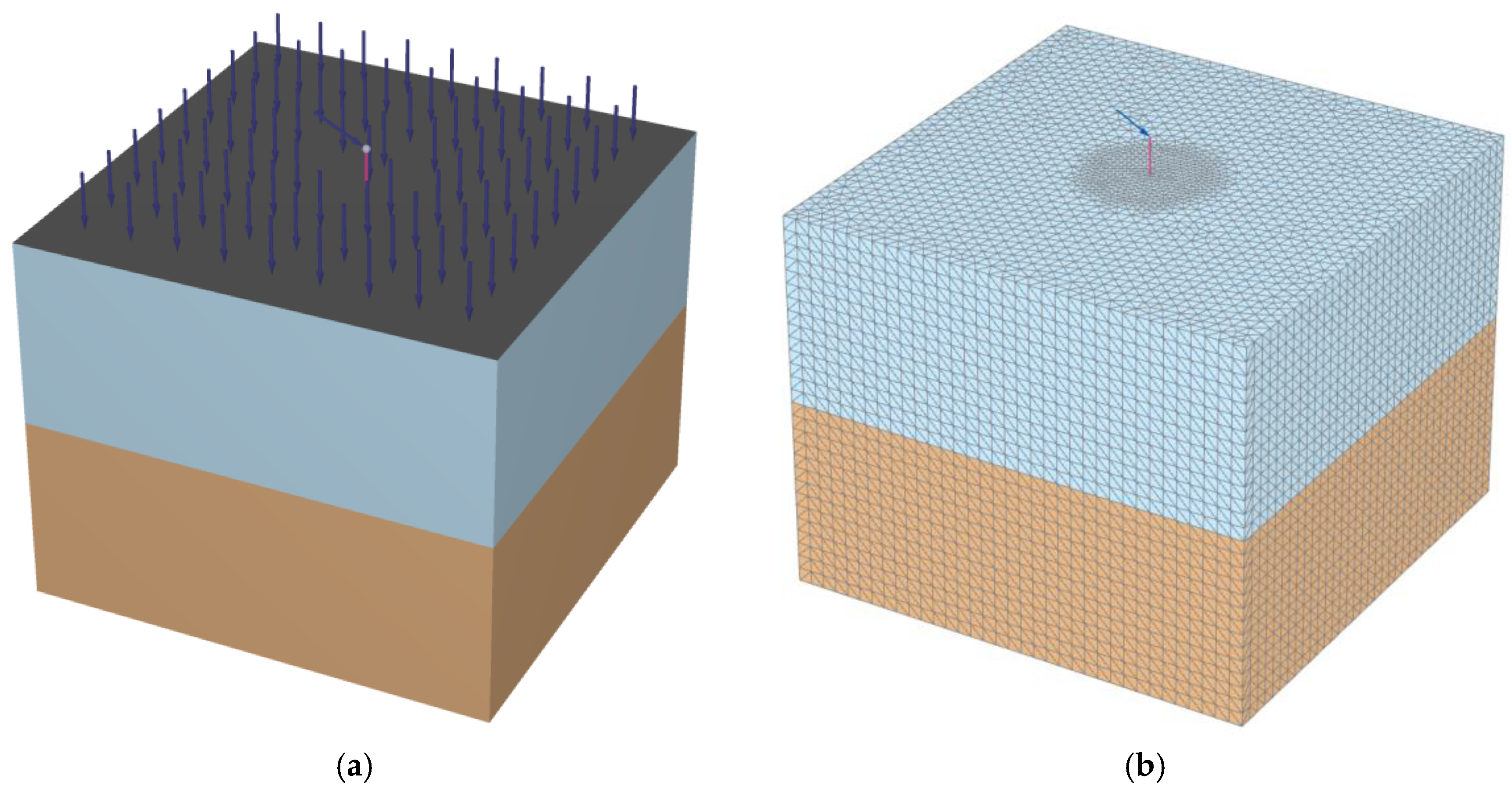

2.1.4. Model Domain and Mesh

2.2. Model Validation

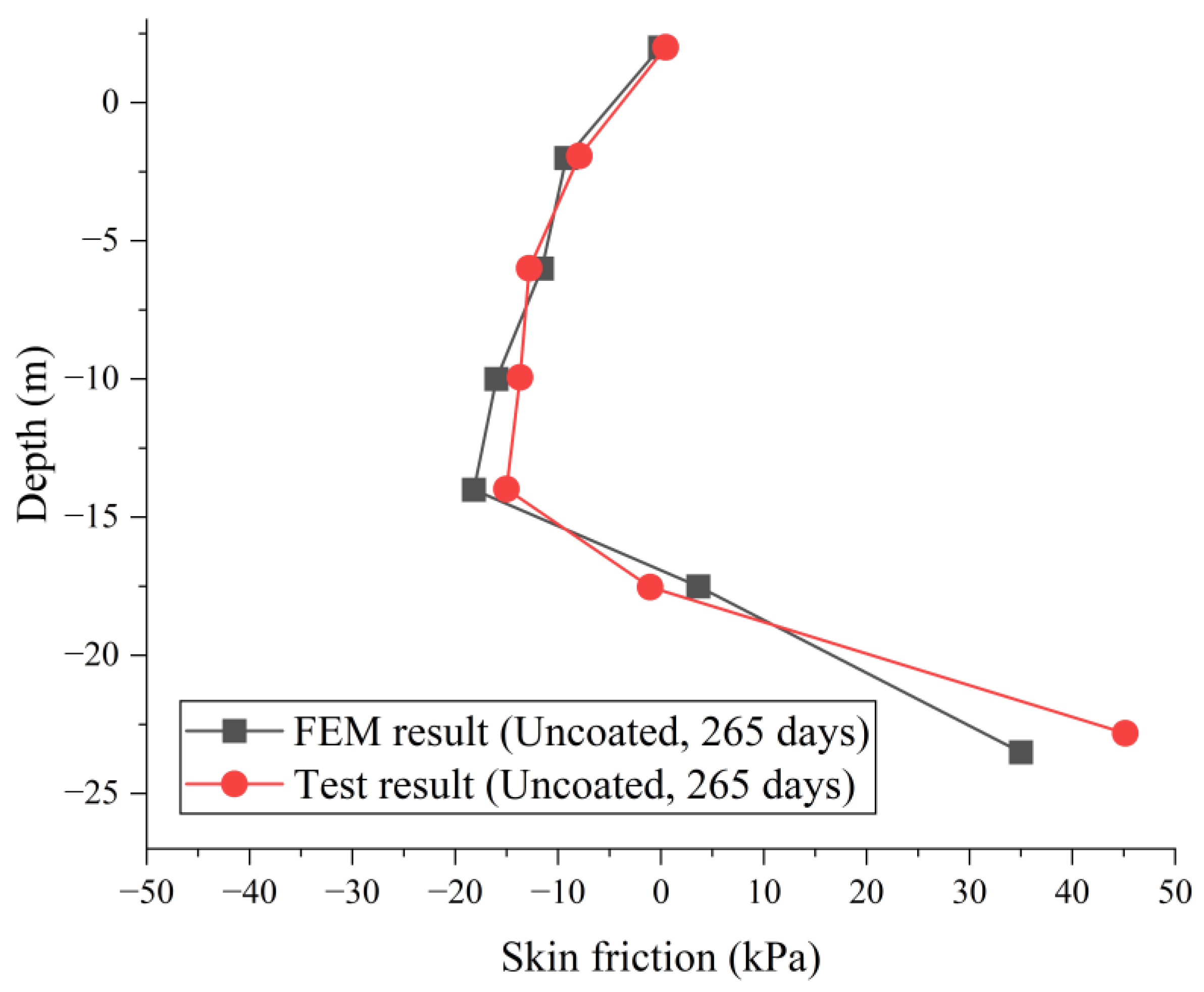

2.2.1. Negative Skin Friction

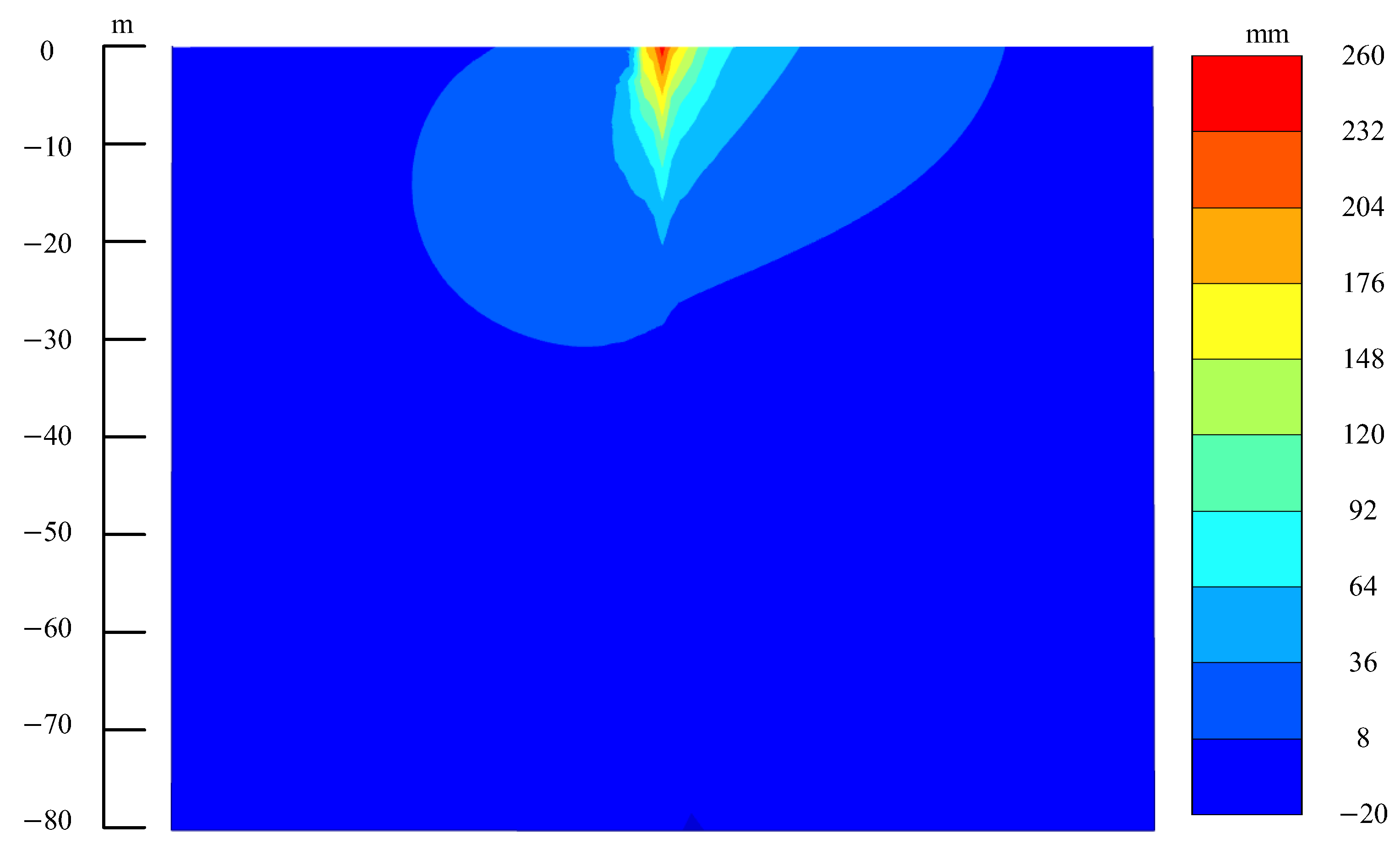

2.2.2. Horizontally Loaded Monopile

3. Numerical Model for Coupled Analysis of Horizontally Loaded Piles and NSF

4. NSF in Large-Diameter Rock-Socketed Monopiles Under Horizontal Loading

5. Parametric Analysis

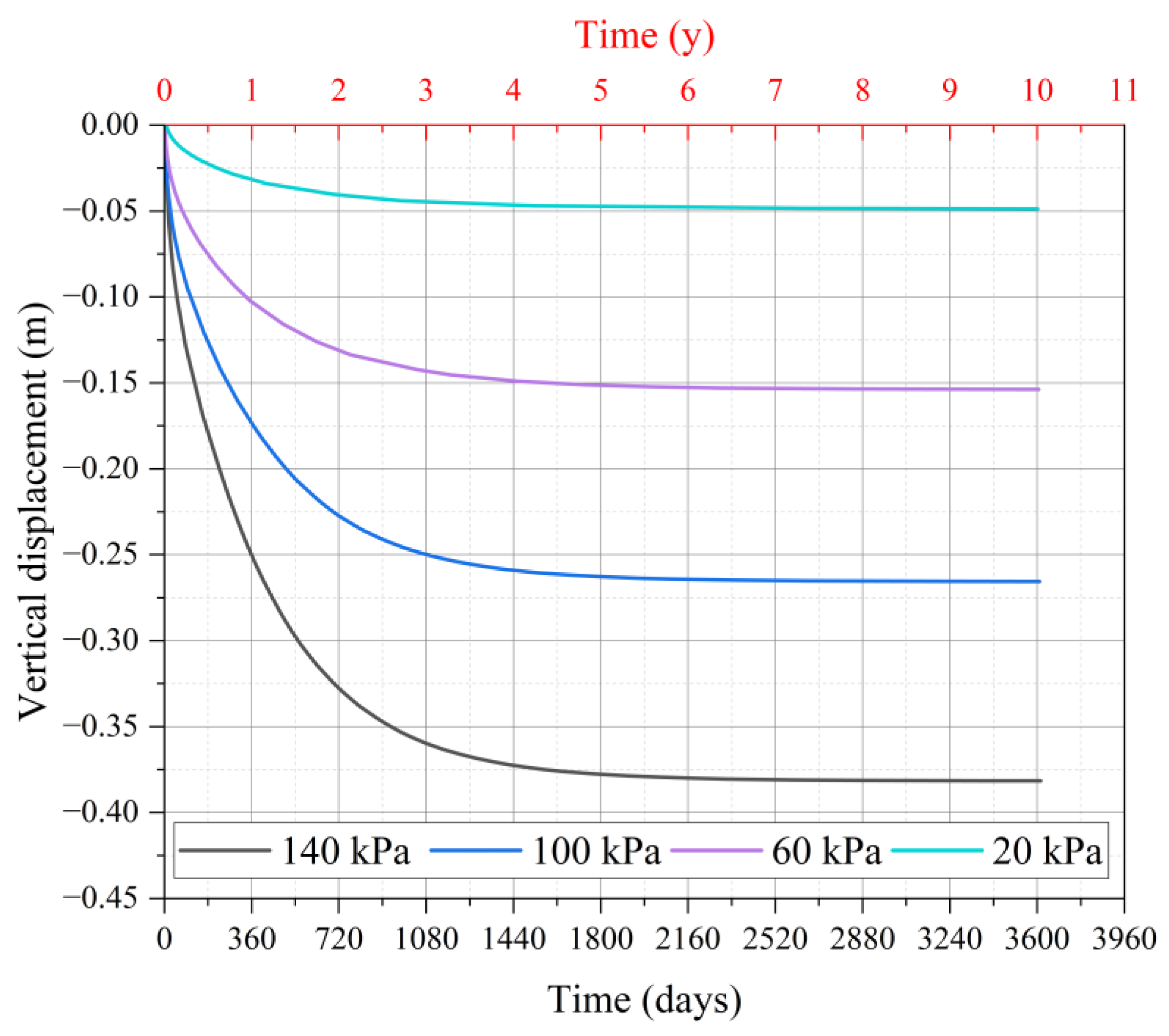

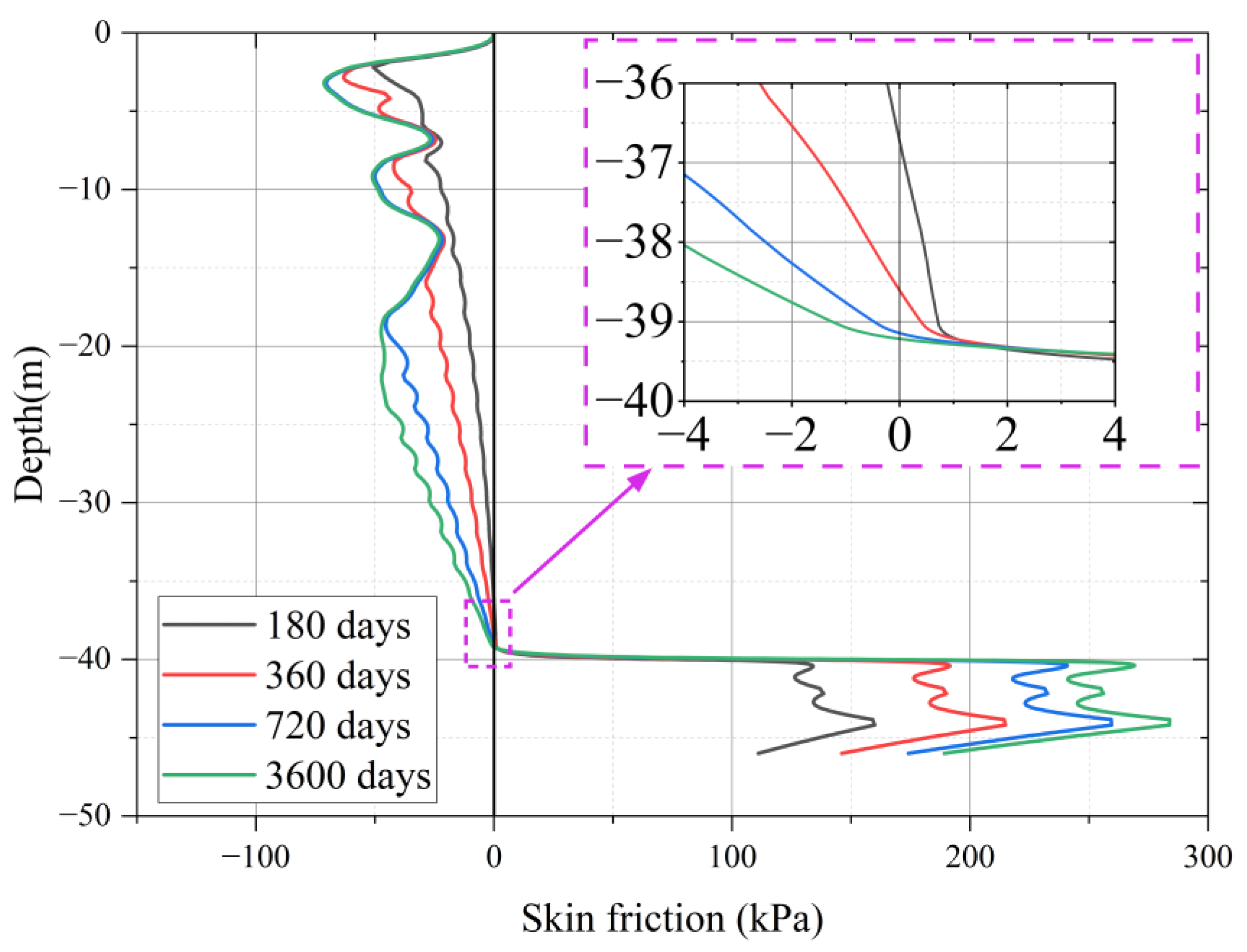

5.1. Effect of Consolidation Time on NSF

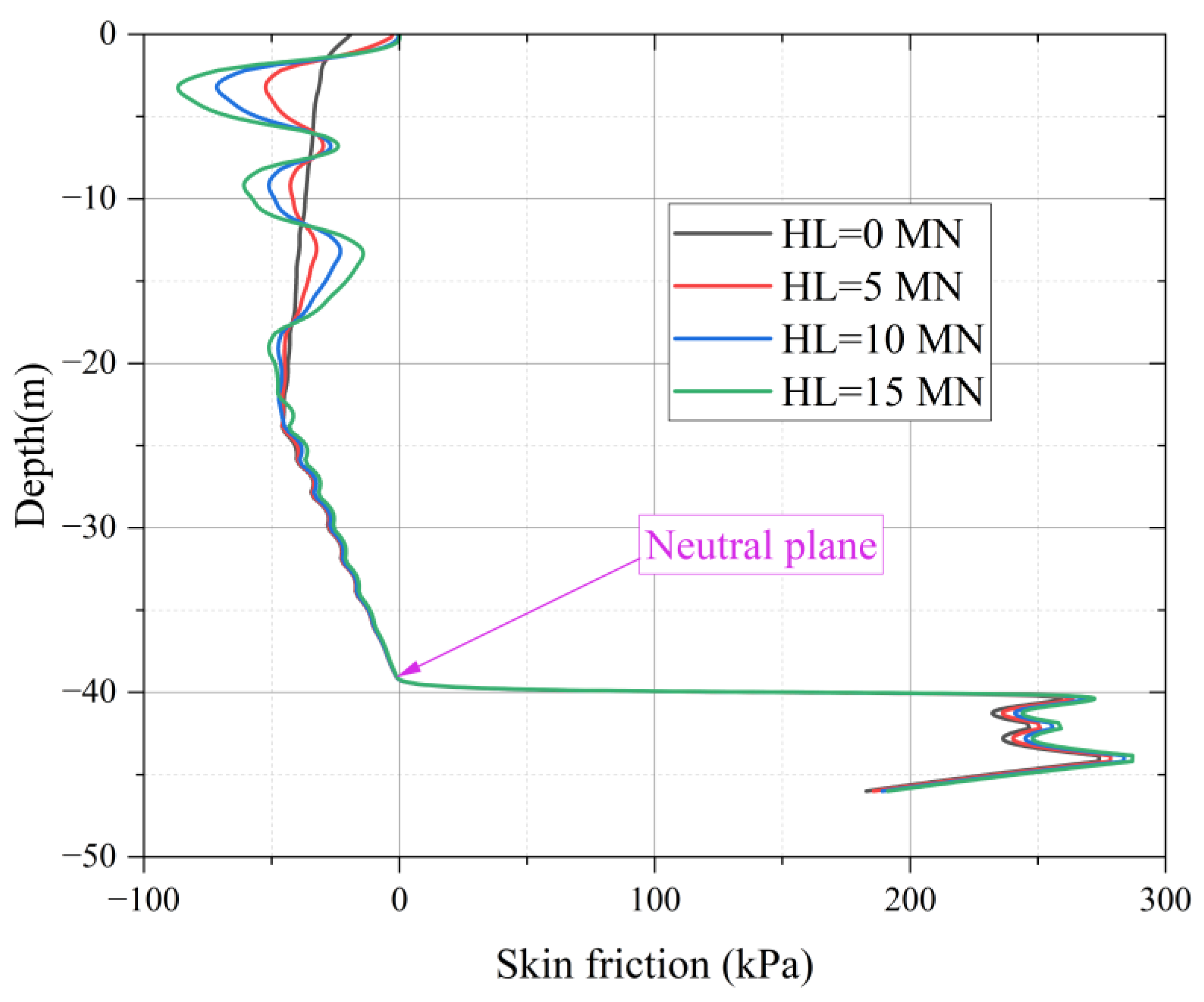

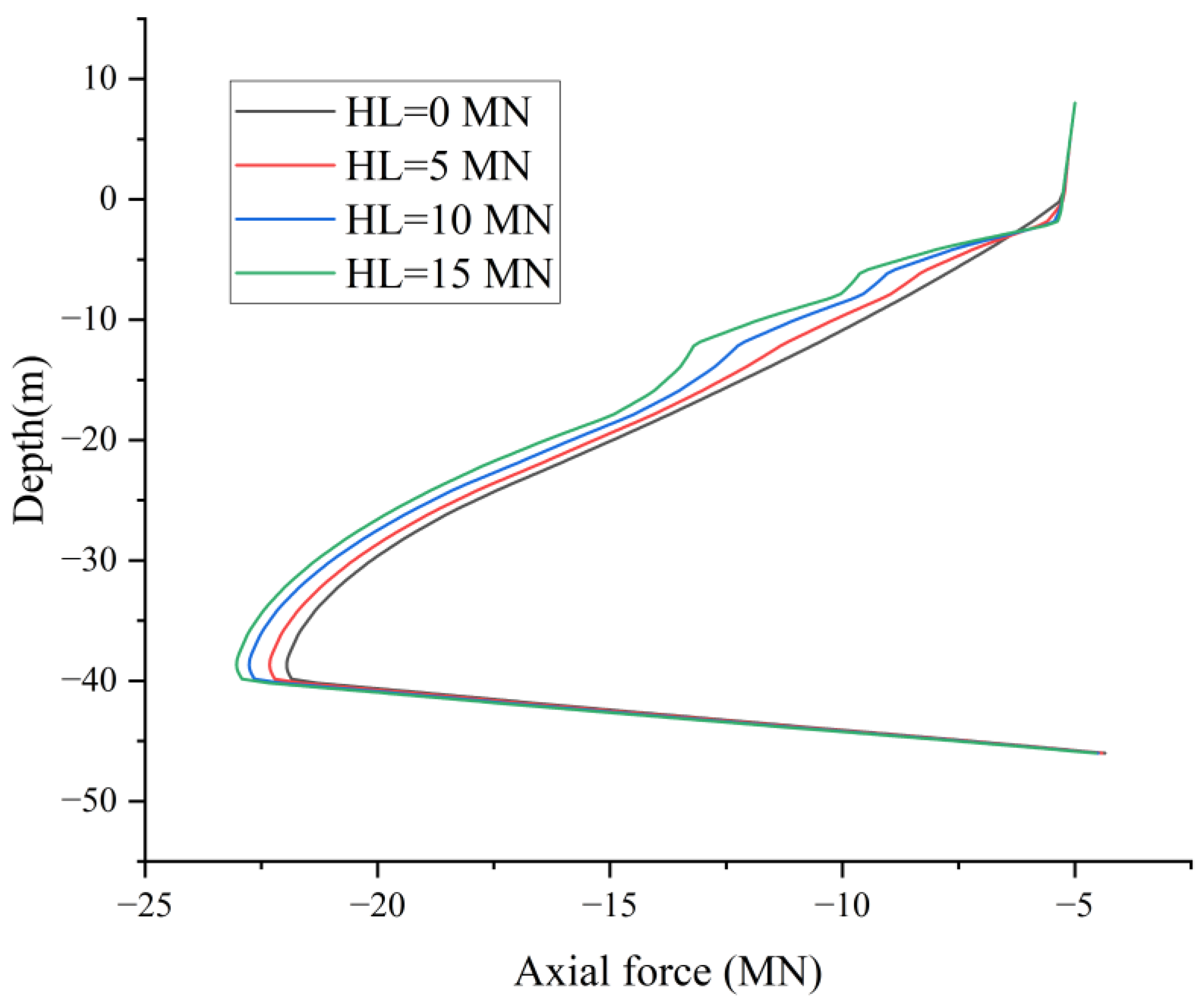

5.2. Effect of Horizontal Load on NSF

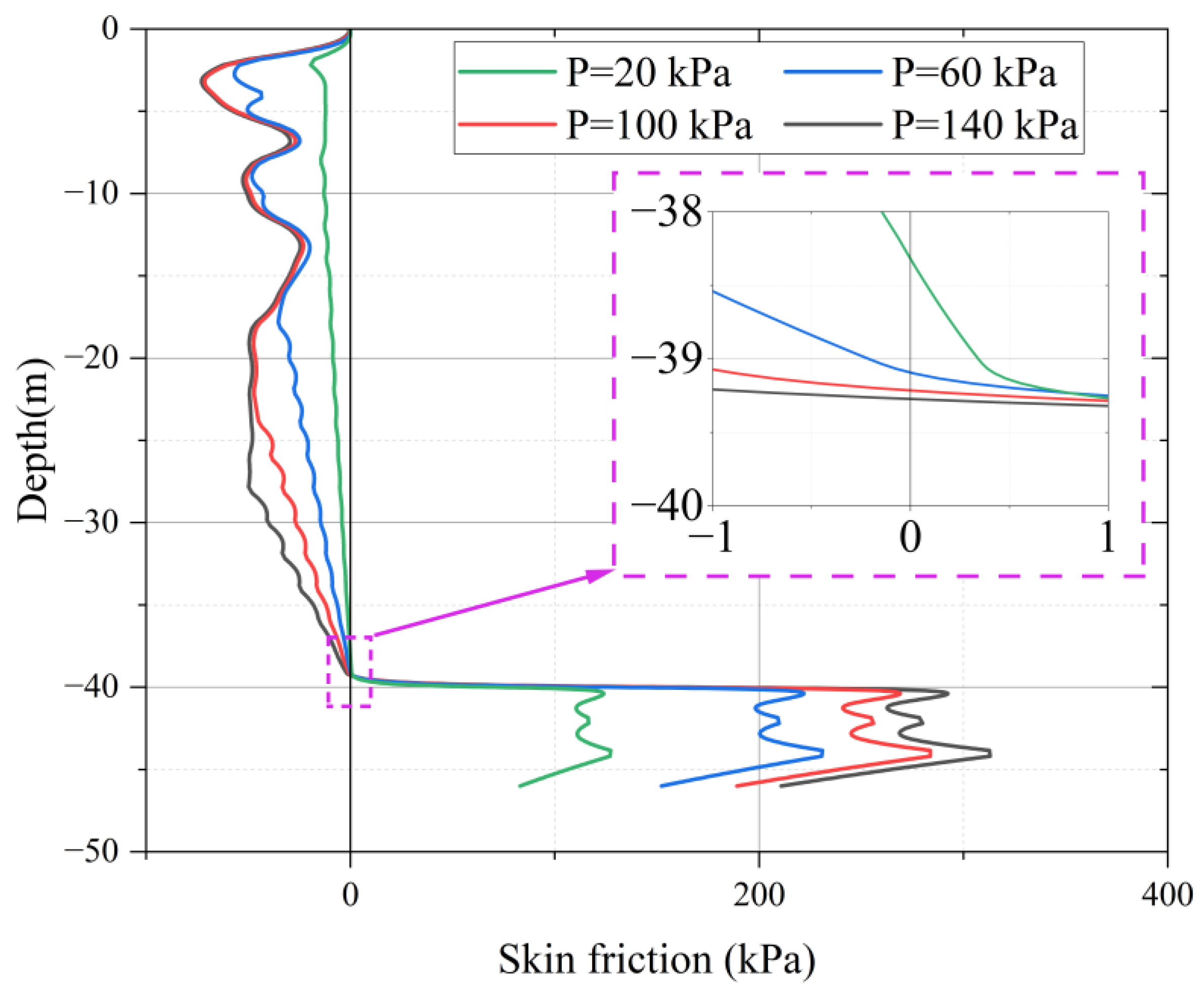

5.3. Effect of Overload on NSF

6. Conclusions

- (1)

- Dual validation against independent case studies—comprising NSF development under surcharge loading and horizontal response of piles—established a finite element model capable of accurately capturing pile–soil interaction mechanisms. This model provides an effective predictive tool for pile foundation NSF under complex loading conditions.

- (2)

- Horizontal load reshapes the distribution morphology of negative skin friction within the upper segment of the pile shaft. Horizontal pile head loads transform the NSF profile from a smooth curve (under pure vertical loading) into a bimodal distribution with distinct peaks and troughs in the upper clay layer (0 to −24 m). The maximum NSF magnitude increases by ~57% (from −45.4 kPa to −71.5 kPa).

- (3)

- Prolonged consolidation significantly amplifies negative skin friction (NSF) and drag load, increasing the maximum axial force by 84% (12.5 MN to 23 MN) from 180 to 3600 days. The neutral plane deepens from −36.5 m to −39.5 m due to progressive stress transfer to lower clay strata, while NSF stabilizes in upper clay (>720 days) but continues growing in deeper zones.

- (4)

- Horizontal loading transforms upper-segment NSF (0 to −20 m) into a bimodal distribution with linearly increasing peak values. Crucially, it leaves lower-layer NSF and the neutral plane depth (−39 m) unaffected, confirming horizontal loads primarily reshape shallow NSF patterns.

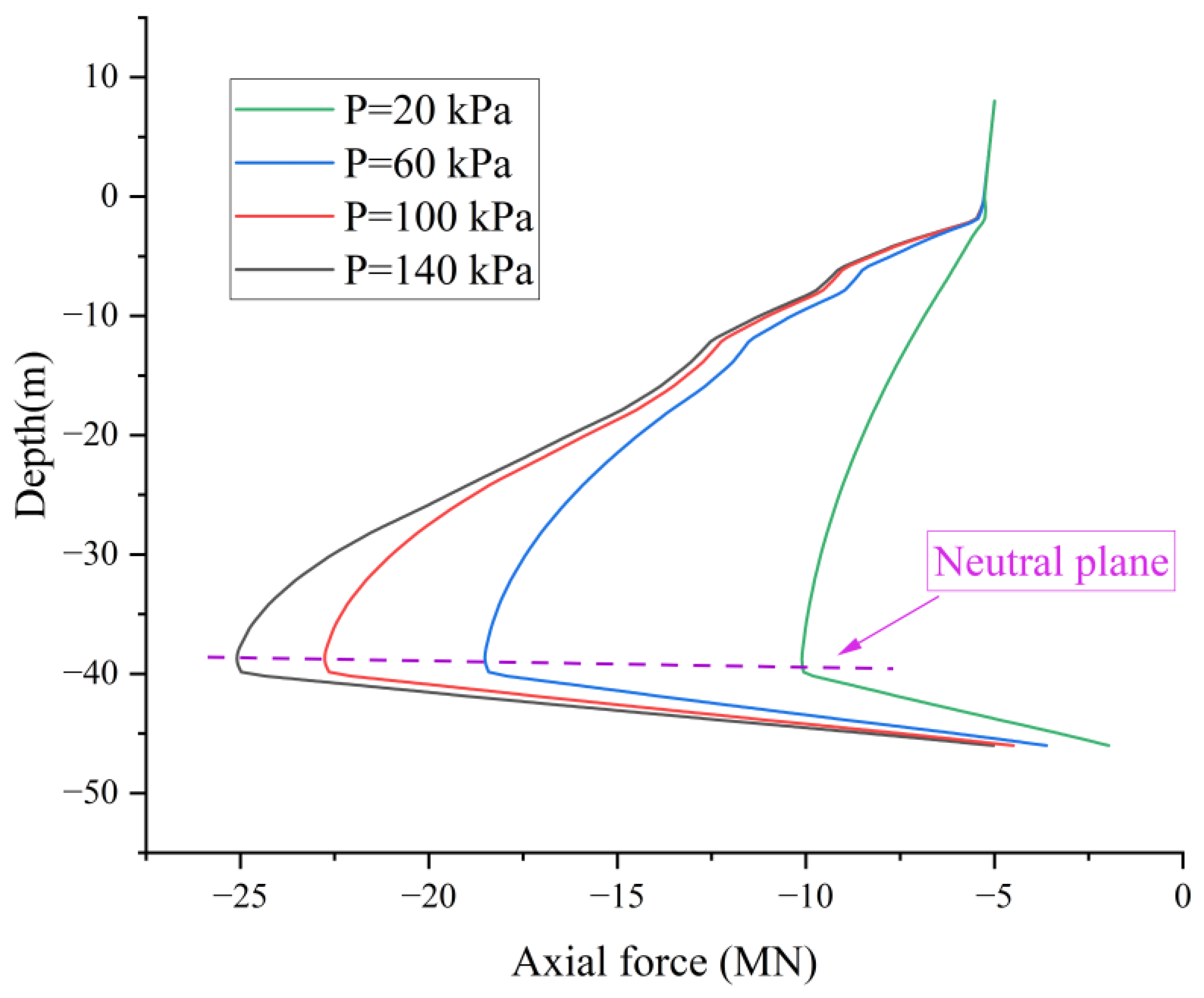

- (5)

- The magnitude of surcharge loading governs both the development and spatial distribution of NSF. While NSF increases throughout the clay layer (0 to −40 m) with higher surcharges (20–140 kPa), its response exhibits distinct depth-dependent saturation: in the upper clay stratum (0 to −18 m), NSF peaks saturate beyond 100 kPa, stabilizing near 72.8 kPa; conversely, in the deeper clay (−18 m to −39 m), NSF continues to rise with surcharge magnitude as stresses propagate downward.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Díaz, H.; Soares, C.G. Review of the current status, technology and future trends of offshore wind farms. Ocean Eng. 2020, 209, 107381. [Google Scholar] [CrossRef]

- Jeong, S.; Ko, J.; Lee, C.; Kim, J. Response of single piles in marine deposits to negative skin friction from long-term field monitoring. Mar. Georesources Geotechnol. 2014, 32, 239–263. [Google Scholar] [CrossRef]

- He, R.; Ji, J.; Zhang, J.; Peng, W.; Sun, Z.; Guo, Z. Dynamic Impedances of Offshore Rock-Socketed Monopiles. J. Mar. Sci. Eng. 2019, 7, 134. [Google Scholar] [CrossRef]

- He, R.; Zhu, T.; Ma, B.; Guo, Z. Lateral static stiffness of offshore monopile socketed in soft rock. Mar. Struct. 2022, 86, 103302. [Google Scholar] [CrossRef]

- Gan, M.; Huang, L.; You, S.; Hua, Y.; Pan, Y.; Deng, J.; Wang, K. Monitoring coastal land reclamation and land use change around Hangzhou Bay using Landsat dataset (1970s–2014). In Proceedings of the Land Surface Remote Sensing II, Beijing, China, 13–16 October 2014; pp. 734–743. [Google Scholar]

- Huang, F.; Chen, Z.; Deng, H.; Zhu, W. Lateral Deformation Mechanisms of Piles in Coastal Regions Under Seawall Surcharge Loading and Mitigation Using Deep Cement Mixing (DCM) Piles. Buildings 2025, 15, 1936. [Google Scholar] [CrossRef]

- Chen, Z.; Deng, H.; Dai, G.; Zhu, M.; Gong, W.; Azadi, M.R. Study on the influence of unsymmetrical surcharge on adjacent pile foundations in a coastal soft soil area. Soil Dyn. Earthq. Eng. 2025, 194, 109365. [Google Scholar] [CrossRef]

- Yan, Y.; Dai, G.; Chen, Z.; Hu, T.; Gong, W.; Shi, C. Experimental Study of Negative Skin Friction of Pile Group Foundations for Offshore Wind Turbines on Artificial Islands. J. Mar. Sci. Eng. 2024, 12, 1386. [Google Scholar] [CrossRef]

- Carrubba, P. Skin friction on large-diameter piles socketed into rock. Can. Geotech. J. 1997, 34, 230–240. [Google Scholar] [CrossRef]

- Ren, Y.-x.; Li, Y.; Cui, W.; Guo, W.; Zhuang, D.; Cui, S.; Zhang, L. Analysis of negative skin friction and bending moment on batter rock-socketed pile. Mar. Georesources Geotechnol. 2024, 42, 927–944. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Z.; Zhang, Y.; El Naggar, M.H.; Wu, T.; Wen, M. Semi-analytical solution for negative skin friction development on deep foundations in coastal reclamation areas. Int. J. Mech. Sci. 2023, 241, 107981. [Google Scholar] [CrossRef]

- Poulos, H. Piles subjected to negative friction: A procedure for design. Geotech. Eng. 1997, 28, 23–44. [Google Scholar]

- Jiang, C.; Shi, Z.; Pang, L. Analytical Solution for Negative Skin Friction in Offshore Wind Power Pile Foundations on Artificial Islands under the Influence of Soil Consolidation. J. Mar. Sci. Eng. 2023, 11, 1071. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Y.-K. Calculation and analysis of negative skin of monopile applied for offshore wind turbine. Mar. Georesources Geotechnol. 2017, 35, 275–280. [Google Scholar] [CrossRef]

- Indraratna, B.; Balasubramaniam, A.; Phamvan, P.; Wong, Y. Development of negative skin friction on driven piles in soft Bangkok clay. Can. Geotech. J. 1992, 29, 393–404. [Google Scholar] [CrossRef]

- El-Mossallamy, Y.M.; Hefny, A.M.; Demerdash, M.A.; Morsy, M.S. Numerical analysis of negative skin friction on piles in soft clay. HBRC J. 2013, 9, 68–76. [Google Scholar] [CrossRef]

- Alielahi, H.; Rad, M.A.; Derakhshan, A. 3D Numerical Modeling of Negative Skin Friction Effects on Tapered Piles in Soft Soils. Indian Geotech. J. 2025, 55, 1031–1043. [Google Scholar] [CrossRef]

- Leung, C.F.; Liao, B.K.; Chow, Y.K.; Shen, R.F.; Kog, Y.C. Behavior of Pile Subject to Negative Skin Friction and Axial Load. Soils Found. 2004, 44, 17–26. [Google Scholar] [CrossRef]

- Shen, K.; Wang, K.; Yao, J.; Yu, J. Numerical Investigation on Behavior of Compressive Piles in Coastal Tidal Flat with Fill. J. Mar. Sci. Eng. 2022, 10, 1742. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, T.; Zhang, J.; Liu, Z.; Cheng, W. Finite element analysis of cyclic lateral responses for large diameter monopiles in clays under different loading patterns. Comput. Geotech. 2021, 134, 104104. [Google Scholar] [CrossRef]

- Liu, R.; Shi, J.; Chen, G.; Yang, X. Lateral bearing capacity and calculation method of pile-bucket foundation in clay for offshore wind turbines. Ocean Eng. 2023, 283, 115039. [Google Scholar] [CrossRef]

- Li, Q.; Prendergast, L.J.; Askarinejad, A.; Gavin, K. Influence of Vertical Loading on Behavior of Laterally Loaded Foundation Piles: A Review. J. Mar. Sci. Eng. 2020, 8, 1029. [Google Scholar] [CrossRef]

- Lin, L.; Wang, F.-c. Investigation of analytical behavior of concrete filled steel tubular (CFST) offshore rock-socketed pile under lateral load. Ocean Eng. 2023, 277, 114279. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, F.; Zhang, H.; Zheng, H. Numerical evaluation of the dynamic performance of recommissioned offshore wind turbines under service life extension and repowering strategies. Comput. Geotech. 2025, 186, 107370. [Google Scholar] [CrossRef]

- Hou, Z.; Lehane, B.M.; Watson, P.G. An experimental investigation of the time dependence of shaft friction for displacement piles in lightly over-consolidated clay. Géotechnique 2025, 1–14. [Google Scholar] [CrossRef]

- Hanna, A.M.; Sharif, A. Drag Force on Single Piles in Clay Subjected to Surcharge Loading. Int. J. Geomech. 2006, 6, 89–96. [Google Scholar] [CrossRef]

- Liu, J.; Gao, H.; Liu, H. Finite element analyses of negative skin friction on a single pile. Acta Geotech. 2012, 7, 239–252. [Google Scholar] [CrossRef]

- Alsharedah, Y.; Newson, T.; El Naggar, M.H. A 3-D modelling of monopile behaviour under laterally applied loading. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 173. [Google Scholar] [CrossRef]

- Brinkgreve, R.B.J.; Kumarswamy, S.; Swolfs, W.M.; Waterman, D.; Chesaru, A.; Bonnier, P.G. PLAXIS 2016; Plaxis B.V.: Delft, The Netherlands, 2016. [Google Scholar]

- Hamdan, N.; Bahar, E.; Powell, T. Numerical modelling of rock protected pipelines subjected to multi-directional pull-out forces. In Proceedings of the SUT Offshore Site Investigation and Geotechnics, London, UK, 12–14 September 2023; pp. 682–689. [Google Scholar]

- Jerman, J. Evaluation of a Rigid Element for Offshore Applications. Ph.D. Thesis, Charles University, Prague, Czech Republic, 2014. [Google Scholar]

- Gu, M.; Cai, X.; Fu, Q.; Li, H.; Wang, X.; Mao, B. Numerical Analysis of Passive Piles under Surcharge Load in Extensively Deep Soft Soil. Buildings 2022, 12, 1988. [Google Scholar] [CrossRef]

- Yang, S.; Jia, M. Lateral response of a pile group embedded in the transversely isotropic saturated soil due to surcharge loads. Eng. Anal. Bound. Elem. 2023, 155, 1082–1095. [Google Scholar] [CrossRef]

- Fakharian, K.; Meskar, M.; Mohammadlou, A.S. Effect of Surcharge Pressure on Pile Static Axial Load Test Results. Int. J. Geomech. 2014, 14, 04014024. [Google Scholar] [CrossRef]

- Li, S.; Deng, Z.; Wei, L.; Chen, Q.; Zhang, Y.; He, F. Lateral behavior of high-speed railway bridge pile foundation in soft soils under adjacent surcharge loads considering time-dependent characteristics. Alex. Eng. J. 2025, 110, 451–467. [Google Scholar] [CrossRef]

- Shawky, O.; Altahrany, A.I.; Elmeligy, M. Improved Pile Geometry to Reduce Negative Skin Friction on Single Driven Pile and Pile Groups Subjected to Lateral Loads. Geotech. Geol. Eng. 2022, 40, 4487–4516. [Google Scholar] [CrossRef]

- Alsharedah, Y.A.; Newson, T.; El Naggar, M.H.; Black, J.A. Lateral Ultimate Capacity of Monopile Foundations for Offshore Wind Turbines: Effects of Monopile Geometry and Soil Stiffness Properties. Appl. Sci. 2023, 13, 12269. [Google Scholar] [CrossRef]

- Li, T.; Yu, X.; He, B.; Dai, S. The Lateral Behavior of Large-Diameter Monopiles for Offshore Wind Turbines Based on the p-y Curve and Solid FEM Methods. J. Mar. Sci. Eng. 2023, 11, 2354. [Google Scholar] [CrossRef]

- API. API 2A-WSD: Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms-Working Stress Design; American Petroleum Institute: Washington, DC, USA, 2000. [Google Scholar]

- Malhotra, S. Selection, design and construction of offshore wind turbine foundations. In Wind Turbines; IntechOpen: Rijeka, Croatia, 2011. [Google Scholar]

- Wang, Y.; Zou, X.; Zhou, M.; Zhang, X. Capacity and failure mechanism of monopile-wheel hybrid foundation in clay-overlaying-sand deposits under combined V–H-M loadings. Mar. Struct. 2023, 90, 103443. [Google Scholar] [CrossRef]

- Dai, S.; Bo, H.; Guoxiang, H.; Xiaoqiang, G.; Liu, J.; Liu, S. Failure mode of monopile foundation for offshore wind turbine in soft clay under complex loads. Mar. Georesources Geotechnol. 2022, 40, 14–25. [Google Scholar] [CrossRef]

- He, R.; Zhu, T. Model Tests on the Frequency Responses of Offshore Monopiles. J. Mar. Sci. Eng. 2019, 7, 430. [Google Scholar] [CrossRef]

- Khezri, A.; Park, H.; Lee, D. Numerical Study on the Lateral Load Response of Offshore Monopile Foundations in Clay: Effect of Slenderness Ratio. Appl. Sci. 2024, 14, 8366. [Google Scholar] [CrossRef]

| Type | Thickness (m) | Unit (kN/m3) | E (MPa) | Cohesion (kPa) | Friction Angle (°) | Permeability Coefficient k (m/days) |

|---|---|---|---|---|---|---|

| Clay | 40 | 16.4 | 10.4 | 10.2 | 32.5 | 5.5 × 10−4 |

| Rock | 40 | 24 | 1 × 106 | 300 | 40 | - |

| Pile | - | 78.5 | 210 × 106 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.; Chen, Z.; Zhu, W. Numerical Study of the Negative Skin Friction (NSF) of Large-Diameter Rock-Socketed Monopiles for Offshore Wind Turbines Incorporating Lateral Loading Effects. J. Mar. Sci. Eng. 2025, 13, 1530. https://doi.org/10.3390/jmse13081530

Ren Y, Chen Z, Zhu W. Numerical Study of the Negative Skin Friction (NSF) of Large-Diameter Rock-Socketed Monopiles for Offshore Wind Turbines Incorporating Lateral Loading Effects. Journal of Marine Science and Engineering. 2025; 13(8):1530. https://doi.org/10.3390/jmse13081530

Chicago/Turabian StyleRen, Yuanyuan, Zhiwei Chen, and Wenbo Zhu. 2025. "Numerical Study of the Negative Skin Friction (NSF) of Large-Diameter Rock-Socketed Monopiles for Offshore Wind Turbines Incorporating Lateral Loading Effects" Journal of Marine Science and Engineering 13, no. 8: 1530. https://doi.org/10.3390/jmse13081530

APA StyleRen, Y., Chen, Z., & Zhu, W. (2025). Numerical Study of the Negative Skin Friction (NSF) of Large-Diameter Rock-Socketed Monopiles for Offshore Wind Turbines Incorporating Lateral Loading Effects. Journal of Marine Science and Engineering, 13(8), 1530. https://doi.org/10.3390/jmse13081530