Development and Core Technologies of Long-Range Underwater Gliders: A Review

Abstract

1. Introduction

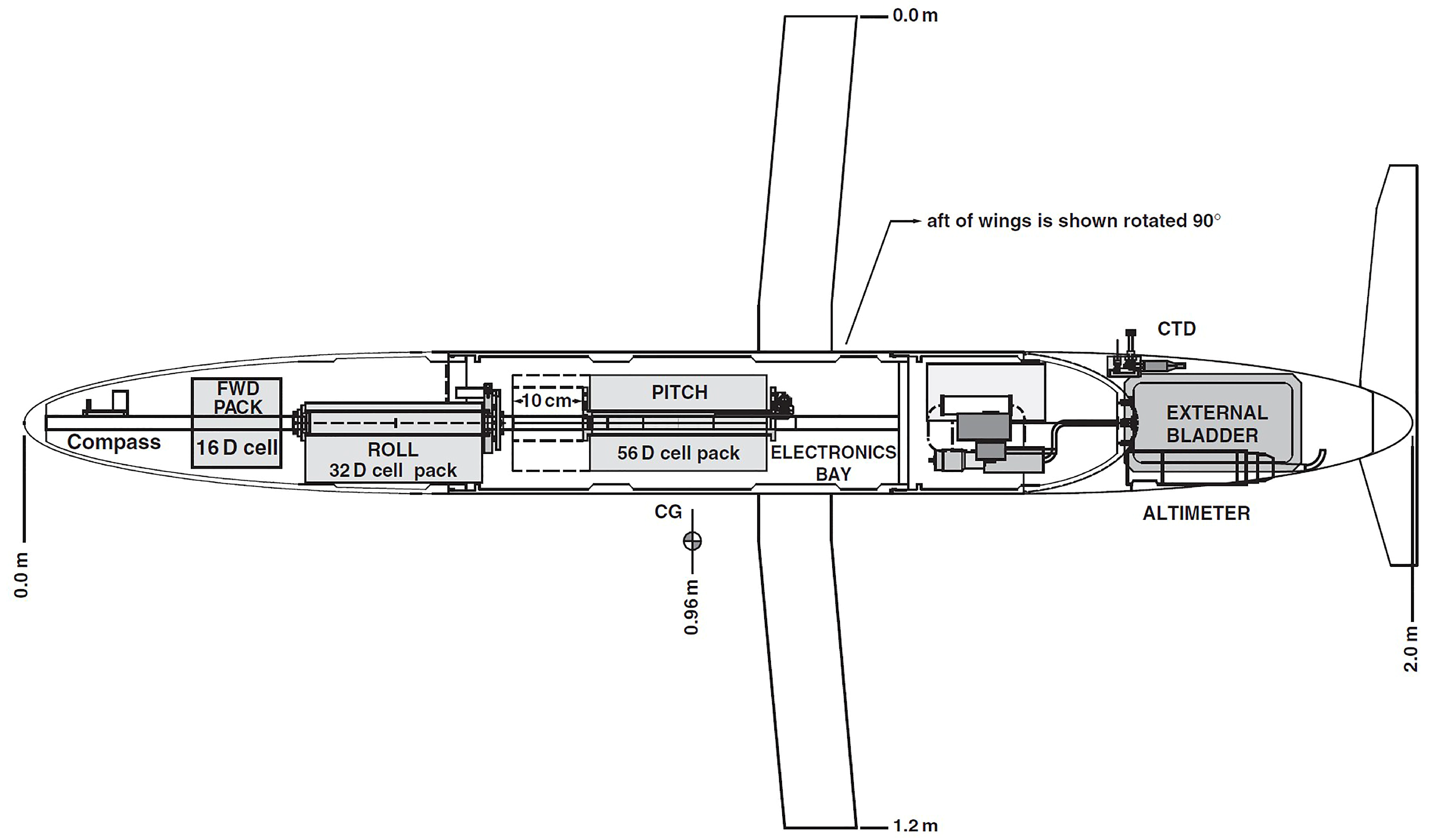

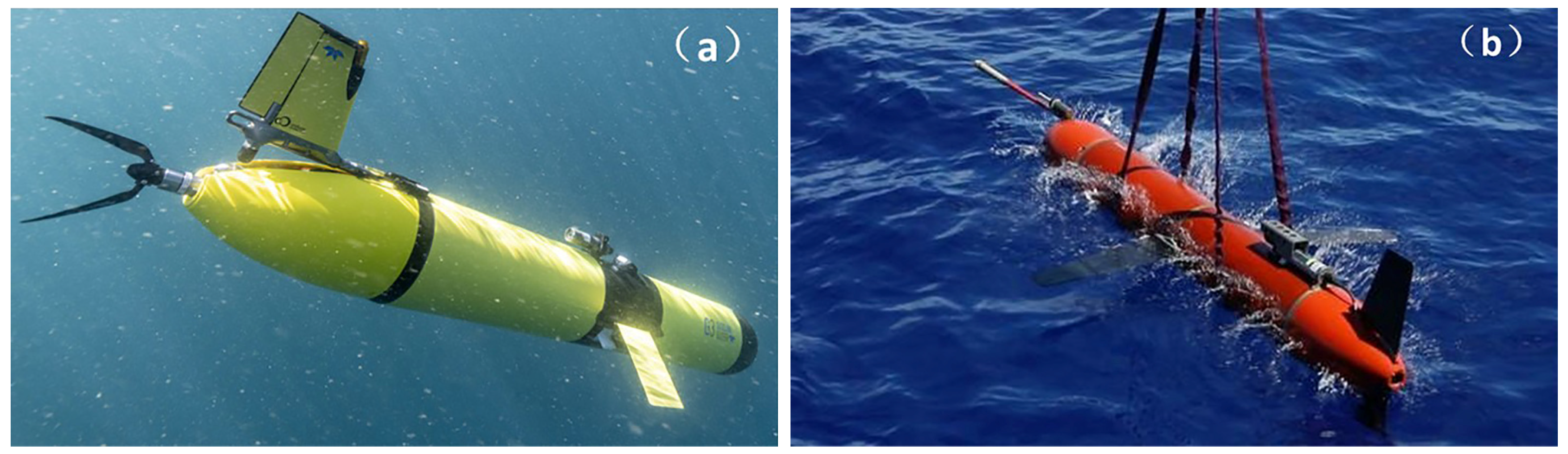

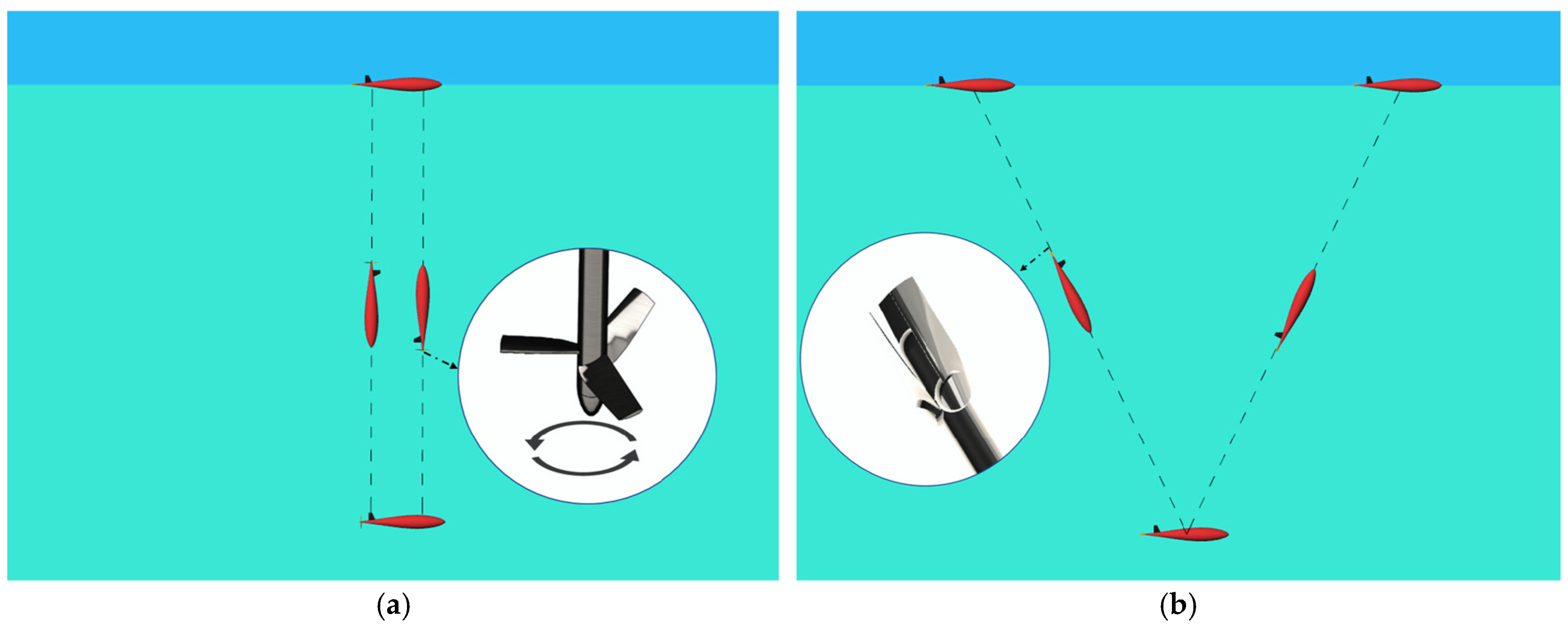

2. The Current Development Status of LRUGs

2.1. Advances in Long-Range Capabilities

2.2. Advances in Long-Range Applications

| Glider | Mechanical Characteristics | Motion Performance | Endurance | |

|---|---|---|---|---|

| Slocum Sentinel [45] (USA) | size: ϕ0.33 × 2.57 m mass: 171 kg shell: Carbon fiber composite material | Max depth: 1000 m Average speed: 1 knots Max speed: 3.5 knots (thrusters) | Max Endurance: over 2 Years |  |

| Slocum G3 [46] (USA) | size: ϕ0.22 × 1.8 m mass: 70 kg shell: Carbon fiber composite material | Max depth: 1000 m Average speed: 0.5 knots Max speed: 2 knots (thruster) | Max Range: 13,000 km Max Endurance: 18 Months |  |

| Seaglider [47] (USA) | size: ϕ0.3 (max) × 2 m mass: 52 kg | Max depth: 1000 m Average speed: 0.5 knots | Max Range: 4600 km Max Endurance: 10 Months |  |

| Spray [48] (USA) | size: ϕ0.2 × 2.13 m mass: 52 kg | Max depth: 1500 m Average speed: 0.5 knots | Max Range: 4800 km Max Endurance: 6 Months |  |

| SeaExplorer X2 [49] (France) | size: ϕ0.25 × 2 m mass: 59 kg | Max depth: 1000 m Average speed: 0.5 knots Max speed: 1 knots | Max Range: 3200 km Max Endurance: 160 Days |  |

| SeaWing G2 (China) | size: ϕ0.22 × 2.25 m mass: 85 kg shell: T6061 Aluminum alloy | Max depth: 1000 m Average speed: 0.5 knots Max speed: 1 knots | Max Range: 6500 km Max Endurance: 12 Months |  |

3. Core Technologies of LRUGs

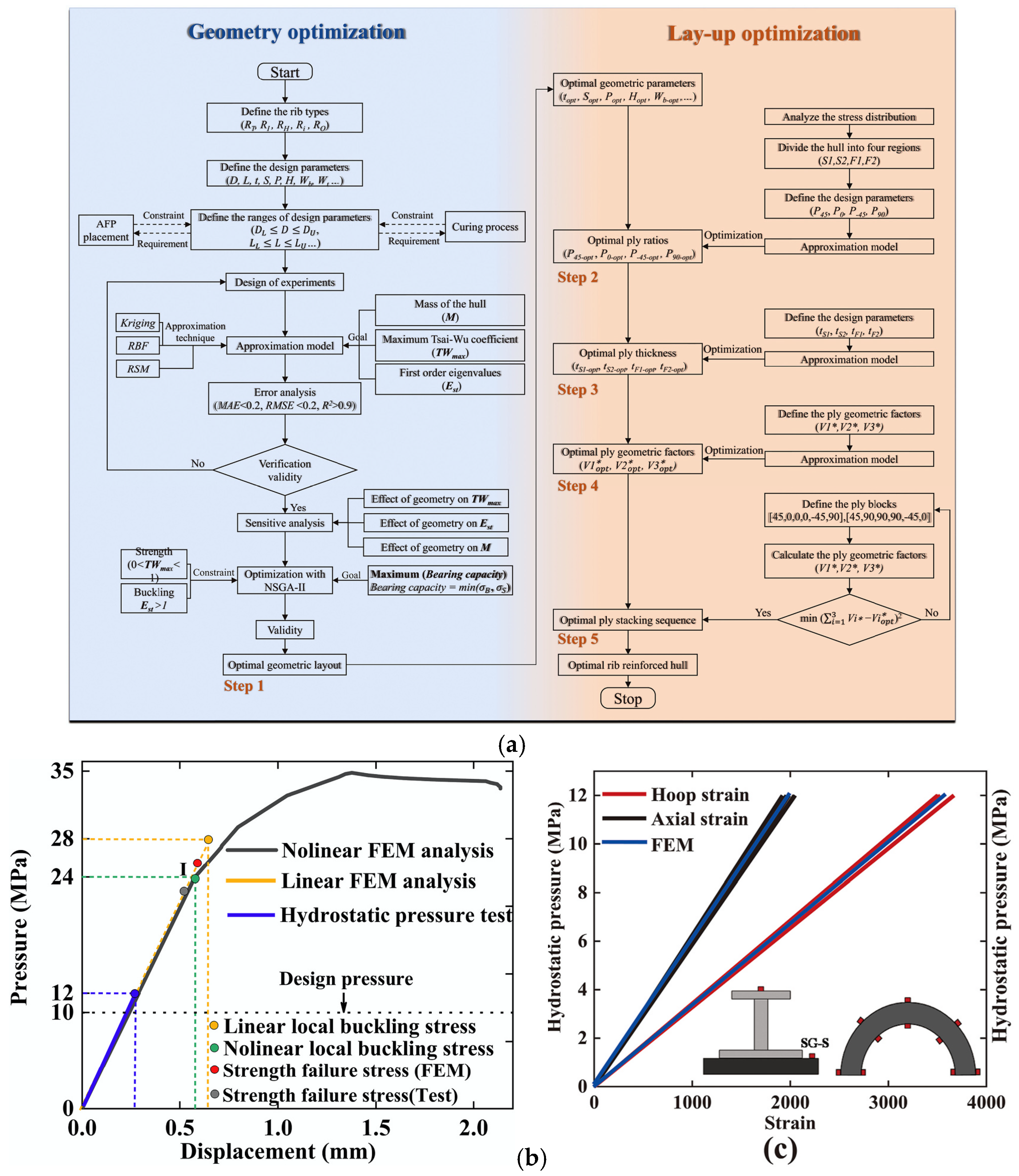

3.1. Lightweight and Pressure-Resistant Cabin Shell Technology

3.1.1. Material Lightweighting

3.1.2. Optimization of the Molding Process

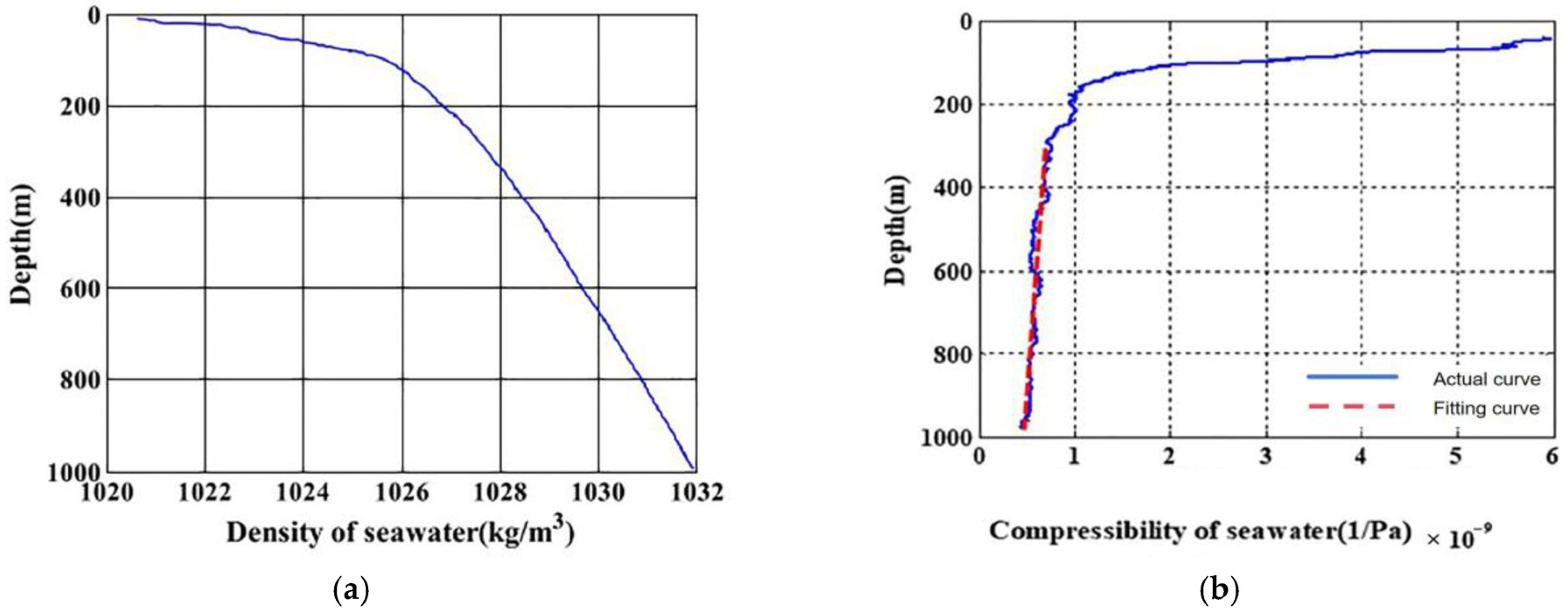

3.1.3. Optimization of Compressibility and Seawater Density Matching

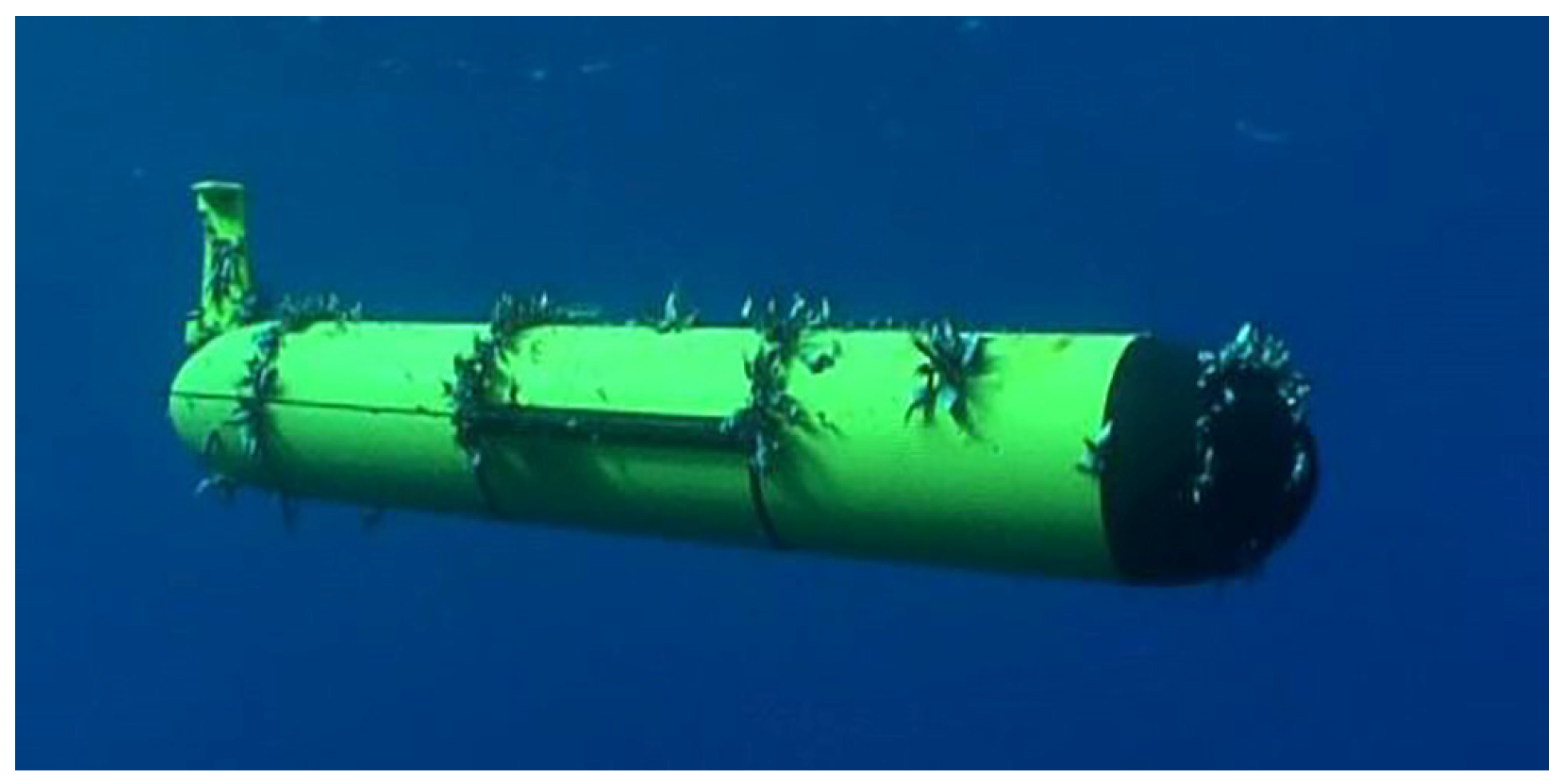

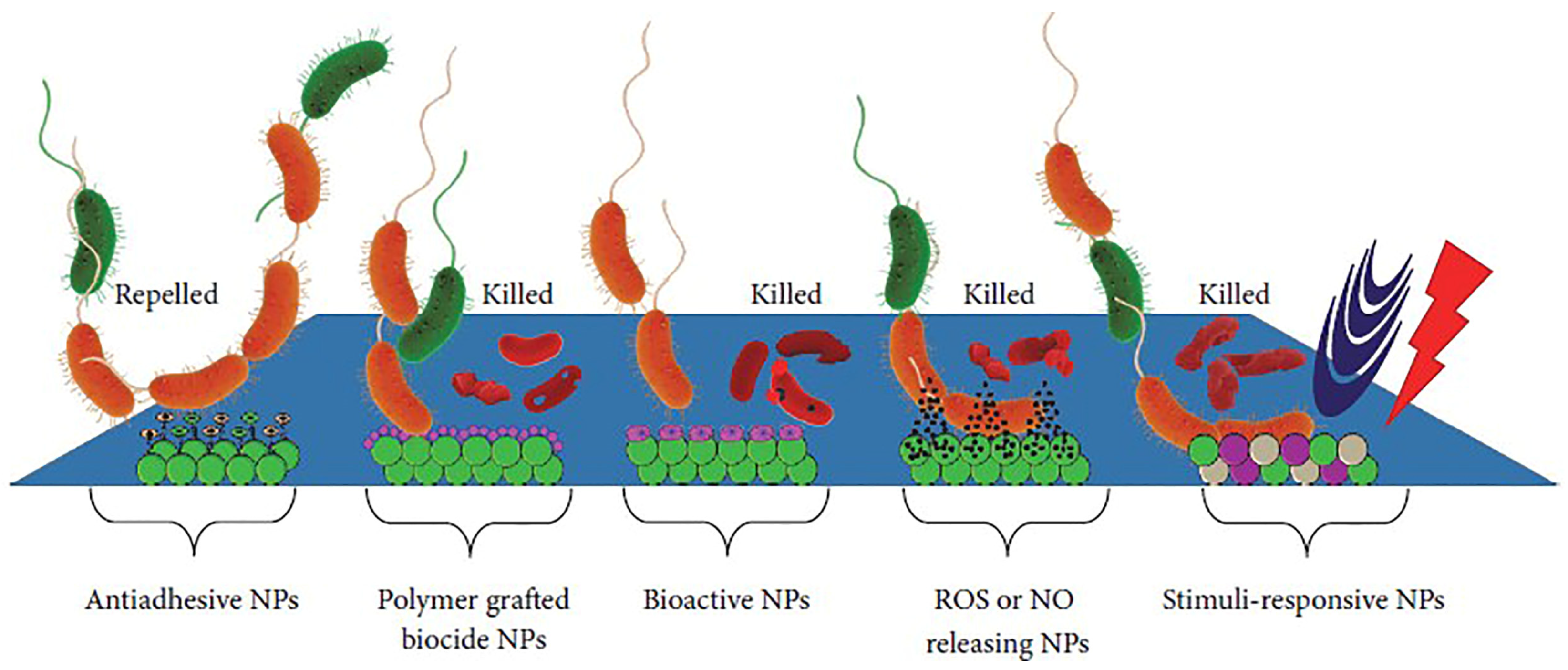

3.1.4. Anti-Biological Attachment of the Pressure-Resistant Cabin Shell

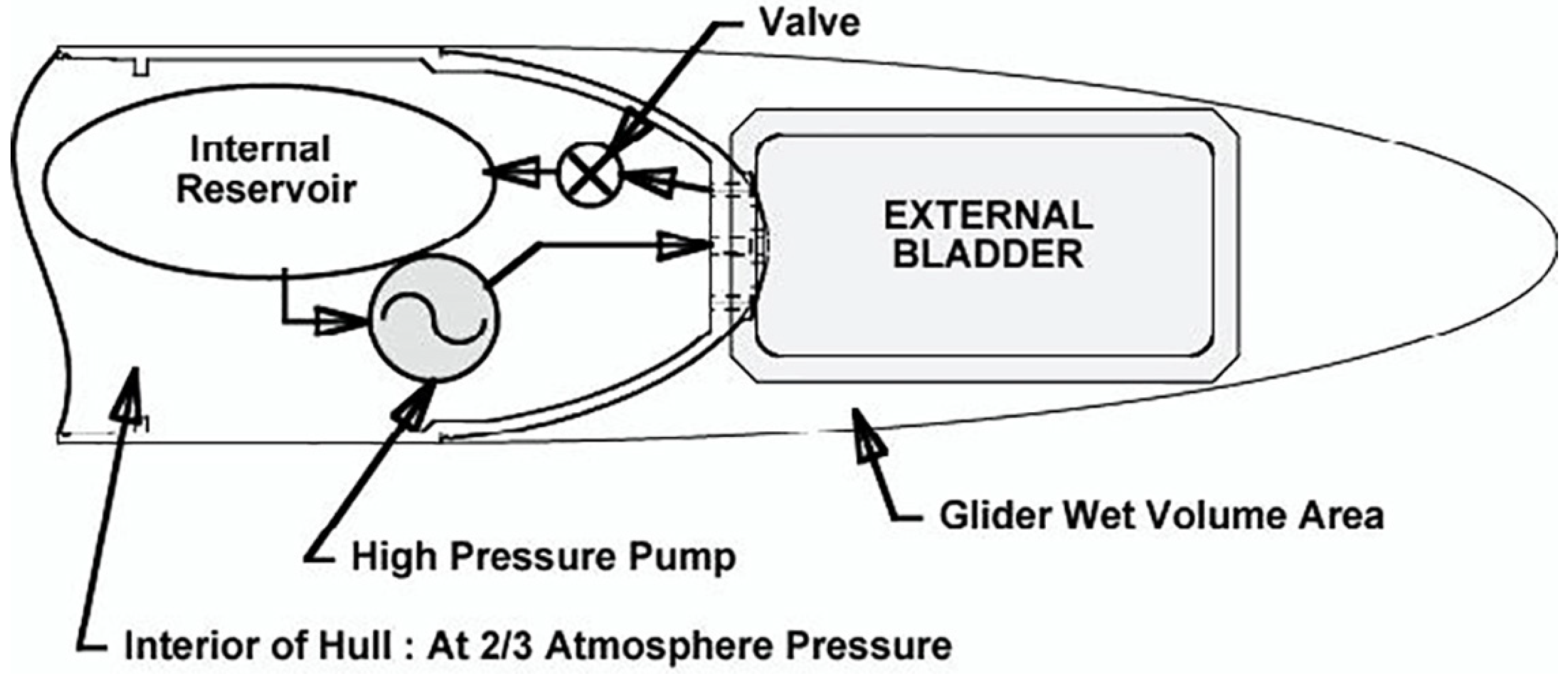

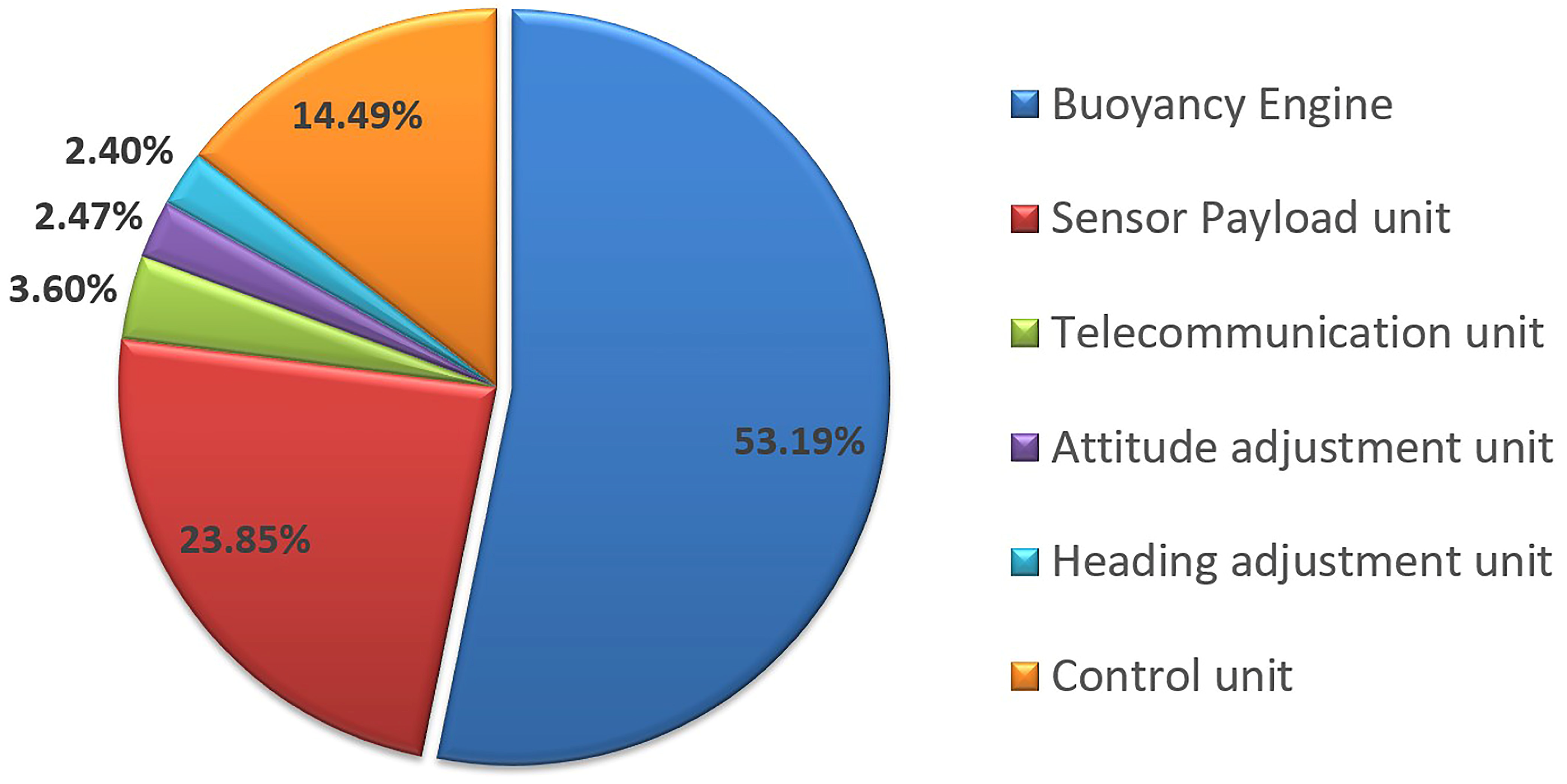

3.2. High-Efficiency Buoyancy Drive Technology

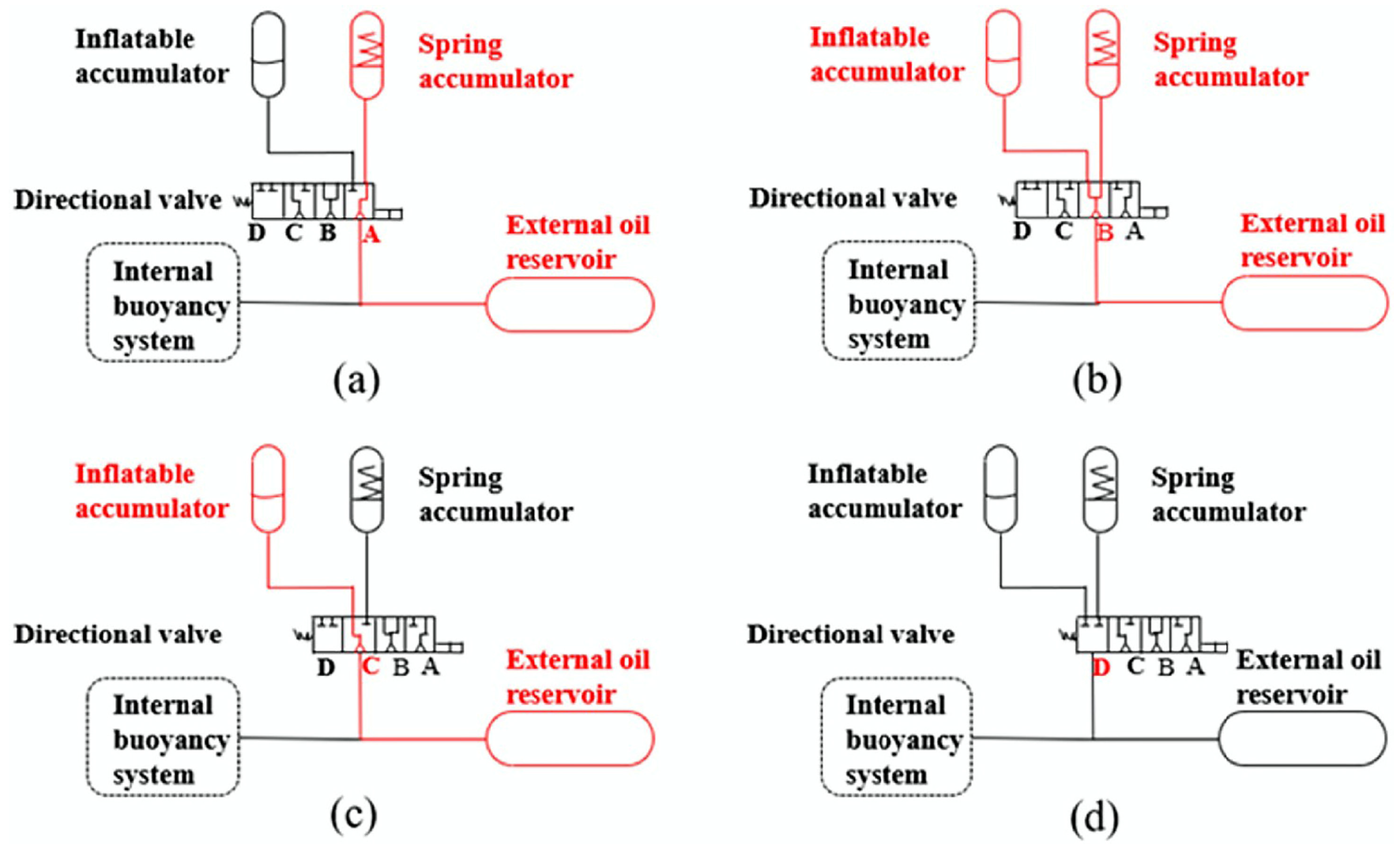

3.2.1. Active–Passive Coupled Buoyancy Adjustment Mechanism

- (1)

- Spring-supported piston–cylinder structures: Rossby et al. [98] developed a device of this type to enable adaptive density regulation, which closely aligns with the compressibility characteristics of seawater, thereby enhancing vertical profile control accuracy;

- (2)

- Gas-charged accumulator-type compensators: Chen et al. [99] utilized an accumulator-based design to mitigate buoyancy fluctuations in underwater gliders. Simulation results indicate strong potential for addressing buoyancy instability in such systems;

- (3)

- Compressible fluid compensators: Wang et al. [100] proposed a compensator employing low-viscosity silicone oil as the working fluid, achieving a measured 70.8% reduction in net buoyancy variation.

3.2.2. High-Response Execution Mechanism Based on Smart Materials

- (1)

- Environmentally Driven Temperature-Differential Passive System

- (2)

- An Active Actuation Mechanism Based on Electrothermal Excitation

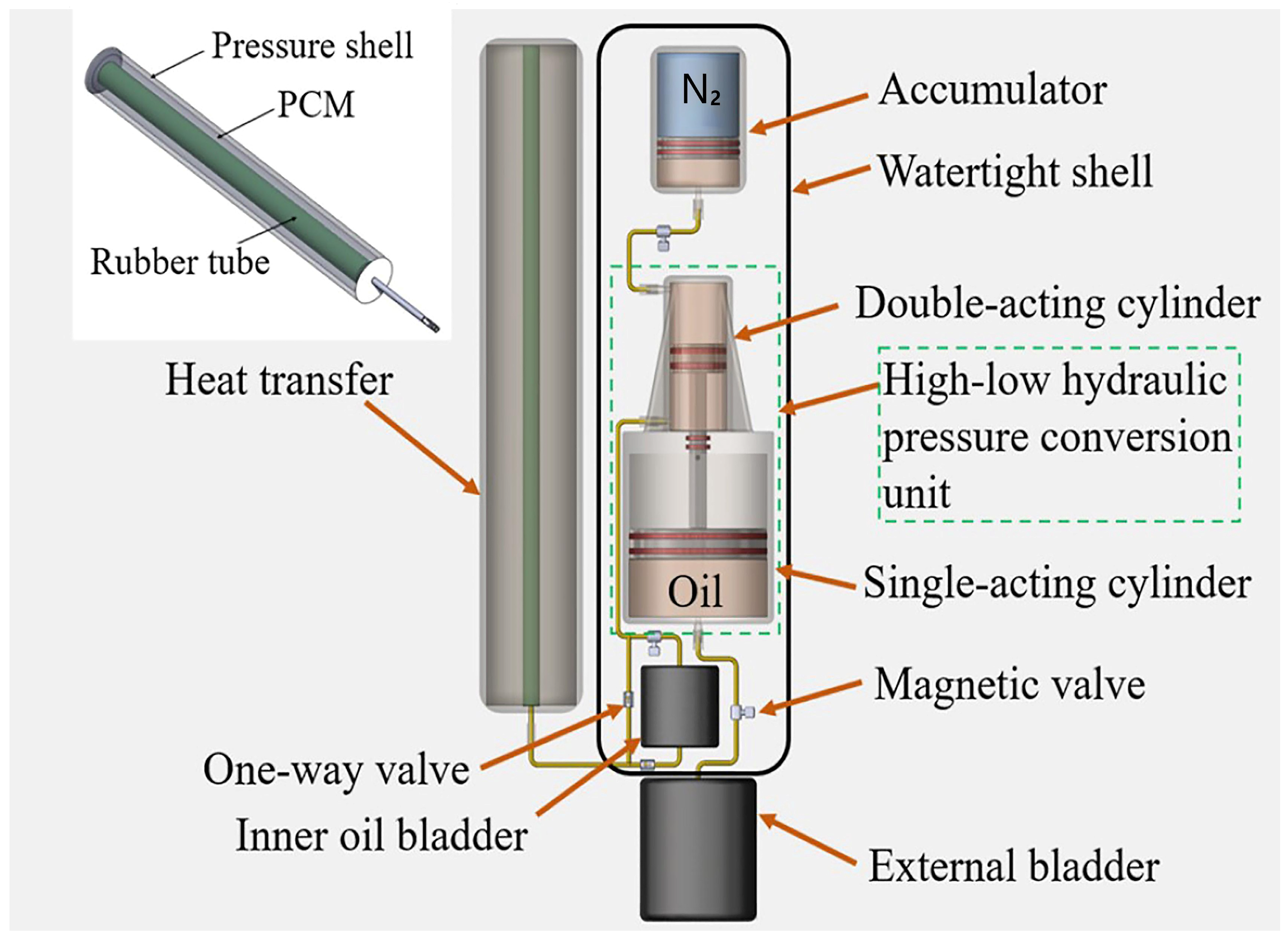

3.2.3. Ocean Thermal Gradient Energy Drive and Energy Recovery Mechanism

- (1)

- Proof-of-concept stage (2001–2010)

- (2)

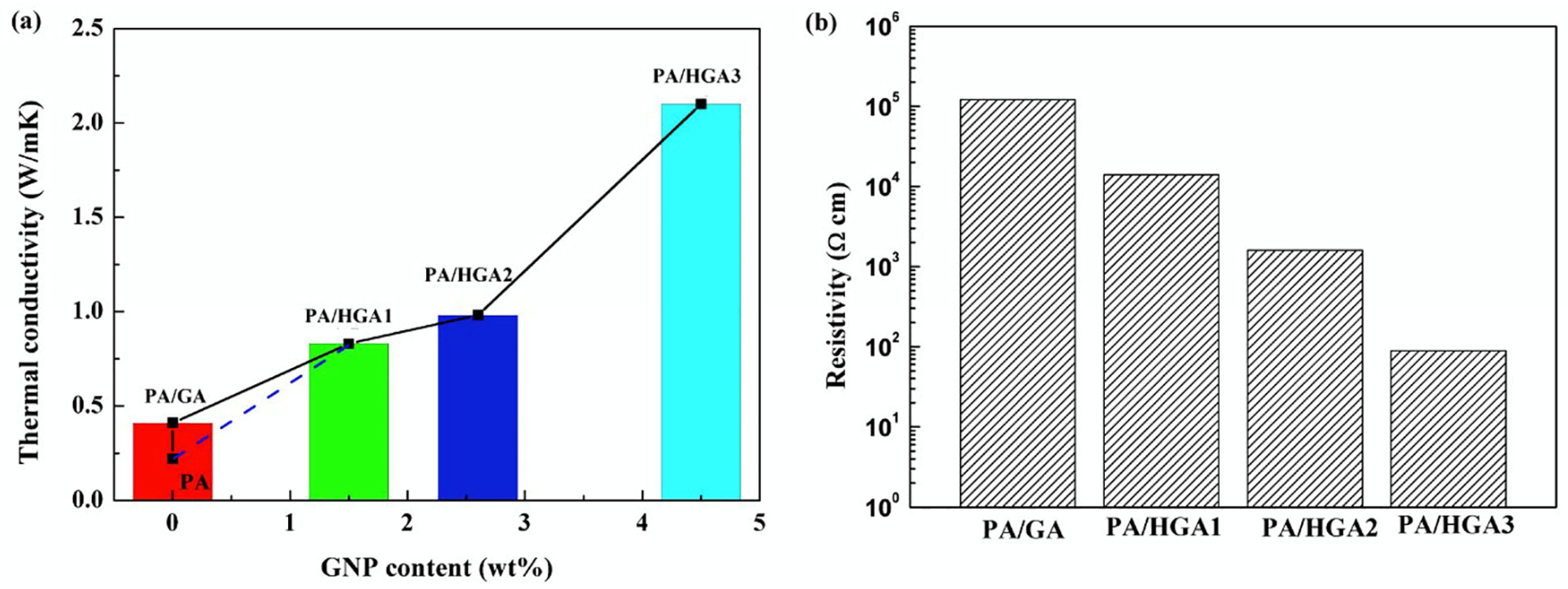

- Thermal Cycle Optimization Stage (2010–2020)

- (3)

- Energy Recovery Integration Phase (2020–Present)

4. Discussion and Future Development

4.1. Challenges

- (1)

- Trade-off Between Lightweighting and Reliability of Pressure-Resistant Housings

- (2)

- Biofouling Risks to Pressure-Resistant Structures During Long-Term Deployment

- (3)

- Energy Efficiency Bottlenecks in Buoyancy Regulation Systems

- (4)

- Limitations in Efficiency and System Integration of Thermal Gradient–Driven Buoyancy Regulation

4.2. Future Development

- (1)

- Material Innovations for Ultralight, High-Strength Pressure-Resistant Structures

- (2)

- Multi-Mechanism Coupled Antifouling Technology System

- (3)

- Efficient Hybrid Active–Passive Buoyancy Regulation Systems

- (4)

- High-Efficiency, Self-Sustaining Gliding Platform Powered by Environmental Thermal Energy

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wunsch, C. Vertical Mixing, Energy, and the General Circulation of the Oceans. Annu. Rev. Fluid Mech. 2004, 36, 281–314. [Google Scholar] [CrossRef]

- Chelton, D.B.; Gaube, P.; Schlax, M.G.; Early, J.J.; Samelson, R.M. The Influence of Nonlinear Mesoscale Eddies on Near-Surface Oceanic Chlorophyll. Science 2011, 334, 328–332. [Google Scholar] [CrossRef] [PubMed]

- Mahadevan, A. The Impact of Submesoscale Physics on Primary Productivity of Plankton. Ann. Rev. Mar. Sci. 2016, 8, 161–184. [Google Scholar] [CrossRef]

- Moum, J.N.; Klymak, J.M.; Nash, J.D.; Perlin, A.; Smyth, W.D. Energy Transport by Nonlinear Internal Waves. J. Phys. Oceanogr. 2007, 37, 1968–1988. [Google Scholar] [CrossRef]

- Xuan, J.; Ding, R.; Ni, X.; Huang, D.; Chen, J.; Zhou, F. Wintertime Submesoscale Offshore Events Overcoming Wind-Driven Onshore Currents in the East China Sea. Geophys. Res. Lett. 2021, 48, e2021GL095139. [Google Scholar] [CrossRef]

- Le Quere, C.; Rodenbeck, C.; Buitenhuis, E.T.; Conway, T.J.; Langenfelds, R.; Gomez, A.; Labuschagne, C.; Ramonet, M.; Nakazawa, T.; Metzl, N.; et al. Saturation of the southern ocean CO2 sink due to recent climate change. Science 2007, 316, 1735–1738. [Google Scholar] [CrossRef]

- Rahmstorf, S. Ocean circulation and climate during the past 120,000 years. Nature 2002, 419, 207–214. [Google Scholar] [CrossRef]

- Cheng, L.; Trenberth, K.E.; Fasullo, J.; Boyer, T.; Abraham, J.; Zhu, J. Improved estimates of ocean heat content from 1960 to 2015. Sci. Adv. 2017, 3, e1601545. [Google Scholar] [CrossRef]

- Bryden, H.L.; Longworth, H.R.; Cunningham, S.A. Slowing of the Atlantic meridional overturning circulation at 25 degrees N. Nature 2005, 438, 655–657. [Google Scholar] [CrossRef]

- Vellinga, M.; Wood, R.A. Global Climatic Impacts of a Collapse of the Atlantic Thermohaline Circulation. Clim. Change 2002, 54, 251–267. [Google Scholar] [CrossRef]

- Trenberth, K.E.; Fasullo, J.T. Atlantic meridional heat transports computed from balancing Earth’s energy locally. Geophys. Res. Lett. 2017, 44, 1919–1927. [Google Scholar] [CrossRef]

- McWilliams, J.C. Submesoscale currents in the ocean. Proc. Math. Phys. Eng. Sci. 2016, 472, 20160117. [Google Scholar] [CrossRef] [PubMed]

- Momeni, K.; Ma, Y.; Peltier, W.R.; Menemenlis, D.; Thakur, R.; Pan, Y.; Arbic, B.K.; Skitka, J.; Alford, M.H. Breaking Internal Waves and Ocean Diapycnal Diffusivity in a High-Resolution Regional Ocean Model: Evidence of a Wave-Turbulence Cascade. J. Geophys. Res. Ocean 2024, 129, e2023JC020509. [Google Scholar] [CrossRef]

- Roemmich, D.; Johnson, G.; Riser, S.; Davis, R.; Gilson, J.; Owens, W.B.; Garzoli, S.; Schmid, C.; Ignaszewski, M. The Argo Program: Observing the Global Oceans with Profiling Floats. Oceanography 2009, 22, 34–43. [Google Scholar] [CrossRef]

- Riser, S.C.; Freeland, H.J.; Roemmich, D.; Wijffels, S.; Troisi, A.; Belbéoch, M.; Gilbert, D.; Xu, J.; Pouliquen, S.; Thresher, A.; et al. Fifteen years of ocean observations with the global Argo array. Nat. Clim. Change 2016, 6, 145–153. [Google Scholar] [CrossRef]

- D’Asaro, E.A.; Shcherbina, A.Y.; Klymak, J.M.; Molemaker, J.; Novelli, G.; Guigand, C.M.; Haza, A.C.; Haus, B.K.; Ryan, E.H.; Jacobs, G.A.; et al. Ocean convergence and the dispersion of flotsam. Proc. Natl. Acad. Sci. USA 2018, 115, 1162–1167. [Google Scholar] [CrossRef] [PubMed]

- Roemmich, D.; Alford, M.H.; Claustre, H.; Johnson, K.; King, B.; Moum, J.; Oke, P.; Owens, W.B.; Pouliquen, S.; Purkey, S.; et al. On the Future of Argo: A Global, Full-Depth, Multi-Disciplinary Array. Front. Mar. Sci. 2019, 6, 439. [Google Scholar] [CrossRef]

- Smeed, D.A.; Josey, S.A.; Beaulieu, C.; Johns, W.E.; Moat, B.I.; Frajka-Williams, E.; Rayner, D.; Meinen, C.S.; Baringer, M.O.; Bryden, H.L.; et al. The North Atlantic Ocean Is in a State of Reduced Overturning. Geophys. Res. Lett. 2018, 45, 1527–1533. [Google Scholar] [CrossRef]

- Karuppanan, S.; Javaid, M.Y.; Ovinis, M.; Nagarajan, T.; Hashim, F.B.M.; Abdul Karim, Z.A.; Ovinis, M.; Tesfamichael Baheta, A. Underwater Gliders: A Review. MATEC Web Conf. 2014, 13, 02020. [Google Scholar] [CrossRef]

- Petritoli, E.; Leccese, F. Autonomous Underwater Glider: A Comprehensive Review. Drones 2024, 9, 21. [Google Scholar] [CrossRef]

- Rudnick, D.L.; Davis, R.E.; Eriksen, C.C.; Fratantoni, D.M.; Perry, M.J. Underwater Gliders for Ocean Research. Mar. Technol. Soc. J. 2004, 38, 73–84. [Google Scholar] [CrossRef]

- Ren, A.S.; Todd, R.E. Springtime Warming by Ocean Advection in the Gulf Stream. Geophys. Res. Lett. 2025, 52, e2024GL111000. [Google Scholar] [CrossRef]

- Rudnick, D.L. Ocean Research Enabled by Underwater Gliders. Annu. Rev. Mar. Sci. 2016, 8, 519–541. [Google Scholar] [CrossRef]

- Davis, R.E.; Ohman, M.D.; Rudnick, D.L.; Sherman, J.T. Glider surveillance of physics and biology in the southern California Current System. Limnol. Oceanogr. 2008, 53, 2151–2168. [Google Scholar] [CrossRef]

- Molemaker, M.J.; McWilliams, J.C.; Dewar, W.K. Submesoscale Instability and Generation of Mesoscale Anticyclones near a Separation of the California Undercurrent. J. Phys. Oceanogr. 2015, 45, 613–629. [Google Scholar] [CrossRef]

- Consortium, S.-C.; Sallee, J.B.; Abrahamsen, E.P.; Allaigre, C.; Auger, M.; Ayres, H.; Badhe, R.; Boutin, J.; Brearley, J.A.; de Lavergne, C.; et al. Southern ocean carbon and heat impact on climate. Philos. Trans. A Math. Phys. Eng. Sci. 2023, 381, 20220056. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Z.; Dong, H.; Tan, M.; Yu, J. Development and Control of Underwater Gliding Robots: A Review. IEEE/CAA J. Autom. Sin. 2022, 9, 1543–1560. [Google Scholar] [CrossRef]

- Eriksen, C.C.; Osse, T.J.; Light, R.D.; Wen, T.; Lehman, T.W.; Sabin, P.L.; Ballard, J.W.; Chiodi, A.M. Seaglider: A long-range autonomous underwater vehicle for oceanographic research. IEEE J. Ocean Eng. 2001, 26, 424–436. [Google Scholar] [CrossRef]

- Miles, T.; Seroka, G.; Kohut, J.; Schofield, O.; Glenn, S. Glider observations and modeling of sediment transport in Hurricane Sandy. J. Geophys. Res. Ocean 2015, 120, 1771–1791. [Google Scholar] [CrossRef]

- Schaeffer, A.; Roughan, M. Subsurface intensification of marine heatwaves off southeastern Australia: The role of stratification and local winds. Geophys. Res. Lett. 2017, 44, 5025–5033. [Google Scholar] [CrossRef]

- Testor, P.; de Young, B.; Rudnick, D.L.; Glenn, S.; Hayes, D.; Lee, C.M.; Pattiaratchi, C.; Hill, K.; Heslop, E.; Turpin, V.; et al. OceanGliders: A Component of the Integrated GOOS. Front. Mar. Sci. 2019, 6, 422. [Google Scholar] [CrossRef]

- Gongwer, C.A. Some Aspects of Underwater Jet Propulsion Systems. ARS J. 1960, 30, 1148–1151. [Google Scholar] [CrossRef]

- Seireg, A.; Baz, A. Optimum Design and Control of Underwater Gliders. J. Eng. Ind. 1974, 96, 304–310. [Google Scholar] [CrossRef]

- Stommel, H.M. The slocum mission. Oceanography 1989, 32, 93–96. [Google Scholar] [CrossRef]

- Schofield, O.; Kohut, J.; Aragon, D.; Creed, L.; Graver, J.; Haldeman, C.; Kerfoot, J.; Roarty, H.; Jones, C.; Webb, D.; et al. Slocum Gliders: Robust and ready. J. Field Robot. 2007, 24, 473–485. [Google Scholar] [CrossRef]

- Sherman, J.; Davis, R.E.; Owens, W.B.; Valdes, J. The autonomous underwater glider “Spray”. IEEE J. Ocean Eng. 2001, 26, 437–446. [Google Scholar] [CrossRef]

- Pla, P.; Tricarico, R. Towards a low cost observing system based on low logistic SeaExplorer glider. In Proceedings of the 2015 IEEE Underwater Technology (Ut), Chennai, India, 23–25 February 2015; pp. 1–3. [Google Scholar] [CrossRef]

- Claustre, H.; Beguery, L.; Patrice, P. SeaExplorer glider breaks two world records multisensor UUV achieves global milestones for endurance, distance. Sea Technol. 2014, 55, 19–22. [Google Scholar]

- de Fommervault, O.; Besson, F.; Beguery, L.; Le Page, Y.; Lattes, P. SeaExplorer Underwater Glider: A New Tool to Measure depth-resolved water currents profiles. In Proceedings of the OCEANS 2019—Marseille, Marseille, France, 17–20 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Arima, M.; Tonai, H.; Kosuga, Y. Underwater glider ‘SOARER’ for ocean environmental monitoring. In Proceedings of the 2013 IEEE International Underwater Technology Symposium (UT), Tokyo, Japan, 5–8 March 2013; pp. 1–5. [Google Scholar] [CrossRef]

- Caffaz, A.; Caiti, A.; Casalino, G.; Turetta, A. The Hybrid Glider/AUV Folaga. IEEE Robot. Autom. Mag. 2010, 17, 31–44. [Google Scholar] [CrossRef]

- Ji, D.-H.; Lee, J.-H.; Ko, S.-H.; Hyeon, J.-W.; Lee, J.-H.; Choi, H.-S.; Jeong, S.-K. Design and Analysis of the High-Speed Underwater Glider with a Bladder-Type Buoyancy Engine. Appl. Sci. 2023, 13, 11367. [Google Scholar] [CrossRef]

- Miles, T.; Lee, S.H.; Wåhlin, A.; Ha, H.K.; Kim, T.W.; Assmann, K.M.; Schofield, O. Glider observations of the Dotson Ice Shelf outflow. Deep Sea Res. Part II Top. Stud. Oceanogr. 2016, 123, 16–29. [Google Scholar] [CrossRef]

- Miles, T.; Glenn, S.; Kohut, J.; Seroka, G.; Xu, Y. Observations of Hurricane Sandy from a glider mounted aquadopp profiler. In Proceedings of the 2013 OCEANS—San Diego, San Diego, CA, USA, 23–27 September 2013; pp. 1–8. [Google Scholar]

- Marine, T. Slocum Sentinel Glider. Available online: https://www.teledynemarine.com/slocum-sentinel-glider (accessed on 1 July 2025).

- Marine, T. Slocum Glider. Available online: https://www.teledynemarine.com/brands/webb-research/slocum-glider (accessed on 1 July 2025).

- KONGSBERG. SEAGLIDER. Available online: https://www.kongsberg.com/globalassets/kongsberg-maritime/km-products/documents/seaglider_product_specification.pdf (accessed on 1 July 2025).

- BLUEFIN. Spray Glider. Available online: https://pdf.nauticexpo.com/pdf/bluefin-robotics-corporation/spray-glider/25481-31520.html (accessed on 2 July 2025).

- RSAQUA. Alseamar SEAEXPLORER X2 Glider. Available online: https://rsaqua.co.uk/product/seaexplorer-x2/ (accessed on 2 July 2025).

- Barker, L.D.L.; Jakuba, M.V.; Bowen, A.D.; German, C.R.; Maksym, T.; Mayer, L.; Boetius, A.; Dutrieux, P.; Whitcomb, L.L. Scientific Challenges and Present Capabilities in Underwater Robotic Vehicle Design and Navigation for Oceanographic Exploration Under-Ice. Remote Sens. 2020, 12, 2588. [Google Scholar] [CrossRef]

- Ramos, A.G.; Garcia-Garrido, V.J.; Mancho, A.M.; Wiggins, S.; Coca, J.; Glenn, S.; Schofield, O.; Kohut, J.; Aragon, D.; Kerfoot, J.; et al. Lagrangian coherent structure assisted path planning for transoceanic autonomous underwater vehicle missions. Sci. Rep. 2018, 8, 4575. [Google Scholar] [CrossRef]

- Zhang, B.; Ji, D.; Liu, S.; Zhu, X.; Xu, W. Autonomous Underwater Vehicle navigation: A review. Ocean Eng. 2023, 273, 113861. [Google Scholar] [CrossRef]

- Zhang, R.; He, B.; Wang, Y.; Ma, W.; Yang, S. Recent advances in path planning for underwater gliders: A comprehensive review. Ocean Eng. 2024, 299, 117166. [Google Scholar] [CrossRef]

- Ullah, B.; Ovinis, M.; Baharom, M.B.; Javaid, M.Y.; Izhar, S.S. Underwater gliders control strategies: A review. In Proceedings of the 2015 10th Asian Control Conference (ASCC), Kota Kinabalu, Malaysia, 31 May–3 June 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Sun, K.; Cui, W.; Chen, C. Review of Underwater Sensing Technologies and Applications. Sensors 2021, 21, 7849. [Google Scholar] [CrossRef]

- Zou, S.; Sun, Q. An Acoustic Underwater Glider for the Real-Time Transmission of Observation Data via an Underwater Acoustic Communication Modem. Sensors 2025, 25, 849. [Google Scholar] [CrossRef]

- Jing, G.; Lei, L.; Gang, Y. Dynamic modeling and experimental analysis of an underwater glider in the ocean. Appl. Math. Model. 2022, 108, 392–407. [Google Scholar] [CrossRef]

- Osse, T.J.; Lee, T.J. Composite Pressure Hulls for Autonomous Underwater Vehicles. In Proceedings of the OCEANS 2007, Vancouver, BC, Canada, 29 September–4 October 2007; pp. 1–14. [Google Scholar] [CrossRef]

- Falcão Carneiro, J.; Gomes de Almeida, F. Model of a thermal driven volumetric pump for energy harvesting in an underwater glider. Energy 2016, 112, 28–42. [Google Scholar] [CrossRef]

- Siqueira Nóbrega de Freitas, A.; Alfonso Alvarez, A.; Ramos, R.; de Barros, E.A. Buckling Analysis of an AUV Pressure Vessel with Sliding Stiffeners. J. Mar. Sci. Eng. 2020, 8, 515. [Google Scholar] [CrossRef]

- Vardhan, H.; Sztipanovits, J. Deep Learning based FEA Surrogate for Sub-Sea Pressure Vessel. In Proceedings of the 2022 6th International Conference on Computer, Software and Modeling (ICCSM), Rome, Italy, 21–23 July 2022; pp. 36–39. [Google Scholar]

- Wu, Y.; Luo, R.; Wang, F.; Zhao, M.; Xia, J. Effect of the implosion of a deep-sea pressure hull on surrounding structures. Appl. Ocean Res. 2023, 132, 103477. [Google Scholar] [CrossRef]

- Wang, S.; Mei, Z.; Fu, X.; Zhong, Y. Pressure hull material selection and load law of unmanned underwater vehicle. Chin. J. Ship Res. 2024, 19, 247–253. [Google Scholar] [CrossRef]

- Kang, J.I.; Jeoung, S.K.; Oh, J.Y.; Choi, H.S.; Kim, Y.H.; Kim, J.Y.; Yu, S.H.; Cho, H.K. An analysis of carbon fiber hull structure of a new underwater glider. Int. J. Mod. Phys. B 2018, 32, 1840065. [Google Scholar] [CrossRef]

- Yigezu, B.; Jha, P.; Mahapatra, M. The Key Attributes of Synthesizing Ceramic Particulate Reinforced Al-Based Matrix Composites through Stir Casting Process: A Review. Mater. Manuf. Process. 2013, 28, 969–979. [Google Scholar]

- Singh, H.; Singh, K.; Vardhan, S.; Mohan, S. A comprehensive review on the new developments consideration in a stir casting processing of aluminum matrix composites. Mater. Today Proc. 2022, 60, 974–981. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Gellert, E.; Burchill, P.; Challis, K. Review of advanced composite structures for naval ships and submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Song, B.; Pan, G.; Zhang, L.; Li, B. Development trend and key technologies of autonomous underwater vehicles. Chin. J. Ship Res. 2022, 17, 27–44. (In Chinese) [Google Scholar]

- Griffiths, G.; Smeed, D.; Merckelbach, L. Vertical Water Velocities from Underwater Gliders. J. Atmos. Ocean Technol. 2010, 27, 547–563. [Google Scholar] [CrossRef]

- Yu, J.; Jin, W.; Tan, Z.; Huang, Y.; Luo, Y.; Wang, X. Development and experiments of the Sea-Wing7000 underwater glider. In Proceedings of the OCEANS 2017—Anchorage, Anchorage, AK, USA, 18–21 September 2017; pp. 1–7. [Google Scholar]

- alcocer, a.; Elkolali, M. Design and testing of a composite pressure hull for deep autonomous underwater vehicles. IEEE Access 2022, 10, 85831–85842. [Google Scholar] [CrossRef]

- Imran, M.; Shi, D.; Tong, L.; Waqas, H.M. Design optimization of composite submerged cylindrical pressure hull using genetic algorithm and finite element analysis. Ocean Eng. 2019, 190, 106443. [Google Scholar] [CrossRef]

- Boon, Y.D.; Joshi, S.C.; Bhudolia, S.K. Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers 2021, 13, 1951. [Google Scholar] [CrossRef]

- System, I.M.O. Ocean Gliders. Available online: https://imos.org.au/facility/ocean-gliders (accessed on 3 July 2025).

- Liang, J.; Liu, L.; Qin, Z.; Zhao, X.; Li, Z.; Emmanuel, U.; Feng, J. Experimental Study of Curing Temperature Effect on Mechanical Performance of Carbon Fiber Composites with Application to Filament Winding Pressure Vessel Design. Polymers 2023, 15, 982. [Google Scholar] [CrossRef]

- Iacopo, B.; Chiara, M.; Michela, S.; Tommaso, V. Life cycle analyses of a composite towbar realized via filament winding and comparison with traditional metallic alternatives. Sustain. Mater. Technol. 2024, 40, e00980. [Google Scholar] [CrossRef]

- Lukaszewicz, D.H.J.A.; Potter, K. Through-thickness compression response of uncured prepreg during manufacture by automated layup. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 226, 193–202. [Google Scholar] [CrossRef]

- Eckrich, M.; Arrabiyeh, P.A.; Dlugaj, A.M.; May, D. Structural topology optimization and path planning for composites manufactured by fiber placement technologies. Compos. Struct. 2022, 289, 115488. [Google Scholar] [CrossRef]

- Blom, A.W.; Abdalla, M.M.; Gürdal, Z. Optimization of course locations in fiber-placed panels for general fiber angle distributions. Compos. Sci. Technol. 2010, 70, 564–570. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A Review on the Mechanical Modeling of Composite Manufacturing Processes. Arch. Comput. Methods Eng. 2017, 24, 365–395. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Yang, S.; Wang, Y.; Liang, Y.; Wang, S.; Zhang, L. Optimization design of neutrally buoyant hull for underwater gliders. Ocean Eng. 2020, 209, 107512. [Google Scholar] [CrossRef]

- Yang, M.; Wang, Y.; Wang, S.; Yang, S.; Song, Y.; Zhang, L. Motion parameter optimization for gliding strategy analysis of underwater gliders. Ocean Eng. 2019, 191, 106502. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, H.; Deng, S.; Liu, S.; Wang, S.; Lan, S.; Li, X.; Li, H.; Wang, Z. Seal-Inspired Underwater Glider With a Rigid-Flexible Composite Hull. IEEE J. Ocean Eng. 2024, 49, 92–104. [Google Scholar] [CrossRef]

- Osse, T.J.; Eriksen, C.C. The Deepglider: A Full Ocean Depth Glider for Oceanographic Research. In Proceedings of the OCEANS 2007, Vancouver, BC, Canada, 29 September–4 October 2007; pp. 1–12. [Google Scholar]

- Gao, Y.; Gao, J.; Song, X.; Ding, H.; Wang, H. A collaborative grading optimization method of rib-reinforced ultra-thick composite pressure hull. Ocean Eng. 2023, 274, 114038. [Google Scholar] [CrossRef]

- Haldeman, C.D.; Aragon, D.K.; Miles, T.; Glenn, S.M.; Ramos, A.G. Lessening biofouling on long-duration AUV flights: Behavior modifications and lessons learned. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016; pp. 1–8. [Google Scholar]

- Davis, R.E.; Kessler, W.S.; Sherman, J.T. Gliders Measure Western Boundary Current Transport from the South Pacific to the Equator*. J. Phys. Oceanogr. 2012, 42, 2001–2013. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B. Biofouling: Lessons from nature. Philos. Trans. A Math. Phys. Eng. Sci. 2012, 370, 2381–2417. [Google Scholar] [CrossRef]

- Yang, S.; Wang, X.; Miao, Z.; Chen, Y.; Sun, T.; Wang, P.; Wang, C. Drag reduction mechanism of the biomimetic superhydrophobic surface on the boundary layer of underwater gliders. Phys. Fluids 2025, 37, 025154. [Google Scholar] [CrossRef]

- Li, S.; Feng, K.; Li, J.; Li, Y.; Li, Z.; Yu, L.; Xu, X. Marine antifouling strategies: Emerging opportunities for seawater resource utilization. Chem. Eng. J. 2024, 486, 149859. [Google Scholar] [CrossRef]

- Callow, J.A.; Callow, M.E. Trends in the development of environmentally friendly fouling-resistant marine coatings. Nat. Commun. 2011, 2, 244. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.; Li, C.; Xie, Y.; Cao, Z.; Li, S.; Zhao, J.; Wang, M. ZnO/Acrylic Polyurethane Nanocomposite Superhydrophobic Coating on Aluminum Substrate Obtained via Spraying and Co-Curing for the Control of Marine Biofouling. Surf. Interfaces 2021, 22, 100833. [Google Scholar] [CrossRef]

- Chen, Z.; Jiao, W.; Ren, K.; Yu, J.; Tian, Y.; Chen, K.; Zhang, X. A survey of research status on the environmental adaptation technologies for marine robots. Ocean Eng. 2023, 286, 115650. [Google Scholar] [CrossRef]

- Davis, R.E.; Sherman, J.T.; Dufour, J. Profiling ALACEs and Other Advances in Autonomous Subsurface Floats. J. Atmos. Ocean Technol. 2001, 18, 982–993. [Google Scholar] [CrossRef]

- Elkolali, M.; Al-Tawil, A.; Alcocer, A. Design and Testing of a Miniature Variable Buoyancy System for Underwater Vehicles. IEEE Access 2022, 10, 42297–42308. [Google Scholar] [CrossRef]

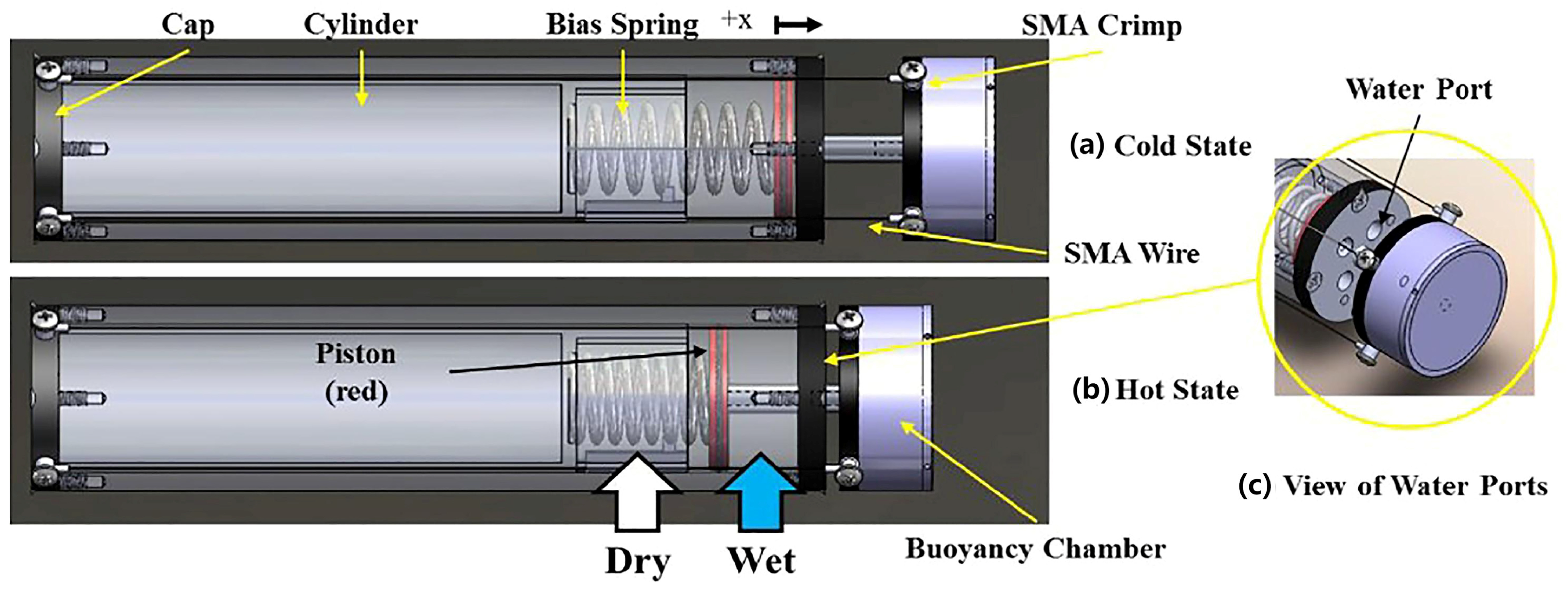

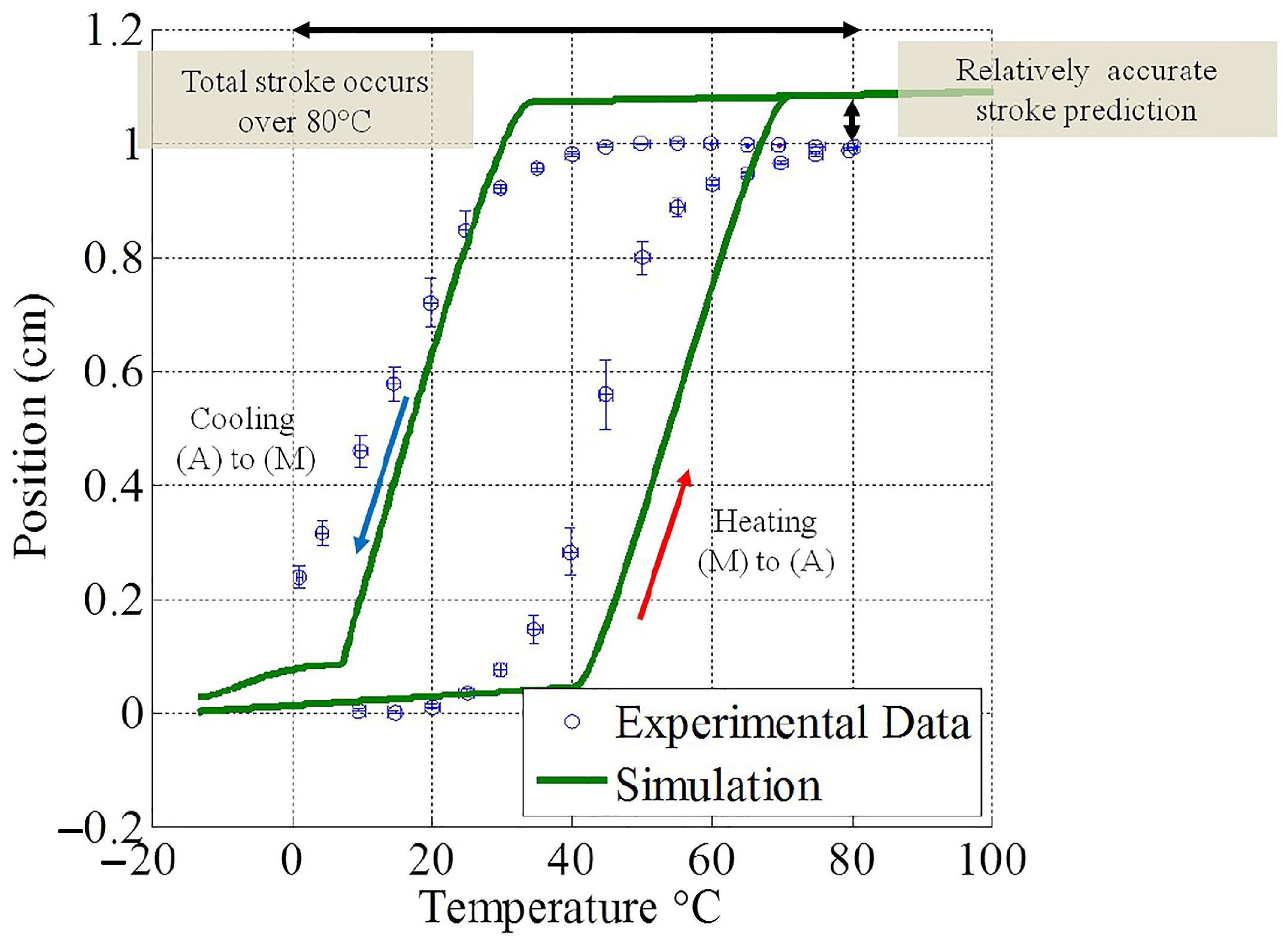

- Angilella, A.J.; Gandhi, F.S.; Miller, T.F. Design and testing of a shape memory alloy buoyancy engine for unmanned underwater vehicles. Smart Mater. Struct. 2015, 24, 115018. [Google Scholar] [CrossRef]

- Wood, S. Autonomous Underwater Gliders. Underw. Veh. 2009, 26, 499–524. [Google Scholar]

- Rossby, H.T.; Levine, E.R.; Connors, D.N. The isopycnal swallow float—A simple device for tracking water parcels in the ocean. Prog. Oceanogr. 1985, 14, 511–525. [Google Scholar] [CrossRef]

- Chen, D.; Li, D.; Cao, J.; Zeng, Z. Dynamic Modeling and Motion Analysis of Deep-Sea Gliders with Energy Accumulator. In Proceedings of the 2018 OCEANS—MTS/IEEE Kobe Techno-Oceans (OTO), Kobe, Japan, 28–31 May 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Wang, S.; Li, H.; Wang, Y.; Liu, Y.; Zhang, H.; Yang, S. Dynamic modeling and motion analysis for a dual-buoyancy-driven full ocean depth glider. Ocean Eng. 2019, 187, 106163. [Google Scholar] [CrossRef]

- Xie, X.; Wang, Y.; Song, Y.; Yang, S.; Luo, C.; Ma, W.; Lian, Y. Development, optimization, and evaluation of a hybrid passive buoyancy compensation system for underwater gliders. Ocean Eng. 2021, 242, 110115. [Google Scholar] [CrossRef]

- Guo, J.; Pan, B.; Cui, W.; Xiang, H. Modeling and Analysis of Resistance-Sensing Characteristics for Two-Way Shape Memory Alloy-Based Deep-Sea Actuators. J. Mar. Sci. Eng. 2024, 12, 1703. [Google Scholar] [CrossRef]

- Singh Rajput, G.; Vora, J.; Prajapati, P.; Chaudhari, R. Areas of recent developments for shape memory alloy: A review. Mater. Today Proc. 2022, 62, 7194–7198. [Google Scholar] [CrossRef]

- Yang, S.; Jia, L.; Sun, A.; Wan, X.; Ma, W.; Niu, W.; Yang, M.; Sun, T. Design and analysis of a shape memory alloy buoyancy actuator. Ocean Eng. 2024, 296, 117005. [Google Scholar] [CrossRef]

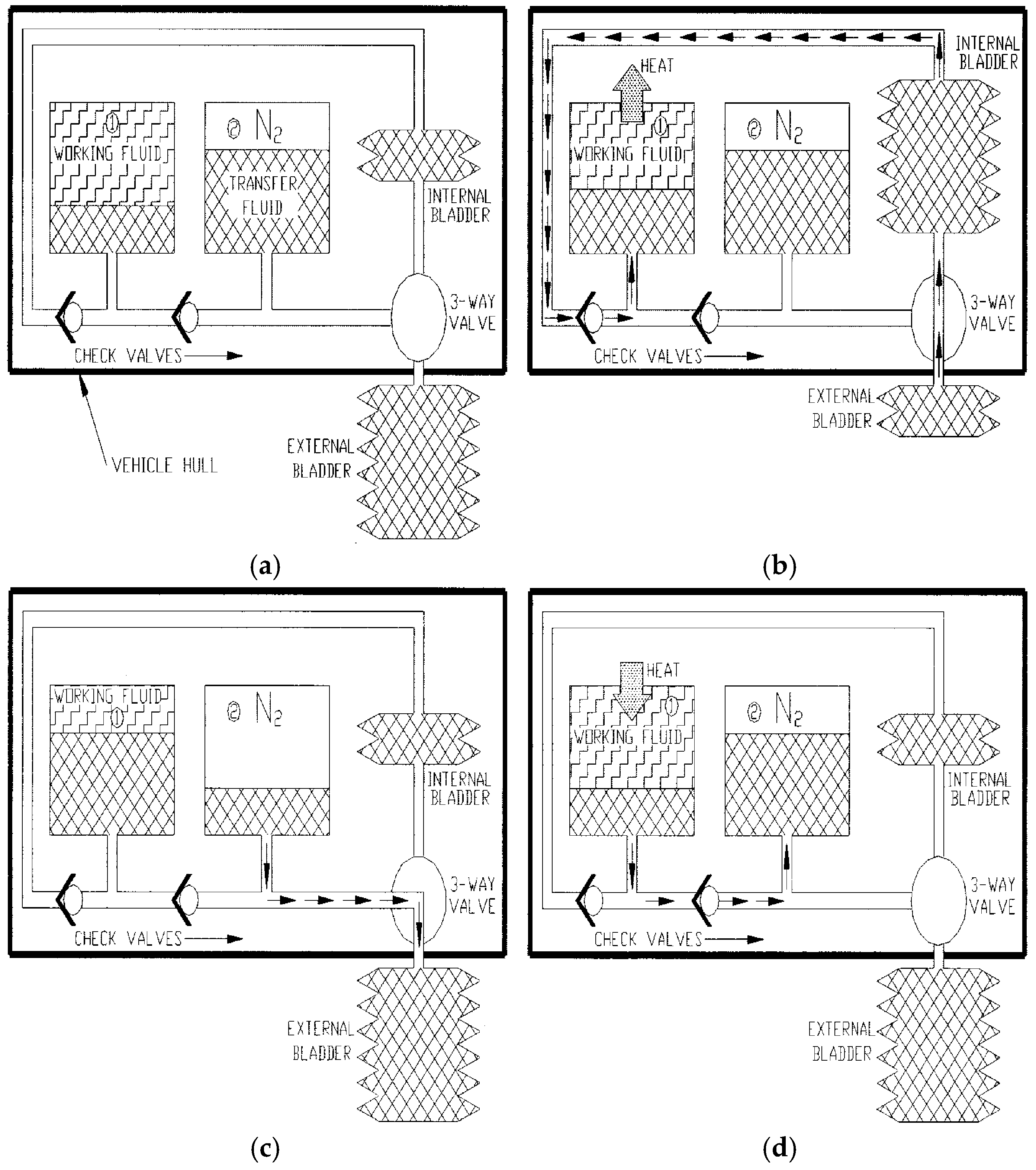

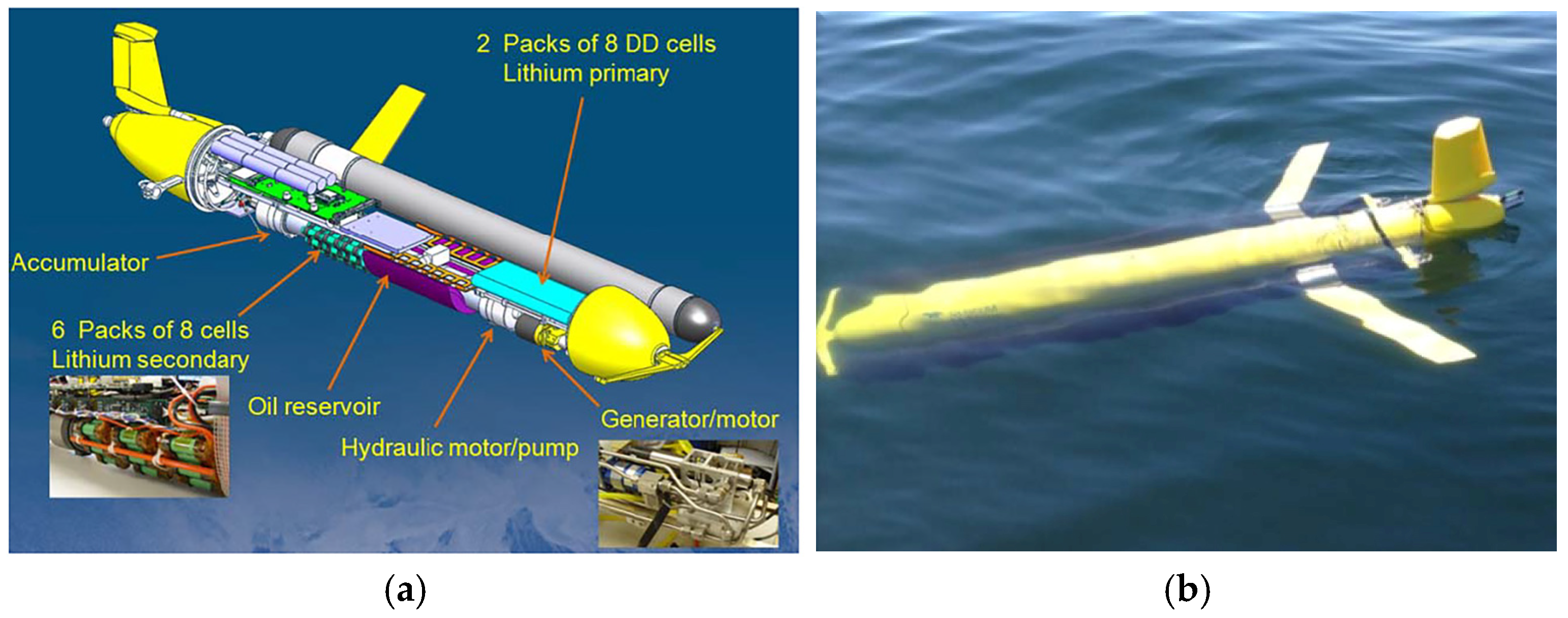

- Webb, D.C.; Simonetti, P.J.; Jones, C.P. SLOCUM: An underwater glider propelled by environmental energy. IEEE J. Ocean Eng. 2001, 26, 447–452. [Google Scholar] [CrossRef]

- Jones, C.; Allsup, B.; DeCollibus, C. Slocum glider: Expanding our understanding of the oceans. In Proceedings of the 2014 Oceans—St. John’s, St. John’s, NL, Canada, 14–19 September 2014; pp. 1–10. [Google Scholar] [CrossRef]

- Hou, H.; Arredondo Galeana, A.; Song, Y.; Xu, G.; Xu, Y.; Shi, W. Design of a novel energy harvesting mechanism for underwater gliders using thermal buoyancy engines. Ocean Eng. 2023, 278, 114310. [Google Scholar] [CrossRef]

- Falcão Carneiro, J.; Gomes de Almeida, F. Model and simulation of the energy retrieved by thermoelectric generators in an underwater glider. Energy Convers. Manag. 2018, 163, 38–49. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, Q.; Ji, F.; Zhou, W. Research advances in energy management and harvesting technologies for autonomous profiling floats. Front. Mar. Sci. 2025, 12, 1598701. [Google Scholar] [CrossRef]

- Nittel, S. A Survey of Geosensor Networks: Advances in Dynamic Environmental Monitoring. Sensors 2009, 9, 5664–5678. [Google Scholar] [CrossRef] [PubMed]

- Lobe, H.; Haldeman, C.; Glenn, S. ClearSignal Coating Controls Biofouling On the Rutgers Glider Crossing. Sea Technol. 2010, 51, 31–34. [Google Scholar]

- Shelly, D.; Lee, S.-Y.; Park, S.-J. Compatibilization of ultra-high molecular weight polyethylene (UHMWPE) fibers and their composites for superior mechanical performance: A concise review. Compos. Part B Eng. 2024, 275, 111294. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, D.; Zhan, S.; Tu, J.; Yang, T.; Li, J.; Duan, H. Properties of compression molded ultra-high molecular weight polyethylene: Effects of varying process conditions. J. Polym. Eng. 2023, 43, 66–79. [Google Scholar] [CrossRef]

- Ramasamy, M.; Lee, J. Recent Nanotechnology Approaches for Prevention and Treatment of Biofilm-Associated Infections on Medical Devices. Biomed. Res. Int. 2016, 2016, 1851242. [Google Scholar] [CrossRef]

- Asma, S.T.; Imre, K.; Morar, A.; Herman, V.; Acaroz, U.; Mukhtar, H.; Arslan-Acaroz, D.; Shah, S.R.A.; Gerlach, R. An Overview of Biofilm Formation-Combating Strategies and Mechanisms of Action of Antibiofilm Agents. Life 2022, 12, 1110. [Google Scholar] [CrossRef]

- Huang, J.; Sun, X.; Liang, B.; Li, Z.; Zheng, D.; Yang, B.; Xu, J.; Zhu, Y. Preparation and properties of phase-change materials with enhanced radial thermal conductivities based on anisotropic graphene aerogels. RSC Adv. 2024, 14, 2763–2769. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; An, M.; Li, Z. Enhanced Thermal Performance of Composite Phase Change Materials Based on Hybrid Graphene Aerogels for Thermal Energy Storage. Materials 2022, 15, 5380. [Google Scholar] [CrossRef]

| Parameters | Aluminum Alloy | Titanium Alloy | Carbon Fiber | Glass Fiber |

|---|---|---|---|---|

| E1 (E)/GPa | 71 | 110 | 120 | 38.6 |

| E2/GPa | 7.3 | 8.3 | ||

| G12 (G)/GPa | 27.6 | 41.9 | 5.9 | 4.4 |

| G13/GPa | 5.9 | 4.4 | ||

| G23/GPa | 3.0 | 2.1 | ||

| ν12 (ν) | 0.33 | 0.33 | 0.32 | 0.14 |

| ρ/(g·cm−3) | 2.70 | 4.51 | 1.65 | 1.85 |

| σs/MPa | 290 | 890 | ||

| Xc/MPa | 1010 | 700 |

| Parameter | SMA Actuator | Pump |

|---|---|---|

| Driving voltage (V) | 5 | 24 |

| Driving current (A) | 8.4 | 1.0 |

| Input power (w) | 42 | 24 |

| Maximum adjustment rate (mL/s) | 1 | 2.5 |

| Minimum adjustment volume (mL) | 1 | 2.5 |

| Type | Environmental Dependence and Controllability | Energy Demand | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|---|

| Active hydraulic drive [28,96] | Independent of environment; fully controllable | High (Dependent on battery for continuous function) | Response speed is fast (in milliseconds) | High energy consumption | Slocum, Spray, Seaglider |

| Passive compensation mechanism [100] | Driven by environmental pressure; non-controllable | Extremely low (no external energy input required) | reduces system energy consumption. | Slow response | Deepglider |

| SMAs drive [95,104] | Triggered by environmental conditions, controllable | Low (temperature difference in the ocean) High (electrical energy for heating) | High response speed (second-level) | Limited fatigue life | Laboratory prototype (SMA-BHE) |

| Thermal energy drive [106,107] | Triggered by environmental conditions, controllable | Low (temperature difference in the ocean) | energy-autonomous missions | Energy conversion efficiency is relatively low | Slocum Thermal E-Twin |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wang, C.; Zhang, K.; Ren, K.; Yu, J. Development and Core Technologies of Long-Range Underwater Gliders: A Review. J. Mar. Sci. Eng. 2025, 13, 1509. https://doi.org/10.3390/jmse13081509

Wang X, Wang C, Zhang K, Ren K, Yu J. Development and Core Technologies of Long-Range Underwater Gliders: A Review. Journal of Marine Science and Engineering. 2025; 13(8):1509. https://doi.org/10.3390/jmse13081509

Chicago/Turabian StyleWang, Xu, Changyu Wang, Ke Zhang, Kai Ren, and Jiancheng Yu. 2025. "Development and Core Technologies of Long-Range Underwater Gliders: A Review" Journal of Marine Science and Engineering 13, no. 8: 1509. https://doi.org/10.3390/jmse13081509

APA StyleWang, X., Wang, C., Zhang, K., Ren, K., & Yu, J. (2025). Development and Core Technologies of Long-Range Underwater Gliders: A Review. Journal of Marine Science and Engineering, 13(8), 1509. https://doi.org/10.3390/jmse13081509